Patents

Literature

58results about How to "Good resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starch-based composite and preparation method thereof

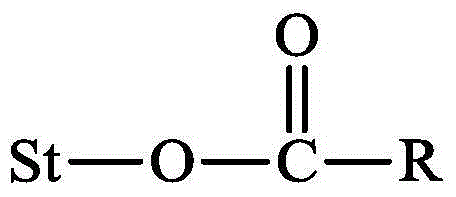

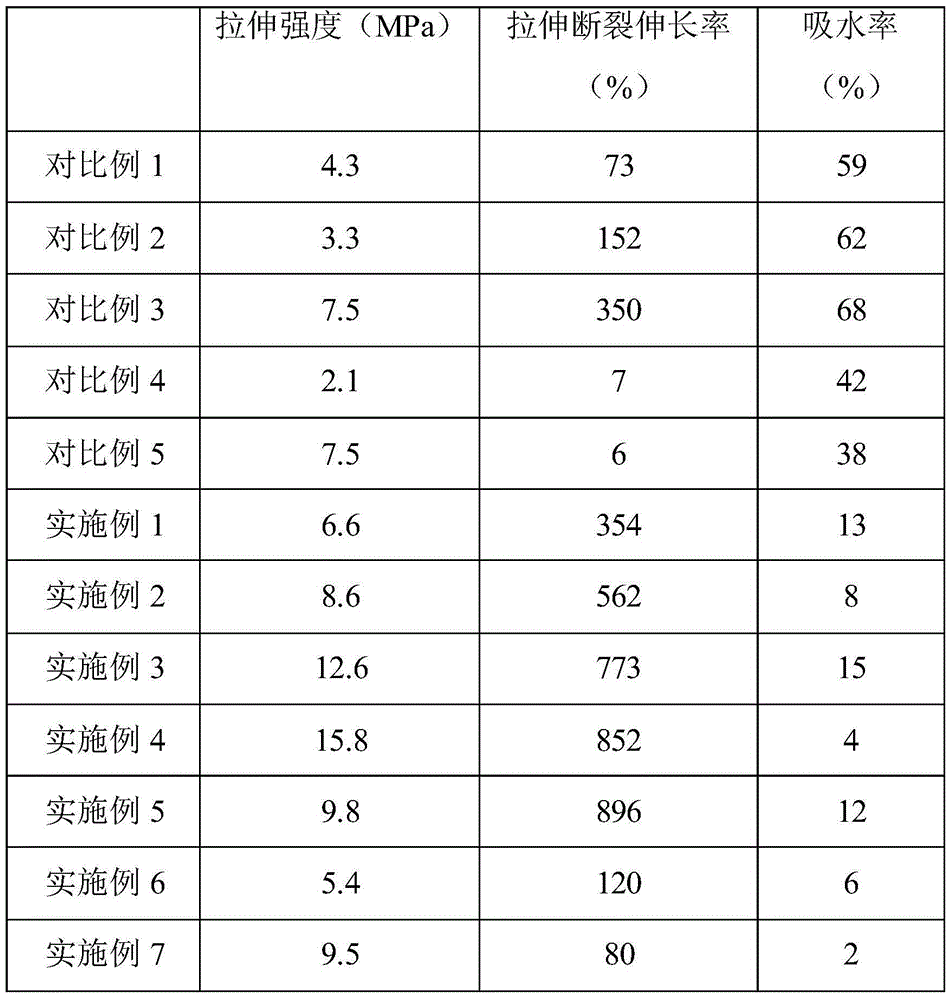

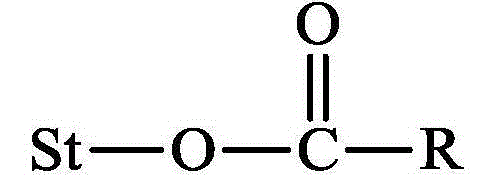

The invention discloses starch-based composite and a preparation method thereof. The composite is formed by, by weight, 100 parts of modified starch and 10-100 parts of polyester through melt blending. The structural formula of the modified starch is showed in the description and claims, wherein St refers to starch molecules and R group is alkyl group (CnH2n+1). Esterified starch comprises, by weight, 100 parts of natural starch, 0-200 parts of solvent, 10-50 parts of catalyst and 1-50 parts of modifier. The preparation method includes melt blending the components according to the weight to obtain the starch-based composite. The preparation method is high in efficiency, low in cost, simple in process, controllable in performance, and suitable for preparing thermoplastic materials with various performance requirements.

Owner:JIANGNAN UNIV

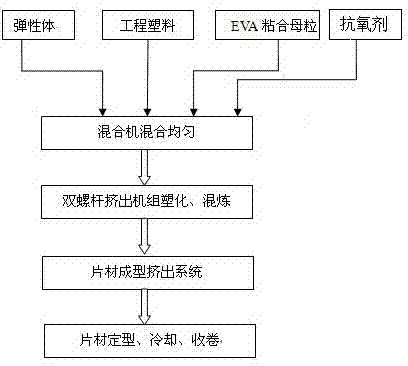

Shoe material hot-melt adhesive sheet and production process and equipment thereof

ActiveCN103613919AImprove physical performanceGood resilienceInsolesFlat articlesAntioxidantHot pressing

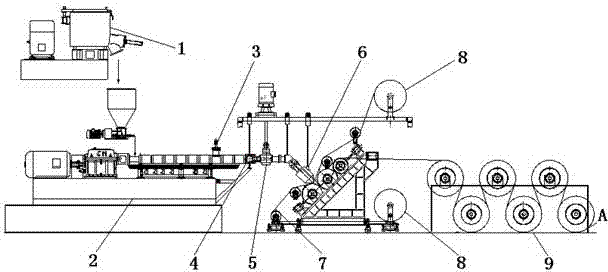

The invention discloses a shoe material hot-melt adhesive sheet. The shoe material hot-melt adhesive sheet comprises the following raw material components: 35-40% of elastomer, 45-50% of engineering plastic, 10-15% of EVA (ethylene vinyl acetate) binding masterbatch and 0.5-1.5% of antioxidant. A production process of the shoe material hot-melt adhesive sheet provided by the invention comprises the steps of mixing the elastomer, the EVA binder masterbatch, the engineering plastic and the antioxidant in a twin-screw extruder, pressurizing a melt by a melt pump, then enabling the melt to flow out of a T-shaped die head, hot-bonding double surfaces of polyester non-woven mesh fabric on the upper surface and lower surface of the melt of the sheet in a three-roller calendering machine, further calendering and shaping, cooling and shaping the sheet by a cooling roller cylinder after shaping, cutting edges, and then rolling or cutting according to a fixed size. The elastomer hot-melt adhesive sheet can be used for manufacturing finished products of shoe heads and back liners after being stamped by a mold, the shaped adhesive sheet finished products are placed into shoe inner liners and interlayers of shoe vamps for hot-pressing, binding and solidifying, and the production process flow is simplified and is suitable for mass production of an assembly line.

Owner:江苏诚盟装备股份有限公司

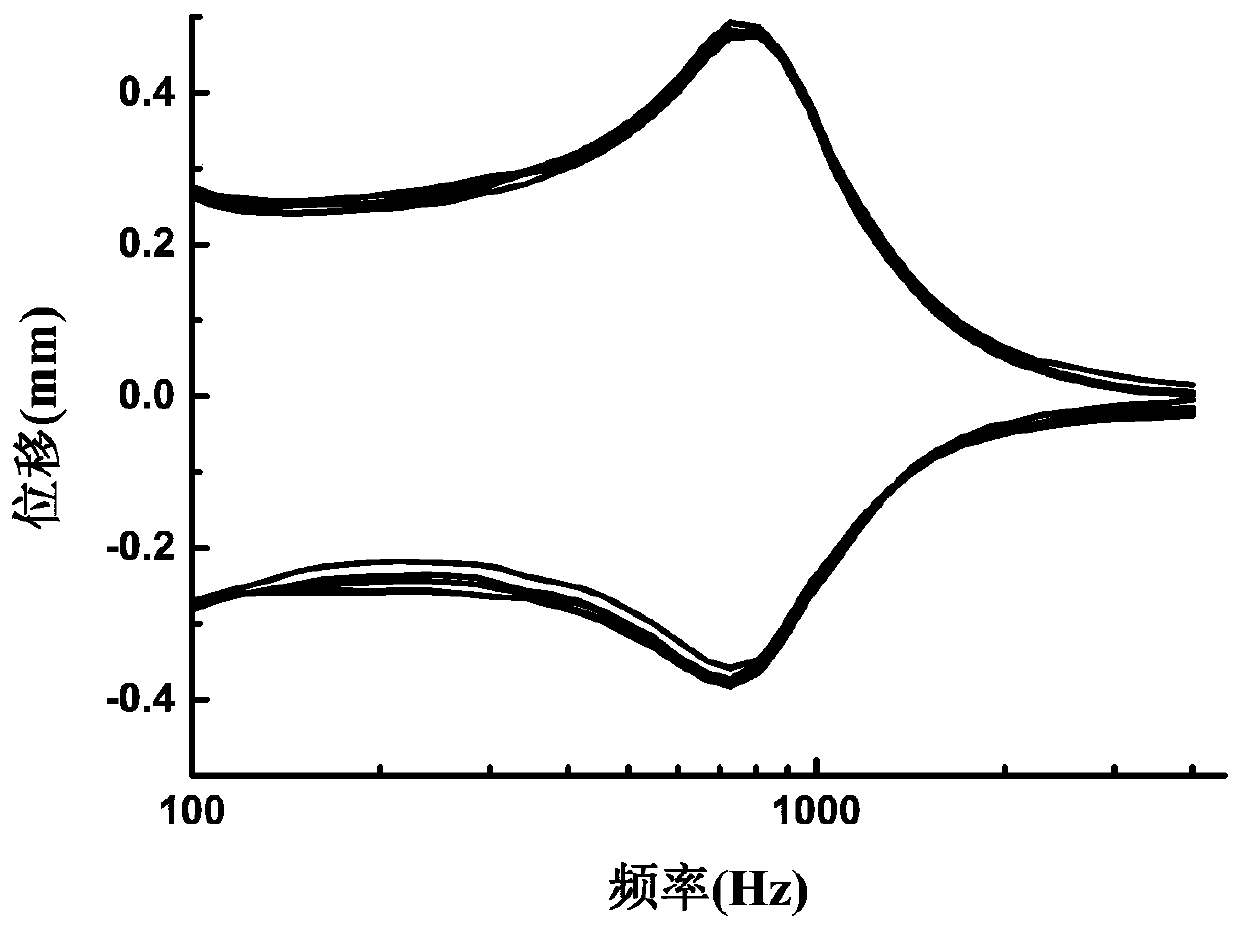

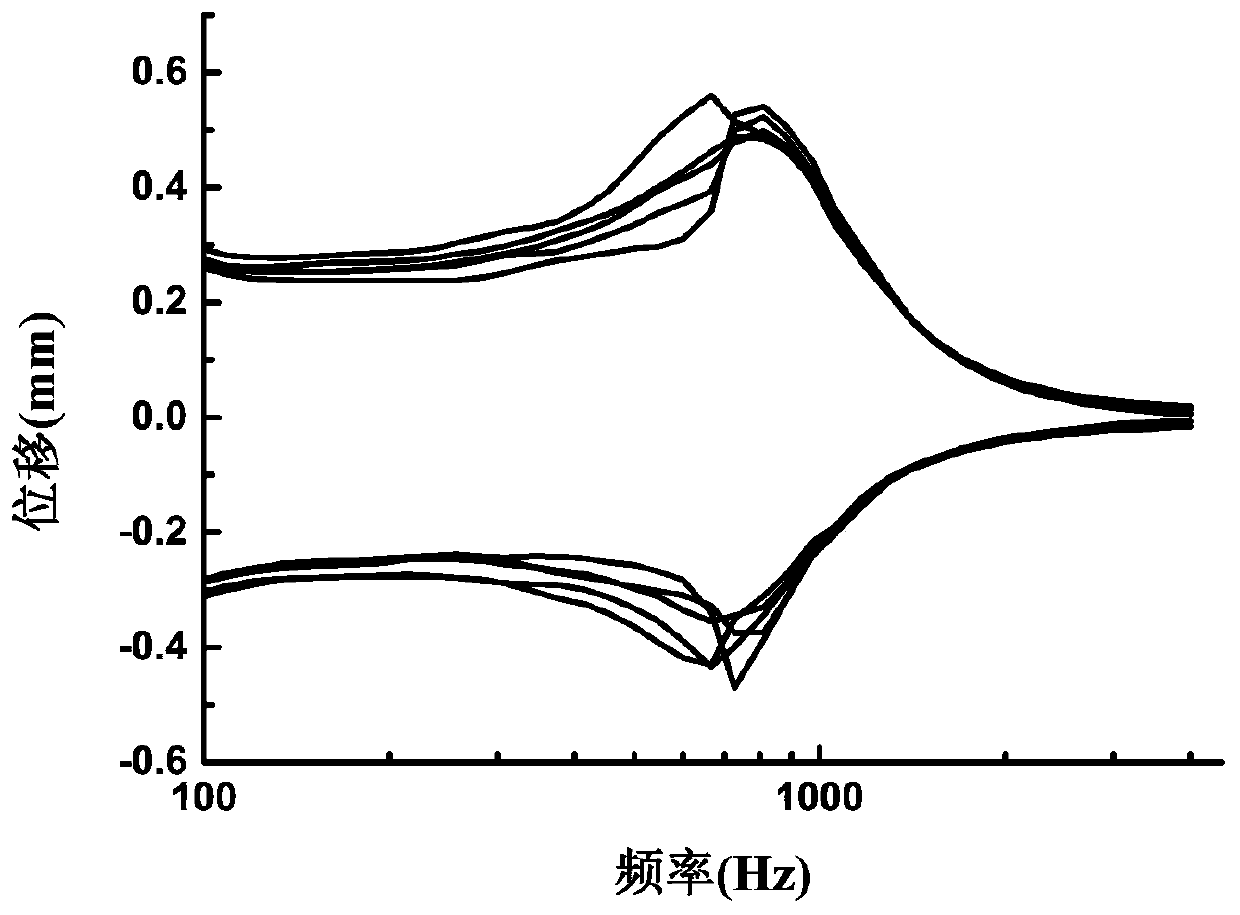

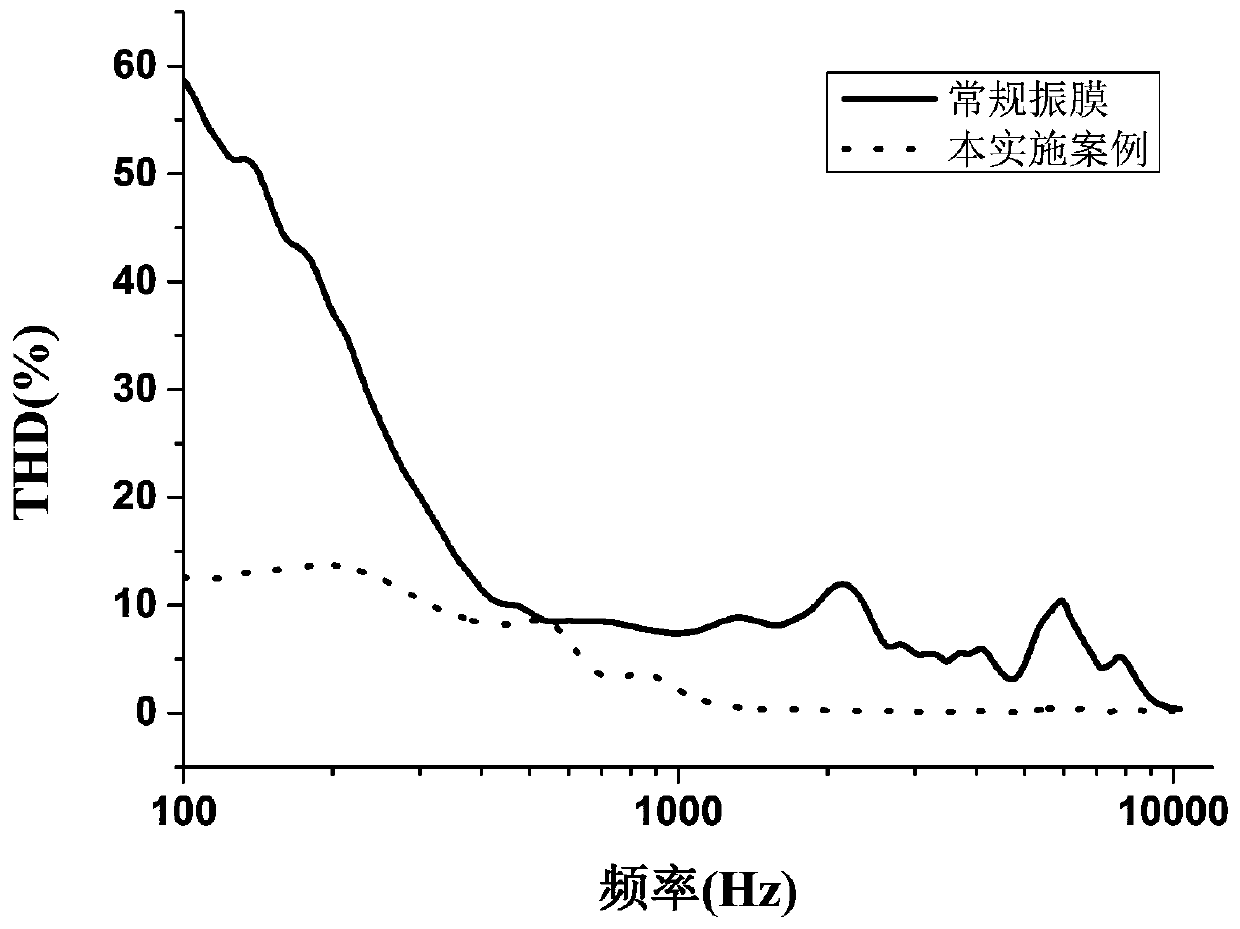

Vibrating diaphragm of sound production device and sound production device

ActiveCN110267167AGood resilienceIncrease elasticityPolymeric diaphragmsNon-planar diaphragms/conesChemistryPolymer

The invention discloses a vibrating diaphragm of a sound production device and the sound production device, the vibrating diaphragm comprises at least one elastomer layer, the elastomer layer is made of a hydrogenated butyronitrile polymer, the hydrogenated butyronitrile polymer comprises an acrylonitrile block, and the content range of the acrylonitrile block in the hydrogenated butyronitrile polymer is 10-70 wt%, the hydrogenated butyronitrile polymer is added with a vulcanizing agent, and the content of the vulcanizing agent is 1%-15% of the total amount of the hydrogenated butyronitrile polymer. The vibrating diaphragm is good in rebound resilience, can keep high elasticity in a low-temperature environment, and can work for a long time in a high-temperature environment, so that the sound production device can be applied to an extremely severe environment, and meanwhile, the acoustic performance of the sound production device is kept in a good state.

Owner:GOERTEK INC

High springback wet method polyurethane resin for superfine fiber chemical leather

The invention relates to high resilience wet urethane resin for superfine fiber synthetic leather, which is mainly composed of polyether or polyester polyol, chain extenders and diisocyanate, and the mol ratio of the components is 1 of the polyester polyol, 1.5 to 3 of the chain extenders and 2.5 to 4 of diisocyanate. The high resilience wet urethane resin has the advantages that base cloth impregnated by the urethane resin has good resilience, strong real leather feeling, subtle lines of the base cloth after being reduced in weight, split, expanded, enlarged in size, dried, oiled and kneaded, the lines of the shoes made of shoe synthetic leather (especially for sports shoes and casual shoes) prepared by the base cloth, which are generated during wearing, can automatically restore due to the good resilience, the gauffer of the shoe upper is small, therefore the shoes can have good shape, and the quality is lifted to a higher level.

Owner:HUAFON MICROFIBER SHANGHAI

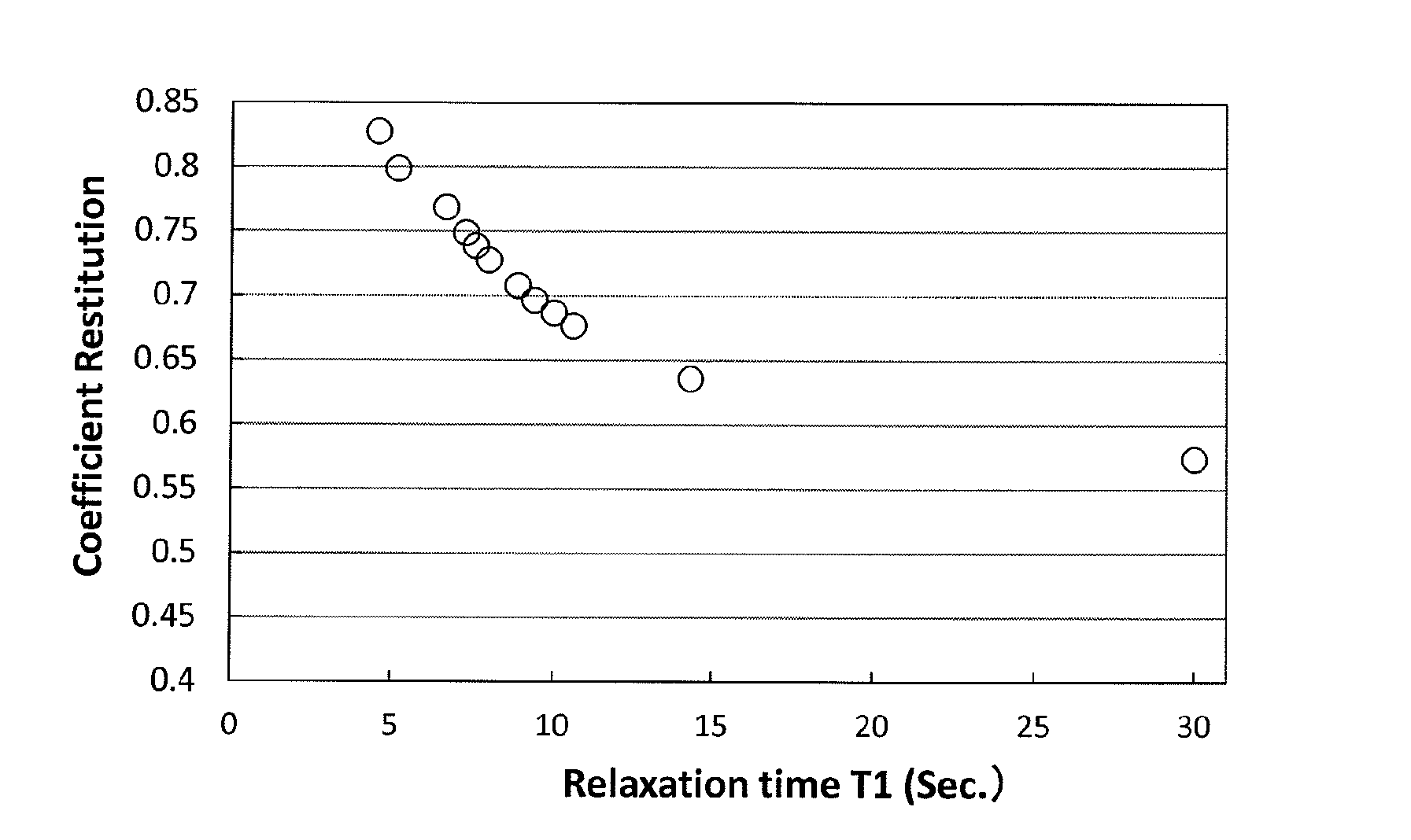

Golf ball polyurethane composition and golf ball

ActiveUS20130053184A1Good resilienceExcellent shot feeling and resilienceGolf ballsSolid ballsEngineeringCarbon atom

An object of the present invention is to provide a golf ball polyurethane composition excellent in resilience. Another object of the present invention is to provide a golf ball excellent in a shot feeling and resilience. The present invention provides a golf ball polyurethane composition comprising, as a resin component, a polyurethane elastomer including a polyisocyanate with one alicyclic hydrocarbon structure having 3 or more carbon atoms as a constituting component, and having a spin-lattice relaxation time (T1) of 13C nucleus of 8.9 seconds or less measured by a High resolution solid state nuclear magnetic resonance (NMR) method.

Owner:SUMITOMO RUBBER IND LTD

Cross-linked polypropylene microcellular foam material and production method thereof

The invention relates to a cross-linked polypropylene microcellular foam material. The cross-linked polypropylene microcellular foam material comprises the following raw materials in parts by weight: 99-100 parts of polypropylene resin, 0.1-2 parts of irradiation sensitizer and 0.1-3 parts of antioxidant and is produced through the following steps: mixing the raw materials; dipping a substrate with CO2 gas; foaming the substrate; performing irradiation treatment on the foam material; performing high-temperature annealing; detecting the foam material. The cross-linked polypropylene microcellular foam material has the advantages that the polypropylene resin, the irradiation sensitizer and the antioxidant are subjected to the steps of mixing the raw materials, dipping the substrate with CO2 gas, foaming the substrate, performing irradiation treatment on the foam material, performing high-temperature annealing and detecting the foam material in sequence to obtain a high-resilience polypropylene microcellular foam product with small cell size and high cell density; the cross-linked polypropylene microcellular foam material prepared by the method has the characteristics of good resilience, fine handfeel, no toxicity and no smell, and can be widely applied to the fields with high requirements on the resilience and the sanitation level of the foam material.

Owner:浙江新恒泰新材料股份有限公司

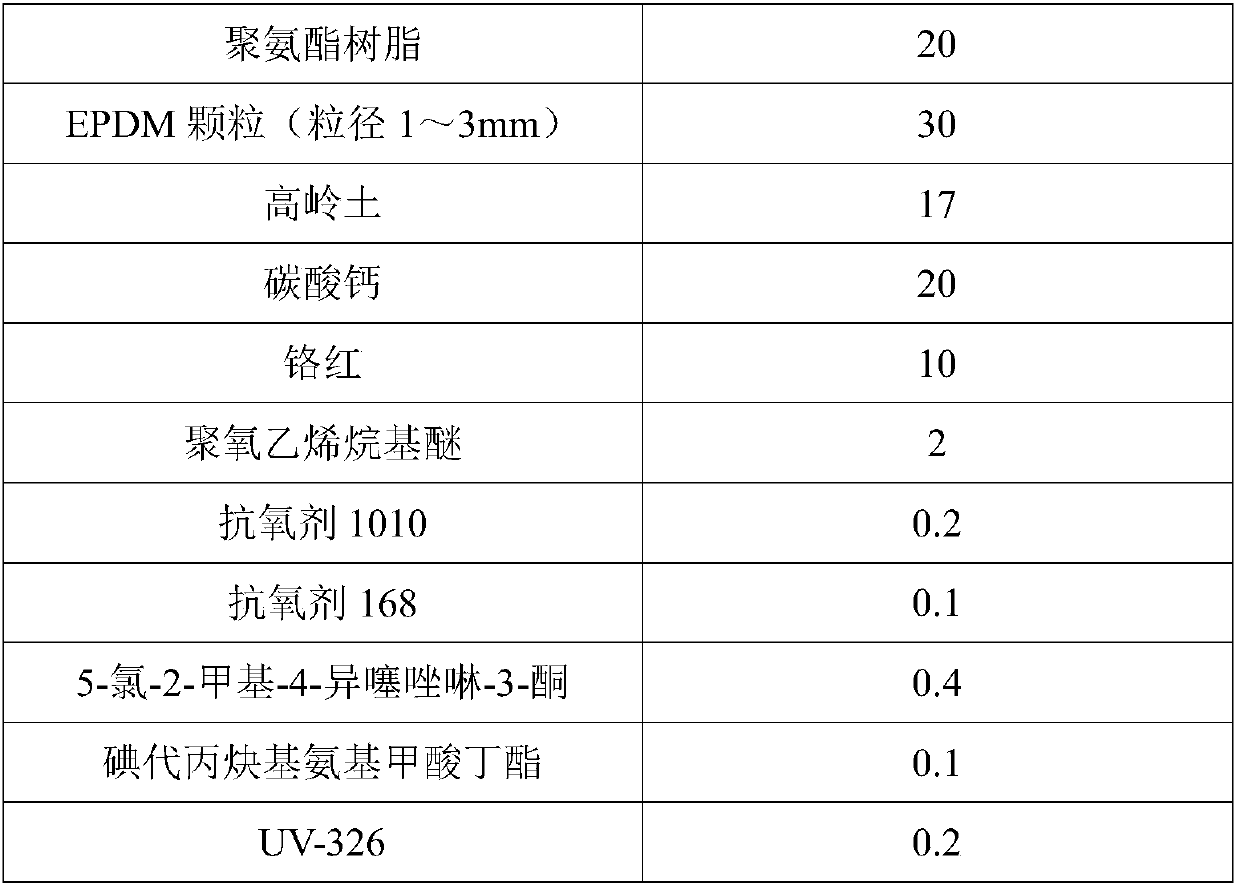

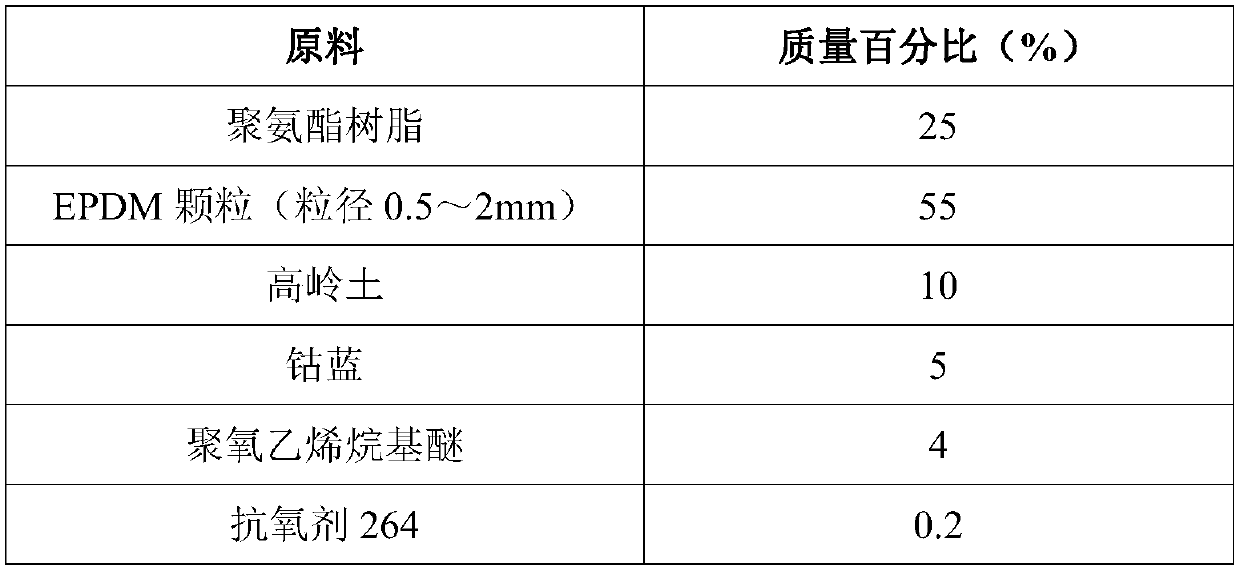

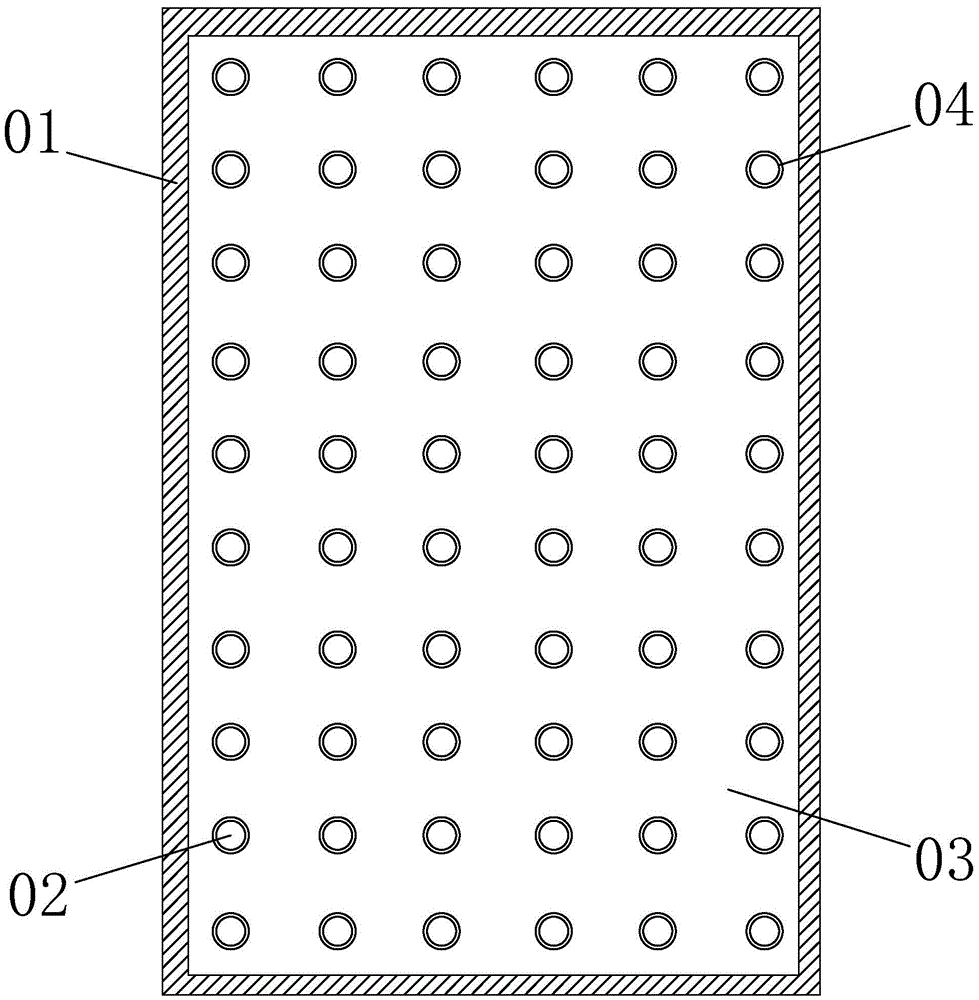

Permeable plastic runway and preparing method thereof

The invention discloses a permeable plastic runway and a preparing method thereof. The permeable plastic runway comprises a concrete foundation layer, a bonding layer, an elastic layer and a polyurethane surface layer from bottom to top in sequence; TPEE particles are added in the elastic layer. The preparing method comprises the steps of 1, pretreating the surface of the concrete foundation layer, 2, applying the bonding layer, 3, laying the elastic layer, and 4, laying the polyurethane surface layer. The permeable plastic runway has the advantages of being moderate in elasticity, good in rebound resilience, high in toughness and stretching strength, good in air permeability, high in stability and long in service life, the preparing technology is simple, and the permeable plastic runway can be widely applied to sites such as schools, gymnasiums, residential quarters and parks.

Owner:GUANGDONG BOSHENG NEW MATERIAL TECH CO LTD

High polymer elastomer material for balloon catheter type medical apparatuses and instruments and preparation method thereof

The invention discloses a high polymer elastomer material for balloon catheter type medical apparatuses and instruments and a preparation method thereof. The product comprises SEBS (Styrene Ethylene Butadiene) I, SEBS II, medical-grade polypropylene, a polyolefin elastomer, medical-grade extending oil, an antioxidant and other auxiliaries. The material disclosed by the invention has high tensile strength, excellent rebound resilience, high and low temperature resistance, high transparency, non-toxicity, excellent biocompatibility and blood compatibility and no anaphylactic reaction with a human body, and is easy to process. Besides, the production technology is advanced, the process is reasonable and simplified, the investment scale is small, the energy consumption is low, the production efficiency is high, and the preparation method is safe and environment-friendly.

Owner:NANTONG POLYMAX ELASTOMER TECH

Air interlayer quilt and manufacturing technology thereof

The invention discloses an air interlayer quilt and a manufacturing technology thereof. The air interlayer quilt is manufactured by wrapping quilt batt with a quilt cover; the quilt batt is composed of outer wrapping cotton layers, supporting columns and a seal film bag, the seal film bag is filled with air and wrapped by the outer wrapping cotton layers, the supporting columns penetrate through penetrating holes in the seal film bag, and the two ends of each supporting column are fixedly connected with the inner surfaces of the outer wrapping cotton layers respectively; each outer wrapping cotton layer is made of raw cotton, polynosic, viscose acetal fiber, silk, spandex fiber, rabbit hair, sheep wool and polyester fiber; each supporting column is made of raw cotton, polyvinyl alcohol fiber, polyvinyl chloride fiber, coconut fiber and polyacrylonitrile fiber. The air interlayer quilt is low in weight, and the seal film bag in the quilt batt effectively prevents the quilt from deforming; the seal film bag is filled with the air, so that the quilt is high in rebound resilience, and due to the water resistance of the seal film bag, the quilt batt has good dampproof performance.

Owner:SHANDONG JINCHENG IND & TRADE

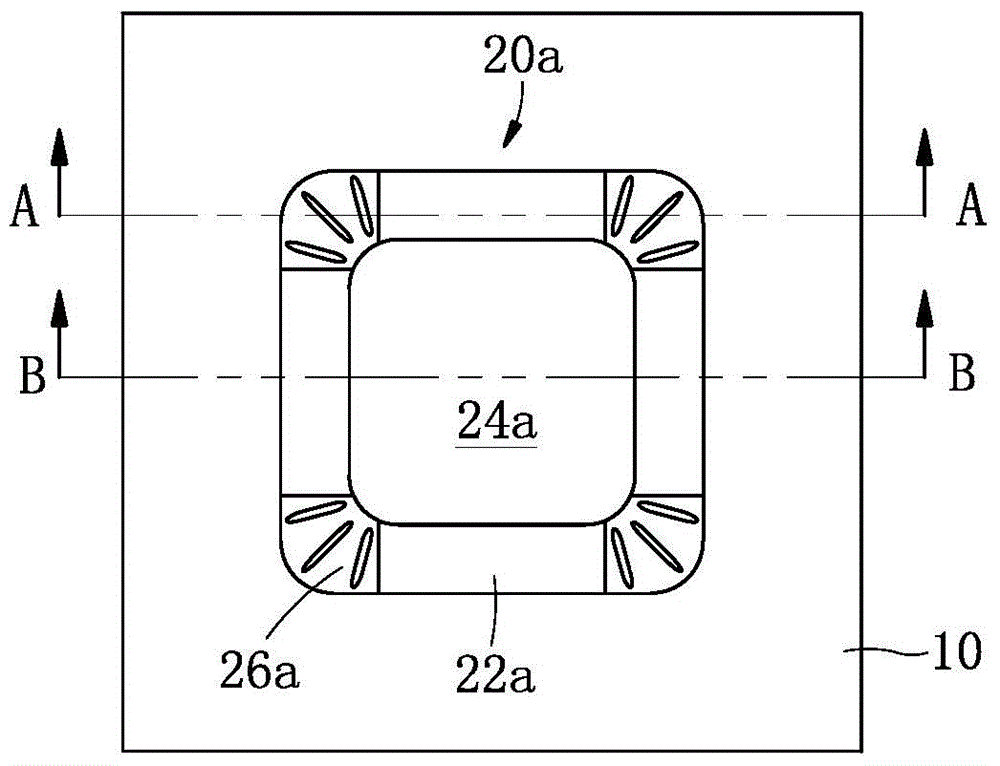

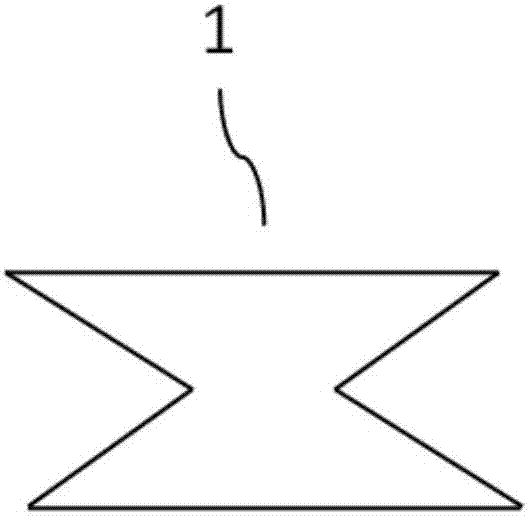

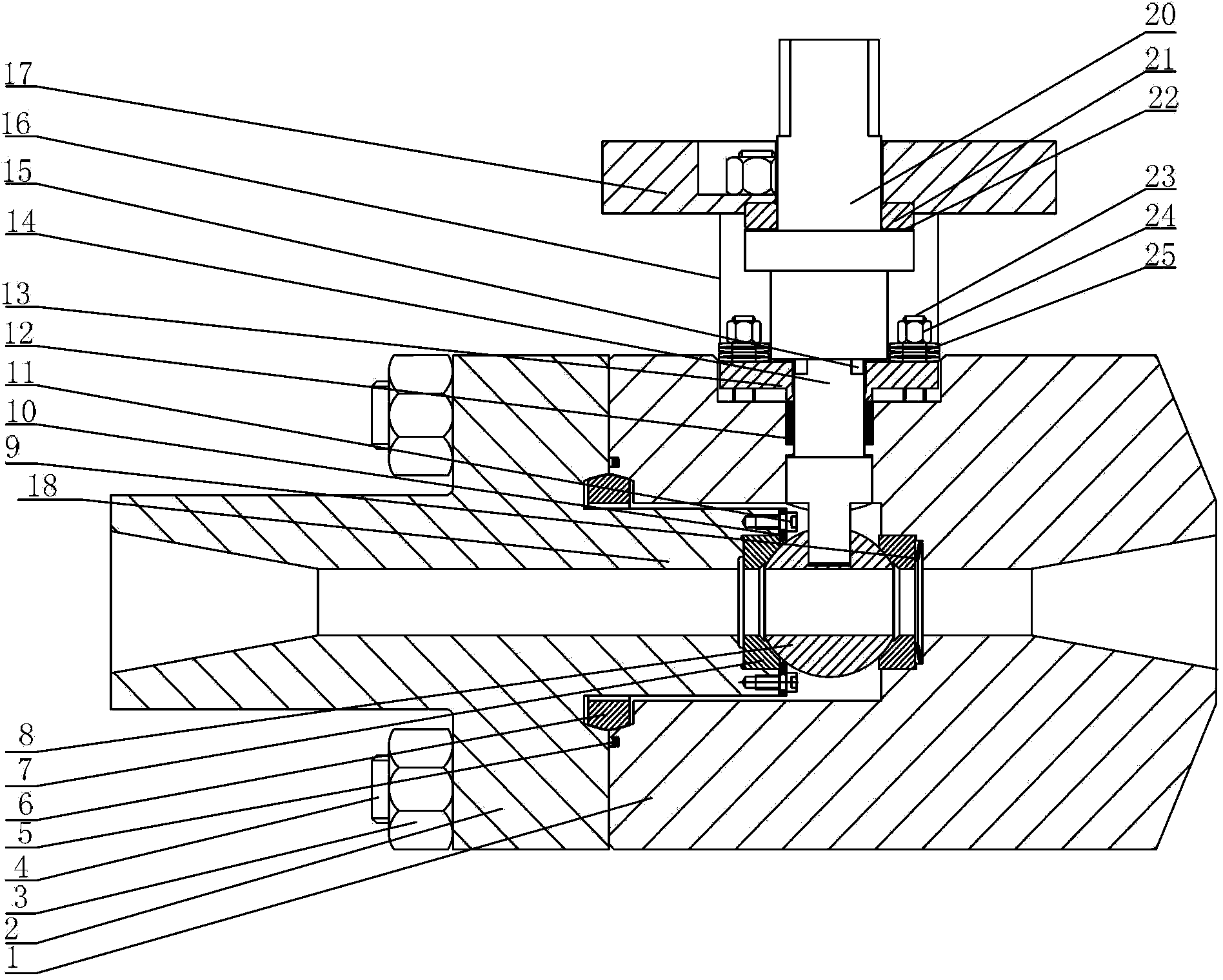

Vibrating diaphragm forming mold base and vibrating diaphragm forming mold including the mold base

The invention discloses a vibrating diaphragm forming mold base and a vibrating diaphragm forming mold including the mold base, and relates to the technical field of electric-acoustic product machining molds. The mold base comprises a vibrating diaphragm forming base which is the same as a vibrating diaphragm in structure, pedestals are arranged around the vibrating diaphragm forming base, and the vibrating diaphragm forming base and the pedestals are combined together. The vibrating diaphragm forming base comprises straight side parts, corner parts and a globe roof part which are combined together. The straight side parts, the corner parts and the globe roof part are made of at least two metal materials. The vibrating diaphragm forming mold base is made of different materials, the limitations of a single material on the aspects of thermal expansion and thermal transmission are removed, and the produced vibrating diaphragm is clear in outline, good in rebound resilience, not prone to wrinkling, excellent in acoustic performance and high in stability.

Owner:GOERTEK INC

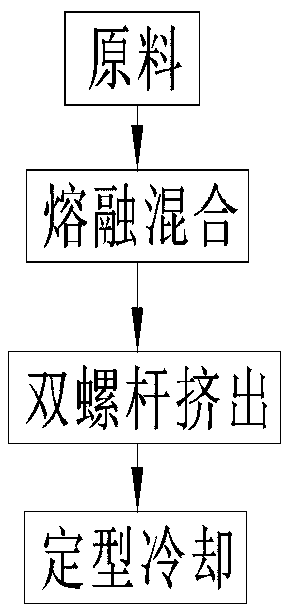

PBT (polybutylene terephthalate) modified fiber and production method of PBT modified fiber

ActiveCN102605464ASoft touchGood resilienceFilament forming substance formingFilament/thread formingChemistryPolyethylene terephthalate glycol

The invention relates to a PBT (polybutylene terephthalate) modified fiber, which comprises the following components in percentage by weight: 40-50% of PET (polyethylene terephthalate), 0-50% of ECDP (easy cationic dyeable poly(ethylene terephthalate)) and 10-60% of PBT. The invention also relates to a production method of the PBT modified fiber, which comprises the following steps: mixing and drying the above components, wherein the moisture content of each component must be less than 50ppm; fusing the dried components so as to prepare a melt, and extruding the fused raw materials into filaments under the action of a screw extruder; bundling the filaments through a winding machine and performing back draft in the condition of keeping the idle speed of the bundling; heating filament tows through a drafting bath and a steam heating box, and mechanically crimping yarn sheets through a crimping machine; realizing a semi-relaxed state by a relaxation heat-setting machine, ensuring a own modified state and eliminating stress; and cutting off the yarn sheets through a cutting machine as the requirements of customers, delivering to a packaging machine through a blower and then packaging into a finished product. The fiber made by the method of the invention has the characteristics of being soft in handfeel, good in resilience force, easy to dye under the normal temperature and pressure, good in color firmness, strong in fouling resistance and so on.

Owner:NANTONG HONGXIN FIBER

High strength hydro-expansive rubber

The invention relates to high-strength water swelling rubber, which is characterized by comprising the following compositions: neoprene, caoutchouc, octadecyl acid, N-phenyl-N'-isopropyl para-phenylene diamine, thiuram, benzothiazole disulfide, pottery clay, calcium carbonate, pigment, polyamine ester, polyether diols, zinc oxide and sulfur. The technique for preparing the high-strength water swelling rubber is as follows: the neoprene and the caoutchouc are respectively plasticated, and preformed polymer and curing agent are fully stirred until foaming; raw materials are poured into a roll mill for rolling until sizing materials wrap the roll without viscous fluid on the surface, and fine stuff and accelerant are added for roll release according to the prior technological requirements; and finally sulfur is added into rolled rubber for sulfurization. The high-strength water swelling rubber has the advantages of high tensile strength, difficulty in stiffening and good swelling effect.

Owner:SHANGHAI JIEQIN RUBBER & PLASTIC

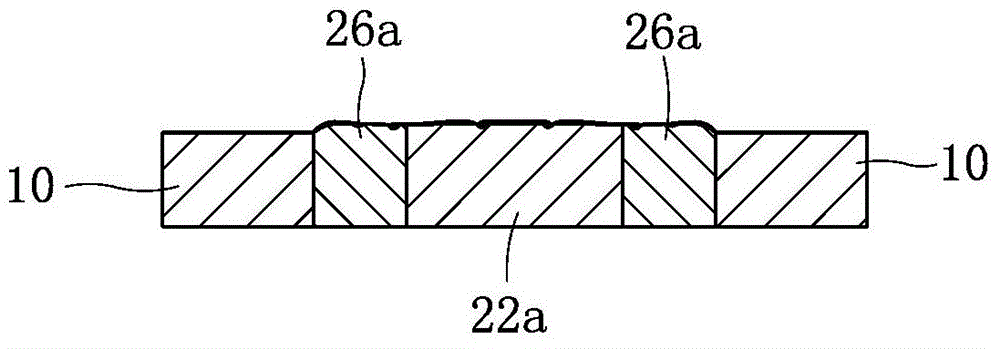

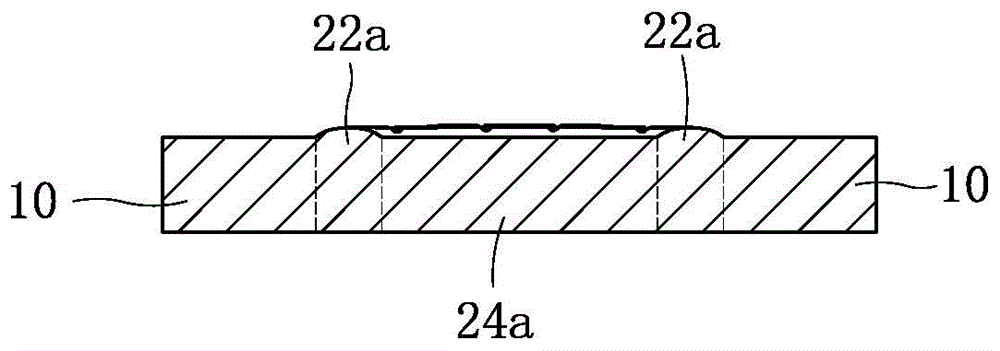

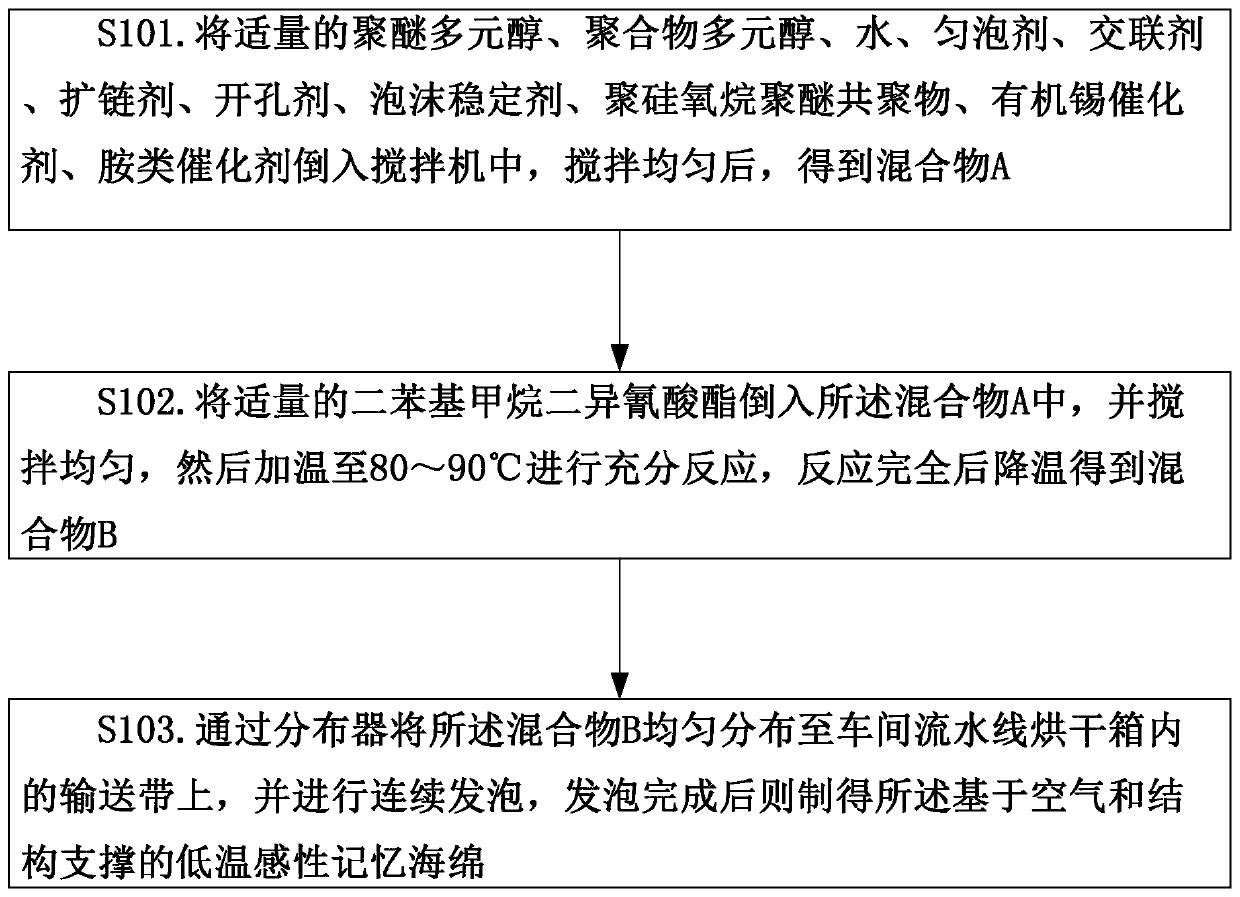

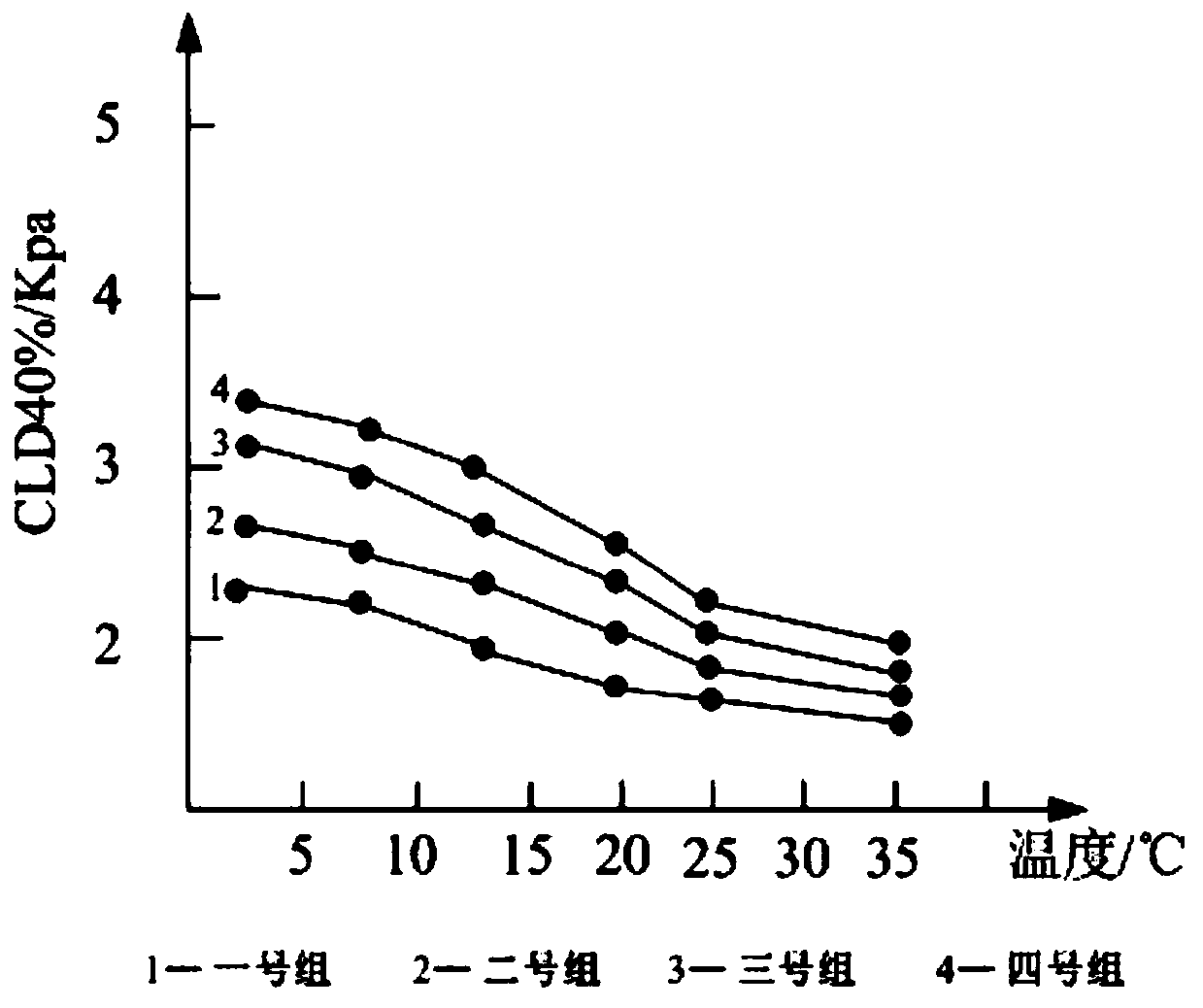

Low-temperature sensitive memory sponge based on air and structural support and preparation method thereof

The invention discloses a low-temperature sensitive memory sponge based on air and structural support and a preparation method thereof, wherein the low-temperature sensitive memory sponge based on airand structural support is made of the following raw materials in parts by weight: 50-90 parts of polyether polyol, 10-40 parts of polymer polyol, 35-50 parts of diphenylmethane diisocyanate, 10-20 parts of water, 0.5-3 parts of foam homogenizer, 0.2-5 parts of crosslinking agent, 0.5-4.5 parts of chain extender, 3-6 parts of opening agent, 1-3 parts of foam stabilizer, 1-3 parts of polysiloxane polyether copolymer, 0.3-1.3 parts of organotin catalyst and 0.5-1.5 parts of amine catalyst. The invention has the advantage that it still has better resilience at low temperature.

Owner:成都世友海绵制品有限公司

Production method of suede elastic fabric

The invention discloses a production method of suede elastic fabric. The method comprises steps such as preparation of fabric raw material fibers, spinning and weaving, after-finishing and the like. According to the method, core-spun yarn made of elastic fiber core filaments and sorona staple fiber surface yarn is adopted as half of weft, characteristics of good rebound resilience, permanent pollution resistance, softness and good skin friendliness, static electricity resistance and pilling resistance of sorona staple fibers are utilized, the obtained fabric has a uniform and fluffy suede surface and an obvious drooping property, and compared with suede elastic fabric in the prior art, the fabric obtained with the method has the advantages that the hand feeling, the style and the wearability are further improved.

Owner:JIANGSU SUNSHINE GRP CO LTD

Icy elastic fabric

InactiveCN102922831AGood elasticityGood resilienceRubber layered productsProtective garmentEngineeringSurface layer

The invention discloses an icy elastic fabric which comprises a surface layer and a bottom layer, wherein both the surface layer and the bottom layer are made of ice silk; an elastic layer is arranged between the surface layer and the bottom layer; the surface layer and the bottom layer are stitched with the elastic layer through a thread; and the stretching degree of the elastic layer is 75 percent. According to the invention, clothes made of the icy elastic fabric are suitable to be worn in summer and have cooling effects; moreover, the icy elastic fabric has an excellent elastic effect, fine resilience force and low possibility of deformation; and the shape of the clothes made of the icy elastic fabric can be kept.

Owner:WUJIANG DONGXU TEXTILE CLOTH FIRM

Sponge for automobile glove box

The invention relates to sponge for an automobile glove box, and belongs to the technical field of automobile accessories. The sponge for the automobile glove box is prepared from, by weight, 150-180 parts of polyether polyol, 100-120 parts of toluene diisocynate, 8-30 parts of a foaming agent, 5-10 parts of a foam stabilizer, 2-4 parts of a catalyst, 1-3 parts of a chain extender, 1-3 parts of a cross-linking agent and 20-50 parts of a fire retardant. The sponge for the automobile glove box has the good elastic resilience and buffering effect. If the body touches the glove box, the buffering effect can be achieved, injuries are reduced, the good dust isolation and fire retardant performance is achieved, and objects inside the glove box can be better protected; if the glove box has the refrigeration performance, the effects of heat isolation and energy loss reduction can be achieved.

Owner:WUHU XINYUAN SPONGE

Sports shoe sole material

The invention discloses a sports shoe sole material. The elasticity of a sports shoe sole prepared by virtue of the technical scheme of the invention is 71 percent, the heat shrinkage rate is 1.2 percent, the compression deformation rate is 30 percent, the hardness is 50 degrees, and the density is 0.18 g / cm3. The sports shoe sole material formula consists of the following components by weight percent: 40 to 50 percent of vinyl-vinyl acetate copolymer (the content of VA is 26 percent); 15 to 25 percent of vinyl-vinyl acetate copolymer (the content of VA is 40 percent), 20 to 30 percent of vinyl-octylene copolymer, 10 to 15 percent of EPDM, 1 to 1.5 percent of transparent zinc oxide, 0.4 to 0.6 percent of stearic acid, 3.5 to 4.5 percent of white foaming agent, and 0.4 to 0.6 percent of cross-linking agent.

Owner:QIAODAN SPORTS CO LTD

Mercerized wool Lisa fiber quilt

InactiveCN102293551AGood moisture absorption and warmth retentionGood resilienceBed-coversWool fiberSleep quality

The invention discloses a mercerized wool Lisai fiber quilt, the filling of the quilt core is prepared by blending mercerized wool and Lisai fiber in different proportions. The mercerized wool Lisa fiber of the present invention solves the shortcomings of pure wool being easy to be eaten by moths and hardens, fully develops the characteristics of mercerized wool and Lisa fiber, and combines the two fibers skillfully, so that the advantages of the two kinds of raw materials complement each other. The obtained quilt not only has good moisture absorption and warmth retention, but also has good resilience, which makes the human body feel more comfortable and improves the quality of sleep. At the same time, the mercerized wool has a natural antibacterial and anti-mite function, which is beneficial to health.

Owner:VIOLET HOME TEXTILE TECH

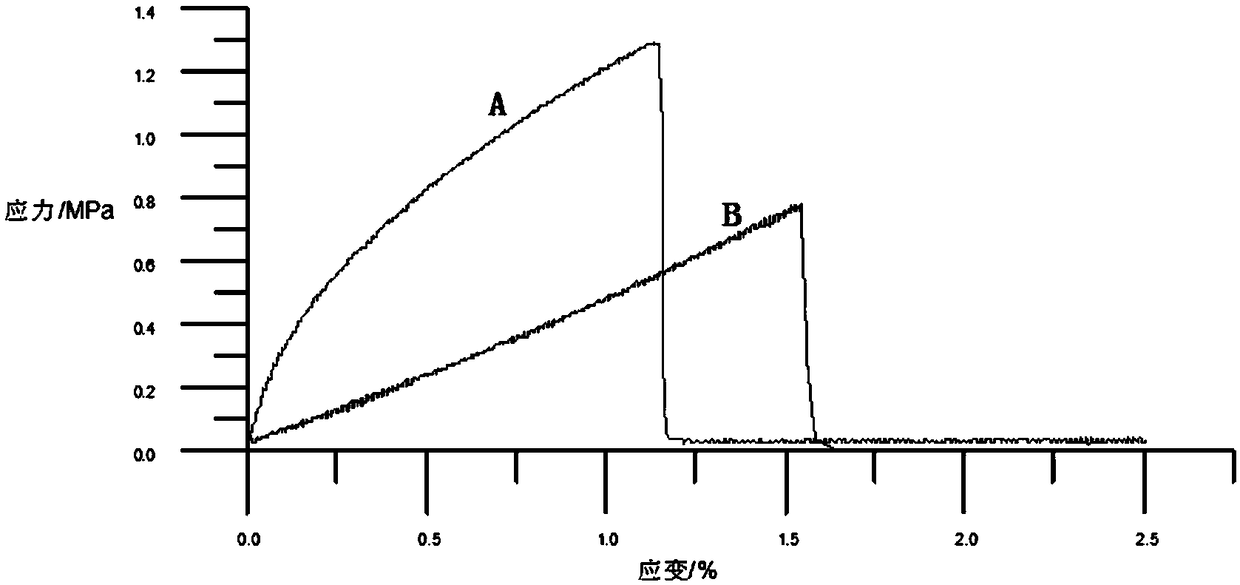

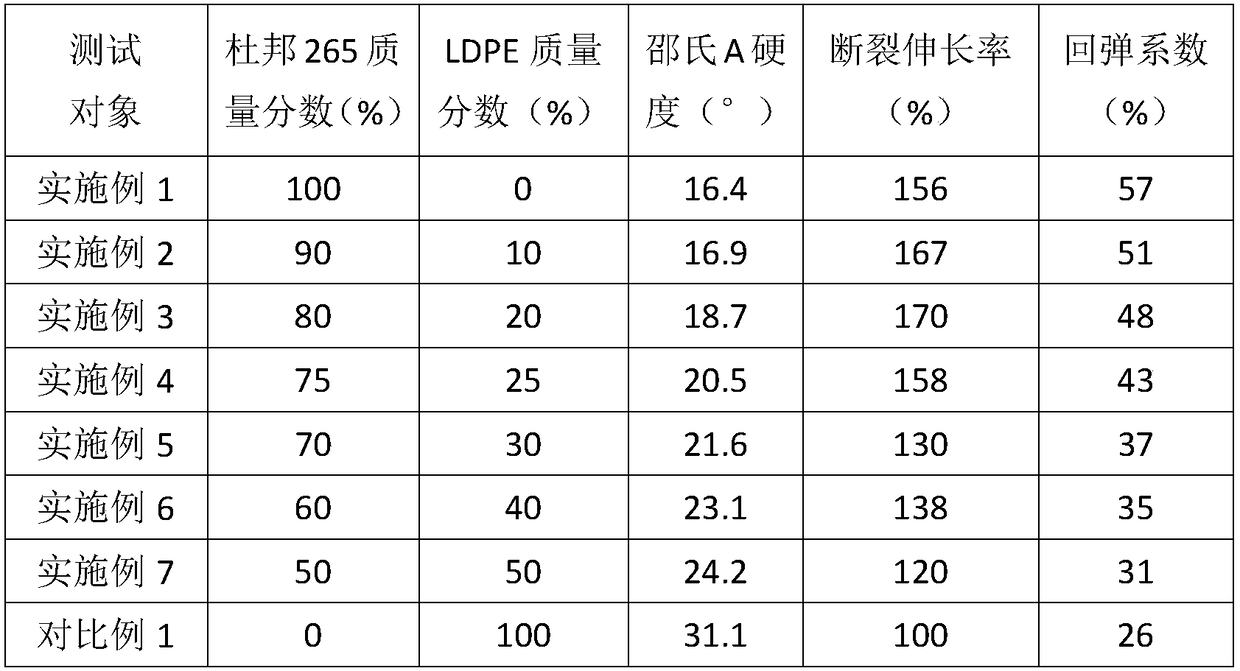

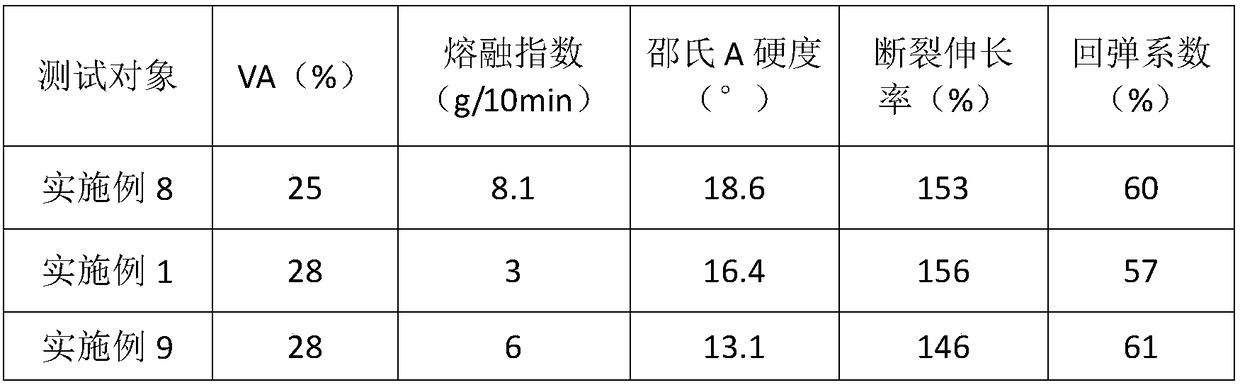

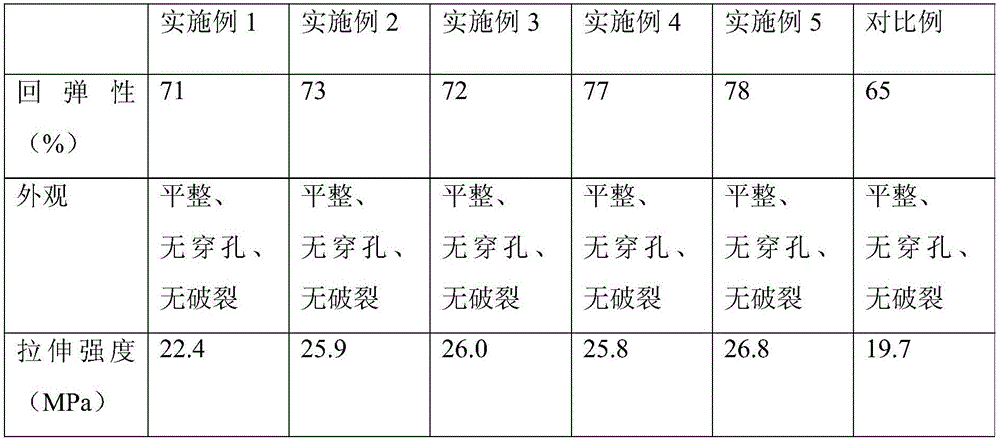

High-elasticity foaming material based on ethylene-vinyl acetate elastomers as well as preparation method and application thereof

The invention discloses a high-elasticity foaming material based on ethylene-vinyl acetate elastomers as well as a preparation method and application thereof. The ethylene-vinyl acetate elastomers with the VA content greater than or equal to 25 percent are adopted to partially or completely substitute an ordinary polymer raw material to prepare the high-elasticity foaming material. The prepared finished product is soft, the shore A hardness is less than 25 and is apparently better than that of the traditional material which is 30 or more; the resilience is good, the elongation rate at break ishigh, and the prepared finished product has an anti-fatigue and non-slip effect; molecules of the ethylene-vinyl acetate elastomers do not contain carbon-carbon dual-bond sensitive to the oxidation,so that the finished product is excellent in anti-aging performance; the preparation material does not contain harmful substances such as formaldehyde, plasticizers and the like and does not contain dioxin generated by chloride, and is high in safety and environmental protection performance; the preparation method can be directly used on an original production line, the process procedures are notincreased, and the industrialized production can be realized; and the production improvement cost can be reduced.

Owner:MEITOKU PLASTIC

Stretch-proof polyethylene winding film and preparation method thereof

The invention discloses a stretch-proof polyethylene winding film and a preparation method thereof. The winding film consists of the following components in parts by mass: 35-45 parts of polyethylene resin, 9-21 parts of polyisobutene, 2-11 parts of o-hydroxybenzophenone, 5-17 parts of triallyl cyanurate, 3-15 parts of methyltriacetoxyl silane, 1-9 parts of propylene glycol alginate, 7-15 parts of diisopropyl phosphite, 4-13 parts of antioxidant 168 and 5-13 parts of calcium stearate. The preparation method comprises the following steps: mixing the components according to the mass parts, putting into a stirrer and stirring uniformly; extruding with a twin-screw extruder; performing film casting; and cooling and packaging to obtain the stretch-proof polyethylene winding film. Through the synergistic effect of the components, the winding film prepared by adopting the preparation method disclosed by the invention has the advantages of flat appearance, no perforation or crack, good resilience and high tensile strength and can be widely applied to the field of packaging.

Owner:SUZHOU DINGLI PACKAGING

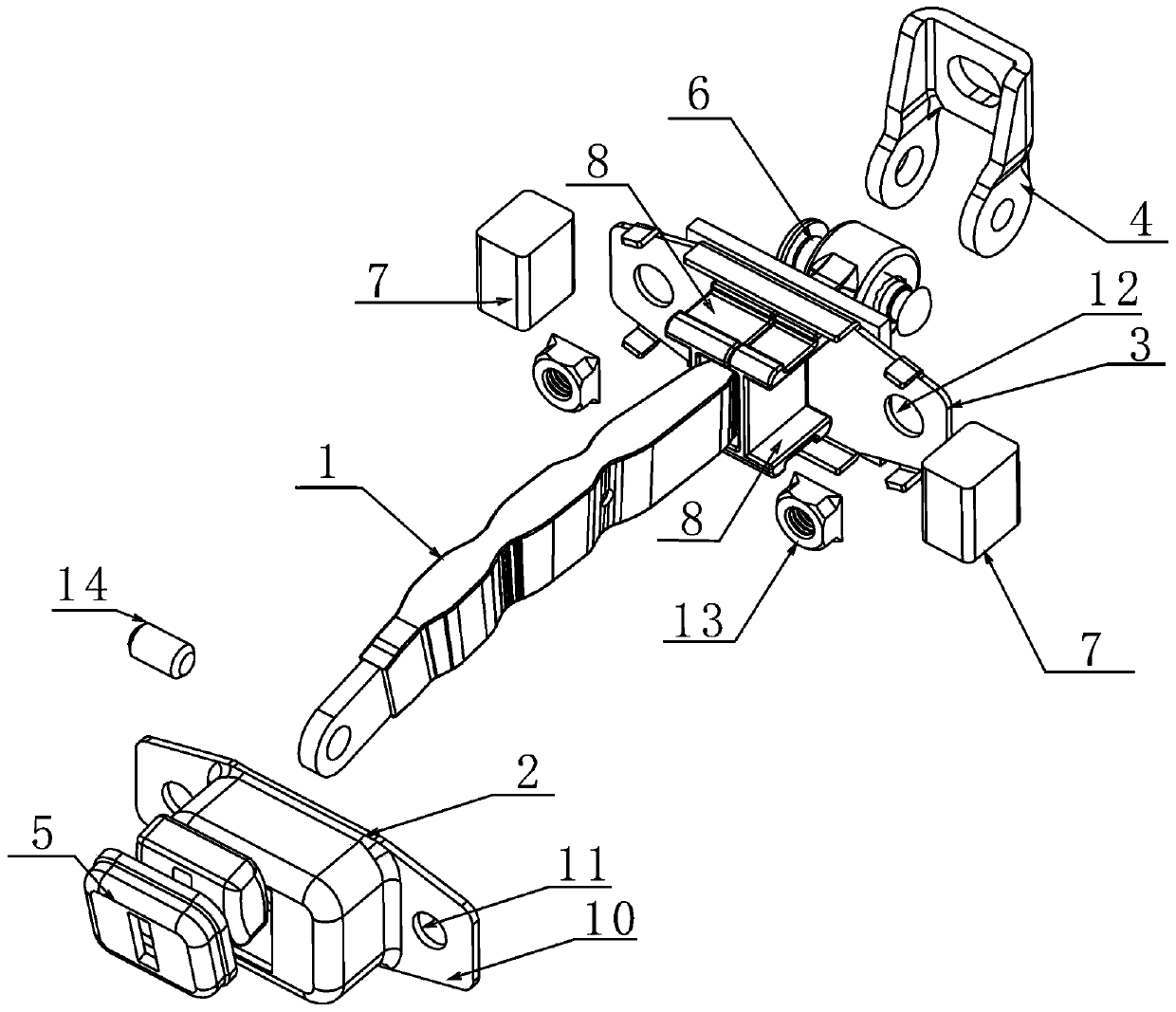

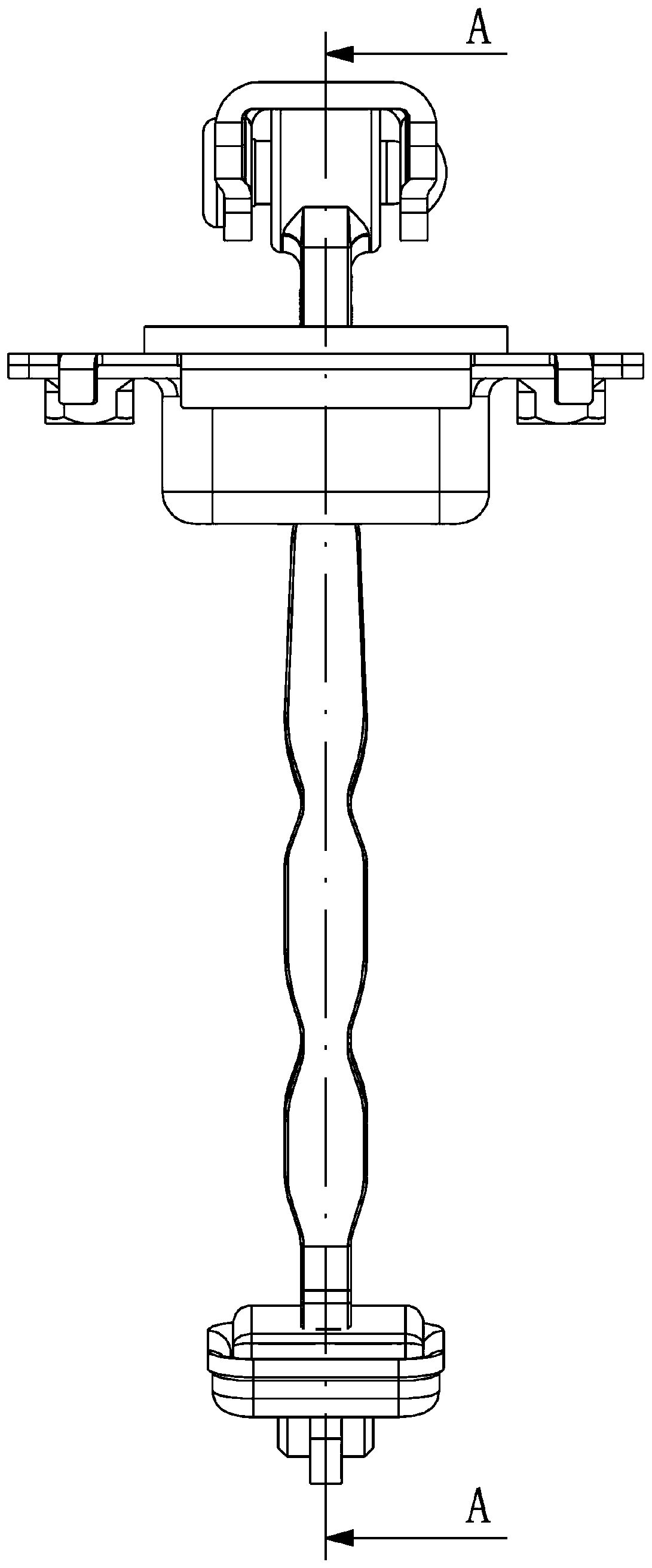

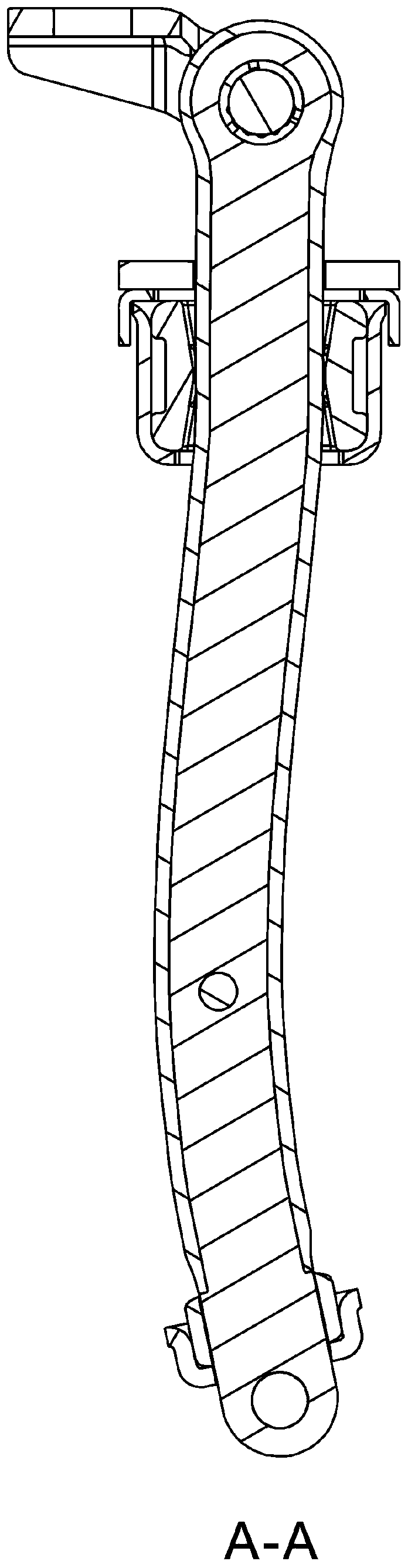

Polyurethane spring slide block stopper

The invention discloses a polyurethane spring slide block stopper which comprises a stopper pull rod, a stopping housing, a fixed cover plate, a fixed bracket and a baffle plate. One end of the stopper pull rod is rotatably connected to the fixed bracket while the other end of the stopper pull rod is connected to the baffle plate. The fixed cover plate and the stopping housing are buckled to forma box-shaped body with a cavity inside, two polyurethane slide block springs and two I-shape-like slide block fixing seats are symmetrically mounted in the inner cavity of the stopping housing, and the stopper pull rod penetrates the box-shaped body and two slide block fixing seats in the box-shaped body and is slidably matched with the two slide block fixing seats. According to the polyurethane spring slide block stopper, the integral service life of a vehicle door stopper is prolonged correspondingly, and the smoothness of opening a vehicle door is further improved greatly. Close-assistant energy comfort degree and hand feeling quality of the stopper in the starting process are improved, and defects that in a conventional stopper, the slide blocks contract to become hard and rubber is poor in ageing for a long time are avoided, so that the quality of the whole vehicle door system is improved.

Owner:ZHEJIANG TAIHONG WANLI TECH CO LTD

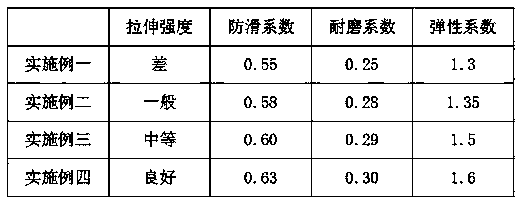

Anti-slip wood-plastic floor and production method

InactiveCN109825102AGood thermoplasticityGood resilienceFlooringCalcium carbonateButadiene-styrene rubber

The invention discloses an anti-slip wood-plastic floor and a production method. The anti-slip wood-plastic floor comprises 15-18 parts of resin, 13-16 parts of butadiene styrene rubber, 30-40 parts of wood powder, 3-4 parts of silicon dioxide, 6-9 parts of epoxy resin, 15-20 parts of calcium carbonate, 5-8 parts of plasticizing oil, 2-3 parts of coupling agents, 3-5 parts of flexibilizers and 2-3parts of other auxiliaries. The added butadiene styrene rubber with good thermoplasticity, rebound elasticity and wear resistance and excellent slip resistance and vibration reducing performance is melted to prepare the wood-plastic floor, the floor can prevent slip and is comfortable and convenient to popularize, active groups of the added flexibilizers can chemically react with the resin, a reaction product is incompletely compatible after curing, so that the phase of the resin is separated, the physical performance and the structure of the epoxy resin can be effectively improved, the elongation of the epoxy resin is increased after curing, the brittleness of the epoxy resin is decreased, cracks of the wood-plastic floor in use are prevented, the flexibility of the floor is improved, and the service life of the floor is prolonged.

Owner:安徽锦汇新材料科技有限公司

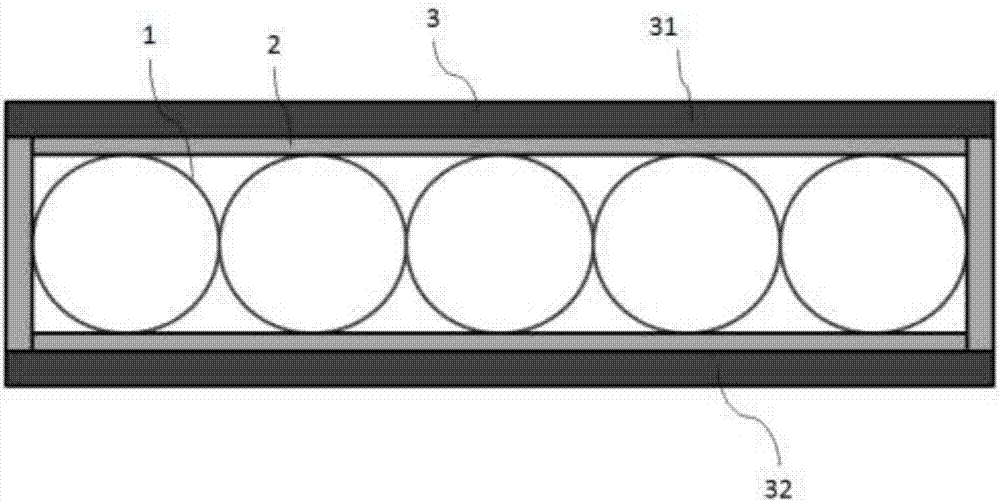

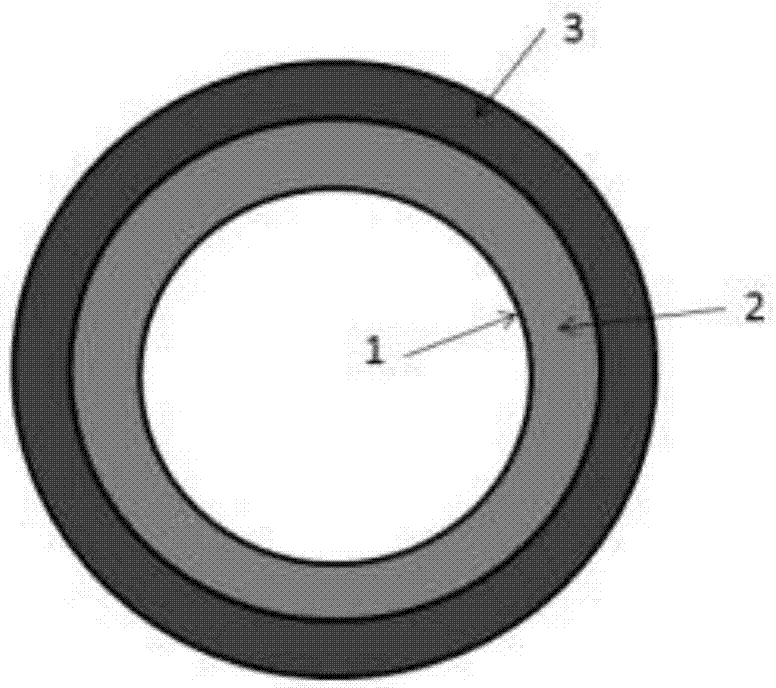

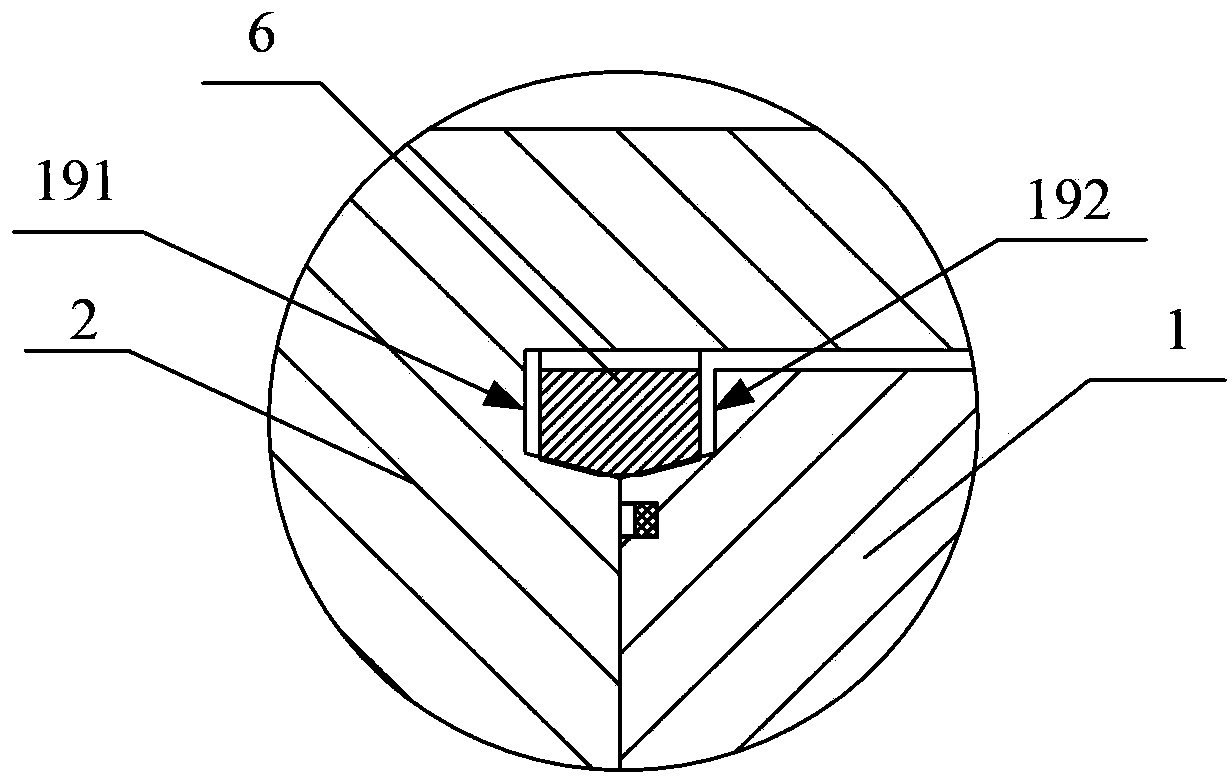

Electromagnetic shielding and grounding device

The invention discloses an electromagnetic shielding and grounding device. The electromagnetic shielding and grounding device comprises hollow tubes made of high molecular material and a conductive layer. The conductive layer is combined with the external surface of the tubes through hot melt adhesive or deposited on the external surface of the tubes through the sputtering process. The conductive layer wraps the tubes. According to the electromagnetic shielding and grounding device, the gasket in the conductive gasket in the prior art is replaced by the high molecular tubes so that the cost can be saved and the elastic deformation and the restoring force of the electromagnetic shielding and grounding device can be enhanced. Besides, free combination use can be realized according to the mechanism characteristics of the circuit board and the packing box of the electronic product so that the electromagnetic shielding and grounding functions can be realized, and the mechanical reliability and the impact resistance of the electronic product can also be enhanced.

Owner:昆山立茂国际贸易有限公司

Ball valve

The invention discloses a ball valve, which comprises a primary valve body, a secondary valve body and a metal hex seal gasket, wherein the primary valve body and the secondary valve body are bolted; the cross section of the outer surface of the metal hex seal gasket is trapezoidal; the secondary valve body is provided with an extended section; the position on the secondary valve body, which is near the extended section, is provided with a first annular pressure groove; the outer wall of the first annular pressure groove is provided with a first slope fitted with the metal hex seal gasket; the position on primary valve body, which is opposite to the first annular pressure groove, is provided with a second annular pressure groove; the outer wall of the second annular pressure groove is provided with a second slope fitted with the metal hex seal gasket; after being assembled, the metal hex seal gasket is clamped in the first annular pressure groove and the second annular pressure groove. According to the ball valve disclosed by the invention, the metal hex seal gasket between the primary ball body and the secondary valve body is high in strength and good in rebound resilience, and suitable for high-temperature and high-pressure occasions. Moreover, a mode that sealing filler is filled in a seal groove is adopted by the second seal of the primary valve body and the secondary valve body, and under the synergistic action of the second seal and the metal hex seal gasket, the goal of seal double insurance is achieved.

Owner:YANKE SHANGHAI VALVE IND CO LTD

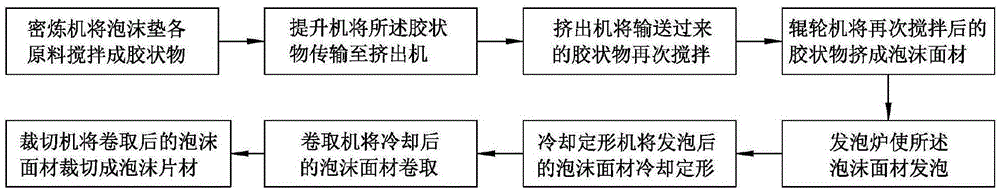

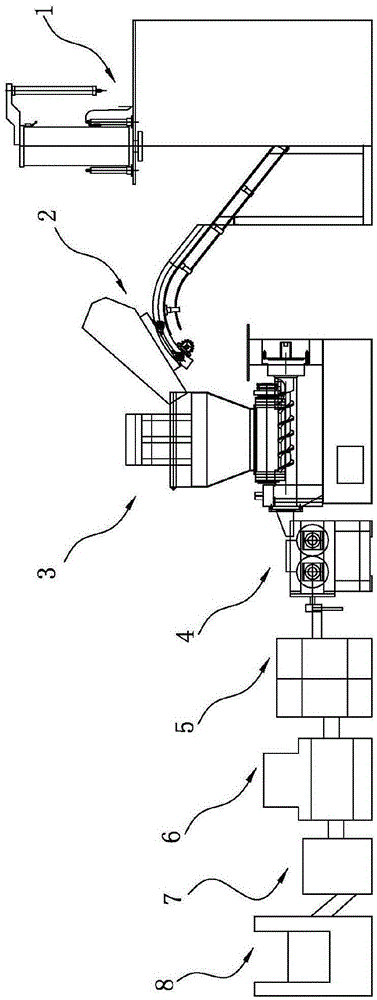

Foamed plastic pad as well as preparation method and production line

The invention relates to the field of foamed plastic technology, and more specifically relates to a foamed plastic pad as well as a preparation method and a production line. The foamed plastic pad is prepared by the following raw materials in percentages by weight: 5-25% of an ethylene-vinyl acetate copolymer, 30-70% of polyethylene, 20-50% of calcium carbonate, 1-3% of a cross-linking agent, 3-5% of an auxiliary agent, and 1-3% of a toner. Compared with prior art, the foamed plastic pad has a higher specific gravity, and has better skid resistance; the pad is odorless and provides better comfortability; the pad has better rebound resilience and a certain buffer effect. The invention also provides a preparation method of the foamed plastic pad, and compared with the prior art, on one hand, calcium carbonate is introduced into the formula in order to increase specific gravity of the foamed plastic pad; on the other hand, raw materials are mixed uniformly with stirring, a whole sheet material is rolled, continuous foaming technology is used for foaming the whole sheet material, so that continuous foaming of the foamed plastic pad with high specific gravity and high efficiency production are realized.

Owner:广东富利时实业有限公司

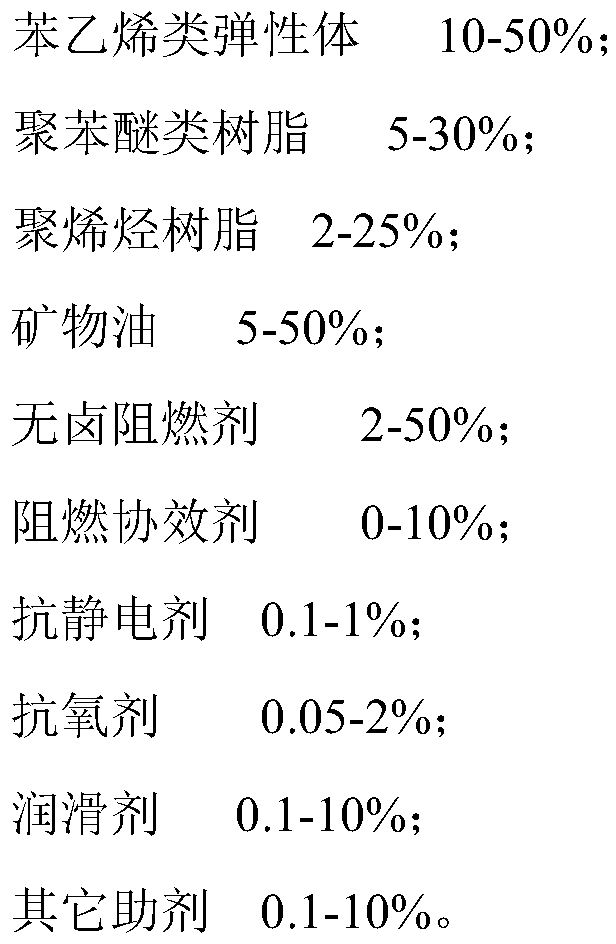

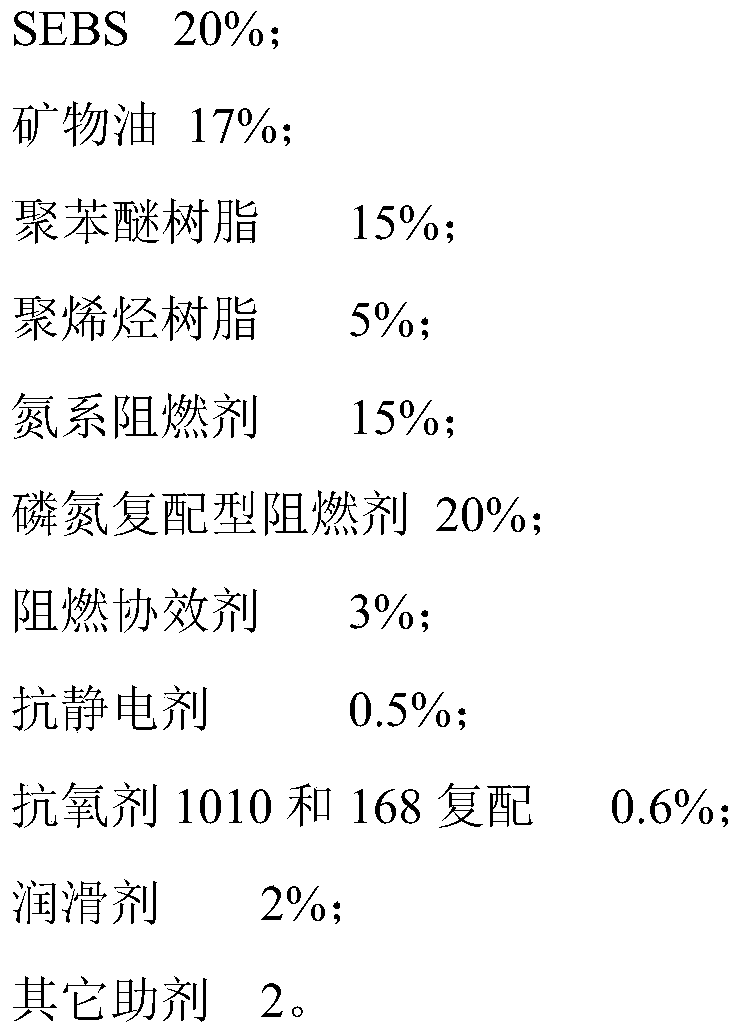

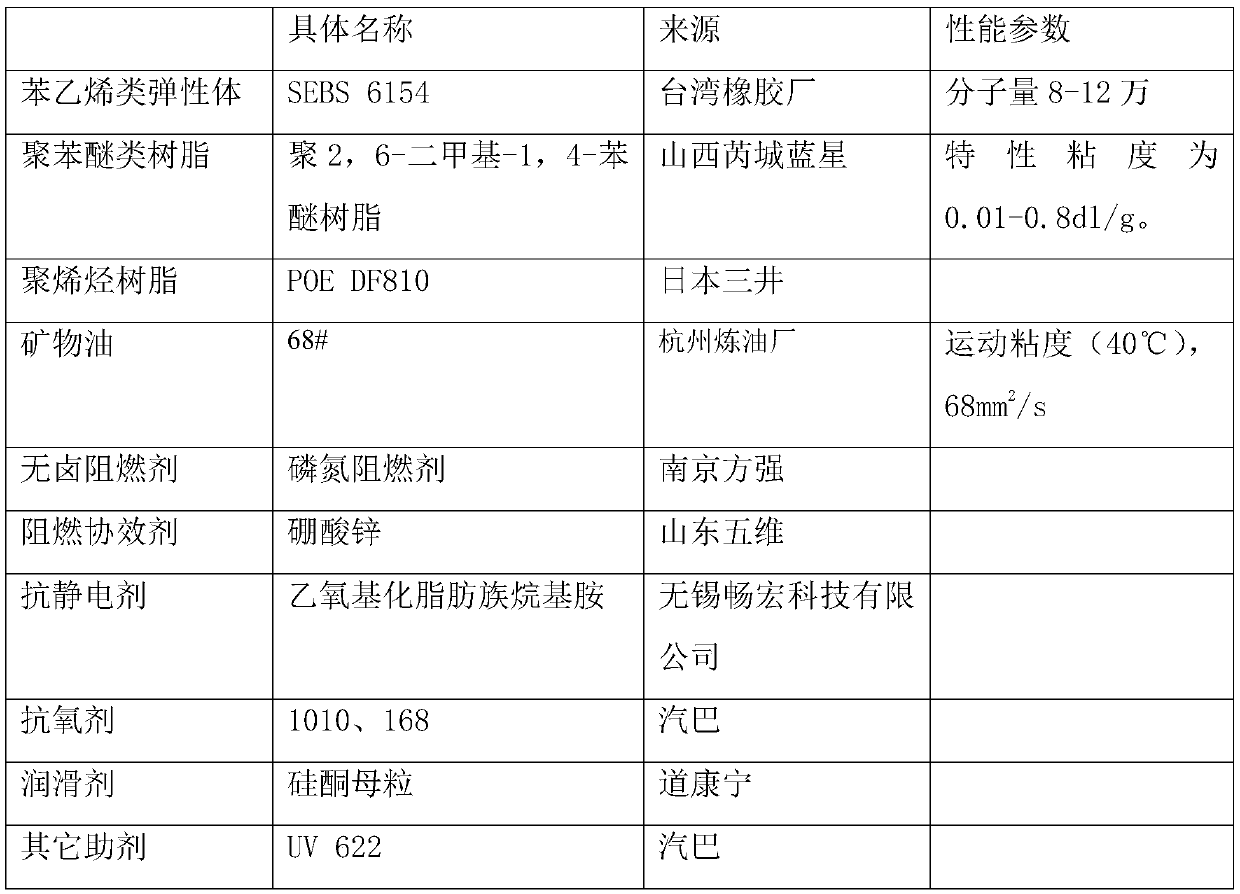

Antistatic type high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

The invention relates to an antistatic high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer, which is composed of the following components: a styrene elastomer, polyphenyl ether resin, polyolefin resin, mineral oil, a halogen-free flame retardant, a flame retardant synergist, an antistatic agent, an antioxidant, a lubricant and other additives. The antistatic agent of theinvention has a small addition amount, and the mechanical properties of the product are reduced to the maximum. The product has excellent processability, can be reused, and is energy-saving and environmentally friendly.

Owner:广东祥利科技有限公司 +1

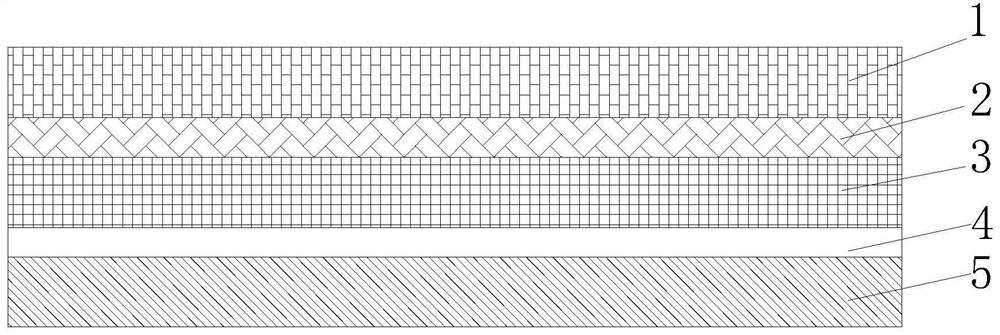

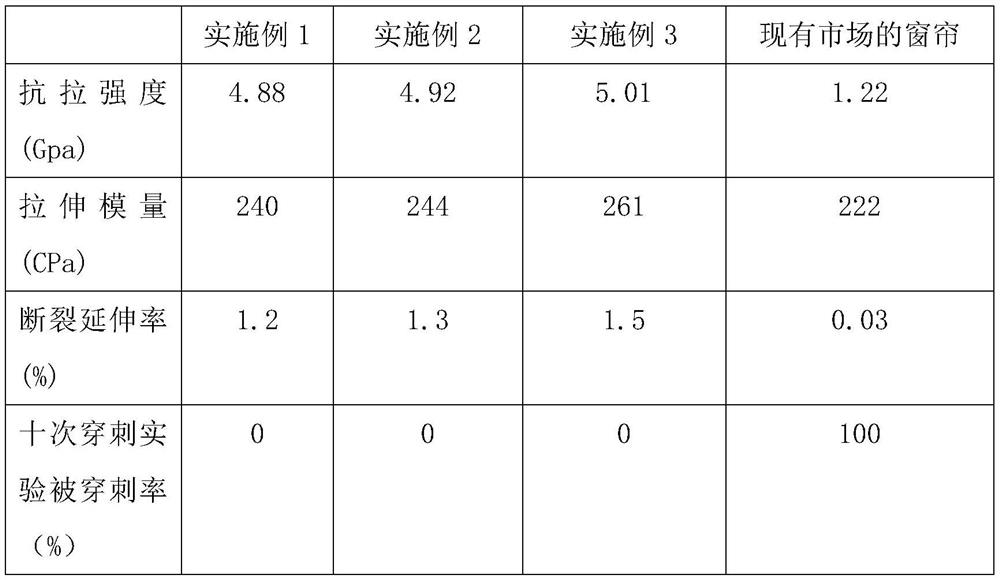

Puncture-resistant high-wear-resistant woven curtain and preparation method thereof

PendingCN112323219AGood resilienceGood recoveryCurtain accessoriesLamination ancillary operationsWeft yarnEngineering

The invention discloses a puncture-resistant high-wear-resistance woven curtain and a preparation method thereof. The puncture-resistant high-wear-resistant woven curtain is formed by weaving a plurality of tissue circulations, and is characterized in that each tissue circulation comprises an outer protective layer, a puncture-resistant layer, a connecting layer and an inner protective layer, theconnecting layer is arranged between the puncture-resistant layer and the outer protective layer, the connecting layer is connected with the outer protective layer and the puncture-resistant layer ina weaving mode through through a weft and warp connecting method, and the inner protective layer is bonded to the face, away from the outer protective layer, of the puncture-resistant layer through anadhesive layer; the outer protective layer comprises eight pieces of warp yarn and eight pieces of weft yarn, the warp yarn is fibers with tensile strength higher than 150 cN / tex, and the weft yarn is glass fibers. The curtain prepared by the invention has the characteristics of high strength, high modulus, heat resistance and flame retardance; the puncture resistance of the curtain is strong, sothat the whole curtain can be completely protected when people carelessly scratch or stab the curtain with a sharp object.

Owner:海宁优韵家居有限公司

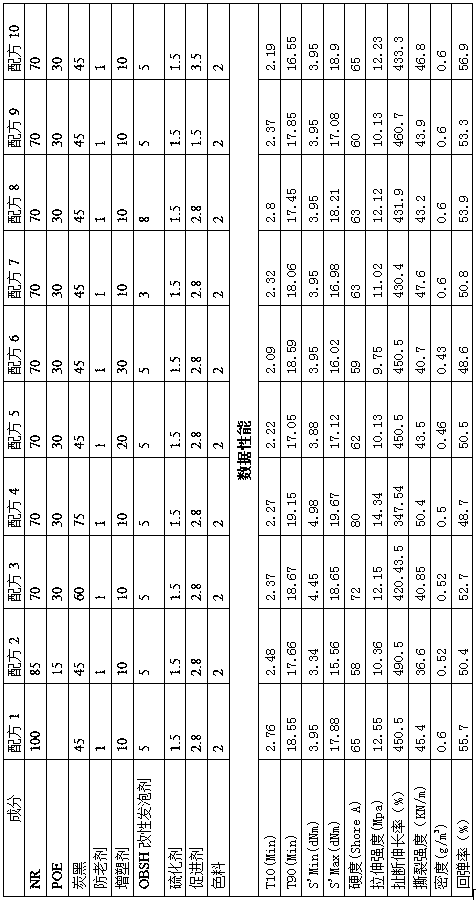

Micro-foamed pet ball and manufacturing method thereof

The invention discloses a micro-foamed pet ball and a manufacturing method thereof, and relates to the technical field of composite material production. The manufacturing method comprises the following steps: mixing NR, POE, carbon black, an anti-aging agent and a plasticizer, mixing through an internal mixer, discharging to obtain a mixed material; putting the mixed material on an open mill for cooling, dispersing and mixing, adding an OBSH modified foaming agent, a vulcanizing agent and an accelerant, uniformly mixing, thinning, sheeting, and cooling to obtain a mixed material; preparing a smooth blank from the mixed material on an extruder through a high shearing force, cutting the blank into a coarse blank, coating the coarse blank by talcum powder, putting the coarse blank into a forming mold, vulcanizing in a high-temperature vulcanizing agent, demolding, cooling, and trimming to obtain the product. The product is light in hand feeling, good in rebound resilience, bright in color, good in toughness and tearing property and smooth in surface, can attract pets to play, and is high in pet biting durability.

Owner:JIANGSU GREENSTAR ECO RUBBER TECH CO LTD

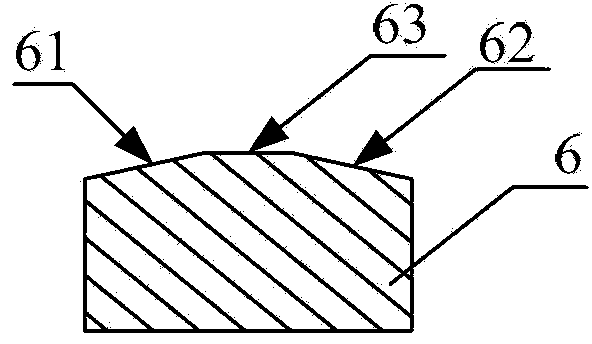

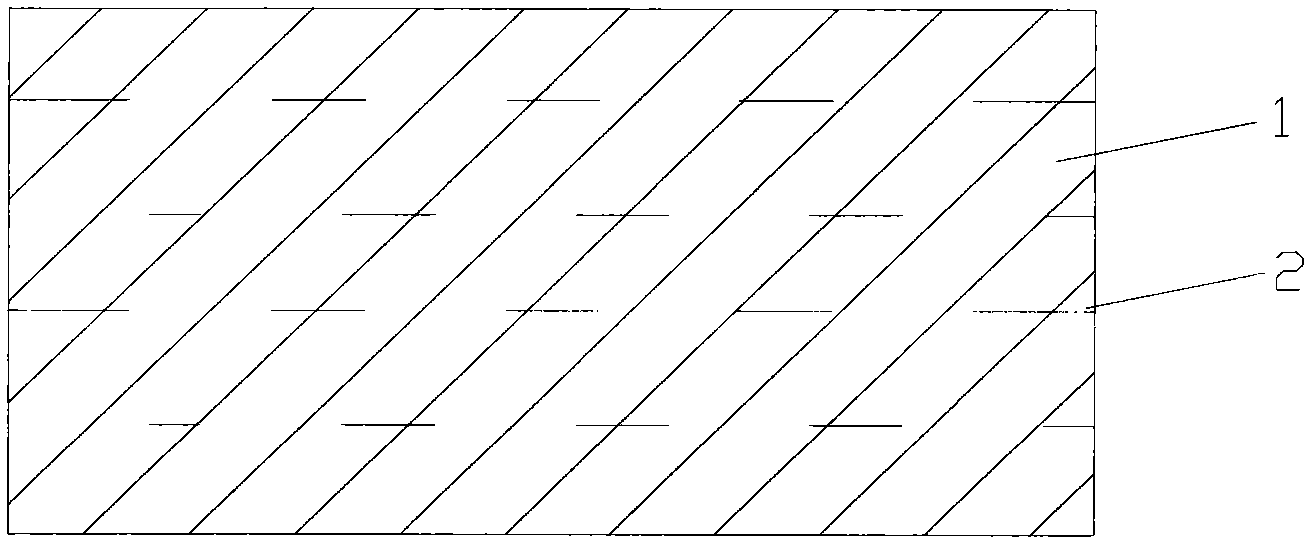

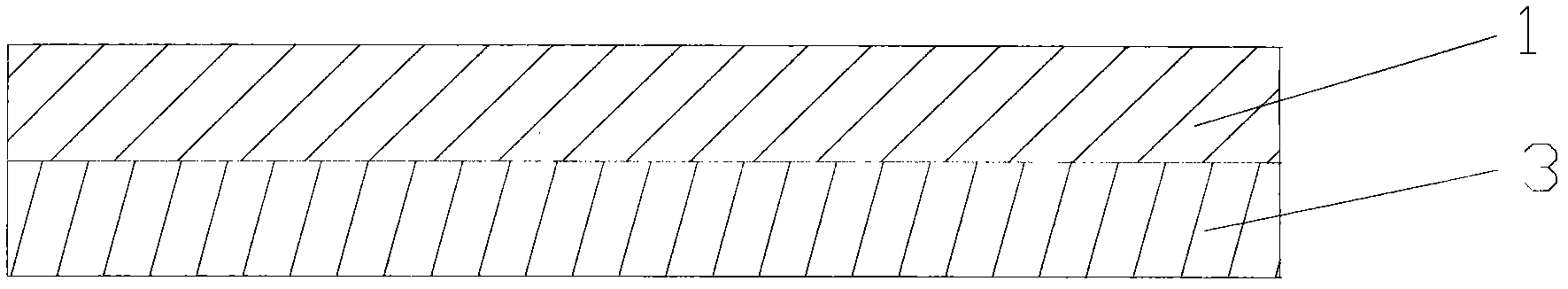

Glittering and permeation-preventing knitted wool fabric

InactiveCN102920076AWaterproof and breathableGood resilienceLayered productsTextile decorationWoolEngineering

The invention relates to a glittering and permeation-preventing knitted wool fabric which is widely applied to the manufacture of high-grade suit-dresses, and belongs to the field of textile fabrics. Multicolored glittering silk threads (2) are fixed on the front side of a knitted wool fabric body (1), and a permeation-preventing layer (3) is fixedly arranged on the back face of the knitted wool fabric body (1) and is made of an elastic rubber film. By the glittering knitted wool fabric, the natural gloss of wool and the bright color of the silk threads are combined, and the limitation of single color of knitted wool fabrics is broken, so that clothes made of the glittering knitted wool fabric is warm-keeping, comfortable, glistening, etherealized and fashionable. The permeation-preventing layer on the back face of the fabric body is made of the elastic rubber film, so that the clothes made of the glittering and permeation-preventing knitted wool fabric have good water resistance, breathability and rebound resilience, and are formfitting, and people feel comfortable when wearing the clothes.

Owner:奚晓莉

Polymer integrally-formed shoe outsole and preparation method thereof

The invention relates to the technical field of shoe soles, and particularly relates to a polymer integrally-formed shoe outsole and a preparation method thereof. The shoe outsole comprises a shoe cover in contact with the ground and a shoe midsole integrated with the shoe cover, wherein the shoe cover is a TPU material; the shoe midsole is composed of two kinds of materials of a PU foaming material and a TPU popcorn material, or two kinds of materials of the PU foaming material and an elastic rubber material; and the two materials in the shoe midsole are mixed and poured into the shoe cover,and the shoe outsole is integrally formed. The integrally-formed shoe outsole provided by the invention has the characteristics of light weight, high resilience, wear-resistant and non-slip characteristics and high wearing comfort, and is integrally formed by adopting a plurality of materials, excellent in performance and low in cost.

Owner:广东康诚新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com