Method for shallow part enhancement type soil-swell soil vertical antifouling separating wall

A technology of bentonite and partition wall, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of unsatisfactory prevention and control effect of soil-bentonite walls, and the easy breakdown of shallow walls by pollutants. , to achieve the effect of easy guarantee of construction quality, long chemical corrosion resistance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

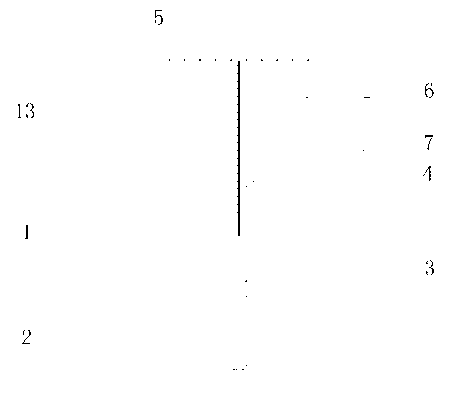

[0020] Such as figure 1 As shown, the steps of this method are as follows: first level the site, excavate the trench to the impermeable layer 2, and increase the width of the shallow trench along both sides of the trench centerline (for example, the overall width is doubled, the details can be determined according to the actual situation adjustment), improve the anti-seepage and anti-fouling performance of the shallow wall, and prevent the shallow wall from being penetrated by pollutants first. The bottom of the widened part of the shallow trench is located below the low water level line 7 upstream of the pollution source, and 6 is the high water level line upstream of the pollution source. Bentonite mud wall protection is carried out in the trench, and soil is backfilled from the bottom of the trench - bentonite wall material replacement Slurry, carry out surcharge or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com