Vertical anti-seepage barrier and construction method thereof

A barrier and construction technology, applied in construction, protection devices, infrastructure engineering, etc., can solve the problems of low elastic modulus, poor chemical corrosion resistance, and impervious performance that is difficult to meet environmental protection requirements, etc., to achieve low permeability coefficient, The effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

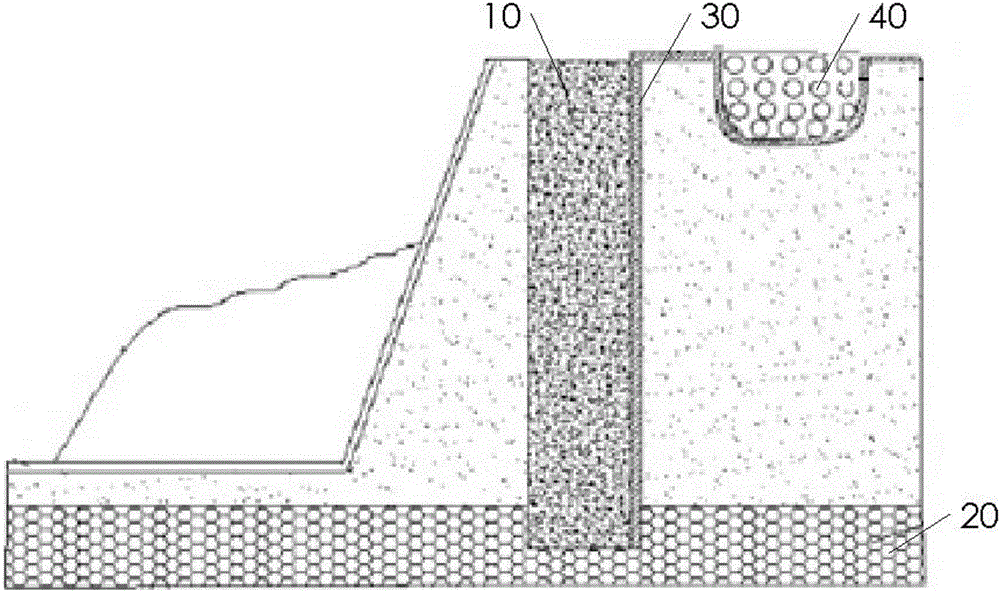

[0045] like figure 1 As shown, a kind of construction method of vertical anti-seepage barrier that one embodiment of the present invention proposes, it comprises:

[0046] Excavating a trench 10, the bottom of which extends into the impermeable layer 20 of the ground;

[0047] The location of the trench can be located on one side, both sides of the landfill or around the ring trench, or the location of the trench can be located on one or both sides of the river or channel; the width of the trench is determined according to the specific anti-seepage requirements , such as 60cm; the bottom of the groove can extend into the impermeable layer for a predetermined distance, specifically 20-100cm;

[0048] A composite geomembrane 30 is laid on at least one side wall of the trench, and on the composite geomembrane 30, there is a non-woven fabric on the side facing the inside of the trench 10;

[0049]Among them, the composite geomembrane contains at least 2 layers, one layer is non-...

Embodiment 2

[0074] The vertical anti-seepage barrier provided by the second embodiment of the present invention can be constructed by the construction method of the vertical anti-seepage barrier described in the first embodiment above, and the construction method of the vertical anti-seepage barrier can adopt the first embodiment The method in, do not go into details here, described vertical anti-seepage barrier comprises:

[0075] vertical cutoff walls formed in trenches;

[0076] A composite geomembrane, the composite geomembrane is located between at least one side wall of the groove and the vertical cut-off wall, and a non-woven fabric is provided on the side of the composite geomembrane facing the inside of the groove cloth, and the non-woven fabric on the composite geomembrane facing the inside of the trench is combined with the vertical cut-off wall.

[0077] Specifically, there is a non-woven fabric on the side of the composite geomembrane facing away from the inside of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com