Patents

Literature

243results about How to "Low permeability coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

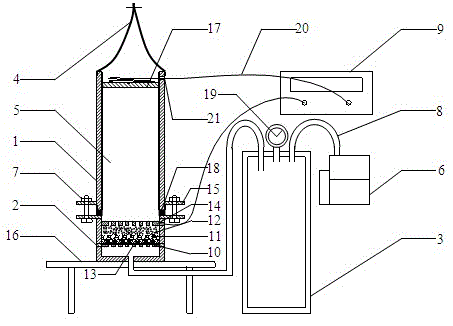

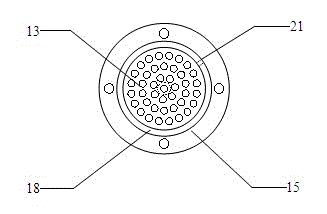

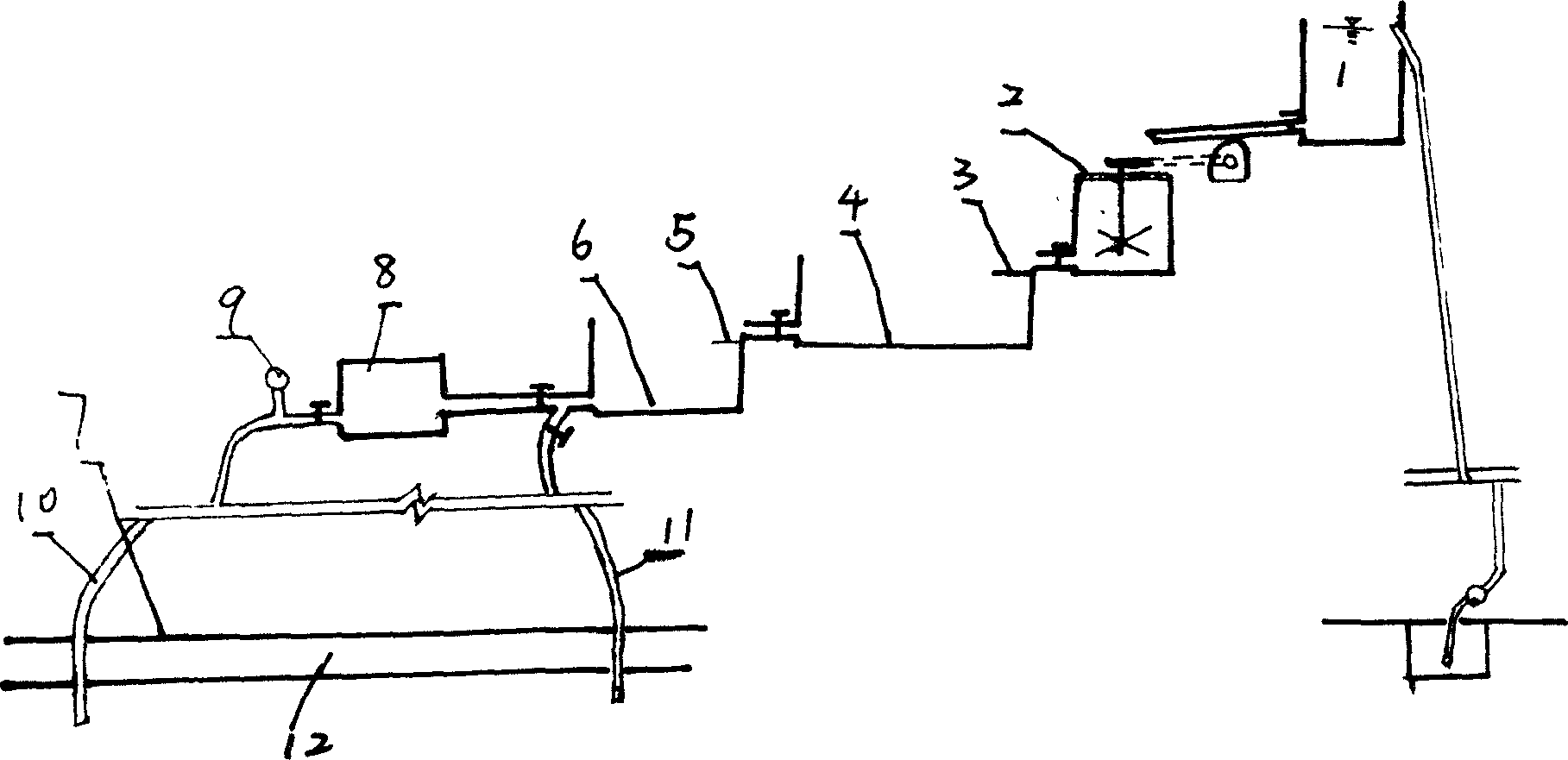

Remoulding soft clay sample preparation device and method based on vacuum combined electron-osmosis effect

The invention discloses a remoulding soft clay sample preparation device and a remoulding soft clay sample preparation method based on a vacuum combined electron-osmosis effect. Nonwoven geotextile, a gravel layer, a sand mat layer and an electron-osmosis cathode are sequentially paved on an osmosis drainage base; the upper and lower ends of a latex film are respectively turned outward and sleeved on a sample loading solidification cylinder and are fixed with the osmosis drainage base by a bolt through a flange; a water vapor separation cylinder is provided with an electric contact vacuum member and is connected with the osmosis drainage base and a vacuum pump respectively through an air pipe; slurry is poured into the designated height of the sample loading solidification cylinder, and an electro-osmosis anode is put in; and the electro-osmosis anode and the electro-osmosis cathode are respectively connected with a programmable direct-current power supply by wires. Under the combined effect of vacuum negative pressure and electro-osmosis, the drainage solidification speed of a soil body is increased, and the solidification stress level in a soil body sample preparation process can be adjusted. According to the device and the method disclosed by the invention, the size of a sample tank is reduced, and meanwhile, the number of sample preparation each time is increased by preparing multiple groups of soil samples; the device has a simple structure and is convenient for operation and sample taking; and the sample preparation period is short, and secondary cutting, disturbance and waste of soil samples are effectively avoided.

Owner:HOHAI UNIV

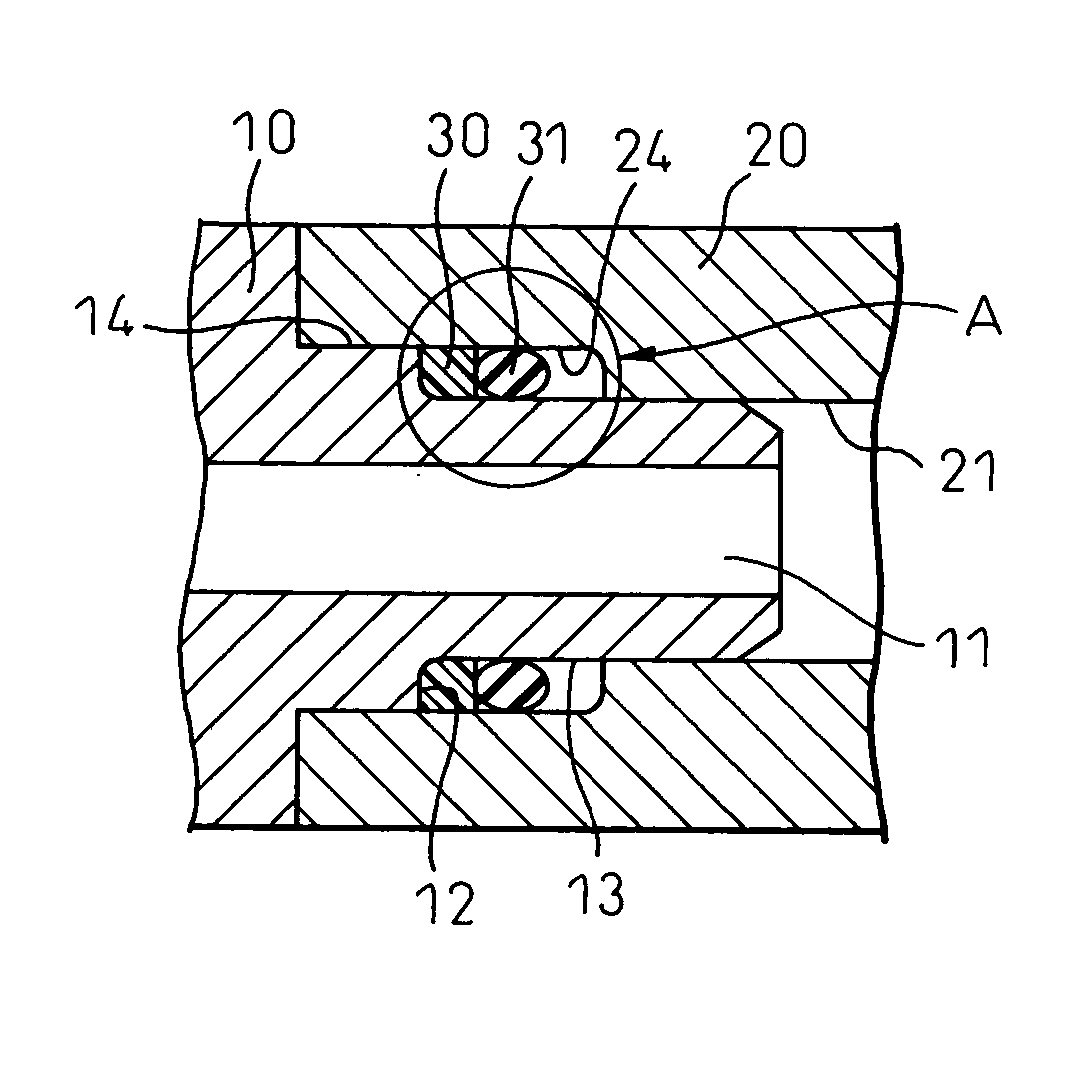

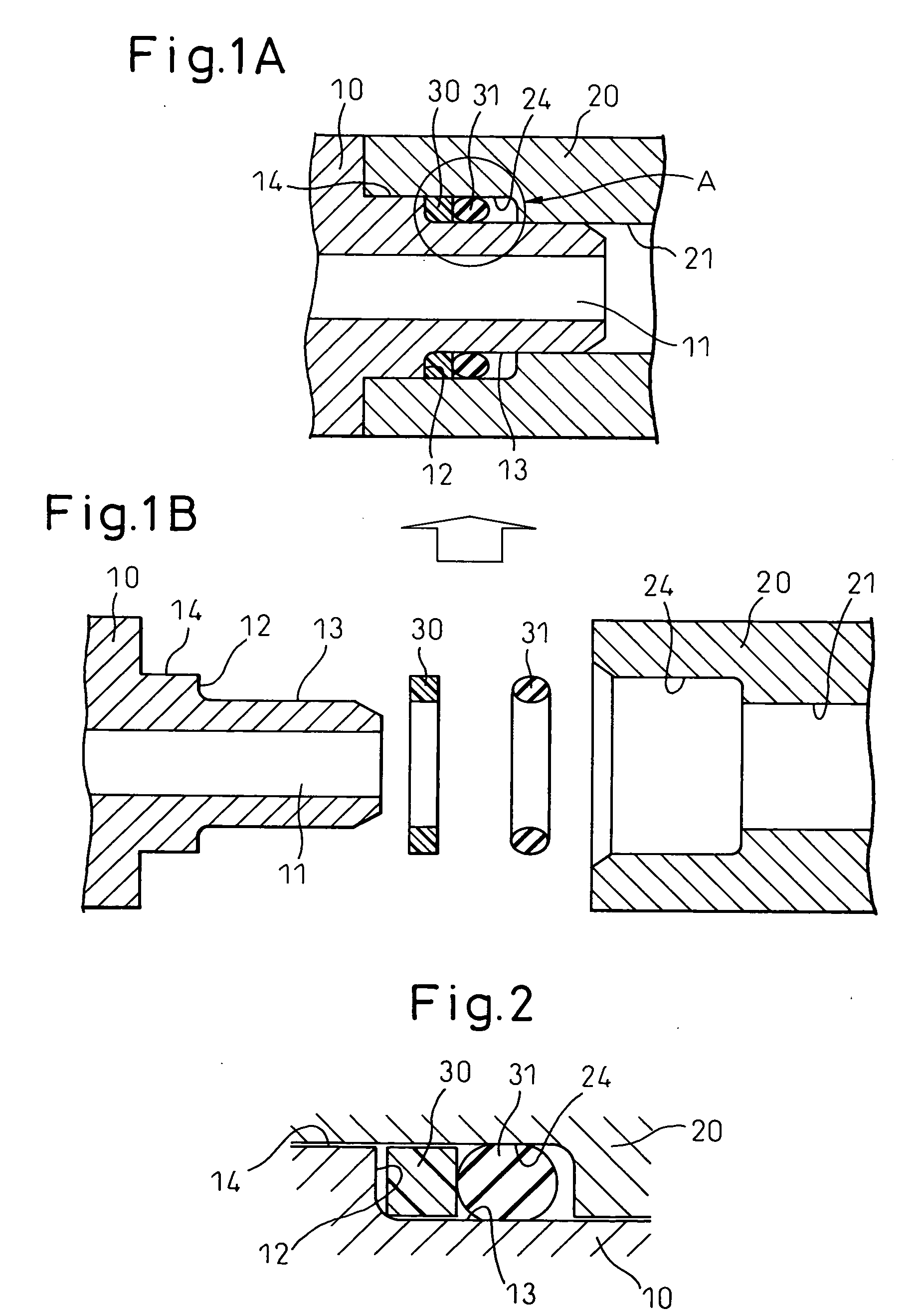

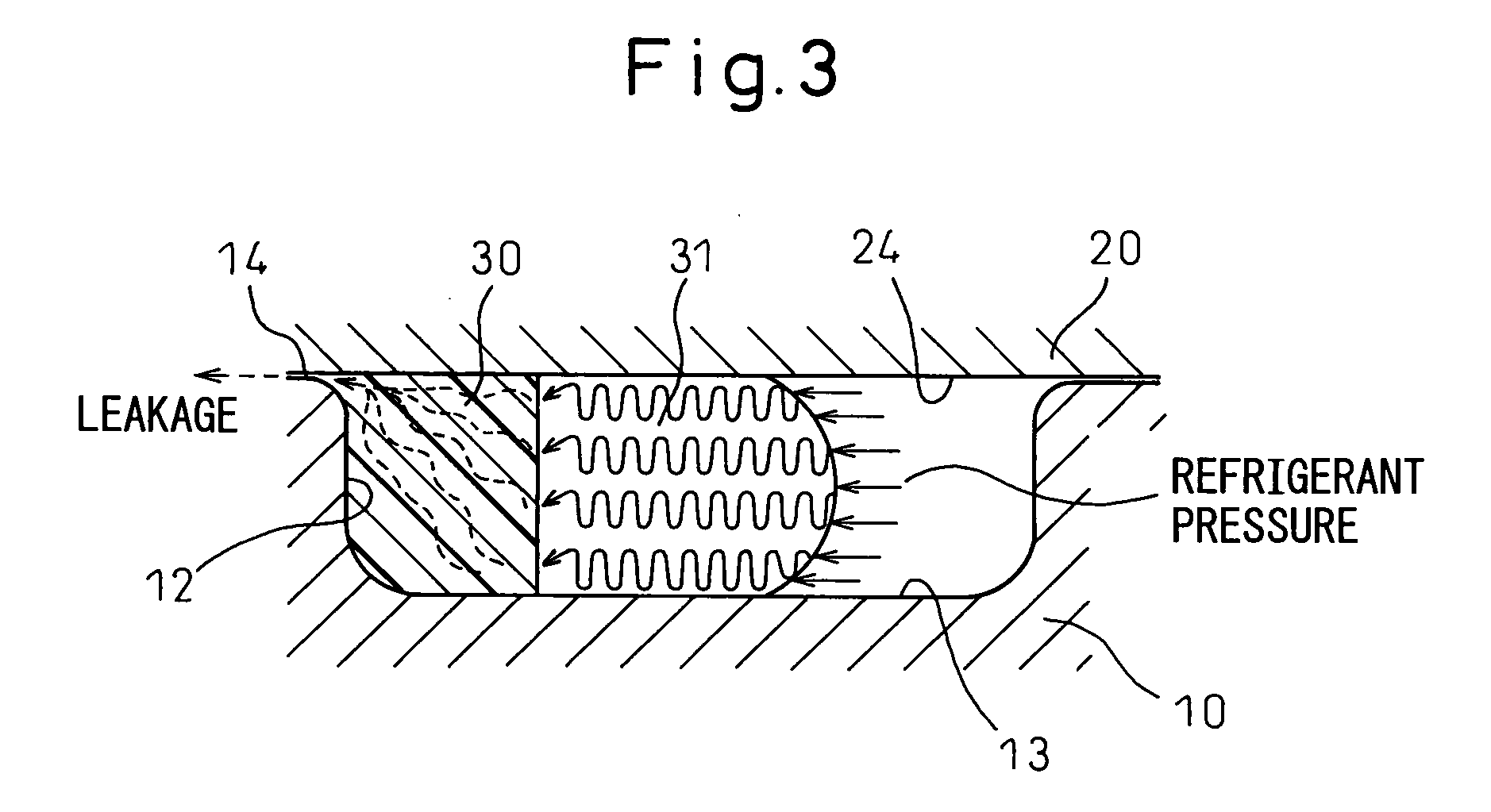

Pipe joint for refrigeration cycle having combination of O-ring and backup ring

InactiveUS20050046187A1Minimize refrigerant leakageMinimizing refrigerant leakageSleeve/socket jointsFluid pressure sealed jointsRefrigerantCarbon dioxide

A pipe joint for the refrigeration cycle is disclosed. A female joint (20) has a fitting recess (24), and a male join (10) has a fitting protrusion (14) and a stepped portion (13). In the male joint (10) and the female joint (20), a backup ring (30) and an O-ring (31) are fitted adjacently to each other in the stepped portion. The fitting protrusion (14), the backup ring (30) and the O-ring (31) are fitted in a fitting recess (24). The O-ring (31) is formed of an elastic material having a high blister resistance to carbon dioxide refrigerant. The backup ring (30) is formed of a resin material having a smaller permeability coefficient than the O-ring (31) against the carbon dioxide refrigerant and plastically deformable under the pressure of the refrigerant imposed on the O-ring (31). The refrigerant leakage amount can thus be minimized.

Owner:DENSO CORP

High barrier coextruded stretch film

ActiveCN102029754AReduce the limit of the stretch ratioImprove controllabilitySynthetic resin layered productsBlow moldingEngineering

A high barrier coextruded stretch film is a transparent multilayer film or a multilayer film with printed pictures and text information; the thickness of the film is 0.008-0.150mm; and the film is the multilayer film suitable for printing, recombination, vacuum packaging or gas flushing packaging and can be subjected to secondary heat sealing. The invention particularly relates to a high barrier coextruded longitudinal stretch film which is obtained through the mixing technology assisted by three or more than three layers of resins and the forming methods of blow molding and casting coextruding longitudinal stretch. When the thickness and structure of the film are fixed, the barrier property of the film to gas and steam is increased by 10%-300% through 0.3-12 times of longitudinal stretch; and when the barrier property and structure of the film are fixed, the thickness of the film is reduced by 30%-1200% through 0.3-12 times of longitudinal stretch. The film can be widely used in the sealed flexible packages of products in the fields of agriculture, food, household chemicals, chemical engineering, war industry and the like, printing substrates and various functional packages with the functions of thermal forming, gasing, vacuumizing and the like; and the film is especially suitable for the high barrier applications in various environments.

Owner:J&A IND (SUZHOU) CO LTD

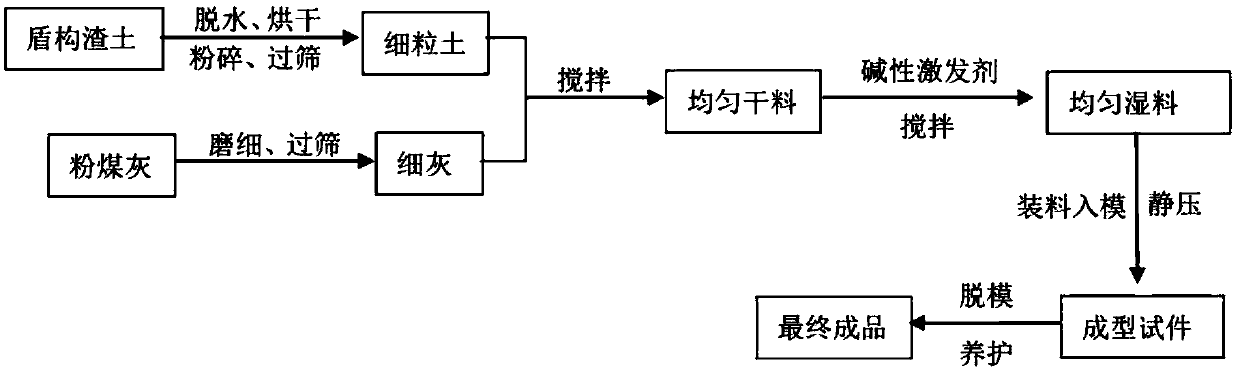

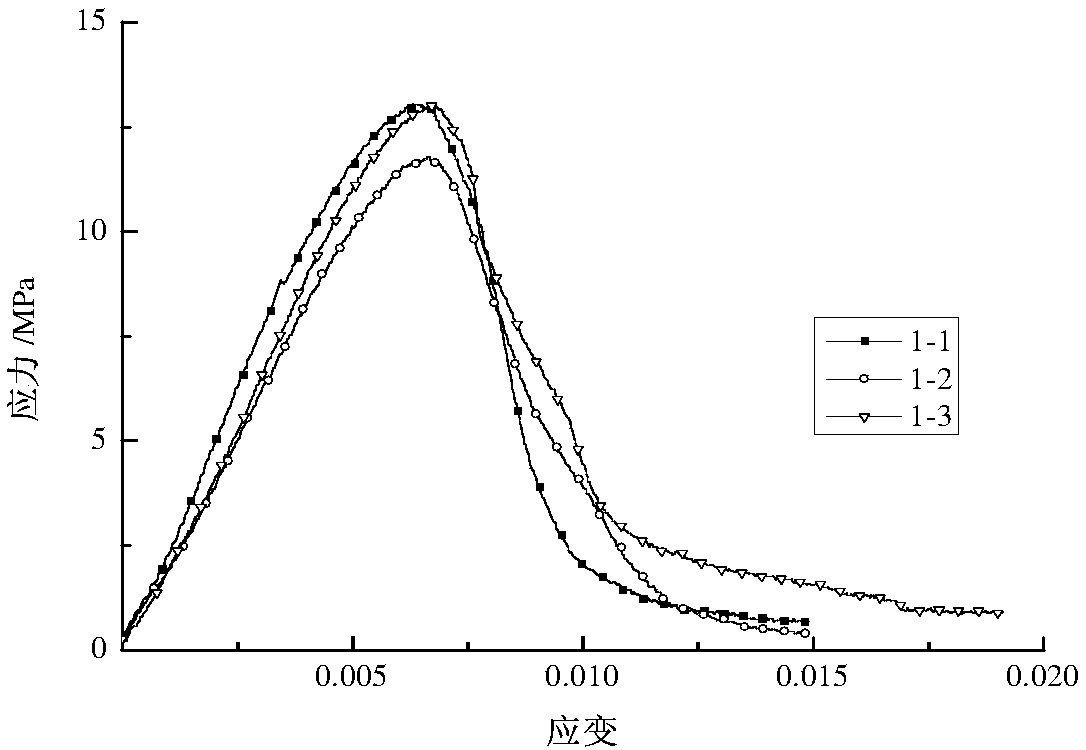

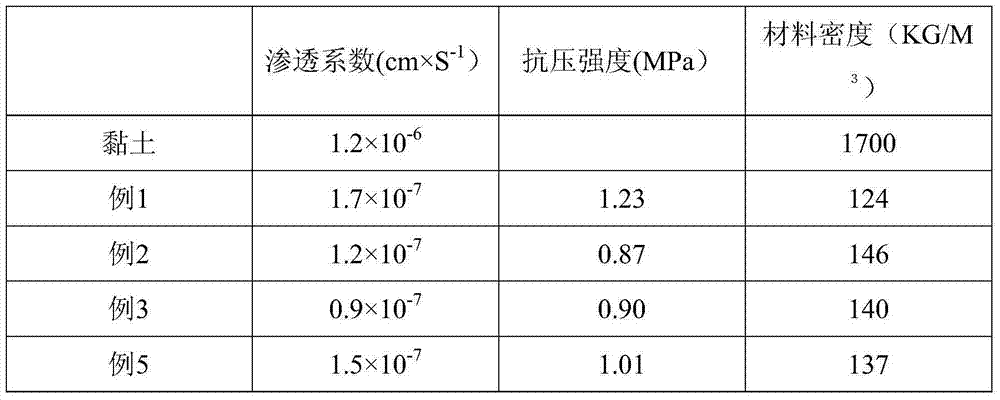

Geopolymer and preparation method and application thereof

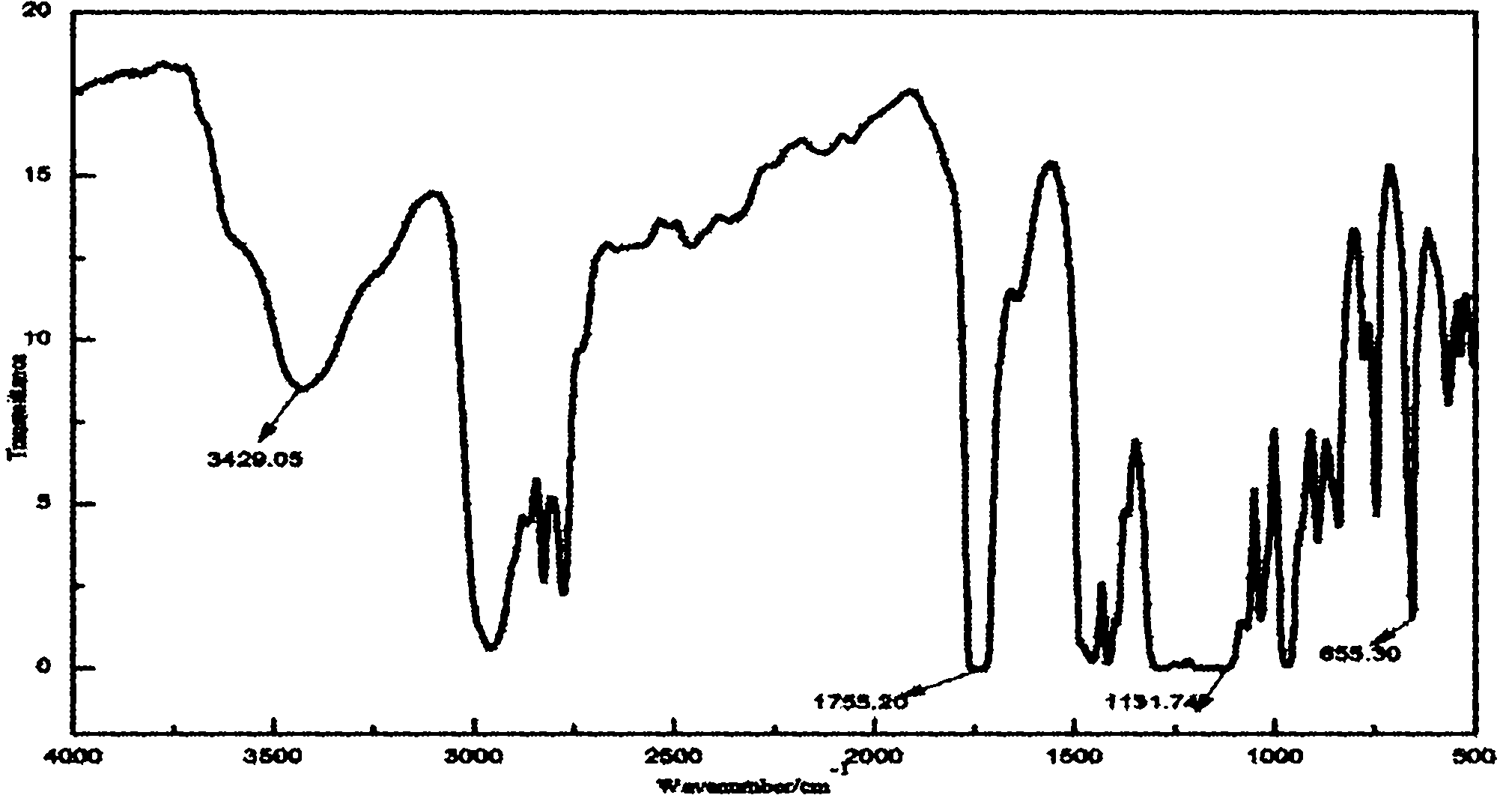

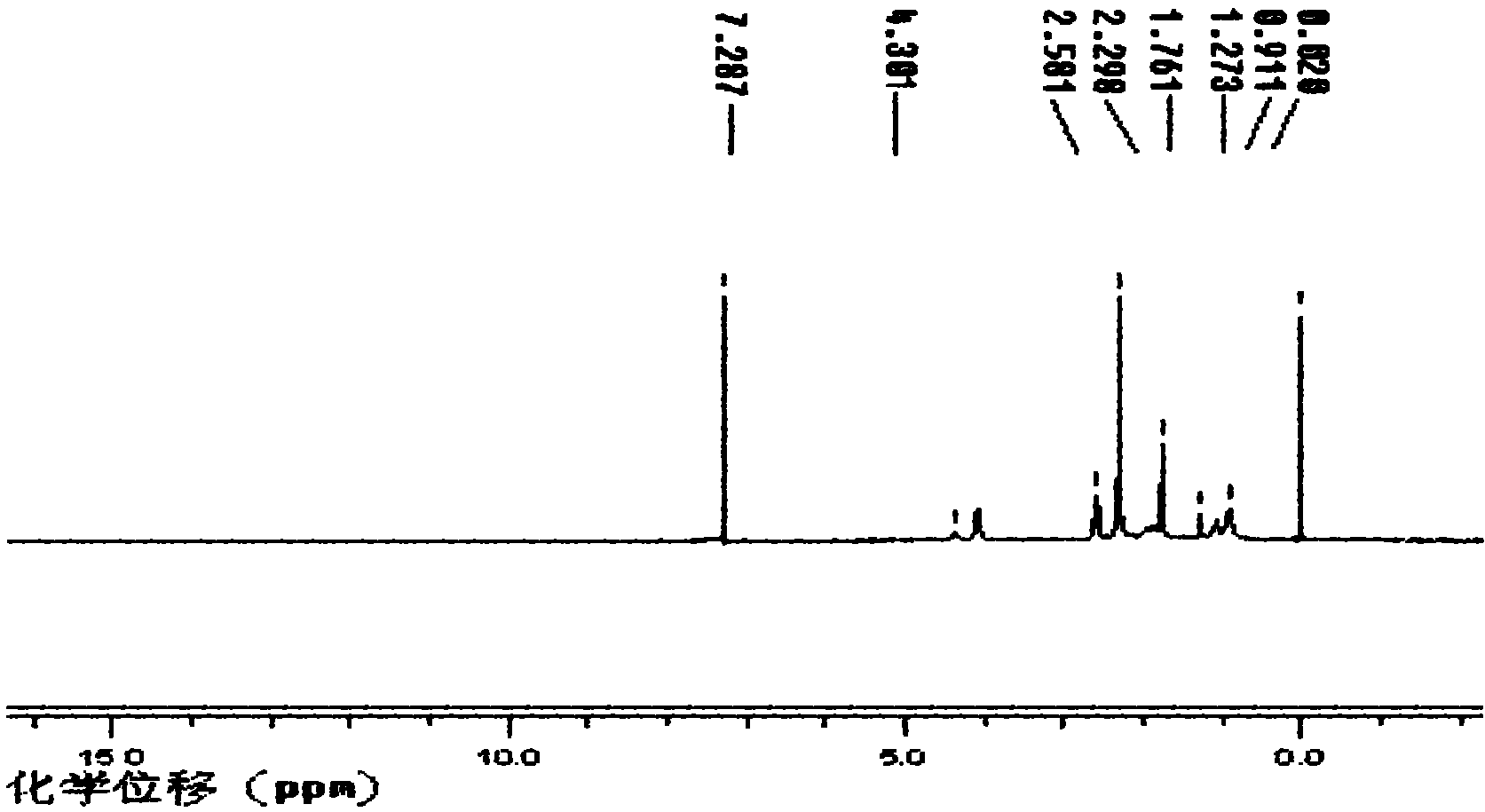

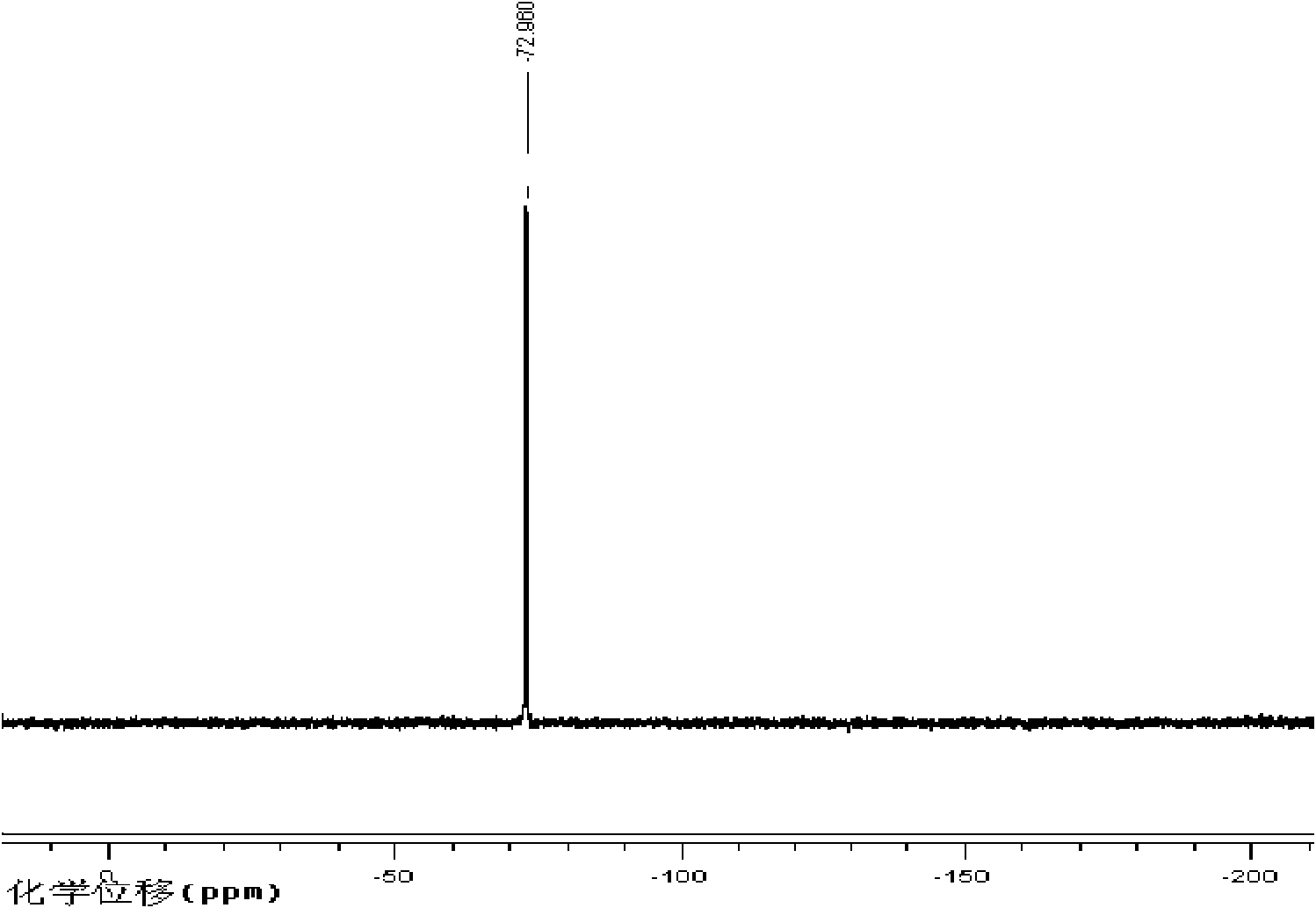

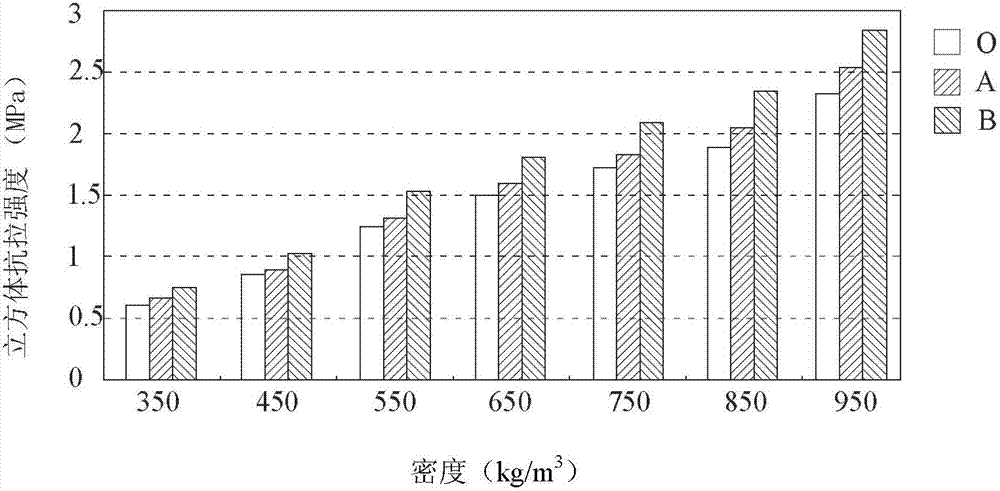

ActiveCN108046669ALow permeability coefficientHigh strengthCement productionGeopolymerUltimate tensile strength

The invention discloses a geopolymer and a preparation method and application thereof. The geopolymer is at least prepared from fly ash, shield muck and an alkaline activator. The main component of the shield muck is clay, and the mass ratio of the fly ash to the dried shield muck is (1-2):3; the mass ratio of a mixture of the fly ash and the dried shield muck to the alkaline activator is 1:(0.14-0.18). According to the geopolymer, the high-mud-content shield muck is subjected to recycling application, and the preparation raw materials do not include any type of traditional cementing materialssuch as cement and lime, so that large carbon emission is avoided, and the cost is low. The geopolymer is high in strength and good in water resistance. The preparation method of the geopolymer includes the steps that the alkaline activator is added into the mixture of the fly ash and the shield muck through spraying to avoid large aggregates; the mixed wet material is tightly pressed in a mold,so that a geopolymer test piece has relatively high strength and water resistance.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

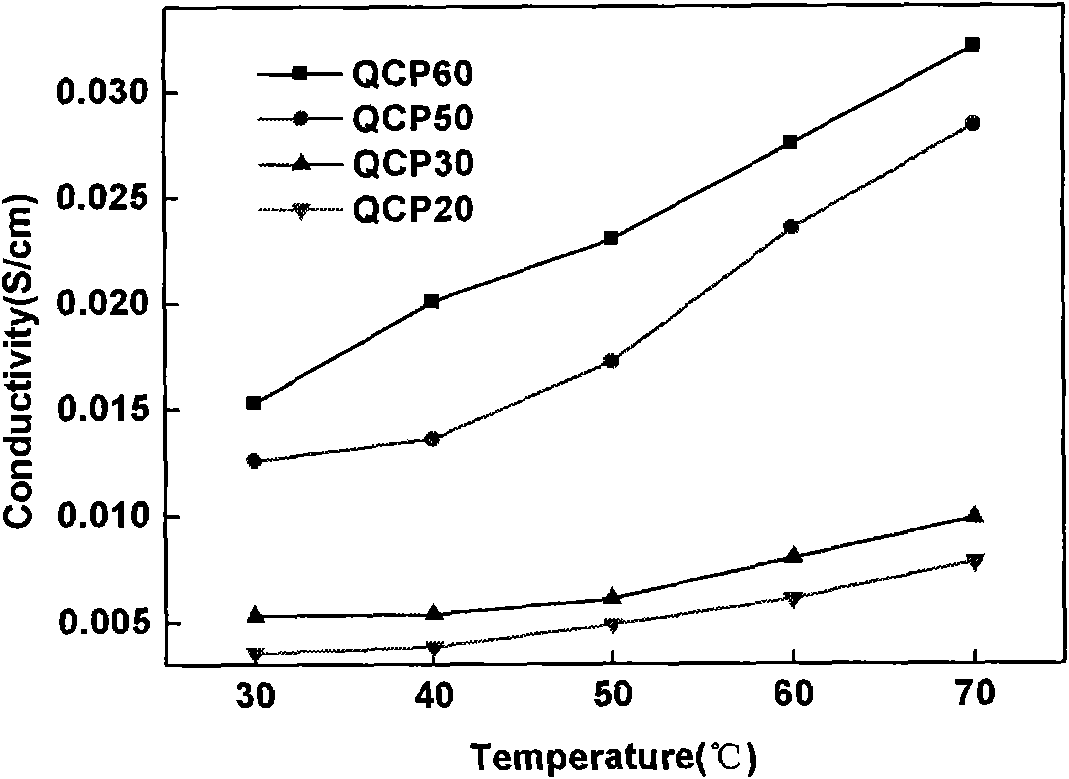

Nanocellulose/sulfonated polyaryletherketone composite film as well as preparation method and application of nanocellulose/sulfonated polyaryletherketone composite film

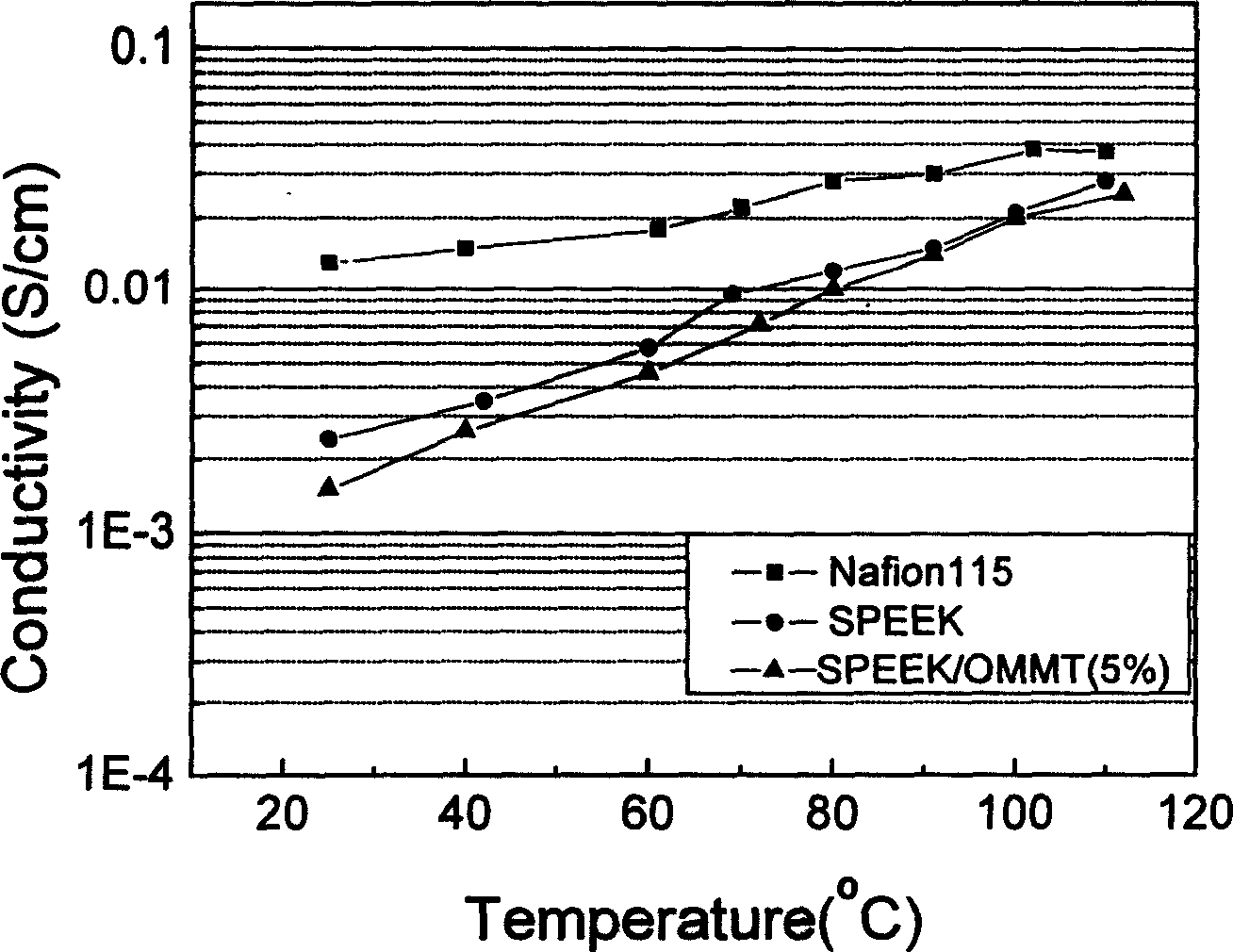

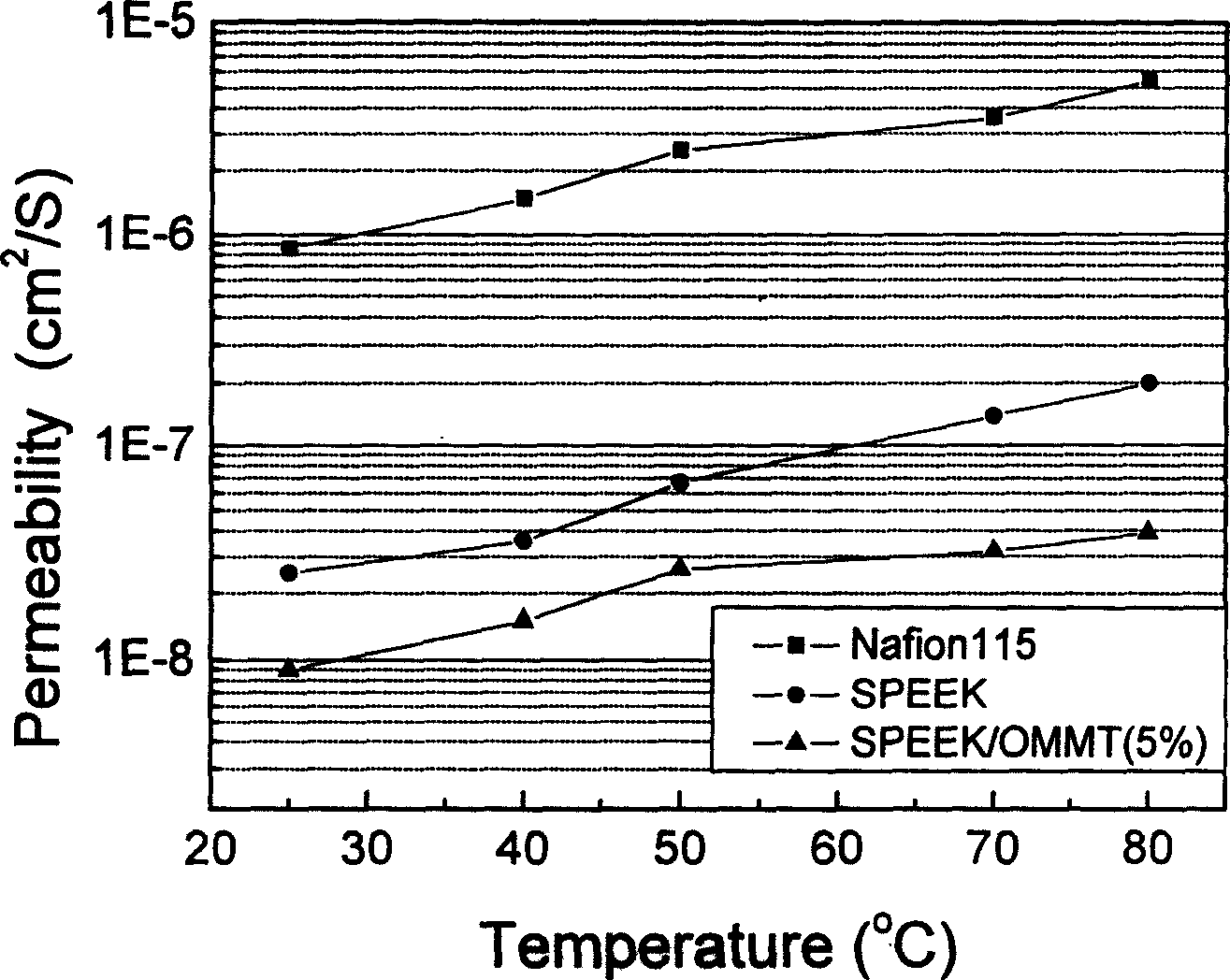

ActiveCN104530682AImprove mechanical propertiesExpand the range of conditions of useSolid electrolyte fuel cellsComposite filmFuel cells

The invention discloses a nanocellulose / sulfonated polyaryletherketone composite film as well as a preparation method and application of the nanocellulose / sulfonated polyaryletherketone composite film, belonging to the technical field of proton conduction films of fuel cells. The mass ratio of nanocellulose to sulfonated polyaryletherketone in the composite film is (0.01-0.05): (0.45-0.49), and the nanocellulose is preferably nanocellulose containing a sulfonic group and hydroxyl. The preparation method comprises the steps of firstly, polymerizing a monomer with the sulfonic group or directly sulfonating a polymer to obtain sulfonated polyaryletherketone; and then, carrying out solution blending on sulfonated polyaryletherketone and the nanocellulose subjected to refining treatment and surface modification to prepare the nanocellulose / sulfonated polyaryletherketone composite film. The composite film disclosed by the invention can be used as a proton conduction film of a fuel cell; the film is 10-300mu m thick and has the proton conductivity of more than 10<-2>S / cm at the temperature of 20-150 DEG C, meanwhile, the permeability coefficient of methanol is reduced, and the size stability and the water absorptivity are improved.

Owner:CHANGCHUN UNIV OF TECH

Preparation and application of municipal dewatering sludge based coating material for seal of landfill site

ActiveCN102690085AWide variety of sourcesRealize resource utilizationSludge treatmentSolid waste disposalVegetationLand resources

The present invention relates to preparation of a municipal dewatering sludge based coating material for seal of landfill site, is mainly used for seal covering of the landfill site, and belongs to the field of environmental geotechnical engineering. The municipal dewatering sludge is employed as a basis material and modified to be used in seal covering of the landfill site. An air-out layer of the coating material for seal of landfill site has good gas guide performance; an impervious layer is not easily cracking and has low permeability; and a vegetation nutrient layer has rich nutrients and good hydrophobicity. The covering material of the present invention realizes resource utilization of municipal dewatering sludge and saves land resource; the covering material can be produced by industrialized production, has a simple construction for application to seal covering of the landfill site, and has advantages of simpleness, fastness, strong operability, high survival ratio of plants, so as to guarantee quality of seal covering of the landfill site, meet various technological indexes of seal of the landfill site, and greatly improve the landfill environment.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

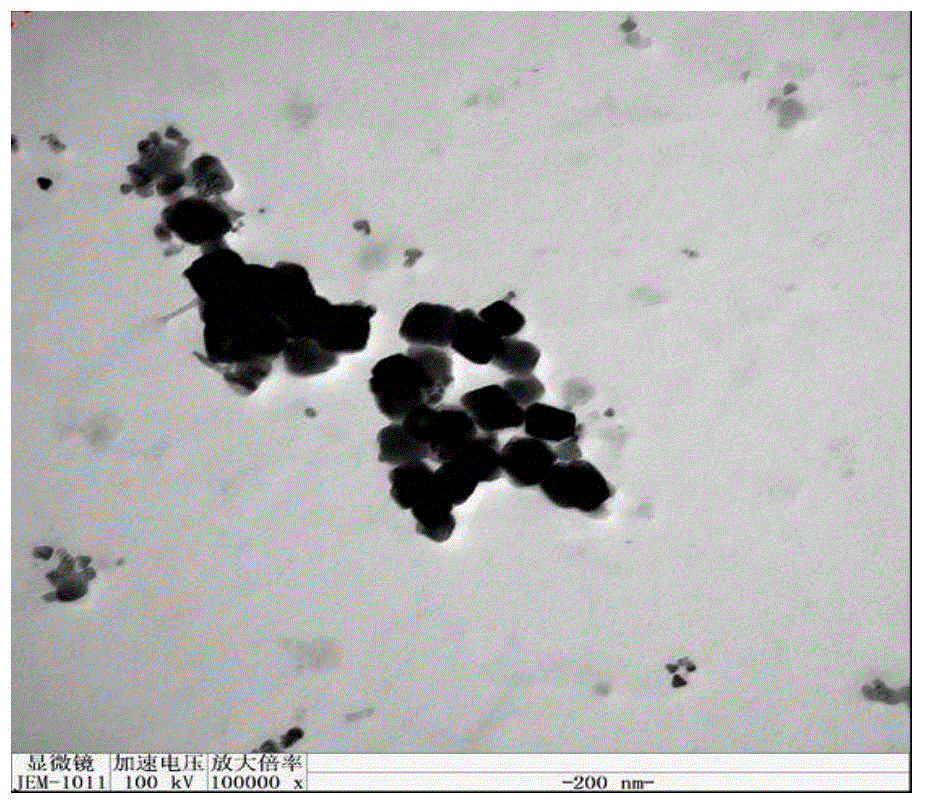

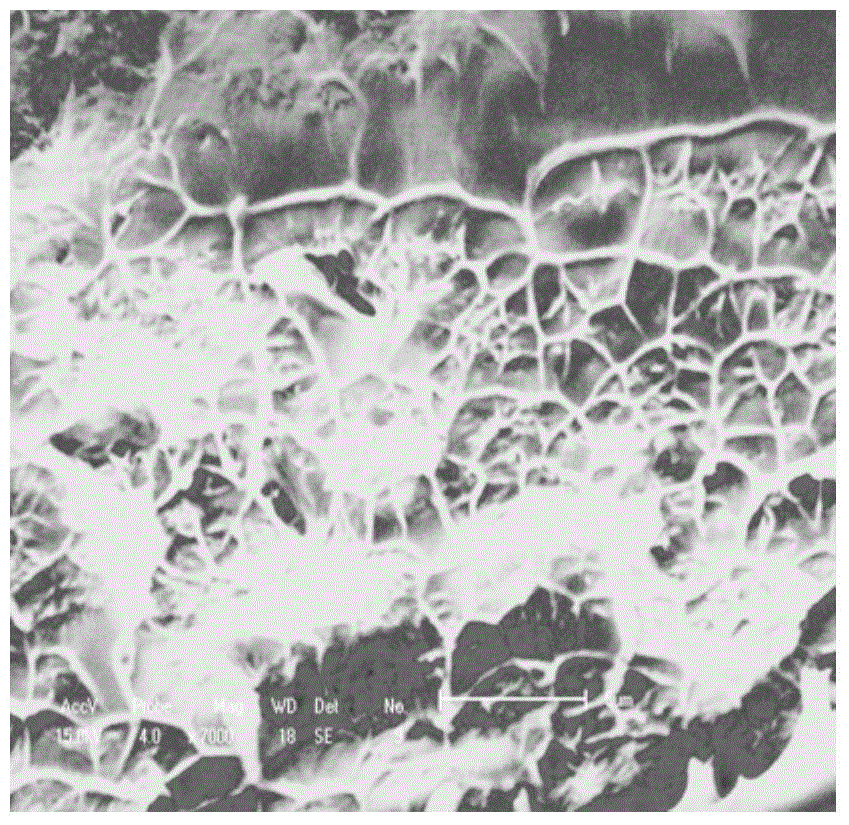

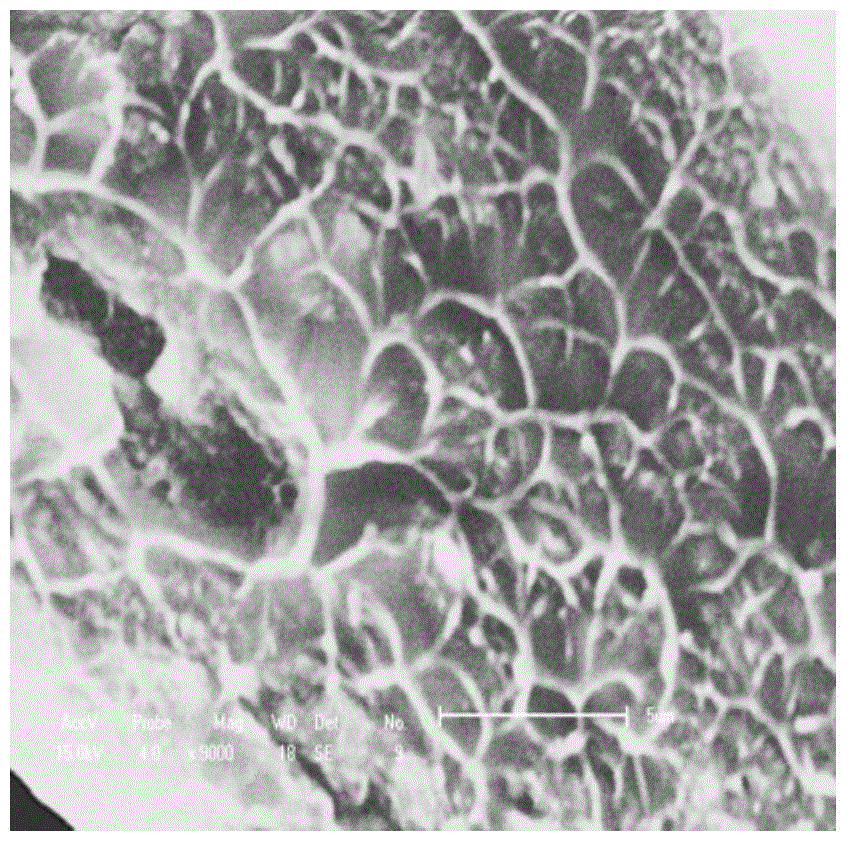

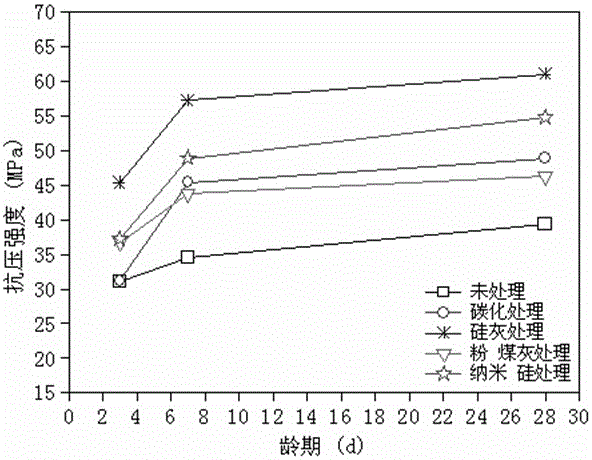

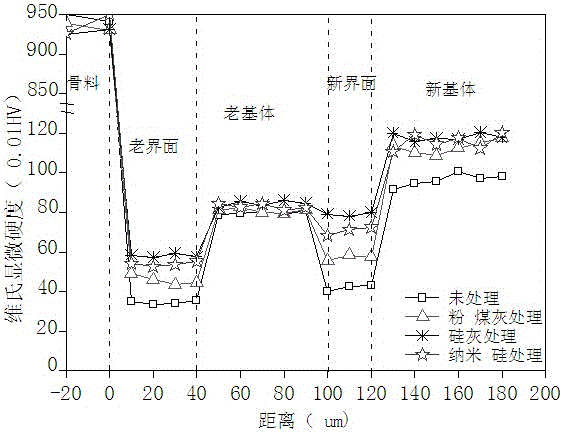

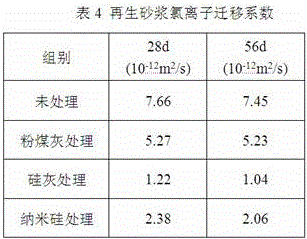

Treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate

ActiveCN106007438AIncrease the reactive surface area of volcanic ashImprove interface performanceSolid waste managementVolcanic ashIon permeability

The invention relates to a treatment method of volcanic-ash-paste-reinforced recycled concrete aggregate. The method comprises the following steps: (1) carrying out crushing treatment and screening on recycled concrete, and drying to obtain recycled aggregate; (2) adding water into a volcanic ash material with the particle size of less than 60 micrometers to prepare a volcanic ash paste, and carrying out ultrasonic dispersion to form a homogeneous paste solution; (3) immersing the dried recycled aggregate in the step (1) in the homogeneous paste solution prepared in the step (2), and stirring; (4) screening the mixture treated in the step (3) to remove the recycled aggregate, and filtering to remove the excessive paste solution; (5) drying the screened recycled aggregate, and carrying out kneading dispersion on the agglomerate aggregate; and (6) screening the recycled aggregate treated in the step (5) to obtain the volcanic-ash-paste-reinforced recycled concrete aggregate. Compared with the mortar prepared from the untreated recycled concrete aggregate, the 3-day compression strength and 28-day compression strength of the mortar prepared from the volcanic-ash-paste-reinforced recycled concrete aggregate are enhanced by 17% or above, the chlorine ion permeability coefficient is lowered by 30% or above, and the new / old interface microhardness of the mortar is enhanced by 30% or above.

Owner:HUNAN UNIV

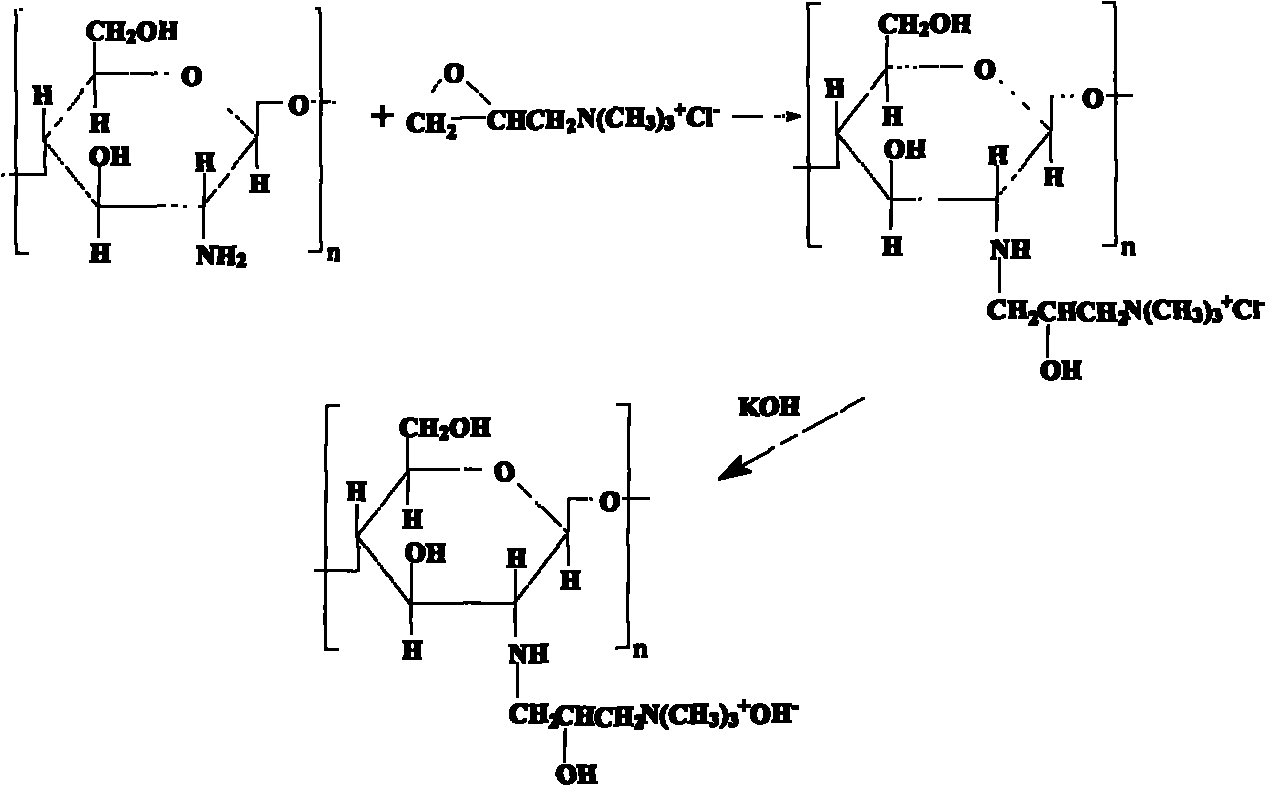

Method for producing a quaternary ammonium chitosan/polyving akohol membrane

InactiveCN101798393AImprove the lack of conductivityRich sourcesCell electrodesPVA - Polyvinyl alcoholQuaternized chitosan

The invention relates to a method for producing a quaternary ammonium chitosan / polyving akohol membrane, comprising the following steps: (1) synthesizing the quaternary ammonium chitosan; (2) washing and drying the quaternary ammonium chitosan; (3) synthesizing the quaternary ammonium chitosan / polyving akohol membrane; and (4) scraping the quaternary ammonium chitosan / polyving akohol membrane on a flat plate and forming the quaternary ammonium chitosan / polyving akohol membrane. Compared with the prior art, the method for producing the quaternary ammonium chitosan / polyving akohol membrane adopts the raw materials of rich source and low cost, is easy and is convenient to operate.

Owner:TONGJI UNIV

Method for installing vertical soft barrier system based on soil-stone foundation

InactiveCN102367672ADoes not affect the anti-seepage functionStop the spreadArtificial islandsProtective foundationGeomembraneChemical grouting

The invention discloses a method for installing a vertical soft barrier system based on a soil-stone foundation. The method comprises the following steps of: digging a ditch for installing the vertical soft barrier system; refilling anti-seepage slurry into the ditch to form a retaining wall protection layer; installing an HDPE (High-Density Polyethylene) geomembrane in the ditch by using a support tool to form an HDPE geomembrane wall; chemically grouting and sealing the bottom of the HDPE geomembrane wall to form a bottom sealing layer; and withdrawing the support tool to form the vertical soft barrier system. Due to the adoption of the method, an anti-seepage function is ensured, seepage at a joint is prevented, and isolated liquid is effectively prevented from being dispersed; the horizontal dispersion of pollutants can be prevented and blocked for a long time; a connecting lock piece has a reversely-rotatable HDPE structure of which the positive and negative surfaces can be replaced by each other, is provided with a plurality of sealing chambers, can be used for accommodating a plurality of sealing materials and joint seepage detection systems, and is easy to install and operate; an expansion water blocking gasket can expand after contacting water, so that liquid is prevented from flowing through a porous sealing device, and persistent sealing is ensured; and a large installation depth is realized.

Owner:BEIJING GEOENVIRON ENG & TECH

Radial truck tire air-tight layer component and preparation process thereof

InactiveCN102604243AImprove stabilityImprove thickness uniformityTyresPneumatic tyre reinforcementsVulcanizationEngineering

The invention belongs to the technical field of processing of rubber tires, and particularly relates to a radial truck tire air-tight layer component and a preparation process thereof. The radial truck tire air-tight layer component comprises the following substances in parts by mass: 100 parts of rubber substrate, 40-100 parts of reinforcing system, 1-10 parts of anti-aging system, 4.7-15 parts of vulcanization system, 0-20 parts of radiation crosslinking sensitizer and 0-50 parts of additive aid. The method comprises the following steps of: mixing other substances except a vulcanizing agent, discharging glue, and adding the vulcanizing agent for preparing a rubber compound; and rolling the prepared rubber compound to obtain an air-tight layer sheet of 3-5 millimeters in thickness, performing cobalt source radiation treatment in the air to obtain the radial truck tire air-tight layer component, wherein the radiation dosage of the air-tight layer sheet is 5-50 kGy. The air-tight layer component which is subjected to radiation pretreatment has the advantages of high Green strength, high structural size stability, high air tightness, and capability of improving the tire quality at a lower radiation dosage.

Owner:河南省科学院同位素研究所有限责任公司 +1

Fluorine-containing acrylate polymer anion exchange membrane and preparation method thereof

InactiveCN102122720AGood chemical stability and mechanical propertiesInhibition of Methanol PermeationCell component detailsFuel cell detailsIon-exchange membranesChemistry

The invention discloses relates to an ion exchange membrane and provides a fluorine-containing acrylate polymer anion exchange membrane with high conductivity, good barrier effect on methanol, good chemical stability and high heat stability and a preparation method thereof, wherein the active group of the prepared exchange membrane is quaternary ammonium salt and the prepared exchange membrane can serve as the anion exchange membrane of an alkaline direct methanol fuel cell. The active group of the fluorine-containing acrylate polymer anion exchange membrane is the quaternary ammonium salt and the preparation method of the fluorine-containing acrylate polymer anion exchange membrane comprises the steps of: subjecting the fluorine-containing acrylate and the acrylate containing a tertiary amine functional group to free radical polymerization to obtain polymer containing the tertiary amine functional group; precipitating, washing, and drying the obtained polymer; dissolving into an organic solvent; forming a membrane through a phase transformation method, and finally soaking the membrane into a quaternary ammonium reagent to react for some time; taking the membrane out; and washing and drying to obtain the fluorine-containing acrylate polymer anion exchange membrane.

Owner:XIAMEN UNIV

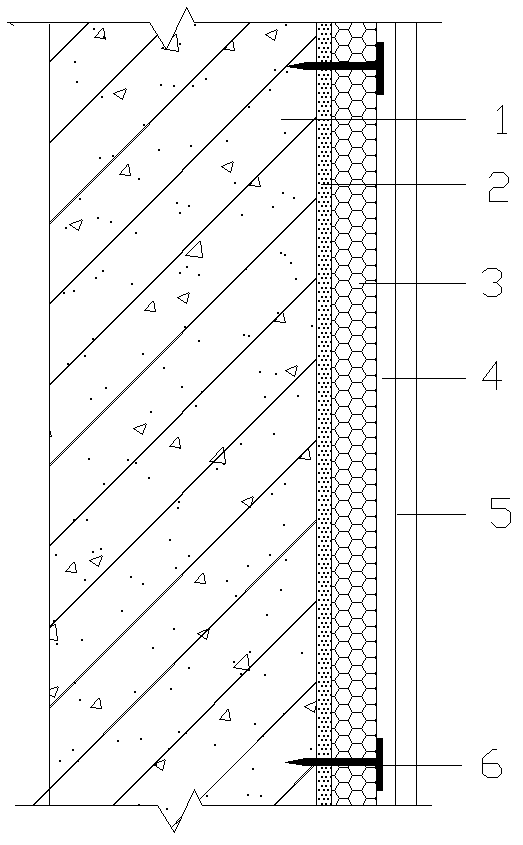

EPS light aggregate concrete composite wall and its construction method

ActiveCN102765905AImprove the indoor environmentIndoor Thermal StabilizationHeat proofingBuilding material handlingInsulation layerMaterials science

The invention provides an EPS light aggregate concrete composite wall and its construction method, belongs to the field of constructional insulation walls, and solves the problem that thermoengineering property of a wall composed of a single material can not meet requirements when the wall is used as a bearing wall. Based on that fact that strength of the composite wall meets requirements, its energy-saving and insulation capabilities are greatly enhanced. The composite wall comprises a base, an adhesive mortar layer, a heat-insulation layer, a rendering coat and a finish coat, wherein the base and the heat-insulation layer are anchored through an anchor bolt; raw materials for the preparation of the heat-insulation layer comprise cement, perlite, fly ash, water, EPS particles, river sand, a polyvinyl acetate solution and silica fume; and raw materials for the preparation of the adhesive mortar comprise cement, river sand, a polymer emulsion, cellulose ether and water. The composite wall provided by the invention can be used to eliminate thermal bridges in building construction and improve indoor environment, has no insulation cut point, and is beneficial to indoor thermostabilization.

Owner:CHINA ELECTRIC POWER RES INST +1

I-shaped water retaining dam for ground-water reservoir in coal mine

ActiveCN109826667AReduce pressureImprove bearing capacityMining devicesUnderground chambersCoalCoal pillar

The invention discloses an I-shaped water retaining dam for a ground-water reservoir in coal mine. The I-shaped water retaining dam is located between coal pillar dam bodies so as to be used for isolating the ground-water reservoir from corresponding coal roadways. The I-shaped water retaining dam comprises an upper flange, a web plate and a lower flange from top to bottom, the vertical face of adam body is in an I shape, the upper flange stretches into a roadway roof, the two ends of the web plate are embedded into the coal pillar dam bodies, and the lower flange stretches into a bottom plate. Because the I-shaped water retaining dam is located in an underground coal rock bed roadway, the surrounding rock stress acting on the I-shaped water retaining dam is relatively complicated, the phenomenon of water-seepage of a weak part on the upper portion of a traditional I-shaped water retaining dam is effectively overcome, the punching stress of the dam body to the bottom plate of the roadway is reduced, the stability of the dam body and the overall stability are improved, and the requirements for water storage and the safety performance of the ground-water reservoir in the coal mine are met.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

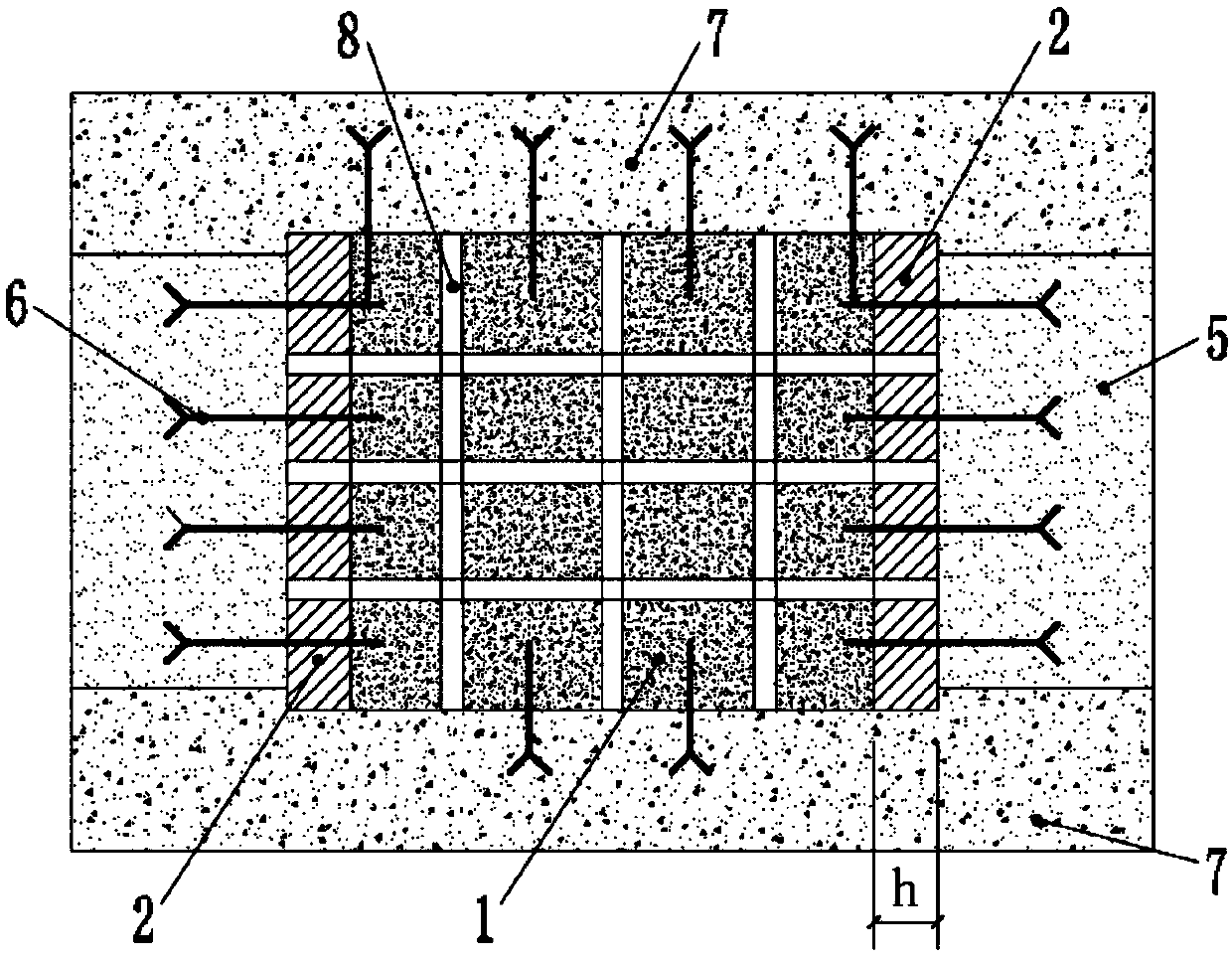

Method for shallow part enhancement type soil-swell soil vertical antifouling separating wall

ActiveCN103174173AExtended service lifeFlexibleArtificial islandsProtective foundationEngineeringSlurry

The invention discloses a method for a shallow part enhancement type soil-swell soil vertical antifouling separating wall. The method comprises the following steps: firstly, a field is flattened, a groove is excavated to a waterproof layer and the width of the shallow part groove is enlarged along two sides of the groove central line, wherein the bottom portion of the width enlargement portion of the shallow part groove is located below an upstream water line of a lowest pollution source; secondly, swell soil slurry is used for protecting the wall in the groove, soil-swell soil wall body materials are backfilled from the bottom of the groove to replace slurry, an impermeable plate is inserted in the center of the width enlargement portion of the shallow part groove and piling loading or vacuum prepressing is conducted at the top portion of the groove and the fields around the groove, so that the soil-swell soil backfilling materials begin to solidify under the collective action of self weight and piling loading or vacuum prepressing and the soil-swell soil separating wall is formed in the shallow part, wherein the pollution dispersal performance of the soil-swell soil separating wall is enhanced. Aimed at the fact that an antifouling protective screen in the shallow part is large in pollution load and can be affected by the negative factors such as weather and temperature easily, the method for the shallow part enhancement type soil-swell soil vertical antifouling separating wall enhances impermeability and durability of weak links. The method for the shallow part enhancement type soil-swell soil vertical antifouling separating wall is strong in pertinency, convenient to construct, low in construction cost, environmental-friendly and capable of satisfying the pollution prevention and control requirements.

Owner:ZHEJIANG UNIV

Organic-inorganic compoiste proton exchange film and preparing method

InactiveCN1677732AReduce penetrationIncrease profitCell electrodesFuel cellsPolymer scienceFuel cells

In the method, sulfonated polymer is dissolved in organic solvent. Added organic modified montorillonite clay is dispersed on basal body of polymer evenly. Membrane is formed through slobbering method. Through drying and stripping membrane in water produces membrane needed. Solving difficult problem of methanol infiltration of proton exchange membrane in use for direct fuel cell of methanol, the invention possesses features of simpler technique, and low cost of material etc.

Owner:SOUTH CHINA UNIV OF TECH

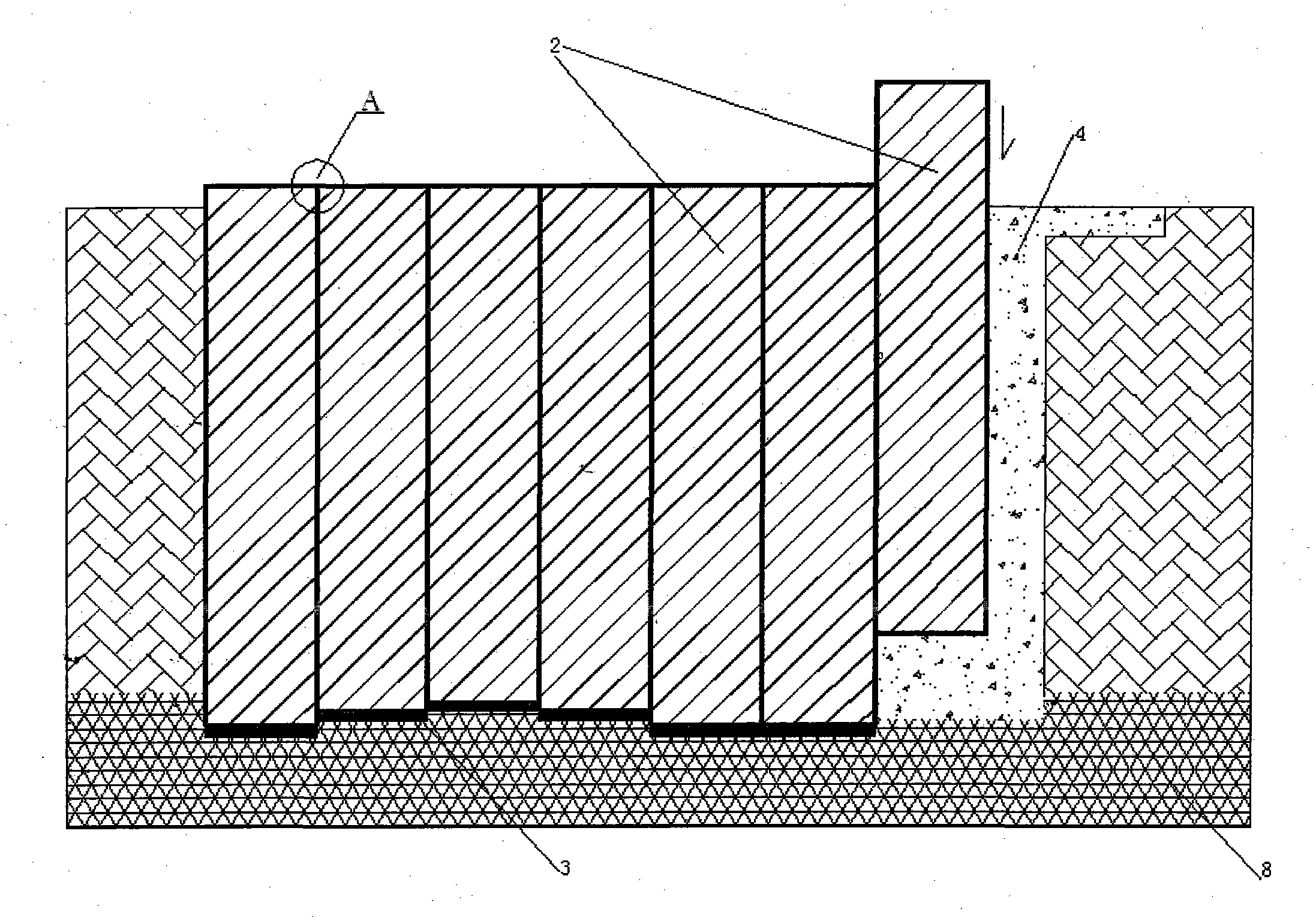

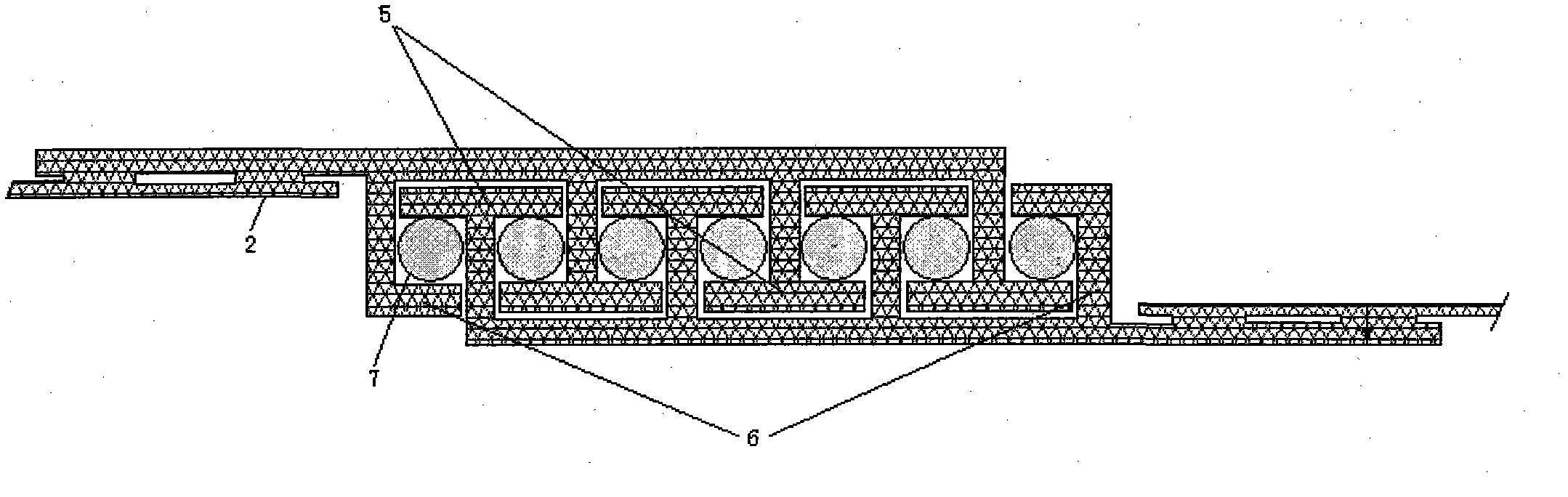

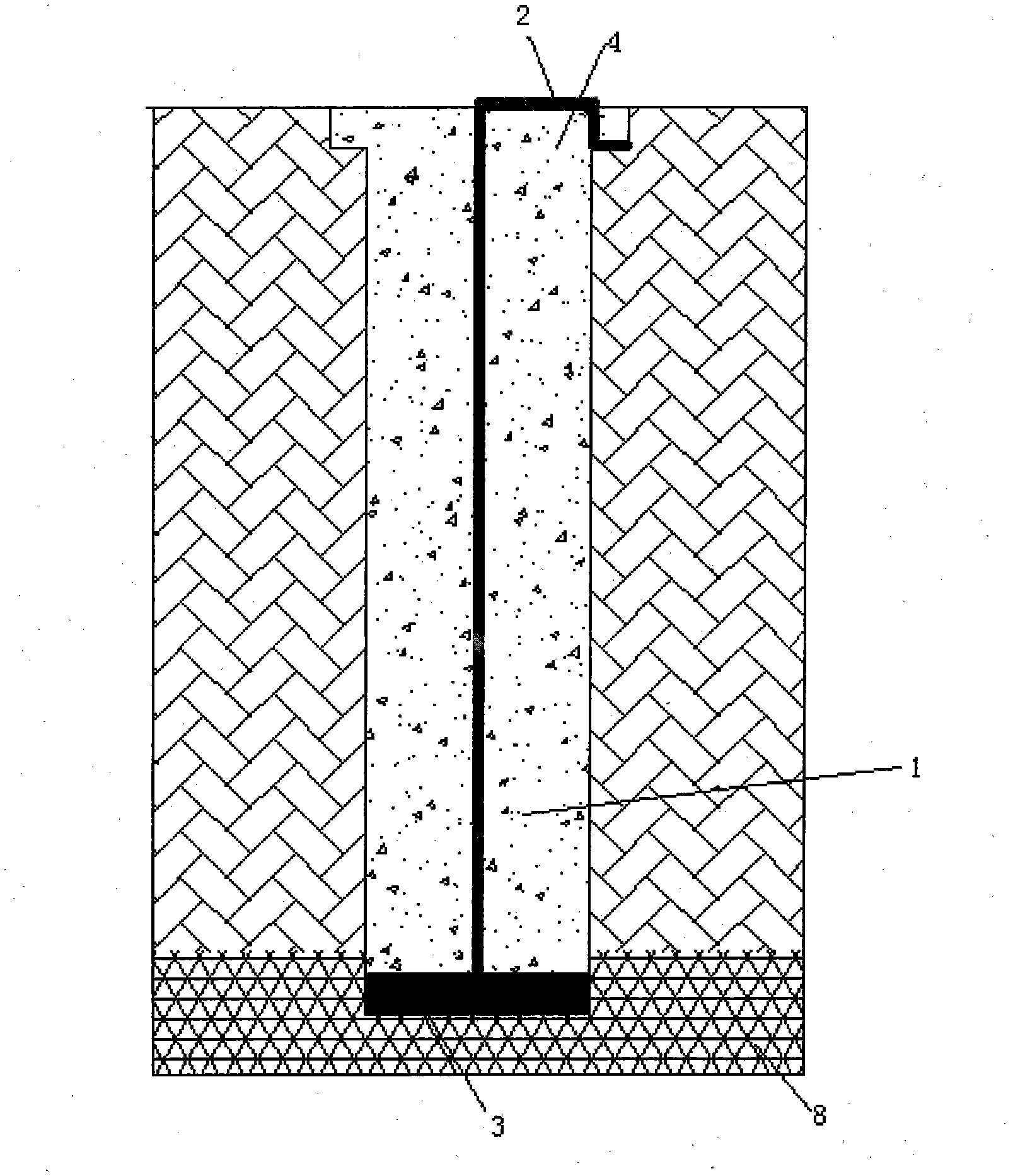

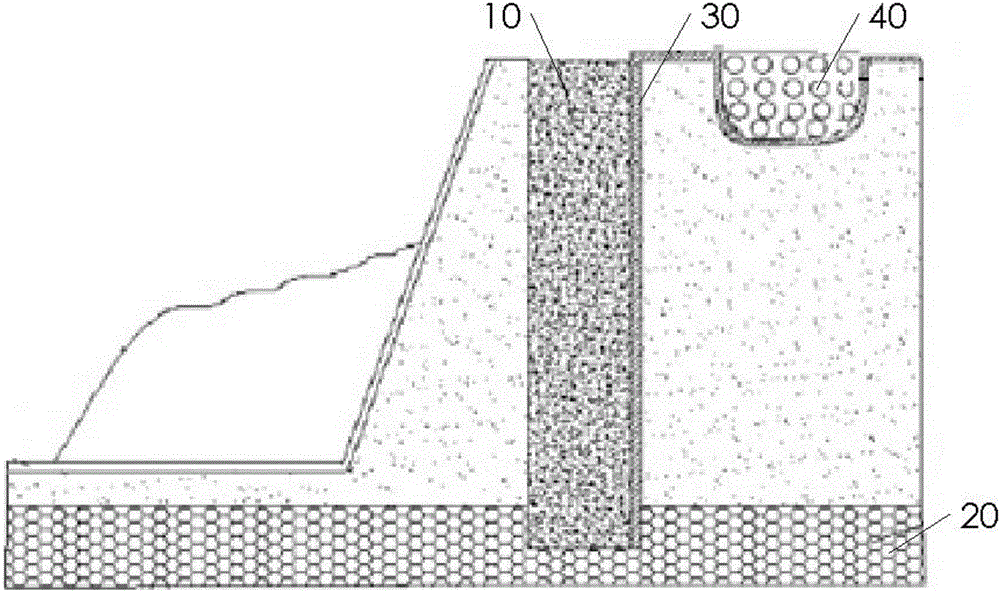

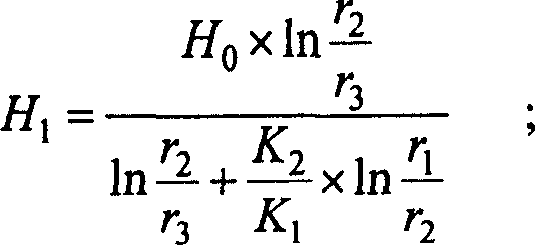

Vertical anti-seepage barrier and construction method thereof

InactiveCN106320385ATightly bondedLow permeability coefficientProtective foundationGeomembraneStructural engineering

The invention relates to a vertical anti-seepage barrier and a construction method thereof, relates to the technical field of vertical anti-seepage walls. The vertical anti-seepage barrier and the construction method mainly aim at improving the chemical corrosion prevention capacity of the vertical anti-seepage walls and improving the anti-seepage effect. According to the main adopted technical scheme, the construction method of the vertical anti-seepage barrier includes the steps that a groove is dug, wherein the bottom of the groove extends into an underground impermeable layer; a composite geo-membrane is laid on the side wall of at least one side of the groove, split bodies of the composite geo-membranes are connected in a lap joint manner through a sealant, and nonwoven fabric is arranged on the sides, facing the inner side of the groove, on the composite geo-membranes; and materials are backfilled in the groove, a vertical anti-seepage wall combined with the nonwoven fabric, facing the inner side of the groove, on the composite geo-membranes is formed in the groove, and the vertical anti-seepage barrier is composed of the composite geo-membranes, combined with one another, and the vertical anti-seepage wall. Compared with a vertical anti-seepage wall in the prior art, the permeability coefficient of the vertical anti-seepage barrier is small and smaller than or equal to 1*10<-7> cm / s, and the environment protection requirement can be met.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

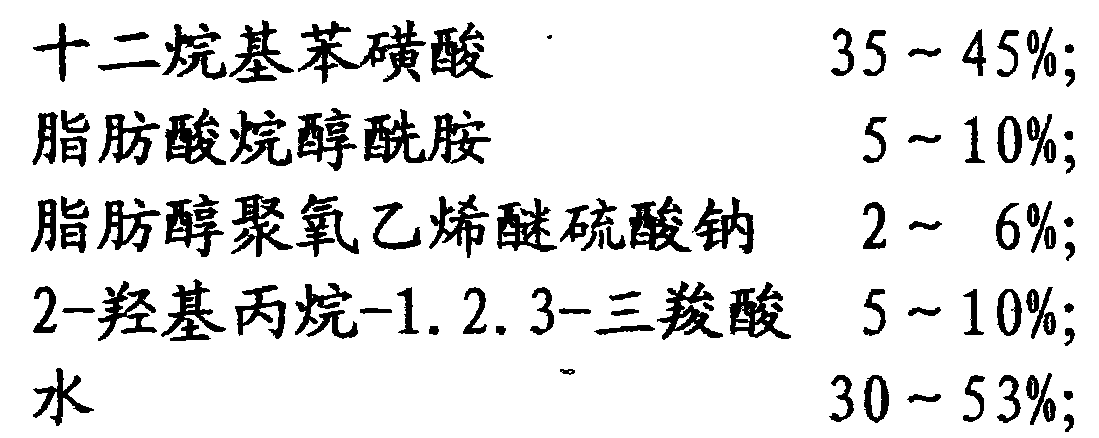

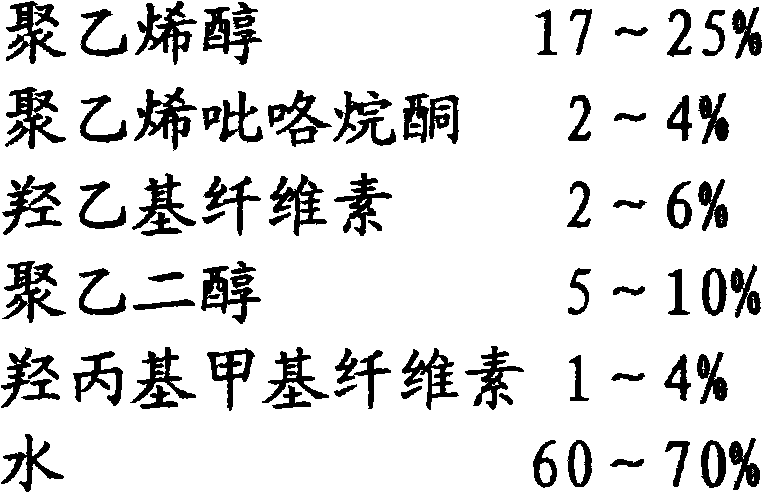

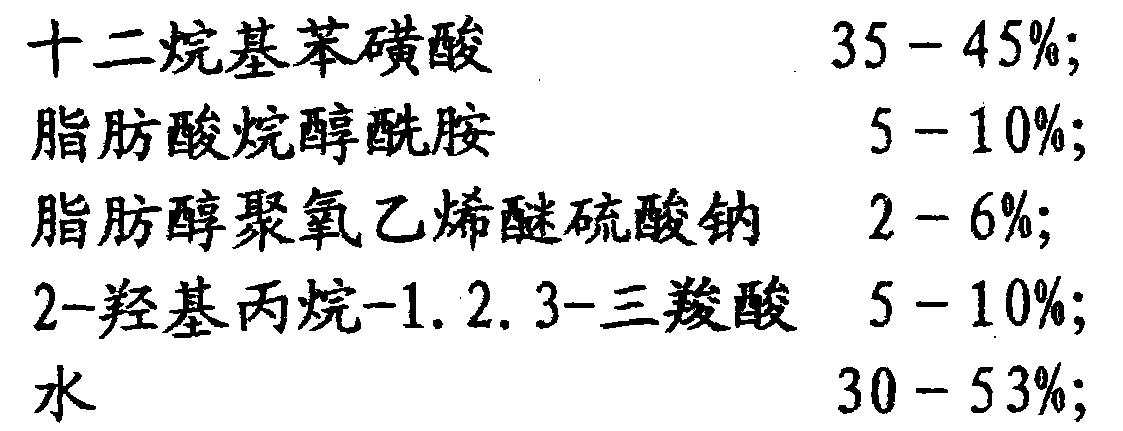

Swelling soil modifier

InactiveCN102079980AUse foreverHigh densityBuilding constructionsOrganic fertilisersRational useSwelling ratio

The invention relates to a material for regulating and improving the soil structure, soil compactness, and soil chemical properties and physical properties of a swelling soil roadbed. The technical scheme is that: a swelling soil stabilizer comprising a main component of dodecylbenzene sulfonic acid and a swelling soil firming agent comprising a main component of polyvinyl alcohol are combined to improve the chemical and physical properties of swelling soil. The swelling soil stabilizer regulates the components and molecular structure of the swelling soil so as to improve the structure, compactness and expansion and shrinkage performance of the swelling soil, and recombine the structure of the swelling soil; the firming agent is used to firm swelling-shrinking soil, reduce the swelling ratio, improve bearing capacity and reduce construction cost so as to reasonably use human, financial and material resources, and the aim that civil engineering including road engineering is durable is fulfilled; and after being rolled, the soil can be compressed to achieve high compactness, reduce an osmotic coefficient and improve soil consolidation capacity, so that the damage of water to the roadbed is reduced and the frost boiling phenomenon of the roadbed is effectively prevented.

Owner:钟维安 +2

Steel slag and slag high-performance composite grout

The invention provides a steel slag and slag high-performance composite grout, which comprises the following raw materials by weight proportion: 0 to 60 portions of steel slag, 0 to 60 portions of granulated blast-furnace slag, 20 to 60 portions of sulphoaluminate cement, 0 to 50 portions of Portland cement, 2 to 8 portions of air entraining agent and excitant, 0.5 to 10 portions of slag activity excitant, 3 to 10 portions of antisettle agent, and 10 to 15 portions of high-performance expanding agent; and the raw materials are evenly mixed. The grout has better durability and wearing resistance, and can save resources and reduce the emission of waste at the same time to achieve the aims of protecting the environment and reducing the cost.

Owner:CHINA JINGYE ENG

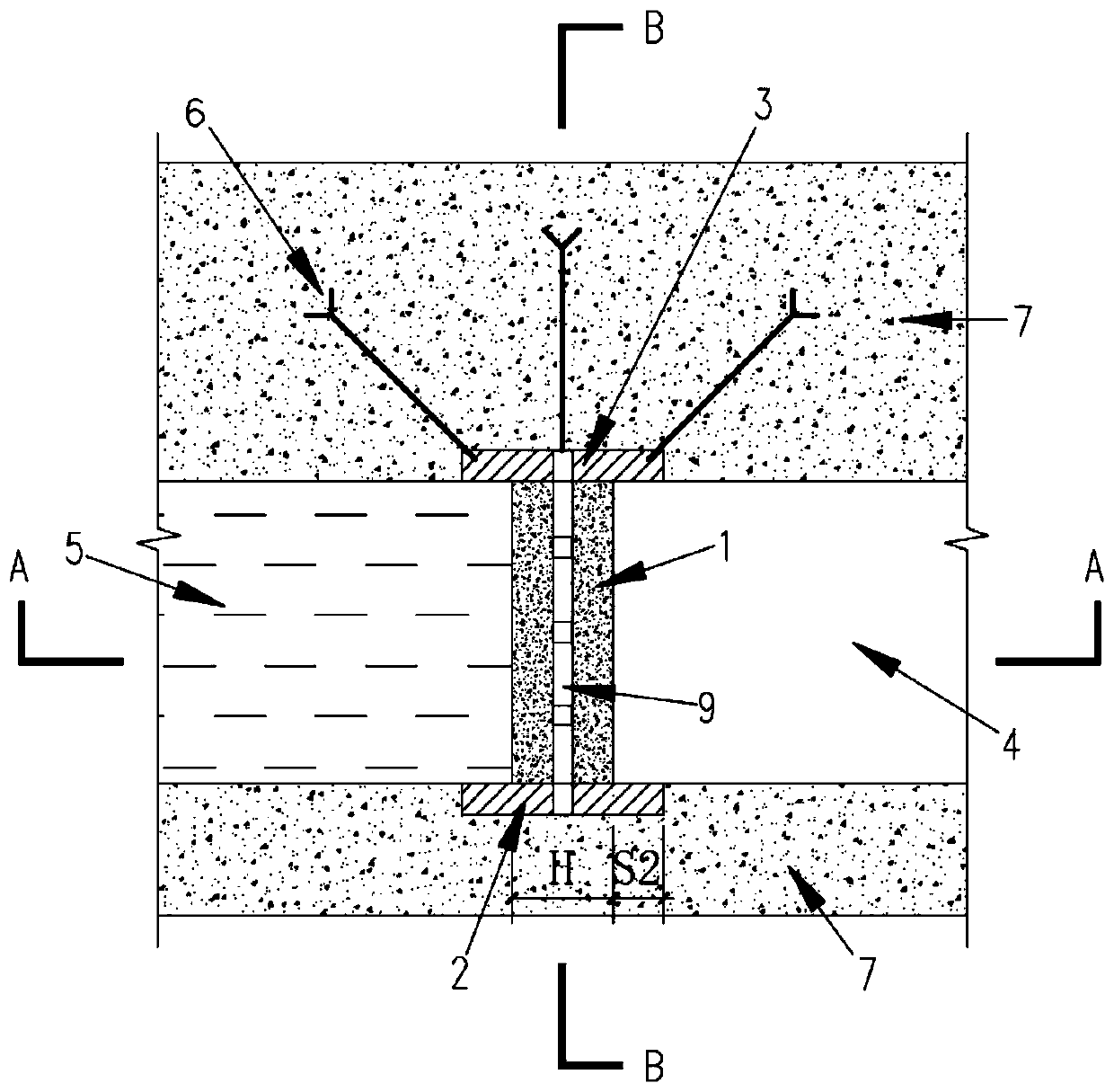

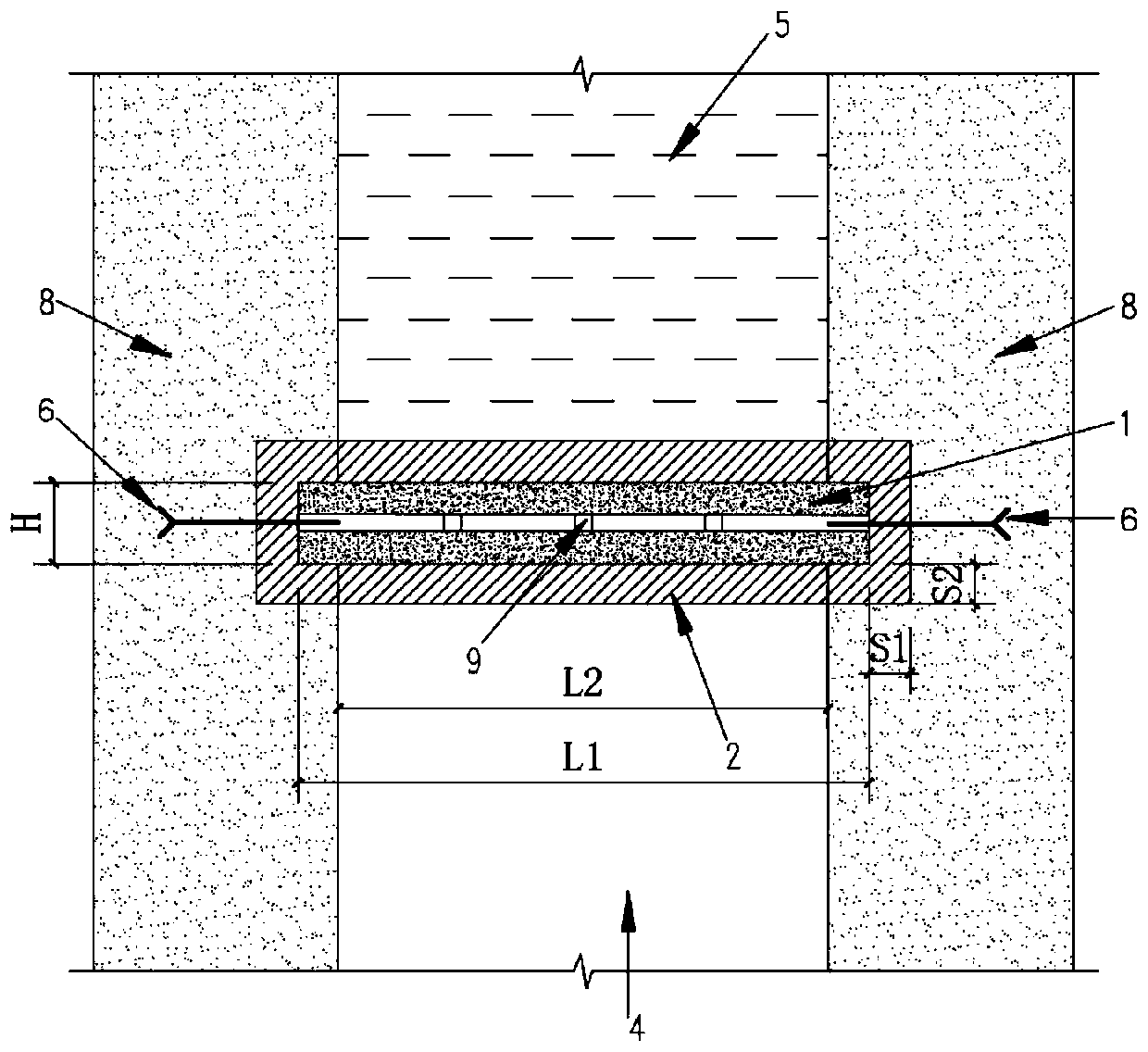

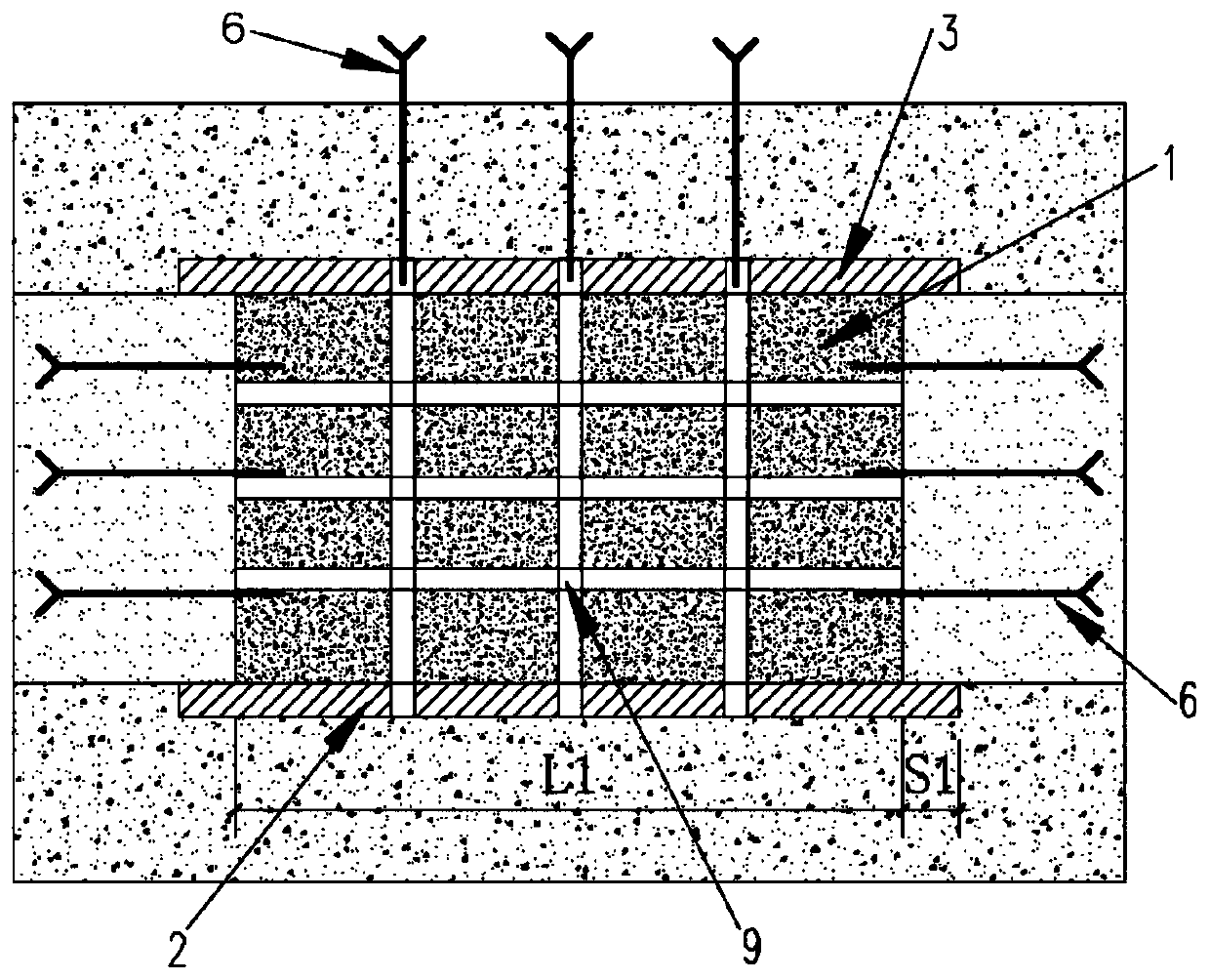

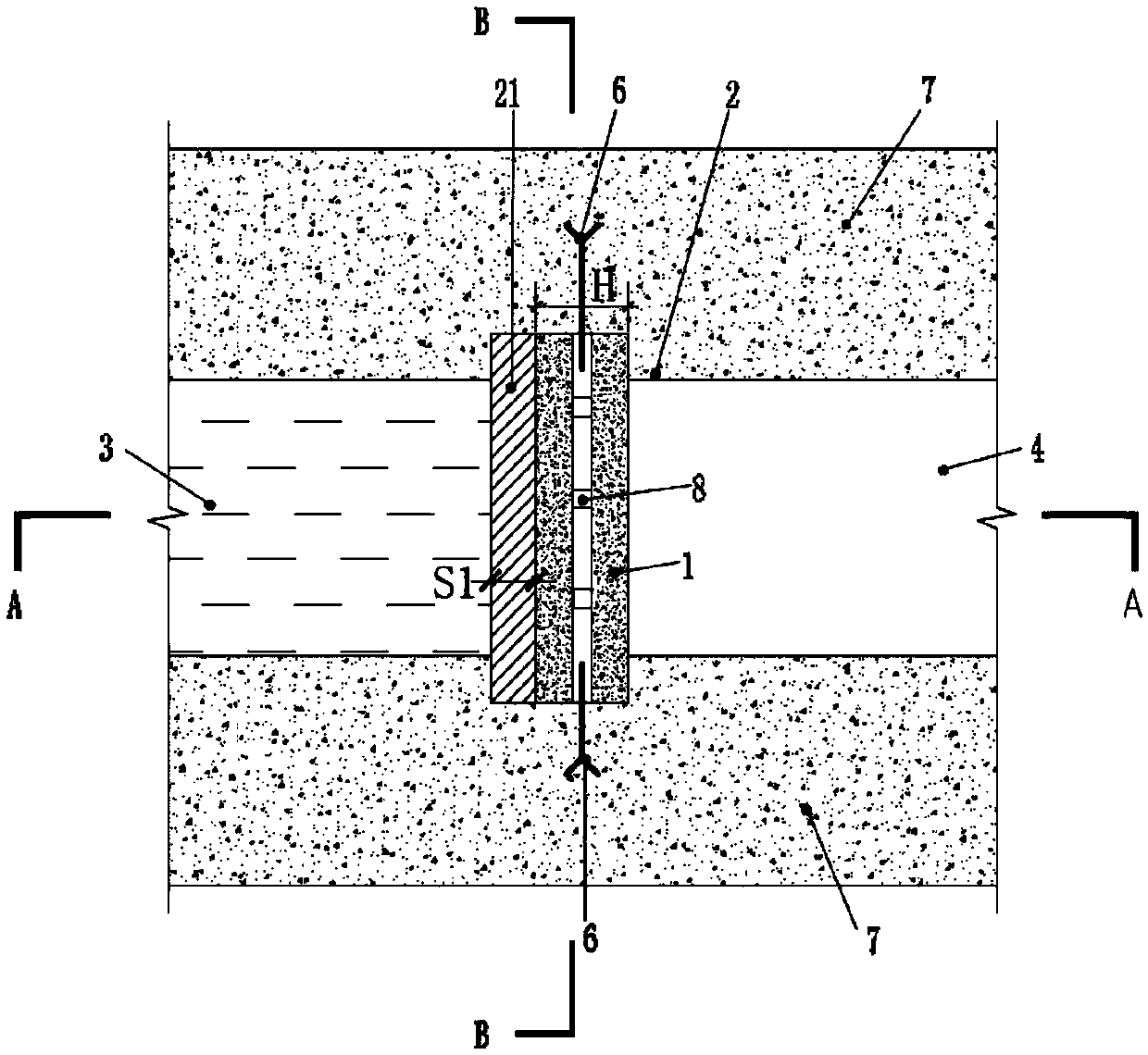

Strong-upper anti-seepage water retaining dam for underground reservoir of coal mine

The invention discloses a strong-upper anti-seepage water retaining dam of an underground reservoir of a coal mine, which is positioned between coal pillar dam bodies to isolate the underground reservoir and a corresponding coal roadway, wherein a dam body comprises a main dam and a strong-upper part, the strong-upper part is formed by extending at least a length of S1 towards the underground reservoir based on the thickness of the main dam, the extended S1 part also forms a first anti-seepage part, the strong-upper part is embedded into the coal pillar dam bodies on both sides, the upper endsof the storing-upper part and main dam are embedded into surrounding rock of the roof of the roadway, and the lower ends of the main dam and the strong-upper part are embedded into the surrounding rock of the floor of the roadway. As the water retaining dam is positioned in the underground coal rock stratum roadway and is subjected to complex surrounding rock stress, the water retaining dam effectively overcomes the phenomena of weak upper parts at two sides of the roadway of a prior water retaining dam and easy water seepage, and also reduces the local pressure of the dam body to the coal pillar dam bodies at two ends of the roadway, the stability of the dam body and the whole body is improved, and the water storage and safety requirements of the underground reservoir of the coal mine are met.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Saline soil curing agent and technical applications thereof

InactiveCN101289850AImprove structural strengthImprove structural stabilityOrganic fertilisersSoil conditioning compositionsAluminateNatural mineral

The invention provides a saline soil curing agent and a method for applying the same in engineering. The mixture ratio of raw materials of the curing agent in portion by weight is: 17-22 portions of silicate, 20-30 portions of aluminate, 18-22 portions of ferrous aluminate, 10-15 portions of sulphate, 8-13 portions of silicon dioxide, 15- 20 portions of sulpho-aluminate, 3-7 portions of chloride and 2-4 portions of oxide. The saline soil curing agent is formed by mixing a plurality of natural mineral materials and inorganic substances. The production process of the curing agent is simple mechanical mixture, and the production cost is low. Powder solids which meet granularity requirements and are very extensive in source are adopted as the raw materials. Products of the invention are off-white powder solids, have the fineness degree over 200 mesh, are scentless and nontoxic, and have the shelf life of 18 months under dry conditions.

Owner:凌贤长 +1

Refuse landfill surface covering material and application thereof

InactiveCN103922649ALow costContains less organic matterSolid waste managementCeramicwareSubstance contentAdhesive

The invention discloses a refuse landfill surface covering material and an application thereof. The refuse landfill surface covering material consists of a gel adhesive, aggregates, a foaming agent, a surfactant and a viscosity regulator. The refuse landfill surface covering material has characteristics of being low in cost, environment-friendly, less in organic substance content, convenient to construct, and the like; and the refuse landfill surface covering material is applied to covering the refuse landfill surface, less in dosage, good in sealing effect, low in cost and capable of being widely popularized and used.

Owner:CENT SOUTH UNIV

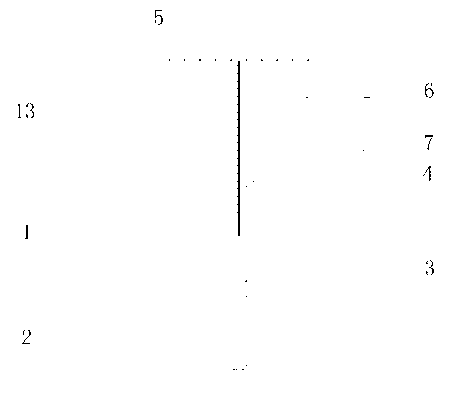

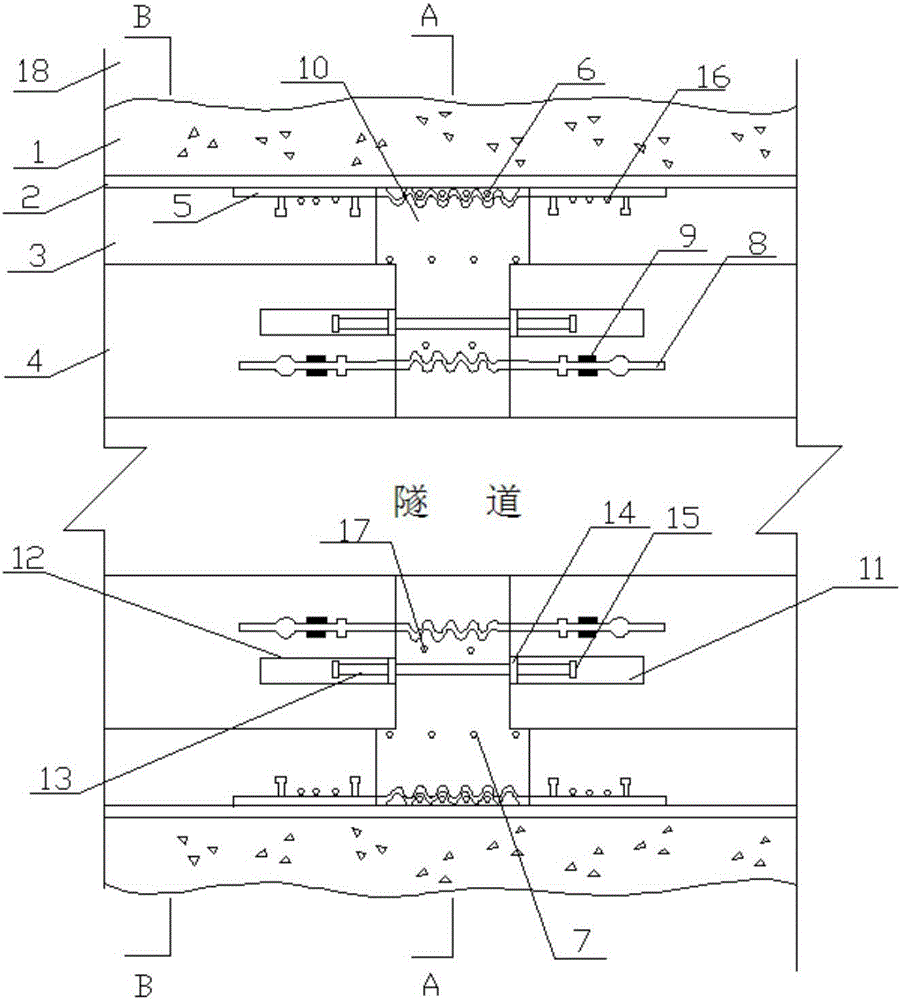

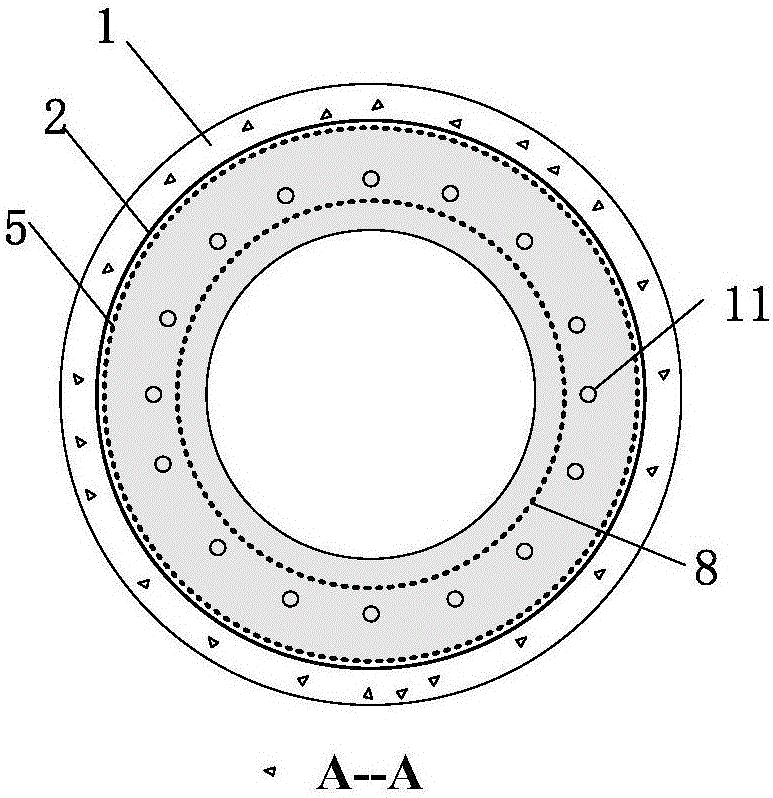

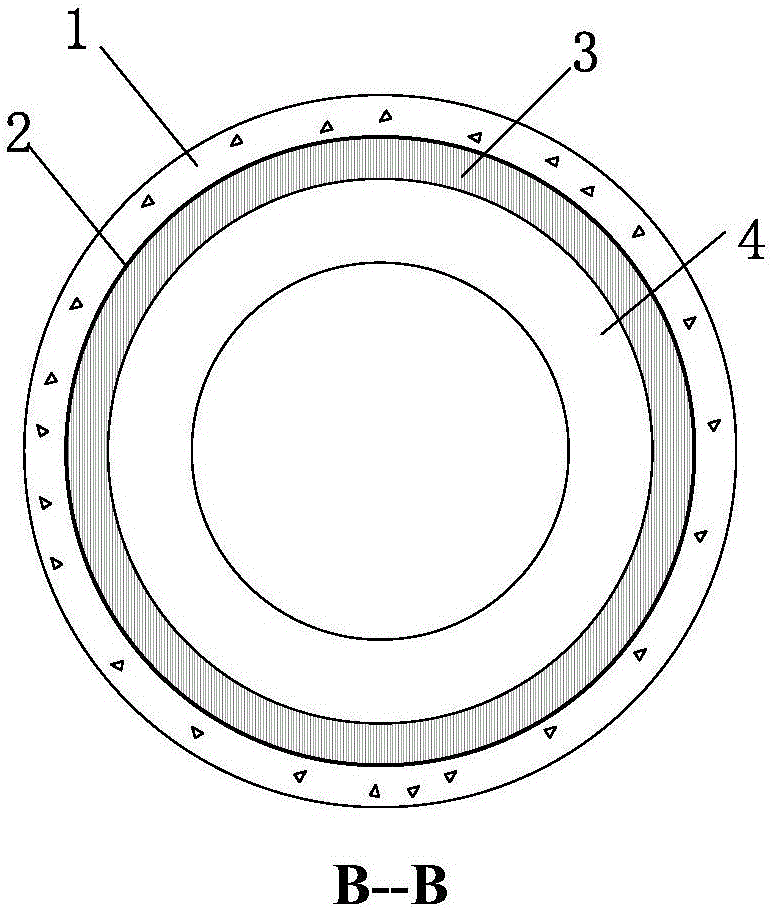

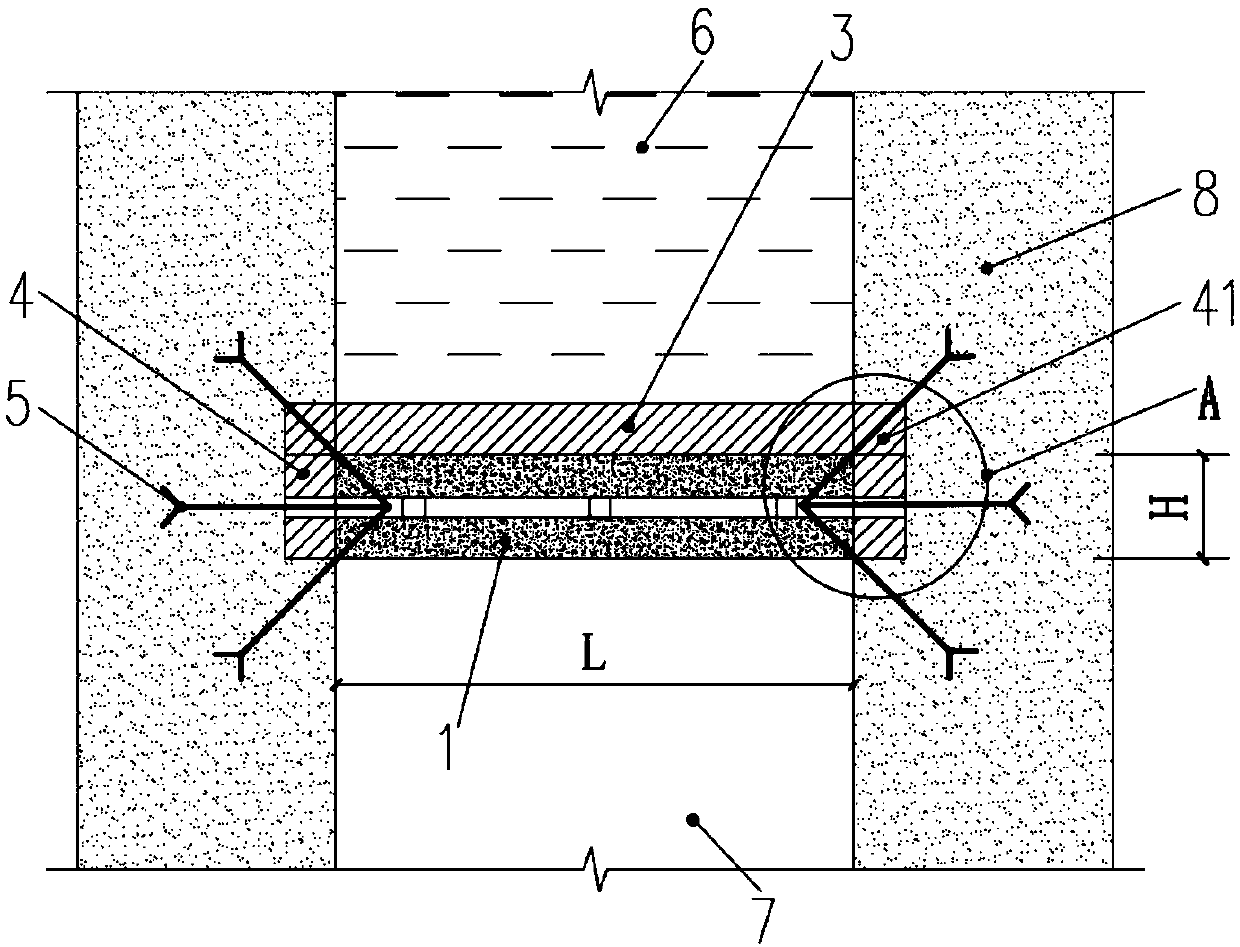

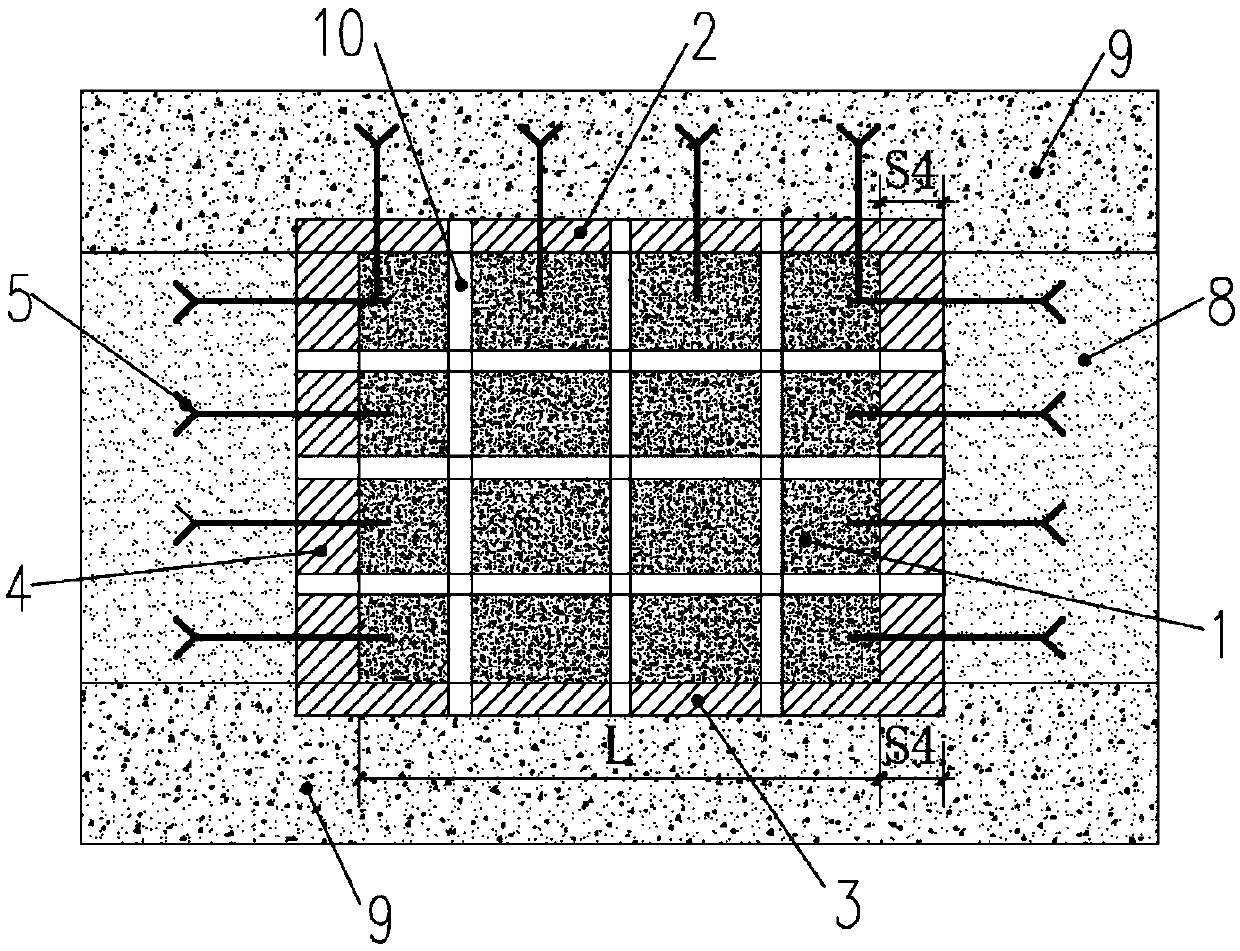

Tunnel lining waterproof joint

ActiveCN106437789AHigh deformation requirementsLow permeability coefficientUnderground chambersTunnel liningFilling materialsPlastic property

The invention relates to a tunnel lining waterproof joint. The tunnel lining waterproof joint comprises a primary lining layer, a waterproof layer, a deformation layer and a secondary lining layer which are sequentially distributed from outside to inside along the section of a tunnel. A flexible joint body is arranged in the annular direction of the tunnel and divides the deformation layer and the secondary lining layer into two adjacent parts in the longitudinal direction of the tunnel. The section of the flexible joint body is in a T shape. The first width of the portion, located in the deformation layer, of the flexible joint body is larger than the second width of the portion, located in the secondary lining layer, of the flexible joint body. The flexible joint body is filled with plastic concrete material. The plastic concrete material is prepared from, by weight, 10-20 parts of cement, 70-80 parts of sand, 20-30 parts of water, 70-90 parts of stone, 2-4 parts of additive, 2-4 parts of bentonite and 6-9 parts of clay. Plastic concrete is adopted as the filling material of a T-shaped deformation joint, the seepage path of seepage water can be prolonged, anti-seepage performance is improved, and the breakage probability of a boundary is reduced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

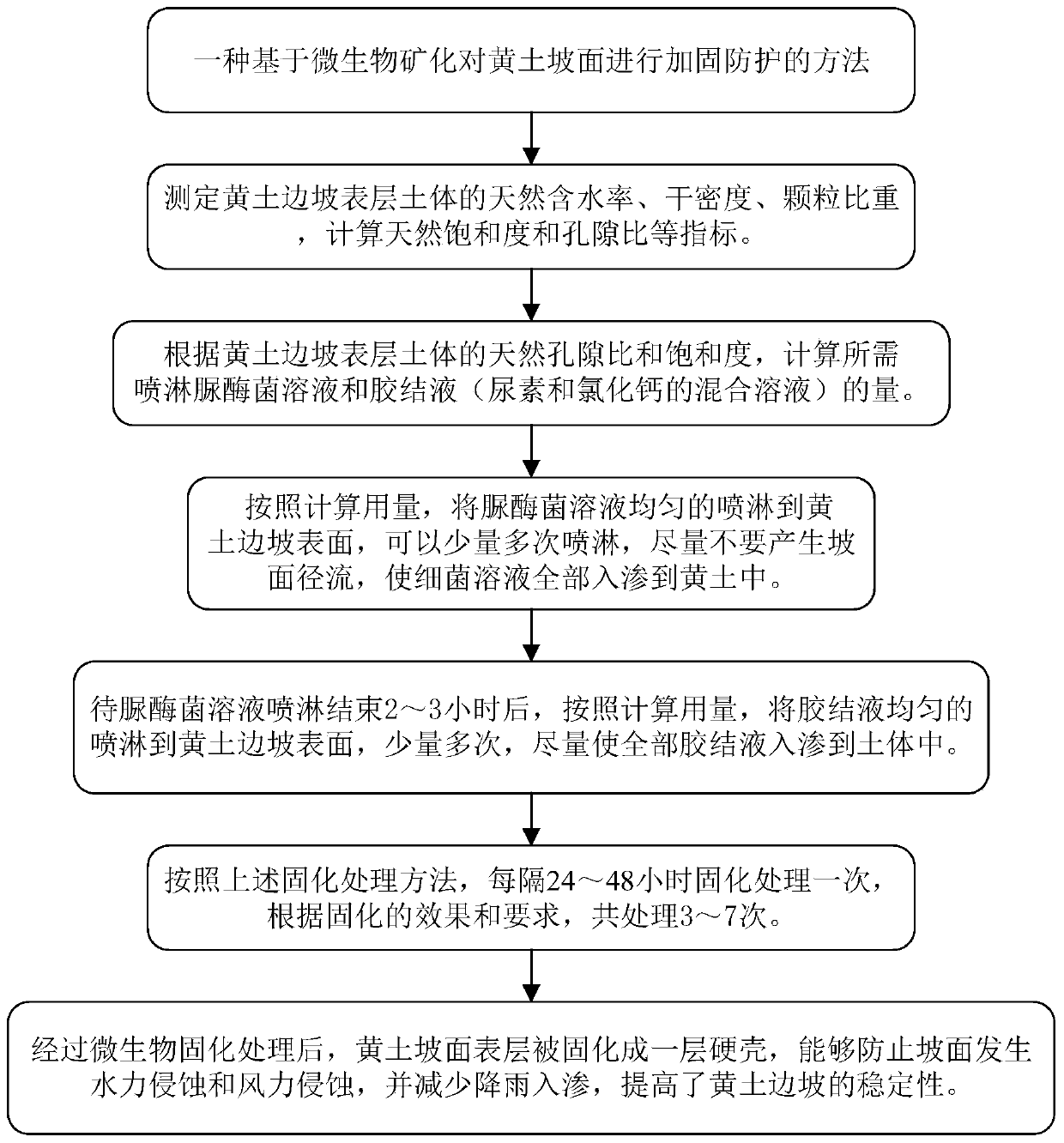

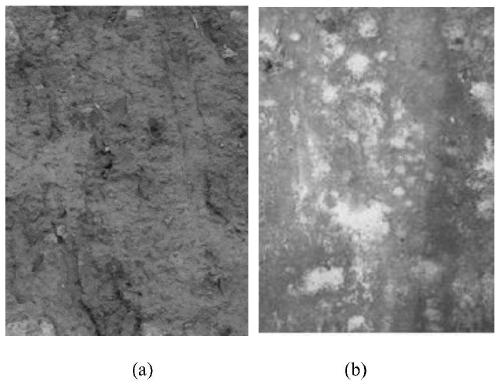

Method of reinforcing and protecting loess slope surface based on microorganism mineralization

InactiveCN111254946AHigh strengthIncreased durabilityExcavationsOrganic fertilisersMicroorganismSoil science

The invention discloses a method of reinforcing and protecting a loess slope surface based on microorganism mineralization. Based on a principle that microorganisms induce a calcium carbonate precipitate, a urease-producing bacterium solution and a cementing fluid are sprayed to the loess slope surface, and urea is hydrolyzed by means of urease secreted by urease bacteria to generate carbonate ions and hydroxyl ions. Thus, in an alkaline environment, the carbonate ions are combined with calcium ions provided by calcium chloride to generate a calcium carbonate precipitate. The precipitate is mostly in a crystal state by taking the urease bacteria as a core. As the urease bacteria are attached to the surfaces of loess particles, calcium carbonate crystals and the loess particles are cementedtogether to cure loess to form a firm soil mass with certain strength and erosion resistance. By curing a soil layer of certain thickness on the surface of the loess slope surface, the shear strengthof the loess slope surface soil mass is improved, rainfall infiltration is reduced, erosion of the slope surface is prevented, the stability of a loess slope is improved, and a role of reinforcing and protecting the slope surface is played. The method is simple to construct, good in durability, environment-friendly and energy-saving and suitable for being popularized and applied.

Owner:NORTHWEST A & F UNIV

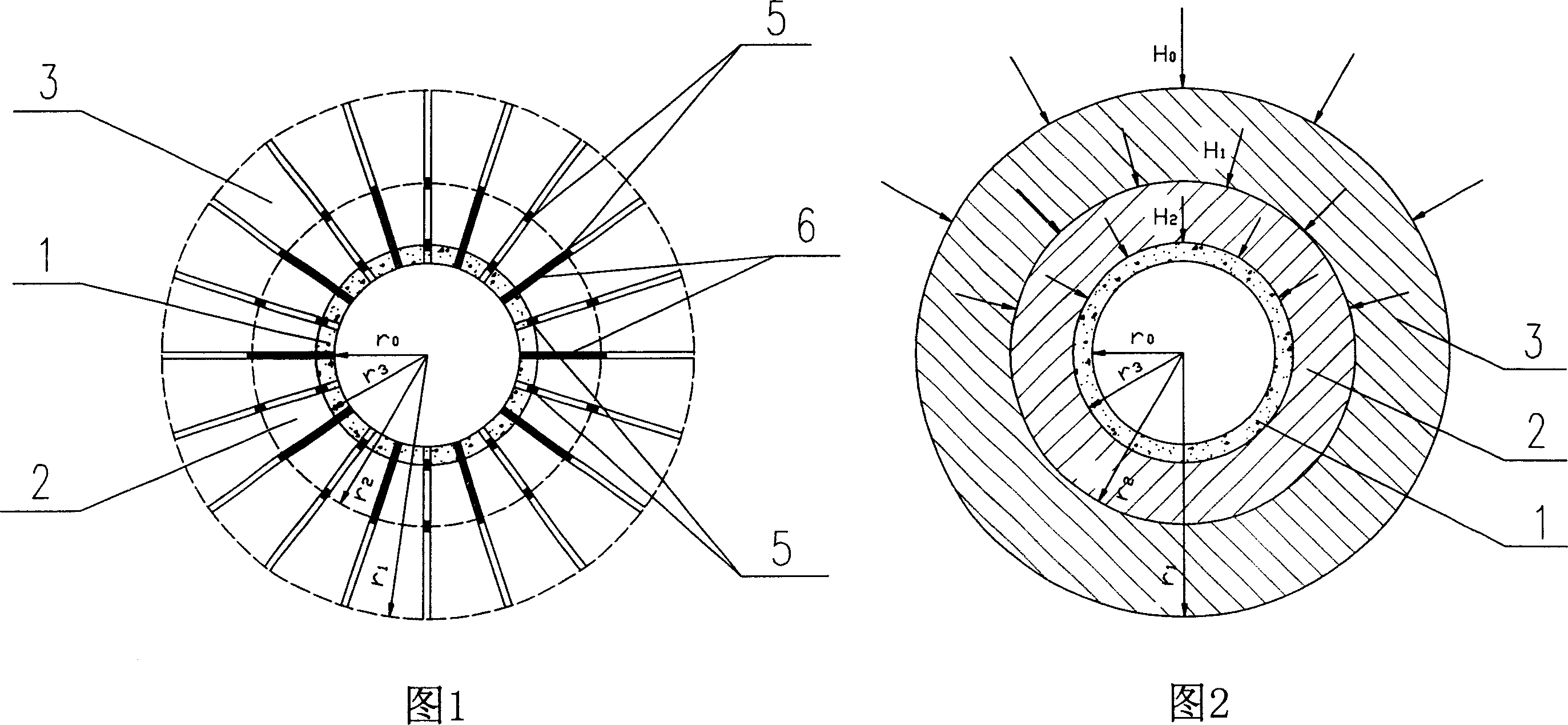

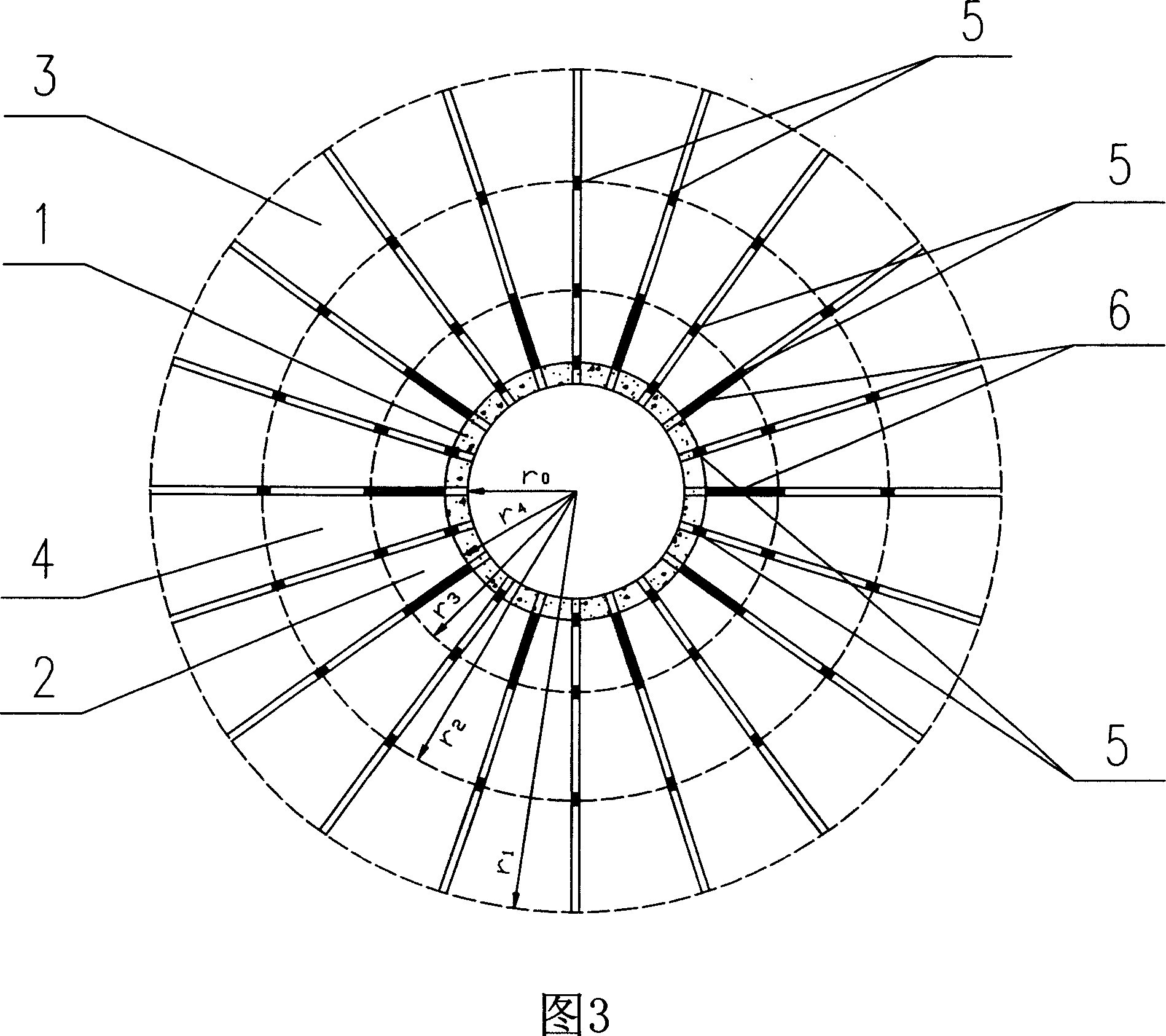

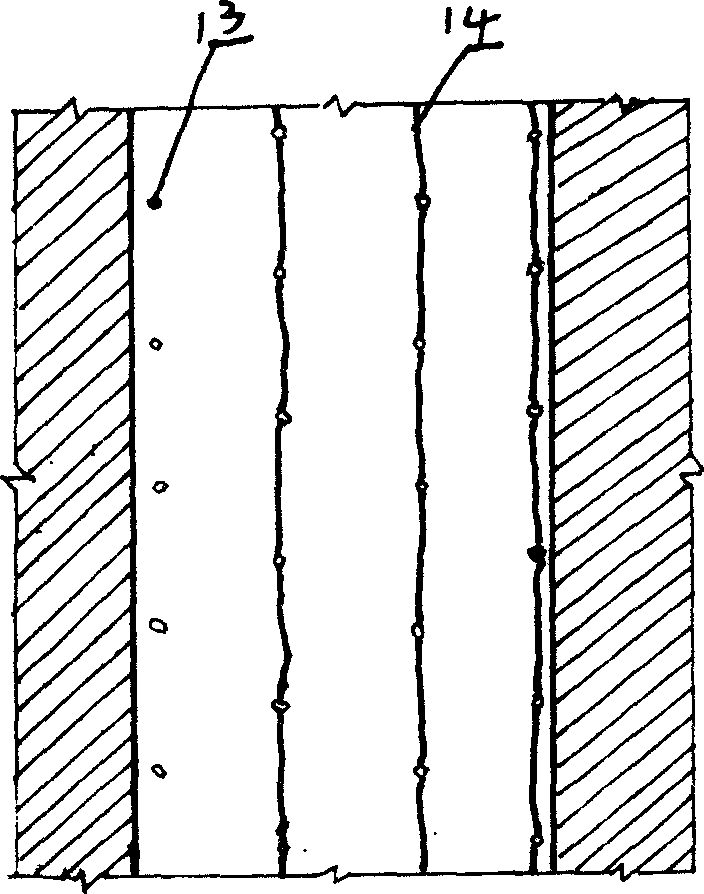

Multilayer enclosing-rock cement-grouting consolidation ring tunnel bearing structure and its construction method

ActiveCN1936270AOsmotic water pressure is smallPenetrating water pressure is highUnderground chambersTunnel liningElectricityStructural engineering

The invention relates to a multilayer wall rock grouting stereosphere tunnel bearing structure and constructing method. It has tunnel and the feature is that two layers or over two layers different consolidation holes density, different grouting pressure, different serum species, and different particle of serum would be coated on the wall rock. The invention could be used in water conservancy water and electricity tunneling under the action of super-high pressure cranny groundwater, and could be also used in traffic tunneling and city water supplying tunneling.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Method for treating depression watertight in hydraulic engineering by employing yellow mud grout

The invention relates to a method for treating depression watertight in hydraulic engineering by employing yellow mud grout, which comprises disposing grouting borehole, pore-creating, formulating yellow mud grout, arranging grouting equipment and grouting. The yellow mud grouting treatment can produce a layer of hard yellow mud between the starching and laying rock block bottom board and the ground foundation.

Owner:葛扬安

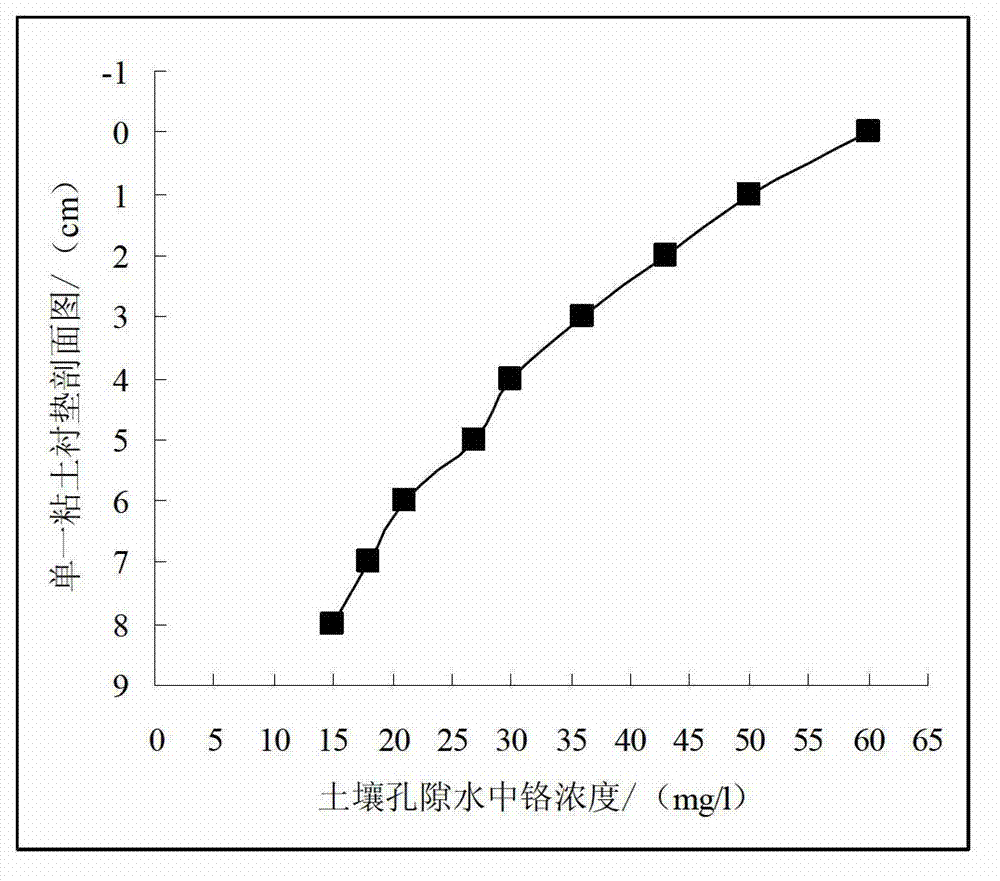

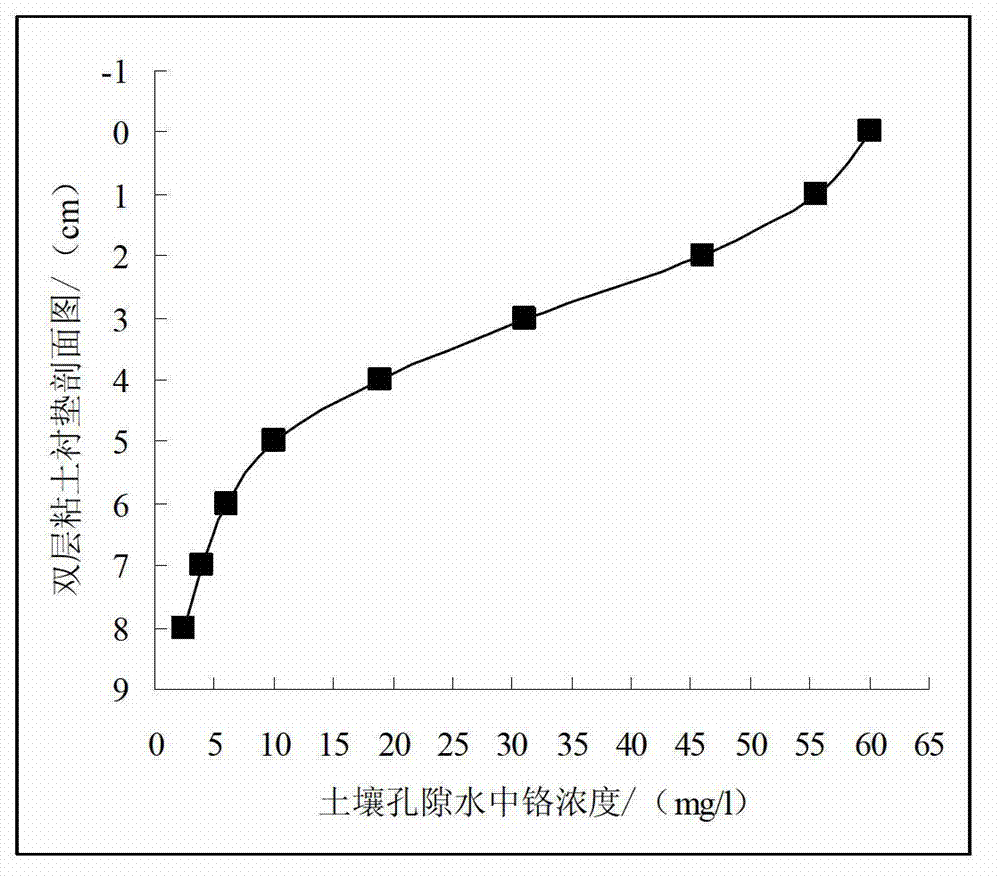

Double-layer clay liner for preventing seepage and resisting compression at bottom of refuse landfill

InactiveCN102966123AReduce seepage velocityReduce diffuseProtective foundationNatural mineral layered productsActivated carbonSoil science

The invention discloses a double-layer clay liner for preventing seepage and resisting compression at the bottom of a refuse landfill. The double-layer clay liner comprises an upper clay liner and a lower clay liner which are arranged in sequence from top to bottom, wherein the upper clay liner is obtained by adding a proper amount of water to clays and limes, uniformly mixing and stirring an obtained mixture and compacting the mixture; and the lower clay liner is obtained by adding a proper amount of water to clays and active carbons, uniformly mixing and stirring an obtained mixture and compacting the mixture. The double-layer clay liner for preventing seepage and resisting compression at the bottom of the refuse landfill, disclosed by the invention, has the advantages as follows: higher compressive strength is obtained; the sedimentation of the refuse landfill is reduced; meanwhile, the double-layer clay liner obtains very strong adsorbing capacity to pollutants in a penetrating fluid of the refuse landfill; the seepage speed of the refuse leachate is reduced; the diffusion effects of the pollutants in the clay transferring process are reduced; and the underground water is more effectively protected.

Owner:HOHAI UNIV

Normal temperature consolidation materials for construction

The provided new building material consolidated at normal temperature is prepared mainly by castoff of building and mine or power plant, controllable on consolidation time and strength, has well physical performance with permeability coefficient less than 5e-7cm / s and compression strength up to 7MPa or 22Mpa as building block, reduces unit cost more than 45%.

Owner:杜绍安 +1

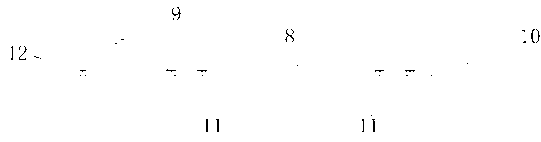

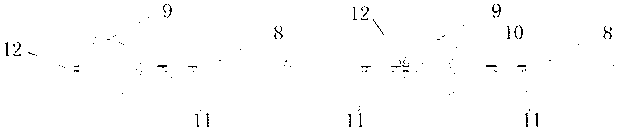

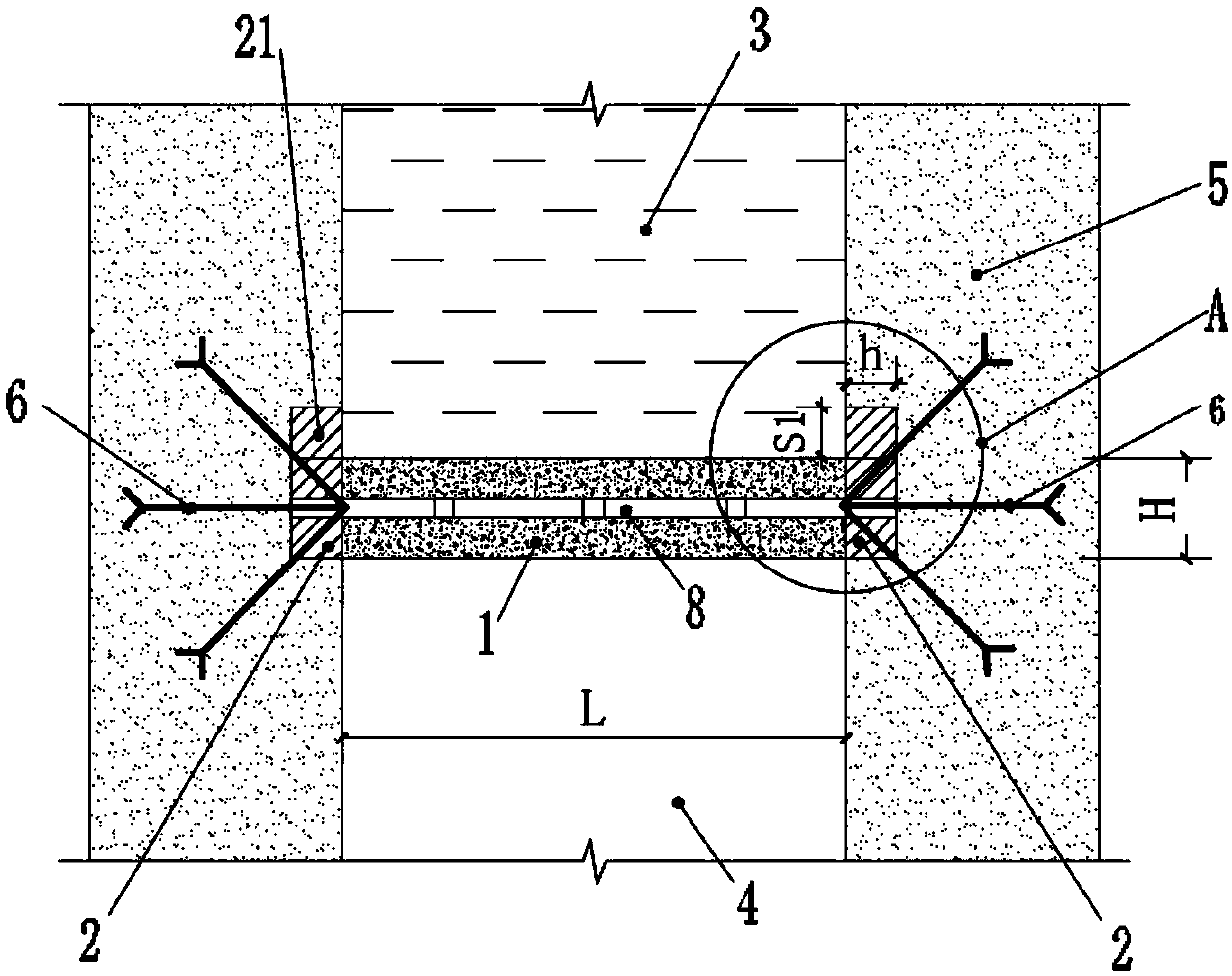

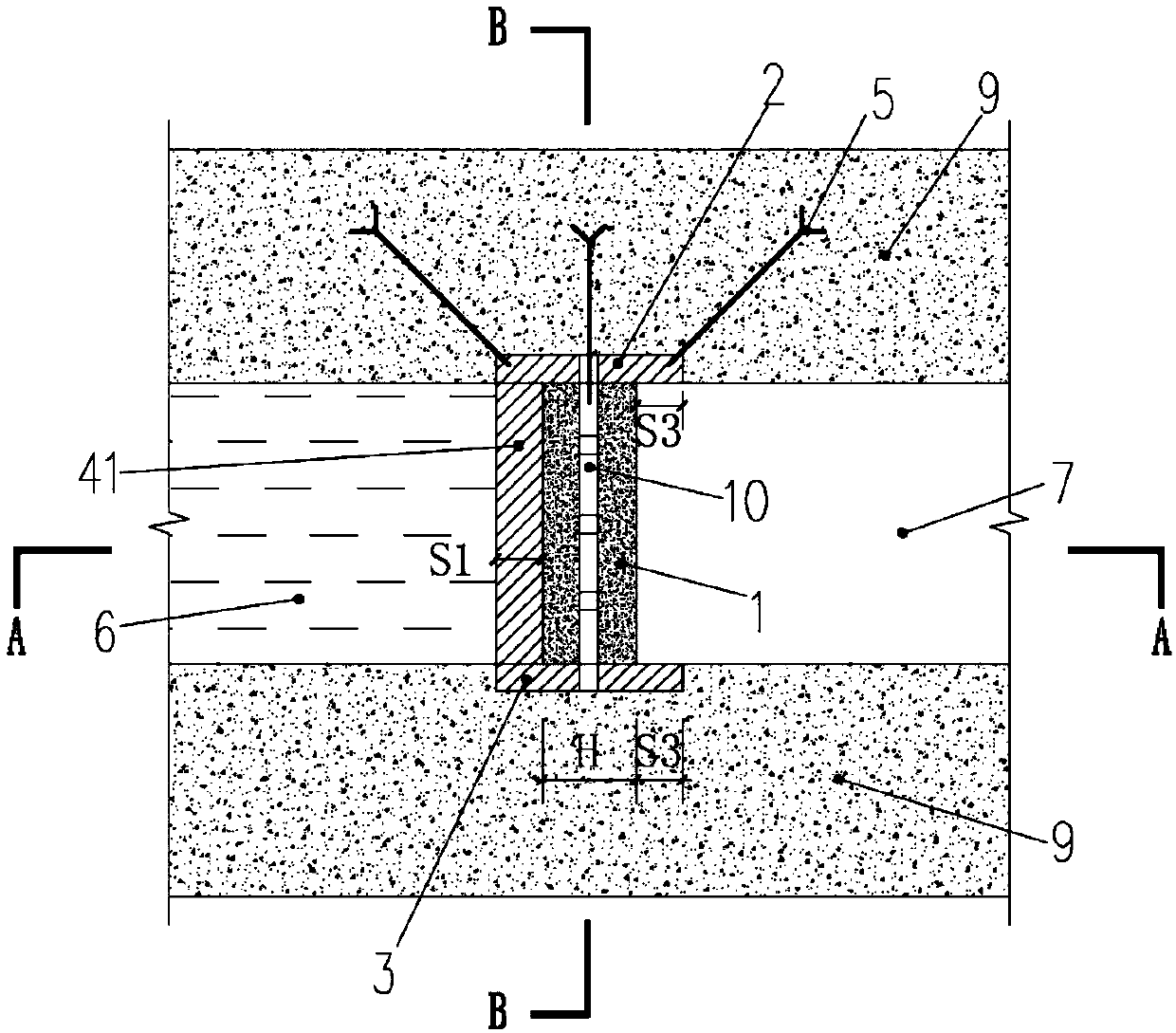

I-type rib-reinforcing and seepage-preventing water retaining dam for coal mine underground reservoir

The invention discloses an I-type rib-reinforcing and seepage-preventing water retaining dam for a coal mine underground reservoir. The I-type rib-reinforcing and seepage-preventing water retaining dam is located between coal pillar dam bodies on left and right sides of a roadway and used for isolating the underground reservoir from the roadway and blocking a water source in the underground reservoir. A dam body of the I-type rib-reinforcing and seepage-preventing water retaining dam comprises an upper wing plate, a web and a lower wing plate from top to bottom sequentially, wherein the vertical section, perpendicular to the dam surface, of the dam body is I-type; the dam body of the I-type rib-reinforcing and seepage-preventing water retaining dam further comprises reinforced rib parts located on left and right sides of the web, and each reinforced rib part comprises a first seepage preventing part which is formed by extending to one side of the underground reservoir by at least S1 length on the basis of the thickness of the web. The water retaining dam is located in an underground coal seam roadway and receives complicated surrounding rock stress, so that through the adoption ofthe water retaining dam, local instability and failure and water seepage due to overhigh local stress of the coal pillar dam bodies can be reduced, the defect that two rib parts of the roadway of thetraditional water retaining dam are weak and prone to water seepage is overcome effectively, and the requirement for water storage and safety of the coal mine underground reservoir are met.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Water power engineering asphalt and preparation method thereof

The present invention discloses one kind of hydrotechnic asphalt and its preparation process. The hydrotechnic asphalt consists of asphalt 95-97 weight portions, SBS modifier 1-5 weight portions and SBR modifier 1-4 weight portions; and may have sulfur in at most 2 weight portions added for further raised hydrotechnic performance. It has high antiseepage performance, osmotic coefficient lower than 10-7 cm / s or similar to that of steel plate, low cost, high plasticity and elasticity, capacity of suiting the inhomogeneous settlement of dam body, convenient construction and other advantages.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Impermeable material based on flue gas desulfurization byproduct and usage in garbage landfill thereof

InactiveCN101157528AOvercoming the problem of stacking land occupationEnhanced advantageSolid waste managementSodium BentoniteMetallurgy

The invention discloses an impermeable material based on flue gas desulphurization by-product and the usage in trash burying. The impermeable material is compounded evenly according the weight by 60-90 percent of circulating fluidized bed flue gas desulphurization dreg and 10-40 percent of chemical additive under the dried powder ugh condition. The chemical additive is the one kind or two kinds of combination of bentonite and kleit at random proportion, and the impermeable material can be applied to be used as an anti-seepage layer in trash burying, wherein, the anti-seepage layer used as the underlay of the trash burying field has a thickness of 80cm to 120cm; the anti-seepage layer used as the intermediate coating has a thickness of 15cm to 30cm; and the anti-seepage layer used as the full closure field has a thickness of 60cm to 100cm. The impermeable material can not only prevent from polluting the underground water of the trash burying field, reduce the treatment of trash infiltrated liquid and ensure that the trash buried gases are collected orderly, but also make full use of the huge desulphurization dreg and change waste into resources, thereby realizing the win-win benefit.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com