Method for improving usability of biomedical degradable magnesium alloy cardiovascular stent

A biomedical and magnesium alloy technology, applied in medical science, surgery, etc., can solve the problems of large expansion and rebound of stents, excessive local stress, and large residual stress, so as to reduce expansion rebound, reduce residual stress, and reduce The effect of stress corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

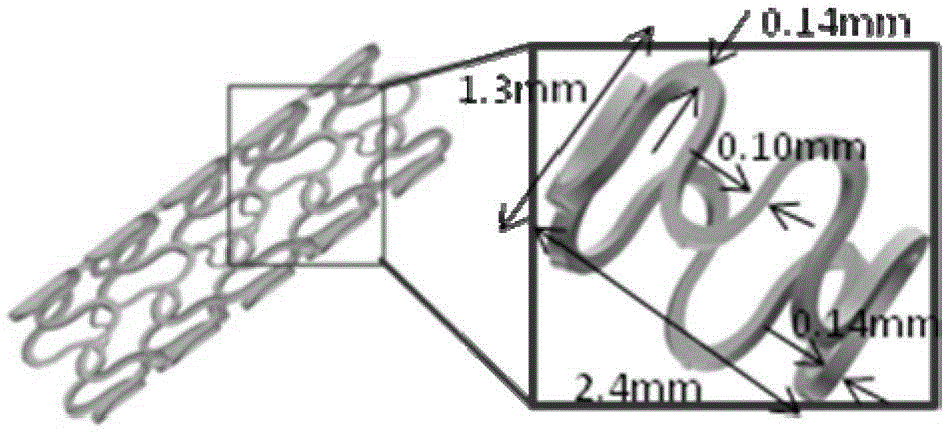

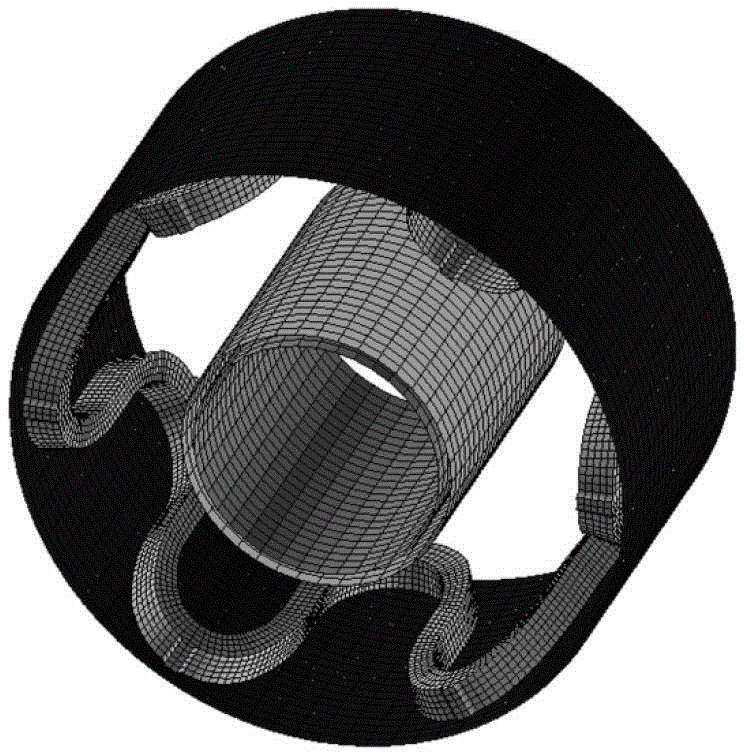

[0032] Bracket models such as figure 1 As shown, the stent crimping expansion model is as follows figure 2 As shown, the scaffold material used is the extruded AZ31 wrought magnesium alloy, and the mechanical properties of the material are shown in Table 1.

[0033] Table 1 Main mechanical property parameters of AZ31 wrought magnesium alloy in extruded state

[0034]

[0035] First, press the stent with an outer diameter of 2.4 mm and an inner diameter of 2.12 mm to an inner diameter of 1.1 mm, remove the stent, and anneal the stent in a vacuum or an inert protective atmosphere at a temperature of 250-400°C for 1-4 hours (this In the embodiment, the temperature is 300°C and the time is 4h); after the annealing treatment (stent surface treatment or drug-loaded coating can be applied at this time), the stent continues to be crimped to an inner diameter of 1.0mm (pre-crowned inner diameter), After removing the gripping force, expand the stent to an inner diameter of 3.0 mm ...

Embodiment 2

[0041] In this example, an extruded AZ31 degradable magnesium alloy stent was produced by laser cutting method. The diameter of the stent is 2.4mm, the wall thickness is 0.14mm, the width of the column and beam of the stent gradually transitions from 0.14mm to 0.10mm, the length of the ring of the stent unit is 1.3mm, and the connecting rib The length is 0.3mm, the total length of the stent is 4.5mm, and the stent passes through the electrodissection light.

[0042] Firstly, the stent is crimped to an inner diameter of 1.1mm by a stent crimping machine, the stent is taken out, annealed at 350°C for 3 hours, and the surface of the stent is treated. It is tightly attached to the balloon, and then inflated by the balloon, and the inner diameter of the expanded diameter reaches 3.0mm, and the stent mesh is complete without broken wires. Continue to expand the inner diameter of the stent to 3.18mm before the stent mesh breaks.

[0043] Then, take another stent and expand it to an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com