Patents

Literature

362results about How to "Good heat sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-polylactic acid-content film and preparation method thereof

The invention relates to a high-polylactic acid-content film and a preparation method thereof, belonging to the technical field of high-polymer materials. The high-polylactic acid-content film is prepared from the following raw materials in parts by weight: 50-65 parts of polylactic acid, 35-50 parts of toughener, 1-10 parts of plasticizer, 0.1-2 parts of chain extender, 0.1-4 parts of antioxidant and 0.5-5 parts of anti-block agent. The polylactic acid content is dominant in the film content and is higher than that in the existing film; and meanwhile, the raw material formula cost is lowered, and the market competitiveness is enhanced. The prepared film is completely biodegradable, and thus, is beneficial to environment protection.

Owner:JILIN COFCO BIOCHEM +2

Heat-Sealing Material for Aluminum Foils and Polyethylene Terephthalate Foils Against Polypropyl, Polyvinyl Chloride, and Polystyrol Containers

ActiveUS20080292893A1Good heat sealingShort cycleSynthetic resin layered productsCoatingsPolyesterMethacrylate

The invention relates to a heat-sealable coating system suitable for the sealing of various types of substrate and comprising a film-forming dispersion,characterized in thata polymer type A is present and is a polyester or a polyester mixture,a polymer type B is present and is a (meth)acrylate homo- or / and copolymer, containing standard methacrylates and / or standard acrylates, anda polymer type AB is present and is a graft copolymer composed of polymer type A and polymer type B, andif appropriate a polymer type C is present and is an olefin polymer or is an olefin copolymer, and a polymer type CB is present and is a graft polymer composed of polymer type C and polymer type B, and alsoif appropriate a polymer type D and / or a polymer type DA is present.

Owner:EVONIK OPERATIONS GMBH

Capacitor thin film containing modified nano-titanium dioxide and preparation method thereof

InactiveCN103102582AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneCross-link

The invention discloses a capacitor thin film containing modified nano-titanium dioxide and a preparation method thereof. The capacitor thin film comprises the following raw materials in parts by weight: 57-65 of metallocene polypropylene resin, 25-30 of LLDPE (Linear low density polyethylene) resin, 10-15 of low-density polyethylene, 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 0.5-1.5 of poly-4-methyl-1-amylene, 7-9 of modified nano-titanium dioxide, 1.5-2.5 of cross-linking agent TAC, 0.2-0.4 of expoxy butyl oleate, 0.8-1.2 of epoxidation triglyceride, 3-5 of calcium stearate and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

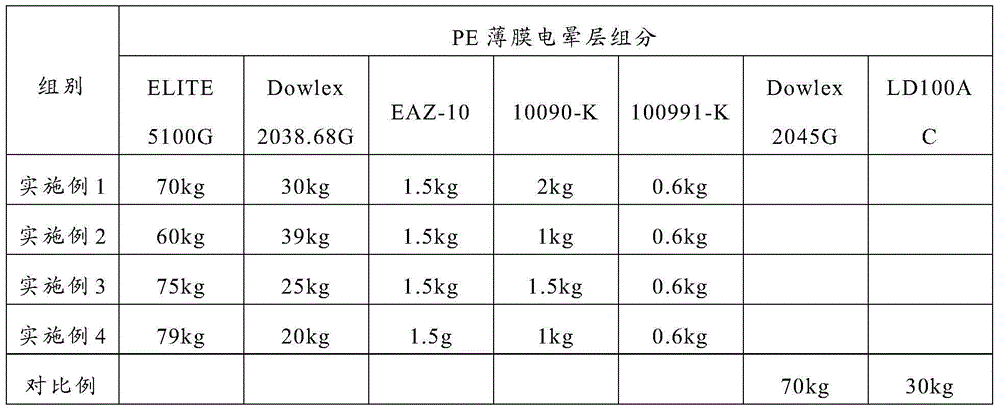

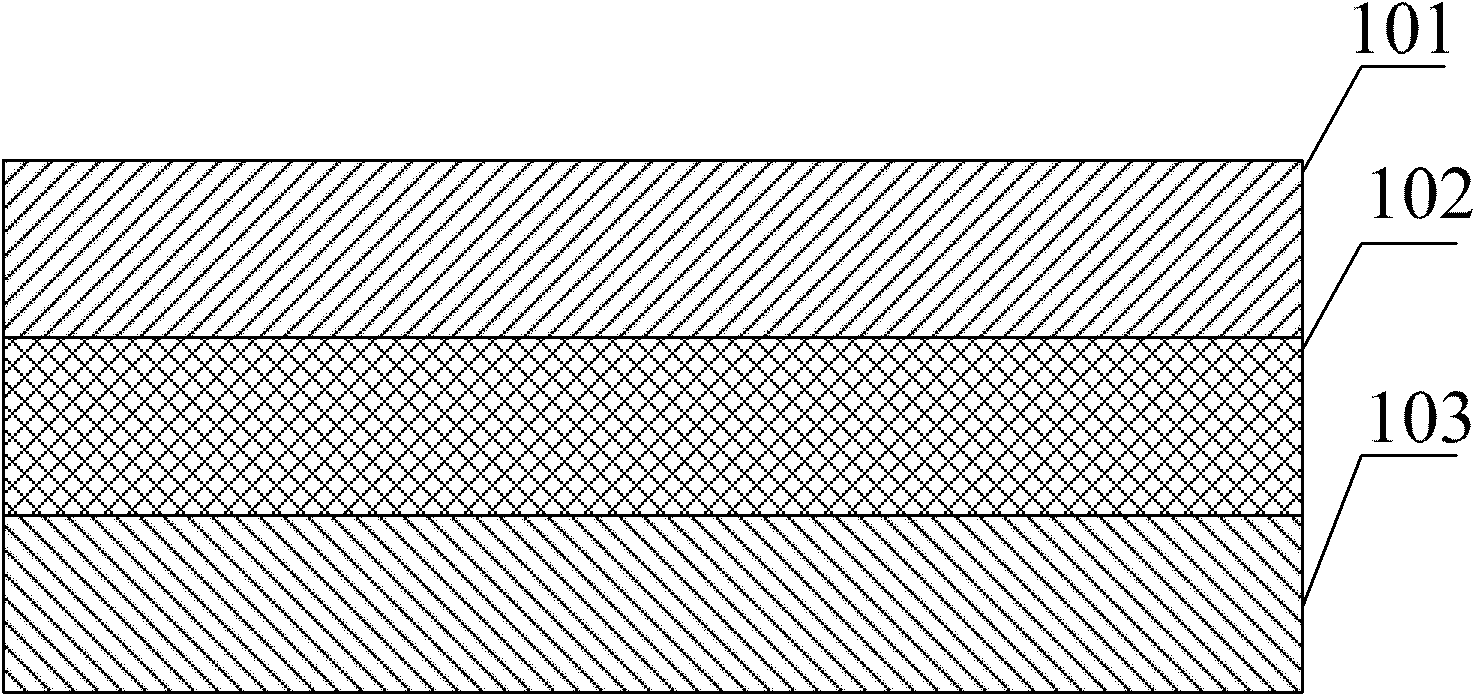

Novel PE film

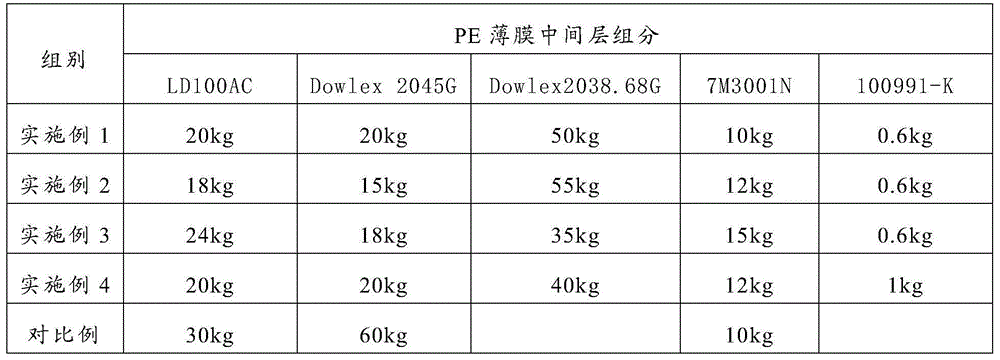

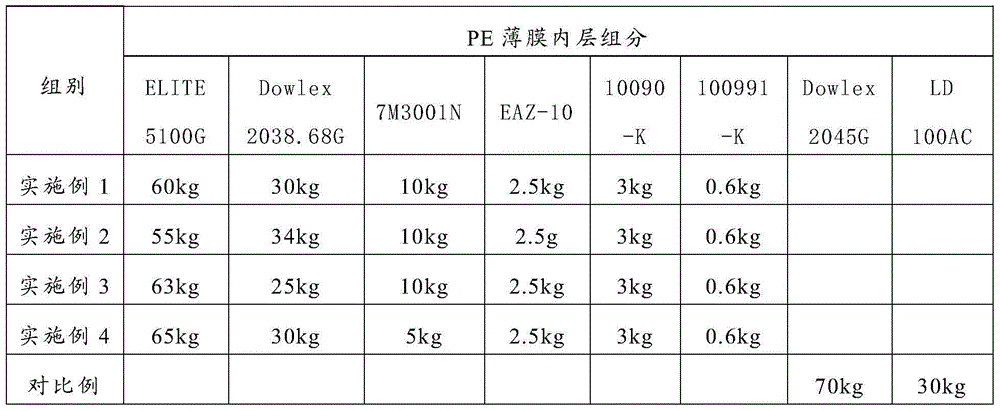

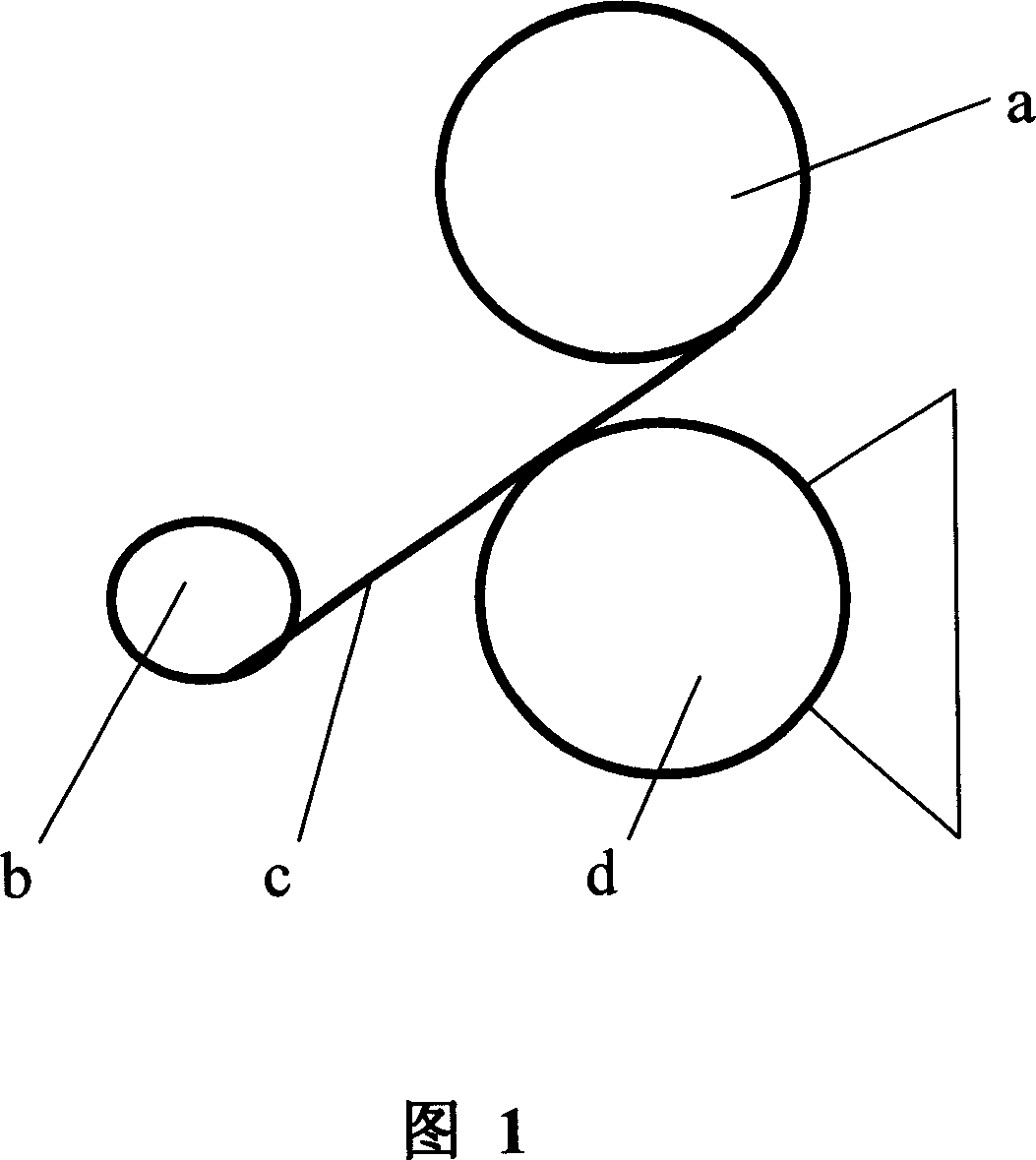

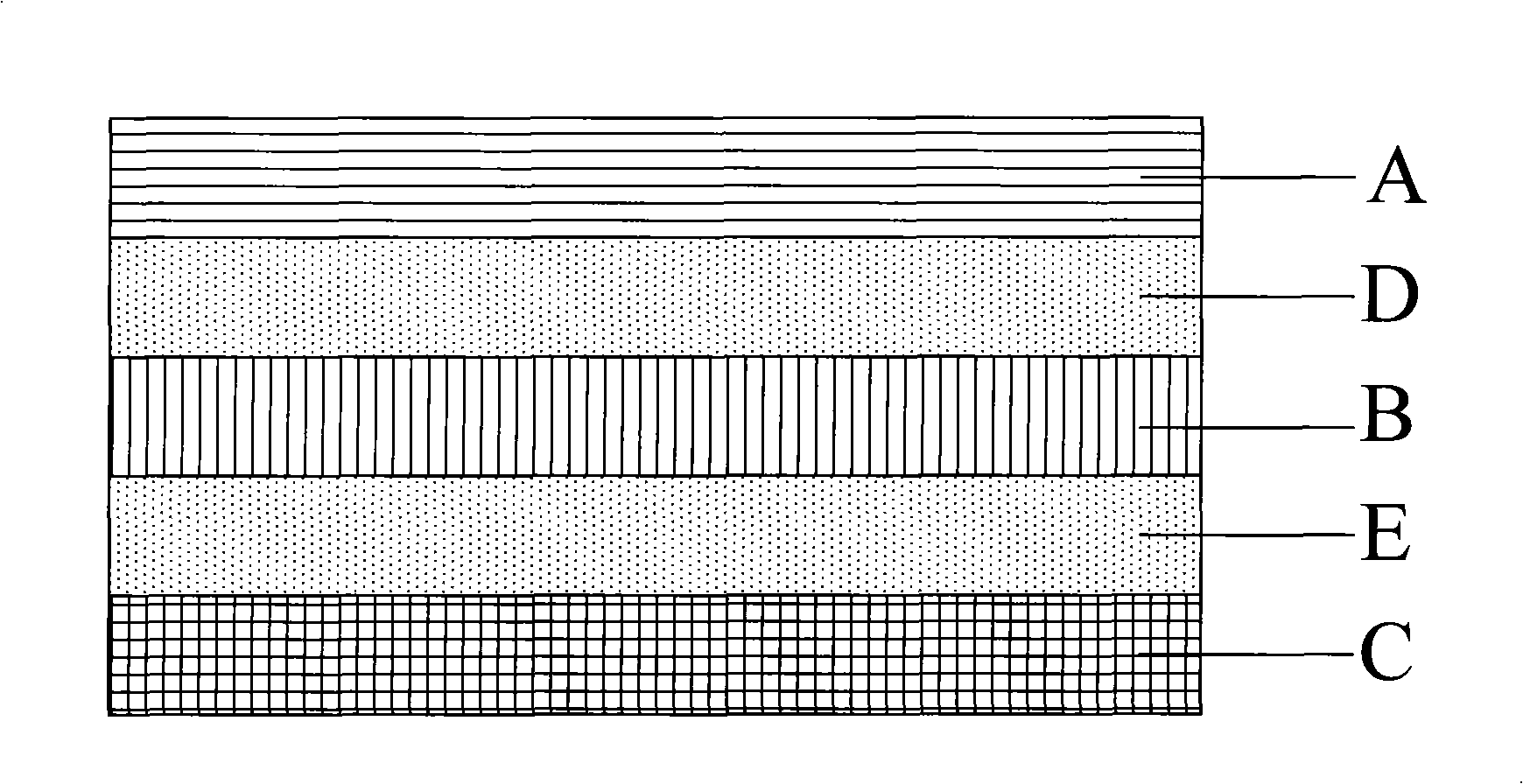

ActiveCN101480861AGood heat sealingGood oil separation functionFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

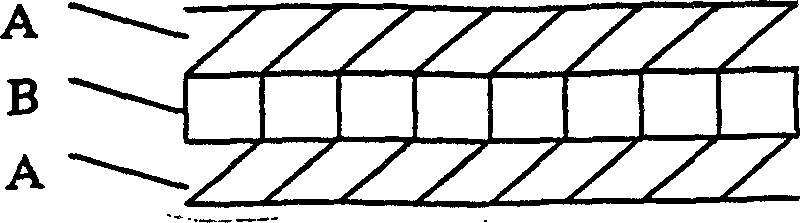

The invention discloses a novel PE film which is formed by coextrusion of three layerswhich are respectively an outer layer, a middle layer and an inner layer; thickness ratio among the outer layer, the middle layer and the inner layer is 1 plus / minus 0.3 : 1 plus / minus 0.3 : 1 plus / minus 0.3; raw materials of the outer layer are low-density polythene and linear low-density polythene with weight ratio of 1 : 1 to 1 : 8; raw materials of the middle layer are polypropylene and metallocene linear low-density polythene with weight ratio of 1 : 0.2 to 1 : 10; and raw materials of the inner layer are the linear low-density polythene, the metallocene linear low-density polythene and anti-block agent with weight ratio of 100 : 100 : 2to 100 : 10 : 1. The novel PE film has the advantages that modification is carried out on the middle layer by the polypropylene, the film has favorable heat sealing performance by adding the metallocene linear low-density polythene into the middle layer and the inner layer to cause molecules of the PE film after the modification to interlink to form a space stereo formation, and the molecule density is increased, thereby the purpose of preventing oil molecules from permeating is achieved, and the PE film is enabled to have favorable oil separation function.

Owner:KINDERWAY PACKAGING XIAMEN CO LTD

Capacitor film with low density polyethylene as substrate and preparation method thereof

ActiveCN102964658AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricEpoxyPolyvinyl alcohol

The invention discloses a capacitor film with low density polyethylene as substrate and a preparation method thereof. The capacitor film comprises the following raw materials by weight: 50-55 parts of LDPE (low density polyethylene), 20-25 parts of LLDPE (linear low density polyethylene), 10-15 parts of homo-polymer, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-pentene, 5-10 parts of calcium carbonate, 2-4 parts of hydrotalcite, 1.3-1.8 parts of zinc dialkyl dithiophosphate, 0.4-0.6 part of phthalic acid ester, 0.4-0.7 part of smoke sheet rubber, 1-3 parts of zinc stearate and 0.9-1.3 parts of modified wood ash. The invention mainly adopts low density polyethylene assisted with linear low density polyethylene; and various accessories and additives are subjected to mixing and extrusion, blown film sizing and cutting to prepare the capacitor film. The preparation method is simple; and diatomite, hydrotalcite and modified wood ash are added into the raw materials at the same time to enhance barrier property and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength, and good heat sealing performance.

Owner:安徽芯智达电子科技有限公司

Foodstuff packaging membrane and its manufacturing method

InactiveCN1736813AHigh transparencyGood air resistanceFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a production of food packaging film and the method for preparation, specifically a degradable complex film prepared with degradable nanometer PA polymer as the obstruct material. Said complex film has a layer structure containing at least two outer layers and one interlayer, at least one layer among which is the obstruct layer, the obstruct layer being made up of degradable nanometer PA polymer, and others being made up of degradable polyolefin or polyolefin. Compared with the high-obstruct film prepared with PVDC, the invention overcomes the shortcomings that the manufacture is hard, the cost is high, environmental pollution is serious, and the recovery is hard. And the high-obstruct packaging film prepared mainly with nanometer PA has identical obstruct effect with PVDA film.

Owner:朱春英

PE film and preparation method thereof

ActiveCN104476889AImprove stiffnessGood flexibilitySynthetic resin layered productsFlat articlesPliabilityMedium-density polyethylene

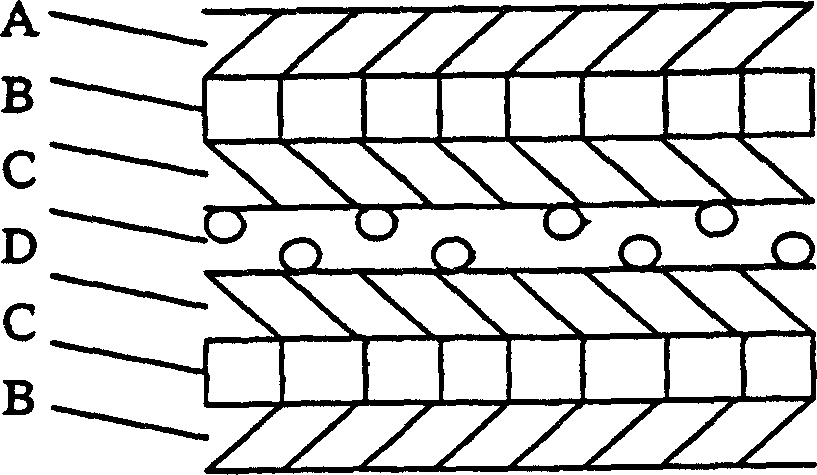

The invention provides a PE film which is formed by co-extruding a corona layer, a middle layer and an inner layer. The corona layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The middle layer comprises low density polyethylene resin, linear low density polyethylene resin and medium density polyethylene resin. The inner layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The corona layer and the inner layer each comprises the high-proportion metallocene linear low density polyethylene resin, so that the PE film has good heat sealing performance, and the medium density polyethylene resin added in the corona layer, the middle layer and the inner layer enable the film to have good stiffness and flexibility, and the PE film is suitable for package of hygienic products.

Owner:永新股份(黄山)包装有限公司

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

Multilayer coextruding pyrocondensation film

ActiveCN101306593AOvercoming low shrinkageOvercome barrierFlexible coversWrappersSurface layerCopolymer

2499. The invention provides a multilayer coextrusion heat shrinking film which comprises a surface layer, a sandwich layer and a heat-sealing layer. The surface layer and the heat-sealing layer are respectively bonded with the sandwich layer through a bonding layer; the sandwich layer comprises a mixture composed of 98Wt% of PVDC resin and 2Wt% of processing aid, wherein, the PVDC resin is a VDC-MA copolymer, the melting point is 150 DEG C, the density is 1.7g / cm<3>, and the processing aid is epoxidized soybean oil or other plasticizing agent systems. The proposal increases the shrinkage factor of the multilayer coextrusion heat shrinking film, and improves the barrier property; the multilayer coextrusion heat shrinking film has excellent heat sealing performance, and is widely applied to the vacuum shrink package.

Owner:SUZHOU TIPACK

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

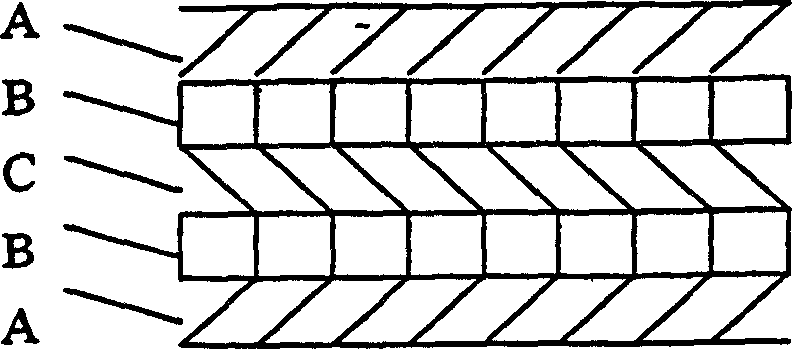

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

Plastic substrate film for food packing and machining process thereof

InactiveCN102380997AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic substrate film for food packing. The plastic substrate film is formed by performing coextruding and blow molding on an inner layer, a middle layer and an outer layer, wherein the inner layer is made from low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE) and metallocene linear low-density polyethylene (mLLDPE); and both the middle layer and the outer layer are made from LDPE and LLDPE. The plastic substrate film for food packing has the characteristics of high barrier property, high airtightness, high pollution resistance, pressure resistance, impact resistance, high heat-sealing strength and high heat-sealing performance, and is accordant with the national food safety certification.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

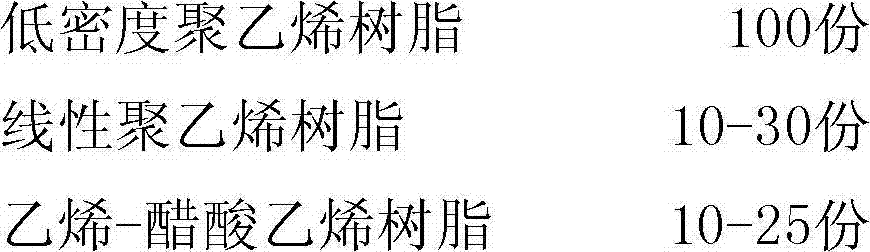

Anti-mildew modified atmosphere packaging film for fruits and vegetables and preparation method for mildew-proof modified atmosphere packaging film

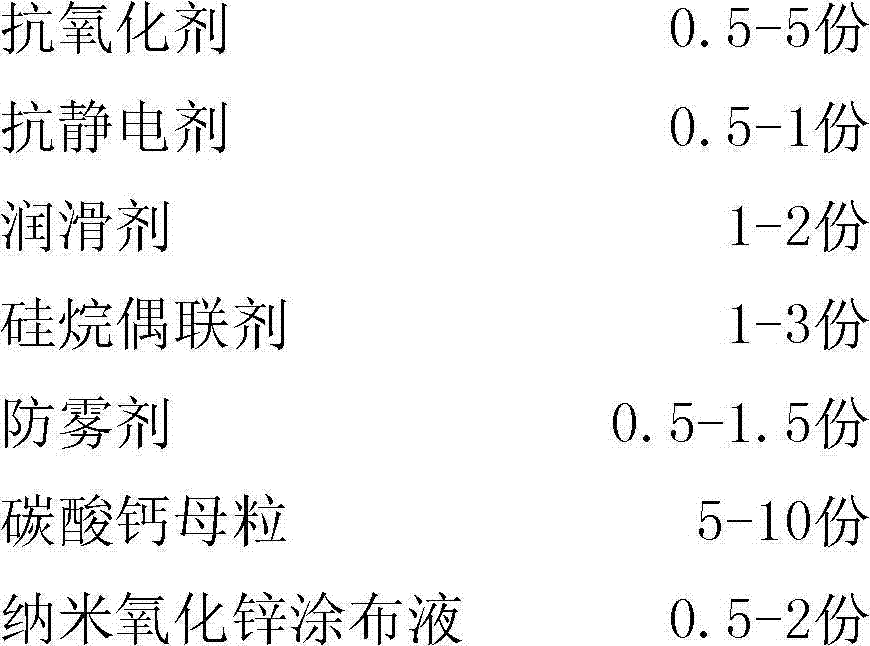

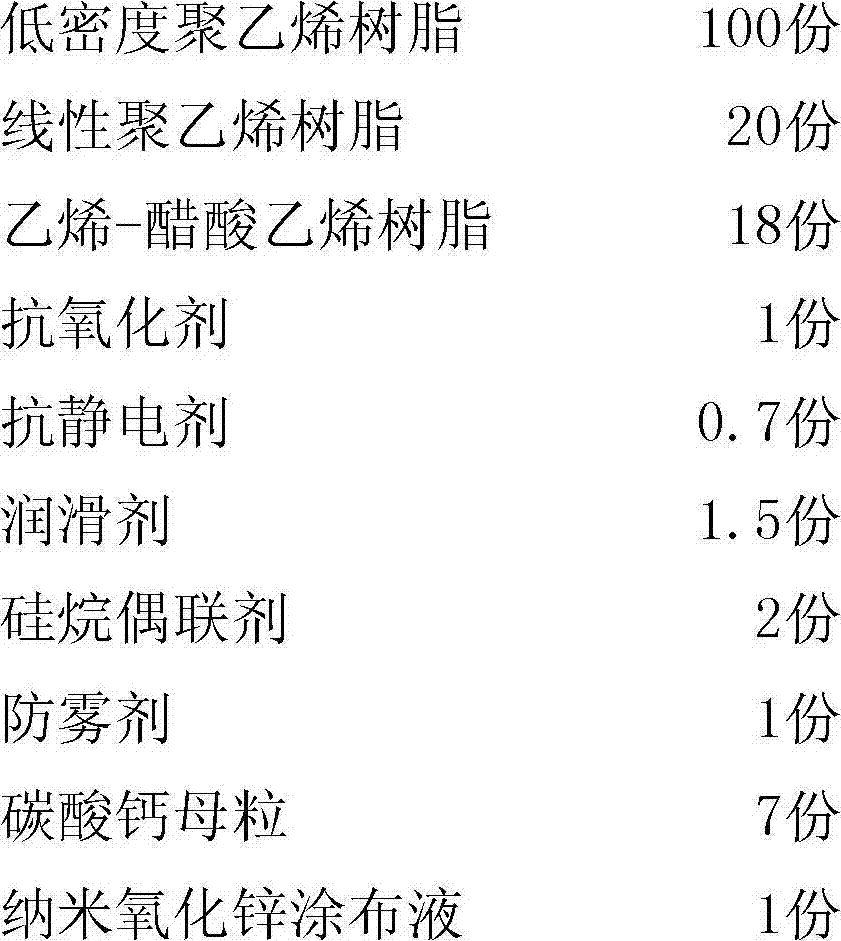

ActiveCN102886950AFixed uniformGood permeabilityFruit and vegetables preservationSynthetic resin layered productsChemistryAntioxidant

The invention discloses an anti-mildew modified atmosphere packaging film, which is prepared from the following components in parts by weight: 100 parts of low density polyethylene resin, 10 to 30 parts of linear polyethylene resin, 10 to 25 parts of ethylene-vinyl acetate resin, 0.5 to 5 parts of antioxidant, 0.5 to 1 part of antistatic agent, 1 to 2 parts of lubricant, 1 to 3 parts of silane coupling agent, 0.5 to 1.5 parts of anti-fogging agent, 5 to 10 parts of calcium carbonate master batch and 0.5 to 2 parts of nano zinc oxide coating solution. The invention also discloses a preparation method for the packaging film. The packaging film prepared by the method has an anti-oxidation function, an anti-fog function, an antibacterial function, an anti-mildew function and a fruit and vegetable respiration adjustment function, the refreshing time of fruits and vegetables can be prolonged, and the quality of the fruits and the vegetables can be improved.

Owner:TIANJIN JIEDONG FRESH PRESERVATION TECH PRODIVITY PROMOTION CENT

Capacitor film with metallocene line-shaped low-density polyethylene resin as base body and preparation method thereof

InactiveCN103102574AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with metallocene line-shaped low-density polyethylene resin as a base body and a preparation method thereof. The capacitor film is prepared from the following raw materials in parts by weight: 45-55 parts of metallocene line-shaped low-density polyethylene resin, 30-35 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy flaxseed oil, 2-3 parts of polyving akohol, 1-2 parts of calmogastrin, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-amylene, 0.1-0.3 parts of polytetrafluoroethene, 9-11 parts of blanc fix, 0.6-0.8 part of antioxygen 1010, 0.3-0.5 part of triethyl acetyl citrate, 0.5-0.7 parts of fumarat, 3-5 parts of calcium stearate, 1.5-2.5 parts of N-2(amino ethyl)-3-ammonia propyl trimethoxy silane, and 1.4-1.8 parts of modified tree ash. The metallocene line-shaped low-density polyethylene resin serving as a primary raw material; the low-density polyethylene resin serving an auxiliary raw material and a plurality of auxiliary material additives are blended, extruded and subjected to film blowing, shaping and cuting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the blanc fixe and the modified tree ash are added to the raw materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

Capacitor film containing modified talc and preparation method thereof

The invention discloses a capacitor film containing modified talc and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 57-63 parts of metallocene polypropylene resin, 35-45 parts of bisphenol A polycarbonate, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.0-1.5 parts of poly-4-methyl-1-pentene, 5-7 parts of vermiculite, 3-5 parts of modified talcum powder, 0.7-1.3 parts of an antioxidant 1010, 0.7-0.9 part of propylene glycol adipate polyester, 0.3-0.5 part of di(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate, 3-5 parts of calcium stearate and 2.2-2.6 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:BENGBU LIQUN ELECTRONICS

Continuous adjustment screen printing process of water-based gloss oil

The invention belongs to the technical field of printing and particularly relates to a continuous adjustment screen printing process of water-based gloss oil. The continuous adjustment screen printing process comprises the following steps of: 1) manufacture of continuous adjustment image files; 2) manufacture of films; 3) cleaning of the films; 4) stretching of a screen; 5) gluing; 6) positioning of the films; 7) exposure; 8) development; 9) drying; and 10) screen printing. The continuous adjustment screen printing process has the advantages that 1) the wear resistance is strong, the scratching is resisted, the screen-printed surface is wear-resistant, water-repellent and oil-repellent, and no color-fading phenomenon occurs on the surface of a printed product; 2) the film forming speed is fast, and the drying is rapid; 3) the high temperature resistance and the hot-sealing performance are good; 4) the degree of planeness is good, and the winding force resistance is strong; 5) the used water-based gloss oil has better leveling property, can realize fast leveling before a coating layer is dried to form a smooth surface, so that the coating layer can have high glossiness; and 6) the water-based gloss oil adopts water as a solvent without toxicity and smell. Compared with the water-based gloss oil used for local glossing, the continuous adjustment screen printing has the advantage that the image layering can be reproduced.

Owner:浙江华人数码科技有限公司

Polyvinyl alcohol nonwoven fabric and preparation method thereof

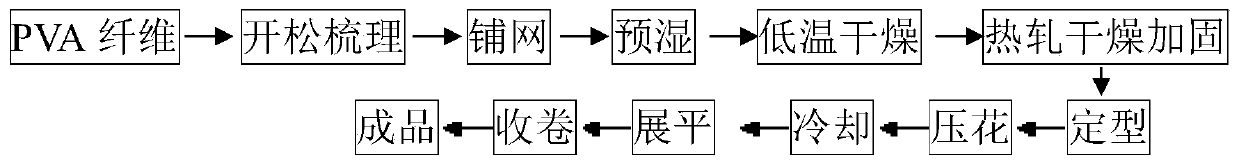

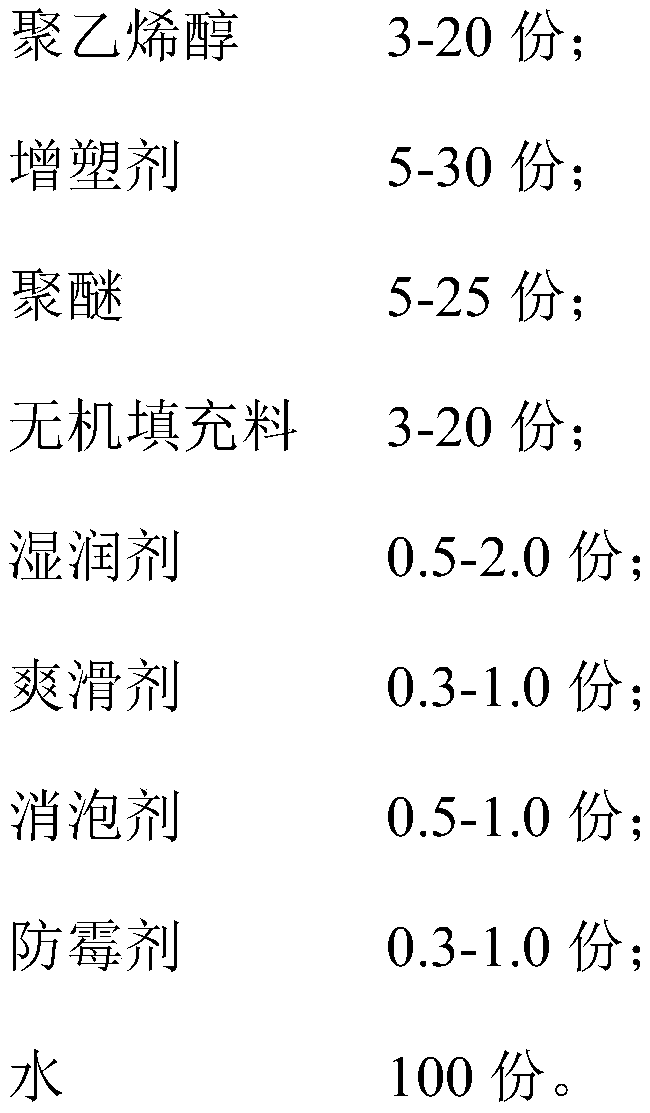

ActiveCN110273299AGood heat sealingImprove processing efficiencyFibre typesLiquid/gas/vapor removalDefoamerPlasticizer

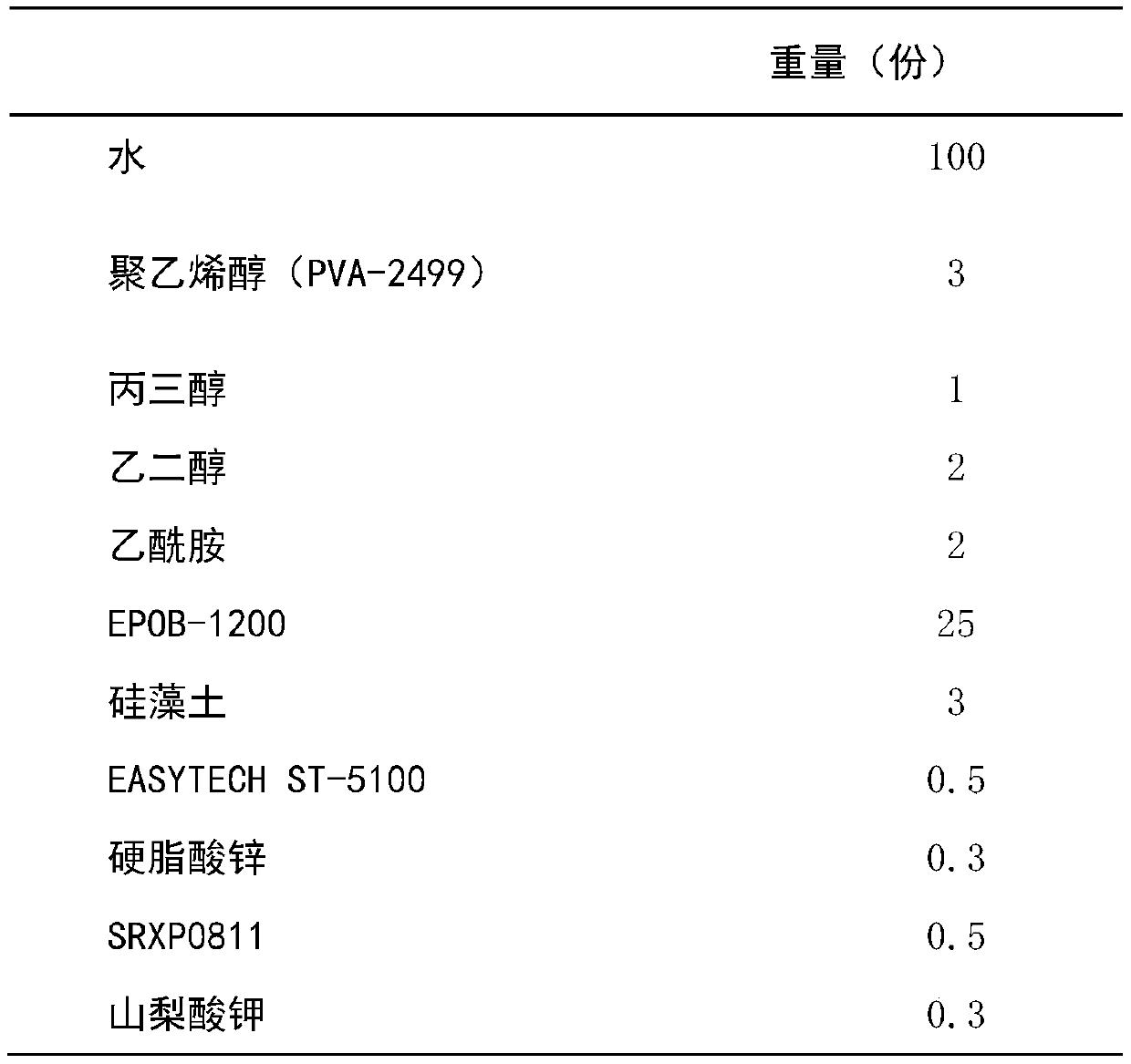

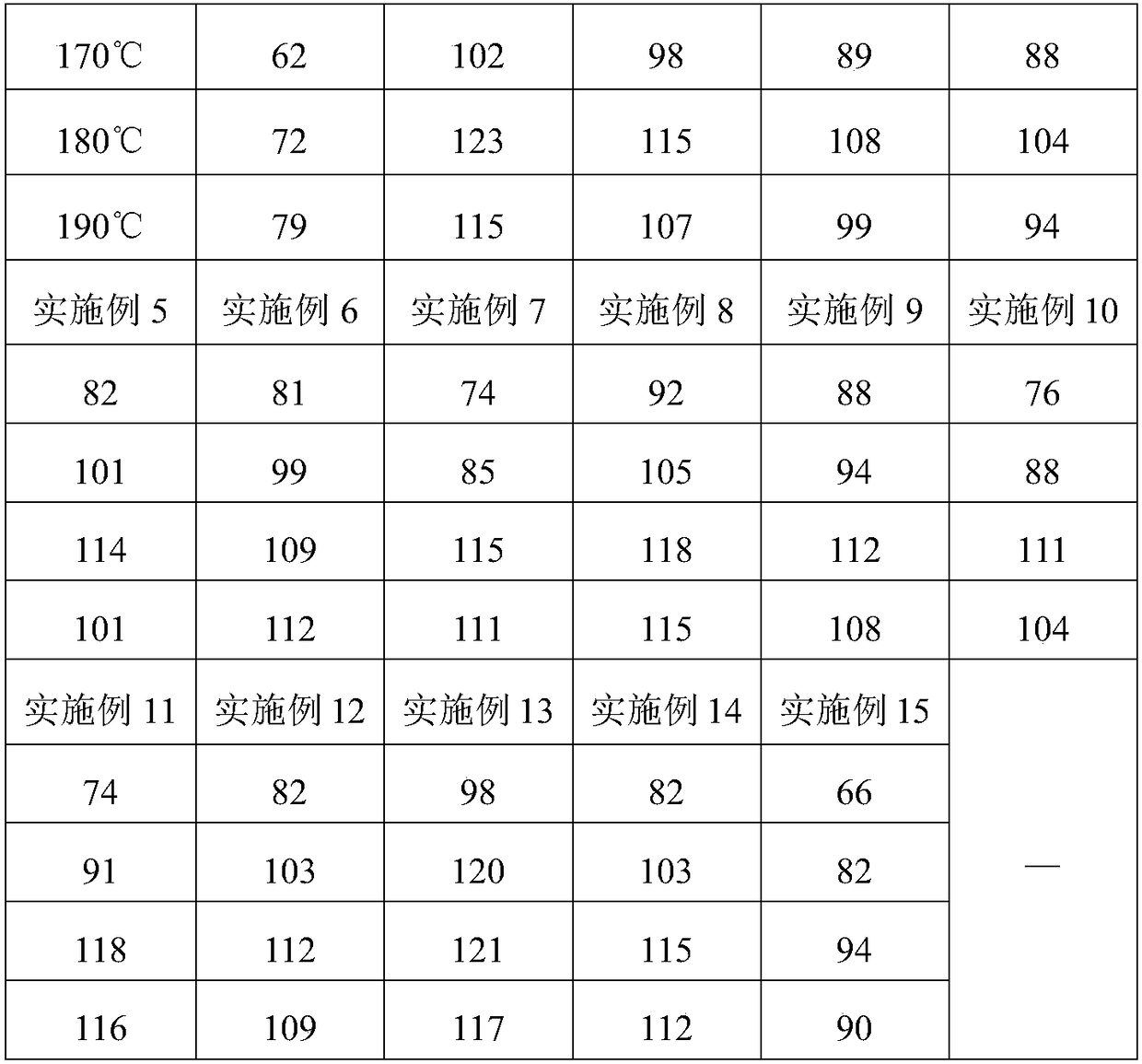

The invention discloses polyvinyl alcohol nonwoven fabric and a preparation method thereof. The method includes preparing polyvinyl alcohol nonwoven fabric modification liquid, and in the preparation process of the polyvinyl alcohol nonwoven fabric, subjecting polyvinyl alcohol fabrics, which enter a pre-wetting zone after opening, carding and mechanical lapping, to double-side spraying; feeding the polyvinyl alcohol fabrics to a low-temperature drying zone for surface drying, hot-rolling and drying the polyvinyl alcohol fabrics for reinforcement, and performing hot-press shaping and embossing by a shaping roll; cooling down by a cooling roll, and performing unfolding and winding to obtain the polyvinyl alcohol nonwoven fabric. The polyvinyl alcohol nonwoven fabric modification liquid comprises, by weight, 100 parts of water, 3-20 parts of PVA (polyvinyl alcohol), 5-30 parts of plasticizers, 5-25 parts of polyether, 3-20 parts of inorganic fillers, 0.5-2.0 parts of wetting agents, 0.3-1.0 part of slipping agent, 0.5-1.0 part of defoamer and 0.3-1.0 part of mould inhibitor. The polyvinyl alcohol nonwoven fabric prepared by the preparation method has improved mechanical and physical properties and excellent thermoplastic properties.

Owner:SOUTH CHINA UNIV OF TECH

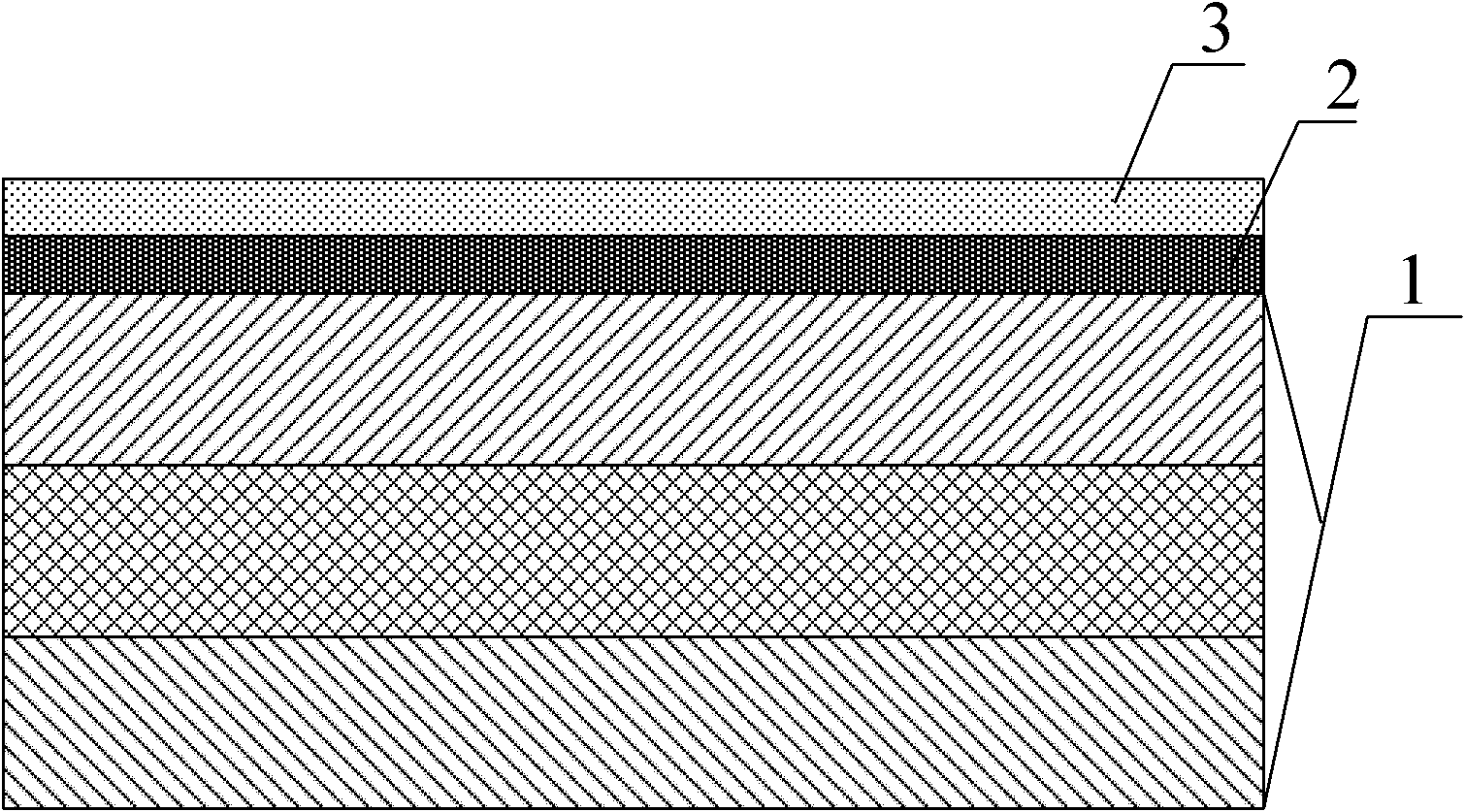

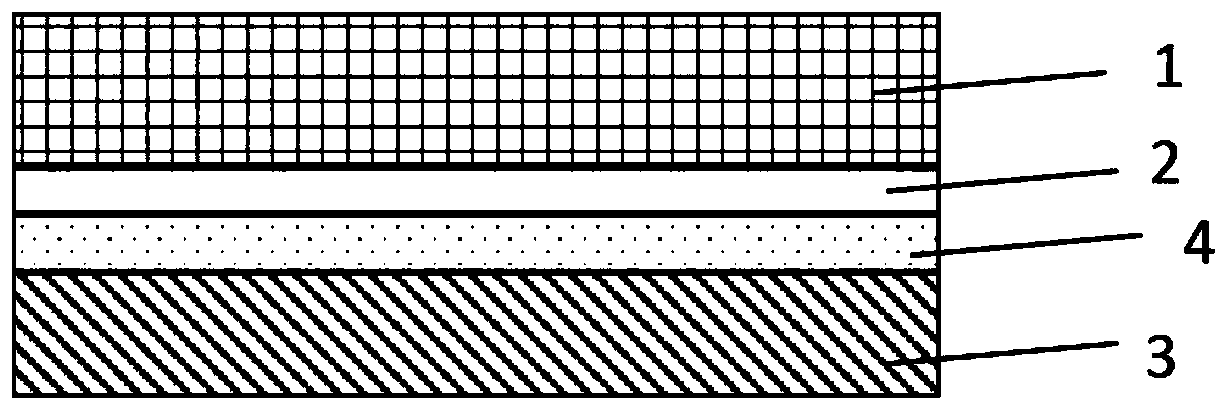

Aluminium foil sealing film and preparation method thereof

ActiveCN102700819ADoes not affect ease of peelingImprove cooking temperatureSynthetic resin layered productsSealingPolymer sciencePolyethylene terephthalate glycol

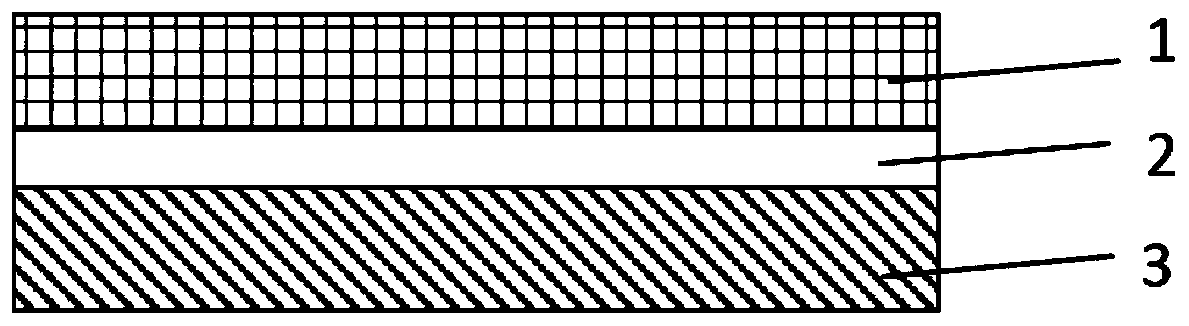

The invention provides an aluminium foil sealing film and a preparation method thereof and belongs to the technical field of plastic packaging. The aluminium foil sealing film comprises a protective layer, a separation layer and a heat-seal layer, wherein the protective layer is a gloss oil layer or a PET (Polyethylene Terephthalate) film layer; the separation layer is an aluminium foil layer; and the heat-seal layer comprises the materials as follows: 15 to 25 wt% of polybutene, 25 to 35 wt% of ethylene-propylene copolymer and 40 to 60 wt% of HDPE (high-density polyethylene). As a sealing film for the bottle mouth of a polypropylene plastic bottle, the aluminium foil sealing film provided by the invention has the excellent properties of cooking resistance and easiness for uncovering, and when the cooking-resistant temperature is 121 DEG C, the sealing film is unchanged in color and is not stratified. The opening force is 5 to 25 N after the sealing film and the polypropylene bottle are heat-sealed at 200 DEG C, and the heat-seal strength of a heat-seal strip with the width of 15 mm is 5 to 25 N, which shows that the aluminium foil sealing film has the excellent properties of cooking resistance and easiness for uncovering at the same time.

Owner:ZHEJIANG GOLDSTONE PACKING

Capacitor thin film containing modified sepiolite powder and preparation method thereof

InactiveCN103102581AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolymer science

The invention discloses a capacitor thin film containing modified sepiolite powder and a preparation method thereof. The capacitor thin film containing modified sepiolite powder comprises the following raw materials in parts by weight: 40-45 of metallocene polypropylene resin, 35-40 of LDPE (Linear low density polyethylene), 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 2.2-2.5 of poly-4-methyl-1-amylene, 7.5-9.5 of modified sepiolite powder, 3.5-5 of zeolite, 1.2-1.5 of antioxidant DSTP, 0.9-1.1 of acetylcitric acid tris(2-ethylhexyl) ester, 0.8-1.2 of di-n-butyl maleate, 3-5 of calcium stearate, 2.5-3 of N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane (triethoxysilane), and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

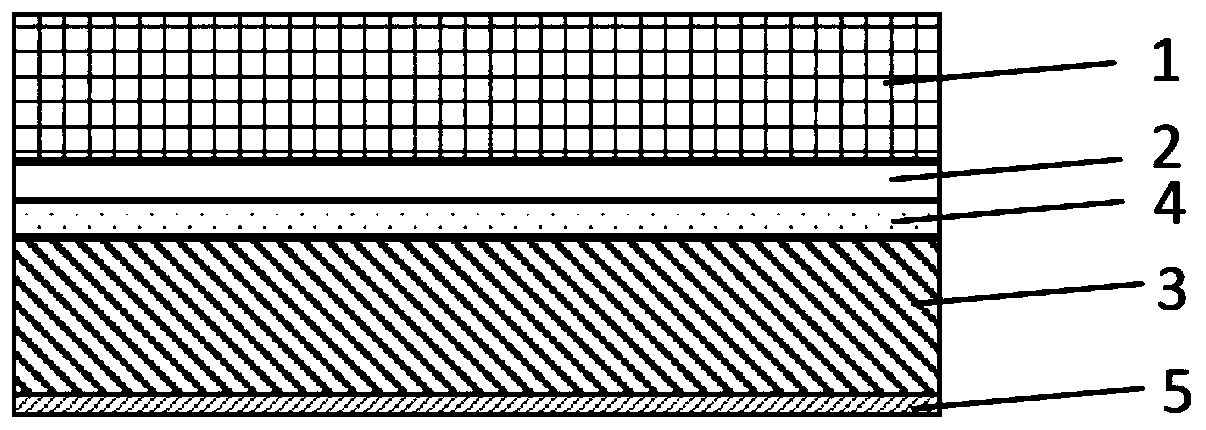

Heat sealing layer, CPP film, preparation method thereof and aluminum-plastic film

ActiveCN108943932AHigh mechanical strengthImprove performanceFlexible coversWrappersElastomerComposite film

The invention provides a heat sealing layer, a CPP (chlorinated polypropylene) film, a preparation method thereof and an aluminum-plastic film. A first raw material of forming the heat sealing layer comprises a first polypropylene randon copolymer, a first block co-polypropylene and a polyolefin elastomer. The melting point range of the first polypropylene randon copolymer is 135-145 DEG C, and the melting point range of the first block co-polypropylene is 155-165 DEG C. According to the heat sealing layer, the CPP film has relatively high heat sealing strength, impact resistance and mechanical strength, so that the CPP film can be used for an inner layer of a dry process aluminum-plastic composite film, and therefore, the comprehensive performance of the dry process aluminum-plastic composite film is improved greatly.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

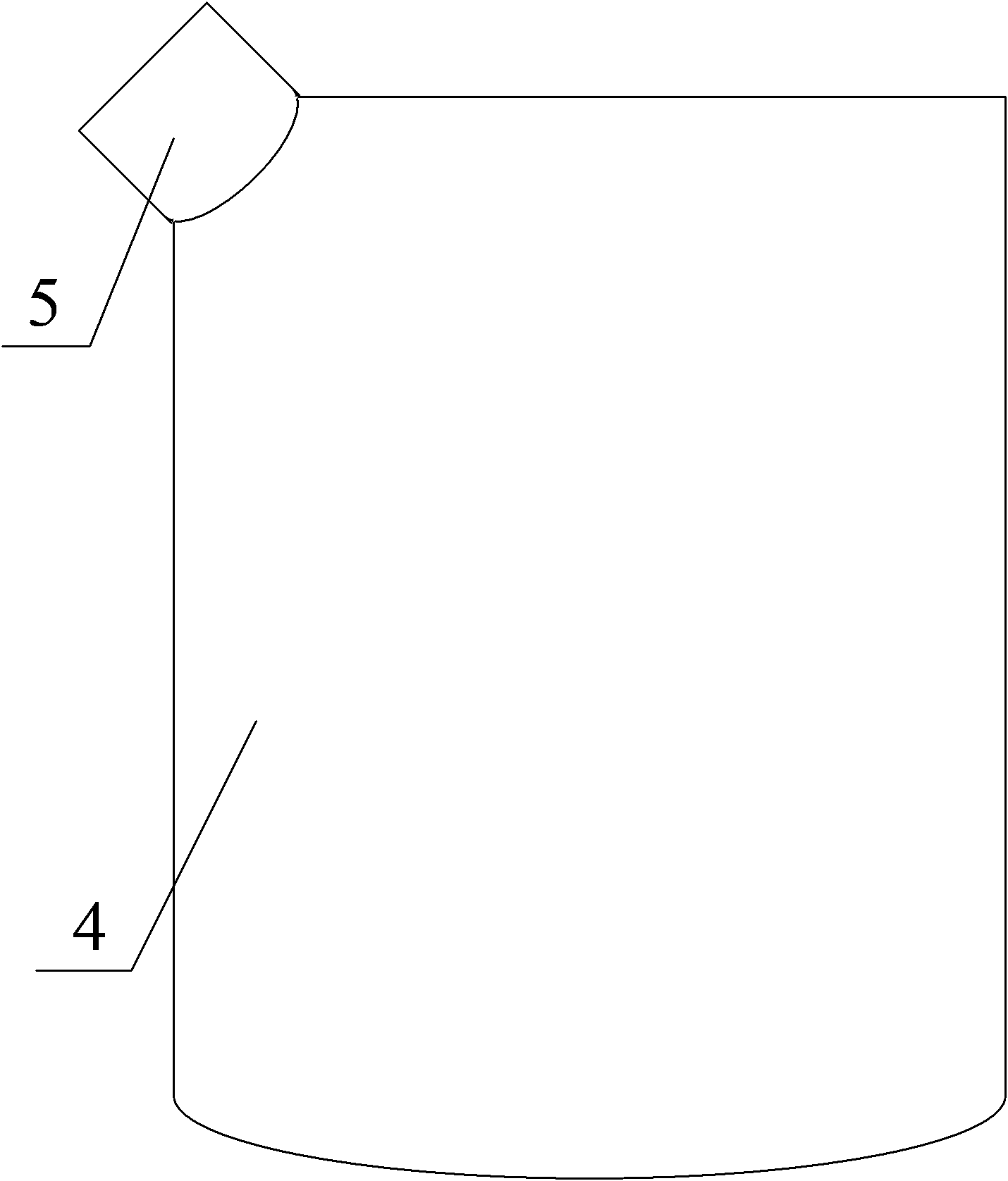

Biological degradable compound packaging film and packaging bag

InactiveCN109968755ABiodegradableDegradation rate adjustableFlexible coversWrappersProtection layerBlocking layer

The invention belongs to the field of packaging materials and packaging products, and relates to a biological degradable compound packaging film and a packaging bag. Particularly, the invention relates to the packaging film which sequentially comprises a biological degradable heat seal layer, a blocking layer and a protection layer. The invention further relates to a method for preparing the packaging film, application of the packaging film, and a packaging product (such as the packaging bag) with the packaging film.

Owner:刘建林 +1

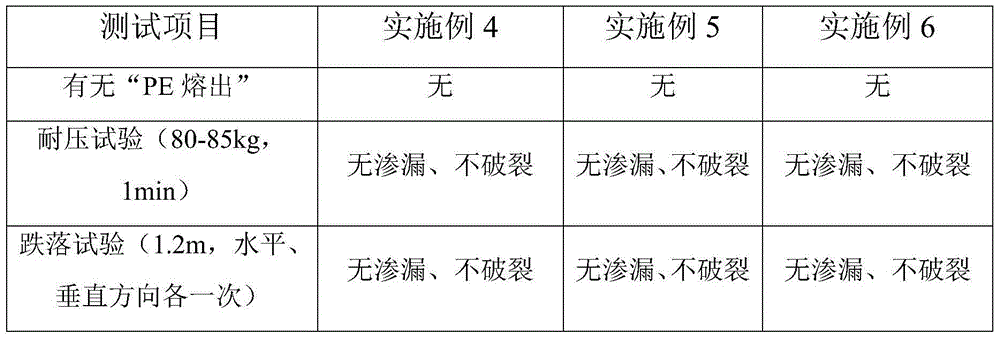

Self-supporting bag and composite film thereof

ActiveCN104924712AGood heat sealingGuaranteed leak-proof effectSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film. The polyethylene film comprises a composite layer, a middle layer and a heat sealing layer which are sequentially overlapped. The composite layer comprises 60-70wt% of metallocene polyethylene and 30-40wt% of low-density polyethylene; the middle layer comprises 30-35wt% of high-density polyethylene, 30-35wt% of linear low-density polyethylene and 30-35wt% of low-density polyethylene; the heat sealing layer comprises 33-35% of low-density polyethylene, 63-65% of reinforcing polyethylene resin, 0.5-0.8wt% of slipping agent and 1.3-2.0wt% of anti-blocking agent. A melting point of the composite layer is higher than that of the middle layer, and the melting point of the middle layer is higher than that of the heat sealing layer. The invention further provides a composite film and a self-supporting bag which are prepared through the polyethylene film. By the adoption of the PE film, PE melting of the heat sealing portion can be effectively avoided, the heat sealing performance of the PE film is greatly improved, and the polyethylene film has excellent adaptation, pressure resistance and falling resistance and meets the requirement of actual production.

Owner:河北永新包装有限公司

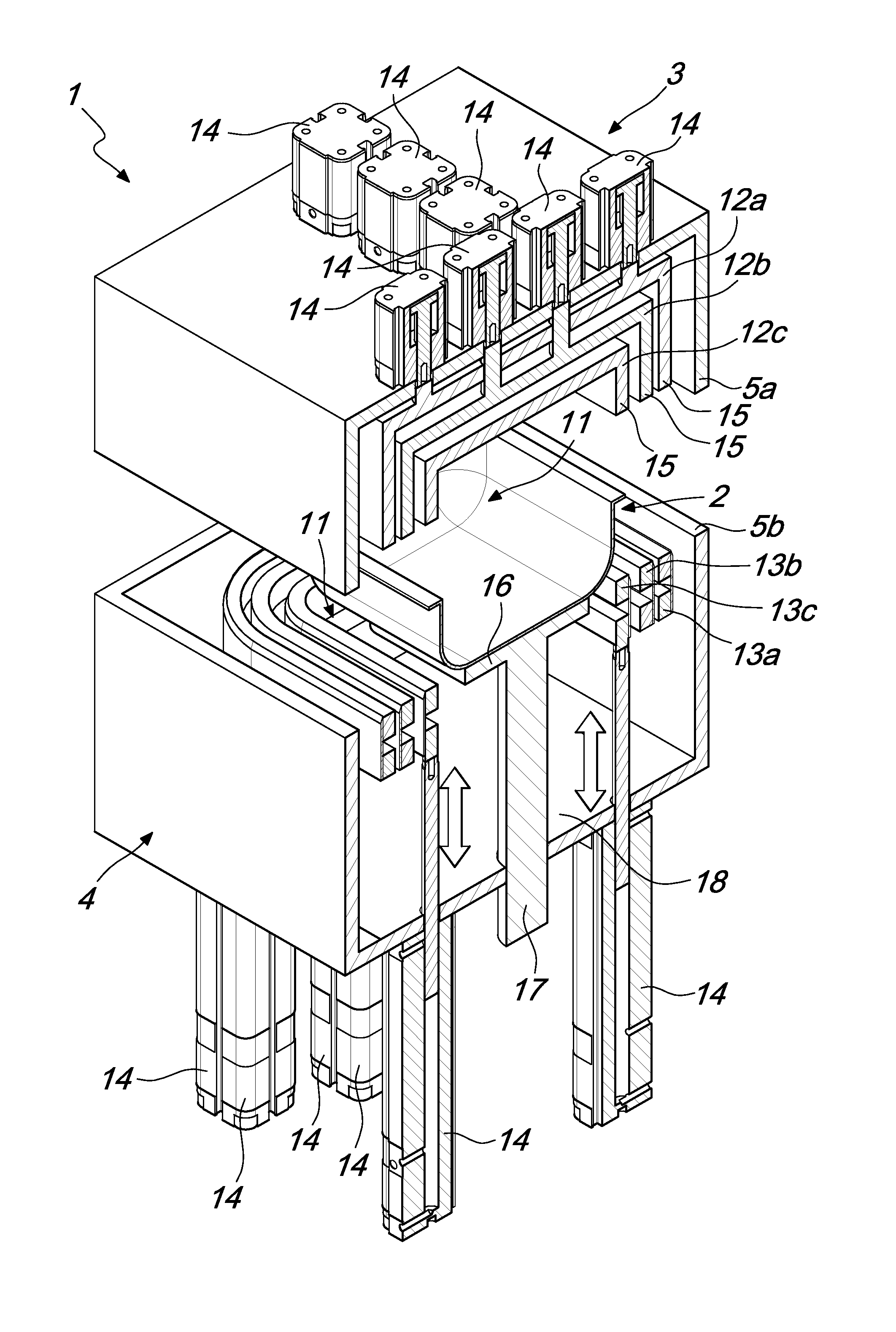

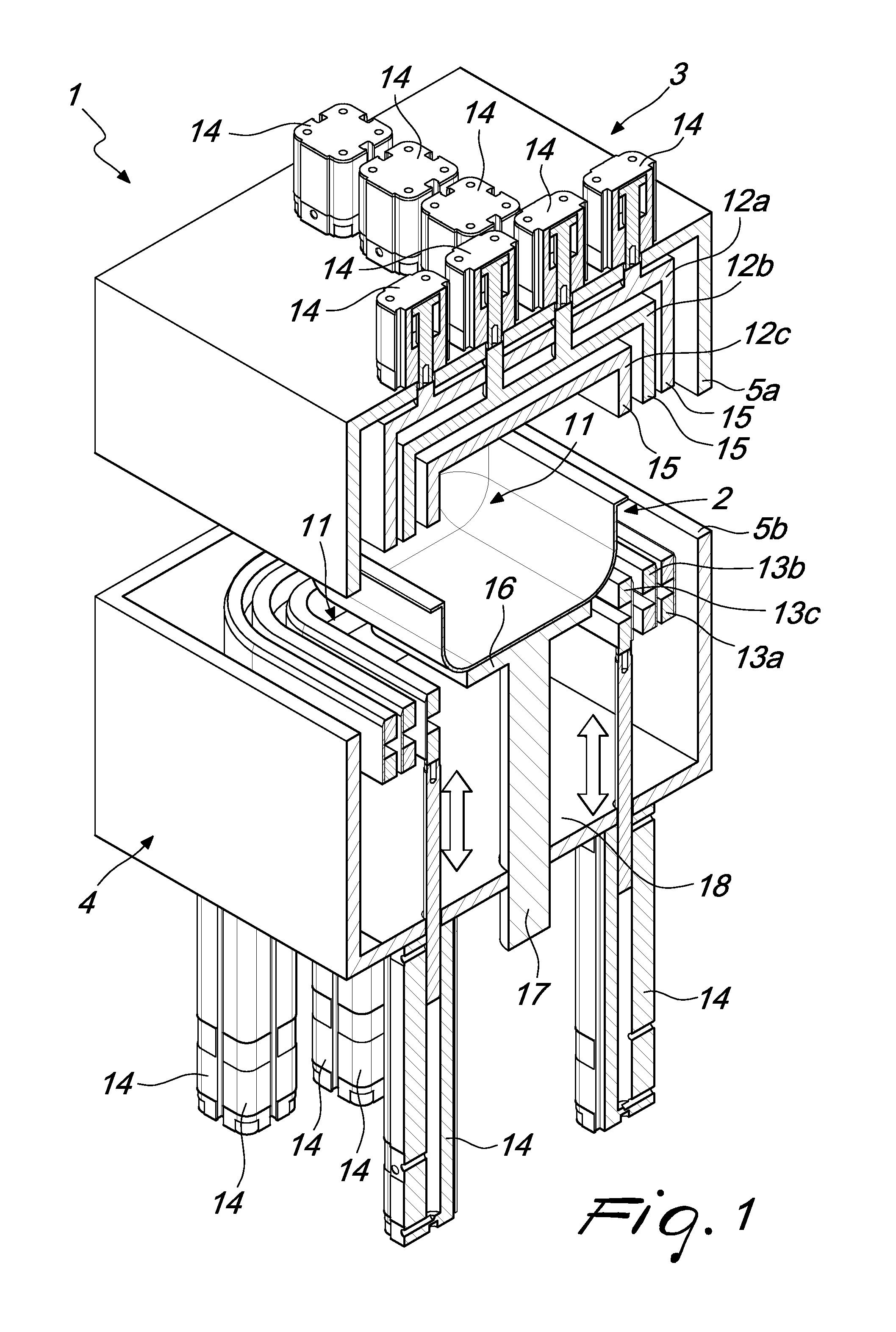

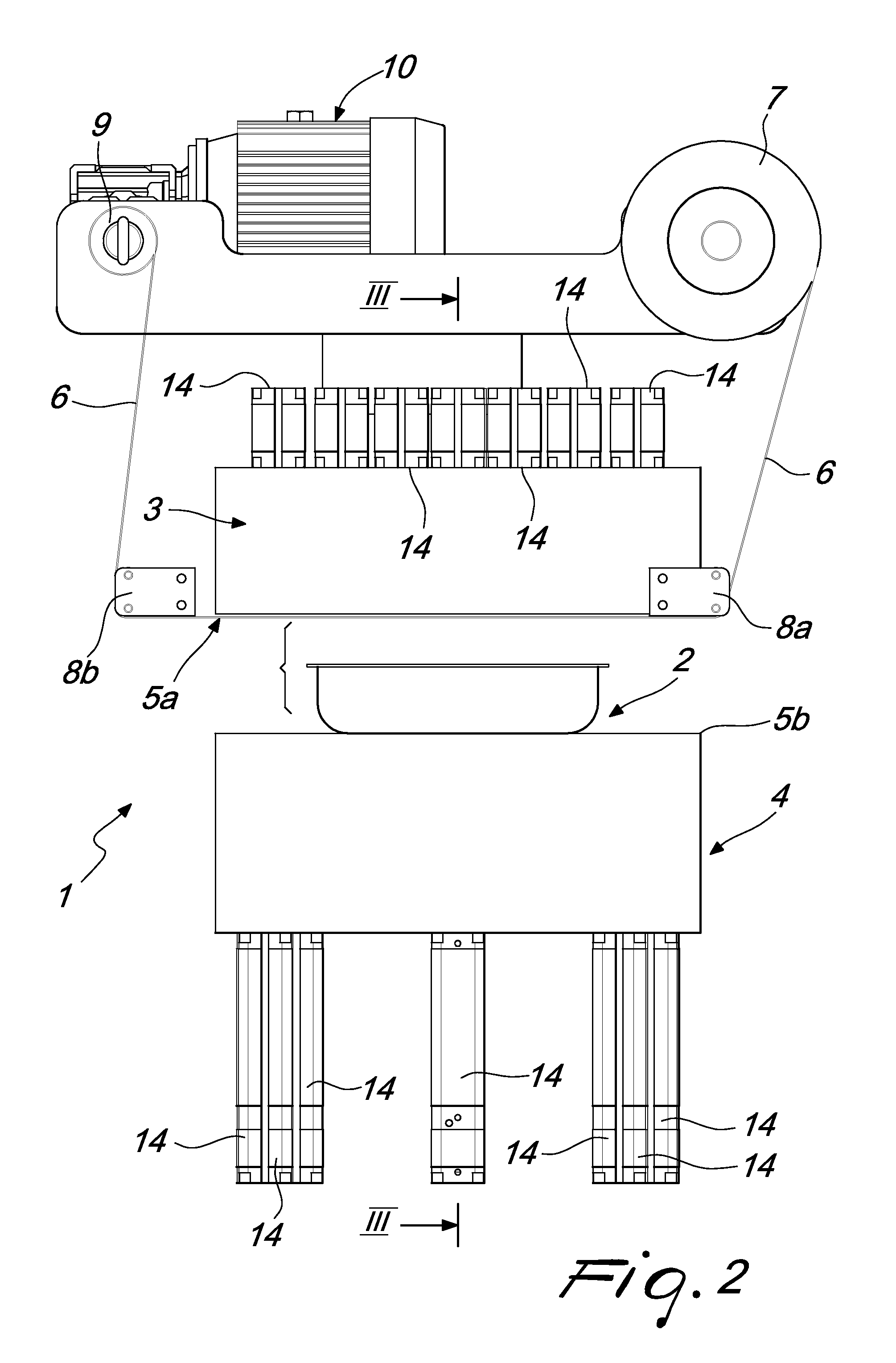

Device for vacuum packaging, particularly of food products

ActiveUS20130263559A1The process is simple and fastGood heat sealingCapsDecorative coversPlastic materialsEngineering

A packaging device, particularly for packaging trays containing food products or technical materials in a controlled atmosphere and by means of a film of plastic material, comprising an upper chamber and a lower chamber, which can be fastened by mutually superimposing them and are each provided internally with a plurality of heat-sealing and / or cutting and / or die-cutting elements arranged concentrically, the lower chamber being provided centrally with a plurality of supporting elements for a tray.

Owner:DAVINCHY SRL +1

Capacitor film containing modified bentonite and preparation method thereof

ActiveCN102964666AImprove barrier propertiesImprove air tightnessThin/thick film capacitorFixed capacitor dielectricLow-density polyethylenePolyester

The invention discloses a capacitor film containing modified bentonite and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 50-55 parts of metallocene linear low-density polyethylene resin, 25-30 parts of metallocene polypropylene resin, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyving akohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.7-1.3 parts of poly-4-methy-l-pentene, 8-12 parts of modified bentonite, 0.9-1.1 parts of an antioxidant 1035, 0.6-0.8 part of phthalic acid polyester, 1-2 parts of epoxy octyl stearate, 4-6 parts of calcium stearate and 1.7-2.0 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:BENGBU LIQUN ELECTRONICS

Polyester film and methods for making same

ActiveCN101367285AWide variety of sourcesReduce pollutionFlexible coversWrappersPolyesterSurface layer

The invention discloses a polyester film. The polyester film at least comprises a first film layer and a second film layer; the first film layer is positioned on a surface layer and is in co-extrusion compounding with the second film layer; the first film layer is a heat-sealing layer which consists of 50 to 90 weight percent of amorphous polyester, 9.7 to 49 weight percent of EVA resin and 0.3 to 1 weight percent of an antisticking agent; the second film layer is a base layer; and main composition of the base layer is crystalline polyester. The invention also discloses a method for manufacturing the polyester film. As the method disclosed by the invention has a simple process and wide source of raw materials, the produced polyester film not only has good heat sealing effect but also is easy to peel off from an APET or CPET tray.

Owner:WEIFANG FUWEI PLASTIC

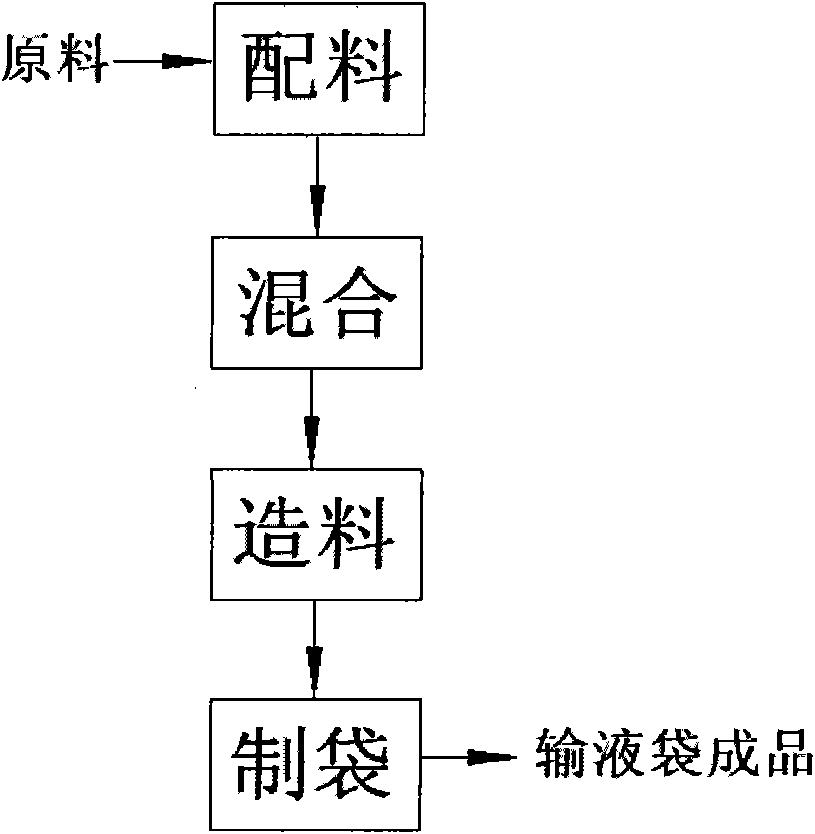

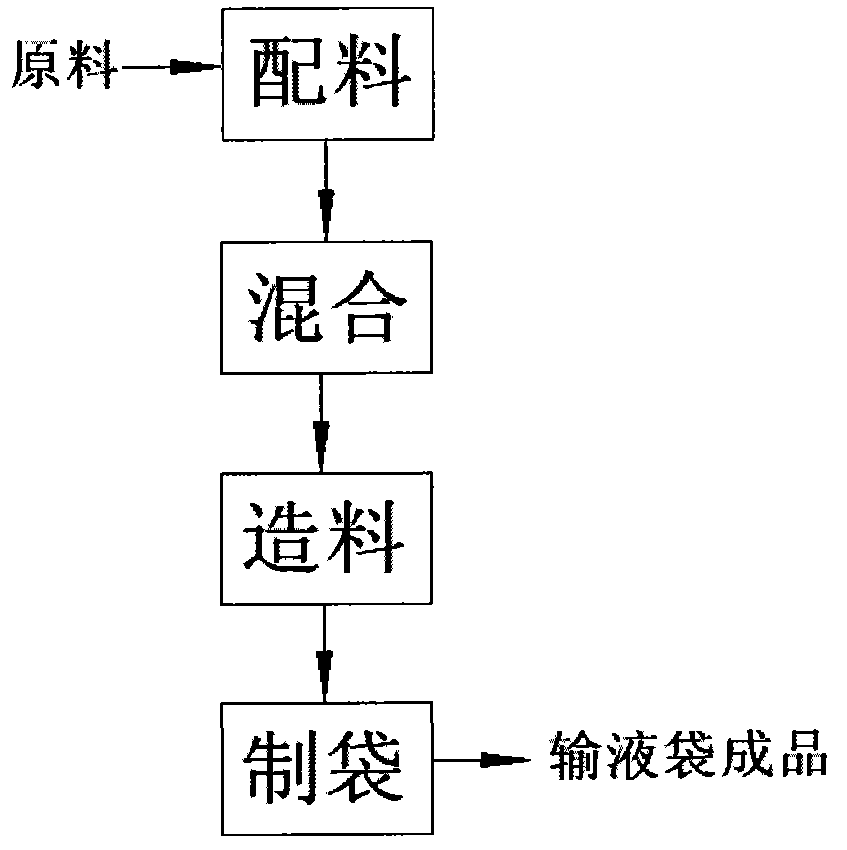

Manufacturing process and production equipment for medical infusion bags

InactiveCN101845173AImprove air tightnessImprove barrier propertiesPharmaceutical containersMedical packagingForeign matterPolypropylene

The invention discloses a medical infusion bag. The infusion bag is manufactured by using polypropylene and polyethylene and styrene-ethylene / butylene-styrene block copolymer. The infusion bag manufactured by adopting the technical scheme has the advantages that: the air-tightness and the steam resistance are excellent, the chemical stability is high, and the infusion bag is suitable to be used for manufacturing liquid medicinal products requiring high-temperature disinfection and sterilization; the transparence is high, and the detection of foreign materials when the infusion bag is produced and used is ensured; the softness is high, the falling resistance is high, the heat-sealing property is high, the high-temperature resistance is high, and the infusion bag can be sterilized at the temperature of 121 DEG C; because the infusion bag does not contain halogens, the infusion bag does not cause any environmental pollution when processed after use; and simultaneously, the barrier property is high, the chemical inertness and the biological inertness are high, the compatibility with medicaments is good, and the infusion bag can be used for packaging various kinds of common fluid, enteral nutrient fluid, parenteral nutrient fluid, dialyzate, flushing fluid, treating type large-capacity injection and the like.

Owner:ANHUI DOUBLE CRANE PHARMA

Food packaging plastic substrate film and production technology thereof

InactiveCN102416744AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention relates to a food packaging plastic substrate film which is of a three-layer structure: an inner layer, an interlayer and an outer layer, wherein the inner layer is made of low-density polyethylene LDPE, linear low-density polyethylene LLDPE and metallocene linear low-density polyethylene mLLDPE; the interlayer is made of low-density polyethylene LDPE and linear low-density polyethylene LLDPE; and the outer layer is made of metallocene linear low-density polyethylene mLLDPE. A production technology of the food packaging plastic substrate film comprises the following steps: extruding the mixed fed materials; blowing a film; forming; dragging and cutting, and the like. The food packaging plastic substrate film provided by the invention has the advantages of high separating property, high air tightness, excellent pollution resistance, excellent heat-seal property, high pressure resistance, excellent shock resistance, and achieves food safety certificate.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

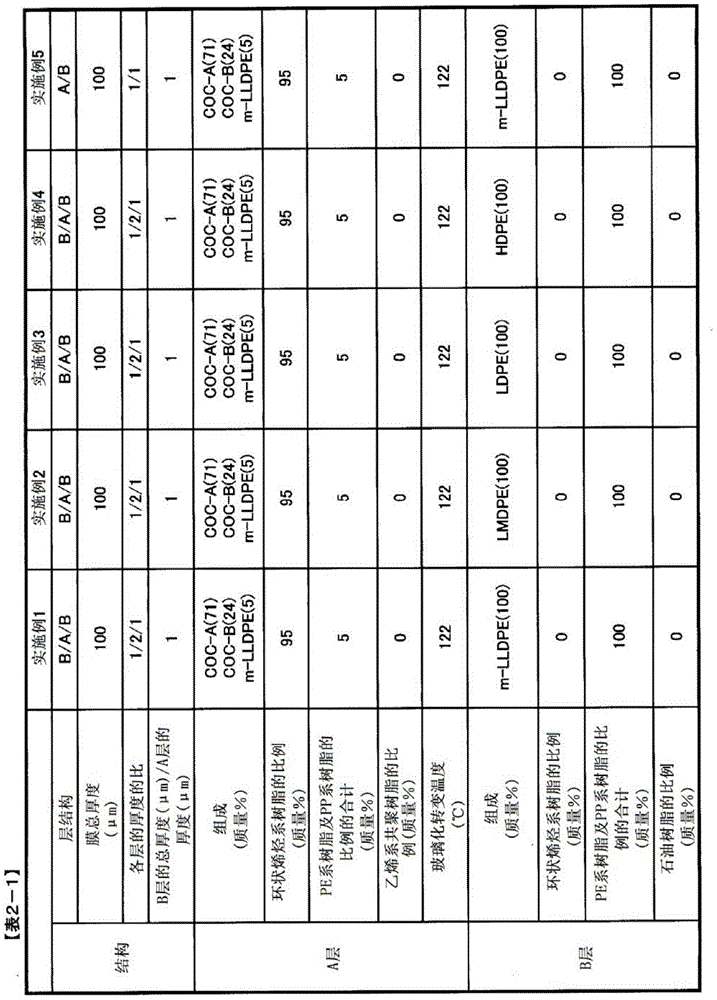

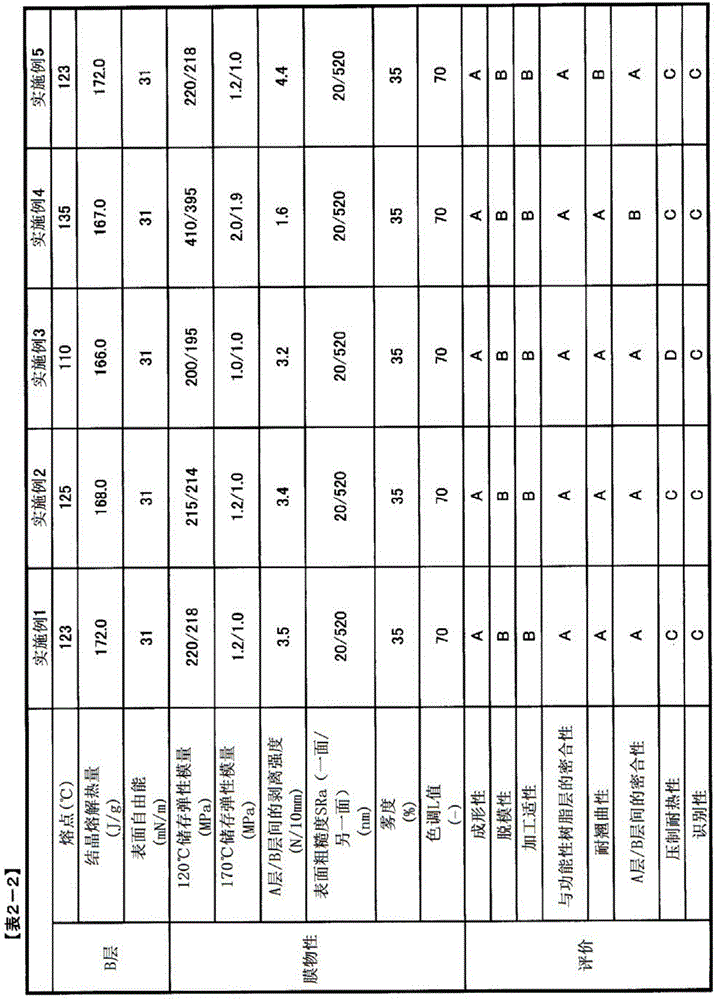

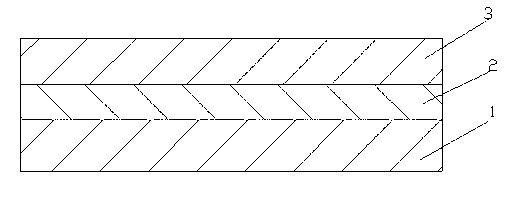

Laminated film

[Problem] To provide a laminated film with superior moldability, mold release property, suitability for processing, water vapor barrier property, and heat-sealing property. [Solution] A laminated film having a layer B, which has a polyethylene resin and / or a polypropylene resin as a main component, on at least one surface of a layer A, which has a cyclic olefin resin as a main component.

Owner:TORAY IND INC

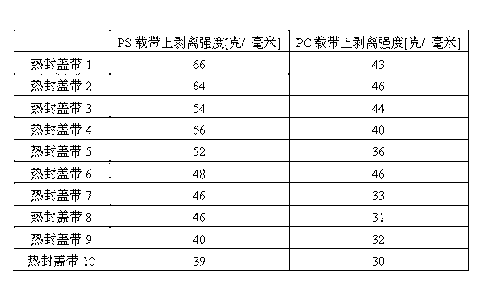

Heat seal cover tape and preparation method of heat seal cover tape

InactiveCN103273714ASimple production processLow requirements for production equipmentSynthetic resin layered productsPolyethylene glycolPolystyrene

The invention discloses a heat seal cover tape and a preparation method of the heat seal cover tape, belonging to the package field of electronic parts and components. A bottom coating is arranged above a base material film layer of the heat seal cover tape; a heat seal layer is arranged above the bottom coating; and the heat seal cover tape is prepared by coating through a coating machine. According to the heat seal cover tape, the production technology is simple and the requirement on production equipment is low. The heat seal cover tape has excellent heat seal property, proper peel strength, even peeling force, high light transmittance, anti-bonding property, high temperature resistance, high humidity resistance, anti-aging performance and enough tensile strength. The heat seal cover tape is suitable for being arranged on a carrier tape made from polystyrene, polycarbonate, polyethylene glycol terephthalate plastic and the like in a way of heat seal. According to the heat seal cover tape and the preparation method of the heat seal cover tape, the problems that the product has dependence on import, high in price and the like can be solved.

Owner:JINGJIANG RUITAI ELECTRIC MATERIAL

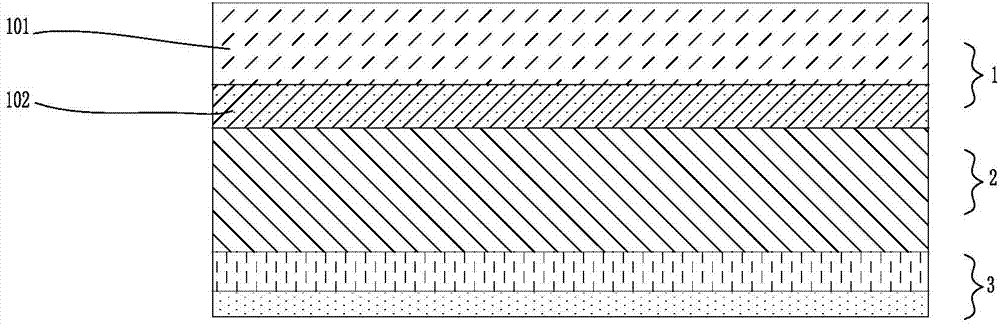

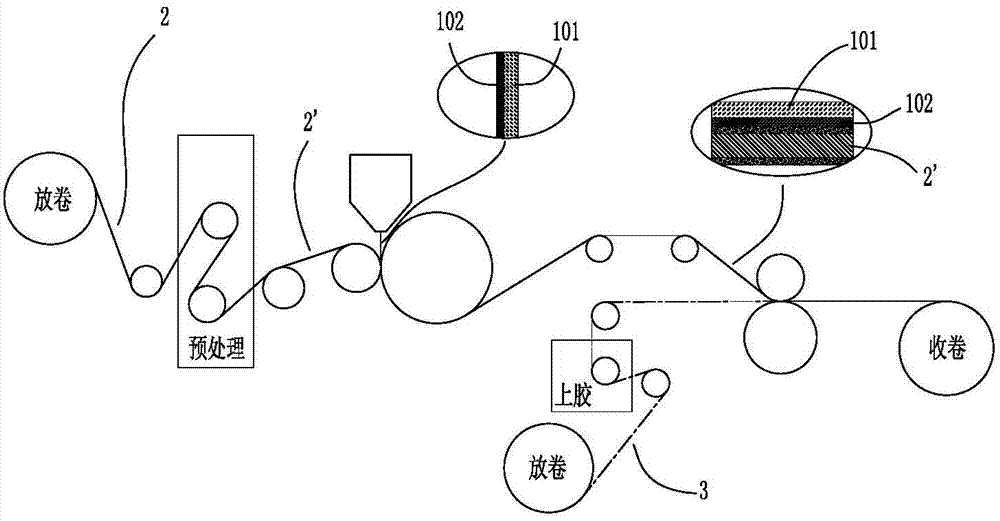

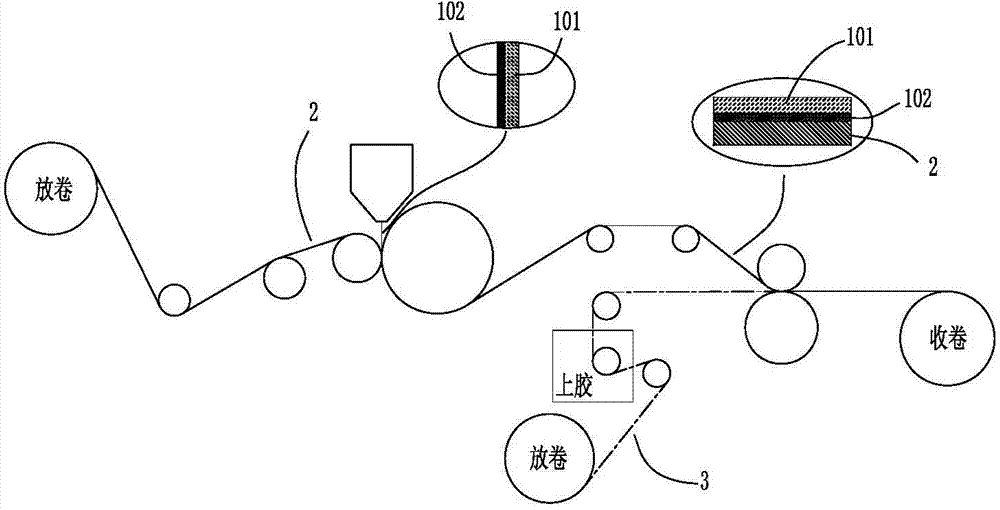

High sealing flexible composite film material for cold punching molding and its manufacturing method

InactiveCN103587165AHigh peel strength between layersImprove interlayer adhesionLamination ancillary operationsLaminationComposite filmPunching

The invention provides a high sealing flexible composite film material for cold punching molding. The composite film material comprises: a thermoplastic resin film inner layer, an aluminum foil metal core layer, and a heat resistant film outer layer. Specifically, the aluminum foil metal core layer is positioned between the thermoplastic resin film inner layer and the heat resistant film outer layer. The thermoplastic resin film inner layer is a multi-layer coextrusion layer containing at least two resin layers. The multi-layer coextrusion layer at least includes a surface heat seal layer and an inner composite layer, and the inner composite layer contacts the aluminum foil metal core layer. The surface heat seal layer contains a non-migrating inorganic additive with lubrication. The upper and lower surfaces of the aluminum foil metal core layer both undergo surface pretreatment. By adding the non-migrating inorganic additive with lubrication to the surface heat seal layer, the bonding problem caused by clinging of a composite material surface and a die can be prevented, and at the same time, air can permeate into the space between the composite material and the die along the gaps between tiny protuberances, so that the whole composite material is easy to undergo cold punching molding and die release. The invention also provides a preparation method of the flexible composite film material.

Owner:FSPG HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com