Micro separated electric connector

A kind of electrical connector, miniature technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of large volume, large space in the axial and radial direction of the separated electrical connector, and the inability to reduce the weight. Achieve the effect of small space occupation, fast locking and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The miniature separation electrical connector of the present invention will be further described in detail below in conjunction with the accompanying drawings:

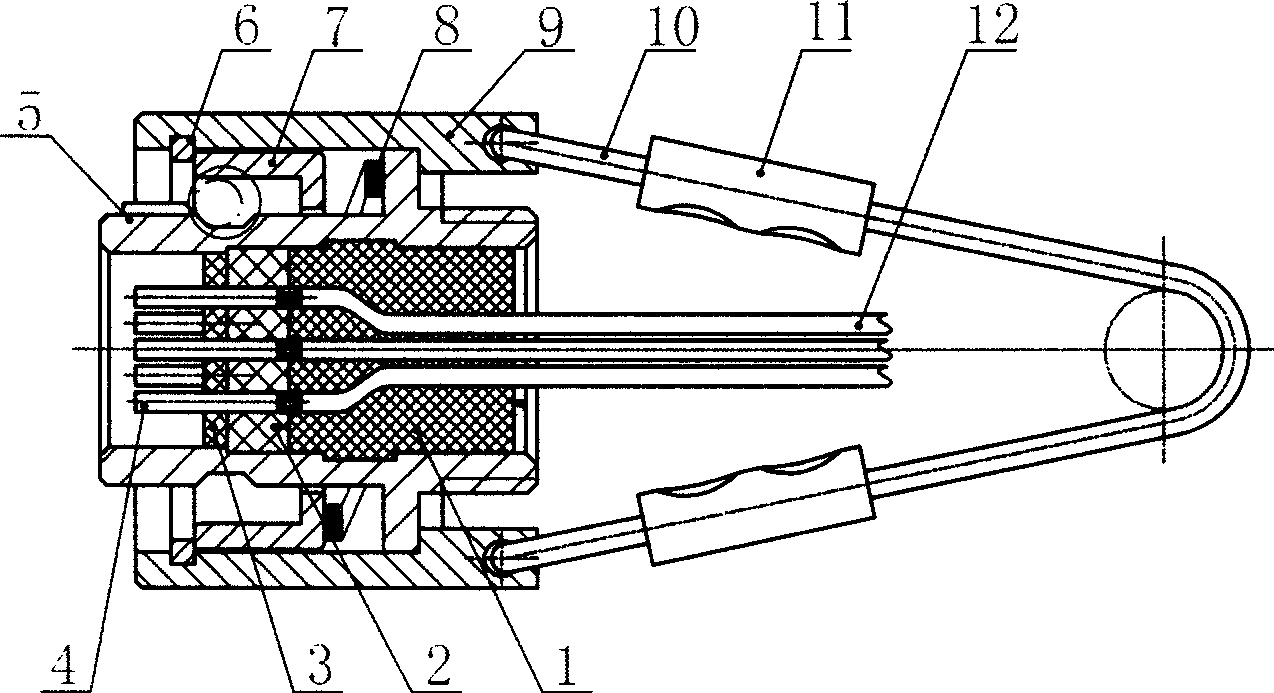

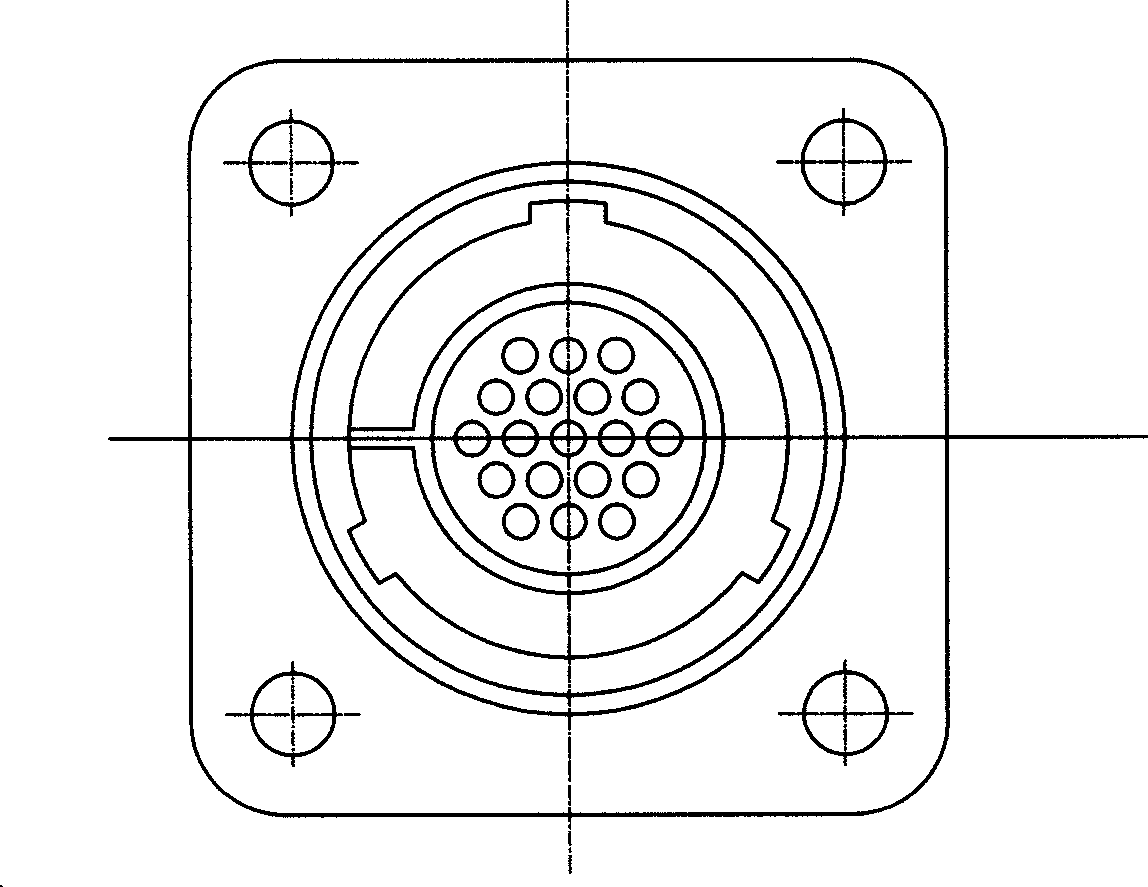

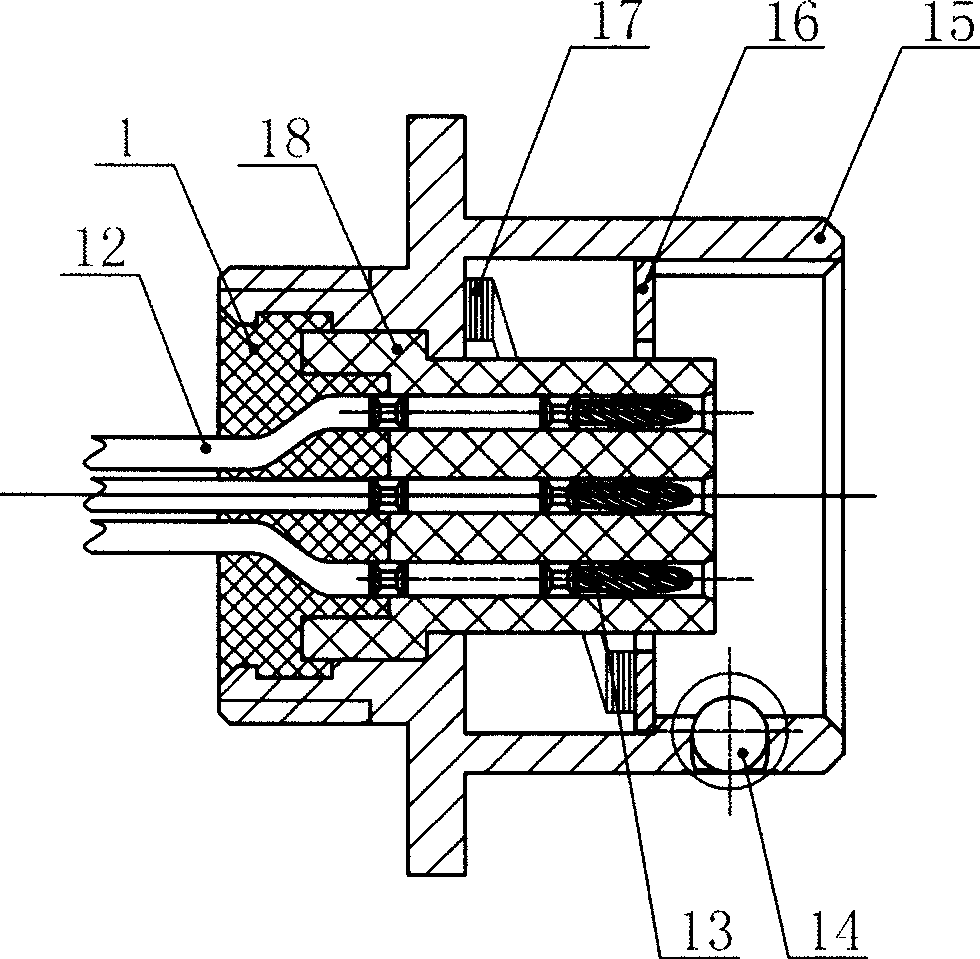

[0012] The miniature discrete electrical connector of the present invention comprises a plug and a receptacle. The plug is composed of rigid glue 1, insulator 2, interface gasket 3, socket 4, plug shell 5, collar 6, locking sleeve 7, wave washer 8, unlocking sleeve 9, pull wire 10, crimping sleeve 11 and wire 12 . Socket is made up of pin 13, steel ball 14, socket housing 15, collar 16, wave washer 17, insulator 18, rigid glue 1 and lead 12.

[0013] The structure of the plug is as figure 1 As shown, the jack 4 is a rigid jack, and the tail end is connected to the wire 12 in the form of crimping, and then held in a certain position by the insulator 2, and the jack 4 and the wire 12 are realized by potting the rigid glue 1 The fixing, forming a stable contact fixing structure. In order to prevent external du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com