Thermally bonded composite structure degradable luminal stent and its preparation method and application

A composite structure and thermal bonding technology, applied in stents, medical science, surgery, etc., can solve the problems of stent structural integrity damage, uneven material degradation, stent collapse, etc., and achieve poor mechanical properties and bond fastness Large, the effect of improving the radial support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a thermally bonded composite structure degradable luminal stent:

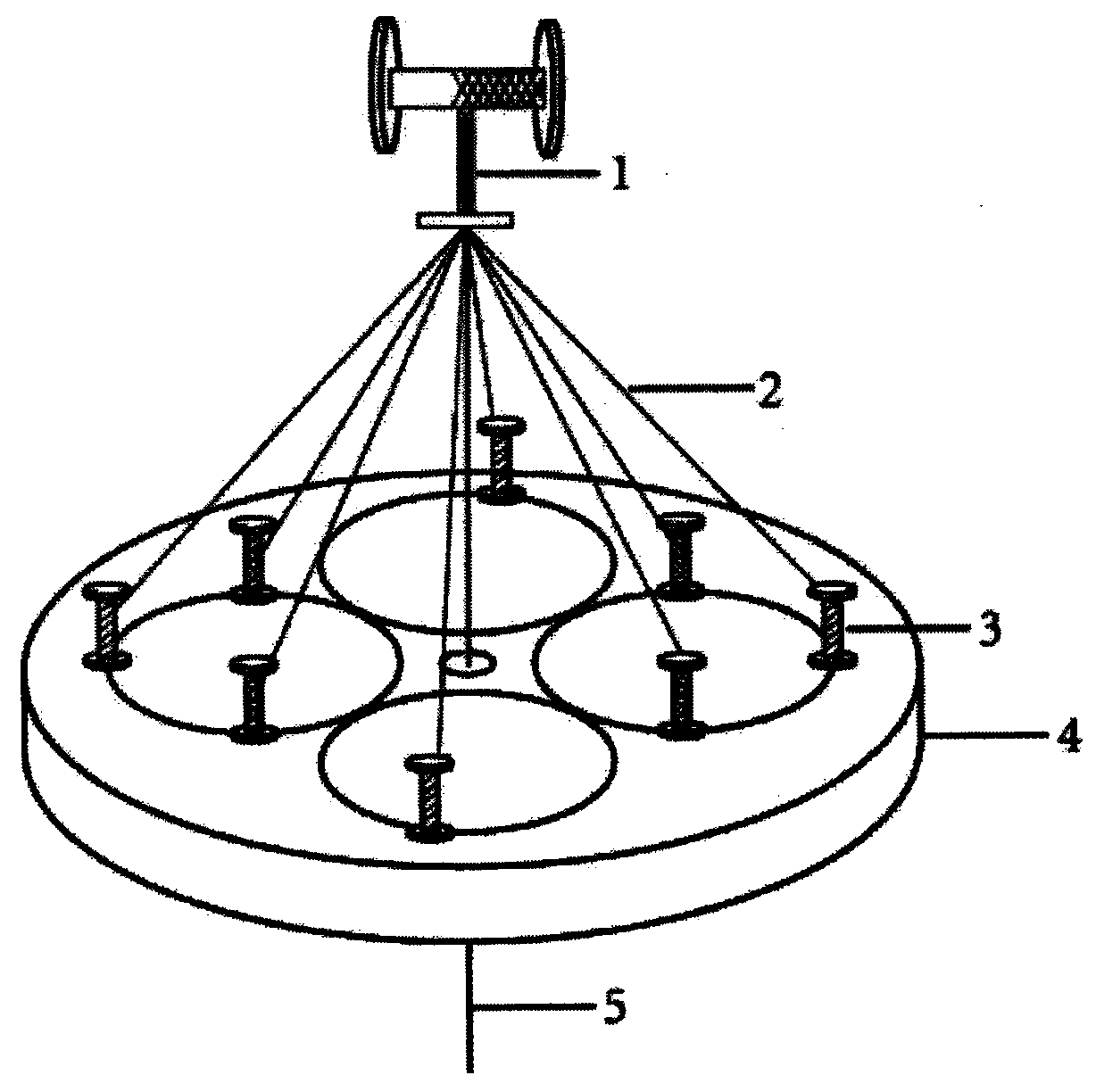

[0037] Step 1: If figure 1 As shown, polycaprolactone (PCL) is used as shell yarn 2 to make four sets of yarn tubes 3 and placed on the yarn carrier 4 of the knitting machine; the yarn carrier 4 drives the yarn tubes 3 carried by it to move to implement the knitting action . The bobbin 3 carrying the PCL moves in reverse around the polydioxanone (PPDO) core yarn 5 drawn out from the through hole in the center of the track disk of the knitting machine to form the knitting yarn 1 of the shell-core structure. The PCL shell yarn is a multifilament with a diameter of 0.10mm, and the PPDO core yarn is a monofilament with a diameter of 0.30mm, and the weaving method used is 8-spindle diamond weaving;

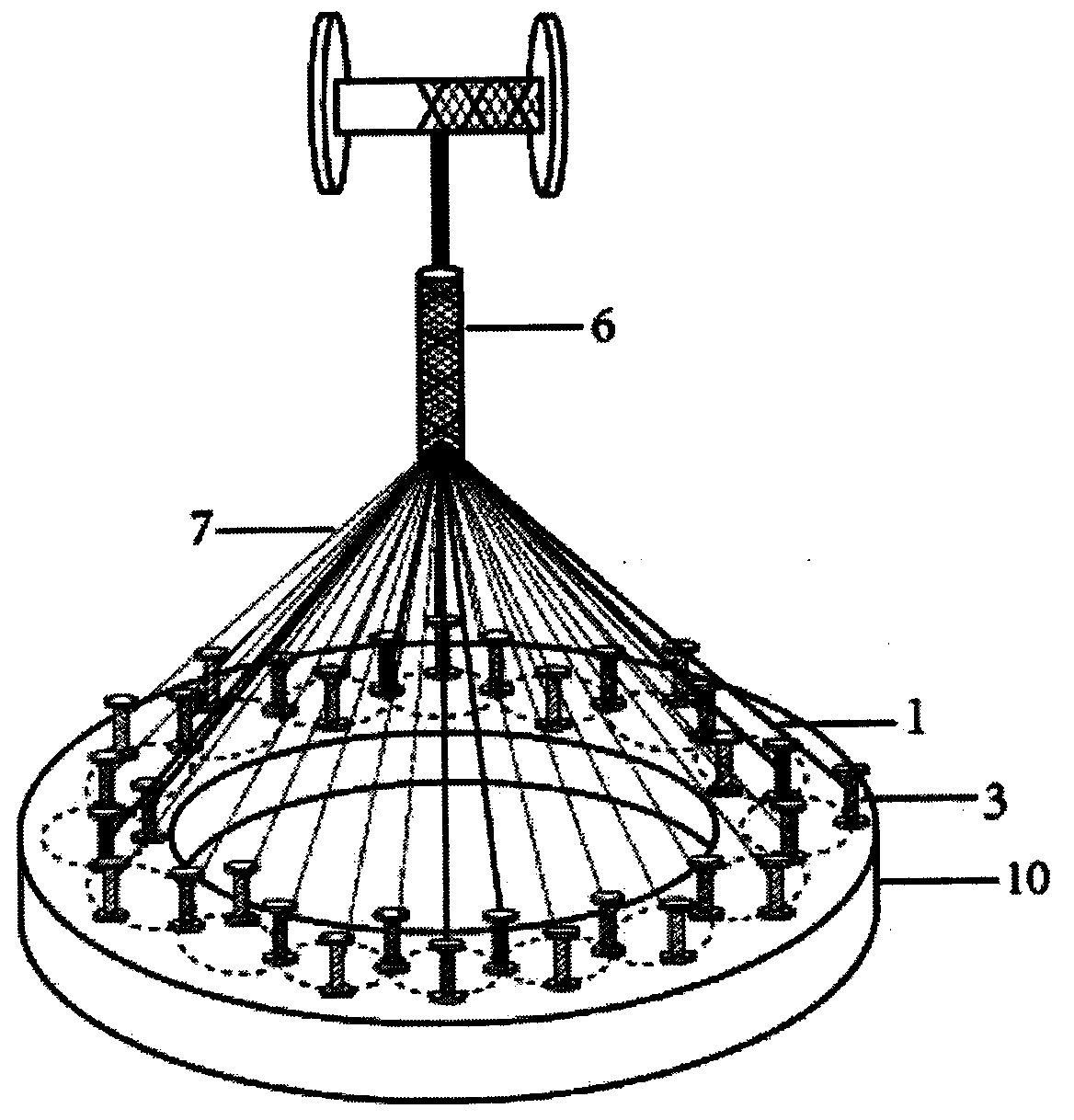

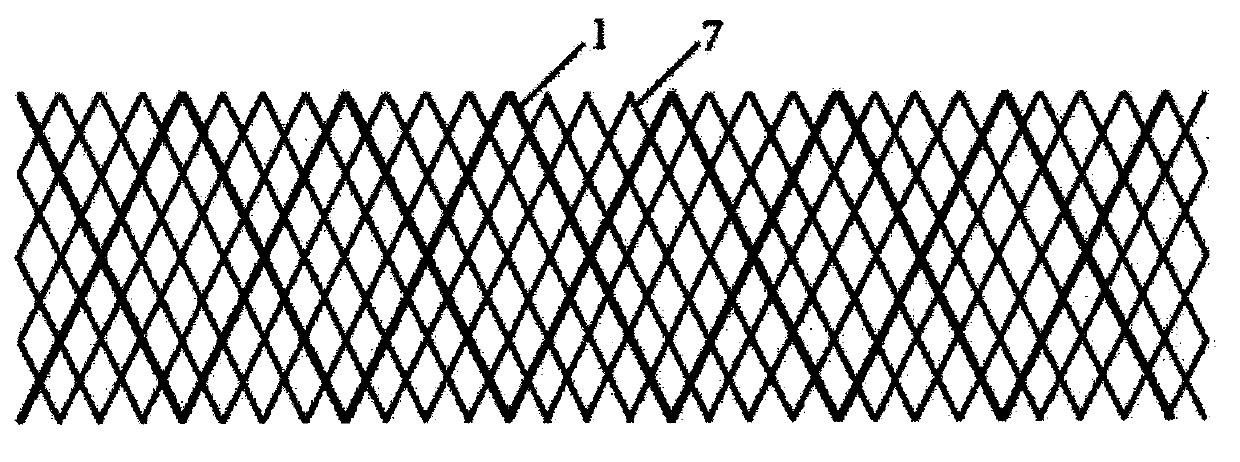

[0038] Step 2: If figure 2 As shown, four groups of weaving yarns 1 and 20 groups of single-component degradable polymer filaments 7 of PPDO monofilaments are respectively made into bob...

Embodiment 2

[0041] A method for preparing a thermally bonded composite structure degradable luminal stent:

[0042] Step 1: If figure 1 As shown, the left-handed polylactic acid (PLLA) is used as the sheath yarn 2 to make 8 sets of yarn bobbins 3 and placed on the yarn carrier 4 of the knitting machine; the yarn carrier 4 drives the yarn bobbins 3 it carries to carry out the knitting action. The bobbin 3 carrying PLLA moves in reverse around the polyglycolide (PGA) core yarn 5 drawn out from the central through hole of the orbital disk of the knitting machine, so that the twist direction of the shell yarn 2 is positively and antisymmetrically staggered with the core yarn 5 as the central axis , forming the braided yarn 1 of the shell-core structure, the PLLA shell yarn 2 is a multifilament with a diameter of 0.05mm, and the PGA core yarn 5 is a monofilament with a diameter of 0.25mm, and the weaving method used is regular weaving with 8 spindles;

[0043] Step 2: If figure 2 As shown, ...

Embodiment 3

[0046] A method for preparing a thermally bonded composite structure degradable luminal stent:

[0047] Step 1: If figure 1 As shown, polyglycolide-lactide (PLGA) is used as shell yarn 2 to make 4 sets of bobbins 3 and place them on the yarn carrier 4 of the knitting machine; the bobbin carried by it is driven by the yarn carrier 4 to move Perform knitting. The bobbins 3 carrying PLGA are divided into two groups on average, and they move in reverse around a group of polyglycolide (PGA) core yarns 5 drawn out from the central through hole of the orbital disk of the knitting machine, so that the twist direction of the shell yarn 2 is the same as that of the core. Yarn 5 is a braided yarn 1 that is symmetrically interlaced with the central axis to form a shell-core structure. The PLGA shell yarn 2 is a multifilament with a diameter of 0.08 mm, and the PGA core yarn 5 is a monofilament with a diameter of 0.20 mm. The weaving method used is 8 Spindle diamond weaving;

[0048] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com