Refuse landfill surface covering material and application thereof

A technology for landfill and surface covering, which is used in the field of surface covering materials for landfills and environmental protection, can solve the problems of low material utilization rate and easy combustion, and achieve the effects of long service life, low cost and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

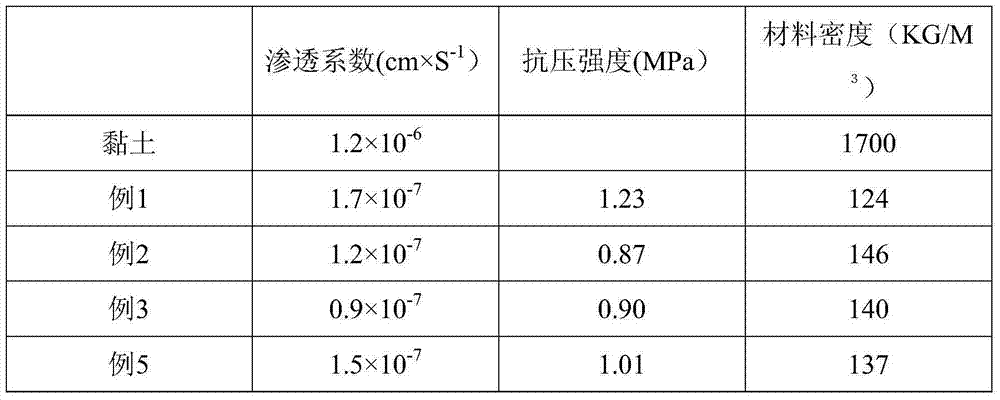

Examples

Embodiment 1

[0022] formula:

[0023] 1) Gel adhesive, gypsum 18 kg;

[0024] 2) Aggregate, fly ash 35 kg;

[0025] 3) Foaming agent, protein foaming agent (commercially available, produced by Tianjin Xiongguan Technology Development Co., Ltd.) 5 kg;

[0026] 4) Surfactant, sodium dodecyl sulfate (SDS) 2 kg;

[0027] 5) Water, 40 kg;

[0028] Pour the raw materials of this formula into a blender, stir for 60 minutes to mix evenly, then pour into a foaming machine (commercially available) for foaming; the foamed material is sprayed on the surface of the garbage dump with a jet machine, and it will lose water and solidify after 24 hours Form a protective layer of about 6cm on the surface of the garbage.

Embodiment 2

[0030] formula:

[0031] 1) Gel adhesive, cement (sulfoaluminate cement) 18 kg;

[0032] 2) Aggregate, vitrified beads 35 kg;

[0033] 3) Foaming agent, protein foaming agent (commercially available, produced by Tianjin Xiongguan Technology Development Co., Ltd.) 5 kg;

[0034] 4) Surfactant, sodium dodecylbenzene sulfate (K12) 2 kg;

[0035] 5) Water, 40 kg;

[0036] Pour the raw materials of this formula into a blender, stir for 60 minutes and mix evenly, then pour into a foaming machine (commercially available) for foaming. The foamed material is sprayed onto the surface of the garbage dump with a jet machine. After 24 hours, it will lose water and solidify to form a protective layer of about 6cm on the surface of the garbage.

Embodiment 3

[0038] 1) Gel adhesive, cement (sulfoaluminate cement) 18 kg;

[0039] 2) Aggregate, fly ash 35 kg;

[0040] 3) Foaming agent, hydrogen peroxide 5 kg;

[0041] 4) Surfactant, sodium dodecylbenzene sulfate (K12) 2 kg;

[0042] 5) Water, 40 kg;

[0043] Pour the raw materials of this formula into a blender, stir for 60 minutes and mix evenly, then pour into a foaming machine (commercially available) for foaming. The foamed material is sprayed onto the surface of the garbage dump with a jet machine. After 24 hours, it will lose water and solidify to form a protective layer of about 5cm on the surface of the garbage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com