Micro-foamed pet ball and manufacturing method thereof

A production method and micro-foaming technology, applied in the production field of composite materials, can solve the problems of pet body injury, easy damage to the surface of the sphere, weak bubble holes, etc., and achieve the effects of bright color, good resilience and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

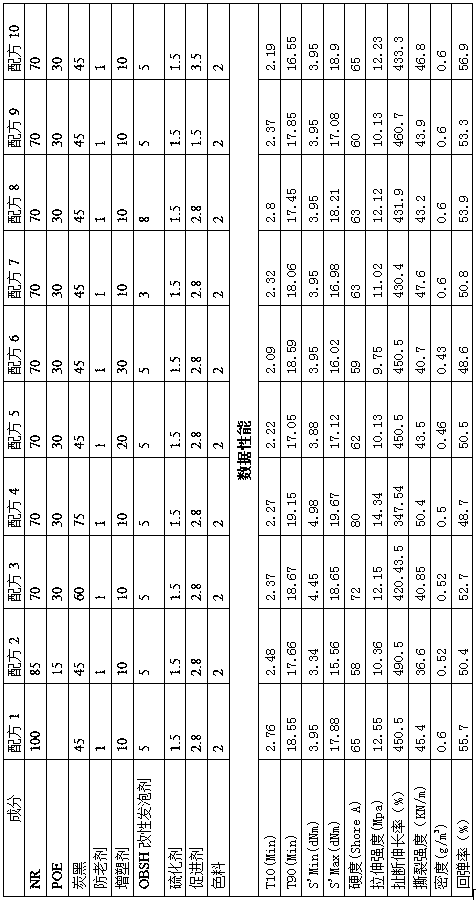

Examples

Embodiment Construction

[0027] 1. Preparation of OBSH modified foaming agent:

[0028] 1. Weighing:

[0029] Weigh 5 kg of 4,4-oxobisbenzenesulfonylhydrazide, 1 kg of zinc stearate and 1.5 kg of urea with a particle size of 1000-2000 mesh, respectively.

[0030] 2. Preparation process:

[0031] Put all the above materials into a high-speed mixer, and the speed is not lower than 5000 rpm.

[0032] After 2 to 5 minutes, stop the machine and let it stand for 30 minutes until the material settles.

[0033] Open the cover after 0.5 hours, visually inspect the surface of the powder to be uniform without impurities, and discharge after uniform color, ready to use.

[0034] 3. The product characteristics and parameters of the obtained OBSH modified foaming agent:

[0035] (1) White particles with uniform color.

[0036] (2) The critical temperature of foaming is 150°C.

[0037] 2. Manufacture of pet balls:

[0038] 1. Manufacturing steps:

[0039] (1) Weigh each raw material according to each recipe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com