CPE heat-sealing composite film and preparation method thereof

A technology of composite film and heat-sealing layer, which is applied in the field of plastic film packaging, can solve the problems of high bag breaking rate and inability to realize heat-sealing, and achieve the effects of high heat-sealing strength, enhanced retort resistance, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

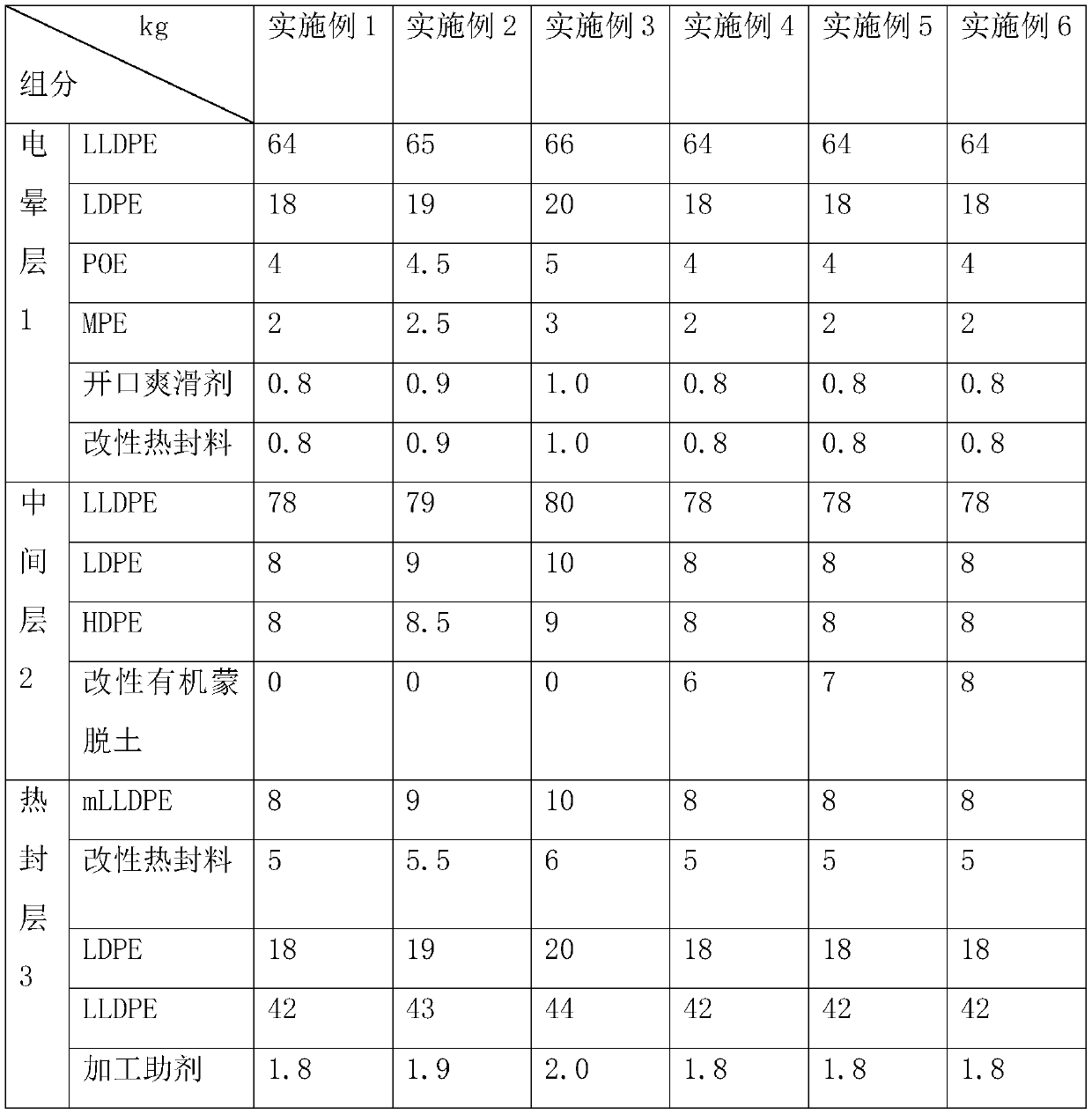

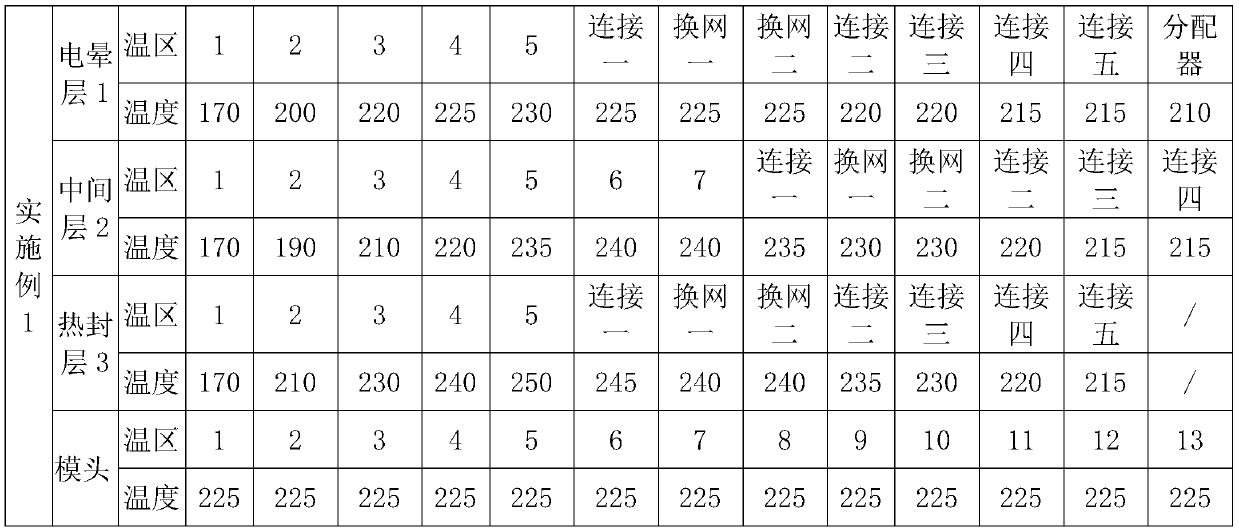

Examples

preparation example 1-3

[0053] In the preparation example 1-3, the nano-silica is selected from the nano-silica of the model A200 sold by Shandong Youso Chemical Science and Technology Strength Co., Ltd., and KH560 is selected from the KH560 with the product number of 0795 sold by Dongguan Kangjin New Material Technology Co., Ltd., EVA Selected from Mitsui Chemicals 7A60H, ULDPE selected from Dow DuPont 4701.

preparation example 1

[0054] Preparation Example 1: (1) Mix nano-silica and KH560, add it to ethanol pentahydrate, and stir at 90°C for 30 minutes, take it out, filter it with suction, and vacuum-dry it at 140°C for 2 hours. The mass ratio is 1:0.2;

[0055] (2) Mix EVA, POP and ULDPE, add silicone powder and nano-silica, stir evenly at a speed of 600r / min, extrude and granulate at 220°C to obtain a modified heat-sealing compound, silicone powder The mass ratio to EVA is 1:0.9, the mass ratio of EVA, ULDPE and POP is 1:0.9:0.6, POP is Dow 1900, the melt index is 500g / 10min, and the mass percentage of vinyl acetate in EVA is 19% , the melt index is 400g / 10min, the melt index of ULDPE is 1g / 10min, and the density is 0.913g / cm 3 .

preparation example 2

[0056] Preparation Example 2: (1) Mix nano white carbon black and KH560, add it to ethanol pentahydrate, and stir at 95°C for 25 minutes, take it out, filter it with suction, and dry it in vacuum at 145°C for 1.8h. Nano white carbon black and KH560 The mass ratio is 1:0.25;

[0057] (2) Mix EVA, POP and ULDPE, add silicone powder and nano-silica, stir evenly at a speed of 700r / min, extrude and granulate at 225°C to obtain a modified heat-sealing compound, silicone powder The mass ratio of EVA to EVA is 1:1, the mass ratio of EVA, ULDPE and POP is 1:1:0.65, POP is Dow 1950, the melt index is 800g / 10min, and the mass percentage of vinyl acetate in EVA is 19% , the melt index is 400g / 10min, the melt index of ULDPE is 1g / 10min, and the density is 0.913g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com