Biological degradable compound packaging film and packaging bag

A biodegradable material and packaging film technology, applied in the direction of bio-packaging, sustainable packaging, packaging, etc., can solve the problems of environmental pollution, non-degradable and uneconomical disposable plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

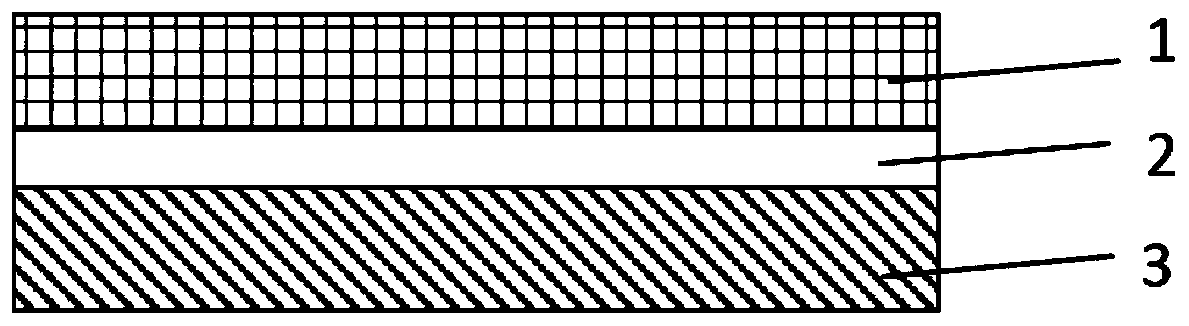

Embodiment 1

[0091] (1) Use a plastic extrusion blown film machine, using polybutylene succinate (BASF E 1200), antioxidant (1010), light stabilizer (508) and triglycidyl isocyanurate ( TGIC) mixture, the mixing ratio is: (98:0.01:0.02:1.97), the processing temperature is: extruder 140-190°C, head 160-190°C, extruded into a heat-sealing layer film with a thickness of 70μm .

[0092] (2) A polyvinyl alcohol coating solution was coated on the EDM-treated surface of the above-mentioned heat-sealing layer film using a coater.

[0093] (3) With a dry laminating machine, the coating surface of the above-mentioned coated heat-sealing layer film and the cellulose film with a thickness of 40 μm are bonded and compounded with an adhesive, and then put into a curing chamber for curing for 48 hours. The temperature of the curing chamber is 45 -55°C.

[0094] (4) Slitting the above-mentioned matured film, and adopting a back-sealing bag-making mechanism to make bags.

[0095] The total thickness of ...

Embodiment 2

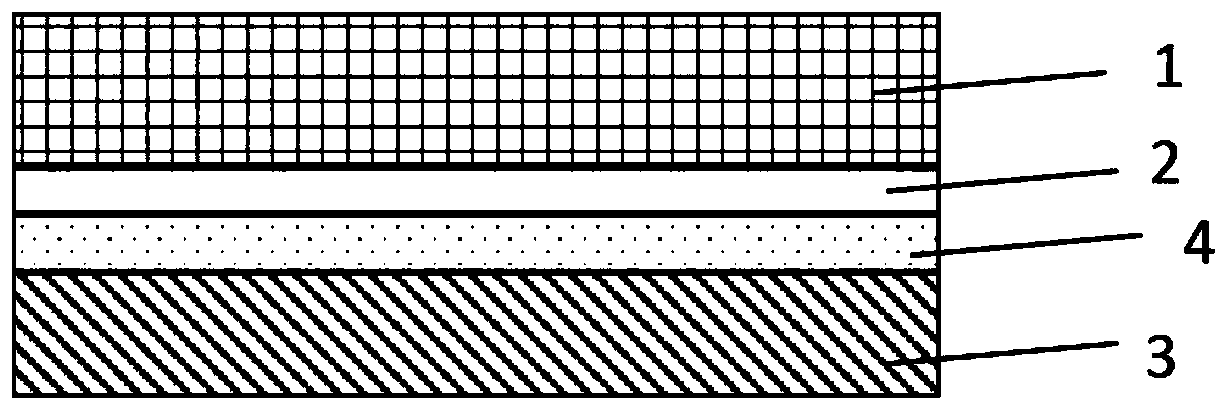

[0098] (1) Use a plastic extrusion casting machine, using polylactic acid (4032D), polycaprolactone (6800), polyethylene (2420) and antibacterial agent (SX25), the mixing ratio is: (50:40:9.99:0.01 ), the processing temperature is: extruder 120-200°C, head 180-200°C, extruded and processed into a heat-sealing layer film with a thickness of 110 μm.

[0099] (2) Using a compound machine, glue and compound the above-mentioned heat-sealing layer film and paper with a thickness of 60 μm with a polyvinyl alcohol water-based adhesive, and put them into a curing room for aging for 36 hours. The temperature of the curing room is 50°C.

[0100] (3) Use a coating machine to coat the outer paper surface of the above-mentioned cured film with polylactic acid varnish.

[0101] (4) Slitting the above-mentioned film coated with varnish, and using an eight-side-seal bag-making machine to make bags.

[0102] The total thickness of the film is 170μm, and the measured oxygen transmission rate of...

Embodiment 3

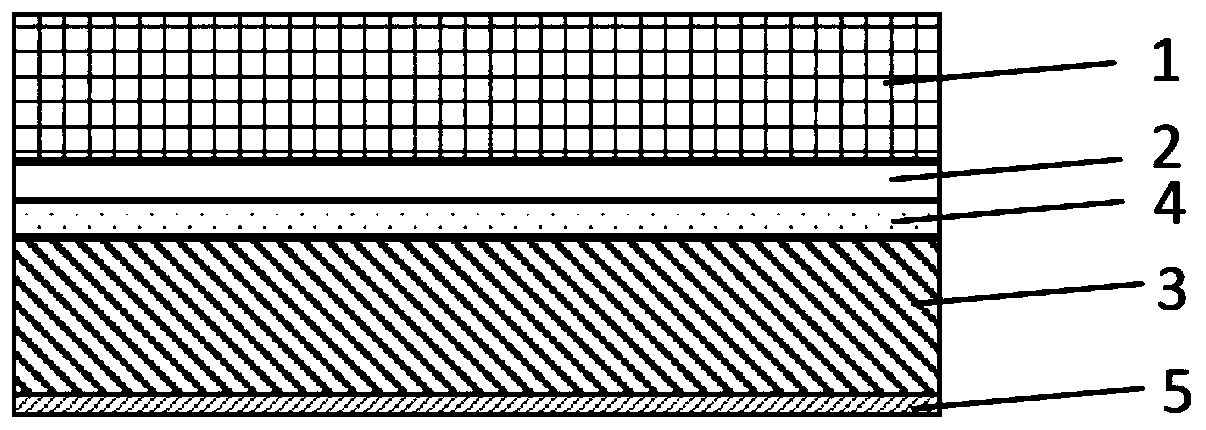

[0104] (1) Use a plastic extrusion blown film machine, using poly(butylene adipate terephthalate) (PBAT) (BASF C1200), maleic anhydride graft modified polyethylene (E226), titanium dioxide (T902) and antibacterial agent (SX25), the mixing ratio is: (95:3:0.2:1.8), the processing temperature is: extruder 140-190°C, head 160-190°C, extruded to a thickness of 50μm heat-sealing film.

[0105] (2) A polyvinyl alcohol coating solution was coated on the corona-treated surface of the above-mentioned heat-sealing layer film using a coater.

[0106] (3) Use a dry compound machine to bond the coated surface of the above-mentioned coated heat-sealing layer film to paper with a thickness of 30 μm, and then put it into the curing room for curing for 48 hours. The temperature in the curing room is 45-55 ℃.

[0107] (4) Slitting the above-mentioned matured film, and adopting a three-side sealing bag-making machine bag.

[0108] The total thickness of the film is: 80μm, and the measured oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com