Anti-mildew modified atmosphere packaging film for fruits and vegetables and preparation method for mildew-proof modified atmosphere packaging film

A technology for air-conditioning fresh-keeping and fresh-keeping film, which is applied in the fields of fruit and vegetable fresh-keeping, chemical instruments and methods, food preservation, etc., can solve the problems of easy particle agglomeration, high cost, large investment, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

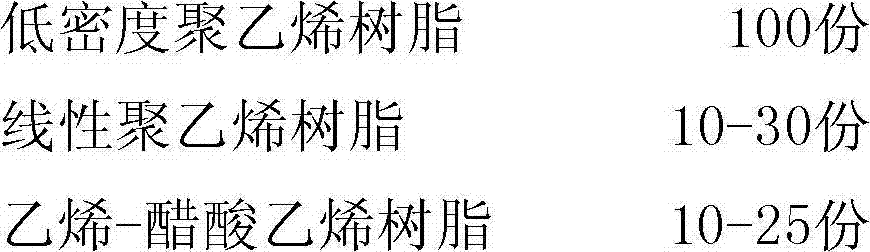

[0033] Weigh the raw materials according to the following ratio:

[0034]

[0035] The method for preparing fruit and vegetable anti-mold air-conditioned fresh-keeping film with the above-mentioned raw materials is as follows:

[0036] (1) Preparation of masterbatch:

[0037]

[0038] Add the above-mentioned raw materials to a high-speed mixer in proportion, first stir at a low speed of 60r / min for 2 minutes, and then stir at a high speed of 130r / min for 5 minutes to obtain a uniformly mixed mixture; After being weighed, it is added to a high-speed twin-screw exhaust type mixing and extruding granulator to be processed into strands, and the strands are made into master batches by a cold cutting machine;

[0039] (2) Preparation of modified atmosphere fresh-keeping film: mix the masterbatch and the remaining 3 resins uniformly, and enter the single screw extrusion blow molding machine with a diameter of 45mm and a rotation speed of 45r / min through the feeding system. Film is blown int...

Embodiment 2

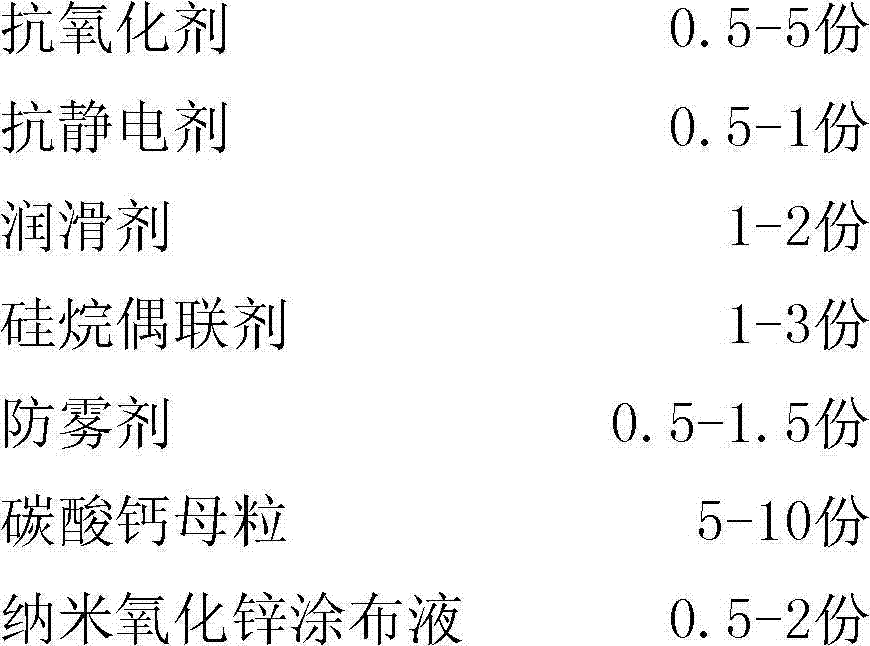

[0043] Weigh the raw materials according to the following ratio:

[0044]

[0045] The method for preparing fruit and vegetable anti-mold air-conditioned fresh-keeping film with the above-mentioned raw materials is as follows:

[0046] (1) Preparation of masterbatch:

[0047]

[0048] Add the above-mentioned raw materials to a high-speed mixer in proportion, first stir at a low speed of 80r / min for 2 minutes, and then stir at a high speed of 150r / min for 5 minutes to obtain a uniformly mixed mixture; After being weighed, it is added to a high-speed twin-screw exhaust type mixing and extruding granulator to be processed into strands, and the strands are made into master batches by a cold cutting machine;

[0049] (2) Preparation of modified atmosphere cling film: mix the masterbatch and the remaining 3 resins uniformly, and enter the single screw extrusion blow molding machine with a diameter of 65mm and a rotation speed of 45r / min through the feeding system. Film is blown into a film...

Embodiment 3

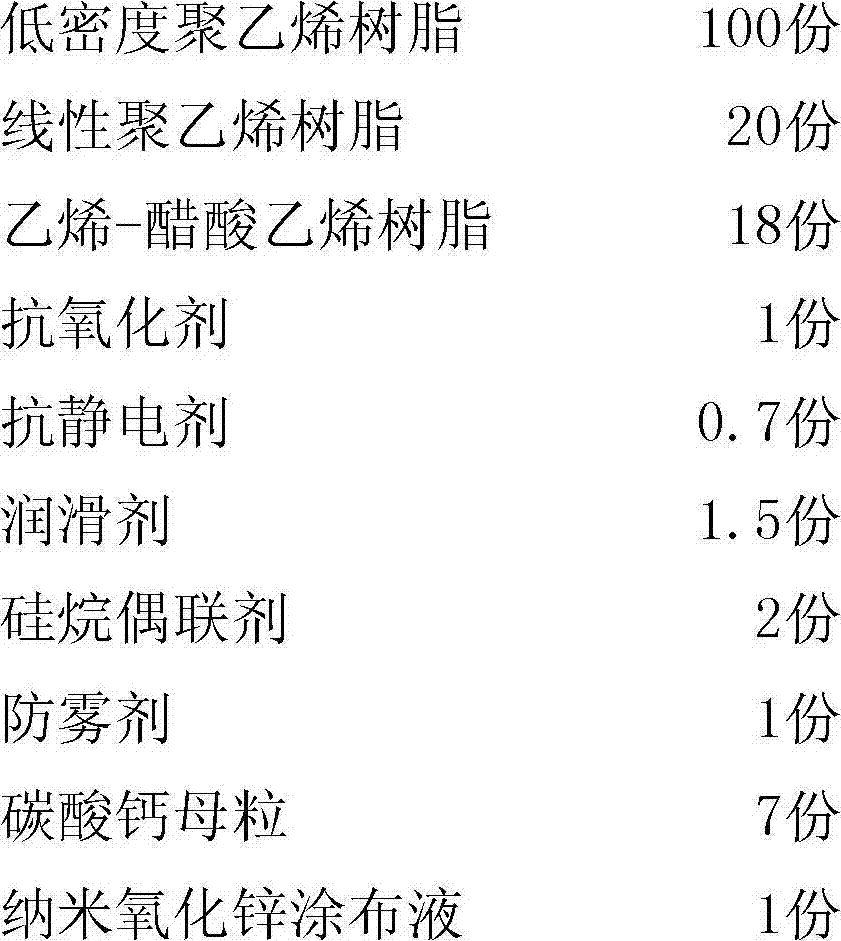

[0053] Weigh the raw materials according to the following ratio:

[0054]

[0055] The method for preparing fruit and vegetable anti-mold air-conditioned fresh-keeping film with the above-mentioned raw materials is as follows:

[0056] (1) Preparation of masterbatch:

[0057]

[0058]

[0059] Add the above-mentioned raw materials to a high-speed mixer in proportion, first stir at a low speed of 50r / min for 1 minute, and then stir at a high speed of 120r / min for 2 minutes to obtain a uniformly mixed mixture; After being weighed, it is added to a high-speed twin-screw exhaust type mixing and extruding granulator to be processed into strands, and the strands are made into master batches by a cold cutting machine;

[0060] (2) Preparation of modified atmosphere cling film: mix the masterbatch and the remaining 3 resins uniformly, and enter the single screw extrusion blow molding machine with a diameter of 65mm and a rotation speed of 45r / min through the feeding system. Film is blown int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com