Prefabricated comprehensive pipe gallery

A technology of comprehensive pipe gallery and pipe gallery, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of poor rectangular cross-section force, difficult construction quality assurance, inconvenient transportation and installation, etc. The quality is easy to guarantee, it is conducive to popularization and use, and it is convenient for construction and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

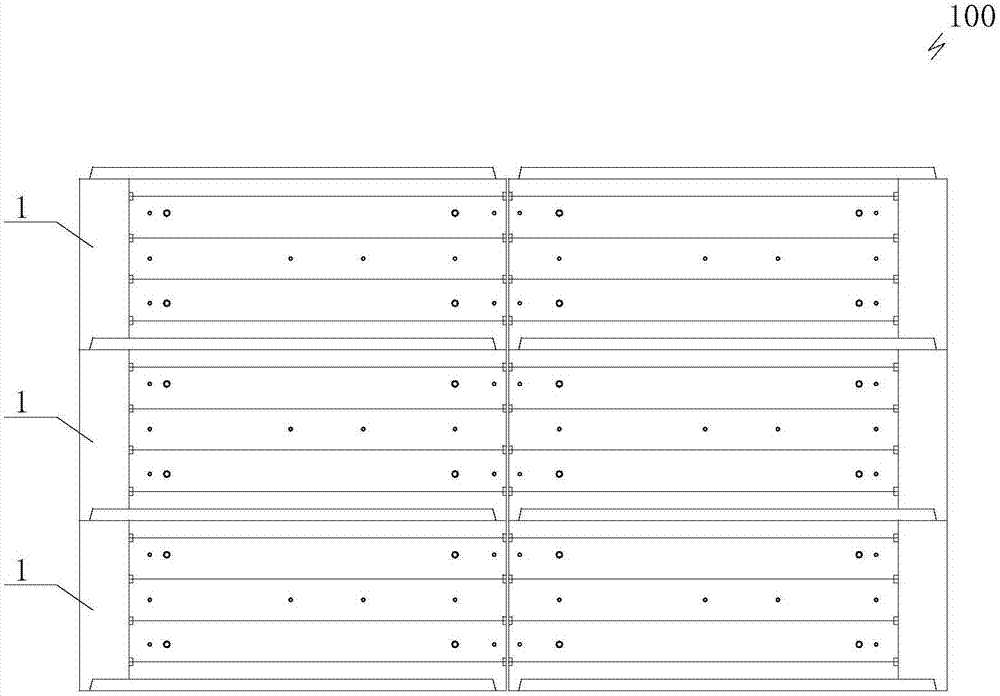

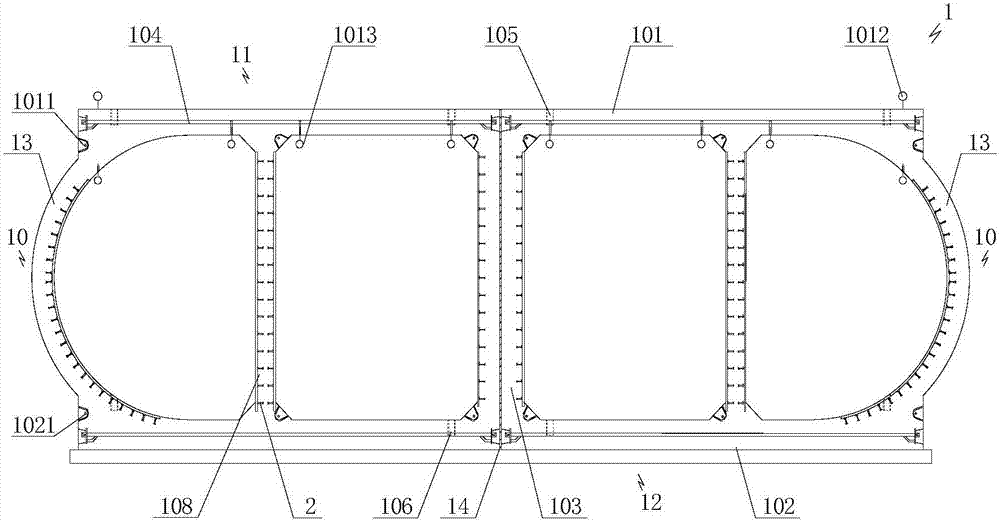

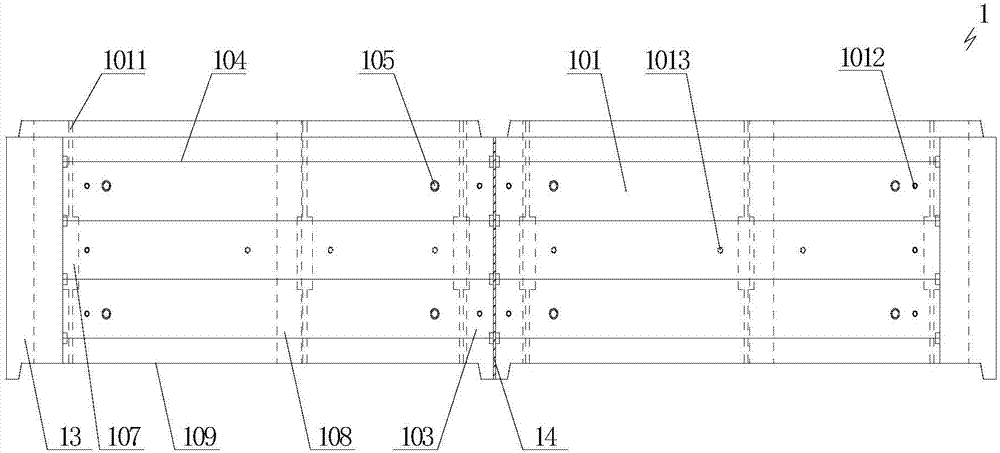

[0037] Such as Figure 1 to Figure 3 As shown, the present invention provides a prefabricated comprehensive pipe gallery 100, the prefabricated comprehensive pipe gallery is a concrete structure pipe gallery, the prefabricated comprehensive pipe gallery 100 is composed of multi-section pipe gallery prefabricated units 1 spliced along the longitudinal direction, and each pipe gallery prefabricated unit 1 includes The top plate 11 and the bottom plate 12 are arranged in parallel, and there is a gap in height between the top plate 11 and the bottom plate 12. Both sides of each pipe gallery prefabricated unit 1 are provided with arc-shaped side walls 13 that seal the top plate 11 and the bottom plate 12. Such as figure 2 , imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com