Continuous carbon fiber reinforced composite material for bone repair

A technology for reinforcing composite materials and composite materials, which is applied in the field of high carbon fiber reinforced molecular materials, can solve problems such as insufficient strength, achieve good fatigue resistance, low cost, and improve wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

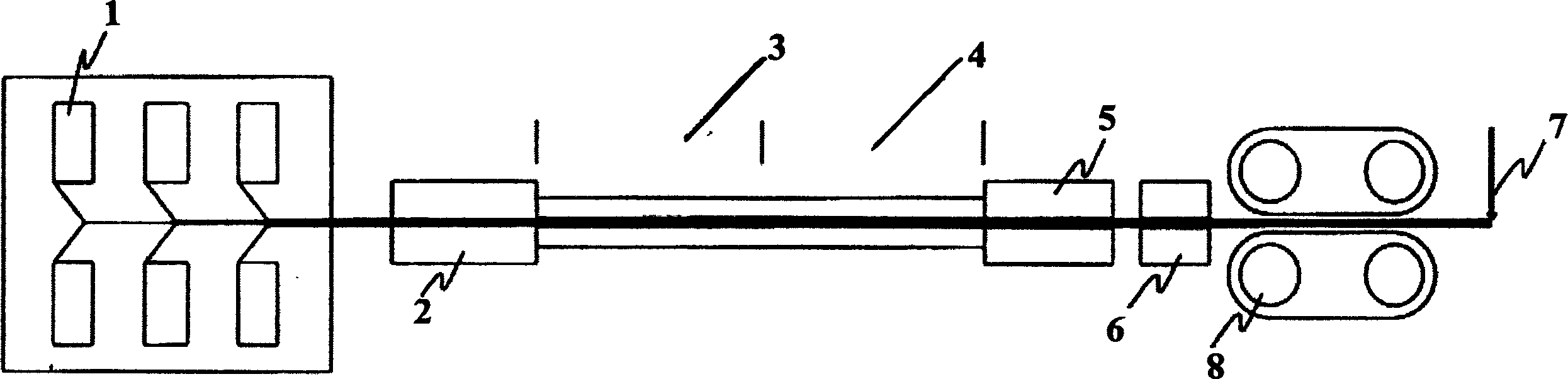

[0028] see figure 1 , the pultrusion preparation method of composite material comprises the following steps:

[0029] The fiber bundles are drawn from the creel (1) under the traction of the tractor (8), impregnated through the impregnation chamber (2), and the impregnated fibers enter the first pre-polymerization section (3) of the polymerization curing chamber. The temperature of this section is Controlled at 60-100°C, the pre-polymerized material enters the second section of heat treatment section (4), the temperature of this section is controlled at 110-140°C, so as to completely polymerize the unpolymerized monomers, and then pass through the shaping mold (5), The temperature of the mold is controlled at 160-220° C., then cooled by the cooling section (6), and then pelletized by the pelletizer (7) as required.

Embodiment 1

[0031] In a water bath at 90°C, 0.045 parts of azobisisobutyronitrile was added to 40 parts of methyl methacrylate to polymerize to obtain a prepolymer of methyl methacrylate. Add 0.3 parts of diisopropyl peroxydicarbonate and 0.015 parts of azobisisobutyronitrile to the prepolymer. The polymerization temperature is 90°C, the heat treatment temperature is 140°C, and the temperature of the shaping die is 200°C. 60 parts of continuous carbon fiber reinforced polymethyl methacrylate composites were obtained by pultrusion. According to the requirements of the product, the fixed bracket or bone plate and intramedullary nail are processed by machine tool. The specific toxicological test results are shown in Table 1. The mechanical properties are shown in Tables 2 and 3.

[0032] Table 1 Toxicological tests of continuous carbon fiber reinforced composites for bone repair

[0033] Test items

Test Results

Cytotoxicity test...

Embodiment 2

[0037] Stack ten layers of carbon fiber cloth in a fixed mold, add methyl methacrylate prepolymer, the prepolymer is to add 0.1 part of azo to 40 parts of methyl methacrylate and 20 parts of butyl methacrylate Diisobutyronitrile is pre-polymerized at 80°C. Vacuum for about 20 minutes to remove air bubbles, then place the mold in a water bath at 50°C for 3 days of polymerization, then treat it at 80°C for 3 hours, then treat it at 120°C for 2 hours, cool and demould, and obtain 40 parts of carbon fiber cloth reinforced polyacrylic acid The base methyl acrylate composite material is hot-pressed into a cranial repair material through a mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com