Patents

Literature

352results about How to "Construction quality is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method for mounting outdoor embedded high-density polyethylene double-wall corrugated drain pipe

InactiveCN101565964AReduce weightConstruction and transportation are convenientSewerage structuresSewer pipelinesLow speedDouble wall

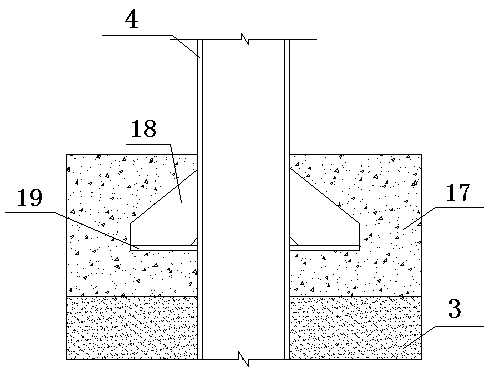

The invention relates to a construction method for mounting an outdoor embedded high-density polyethylene double-wall corrugated drain pipe (CPP).The method is characterized by comprising the following processes of foundation trench digging, pipe mounting and backfilling, wherein the foundation trench digging technical process comprises measuring and setting out, mechanical grooving, levelling and tamping of a groove bottom, grit gravel cushioning and foundation sanding; the pipe mounting technical process comprises pipe mounting, well chamber building and rendering; and the backfilling technical process comprises soil filling for a chest, a water tight test, soil backfilling and tamping. The method solves the problems of discharge of rainwater and sewage of current municipal engineering, industrial wastewater discharge, subdistrict drain engineering, low speed for cement and metal pipe construction in the engineering of pipelines preburying and the like, heavy pipe weight, inconvenience for conveying and carrying, large labor intensity, high mounting cost and the like, and is applicable to the discharge of the rainwater and the sewage of the current municipal engineering, the industrial wastewater discharge, the subdistrict drain engineering, and the construction for mounting engineering drain pipes such as the pipelines preburying and the like.

Owner:QINGDAO HENGSHENGYUAN GROUP CONSTR

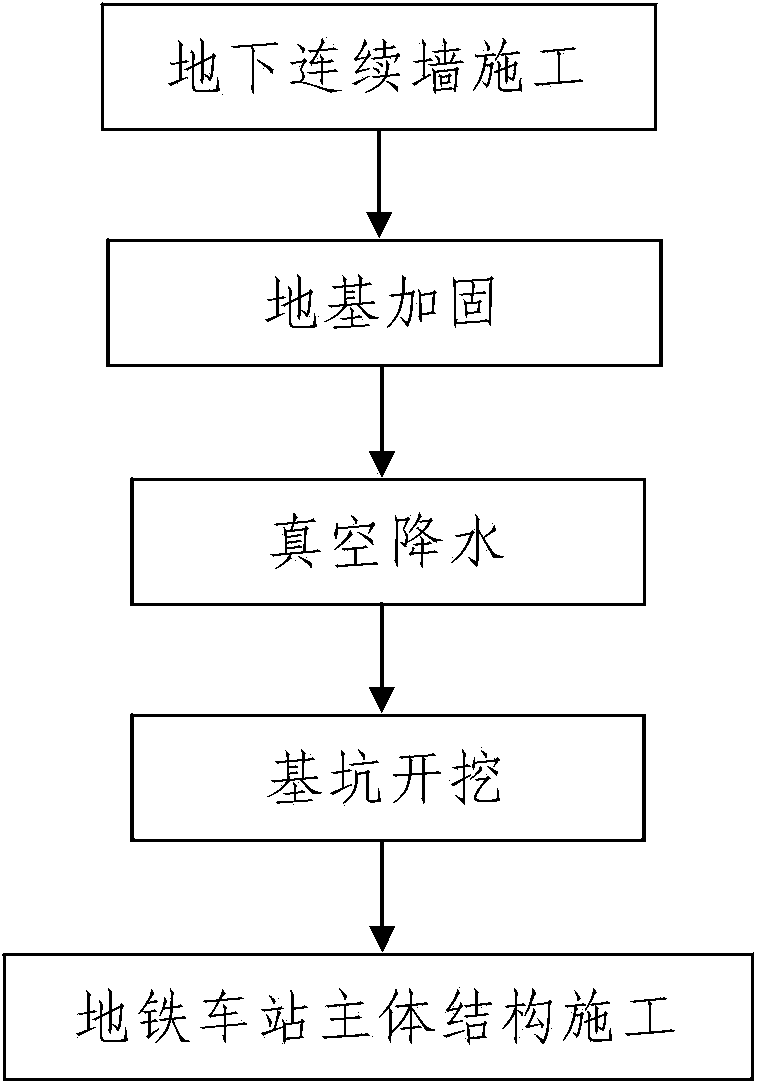

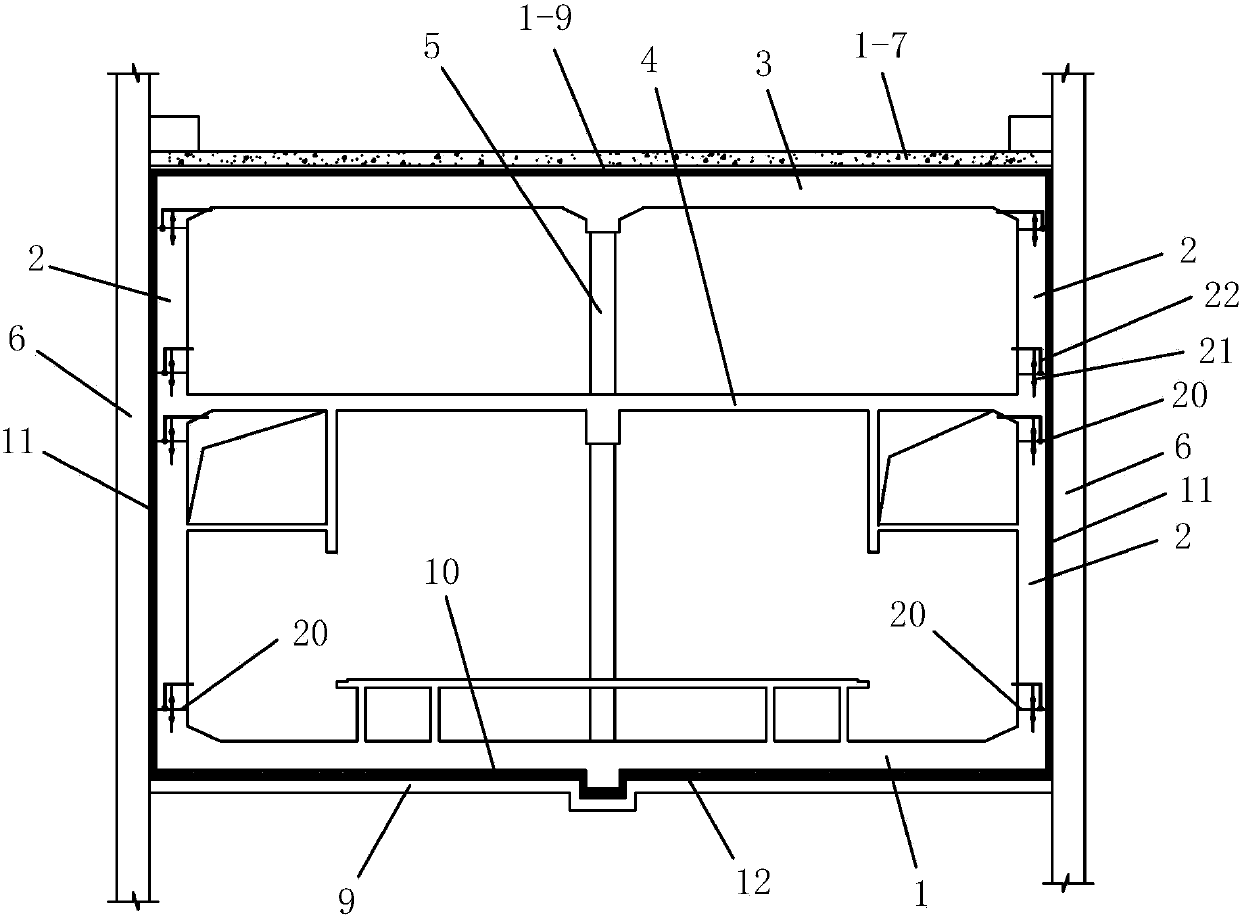

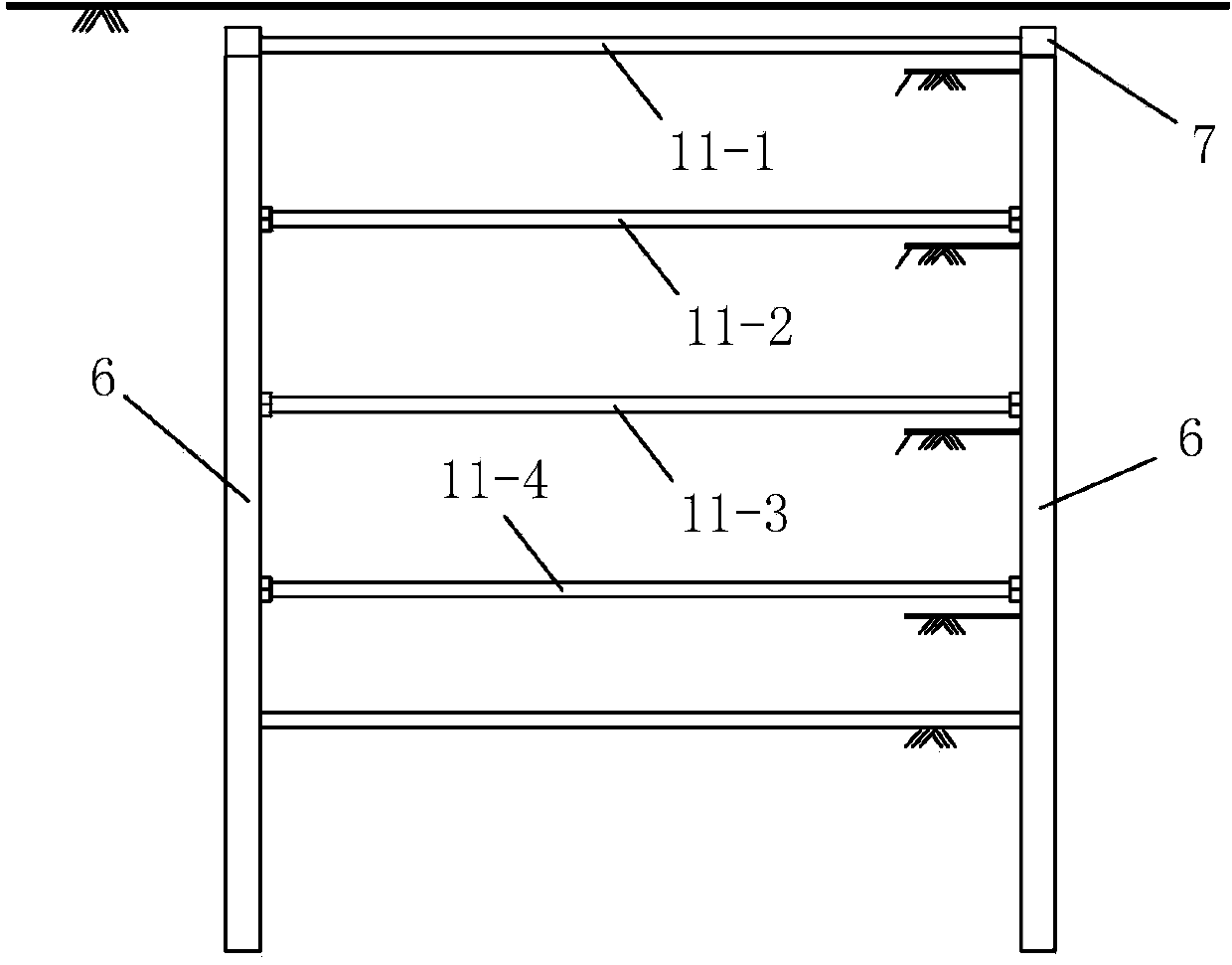

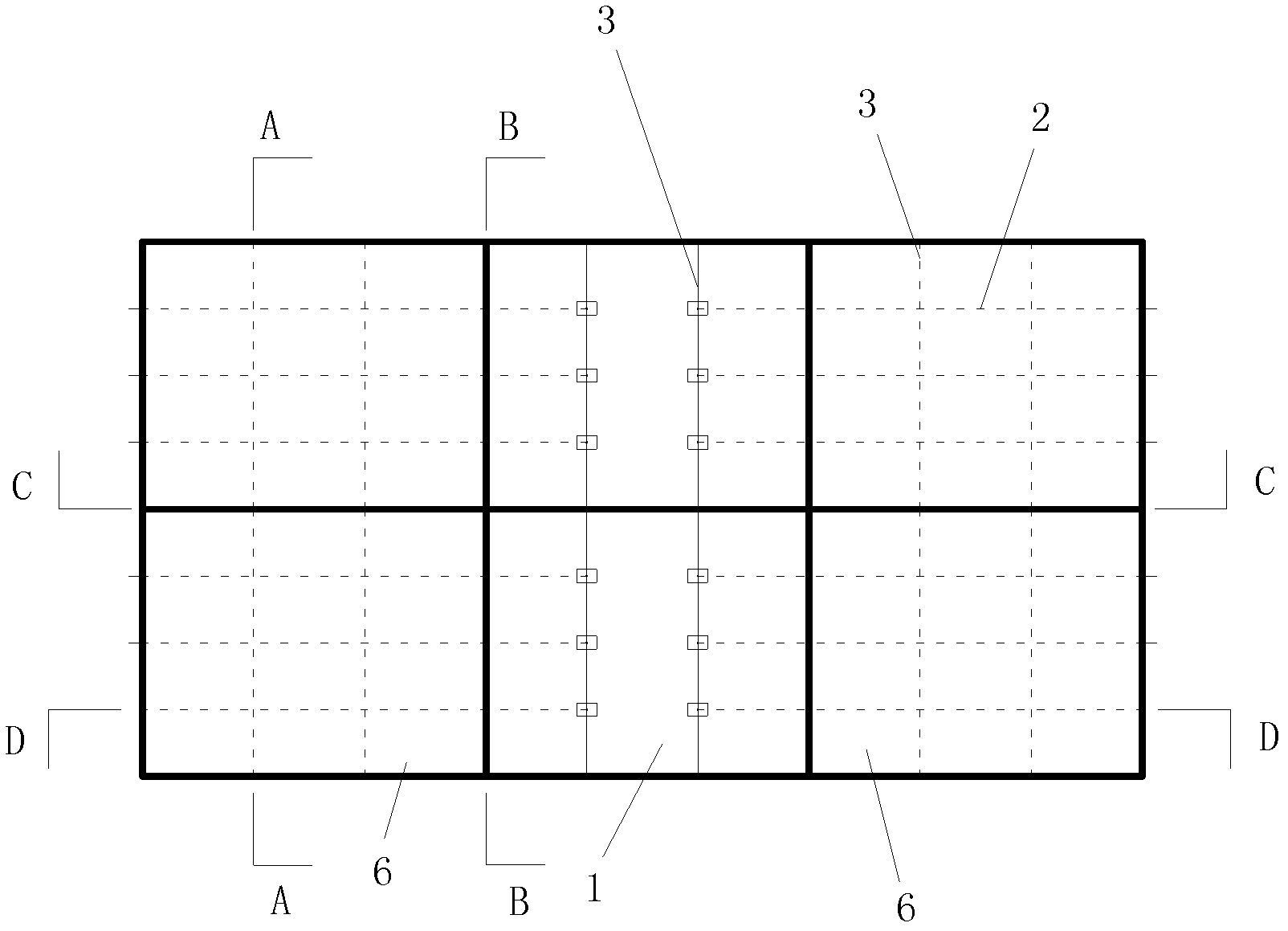

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

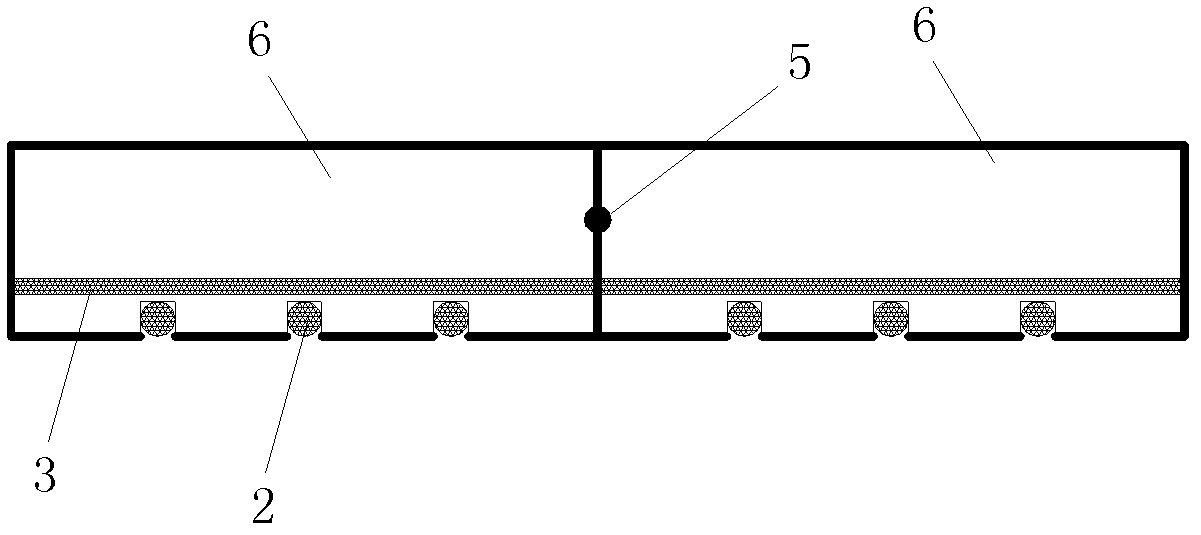

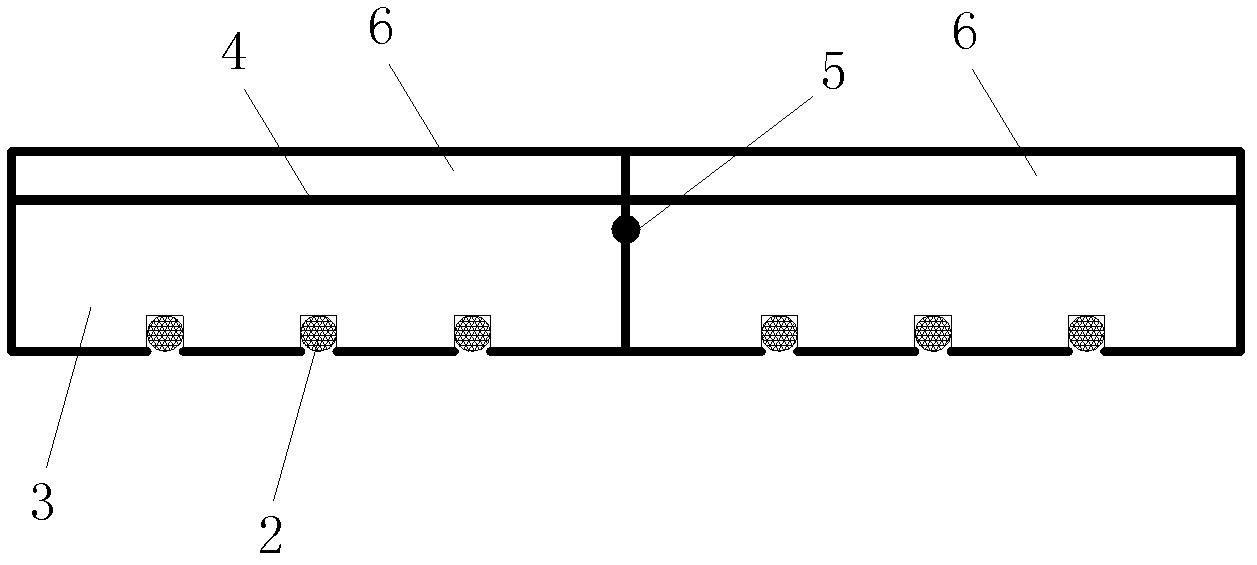

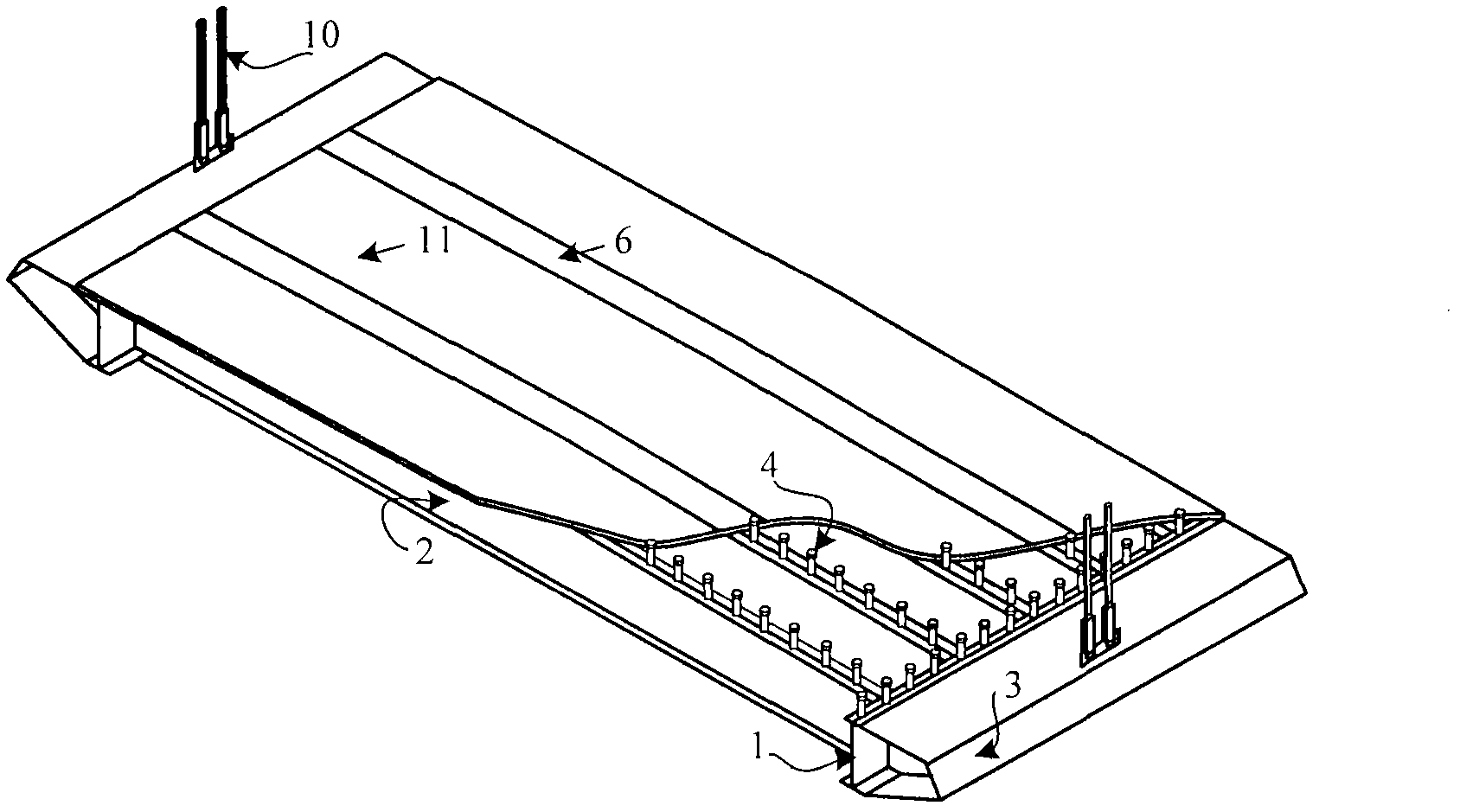

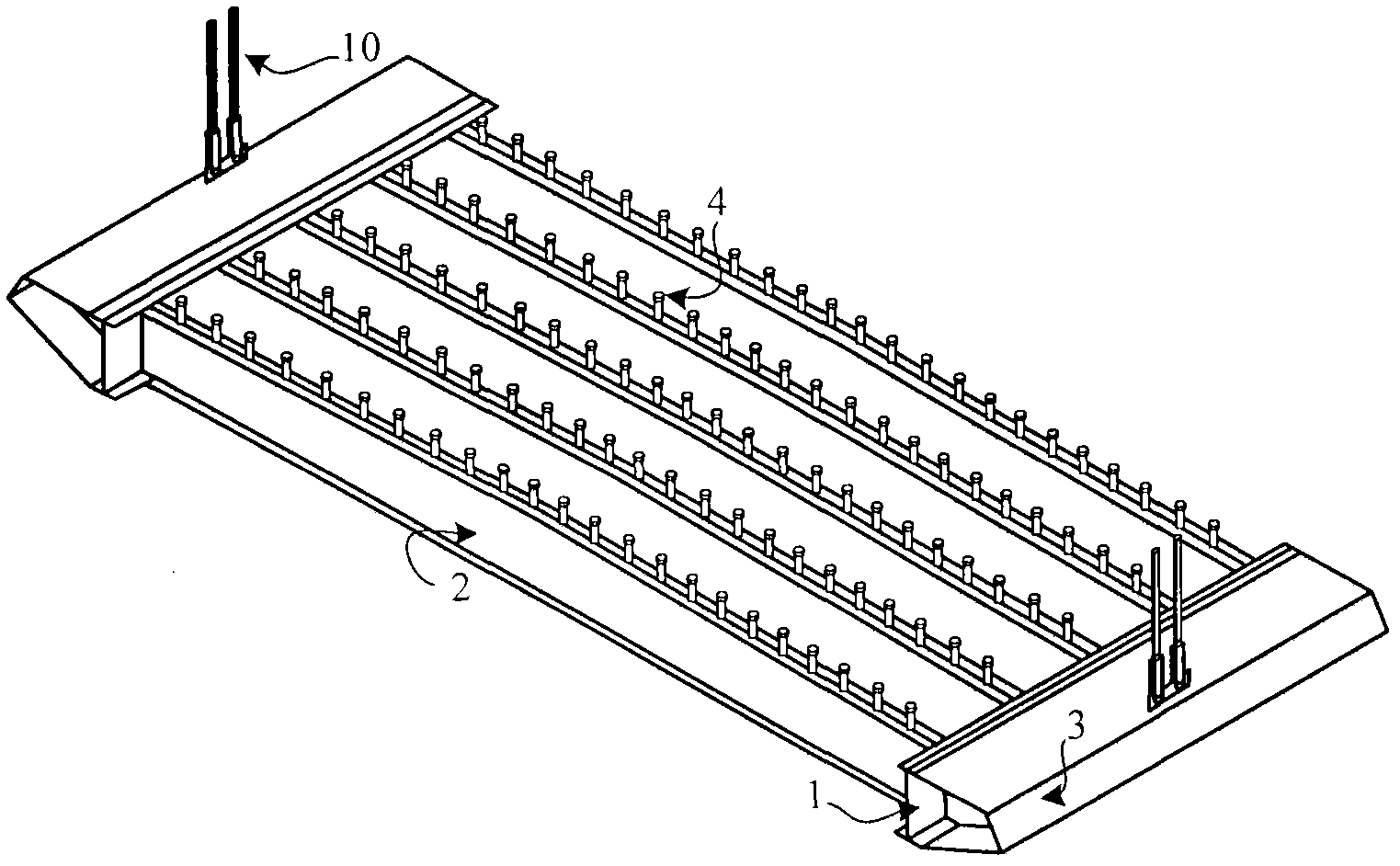

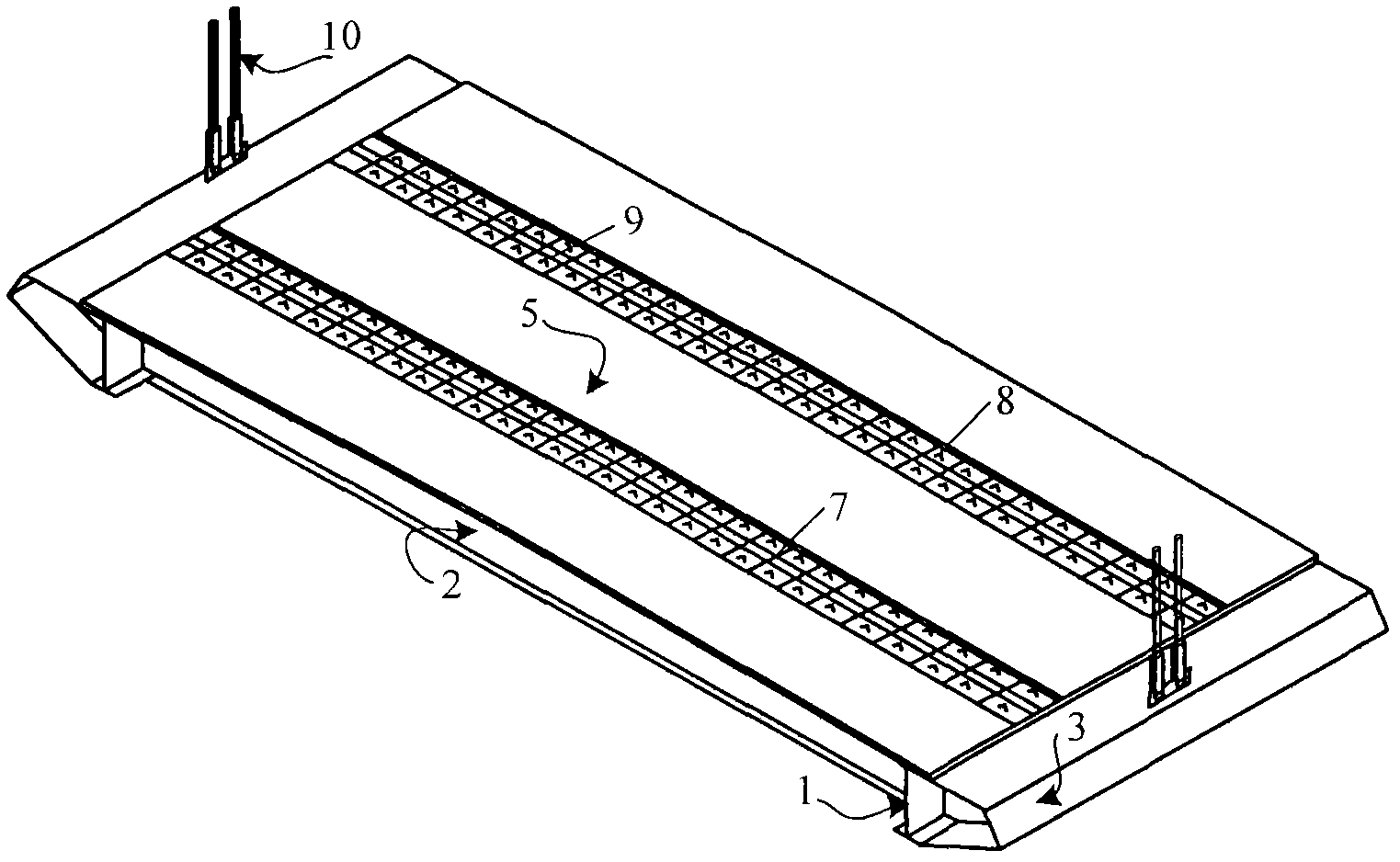

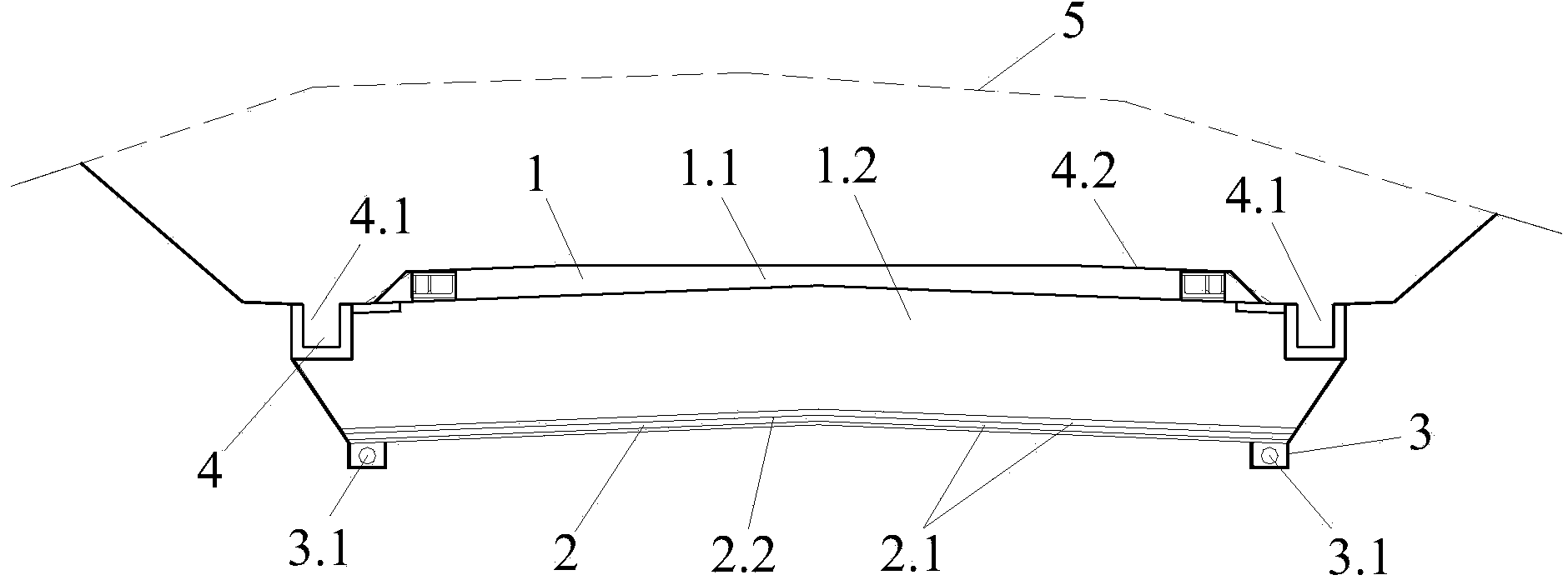

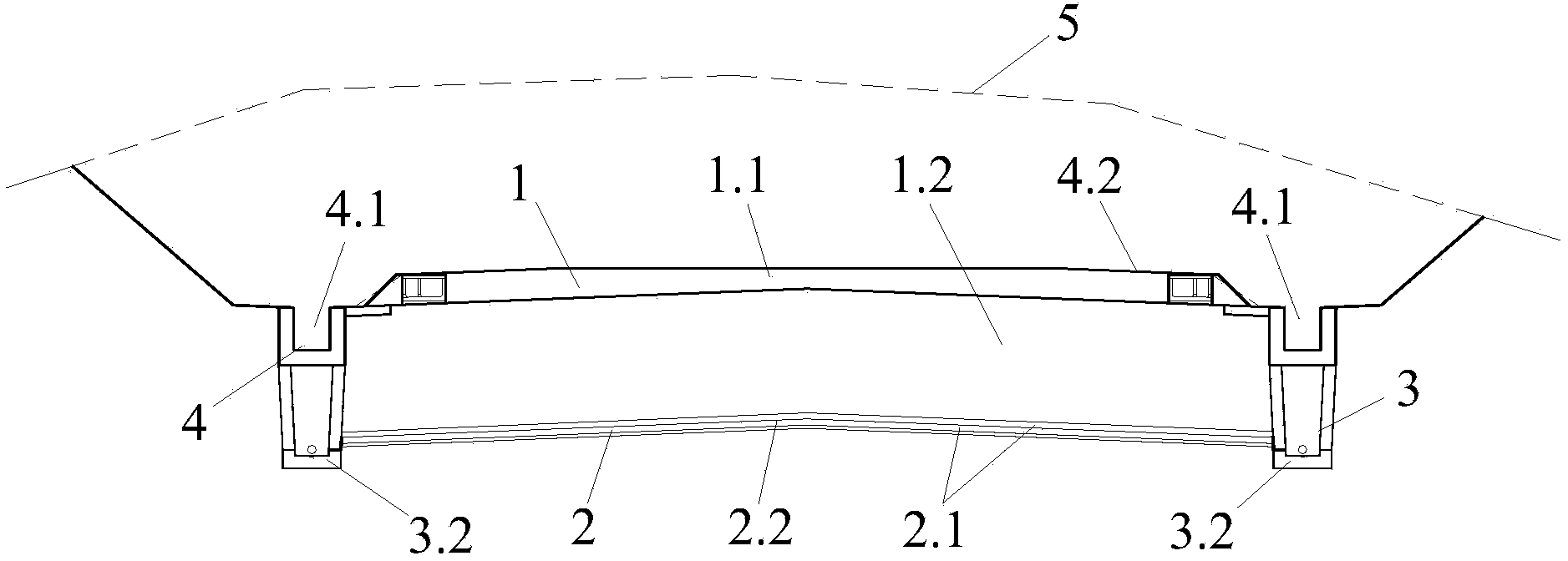

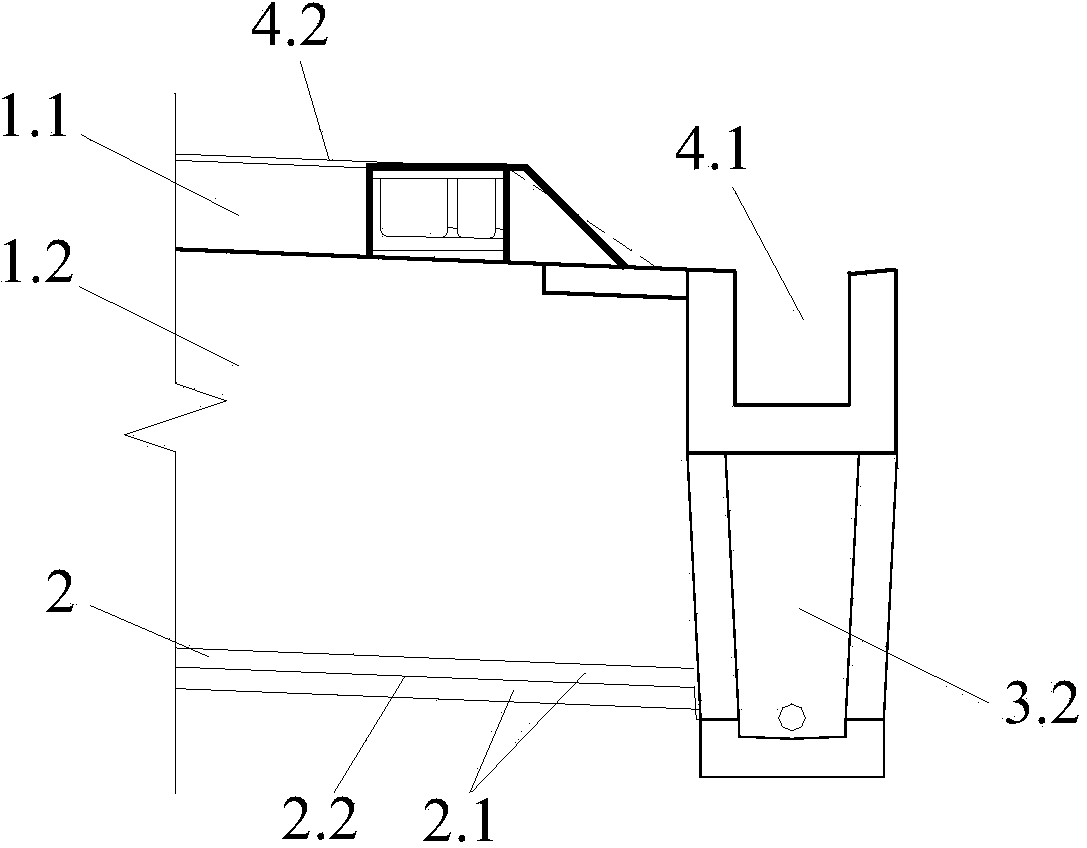

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

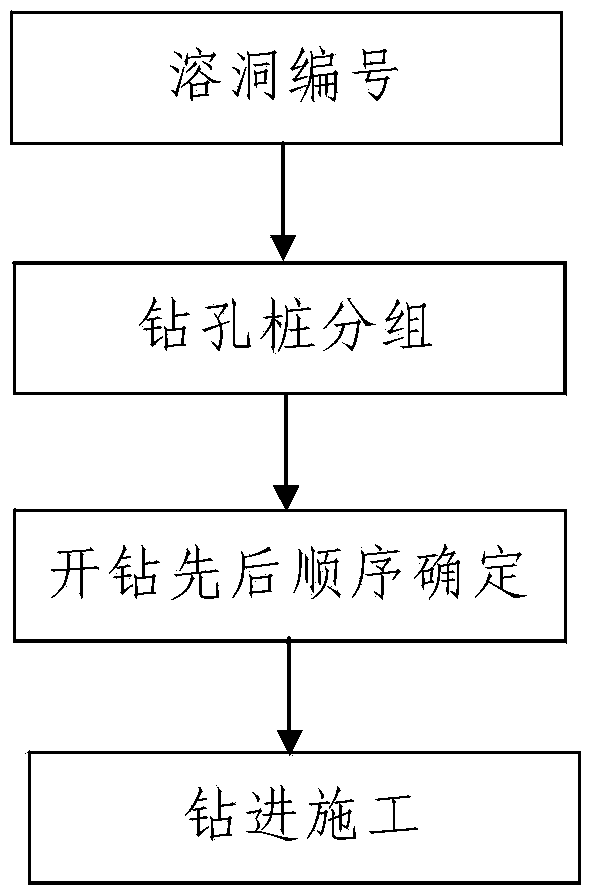

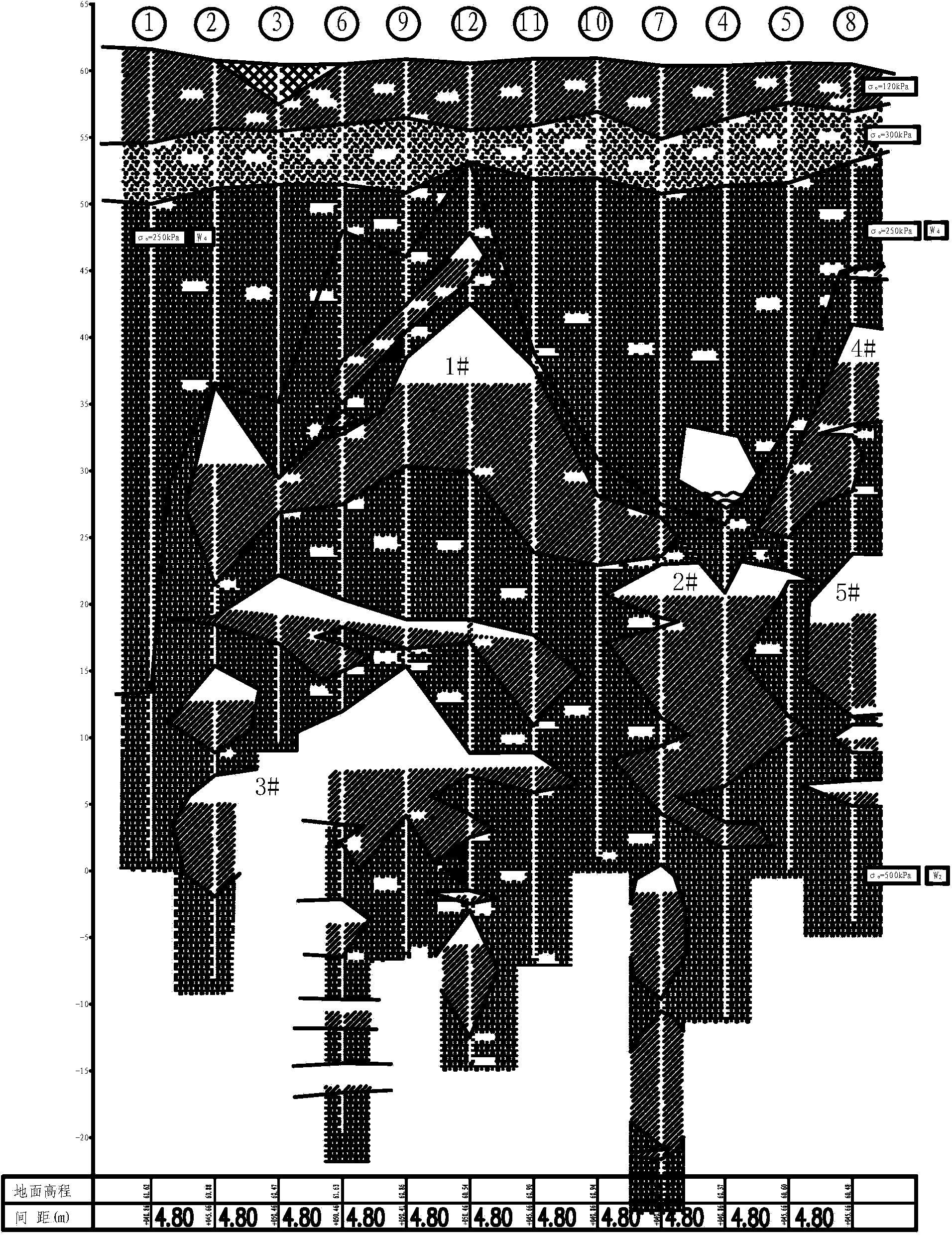

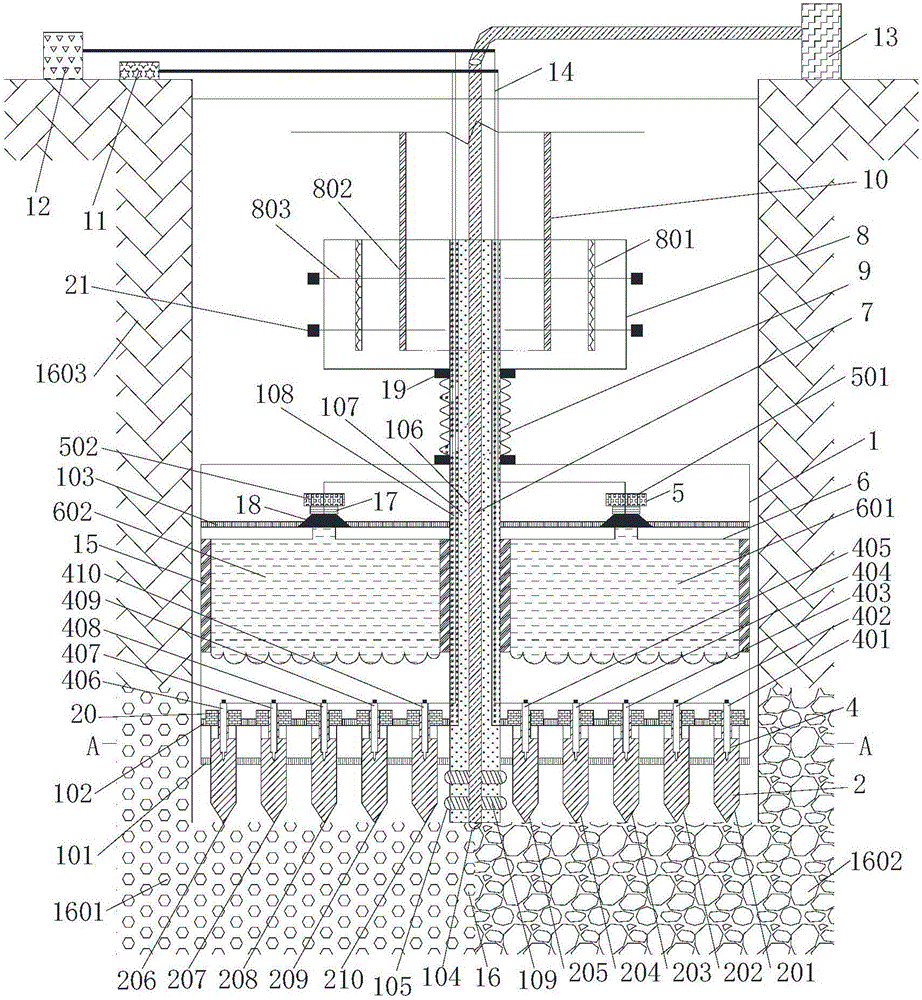

Technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas

ActiveCN103526748AThe process steps are simpleReasonable designEmbankmentsBulkheads/pilesStart timeUnderwater

The invention discloses a technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas. A pile foundation of a constructed underwater pier comprises the multiple first bored piles, and the first bored piles all penetrate through a plurality of karst caves successively from top to bottom. The technology includes the steps of (1) numbering the karst caves, (2) grouping the bored piles: dividing the multiple first bored piles into multiple groups according to serial numbers of the karst caves which are penetrated from top to bottom, and enabling the karst caves which are penetrated by all first bored piles in the same groups from top to bottom for the first time to be the same, (3) determining the drilling starting sequence: determining the drilling starting sequence of all first bored piles in the same group in the step (2), and enabling the drilling starting time of the first bored piles, farther away from the middle of the karst cave penetrated for the first time, in the same group to be earlier, and (4) carrying out drilling construction. The technology is simple in step, reasonable in design, low in investment cost, convenient to achieve and good in construction effect, and large-diameter bored pile construction processes can be easily, conveniently and rapidly completed with low cost and high quality.

Owner:CHINA RAILWAY 20 BUREAU GRP

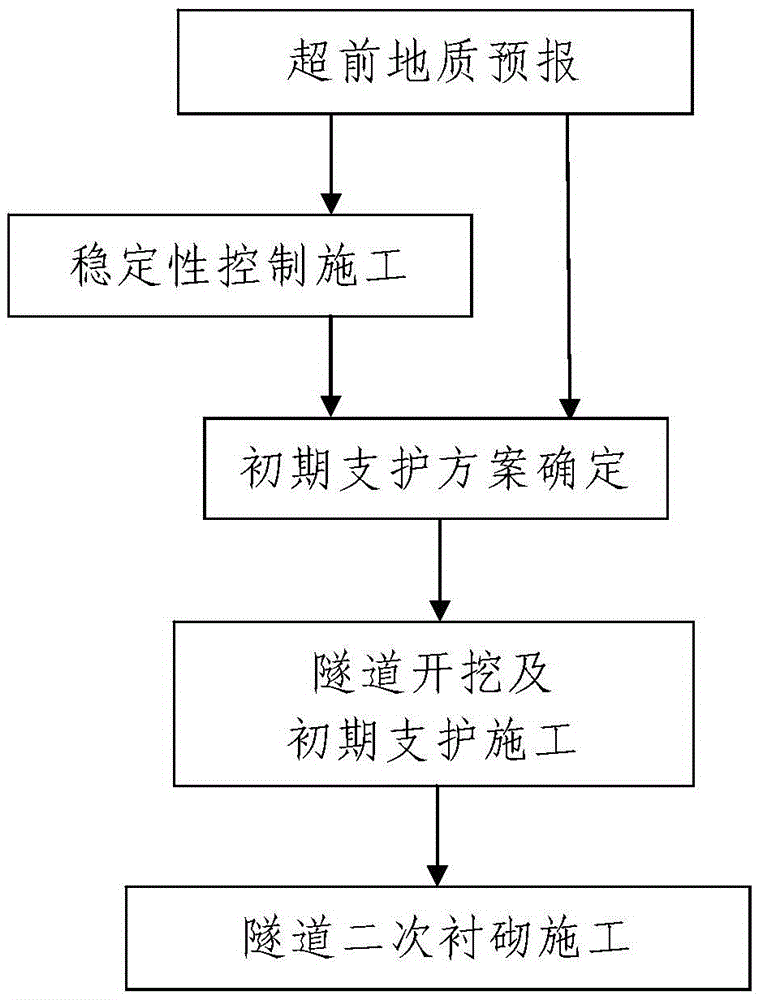

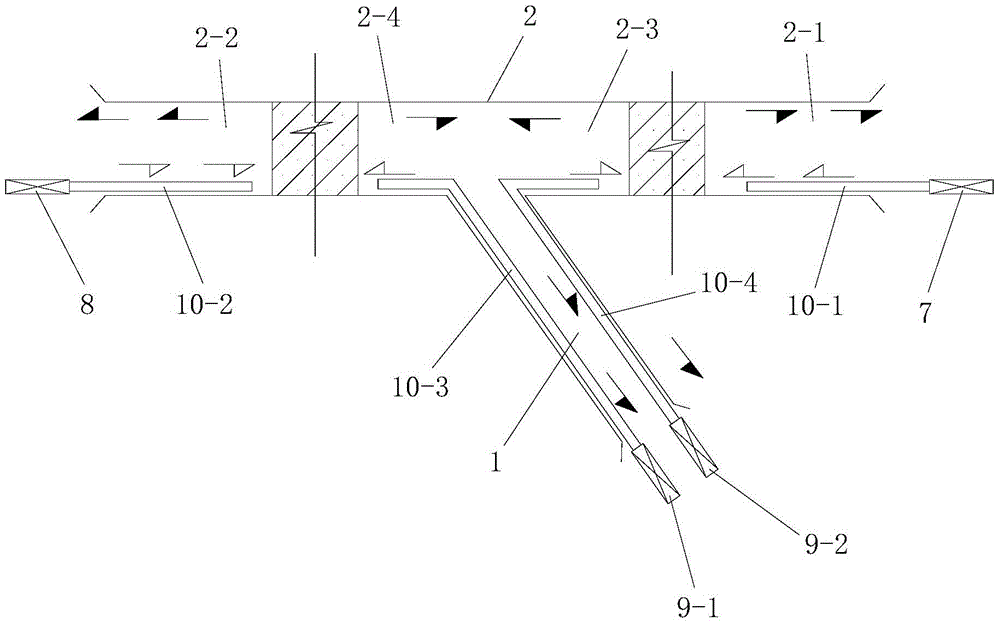

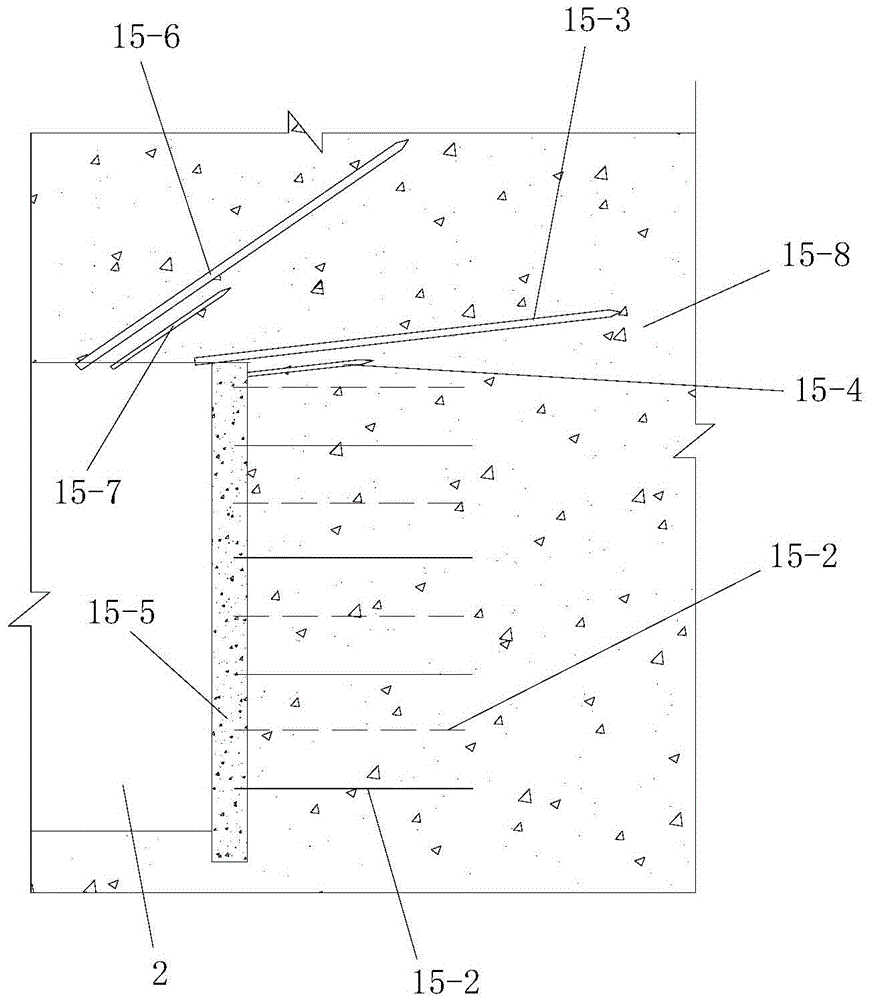

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

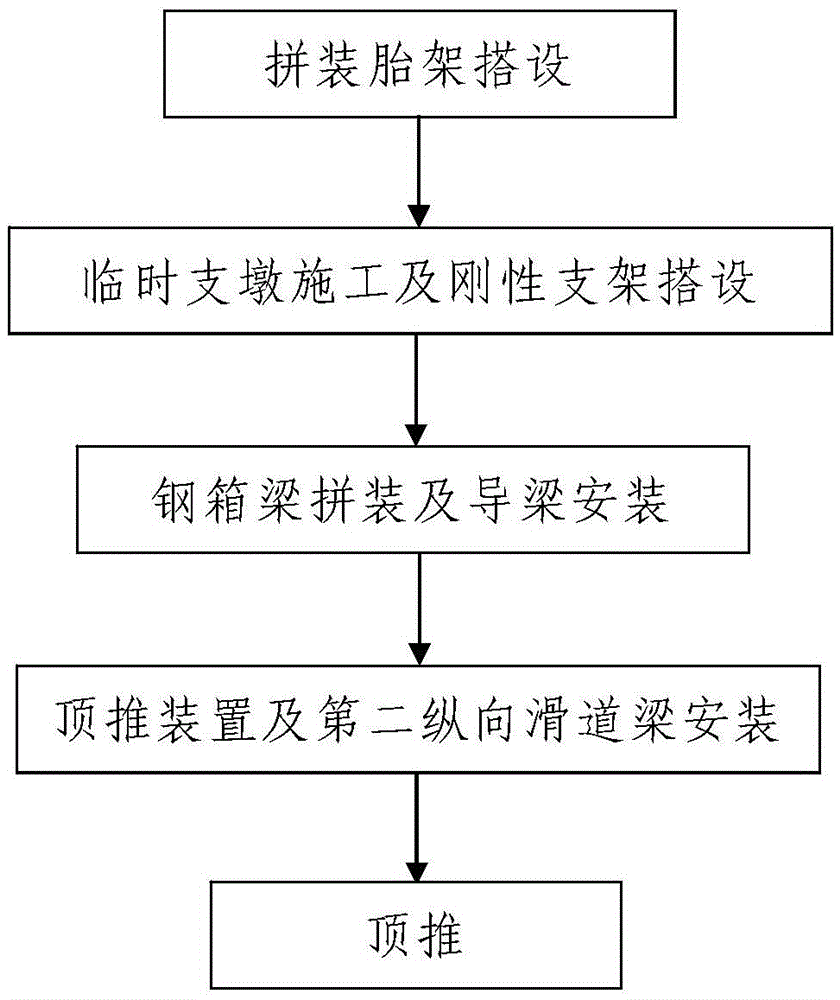

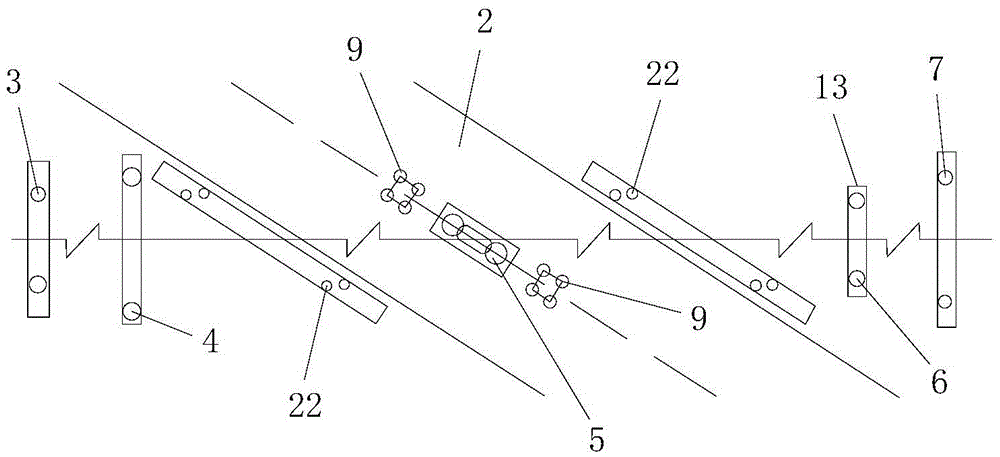

Incremental launching construction method for large-span steel box girder spanning constructed road

ActiveCN105568866AThe method steps are simpleSimple and fast operationBridge erection/assemblyButtressSteel box girder

The invention discloses an incremental launching construction method for a large-span steel box girder spanning a constructed road. An incremental launching steel box girder spans the constructed road, is supported by five permanent buttresses, and is formed by a plurality of steel box girder segments which are spliced back to front; the five permanent buttresses are all uncovered girder double-cylinder pillars; the uncovered girder double-cylinder pillars respectively consist of two cylindrical buttresses which are supported below the left side and the right side of the steel box girder; the incremental launching construction method for the incremental launching steel box girder comprises the following steps: I, splicing jig frames; II, constructing temporary buttresses and rigid brackets; III, splicing the steel box girder and mounting guide beams; IV, mounting an incremental launching device and a second longitudinal slideway beam; V, performing incremental launching. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient to construct and good in use effect, and by constructing the rigid brackets on the outer sides of the buttresses and mounting a longitudinal slideway and a transverse deviation correcting device, the incremental launching construction of the large-span steel box girder can be easily, conveniently and rapidly completed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

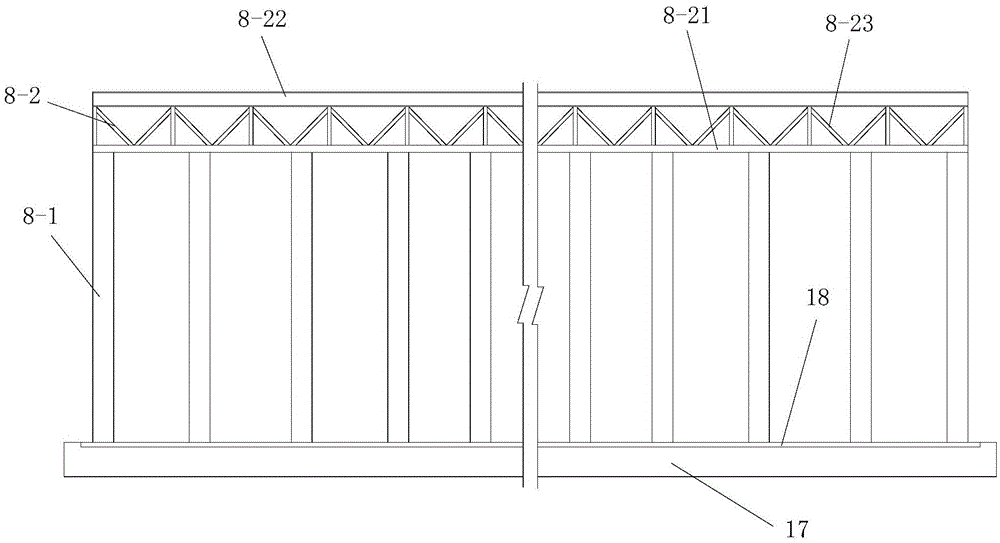

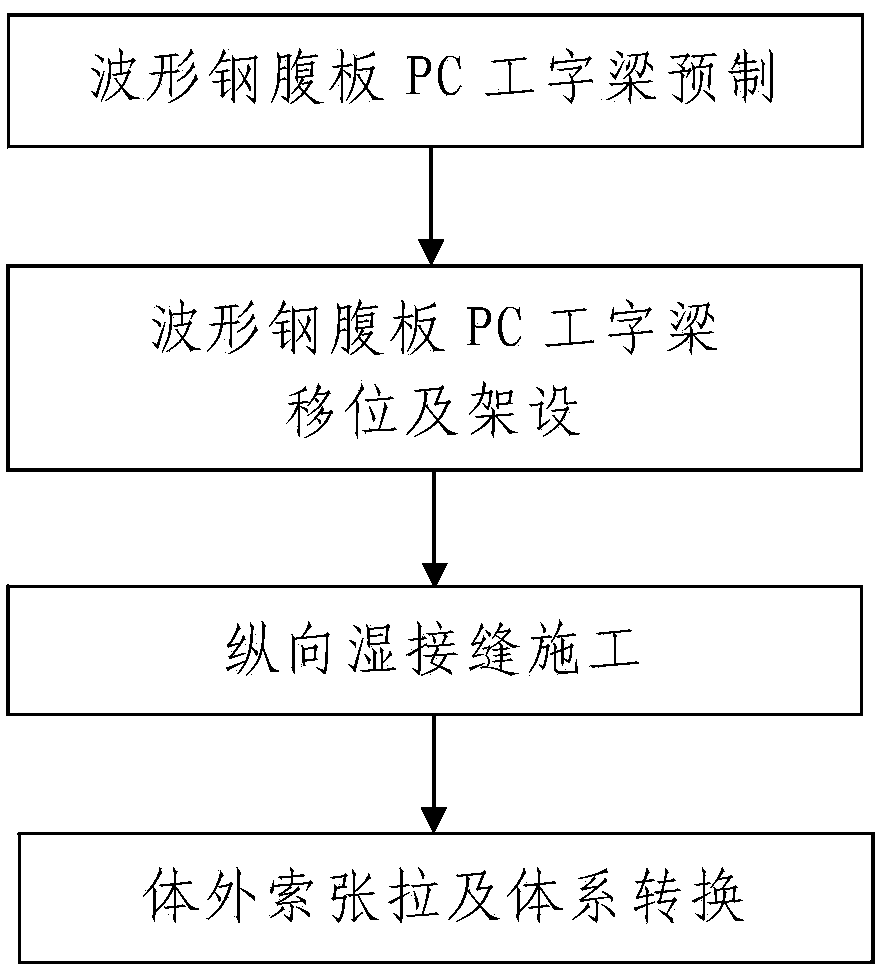

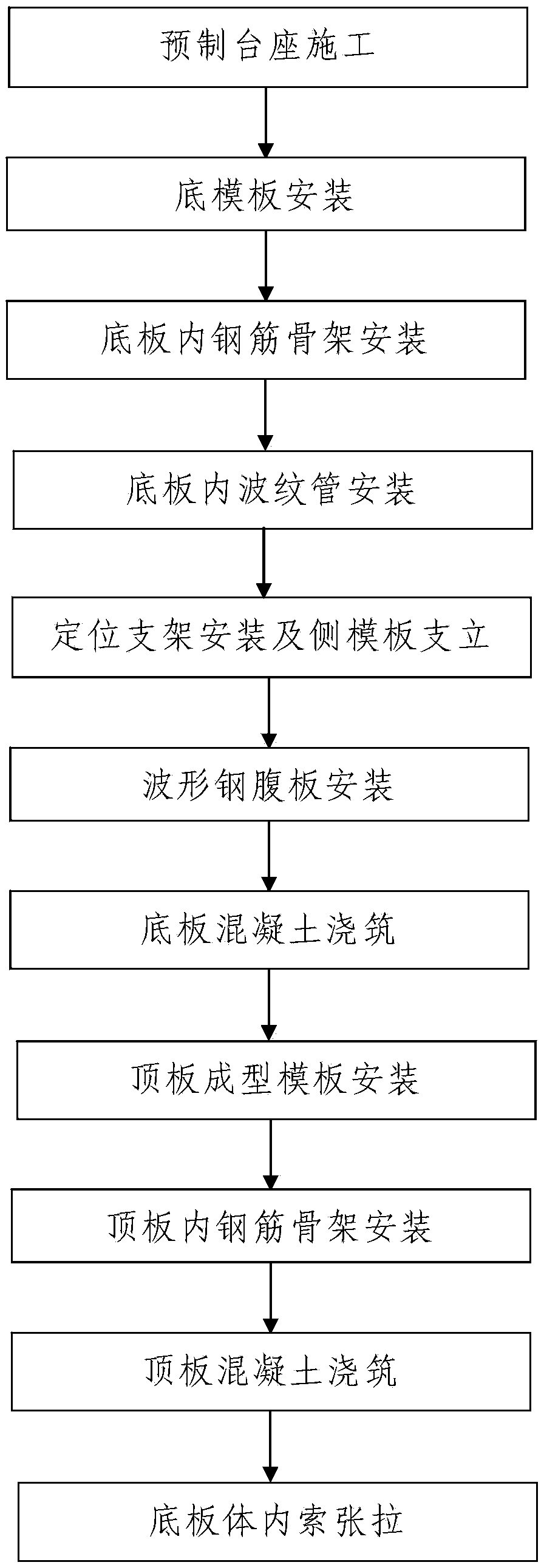

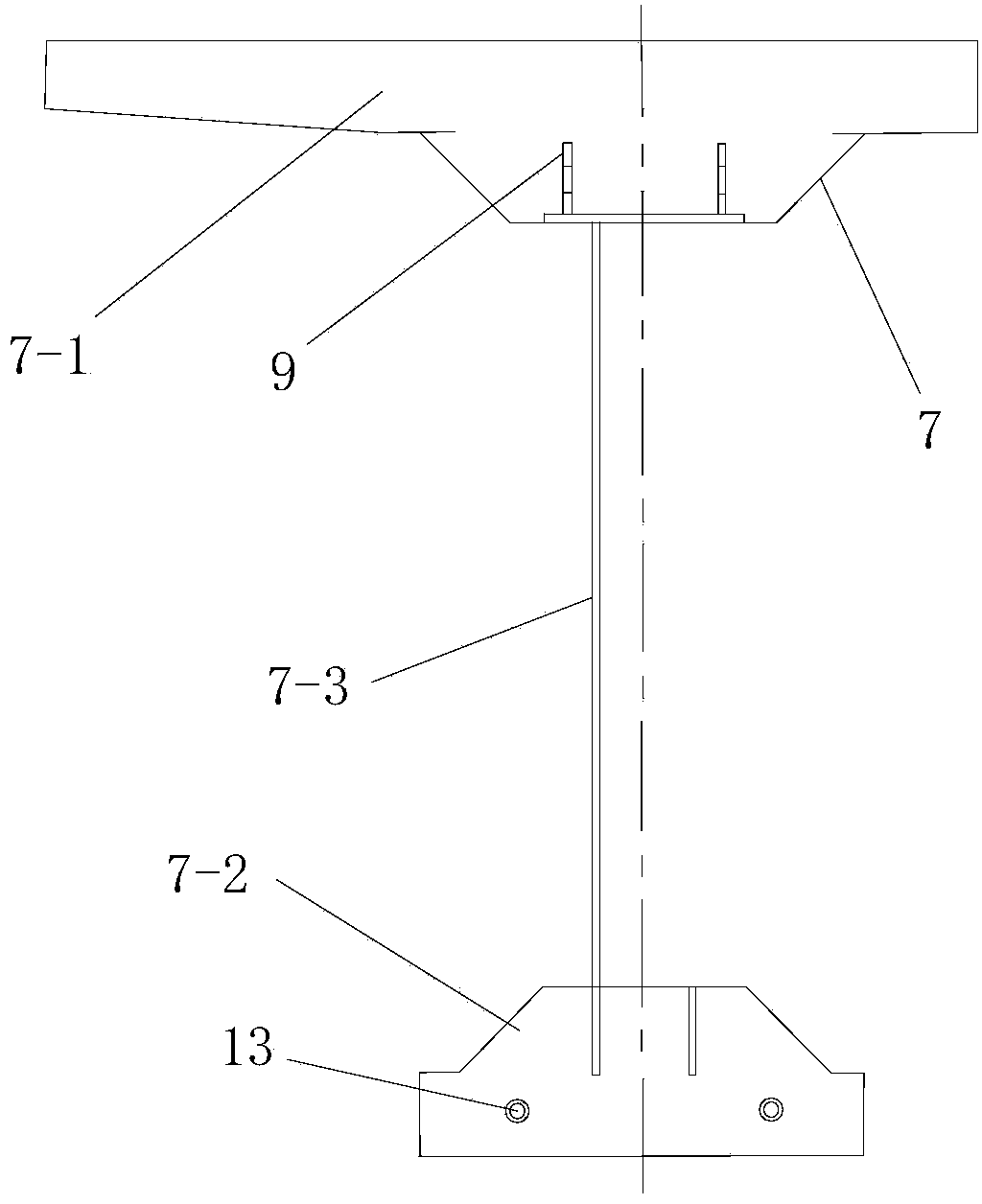

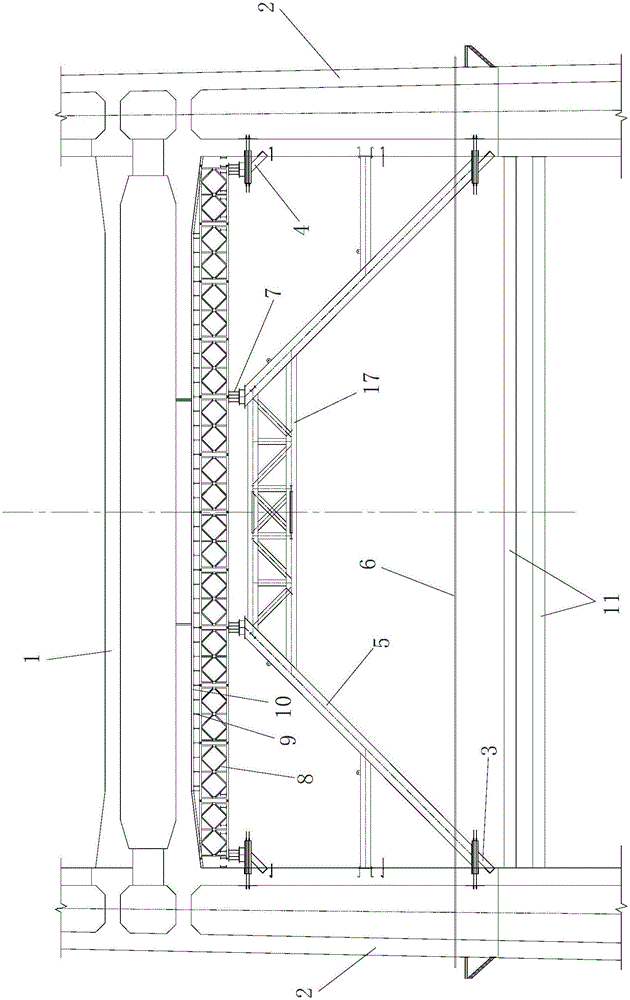

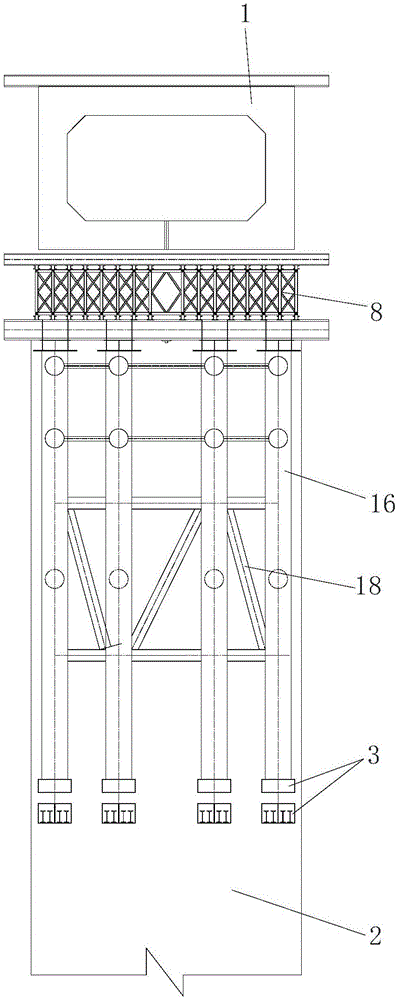

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

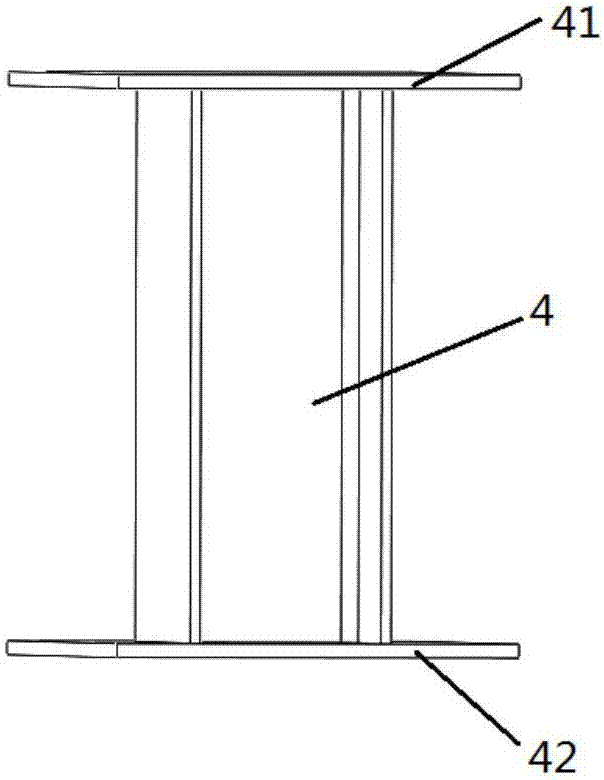

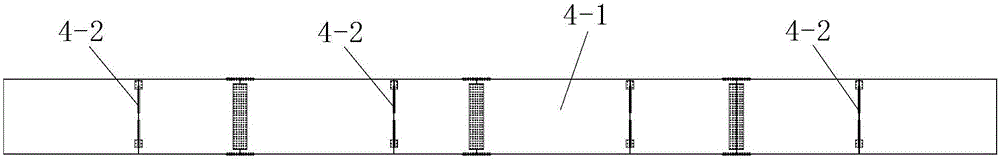

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

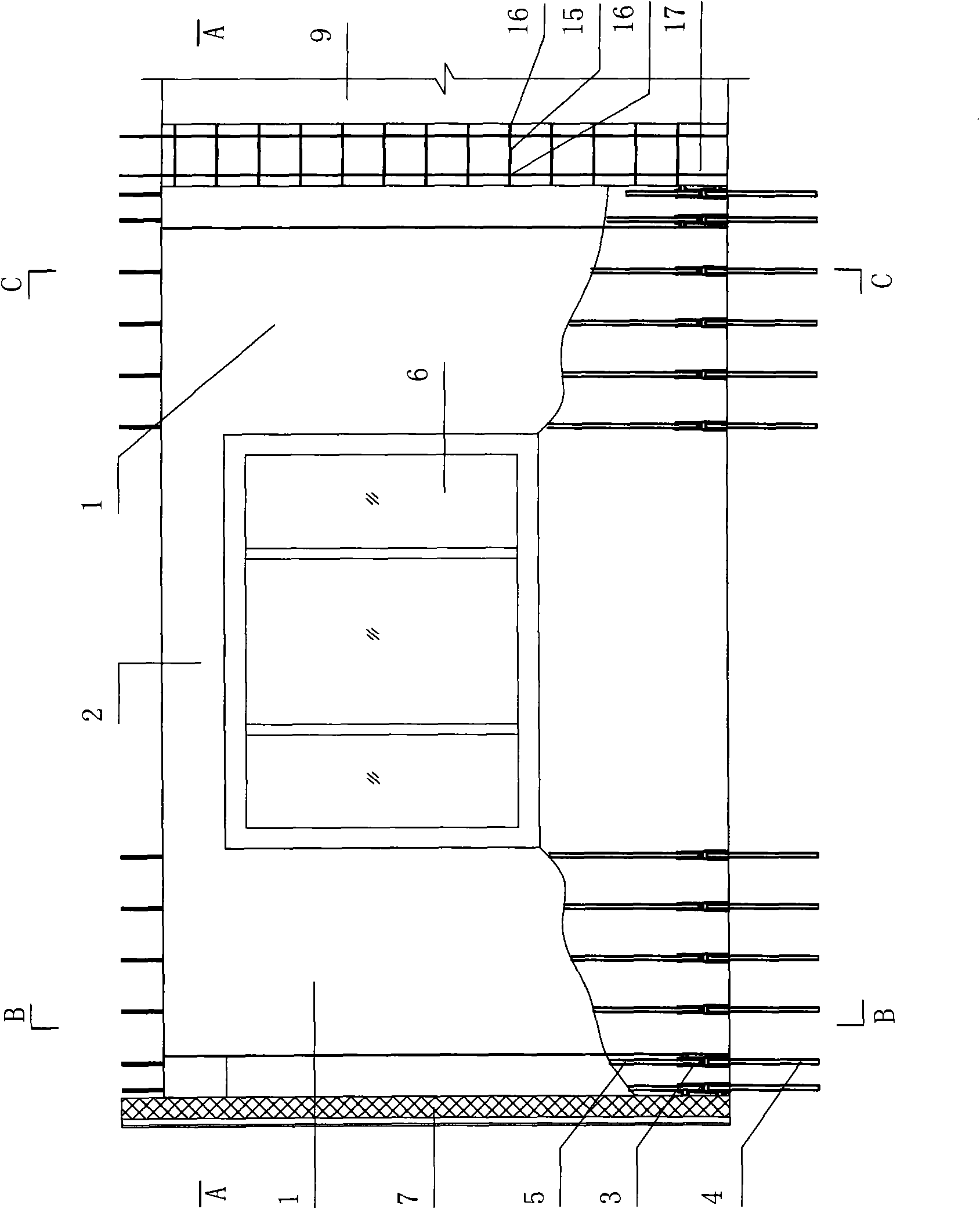

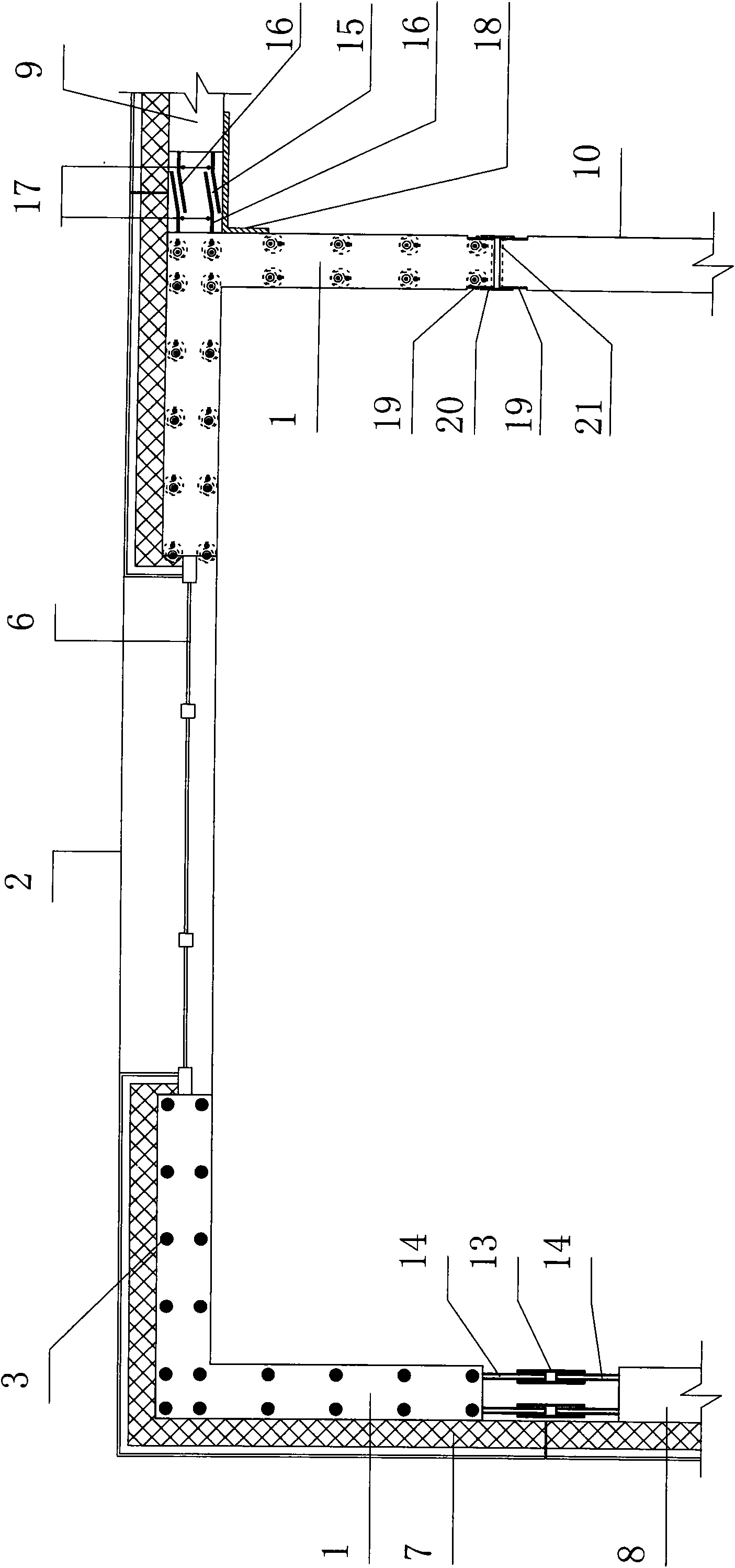

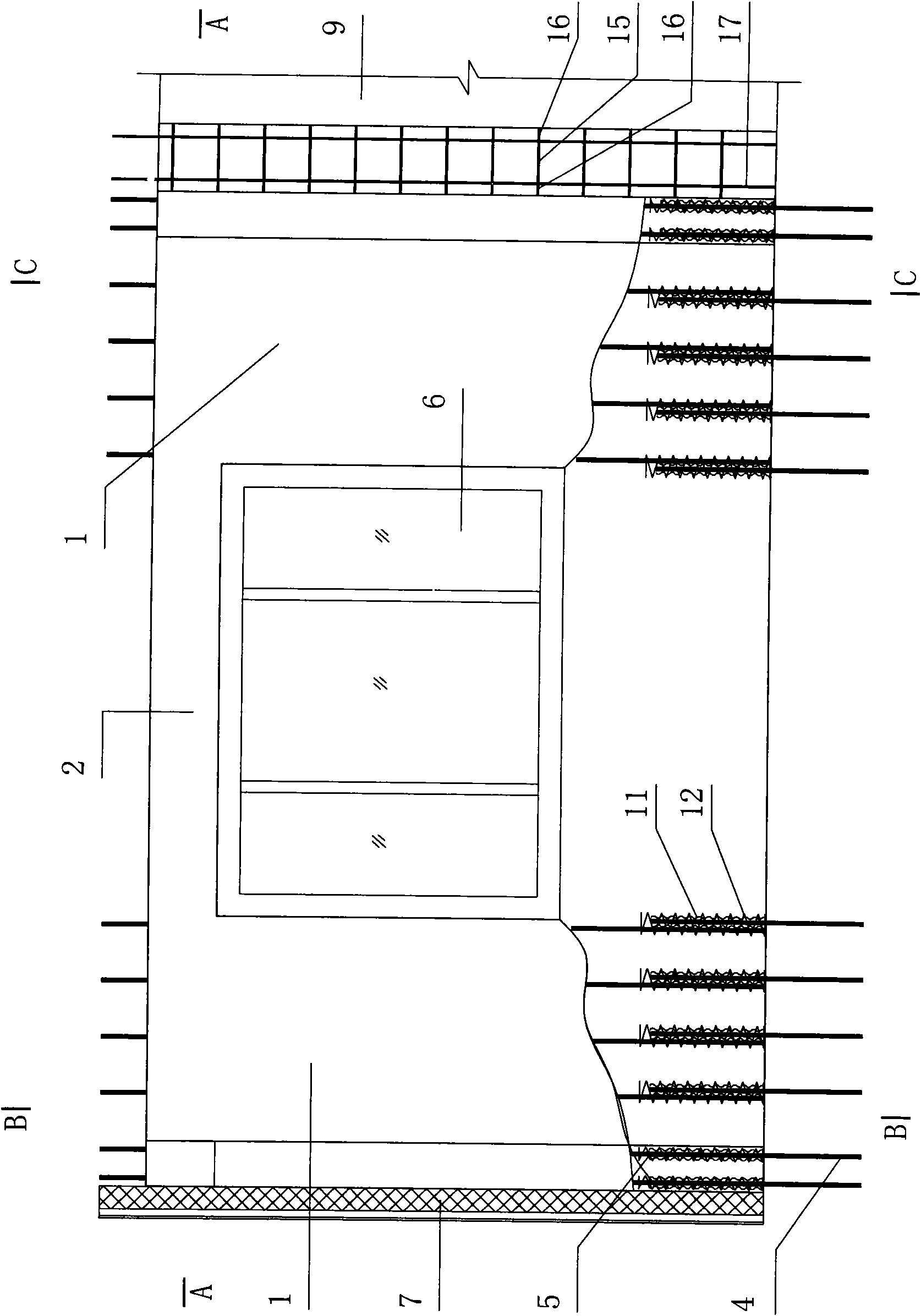

Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

The invention relates to a precast concrete short-limb shear wall provided with door windows and a manufacturing method thereof. The concrete short-limb shear wall refers to a shock-resistant wall of which the ratio of the wall limb cross section height to the thickness is between 5 and 8, and according to the active code requirement in China, the cross section thickness of a wall body is not less than 200 millimeters, and the stress performance of the structure of the concrete short-limb shear wall is between a specially-shaped column and a common shear wall structure. Because of the good performances in various aspects of construction, structure, construction cost, energy conservation and environmental protection and the like, the structural system becomes the structural form which is most suitable for residential constructions. The precast concrete short-limb shear wall comprises precast concrete wall limbs (1), wherein the wall limbs (1) are connected with connecting beams (2), are provided with door windows (6), and are connected with an external wall heat insulation layer and an architectural surface (7), and the wall limbs are connected with each other by assembling steel bars. The precast concrete short-limb shear wall is applied to industrialized fully-assembled shear walls for residential buildings.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Joint section structure for hybrid beam cable-stayed bridge and construction method thereof

InactiveCN104294748ASimple structureReasonable designCable-stayed bridgeBridge structural detailsConcrete beamsCable stayed

The invention discloses a joint section structure for a hybrid beam cable-stayed bridge. The joint section structure comprises a concrete beam-combined beam connecting structure connected between a concrete beam and a combined beam, wherein the combined beam comprises steel girders distributed in the longitudinal direction of the bridge, the steel girders are I-shaped and comprise steel girder top plates, steel girder base plates and steel girder web plates. The steel girder top plates and the steel girder base plates extend into the concrete beam, and the concrete beam-combined beam connecting structure comprises a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web plate. The joint section structure is simple, reasonable in design, high in construction speed and good in using effect, and the problems of complicated structure, poor joint effect and the like existing in a steel-concrete joint portion structure can be solved. The invention further discloses a construction method of the joint section structure. The construction method comprises the steps of 1 erecting a construction support; 2 hoisting a steel structure; 3 constructing the concrete beam-combined beam connecting structure; 4 casting concrete. The construction method is simple in step, reasonable in design, convenient to construct, high in construction speed and good in construction effect.

Owner:TONGJI UNIV

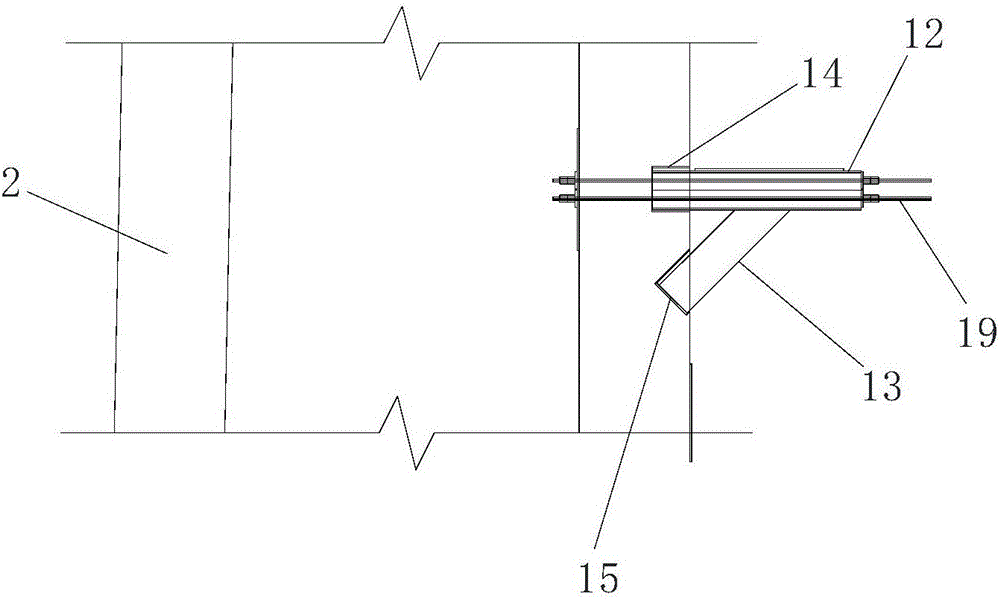

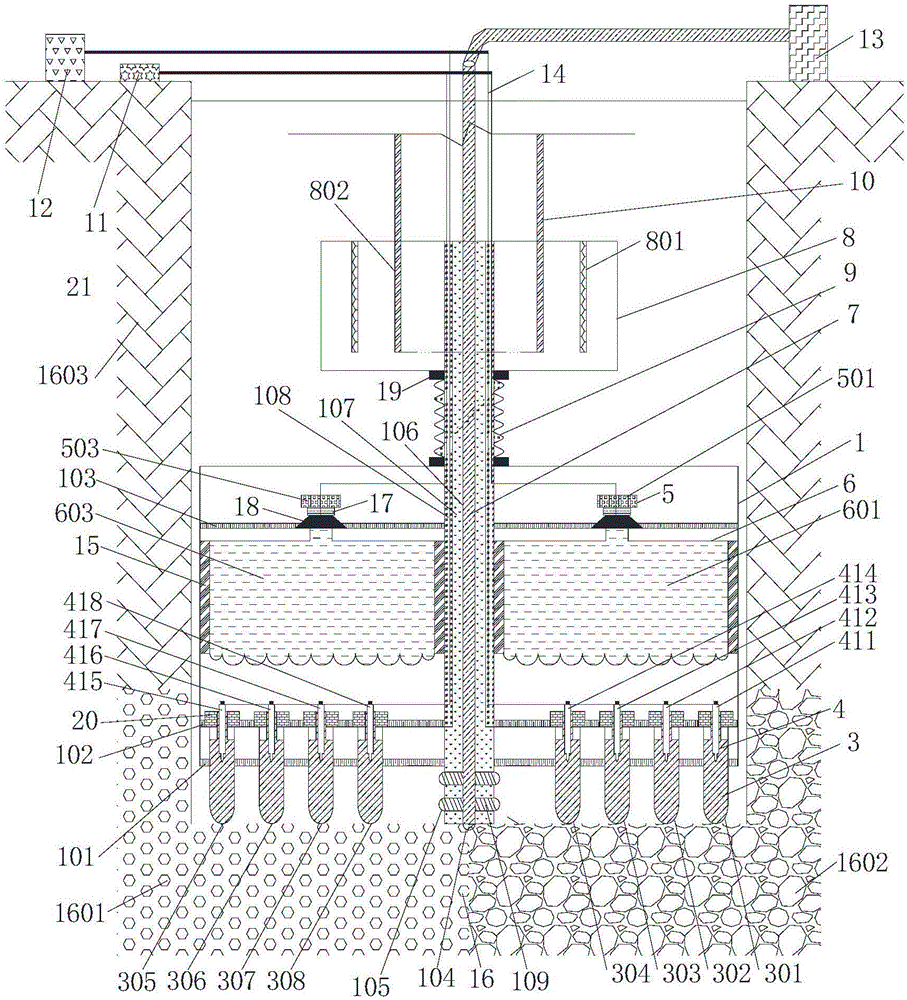

Pneumatic control rock cutting device for rock-embedded pile soft-hard interphase layer

ActiveCN106223855AQuality assuranceReduce construction costsConstructionsLiquid/gas jet drillingVibration controlAdhesive

A pneumatic control rock cutting device for a rock-embedded pile soft-hard interphase layer can meet the accurate drilling requirement of the soft-hard interphase layer in the rock-embedded pile construction process, and ensures drilling quality meeting design standards. The pneumatic control rock cutting device comprises a rock cutting retaining cylinder, a conical cutting tool system, a toothed cutting tool system, a vibration sensing system, a pneumatic sensing system, a pneumatic bag system, a high-pressure water pipe, a multi-path connector, an isolation spring, a drill rod, a pneumatic controller, a vibration controller, a high-pressure water pump, a cable, power adhesives, a pneumatic flow controller, a pneumatic stabilization bolt, a rubber shock pad, an isolation fastening bolt and retaining pins. The pneumatic control rock cutting device has the advantages that according to the stress condition of soft-hard rock cutting, constant pressure of a drilled soft rock is kept, pneumatic pressure is applied to incompletely cut hard rocks, and the device solves the common problems that a rock-embedded pile easily deviates in construction in the soft-hard interphase layer and a reinforcement cage cannot descend for installation by the aid of the criterion of 'constant pressure-pressurization'.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

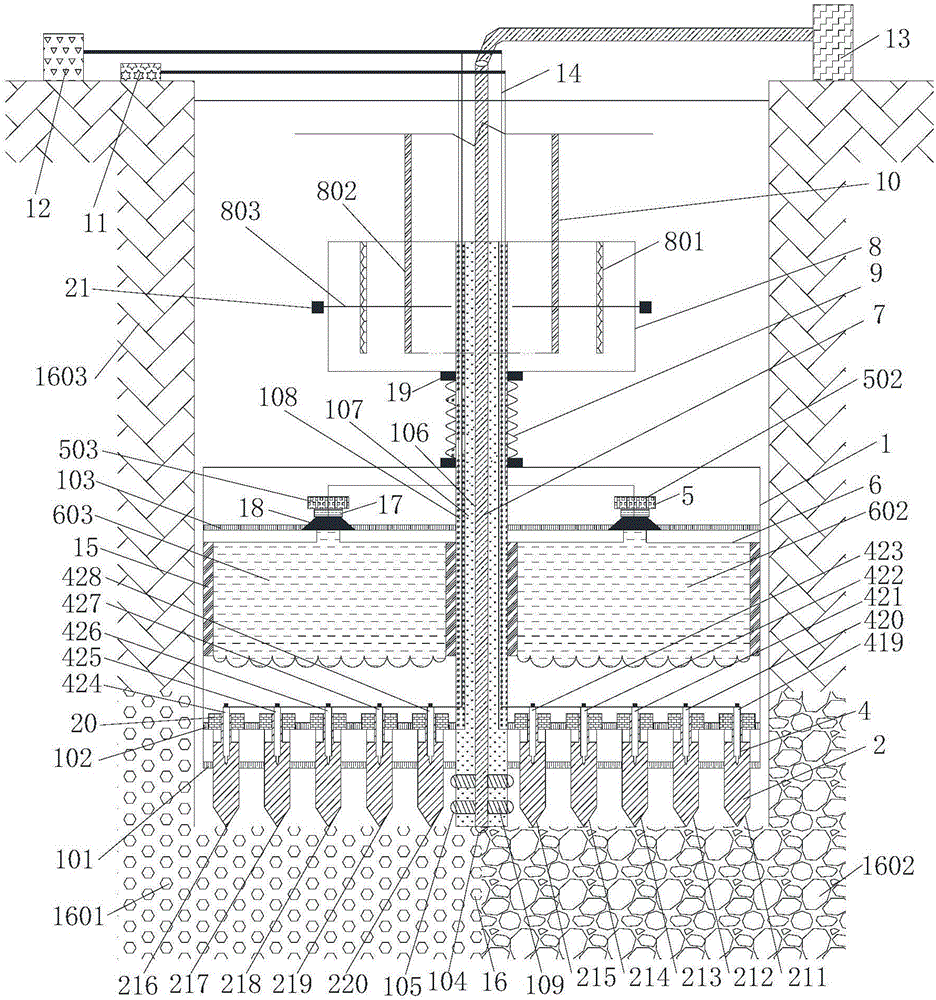

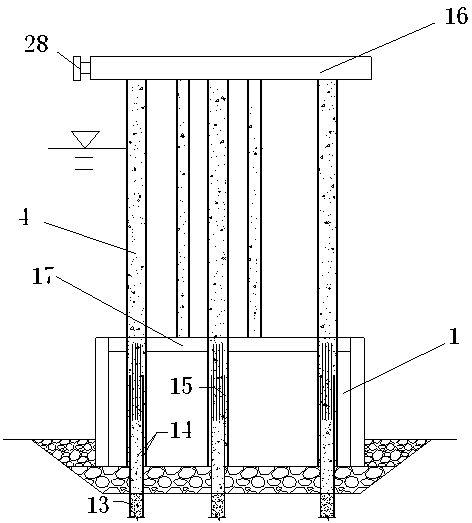

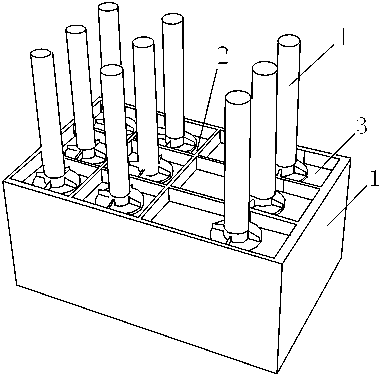

Deepwater open type wharf with combined foundation and method for constructing deepwater open type wharf

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

Construction method for barrel wall of prestressed concrete wind power tower and special construction equipment

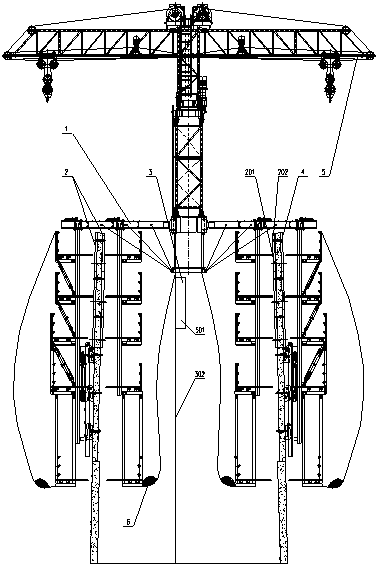

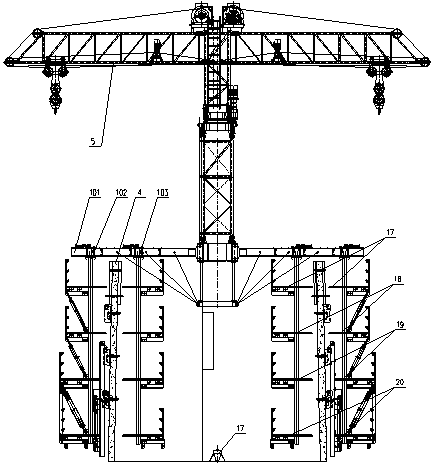

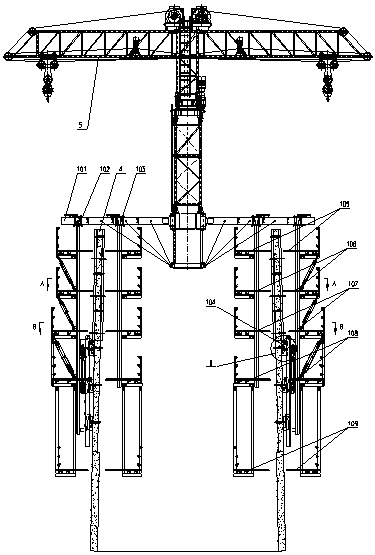

PendingCN107697818ANo strength, no special requirementsImprove the quality of look and feelWind motor supports/mountsWind energy generationElectricityFalsework

The invention relates to a construction method for the barrel wall of a prestressed concrete wind power tower and special construction equipment. The construction method comprises the following steps:mounting a wall-attaching device, the special construction equipment and a 2t double cantilever flat-top crane on the basis that the barrel wall of the wind power tower is poured previously; conveying operating personnel to an annular telescopic construction platform through a manned lifting machine; enabling the annular telescopic construction platform, a turnover lifting platform and an inner suspension platform of the special construction equipment to form a multi-layer annular horizontal conveying platform to carry out constructions such as steel bar binding, concrete pouring and inner and outer adjustable arc template assembling and disassembling; using by turning around the inner and outer adjustable arc templates layer by layer, and lifting the special construction equipment and aclimbing guide rail alternatively until the concrete construction of the barrel wall of the wind power tower frame is completed; and adjusting the pushing device of the annular telescopic constructionplatform in time along with the radius reduction of the wind power tower during the lifting process of the special construction equipment, and contracting the turnover lifting platform; dismantling the inner suspension platform when the construction near the top of the wind power tower is to be carried out, connecting the drum ring of the annular telescopic construction platform with a bracket seat pre-buried when the construction of the top of the wind power tower is carried out, and erecting a temporary scaffolding platform to complete the construction of the barrel wall at the top of the wind power tower.

Owner:KERUN ELECTRO MECHANICAL ENG

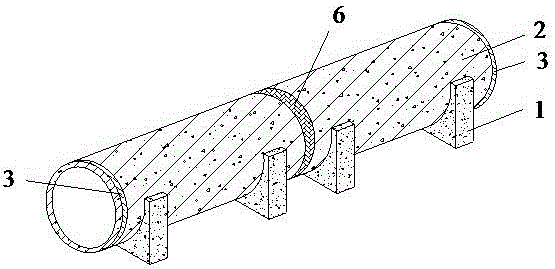

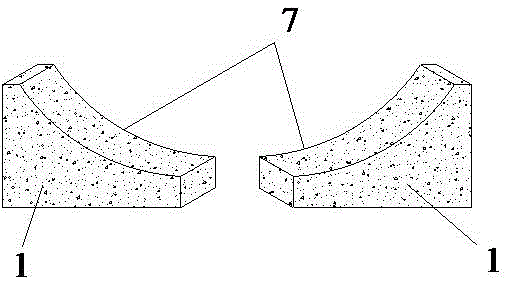

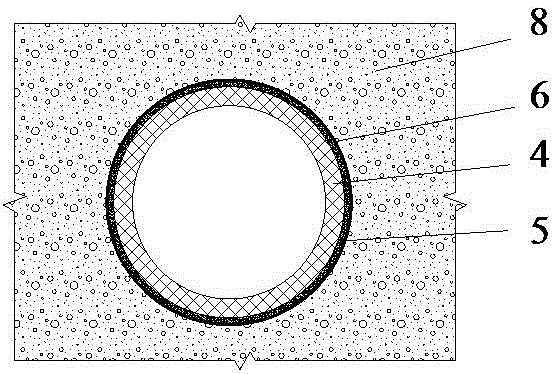

Rainwater pipeline structure and construction method thereof

InactiveCN105113607AElevation is easy to controlEasy to control the installation positionSewer pipelinesArchitectural engineeringSealant

The invention relates to the technical field of municipal pipeline engineering, and particularly discloses a rainwater pipeline structure and a construction method thereof. The rainwater pipeline structure comprises prefabricated rainwater pipe sections. The rainwater pipeline structure is characterized in that the adjacent prefabricated rainwater pipe sections are connected end to end through polysulfide sealant, and the outer sides of the joints are coated with cement mortar and wound with steel wire meshes; the bottom of each prefabricated rainwater pipe section is provided with prefabricated supports which are provided with an arc-shaped contact surfaces, and the contact surfaces of the prefabricated supports and the prefabricated rainwater pipe sections are provided with the cement mortar. According to the rainwater pipeline structure and the construction method thereof, a reasonable combination mode between the prefabricated rainwater pipe sections and the prefabricated supports is utilized, the construction cost is low, construction is convenient, the construction speed is high, the construction quality is easy to guarantee, and then the effect of reducing the cost is achieved.

Owner:JINAN URBAN CONSTR GRP

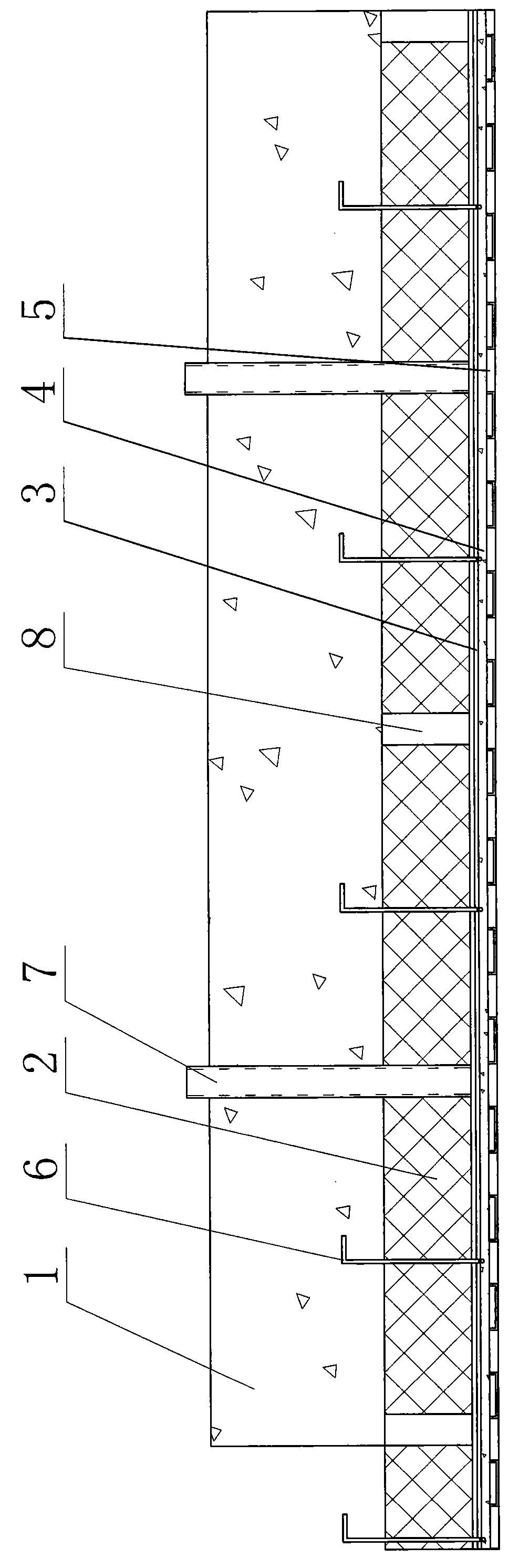

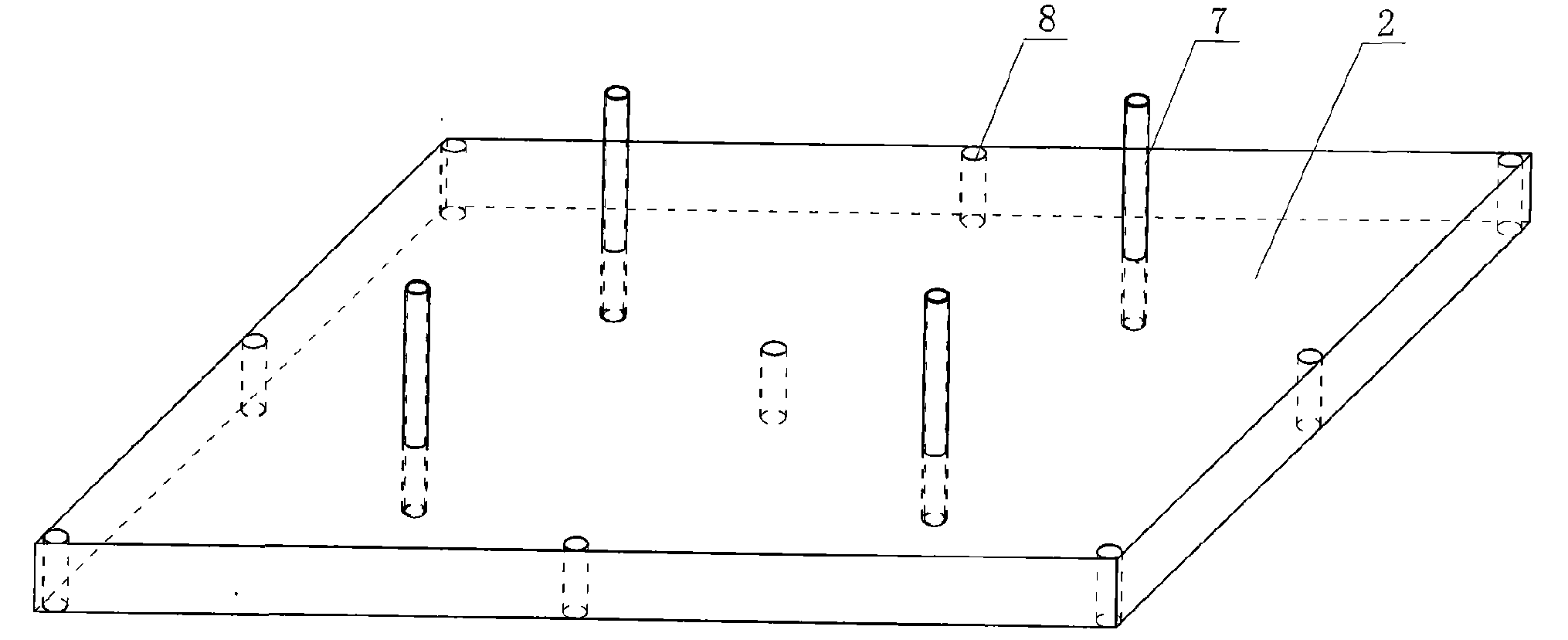

Once formed precast concrete shear wall with heat preserving veneer and production method thereof

InactiveCN101603335AUnified specificationsUniform qualityWallsClimate change adaptationResidenceRebar

The invention relates to a once formed precast concrete shear wall with a heat preserving veneer and a production method thereof. A building structure with an original construction way has higher comprehensive energy consumption and is not beneficial to the environment and energy saving in the construction way. The once formed precast concrete shear wall with a heat preserving veneer comprises a wall body (1) which is connected with an insulating layer (2), a welding reinforcing mesh (3), a sand pulp bonding layer (4) and an architectural surface (5) in sequence, wherein a binding bar is bound with the wall body; the sand pulp bonding layer is connected with a pulp filling pipe (7) passing through the wall body; and the sand pulp bonding layer is provided with an air exit hole (8). The invention is used as a residence industrial all-assembled type construction wall body and a production method thereof.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

ActiveCN102146658AReduce stress concentrationReduced risk of crackingSuspension bridgeBridge structural detailsCrack resistanceBridge deck

The invention discloses a locally uncombined suspension bridge steel-concrete combined bridge deck system and a construction method of the combined bridge deck system, and belongs to the technical field of bridge structures. The bridge deck system consists of concrete slabs, longitudinal steel beams, cross steel beams, air nozzles and toggle pin connectors; and a suspension bridge section steel-concrete combined bridge deck system is prefabricated in a factory. The prefabricated concrete slabs and section steel main beams form a whole through concrete wet joints and the toggle pin connectors. The prefabricated concrete slabs and cast-in-place concrete joints are only connected with the cross steel beams to form a whole through the toggle pin connectors, the longitudinal steel beams are not provided with the toggle pin connectors, and meanwhile, the toggle pin connectors are not arranged in a certain area of the ends of the cross steel beams at hoisting points. The problems of cracking, complex structures of toothed grooves at the slab ends of the prefabricated concrete slabs and the like due to the factors of temperature, contraction, creep and the like of the concrete slabs of the traditional suspension bridge combined bridge deck system are solved by adopting a locally uncombined technology on the premise of keeping the consumption of steel, the manufacturing process of the prefabricated slabs is simplified, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved.

Owner:TSINGHUA UNIV

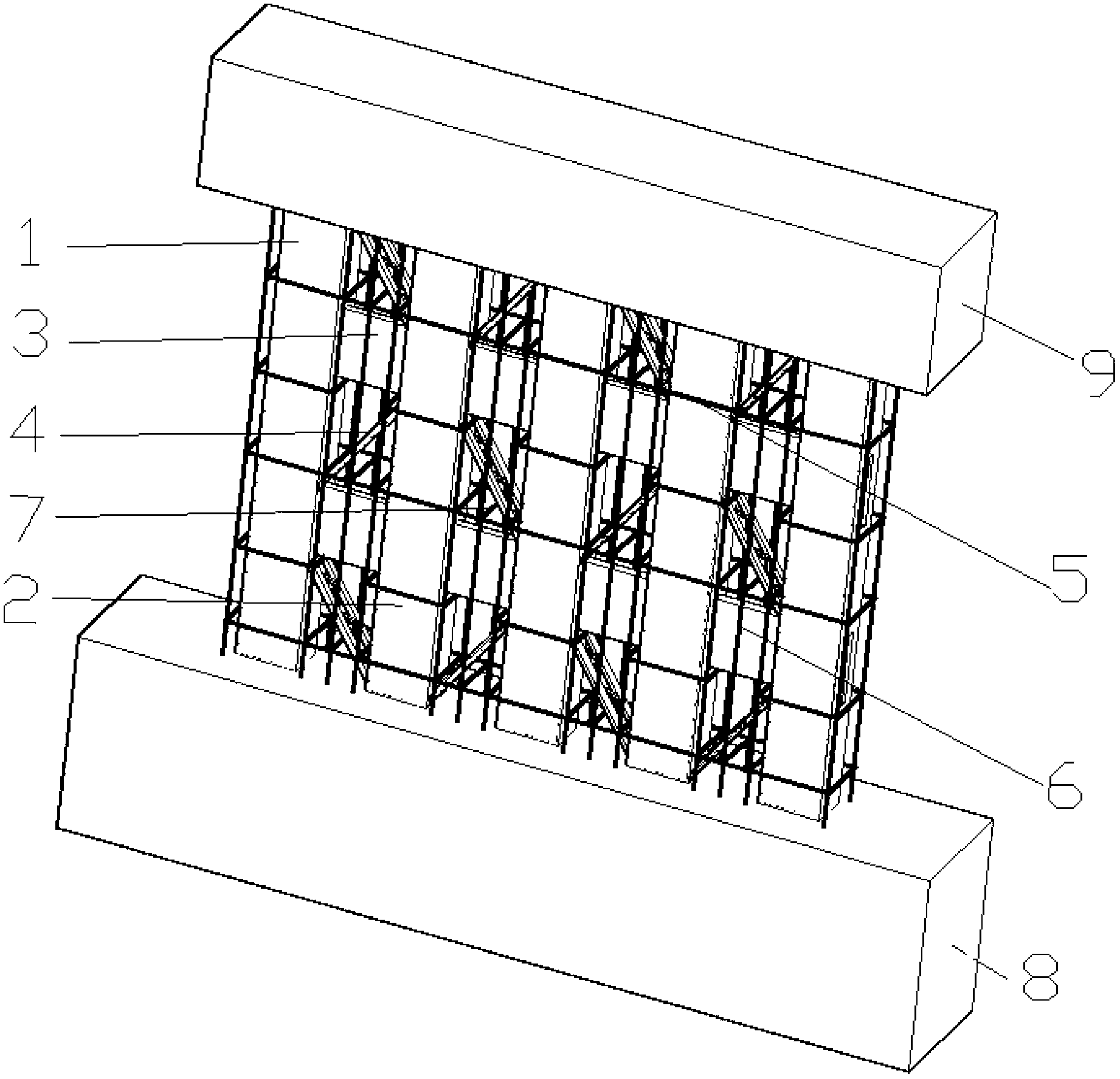

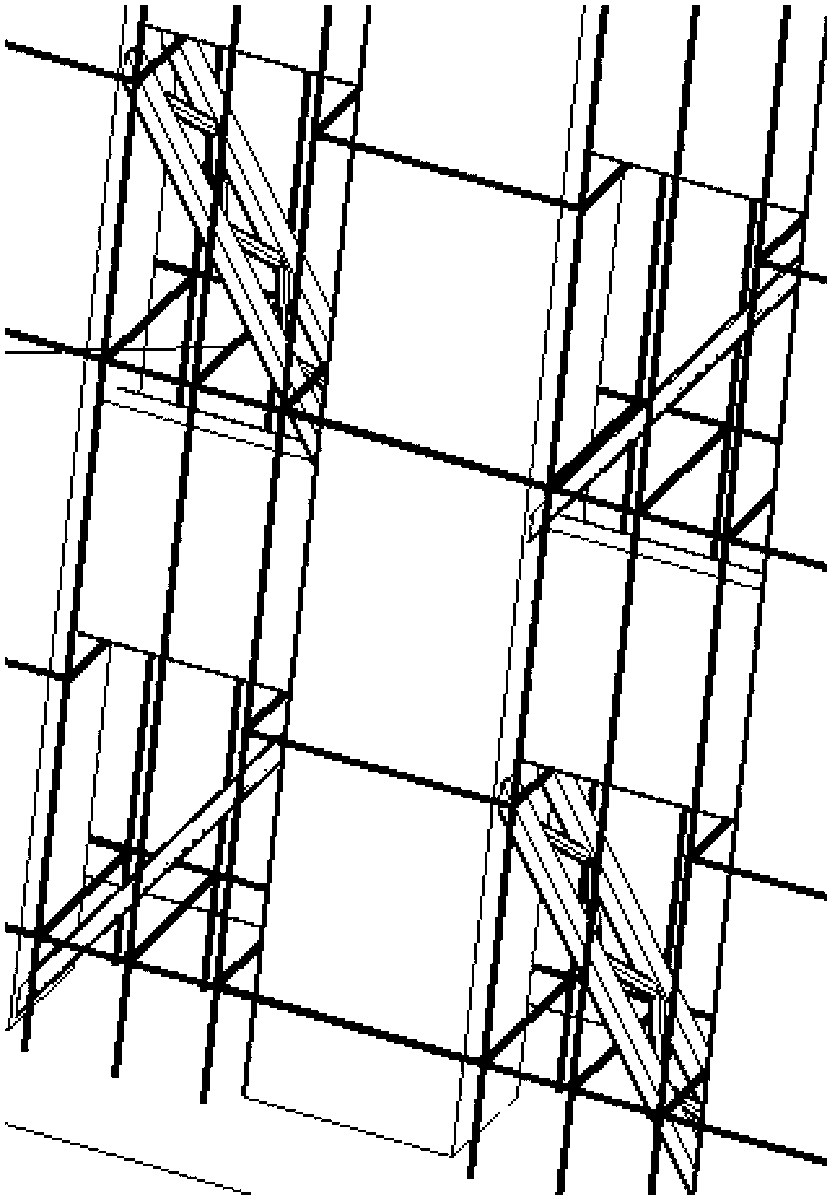

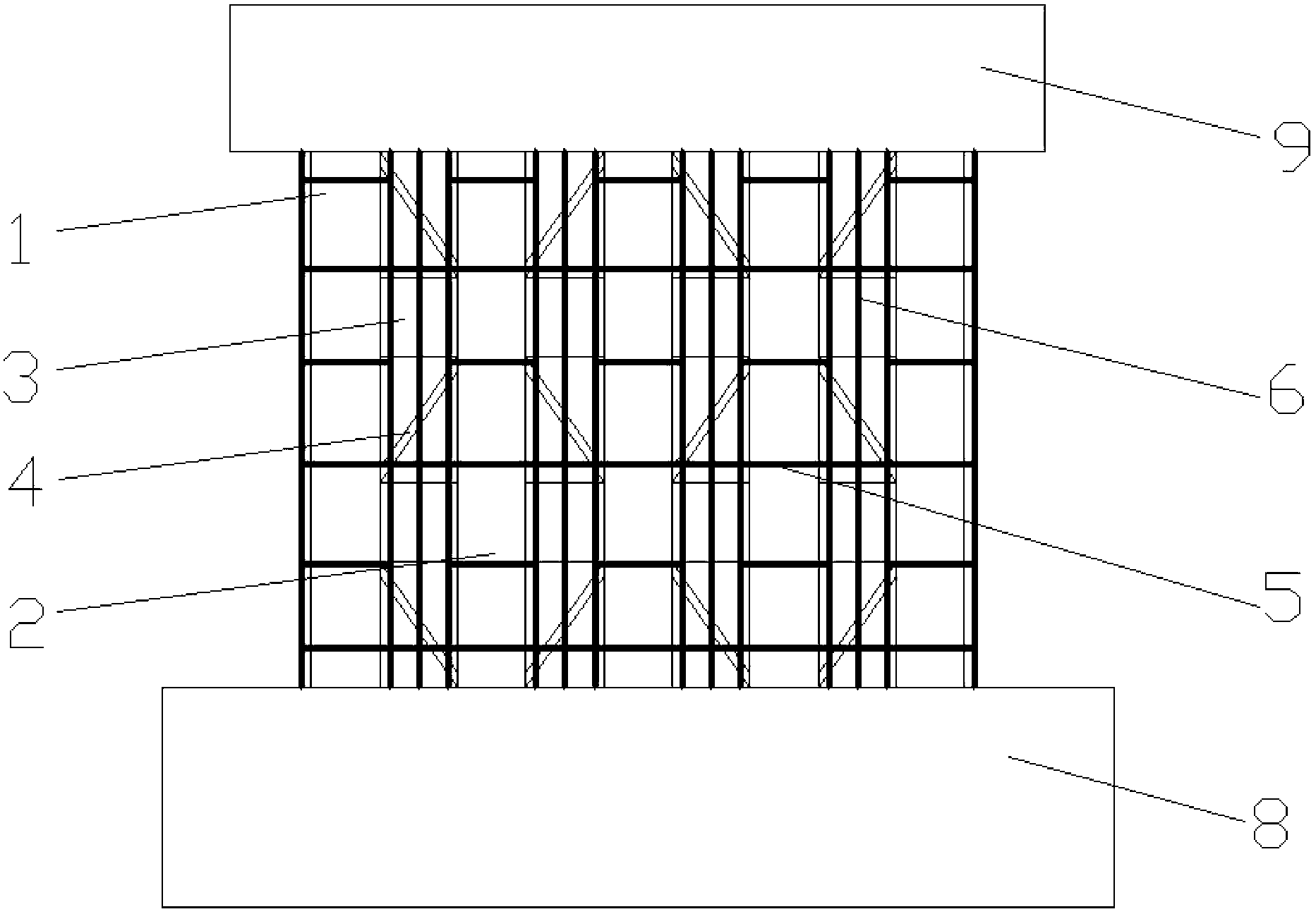

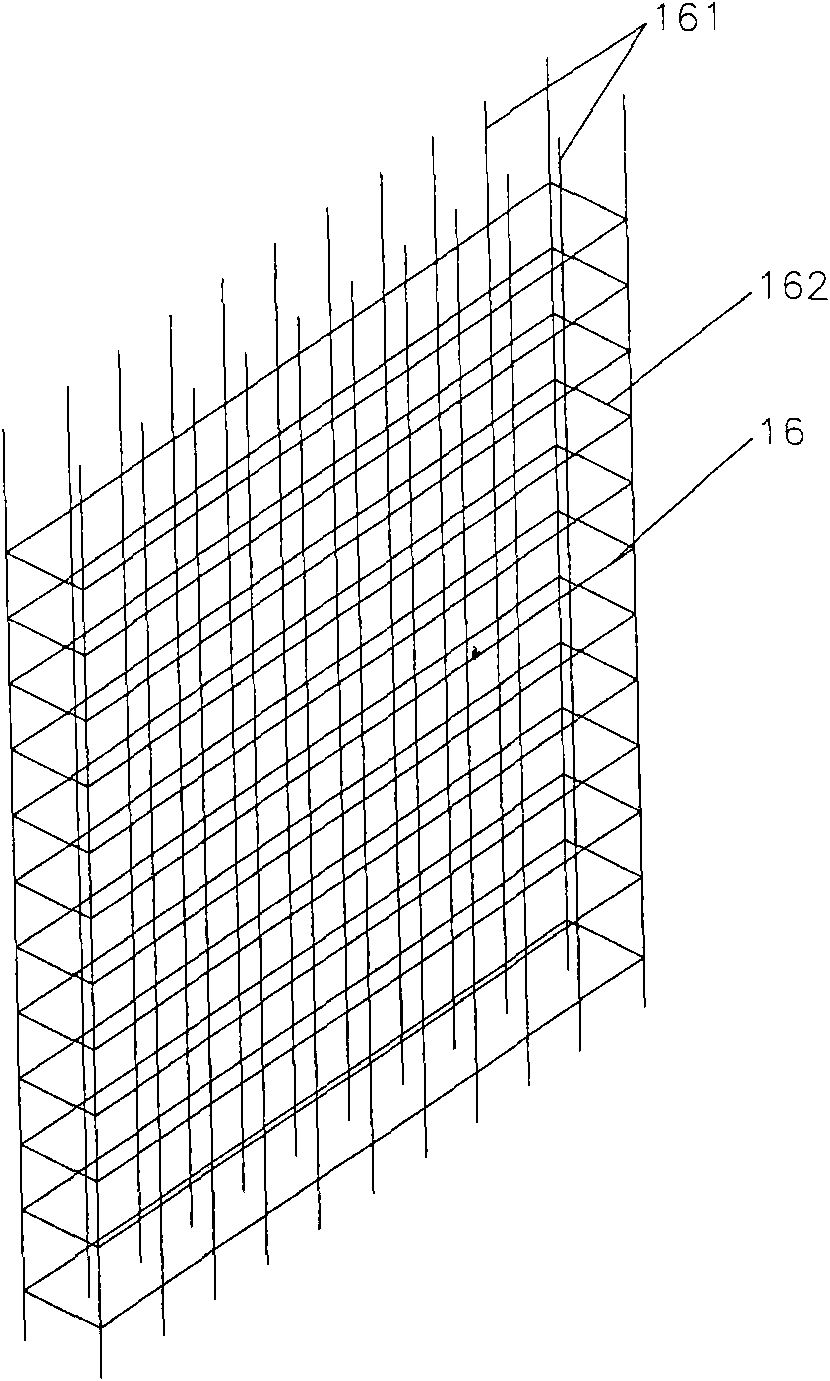

Steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall and manufacturing method

ActiveCN102704593AGive full play to the anti-seismic abilityImprove the compressive capacityWallsBuilding material handlingReinforced concreteSteel bar

The invention discloses a steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall and a manufacturing method, and belongs to the field of steel-concrete combined shear walls. The steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall comprises steel tube reinforced concrete composite frame columns, steel tube reinforced concrete composite core columns, steel beams, lattice steel supports and a reinforced concrete shear wall body, wherein the two ends of the shear wall are provided with the steel tube reinforced concrete composite frame columns between which a plurality of parallel steel tube reinforced concrete composite core columns are arranged; the steel tube reinforced concrete composite frame columns are connected with the steel tube reinforced concrete composite core columns by the steel beams and the lattice steel supports and all the steel tube reinforced concrete composite core columns are connected by the steel beams and the lattice steel supports; the shear wall reinforcements are bound; and concrete is cast to construct the steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall. The steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall has the advantages of improved bearing capacity, slow attenuation in bearing capacity and rigidity, stable later anti-seismic performance, improved shear wall ductility and energy consumption performance due to existence of the combined steel structure framework, more superior anti-seismic performance, convenience in steel structure construction and capability of being used in high-rise or large-sized complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

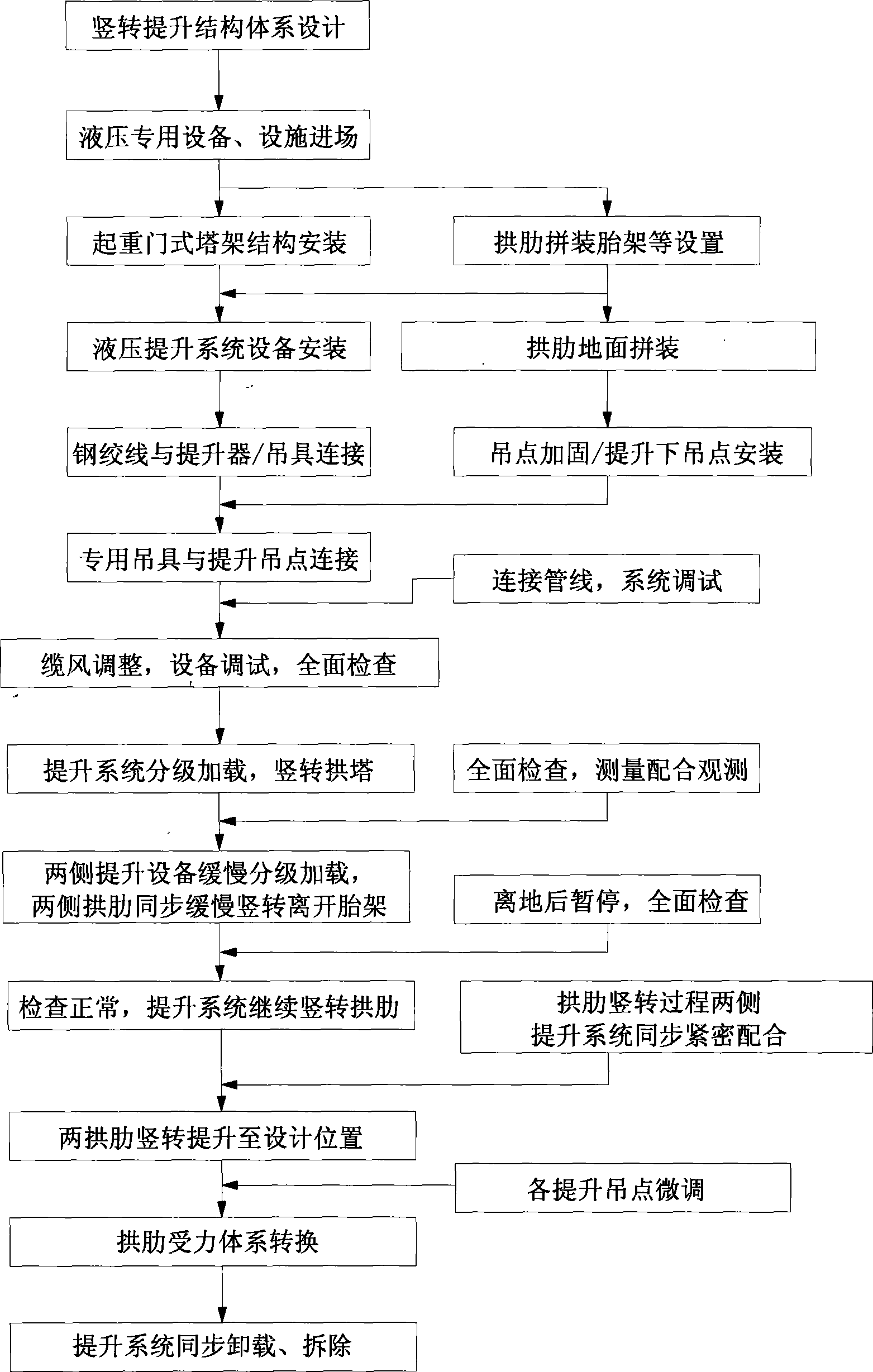

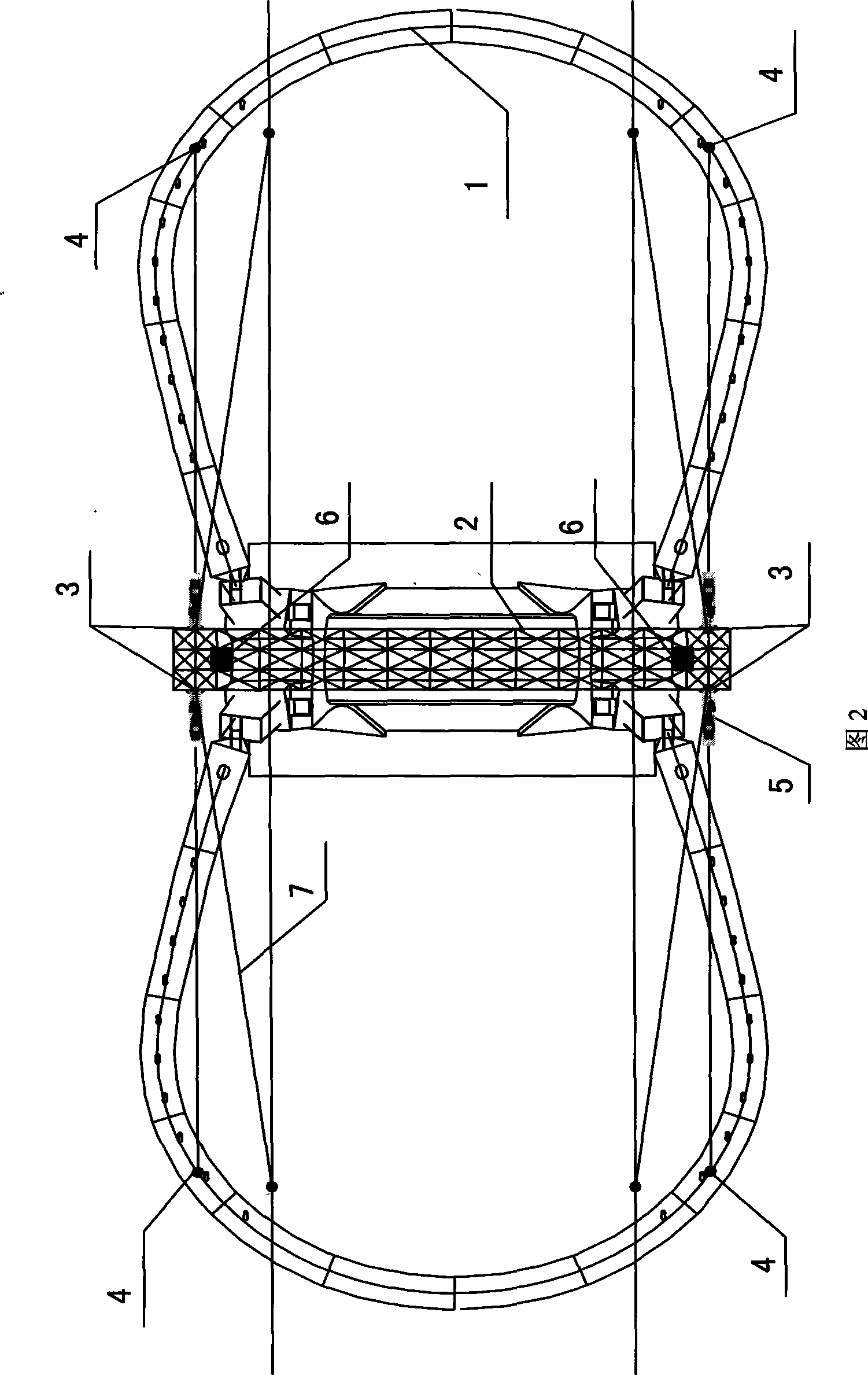

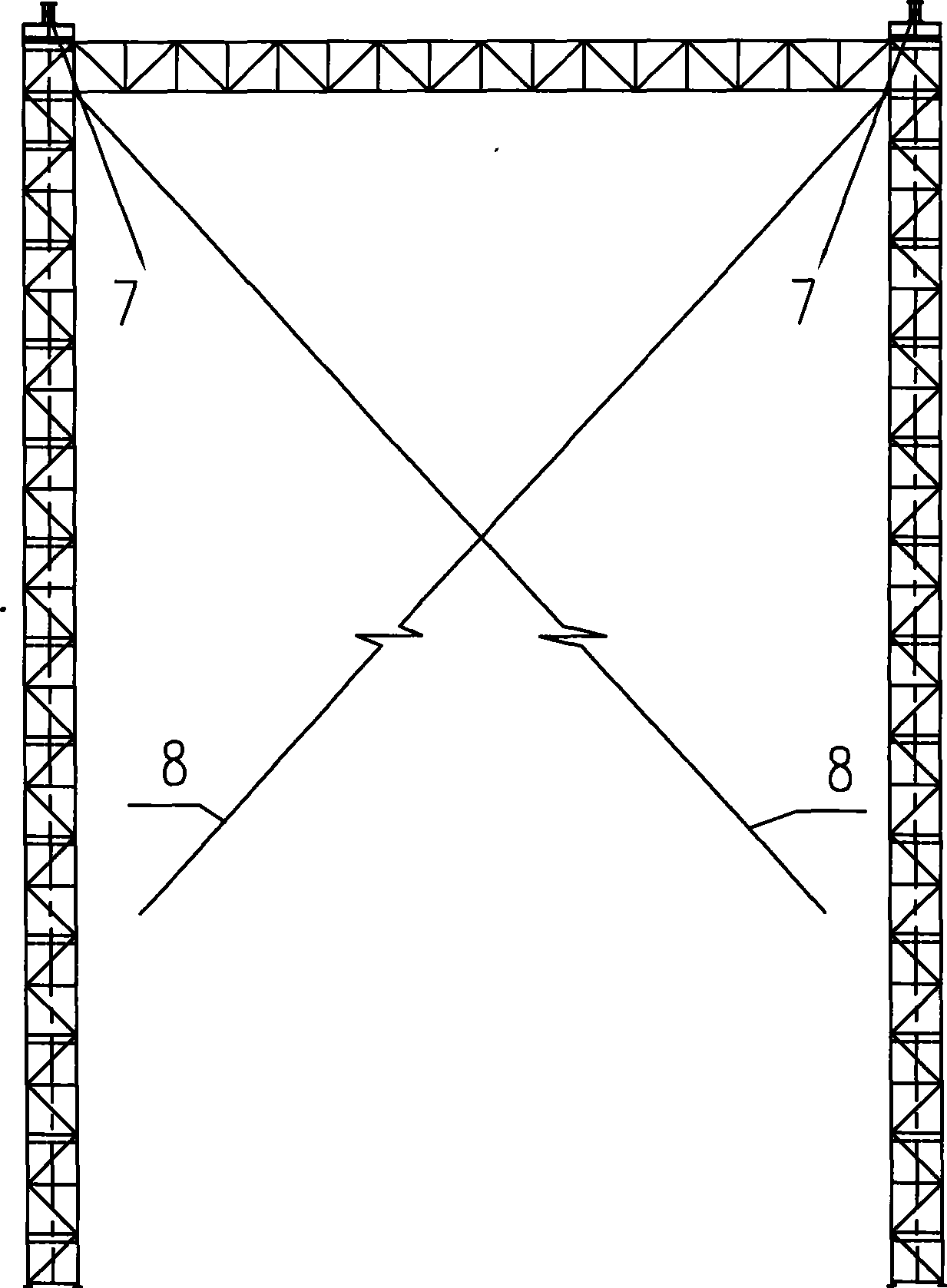

Synchronous vertical swing lift construction method for double inclination arc tower

ActiveCN101446075AIncrease the volume of the facilityReduce weightBridge erection/assemblyReinforced concreteCentral line placement

The invention discloses a synchronous vertical swing lift construction method for a double inclination arc tower. The method comprises the following steps: arranging a vertical swing winch at the combination of two gate-shaped arch ribs and reinforced concrete, arranging a bearing gate type lifting tower at the position of the symmetrical central line of the arch ribs, arranging an upper lifting sustained center and a lower lifting sustained center at the top of the tower and on the arch ribs respectively, and performing symmetrical synchronous vertical swing lift through two pairs of hydraulic lifters by utilizing the symmetry character of the double arch ribs, so as to achieve the purpose of vertically swinging the arch ribs from the planimetric position to the mounting position. The construction method has the advantages that the arc tower construction difficulty is reduced, tools and materials are saved, the construction period is shortened, and the installation of two mammoth arch rib structures can be completed with high precision and high quality; aloft work of the arch ribs is converted into ground integral assembly work, the construction efficiency is high, the safety protection work is easy to organize, and the construction quality is easy to guarantee; machines and equipment required for the construction are in a small quantity, the process is simple, and the operation is safe; the construction speed is high, the manufacture cost is low, and the investment is saved.

Owner:JIANGSU HUNING STEEL MECHANISM

High-speed railway subgrade structure for saline soil areas

The invention belongs to the technical field of high-speed railway subgrade engineering, and particularly relates to a high-speed railway subgrade structure for saline soil areas. The high-speed railway subgrade structure comprises a road cutting structure, wherein the road cutting structure comprises a subgrade bed surface layer and a subgrade bed bottom layer; a partition layer is arranged at the bottom of the subgrade bed bottom layer; a surface drain system is arranged at each of two sides of the road cutting structure, an underground drain system is arranged at the bottom of the surface drain system; the partition layer extends outwards along two sides of the longitudinal direction to intersect the surface drain system or underground drain system. Based on the compact connection of the surface drain system, the underground drain system, the partition layer and the like with the components thereof to achieve special purposes, the high-speed railway subgrade structure is simple, and can effectively cut off capillary water migration pathways between subgrade soil and the road cutting subgrade bed structure, thereby avoiding the problems of salt expansion, break-up expansion, melt sinking and the like and guaranteeing the long-term normal use of high-speed railway subgrade engineering.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

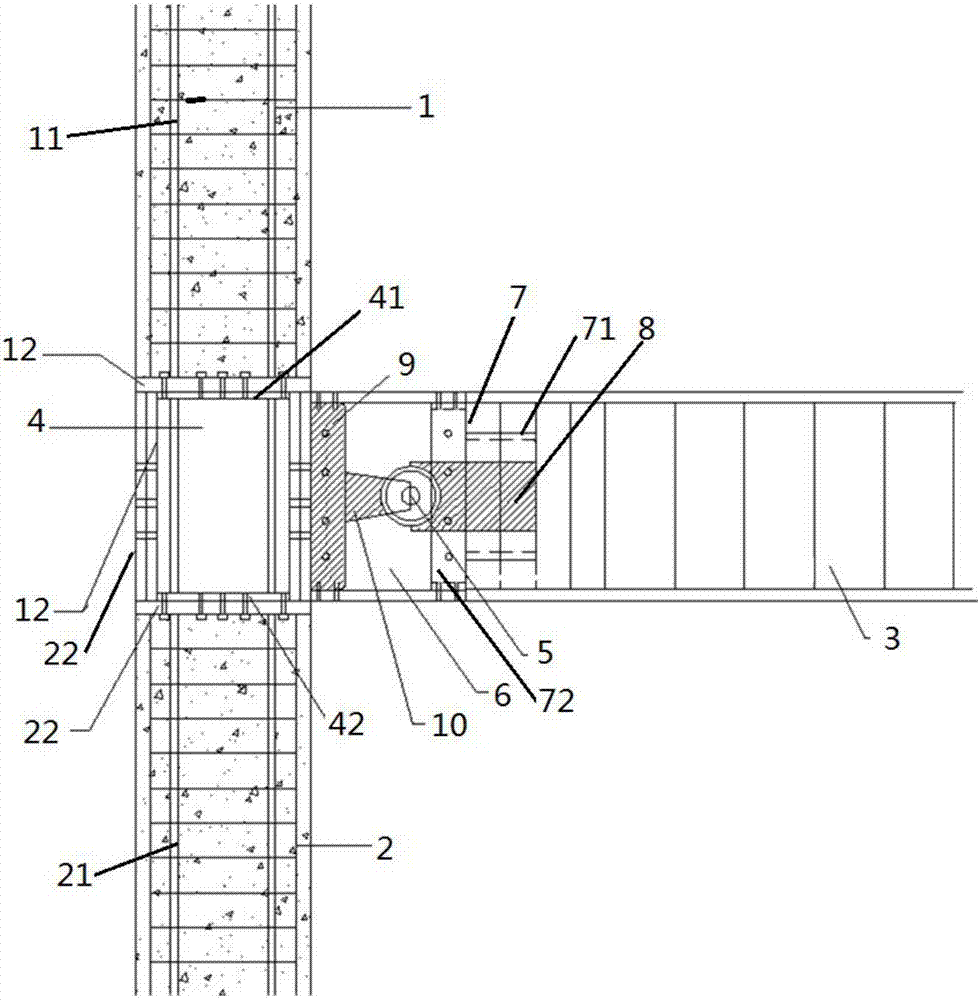

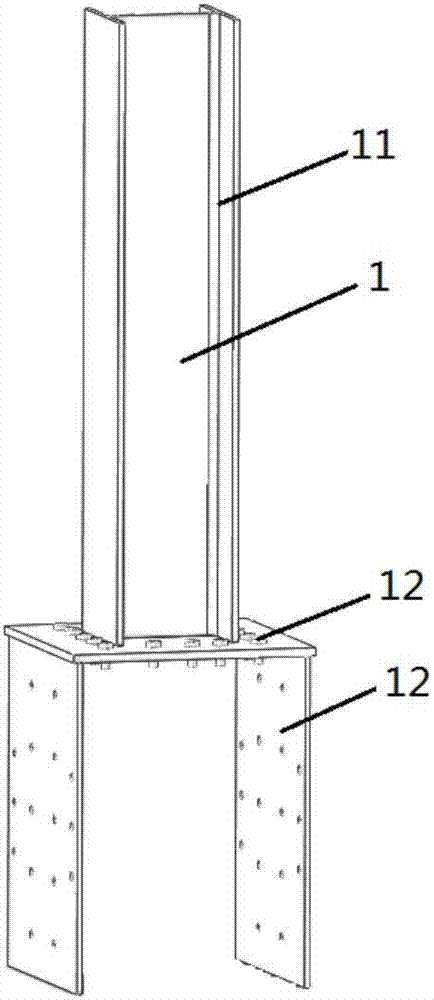

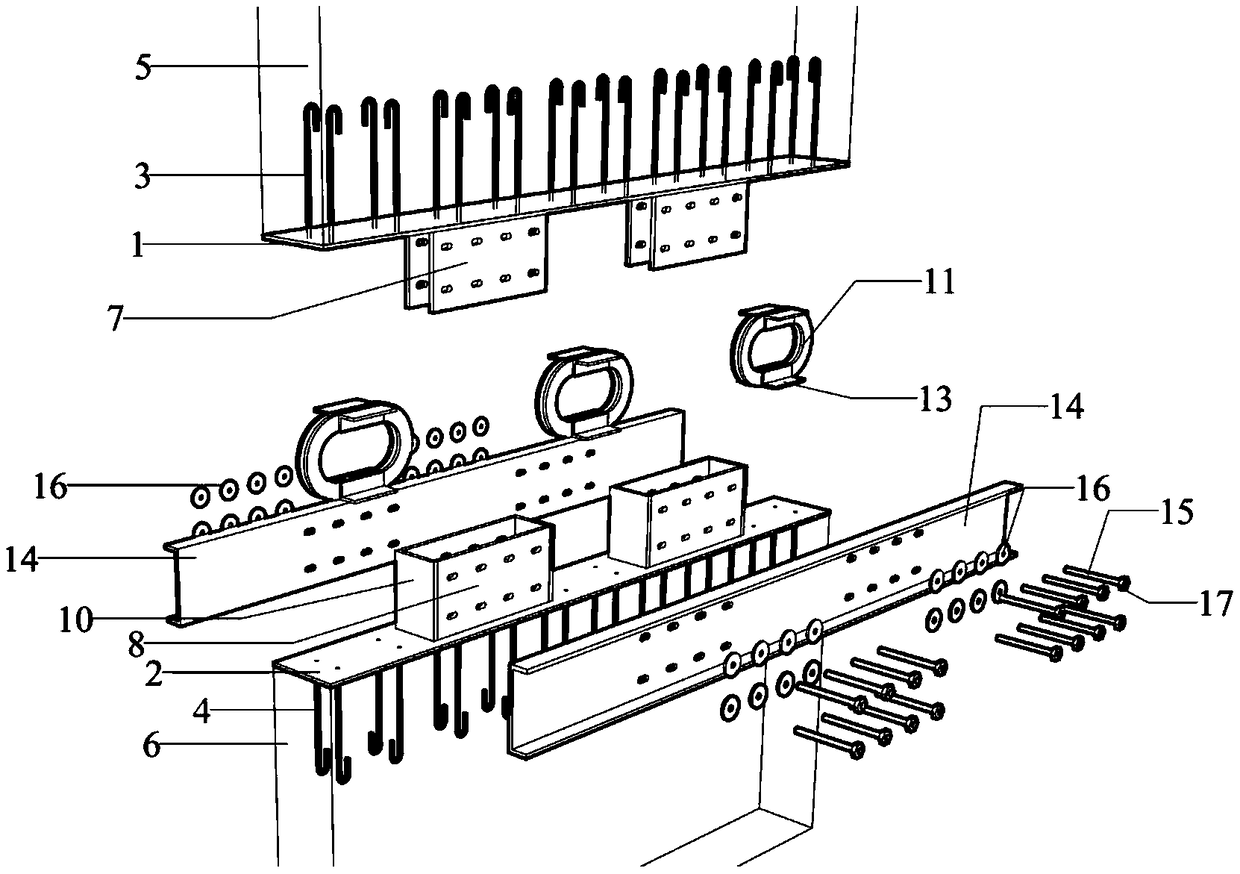

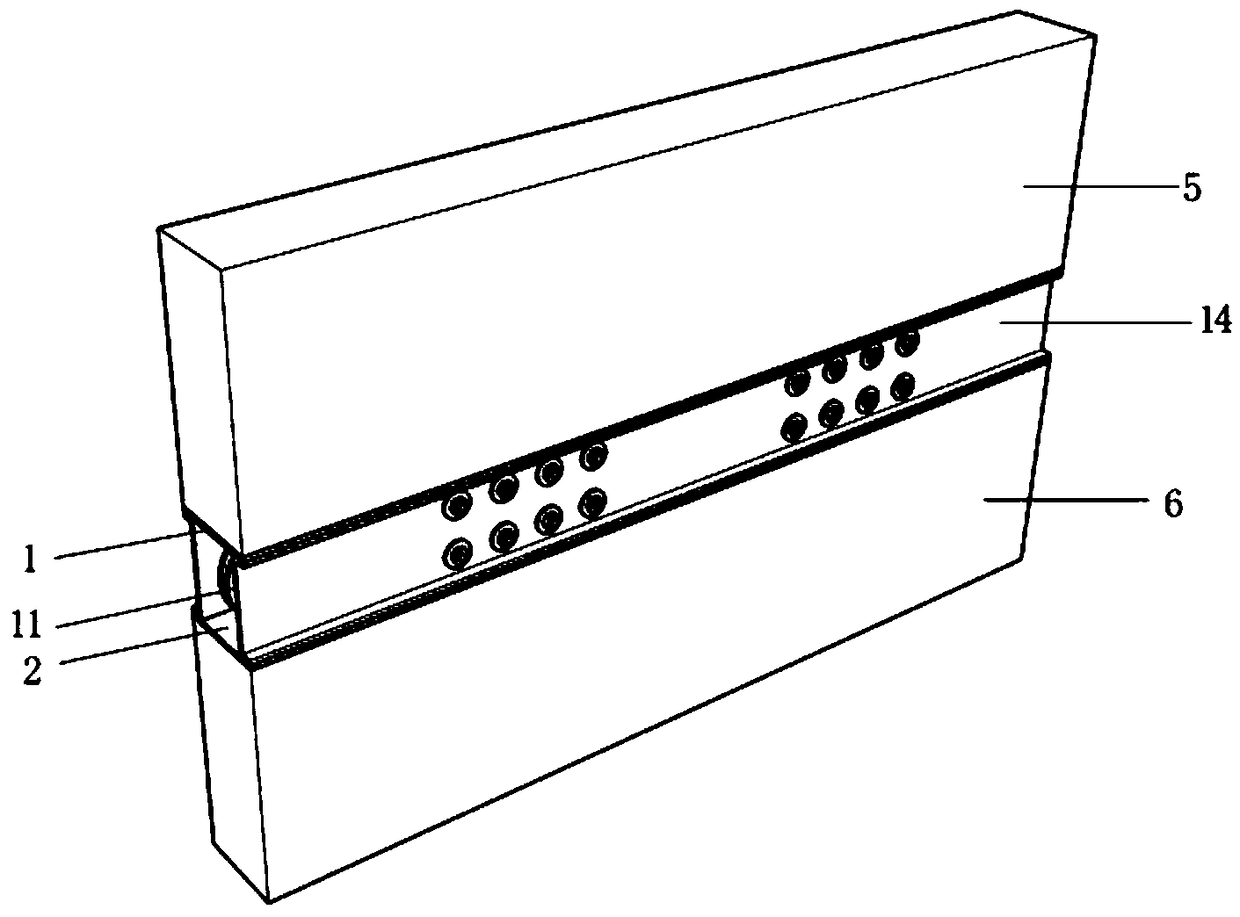

Prefabricated concrete structure plastic controllable steel joints

ActiveCN106978853AConstruction quality is easy to guaranteeReduce construction difficultyProtective buildings/sheltersShock proofingSteel platesPre embedding

The invention provides prefabricated concrete structure plastic controllable steel joints. An upper column of the prefabricated concrete structure is docked with a lower column of the prefabricated concrete structure through a pre-embedded inner ring steel plate and a pre-embedded outer ring steel plate, and force type steel is connected between the middle of the end faces of the upper column and the lower column; a side plate of the outer ring steel plate is connected with a rectangular steel casting member through a fixing member, the rectangular steel casting member is connected with a radial spherical plain bearing, the radial spherical plain bearing is connected with a concrete beam through the steel casting member, the two sides of a box-type energy dissipation sealing plate damper are connected with the rectangular steel casting member and a steel box-type conversion beam section through bolts correspondingly, and the radial spherical plain bearing is located in the box-type energy dissipation sealing plate damper; and the steel box-type conversion beam section is connected with the concrete beam. According to the technical scheme, the whole process of construction is dry, the construction quality is easy to guarantee, and the steel joints are easy to install and detach, small in environmental pollution, controllable in structural plastic and good in shock resistance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

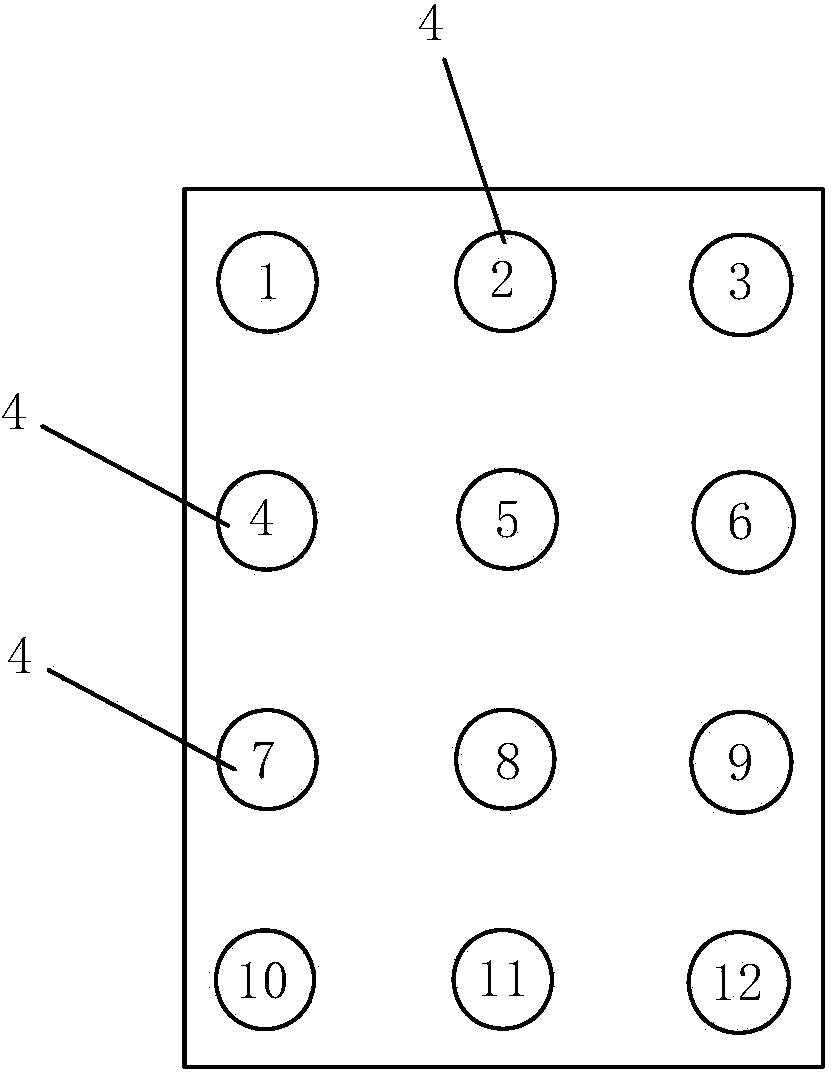

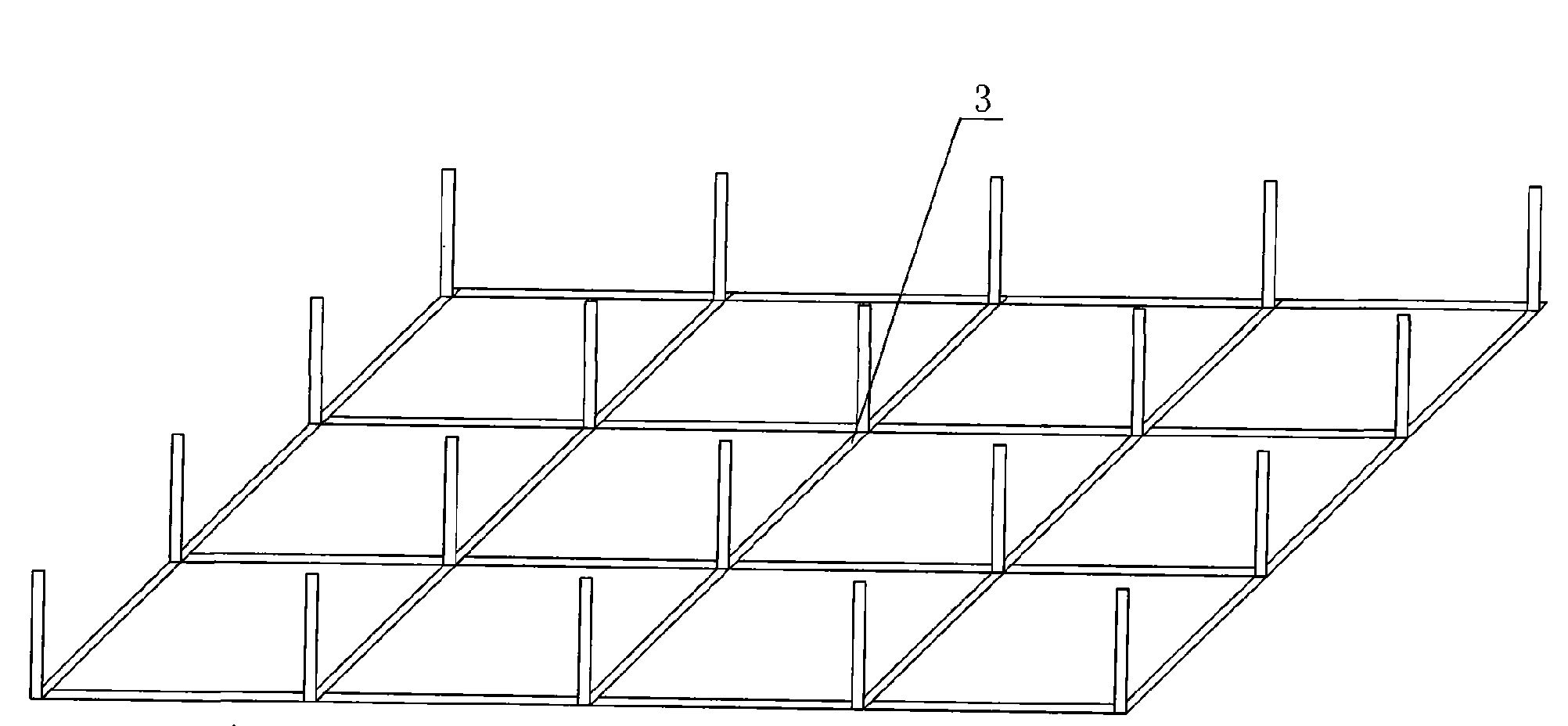

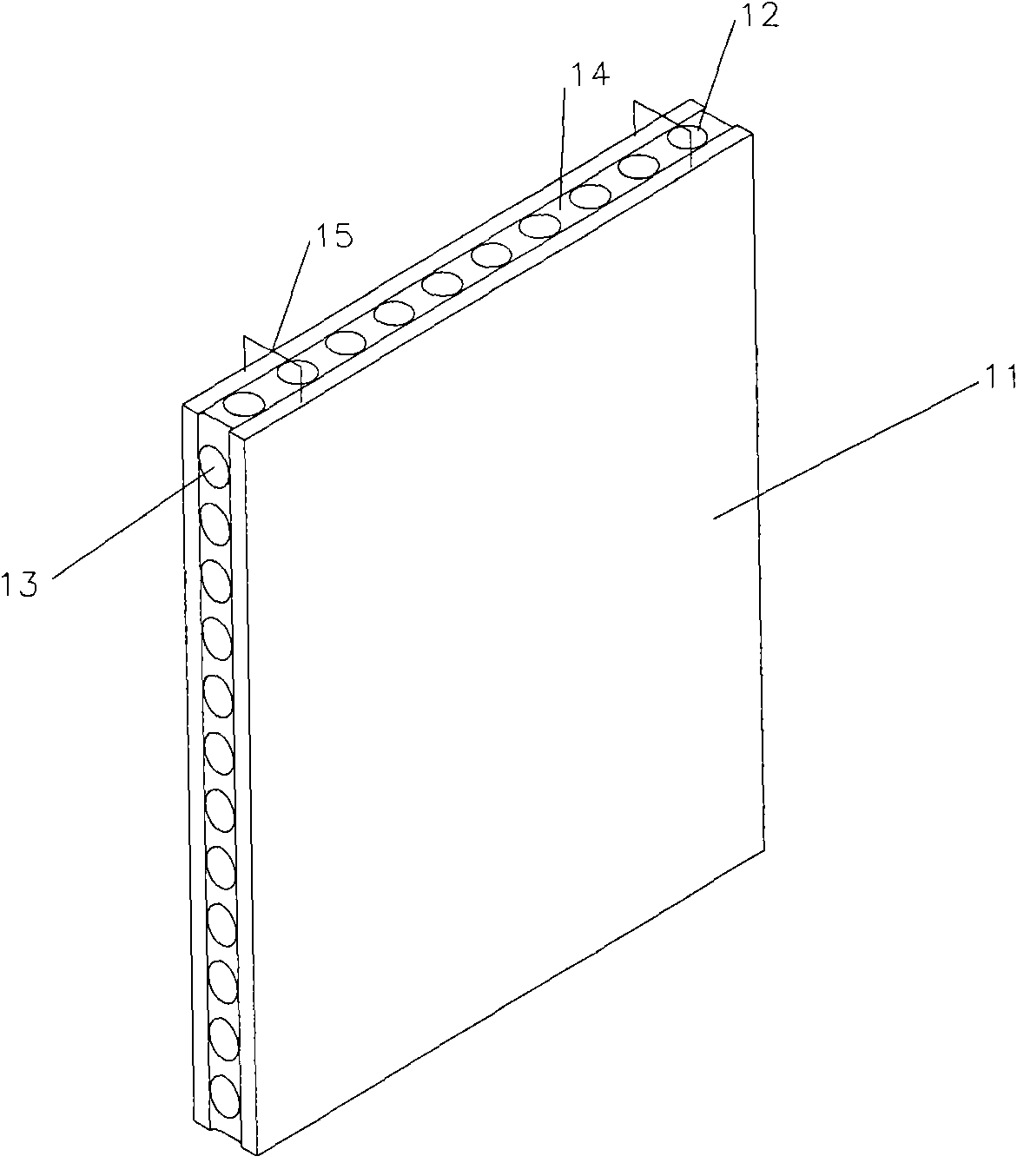

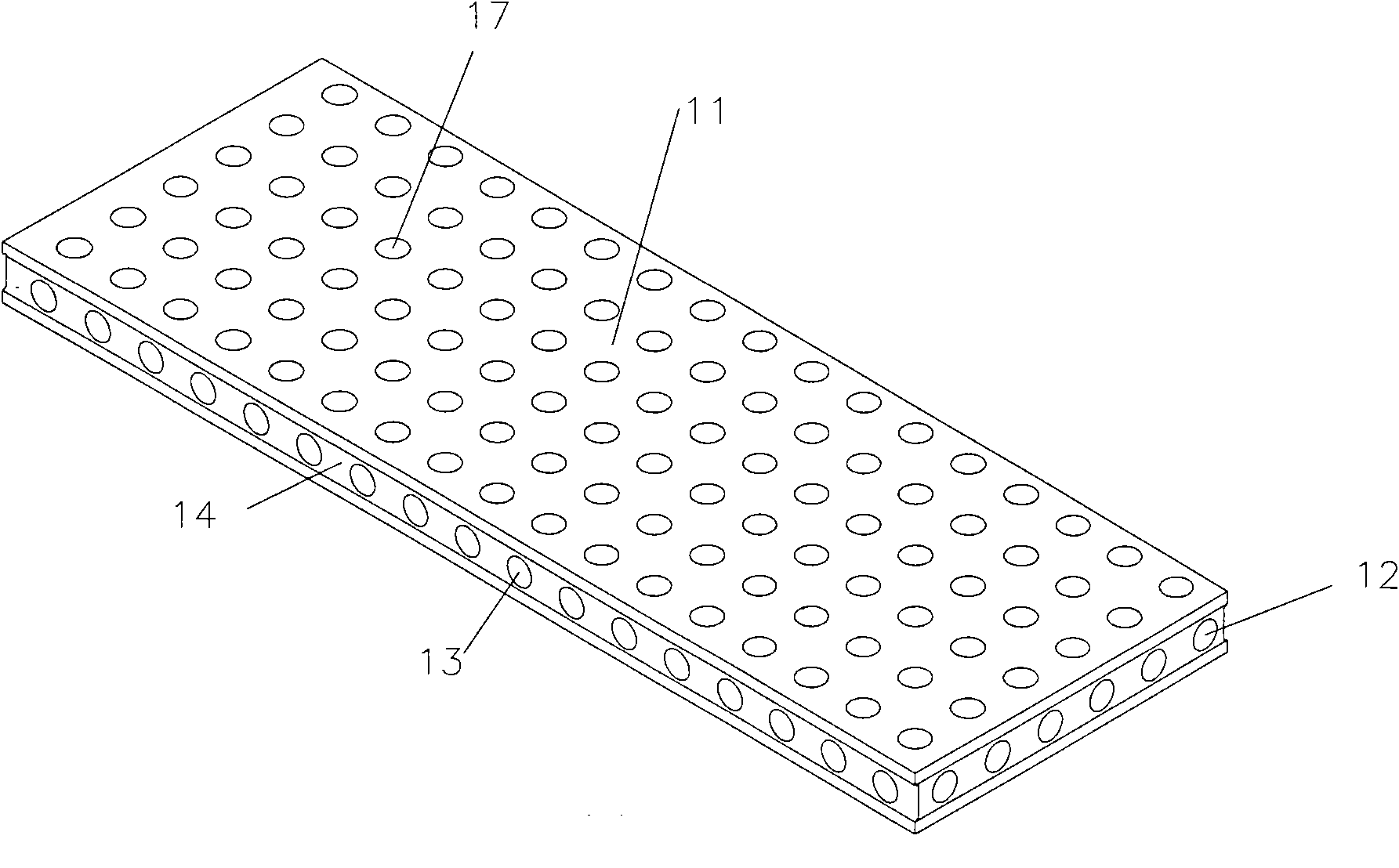

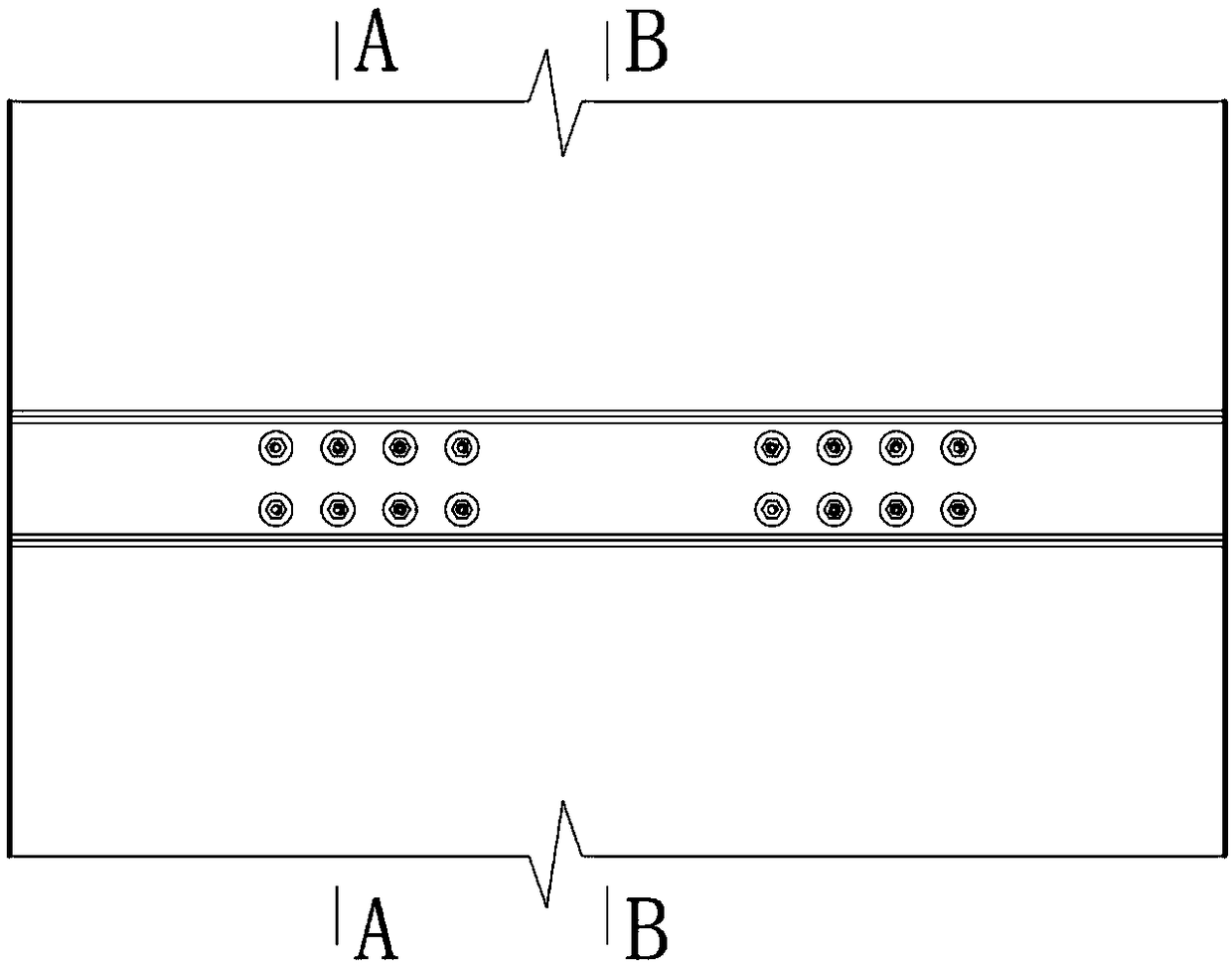

Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

ActiveCN101985856AConstruction quality is easy to guaranteeFlatness is easy to guaranteeForms/shuttering/falseworksForming/stuttering elementsEngineeringRebar

The invention relates to a removal-free prefabricated reinforced concrete template with cross holes inside. The template is a wall template, a floor template, a roof template, a T-shaped template, an L-shaped template, a cross template, a coupling beam template, a beam template or an upright template. A plurality of longitudinal through holes and a plurality of horizontal through holes parallel to the surface are arranged in the template. The plurality of longitudinal through holes and the plurality of horizontal through holes form cross channels. When the removal-free template is prefabricated in factories, 70-80% of stress reinforced concrete is prefabricated in the template, which facilitates industrialization production, transportation and hoisting, and realizes that each layer of house wall template and the floor template are supported once, the concrete is repoured, after the current layer of concrete is poured, the next layer construction is immediately carried out, the construction period of the house is shortened, meanwhile labour is saved, the construction speed is quickened and the house cost is reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

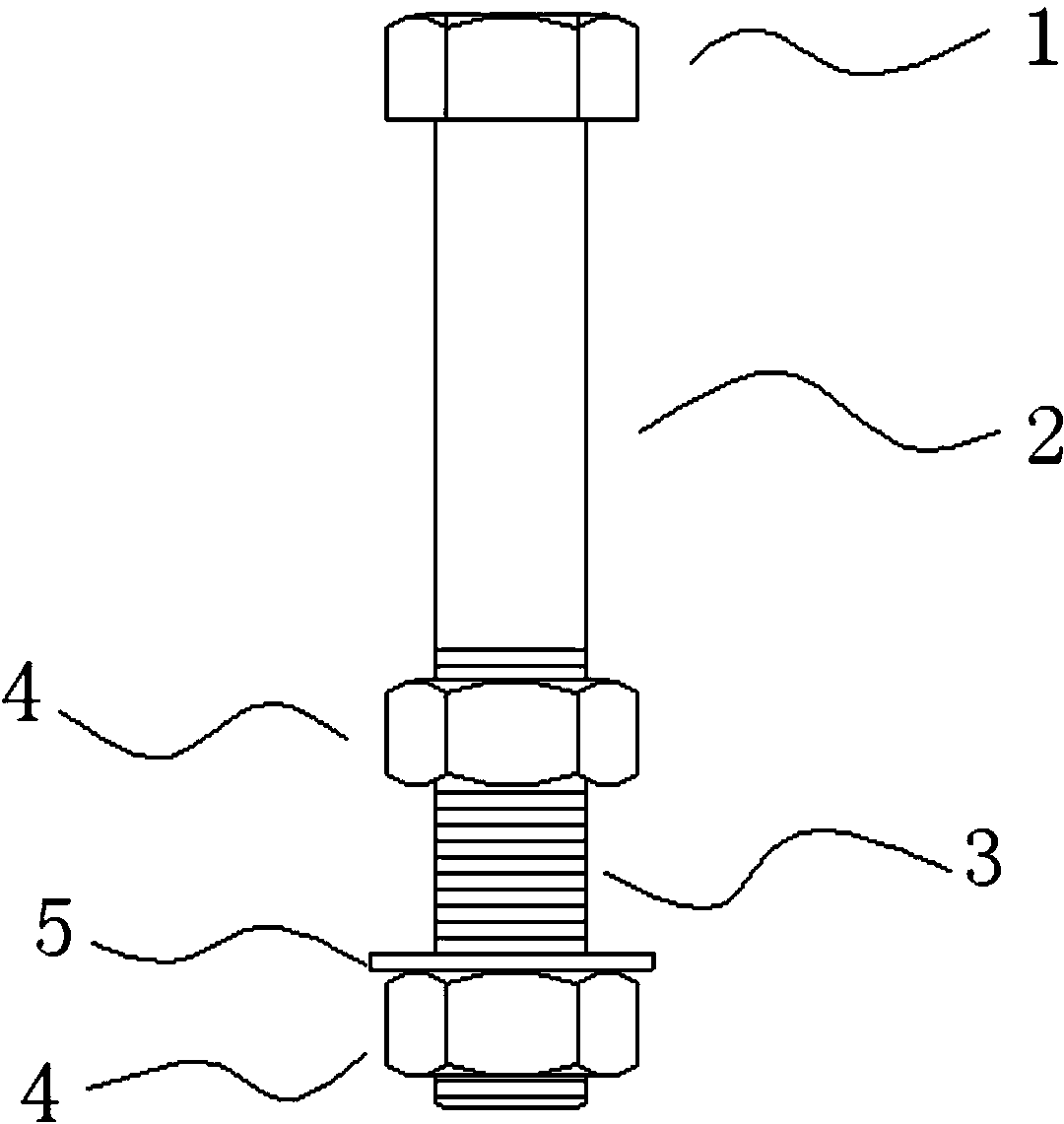

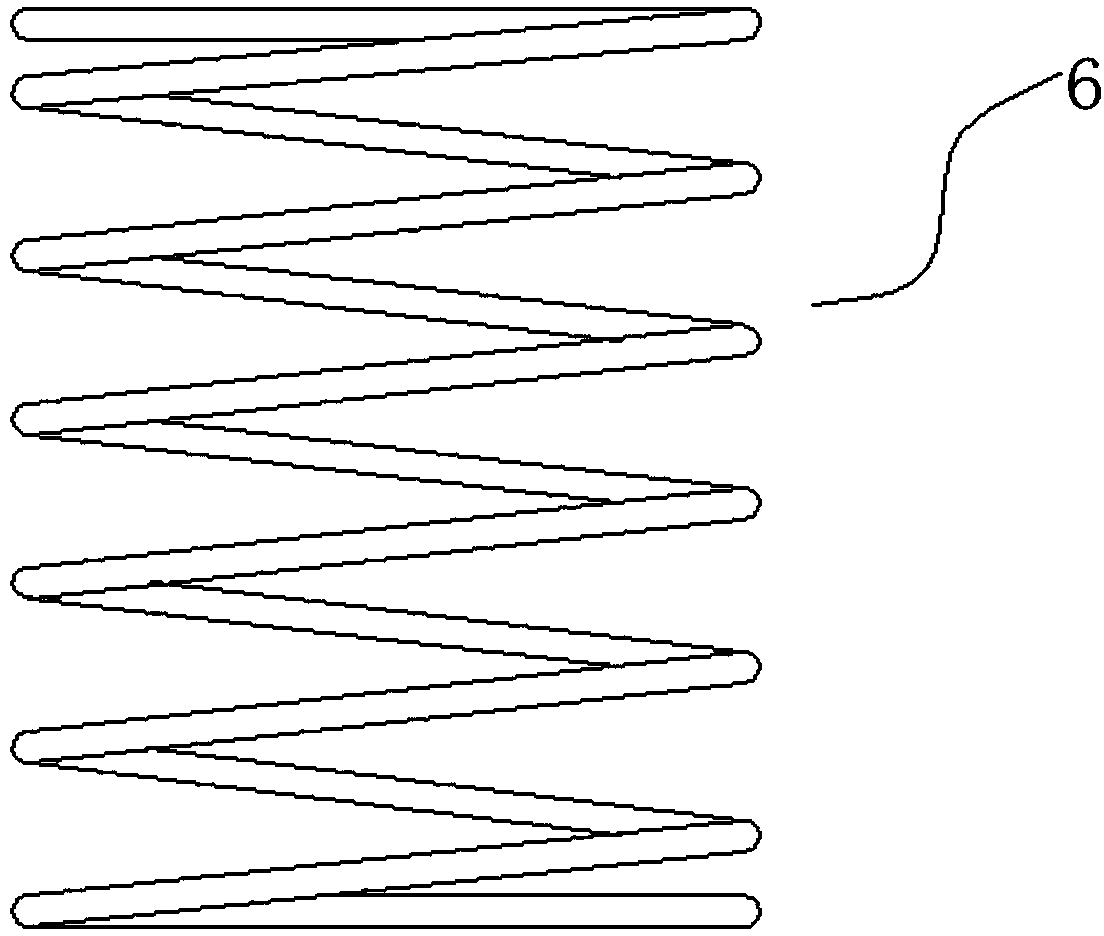

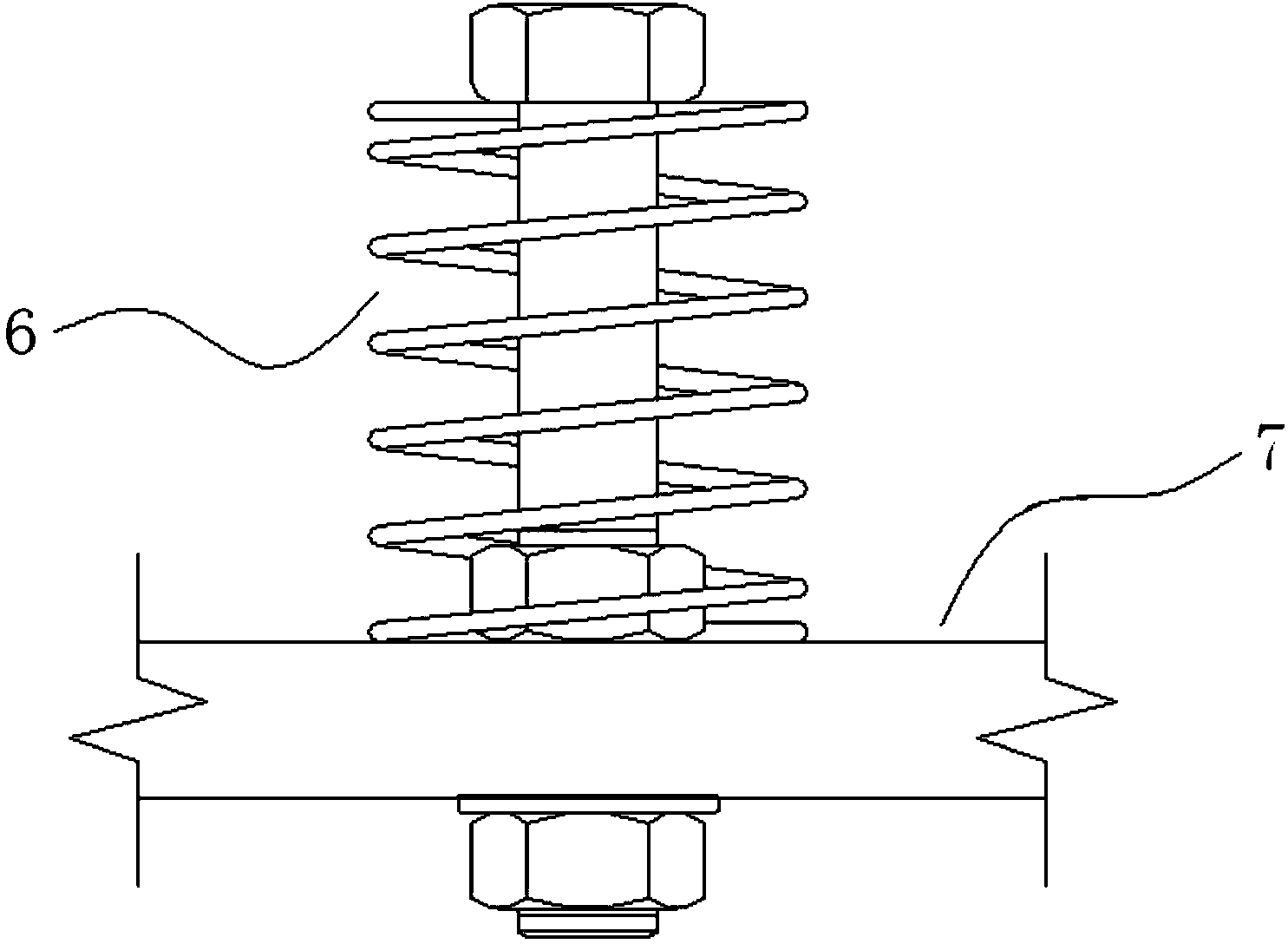

Bolt shear force connecting piece and method for enhancing shear strength by use of spring

InactiveCN103866864AIncrease stiffnessIncreased shear strengthBuilding material handlingMaterial resourcesUltimate tensile strength

Owner:NANJING UNIV OF TECH

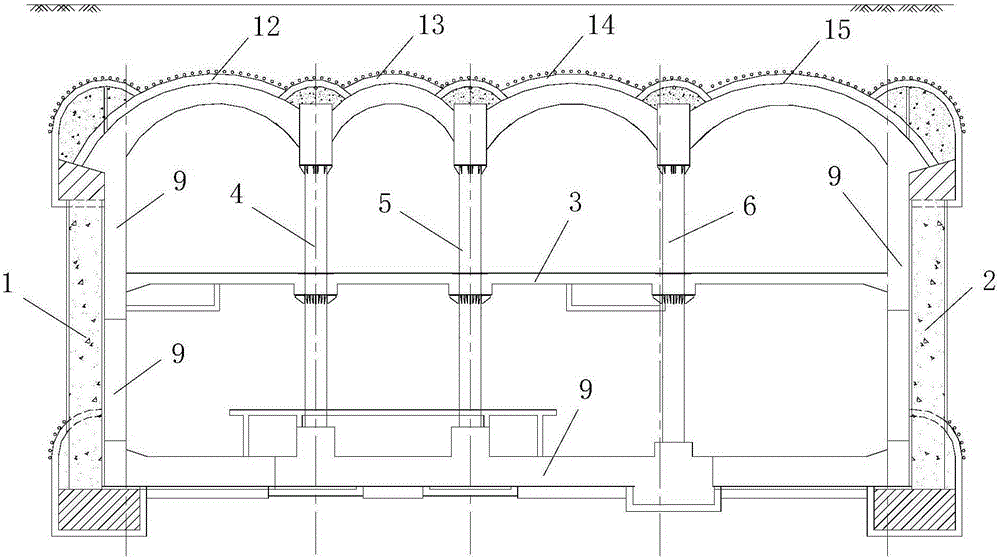

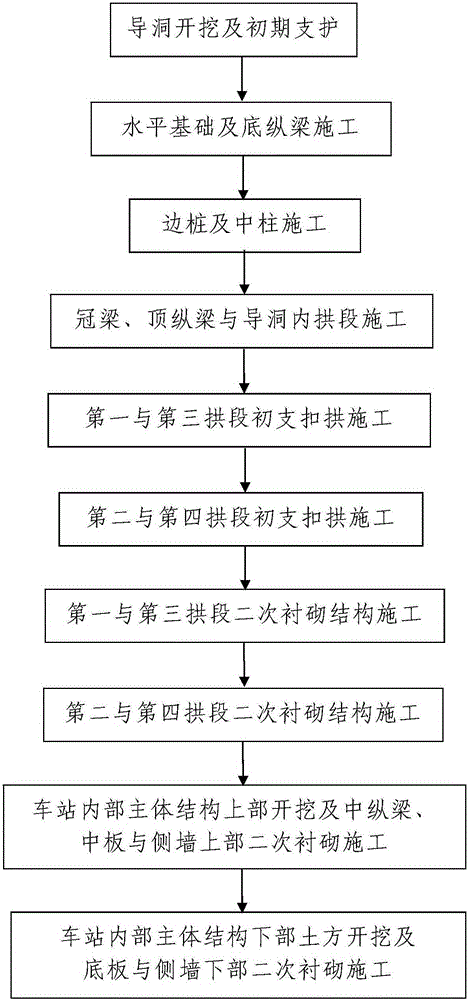

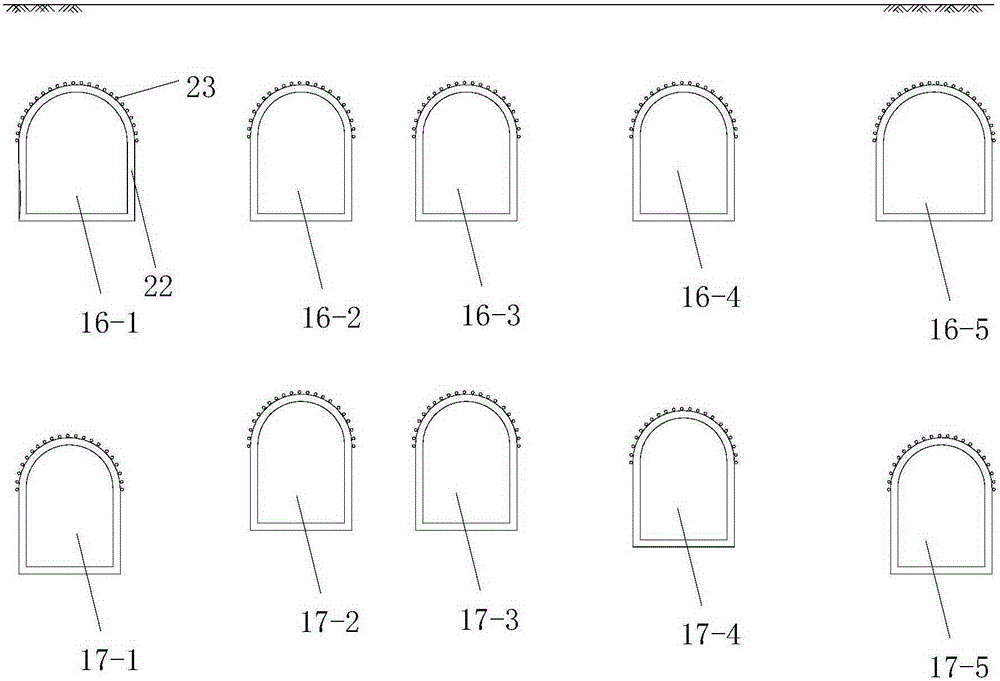

Subway station body structure and four-joint-arch PBA underground excavation construction method thereof

ActiveCN105201516AReasonable structural designStable structureUnderground chambersTunnel liningStructure of the EarthSubway station

The invention discloses a subway station body structure and a four-joint-arch PBA underground excavation construction method thereof. The subway station body structure comprises a station inner body structure, multiple left piles, multiple right piles, three sets of middle columns, middle plates and body arches. The body arches are four-joint arches. The construction method comprises the steps of pilot tunnel excavation and primary support; horizontal base and bottom longitudinal beam construction; side pile and middle column construction; crown beam, top longitudinal beam and pilot tunnel inner arch section construction; first and third arch section primary support buckle arch construction; second and fourth arch section primary support buckle arch construction; secondary lining structure construction of first and third arch sections; secondary lining structure construction of second and fourth arch sections; excavation of the upper portion of the station inner body structure, and secondary lining construction of the middle longitudinal beams, the middle plates and the upper portion of the side wall; earth excavation of the lower portion of the station inner body structure and secondary lining construction of bottom plates and the lower portion of the side wall. The construction is easy, the construction progress is fast, the subway station body structure constructed and formed is firm, and the using effect is good.

Owner:NO 1 ENG LIMITED OF CR20G

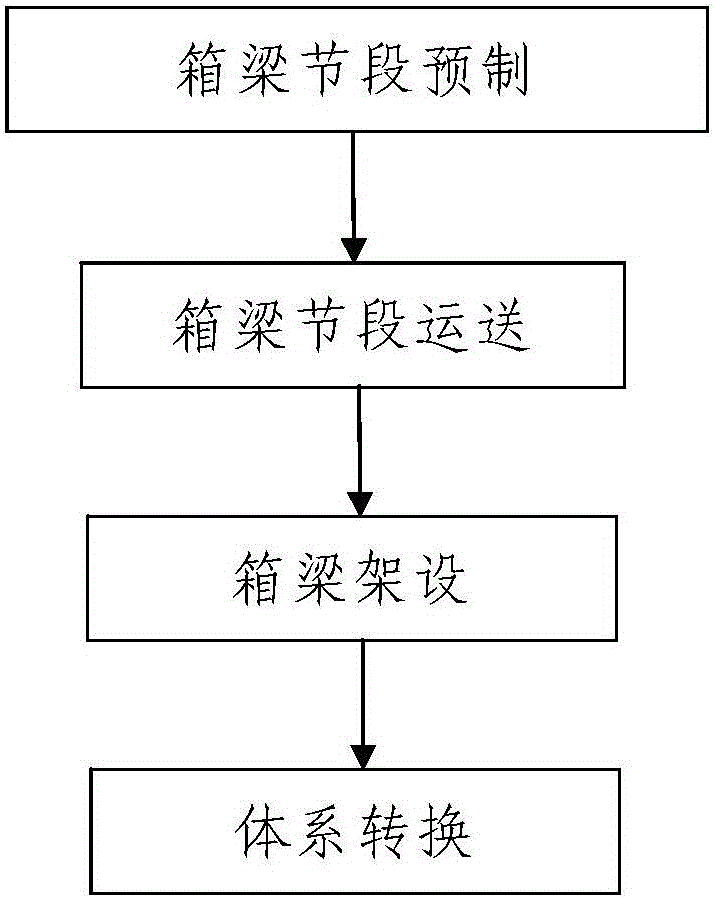

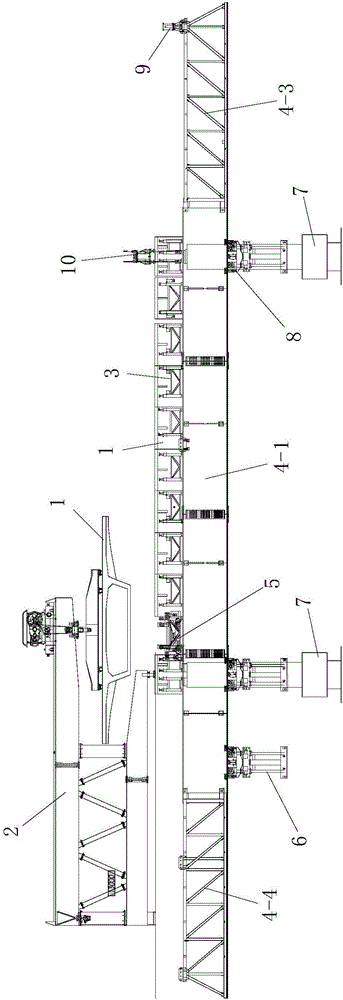

Segmental assembling box girder construction technology

ActiveCN105780660AThe construction process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a segmental assembling box girder construction technology. A constructed box girder is composed of multiple porous girders. Each porous girder is formed by assembling multiple box girder segments from back to front. When the constructed box girder is constructed, the process includes the following steps that firstly, the box girder segments are prefabricated, wherein all the box girder segments used for forming the constructed box girder are prefabricated in a prefabrication site in a concentrated manner; secondly, the box girder segments are transported, wherein all the box girder segments are transported to the erection position of the constructed box girder through a girder transport vehicle; thirdly, the box girder is erected, wherein the constructed box girder is erected and constructed through a descending bridge girder erection machine, and the descending bridge girder erection machine comprises a bottom horizontal supporting system, a main girder system, a longitudinal moving system, a cantilever crane, an assembling frame and an assembling vehicle; and fourthly, a system is converted, wherein the system is converted after the erection construction process is finished. By the adoption of the segmental assembling box girder construction technology, the technological step is simple, design is reasonable, construction is easy and convenient, a construction process is easy to control, a use effect is good, the segmental assembling box girder assembling process can be simply, conveniently and rapidly finished, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Method for shallow part enhancement type soil-swell soil vertical antifouling separating wall

ActiveCN103174173AExtended service lifeFlexibleArtificial islandsProtective foundationEngineeringSlurry

The invention discloses a method for a shallow part enhancement type soil-swell soil vertical antifouling separating wall. The method comprises the following steps: firstly, a field is flattened, a groove is excavated to a waterproof layer and the width of the shallow part groove is enlarged along two sides of the groove central line, wherein the bottom portion of the width enlargement portion of the shallow part groove is located below an upstream water line of a lowest pollution source; secondly, swell soil slurry is used for protecting the wall in the groove, soil-swell soil wall body materials are backfilled from the bottom of the groove to replace slurry, an impermeable plate is inserted in the center of the width enlargement portion of the shallow part groove and piling loading or vacuum prepressing is conducted at the top portion of the groove and the fields around the groove, so that the soil-swell soil backfilling materials begin to solidify under the collective action of self weight and piling loading or vacuum prepressing and the soil-swell soil separating wall is formed in the shallow part, wherein the pollution dispersal performance of the soil-swell soil separating wall is enhanced. Aimed at the fact that an antifouling protective screen in the shallow part is large in pollution load and can be affected by the negative factors such as weather and temperature easily, the method for the shallow part enhancement type soil-swell soil vertical antifouling separating wall enhances impermeability and durability of weak links. The method for the shallow part enhancement type soil-swell soil vertical antifouling separating wall is strong in pertinency, convenient to construct, low in construction cost, environmental-friendly and capable of satisfying the pollution prevention and control requirements.

Owner:ZHEJIANG UNIV

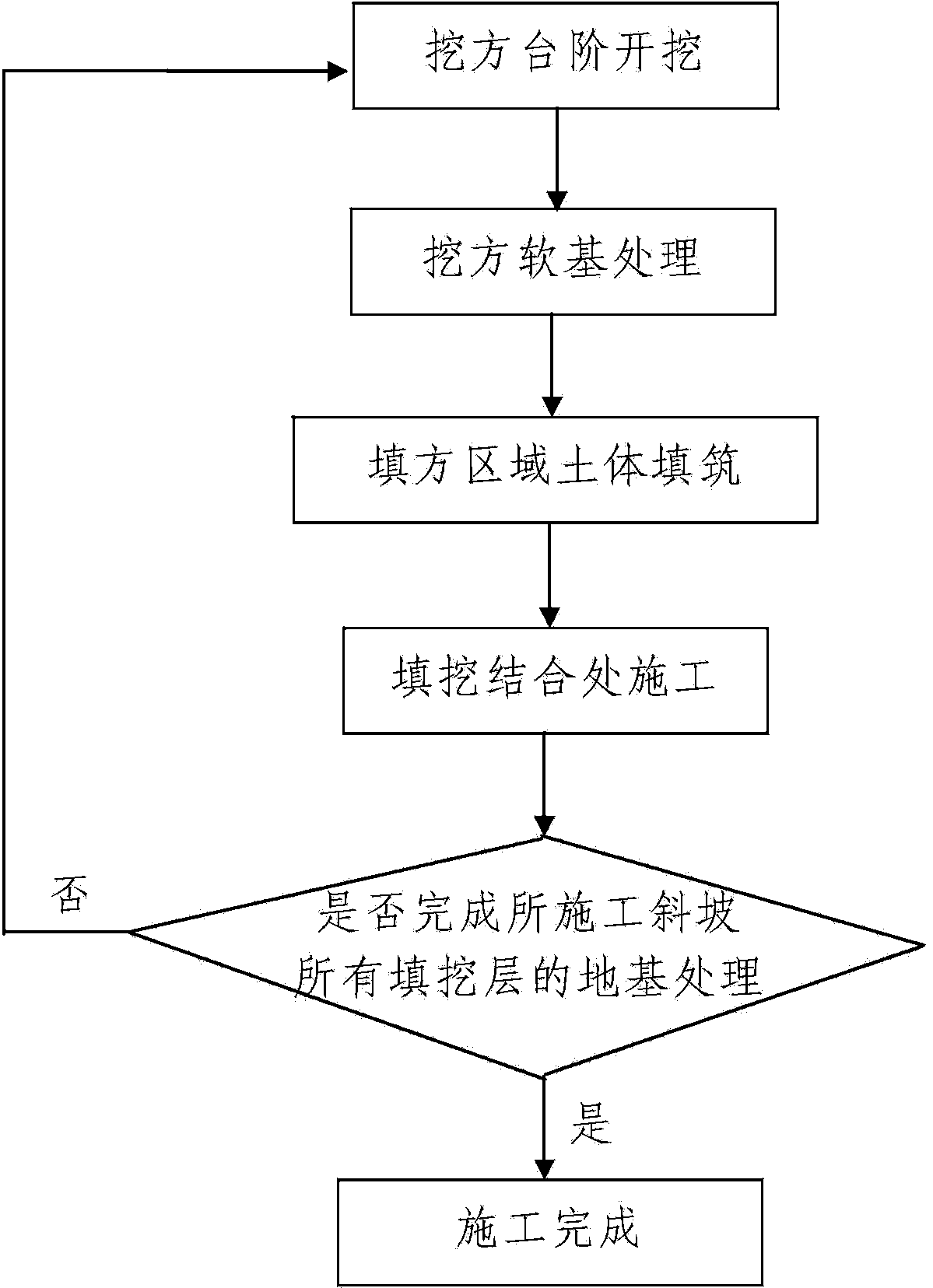

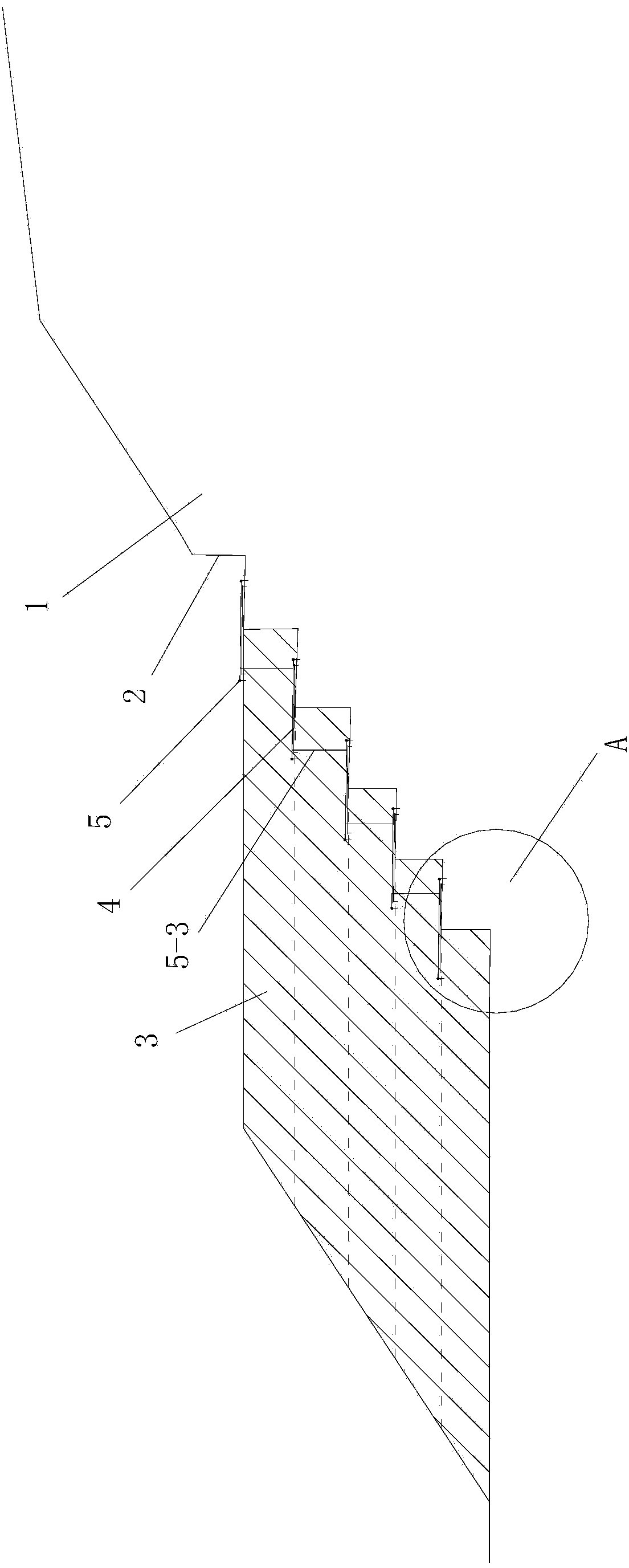

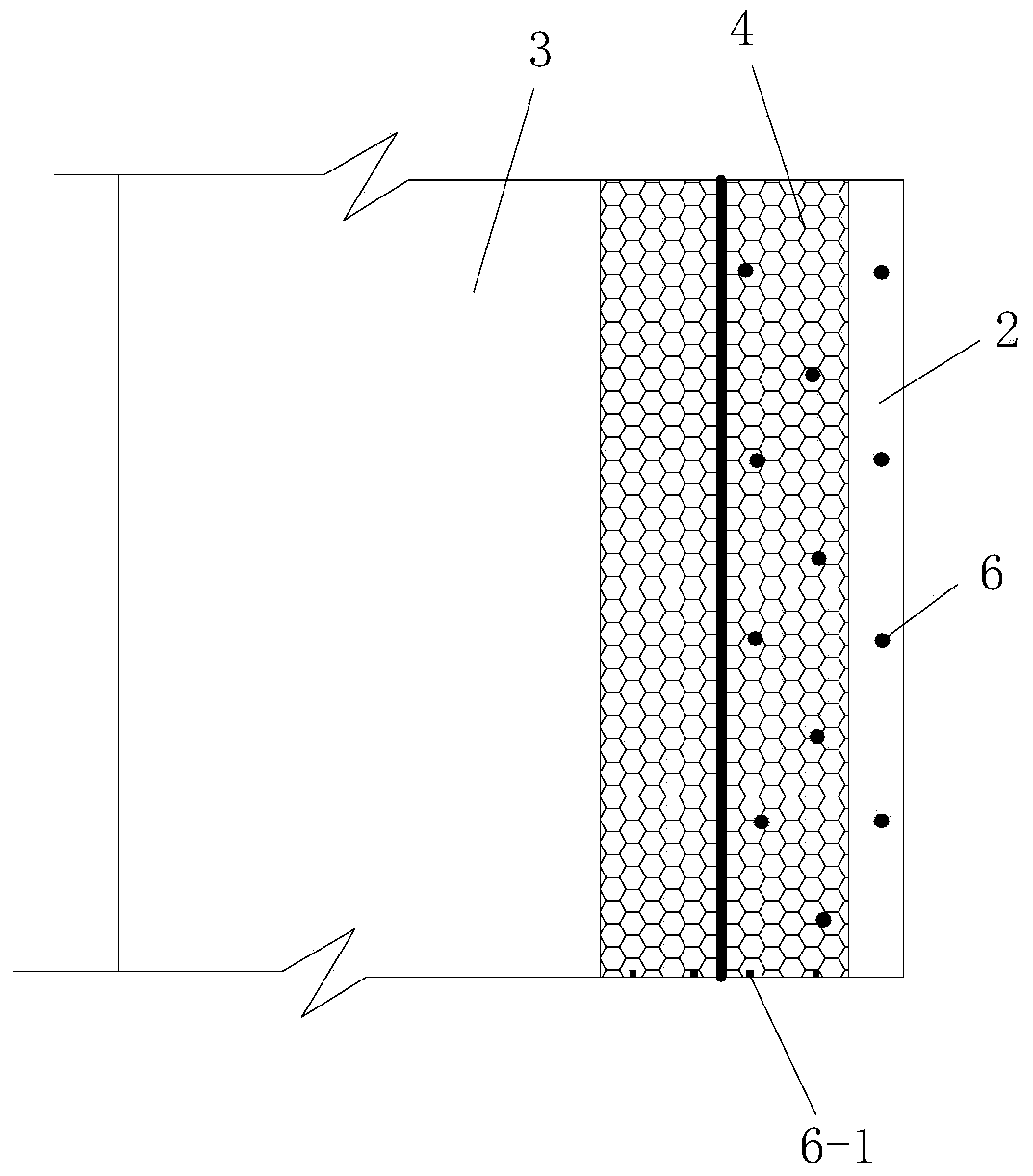

Foundation treatment method of collapsible loess slope cut-and-fill joint part

InactiveCN104264680AThe method steps are simpleSimple and fast operationEmbankmentsExcavationsTreatment effectEngineering

The invention discloses a foundation treatment method of a collapsible loess slope cut-and-fill joint part. The cut-and-fill joint part of a constructed slope is subjected to foundation treatment by M cut-and-fill layers from top to bottom, and a cut-and-fill layer at the bottom of the M cut-and-fill layers is a bottom cut-and-fill layer. The foundation treatment method of the collapsible loess slope cut-and-fill joint part includes a bottom cut-and-fill layer foundation treatment step, a last cut-and-fill layer foundation treatment step and a once or twice repeating step. The bottom cut-and-fill layer foundation treatment step includes excavating a cut step, treating a soft cut foundation and a fill foundation, building a fill area soil body and constructing the cut-and-fill joint part, wherein the construction process of the cut-and-fill joint part includes mounting a geogrid and constructing a rigid connection framework. The once or twice repeating step includes repeating the former two steps until the foundation treatment process of the M cut-and-fill layers is completed. The foundation treatment method is simple in steps, convenient to implement, good in foundation treatment effect and capable of solving the problem that joint effect of cutting and filling of the existing collapsible loess slope cut-and-fill joint part is poor and differential settlement of the cut-and-fill joint part is easy to cause and the like.

Owner:XIAN UNIV OF SCI & TECH +1

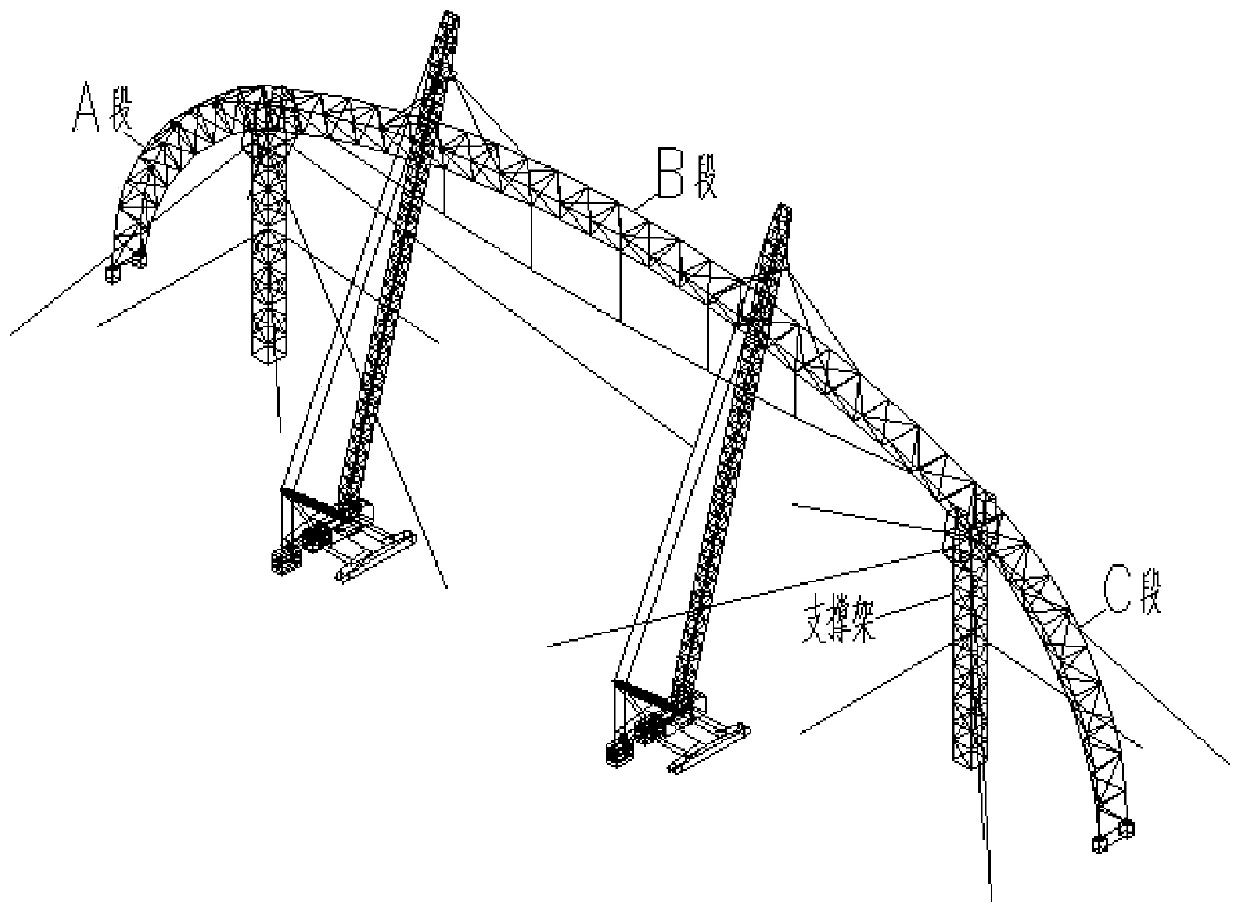

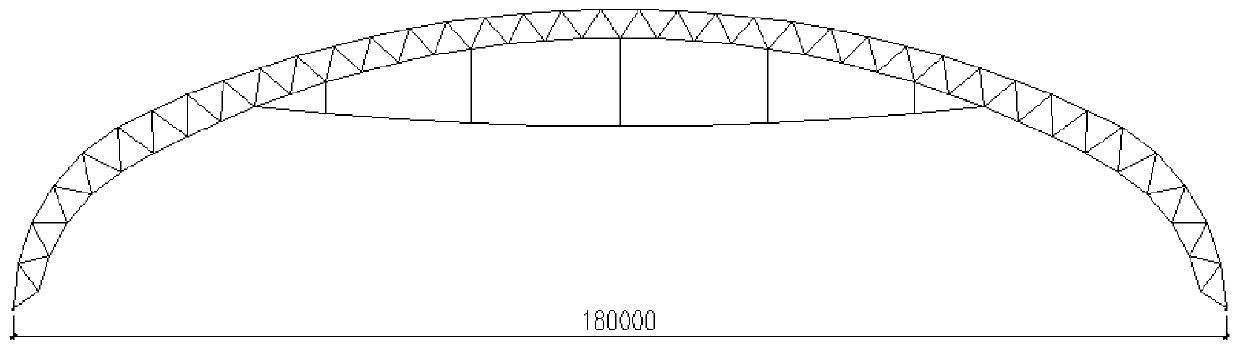

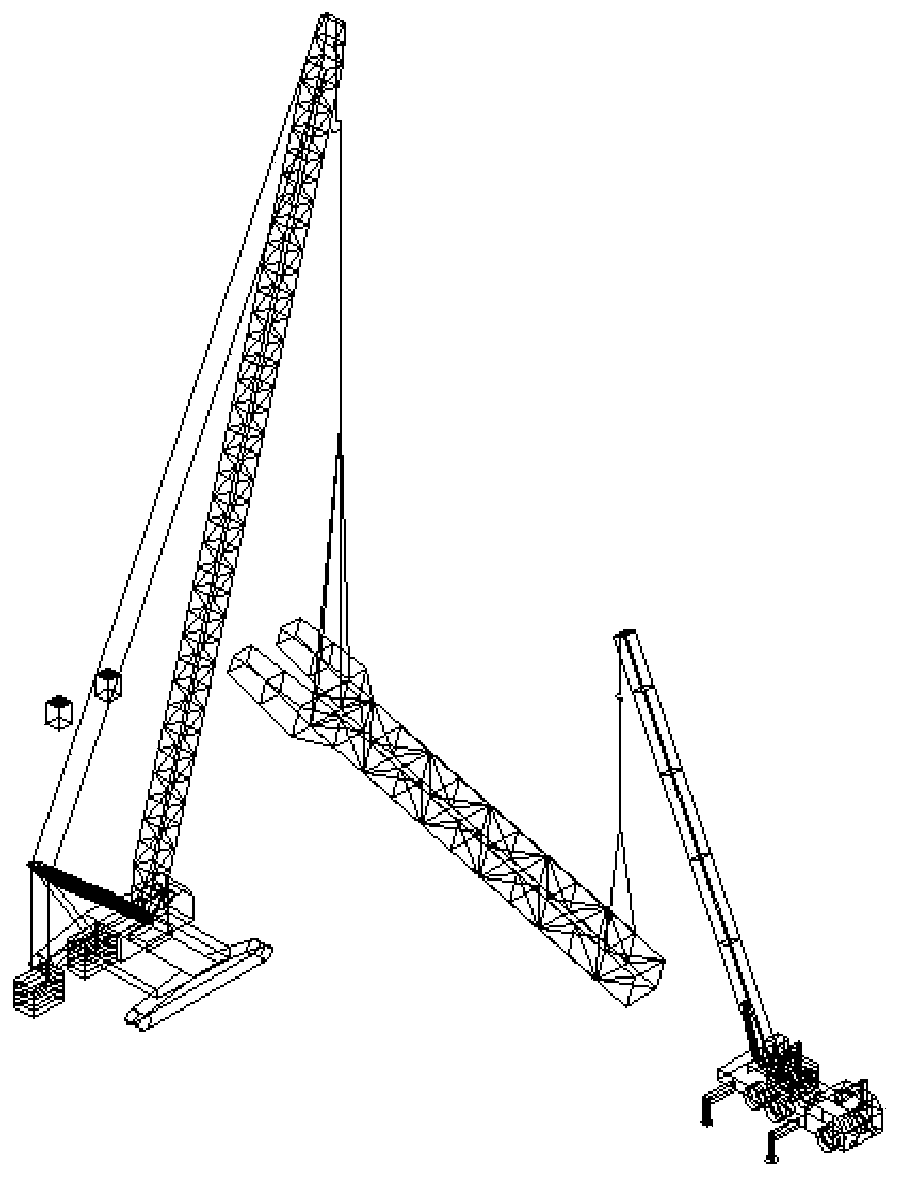

Construction method for ground cable hanging and aerial butt joint of ultra-large-span prestressed pipe truss

The invention discloses a construction method for ground cable hanging and aerial butt joint of an ultra-large-span prestressed pipe truss. The construction method is characterized in that the ultra-large-span prestressed pipe truss is divided into three sections A, B and C according to the characteristics of the ultra-large-span prestressed pipe truss structure, each section is assembled on the ground through a jig frame, and after the procedures of jig separation, transportation, overturning, hoisting and the like, the sections A and C are hoisted to a designed position at first; the sectionB is divided into a subsection B1 and a subjection B2 and spliced on the ground through a jig frame, after jig separation, the subsections B1 and B2 are sequentially hoisted to a ground support framefor aerial butt joint, a prestressed steel inhaul cable is hung, and the steel inhaul cable is primary tensioned according to a simulation checking result; and after primary tensioning, the section Bis hoisted to the designed position through two machines to be in aerial butt joint with the section A and the section C, after butt joint is finished, a connecting truss is installed, the steel inhaul cable is finally tensioned according to the simulation checking result, and the ultra-large-span prestressed pipe truss is installed. The construction method highlights the characteristics of highconstruction speed, low cost, low safety risk, high construction quality and the like in the operation process.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE +2

Fabricated type shear wall vertical connection energy dissipation structure and construction method thereof

PendingCN109440973AImprove prefabrication rateEase of industrial productionWallsProtective buildings/sheltersEngineeringRebar

The invention provides a fabricated type shear wall vertical connection energy dissipation structure and a construction method thereof, and belongs to the technical field of building engineering. Thefabricated type shear wall vertical connection energy dissipation structure comprises a first shear wall prefabricated part, a second shear wall prefabricated part and lateral groove shaped steel parts. The first shear wall prefabricated part comprises a first horizontal steel plate, a plurality of first anchoring reinforcing steel bars, a first shear wall and a plurality of plug steel plate parts, and bolt holes are formed in the plug steel plate parts. The second shear wall prefabricated part comprises a second horizontal steel plate, a plurality of inserted groove steel plate parts, a plurality of second anchoring reinforcing steel bars and a second shear wall, bolt holes are formed in the inserted groove steel plate parts, and bolt holes are formed in the lateral groove shaped steel parts. According to the fabricated type shear wall vertical connection energy dissipation structure and the construction method thereof, the prefabricating ratio is low, industrial production is facilitated, the site construction difficulty can be reduced, the construction efficiency can be improved, the construction quality can be guaranteed, and the mounting precision and effectiveness of connection can be guaranteed and the action of energy dissipation and seismic mitigation is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

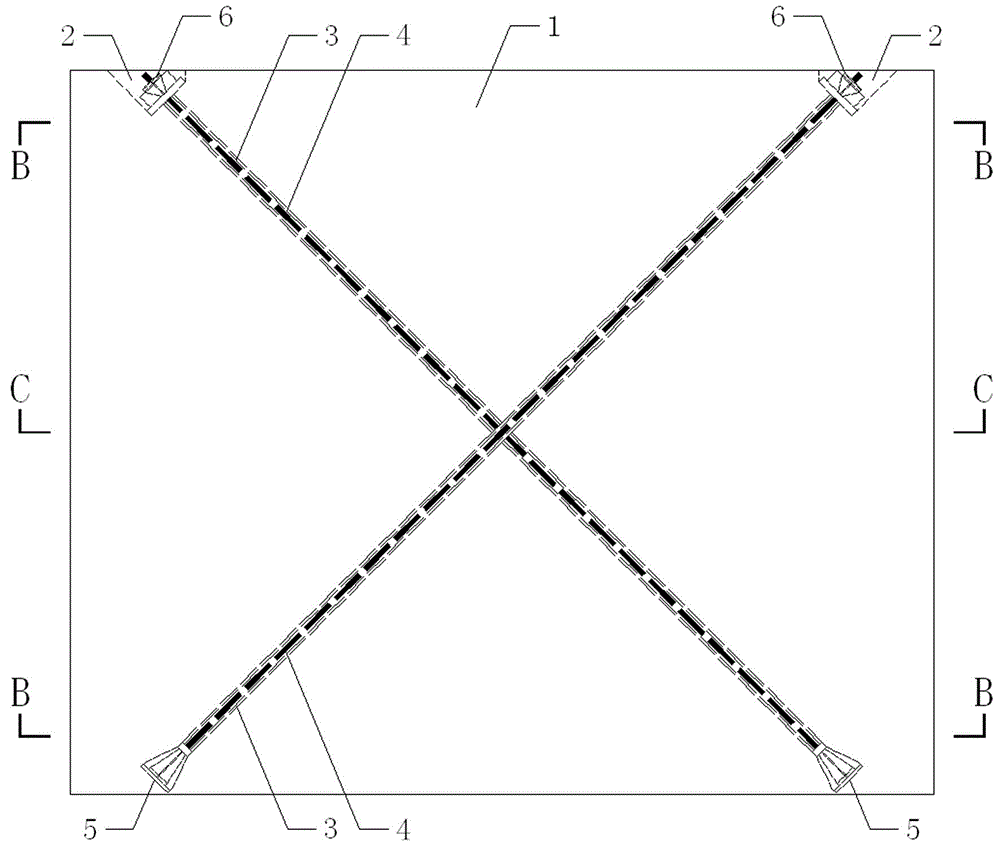

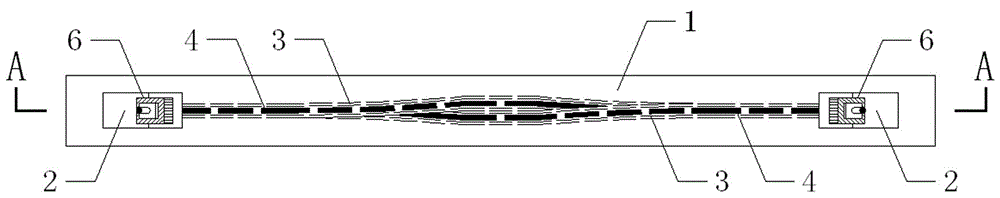

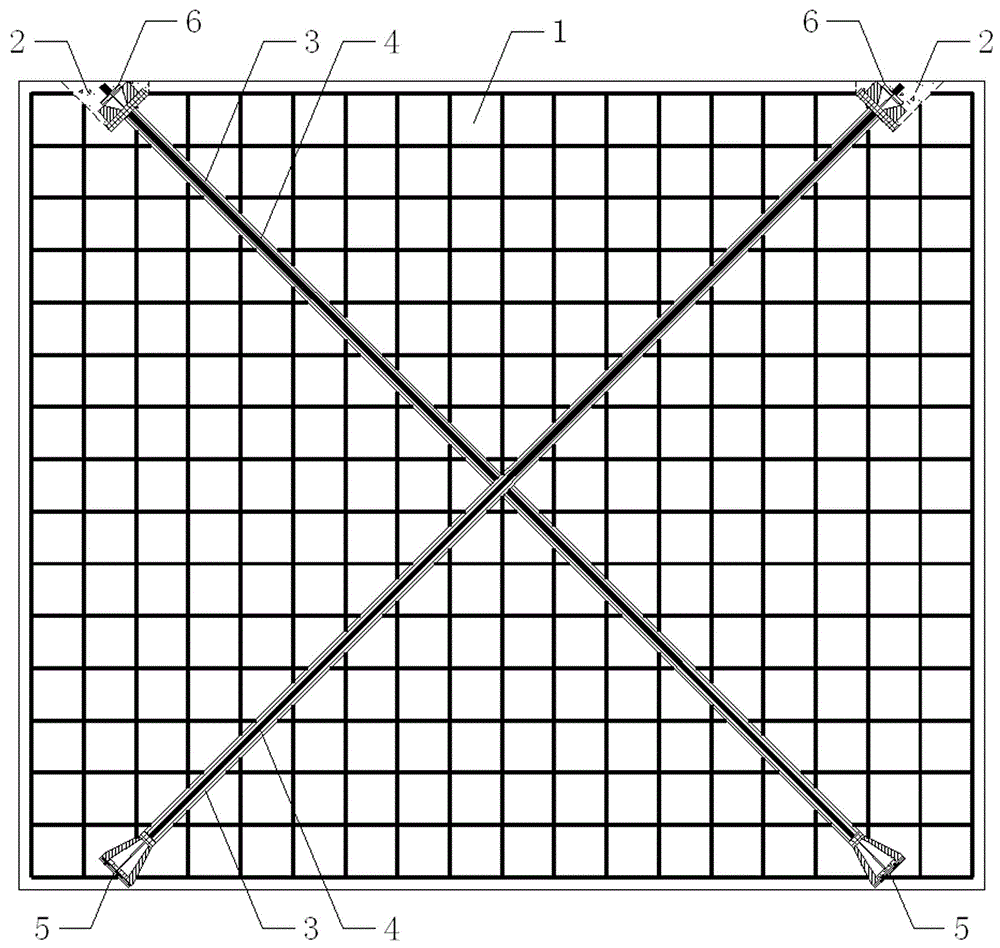

Shear wall structure configured with crossed slant internal prestress and construction method of shear wall structure

InactiveCN102979221ADirect forceReduces the likelihood of crossing oblique cracksWallsBuilding material handlingRebarPre stress

The invention relates to a shear wall structure configured with crossed slant internal prestress. The shear wall structure comprises a shear wall body, horizontal steel bars of the shear wall body and vertical steel bars of the shear wall body, wherein a shear wall tooth plate and a prestress tension end anchor tool are respectively arranged at the left upper corner and the right upper corner of the shear wall body, prestress anchoring end anchor tools are respectively arranged at the left lower corner and the right lower corner of the shear wall body, and a crossed slant prestress steel beam and a crossed slant prestress pipeline are arranged between the prestress anchoring end anchor tool and the prestress tension end anchor tool at the opposite corners. A construction method of the structure comprises steps of shear wall template erection and binding of ordinary steel beams of the wall body; crossed slant prestress pipeline arrangement and installation; prestress steel beam penetration and prestress anchor tool installation; shear wall concrete casting and maintenance; and prestress tension, pipeline grouting and end part anchor sealing. The shear wall structure greatly improves the anti-seismic performance of the shear wall.

Owner:ZHENGZHOU UNIV

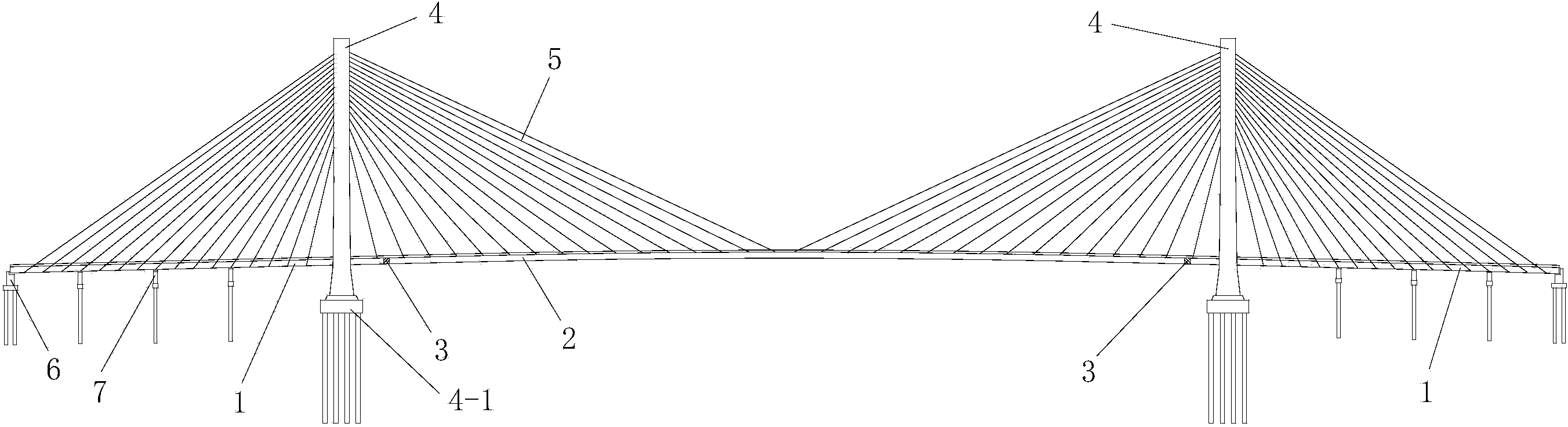

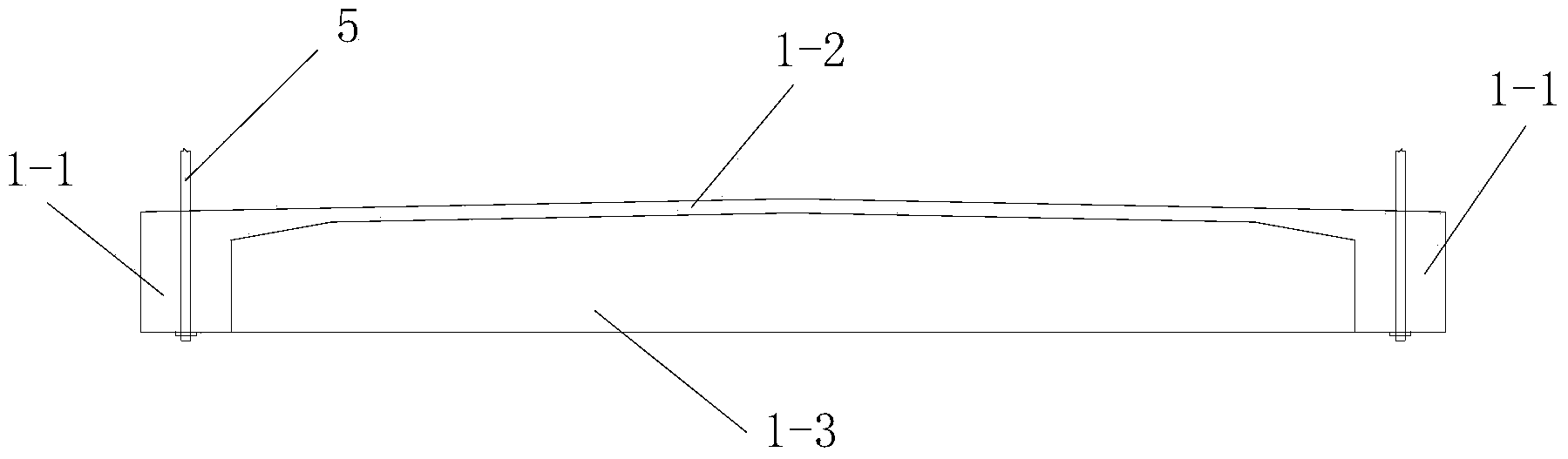

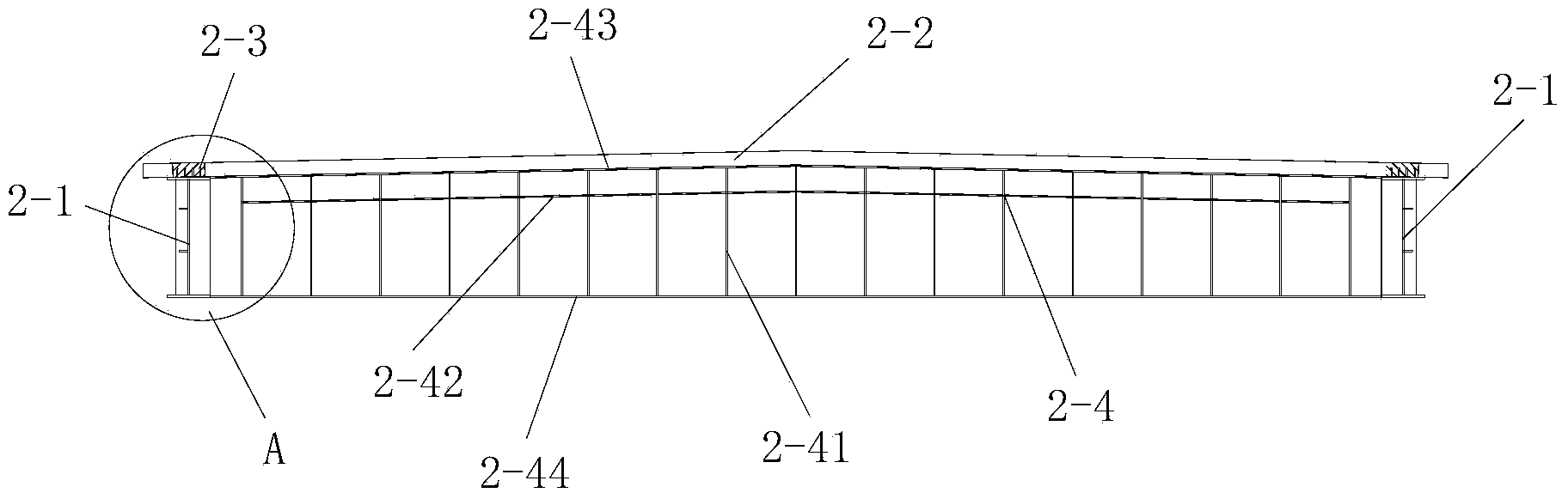

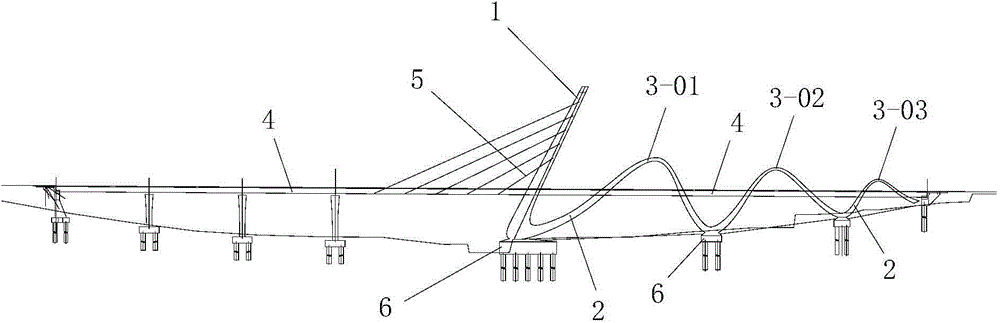

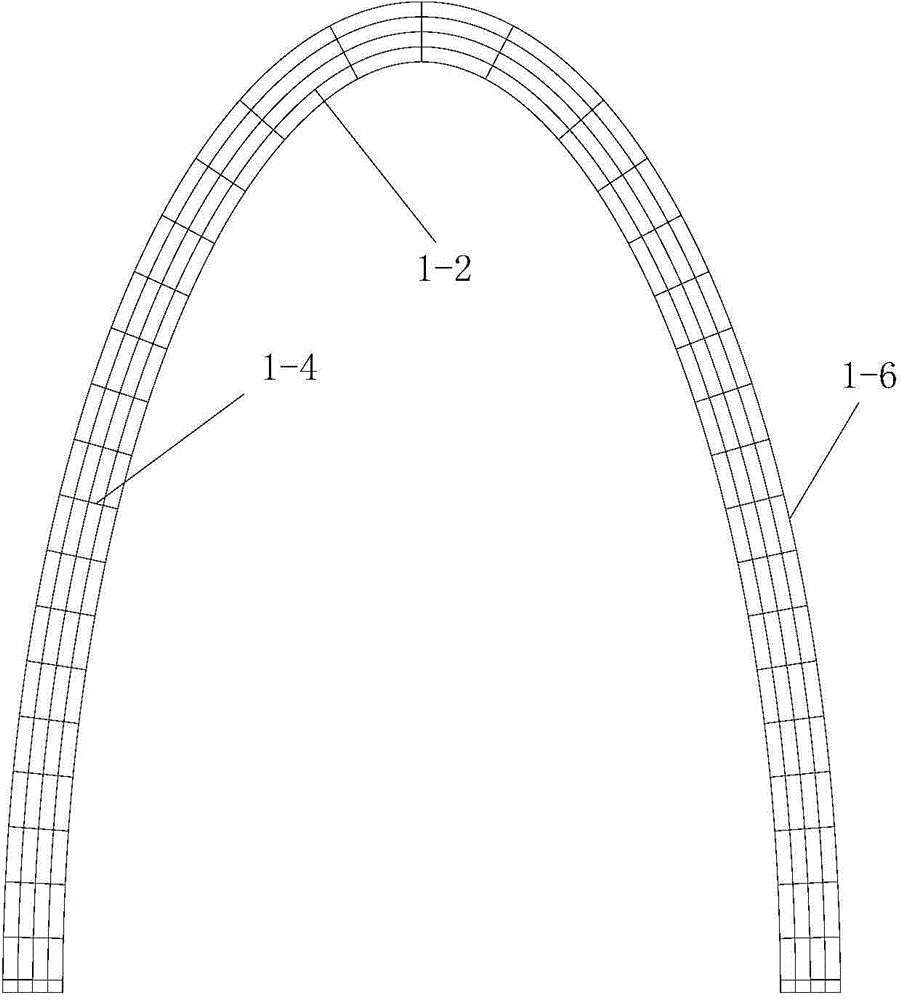

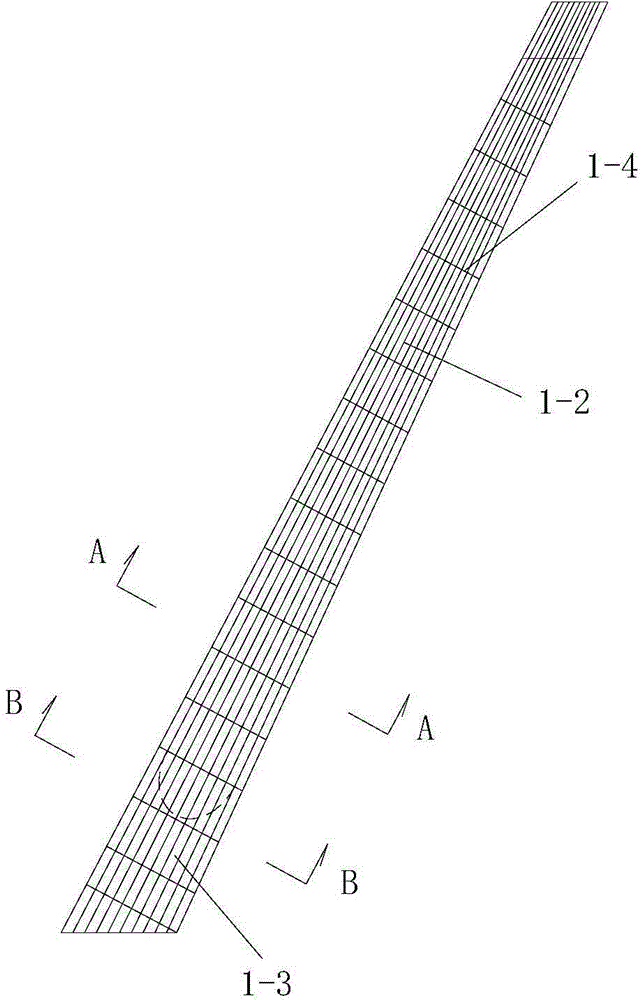

Ribbon-shaped single-tower cable-strayed-steel structure combined bridge and construction process thereof

ActiveCN104562913ASimple structureReasonable designCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses a ribbon-shaped single-tower cable-strayed-steel structure combined bridge and a construction process thereof. The combined bridge comprises a lower supporting structure, a main beam, an arch-shaped main tower which is arranged on the main beam and gradually backwards inclined from bottom to top, and two ribbon-shaped supporting structures which are positioned at the rear side of the main tower; the two ribbon-shaped supporting structures are both integrally fixedly connected with the main beam; the two-ribbon-shaped supporting structures and the main beam are lengthways arranged along the bridge direction; a plurality of cable-strayed ropes are arranged between the main tower and the main beam; each ribbon-shaped supporting structure is divided into a lower ribbon-shaped supporting structure and an upper ribbon-shaped connecting structure through the main beam. The construction process of the combined bridge comprises the steps of 1, constructing the lower supporting structure; 2, constructing the lower ribbon-shaped supporting structure; 3, constructing the main beam; 4, constructing the main tower and the upper ribbon-shaped connecting structure. The combined bridge is reasonable in structural design, convenient to construct, outstanding in mechanical performance and a good in use effect; a non-back cable-stayed bridge and a continuous rigid structural bridge are effectively combined, and the advantages of the two bridges are brought into full play.

Owner:XIAN MUNICIPAL ENG DESIGN & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com