Low-temperature sensitive memory sponge based on air and structural support and preparation method thereof

A technology of structural support and memory foam, which is applied in the field of memory foam manufacturing, can solve the problems of large influence of temperature and stiffness in use conditions, and achieve the effects of improving porosity, comfort, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

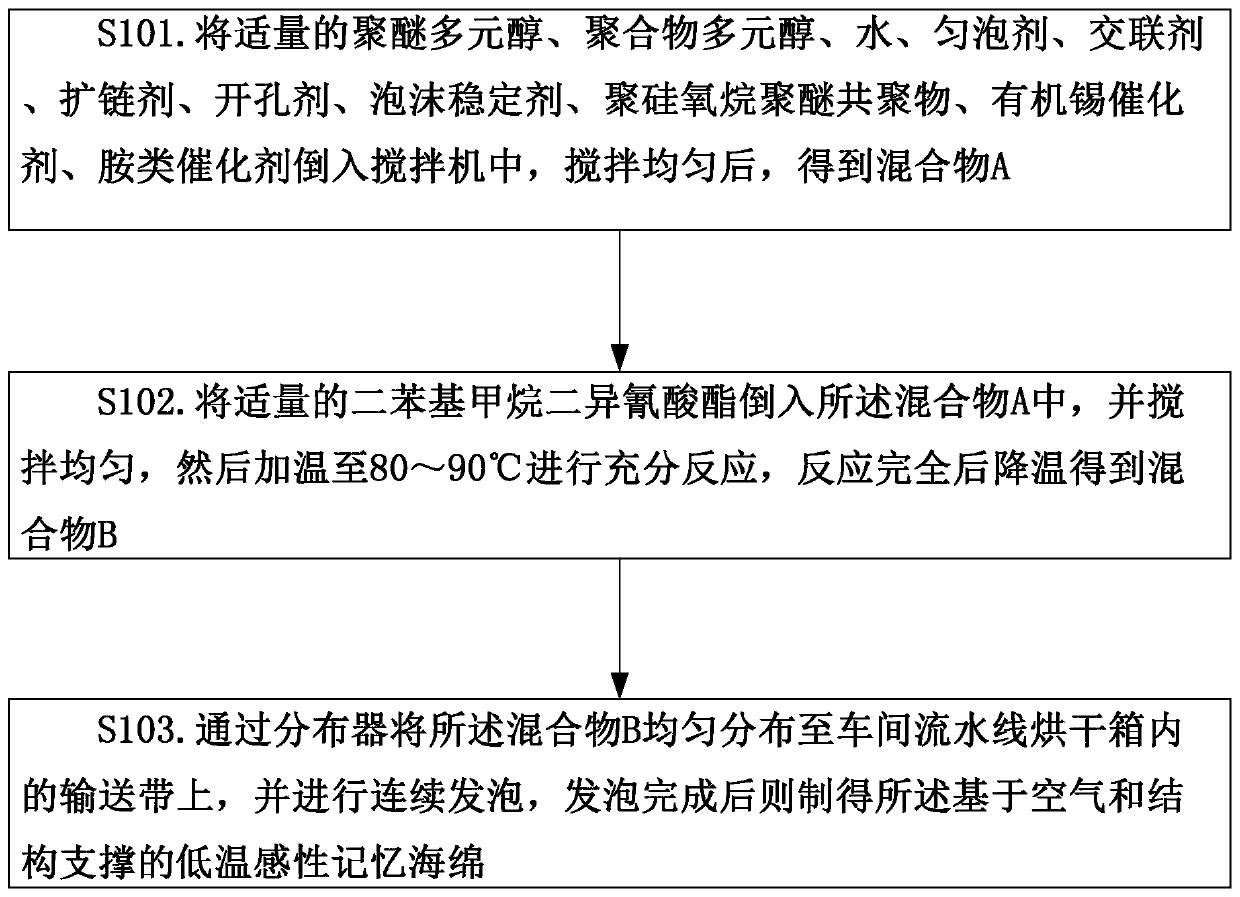

Method used

Image

Examples

Embodiment 1

[0032] The low-temperature perceptual memory foam based on air and structural support provided in this embodiment is made of the following raw materials in parts by weight: 50-90 parts of polyether polyol, 10-40 parts of polymer polyol, 35-50 parts Parts of diphenylmethane diisocyanate, 10-20 parts of water, 0.5-3 parts of foam stabilizer, 0.2-5 parts of cross-linking agent, 0.5-4.5 parts of chain extender, 3-6 parts of opening agent, 1-3 parts of foam stabilizer, 1-3 parts of polysiloxane polyether copolymer, 0.3-1.3 parts of organotin catalyst and 0.5-1.5 parts of amine catalyst.

[0033] The polyether polyol is a kind of chemical, which is an oligomer of terminal hydroxyl groups, the hydroxyl groups on the main chain are connected by ether bonds, and the initiators are low molecular weight polyols, polyamines or compounds containing active hydrogen , formed by ring-opening polymerization with alkylene oxide under the action of a catalyst, and is commonly used in the manufac...

Embodiment 2

[0052] The difference between this example and Example 1 lies in that this example provides the specific content of each raw material in the low-temperature perceptual memory foam based on air and structural support.

[0053] The low-temperature perceptual memory foam based on air and structural support provided by this embodiment is made of the following raw materials in parts by weight: 60 parts of polyether polyol, 30 parts of polymer polyol, 40 parts of diphenylmethane di Isocyanate, 15 parts of water, 2 parts of foam stabilizer, 1.5 parts of crosslinking agent, 2 parts of chain extender, 4 parts of cell opener, 2 parts of foam stabilizer, 2 parts of polysiloxane Ether copolymer, 0.8 part of organotin catalyst and 1 part of amine catalyst.

Embodiment 3

[0055] The difference between this embodiment and the first embodiment is that in this embodiment, the components of the raw materials in the low-temperature sensitive memory foam based on air and structural support are taken as the maximum values in the first embodiment.

[0056] The low-temperature perceptual memory foam based on air and structural support provided in this embodiment is made of the following raw materials in parts by weight: 90 parts of polyether polyol, 40 parts of polymer polyol, 50 parts of diphenylmethane Diisocyanate, 20 parts of water, 3 parts of foam stabilizer, 5 parts of crosslinking agent, 4.5 parts of chain extender, 6 parts of cell opener, 3 parts of foam stabilizer, 3 parts of polysiloxane Polyether copolymer, 1.3 parts of organotin catalyst and 0.5-1.5 parts of amine catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com