Patents

Literature

410results about How to "Uniform foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

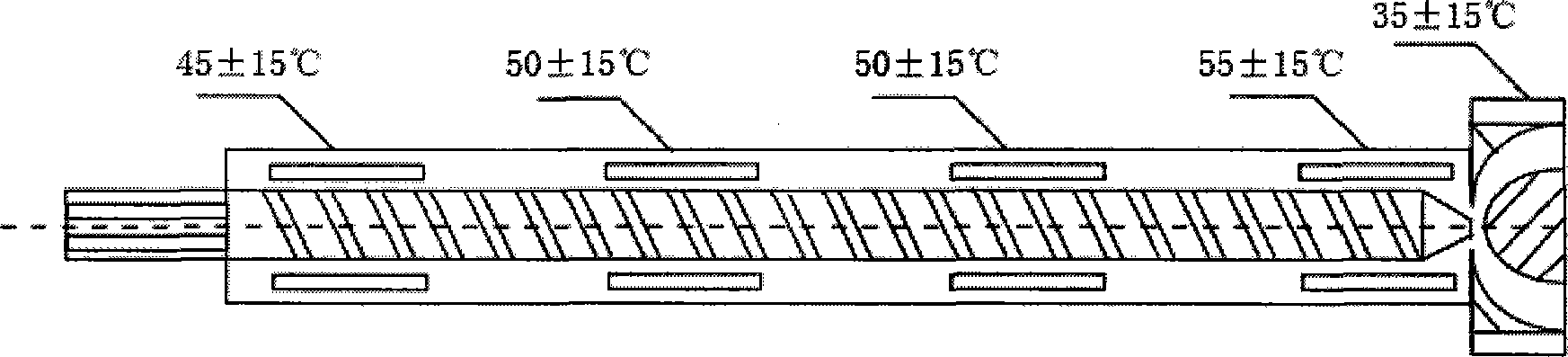

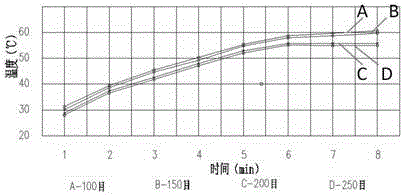

Blown rubber for thick product and variable temperature mould pressing preparation method thereof

The invention relates to a blown rubber for a thick product. The blown rubber comprises a raw rubber matrix, a filler, carbon black, a plasticizer, a vulcanizing agent, a vulcanization accelerator, a blowing agent and an antiager, wherein the blowing agent is compounded by an organic blowing agent, a blowing activator and an inorganic blowing agent, and the organic blowing agent is a blowing agent AC, blowing agent H or a blowing agent OBSH (p,p'-oxybis(benzenesulfonyl hydrazine)). In preparation, the raw materials are mixed and extruded to form mixed material films, the mixed films are placed in a die, the pressure of a plate vulcanizer is regulated to 13-15MPa, and the temperature is regulated according to following time ranges for sulfide forming: the first stage: 60-70 DEG C, 30-60 minutes; the second stage: 80-100 DEG C, 30-40 minutes; the third stage: 110-140 DEG C, 30-40 minutes, and then the blown rubber composite can be obtained. The product has good apparent density and strength and is uniform in foaming.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Material for rubber forming shoes and preparation method of material

The invention provides a material for rubber forming shoes and a preparation method of the material, relating to a rubber foaming material. The material for the rubber foaming shoes consists of the following raw materials in parts by mass: 100 parts of a main material, 1-5 parts of a vulcanizing agent, 1-4 parts of a vulcanizing adjuvant, 2-5 parts of a foaming agent, 8-15 parts of a plasticizer, 6-20 parts of a filler, 2-6 parts of a lubricant, 0-10 parts of an abrasion-resistant agent, 0.5-2 parts of an antioxidant, and 1.5-3 parts of pigment. The preparation method comprises the following steps of: mixing the raw materials according to the ratio into an internal mixer for mixing until a temperature of rubber is increased to 80-90 DEG C; discharging the mixed materials out the internal mixer, and pelleting through a pelleting machine; placing the pelleted material into an injection molding machine for fusing and vulcanizing; and molding through mould pressing, so as to obtain a product. The cost is low, the preparation method is simple, and the foaming rate and the rigidity are controllable; and the preparation method can be used for producing sandals, high-level beach shoes and the materials of insoles of sneakers, outsoles of leather shoes and the like. The material provided by the invention can replace the conventional shoe foaming material EVA (ethylene-vinyl acetate copolymer); and the defects of poor EVA strength, easiness of deformation, low cost performance and the like can be overcome.

Owner:泉州永悦新材料有限公司

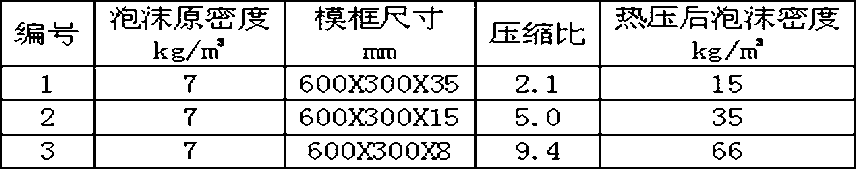

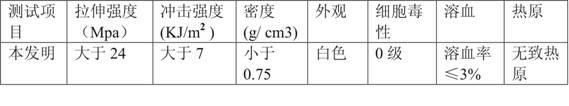

Novel mould-pressing polyimide foamed plastic and preparation method thereof

The invention discloses a novel mould-pressing polyimide foamed plastic and a preparation method thereof. The foamed plastic comprises the following chemical components based on 100 mass parts of aromatic dianhydride: 100 parts of aromatic dianhydride, 60-70 parts of solvent, 60-65 parts of aromatic diamine, 100-130 parts of fatty alcohol, 1-5 parts of a foam stabilizing agent, 0.5-1 part of a catalyst and 20-30 parts of a foaming agent. The preparation method comprises the following steps of: (1) esterifying the aromatic dianhydride and the fatty alcohol to prepare diacid diester; (2) reacting the diacid diester with the aromatic dianhydride to prepare a precursor solution; (3) preparing a surfactant and a catalyst removal solvent by the precursor solution, drying and grinding into powder; (4) preparing a melt by taking the water as a foaming agent; (5) by a microwave foaming process, preparing a thermoplastic polyimide foam body; and (6) cutting the foam body and carrying out mould-pressing to prepare polyimide foam boards differing in density. The novel mould-pressing polyimide foamed plastic disclosed by the invention is simple in preparation process, dense and uniform in foam bubbles, low in preparation cost and easy in industrial production.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Magnesium cement foam material

InactiveCN102101787AUniform foamingFast foamingSolid waste managementCeramicwareThermal insulationMagnesium

The invention relates to a magnesium cement foam material which is prepared by the following steps: mixing 10-90 wt% of light-burnt magnesium oxide powder, 5-89 wt% of filler and 0.8-10% of compound foaming agent, and mixing with a magnesium chloride solution which accounts for 100-150 wt% of the mixture; and evenly stirring, casting and forming to obtain the magnesium cement foam material. The invention can effectively lower the load of the buildings, has favorable thermal insulation property, and can be widely used for building blocks, heat engineering equipment, and various ventilating ducts and industrial ducts in industrial and civil buildings.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A foamed polypropylene material

The invention provides a foamed polypropylene (PP) material which is prepared from the following components in parts by weight: 80-95 parts of PP:T30S, 5-20 parts of polyethylene (PE), 0.8-1.5 parts of foaming agent, 0.5-1 part of foaming aid, 0.2-0.8 part of cross-linking agent, 0.2-0.5 part of nucleating agent and 0.5-1.2 parts of assistant cross-linking agent. In the foamed PP material provided by the invention, the cost can be lowered because of the addition of the PE, the consumption of the PP is greatly reduced at the same volume of a syringe core rod, and the foamed PP material has theadvantages of easy shaping, uniform product foaming, good mechanical strength and the like and is favorable for lowering the cost and protecting the environment.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

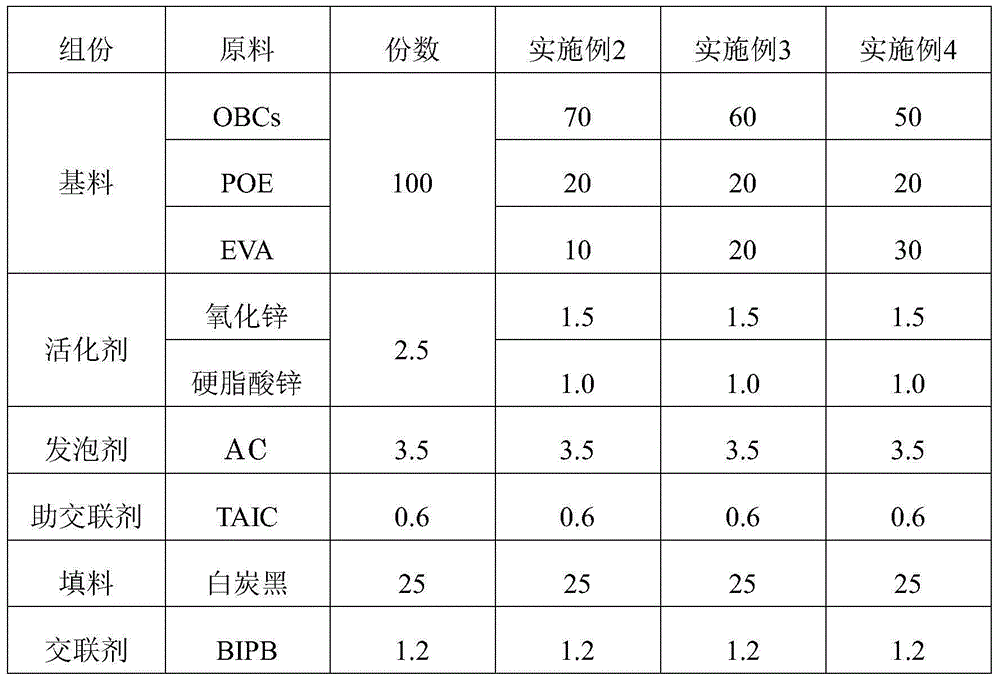

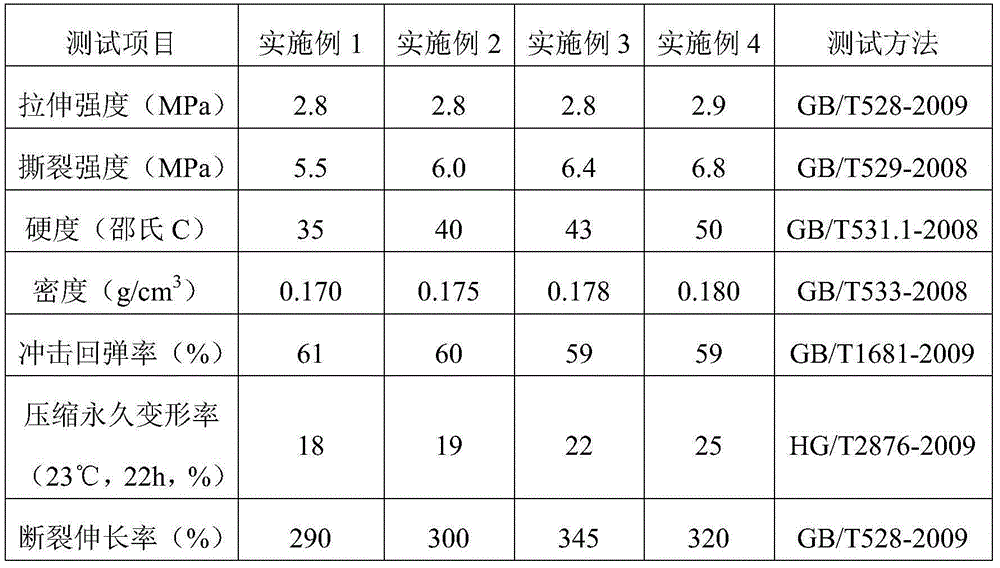

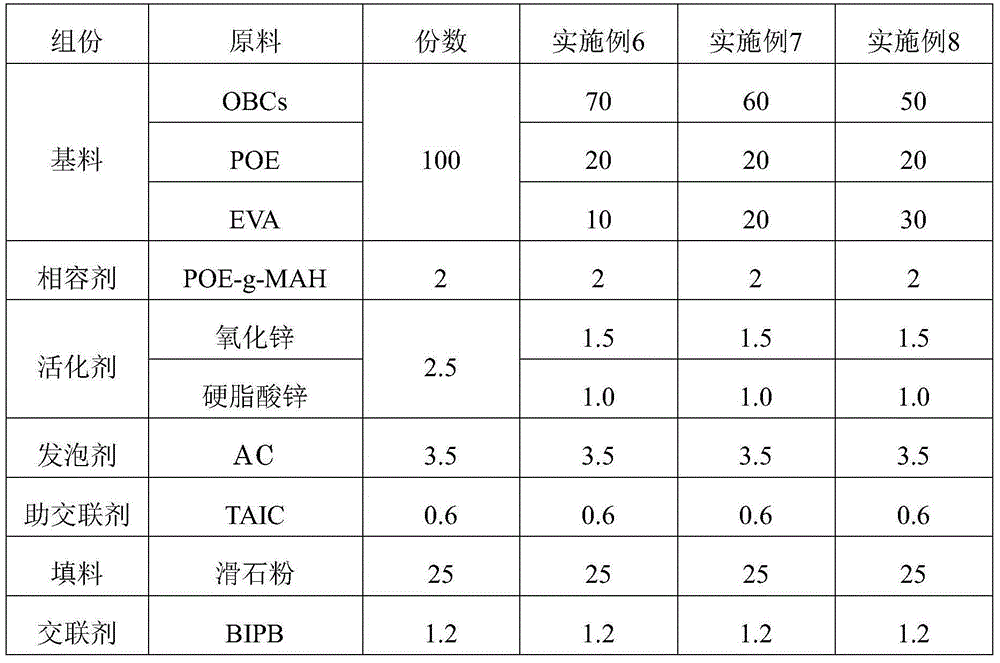

Foaming composite for shoes and preparation method of foaming composite

The invention provides a foaming composite for shoes and a preparation method of the foaming composite. The foaming composite for shoes is prepared from base stock, foaming agents, cross-linking agents, assistant crosslinker, activating agents and fillers. The total mass of the base stock is 100%, and 2%-10% of the foaming agents, 0.8%-3% of the cross-linking agents, 0.1%-2% of the assistant crosslinker, 1%-5% of the activating agents and 5%-50% of the fillers. The base stock is prepared from, by mass, 40%-90% of ethylene-octylene block copolymer, 5%-25% of ethylene-octylene random copolymer and 5%-35% of ethylene-vinyl acetate resin. The foaming composite for shoes is light in mass, high in rebound resilience, low in permanent compression deformation rate, low in cost, wide in application range and simple in preparation method. By means of the foaming composite for shoes, the technical problems that existing shoe soles are not resistant to wear or compression, poor in low-temperature toughness, poor in strength, prone to deformation, low in cost performance and the like are solved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

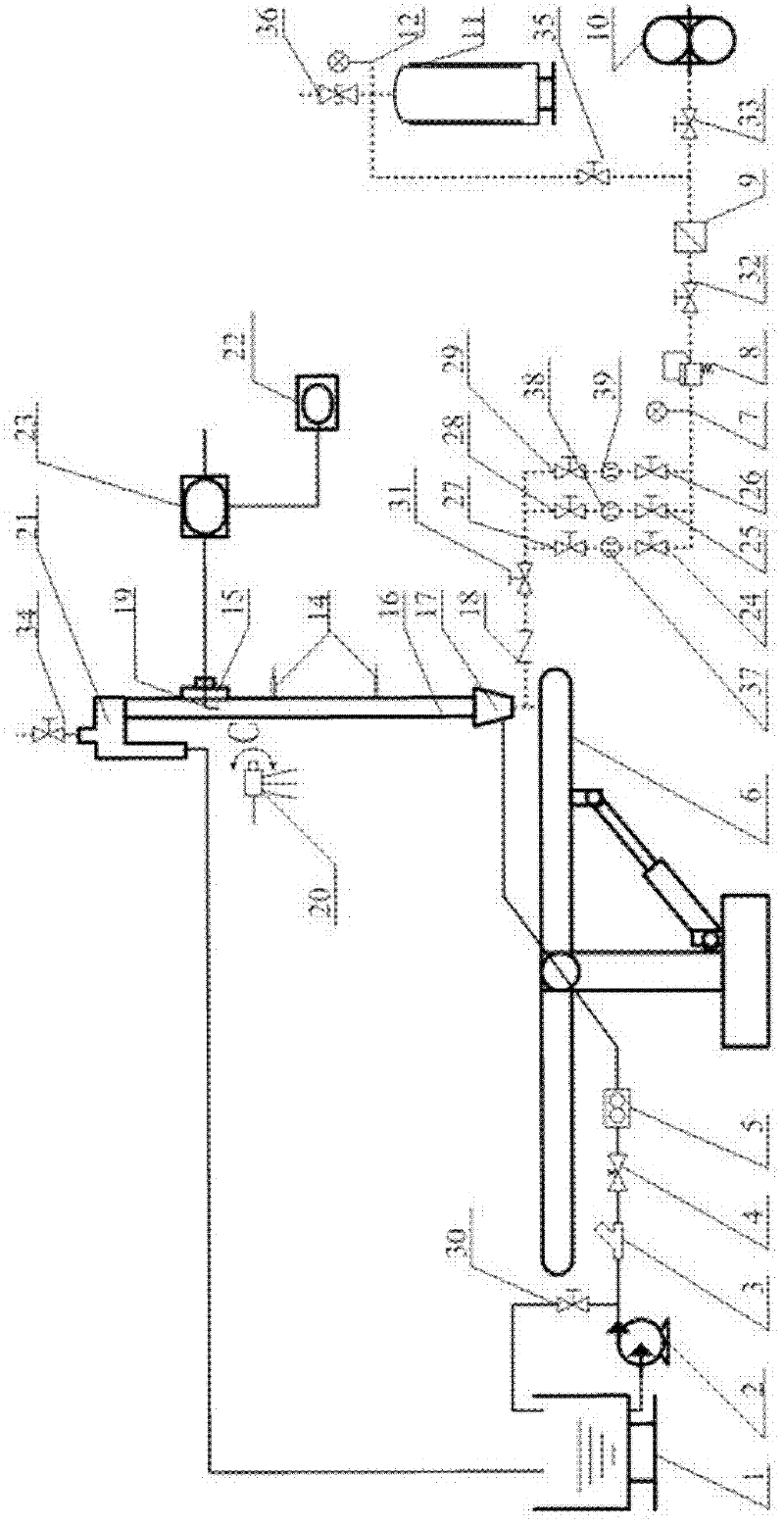

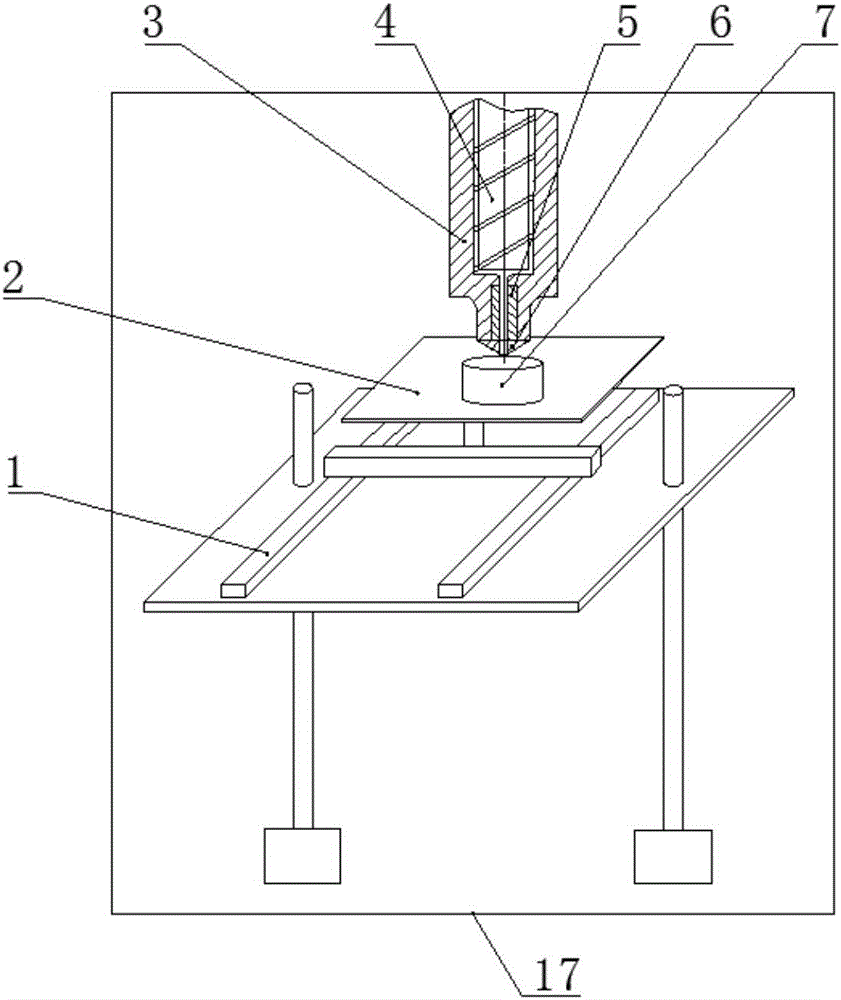

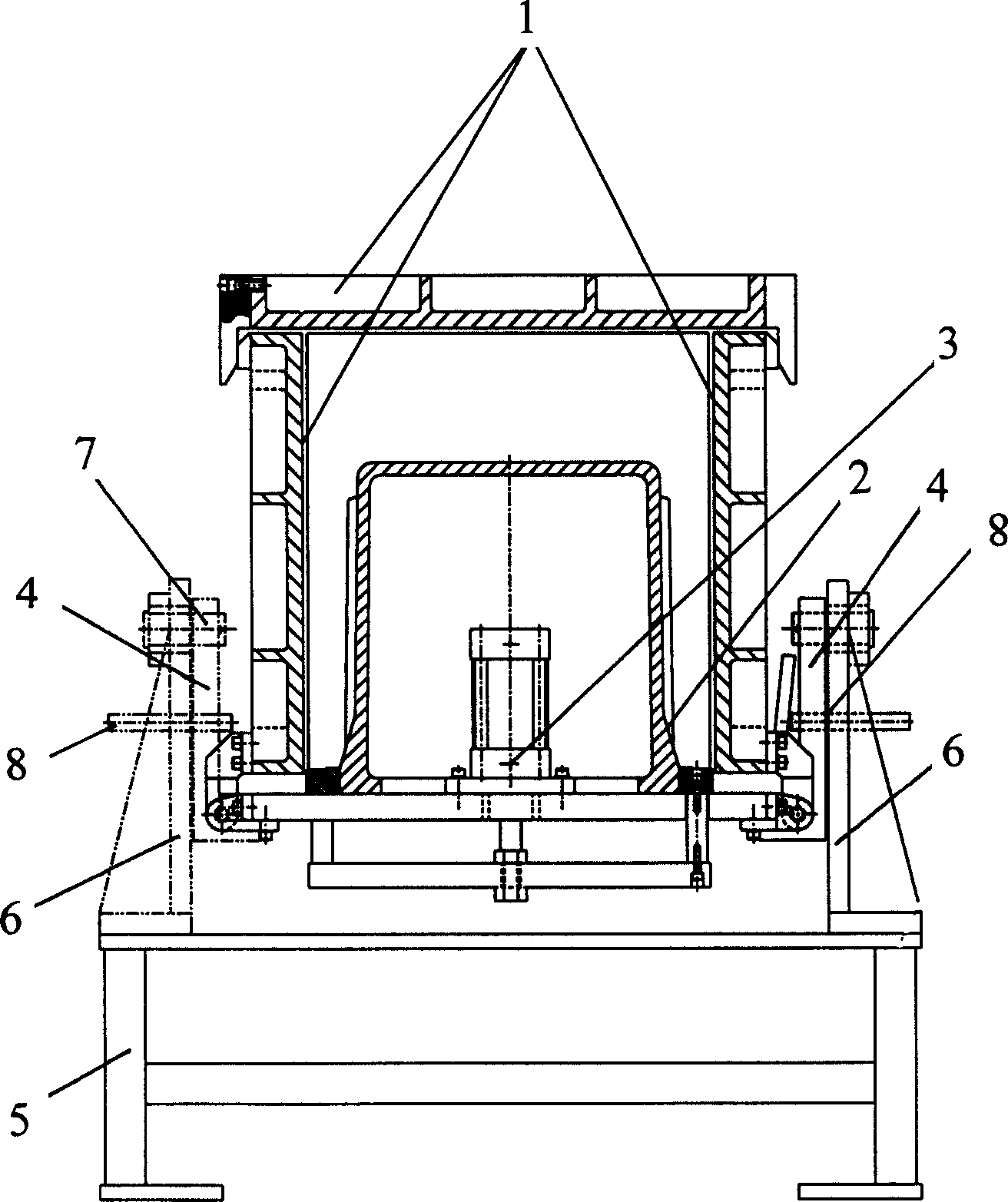

Two-phase flow interface parameter distribution characteristic experiment device under swinging condition

The invention aims at providing a two-phase flow interface parameter distribution characteristic experiment device under swinging condition, which comprises a water storage box, a mixing chamber, an experiment section, an air-water separation device, an air compressor, an air storage tank, a swing table, photoelectric converter and a light source, wherein the mixing chamber and the steam-water separation device are respectively installed at both ends of the experiment section, the water storage box is connected with the air-water separation device and the mixing chamber respectively, the air storage tank and the air compressor are connected in parallel and connected with the mixing chamber, and the mixing chamber is also connected with the swing table; and an optical fiber probe and a pressure sensor are installed on the experiment section, the photoelectric converter faces to the optical fiber probe, and the light source faces to the photoelectric converter. The invention further develops and perfects an experiment device for researching the air-liquid two-phase local parameter distribution and transportation mechanism in a large channel under the steady-state condition, foaming is uniform in the experiment, a stable bubble flow can be obtained, and the outlet pressure of the air-water separation device maintains constant by means of gravity separation.

Owner:三亚哈尔滨工程大学南海创新发展基地

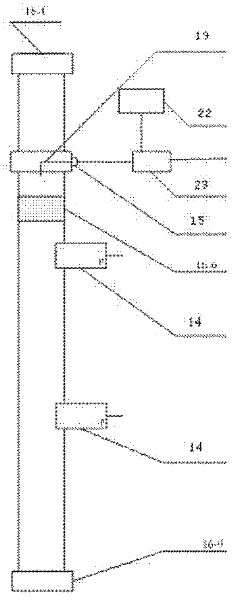

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

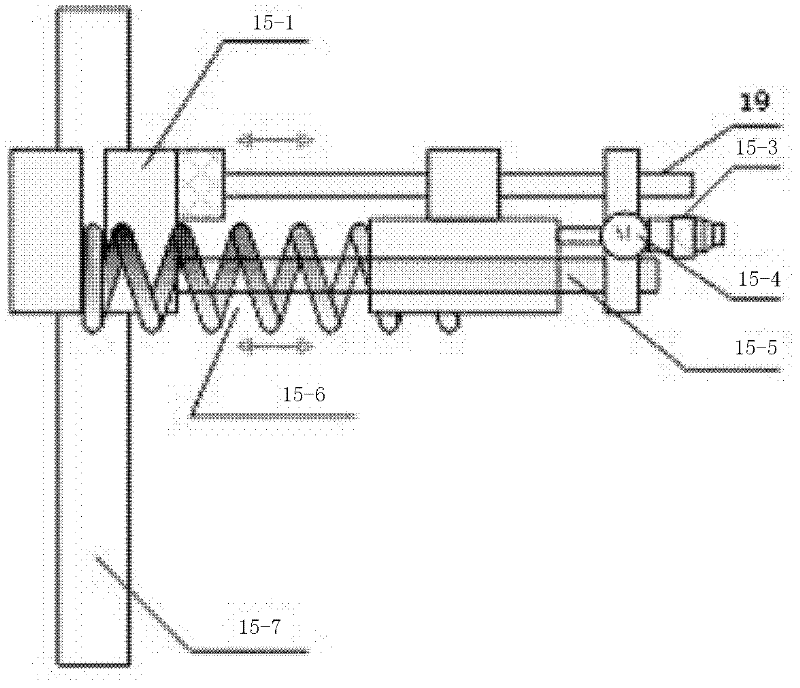

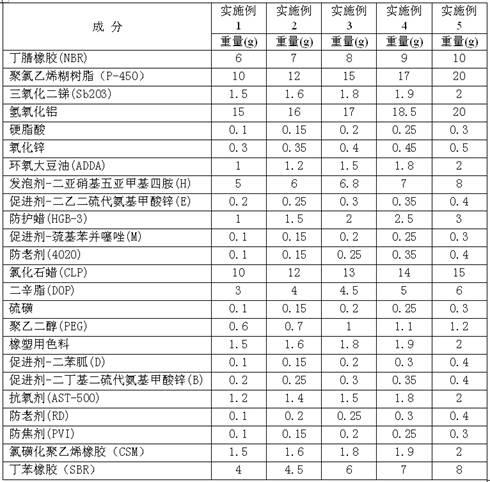

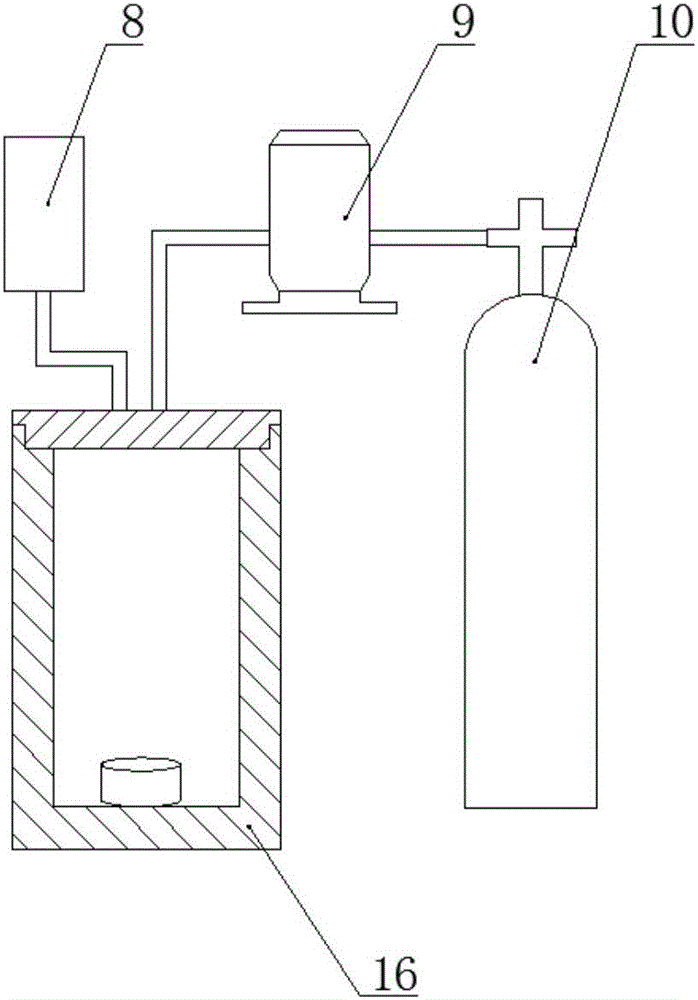

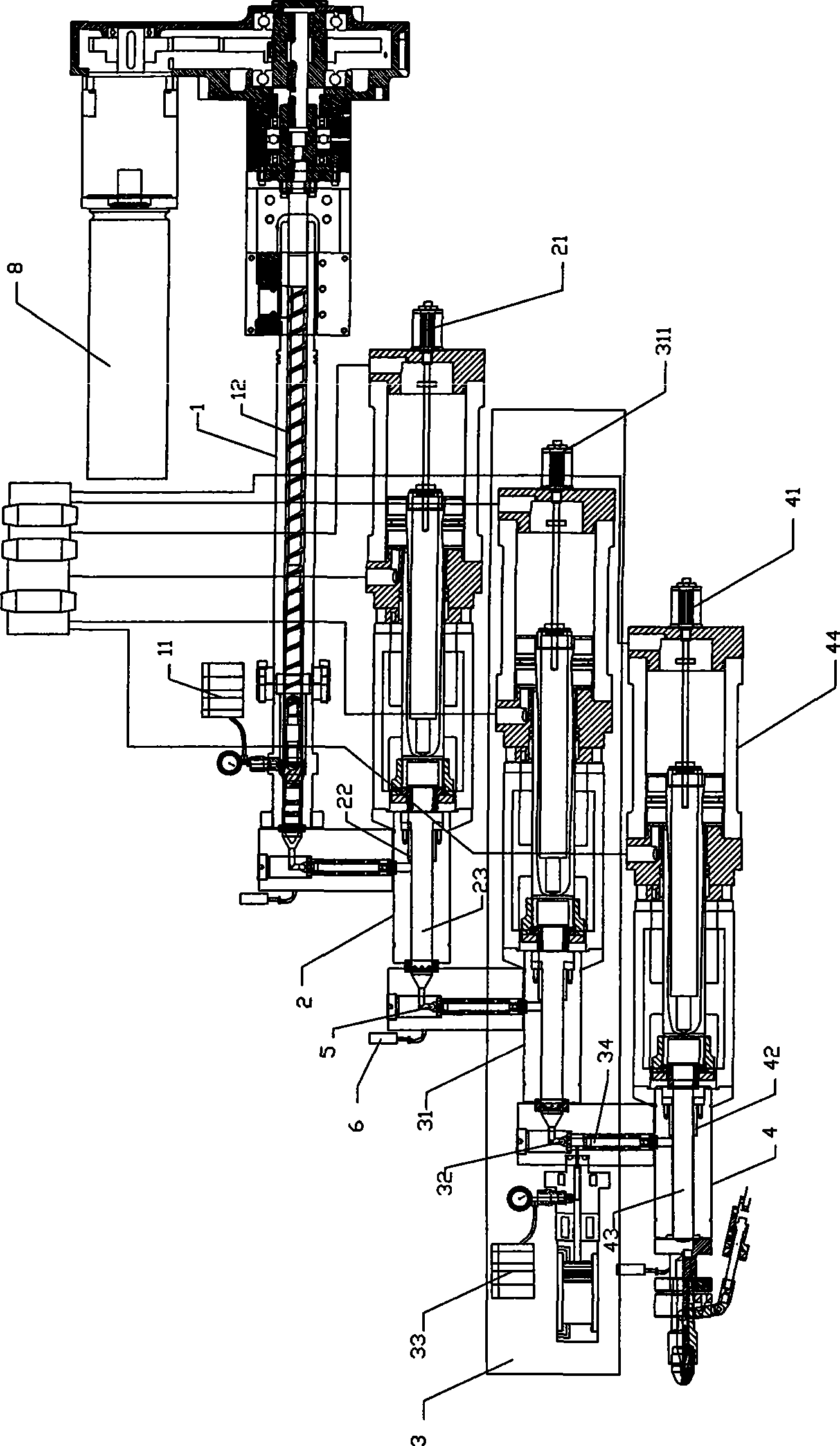

Method and apparatus for producing foamed product based on 3D printing

InactiveCN106493968AHigh forming precisionEasy to produceAdditive manufacturing apparatus3D object support structuresCo2 storageProduct base

The invention discloses a method and apparatus for producing a foamed product based on 3D printing. The apparatus mainly comprises a molding unit, a supercritical infiltration unit and a foaming unit, wherein the molding unit is a 3D printer and mainly comprises a three-dimensional ball screw sliding table, a molding platform, a 3D printer case, a plasticizing screw, a heating ring and a nozzle; the supercritical infiltration unit is mainly composed of a preheater, a booster pump, a CO2 storage tank and an infiltration vessel; and the foaming unit is mainly composed of a steam generator, a foaming case and a cover plate. The method comprises the following steps: printing a three-dimensional model via the molding unit according to product needs; then putting the three-dimensional model into the infiltration vessel in the supercritical infiltration unit and carrying out infiltration by using supercritical CO2; and carrying out steam foaming in the foaming case so as to obtain the foamed product. According to the method and apparatus provided by the invention, production stages are simplified to three production stages, so production cost and process complexity are reduced, and simplified production of foamed products with any complex structures can be realized.

Owner:BEIJING UNIV OF CHEM TECH

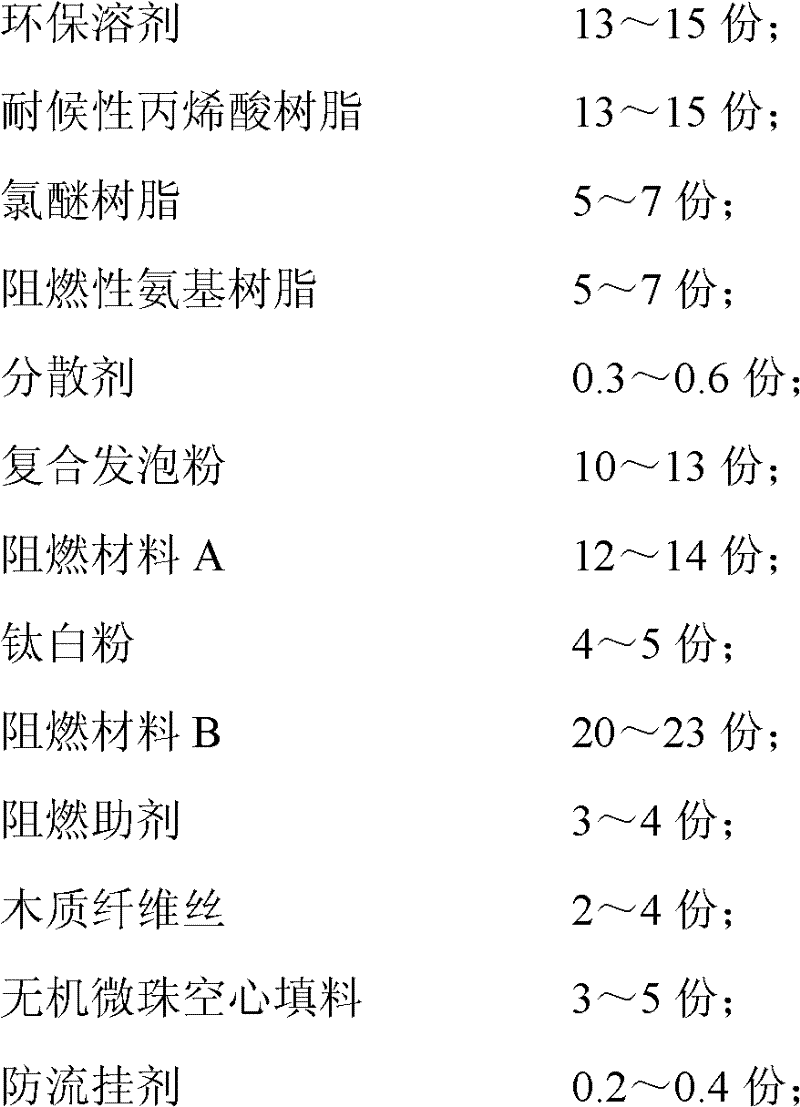

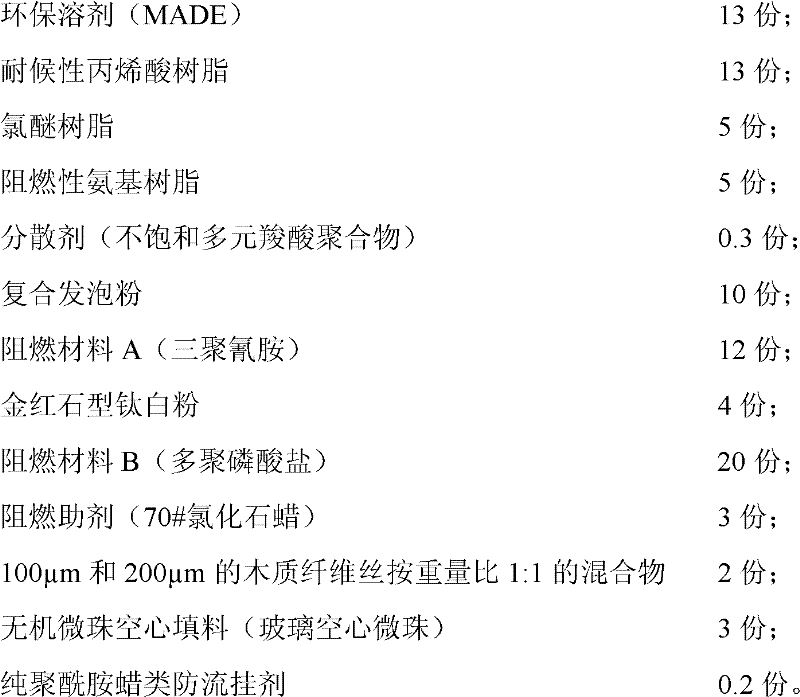

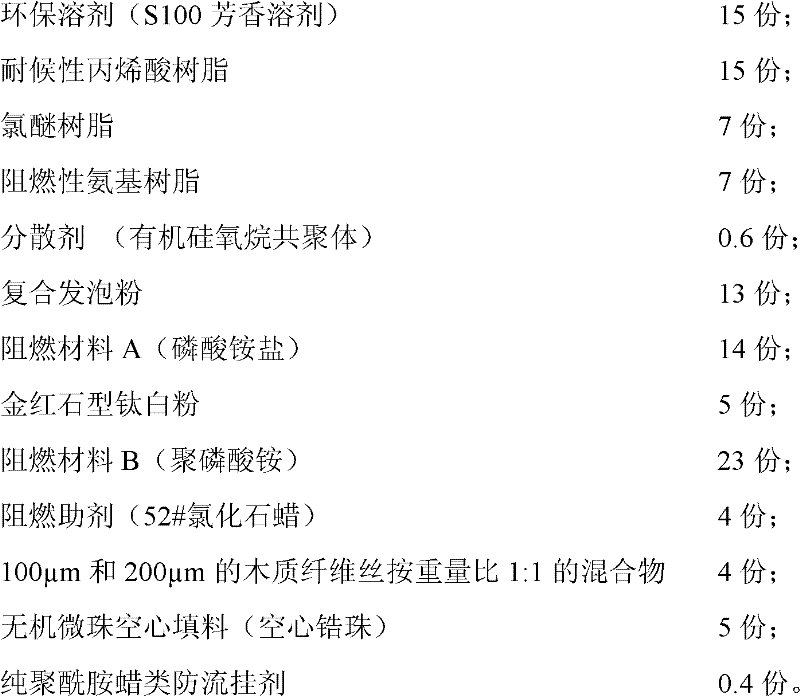

Fire retardant coating and preparation method thereof

ActiveCN102408802AExcellent weather resistanceStrong adhesion and durabilityFireproof paintsSolventWeather resistance

The invention discloses a fire retardant coating, which comprises the following components: an environment-friendly solvent, weather-proof acrylic resin, chlorinated polyether resin, flame retardant amino resin, a dispersing agent, composite foaming powder, a flame retardant material A, titanium white, a flame retardant material B, a flame retardant aid, wood fibers, an inorganic microbead hollowfiller and an anti-sagging agent. The invention also provides a preparation method for the fire retardant coating. The fire retardant coating can be coated on various substrates, is extra-thin, efficient and durable, is specially used outdoors, is resistant to the fire combustion of hydrocarbons, and has high chemical properties such as weather resistance, acid resistance, alkali resistance and the like, high adhesion and an attractive decorative effect, and paint films are fine; the fire retardant coating is uniformly expanded, and has a special foam structure and a high fireproof effect; and the product is environment-friendly and pollution-free, a production process is simplified, and the fire retardant coating is convenient to construct and can be used for coating with various fireproof requirements.

Owner:WUXI HUHUANG PAINT

PVC foaming coating, PVC foaming wallpaper and preparation method thereof

InactiveCN105062246AIdeal pore structureEnsure decompositionCovering/liningsFibre treatmentFoaming agentMicrosphere

The invention discloses a PVC foaming coating. The PVC foaming coating comprises, by weight, 330-350 parts of environmentally-friendly plasticizer, 360-390 parts of PVC paste resin, 15-18 parts of liquid stabilizer, 20-22 parts of AC foaming agent, 20-22 parts of microsphere foaming agent, 75-80 parts of titanium dioxide, 250-275 parts of ground calcium carbonate and 30-33 parts of matting agent. By means of the potassium / zinc liquid stabilizer, the AC foaming agent and the microsphere foaming agent, the foaming function of the PVC foaming coating can be effectively improved, the foaming ratio of PVC foaming wallpaper can be improved, and satisfactory foaming quality can be obtained.

Owner:NINGHAI CHANGHE ENVIRONMENTAL COATINGS

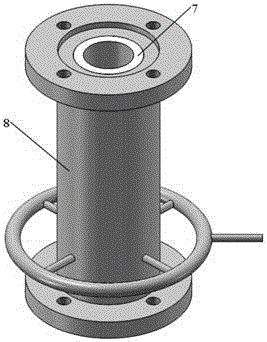

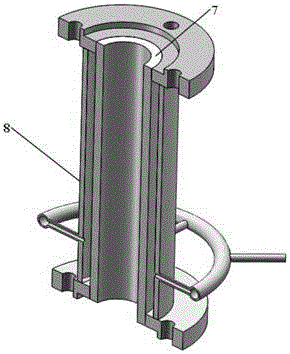

Two-phase flow device for researching enhancement of natural circulation capacity of system

ActiveCN106229017AAvoid disturbanceAdditional resistance is smallNuclear energy generationNuclear monitoringPorous mediumData acquisition

The invention provides a two-phase flow device for researching the enhancement of the natural circulation capacity of a system. The two-phase flow device consists of a circulating water system, an air bubble generation device, an air supply system and a data acquisition system, wherein the circulating water system mainly comprises an open type water tank, a filter device, a heat exchanger and other relevant pipelines and valves; the air bubble generation device is a core of the device and consists of an external sleeve and a multiporous medium sleeve; the air supply system mainly comprises an air compressor, an air storage tank and a pressure reducing valve; the data acquisition system mainly consists of an integrated data acquisition system, a high-speed camera system, a gas mass flow meter, an electromagnetic flow meter, a pressure sensor and a temperature sensor. The two-phase flow device can effectively solve the problem of disturbance to a natural circulation system due to active air injection and reduce the additional resistance involved into a circulation loop; the device is simple, easy to operate and uniform in foaming; stable bubble flow can be obtained; the two-phase flow device is favorable for scientific design of natural circulation and two-phase flow and engineering design of a passive safety system.

Owner:HARBIN ENG UNIV

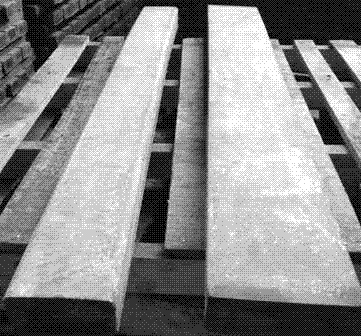

Foam microcrystalline glass made of high-silicon iron tailings and production method of foam microcrystalline glass

ActiveCN104788011AAddress pollution hazardsSave raw materialsGlass shaping apparatusCompressive resistanceFoaming agent

The invention relates to foam microcrystalline glass produced by using high-silicon iron tailings and a production method of the foam microcrystalline glass. Main raw materials of the foam microcrystalline glass comprise 70%-90% of the high-silicon iron tailings, 0.5%-5% of a foaming agent and 5%-30% of an additive, wherein the foaming agent is obtained by mixing carbon powder and calcium carbonate in a mass ratio being 2:1; the additive is obtained by mixing albite and talc in the ratio being 5: (0.5-1). During production, the raw materials are uniformly mixed, and the foam microcrystalline glass is prepared through preheating, sintering, foaming, crystallizing and annealing processes after forming. The foam microcrystalline glass has the advantages of small density, small heat conductivity coefficient, high compressive strength, easiness in processing and forming and the like and can be used for buildings such as a villa, a civic building, an industrial factory building and the like. The problems of high raw material production cost, complicated technology and the like of the foam microcrystalline glass are solved, pollution hazard of tailing accumulation to the environment is avoided, waste is turned into wealth, and energy saving and environmental protection are realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

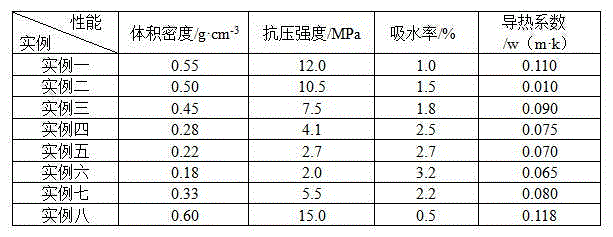

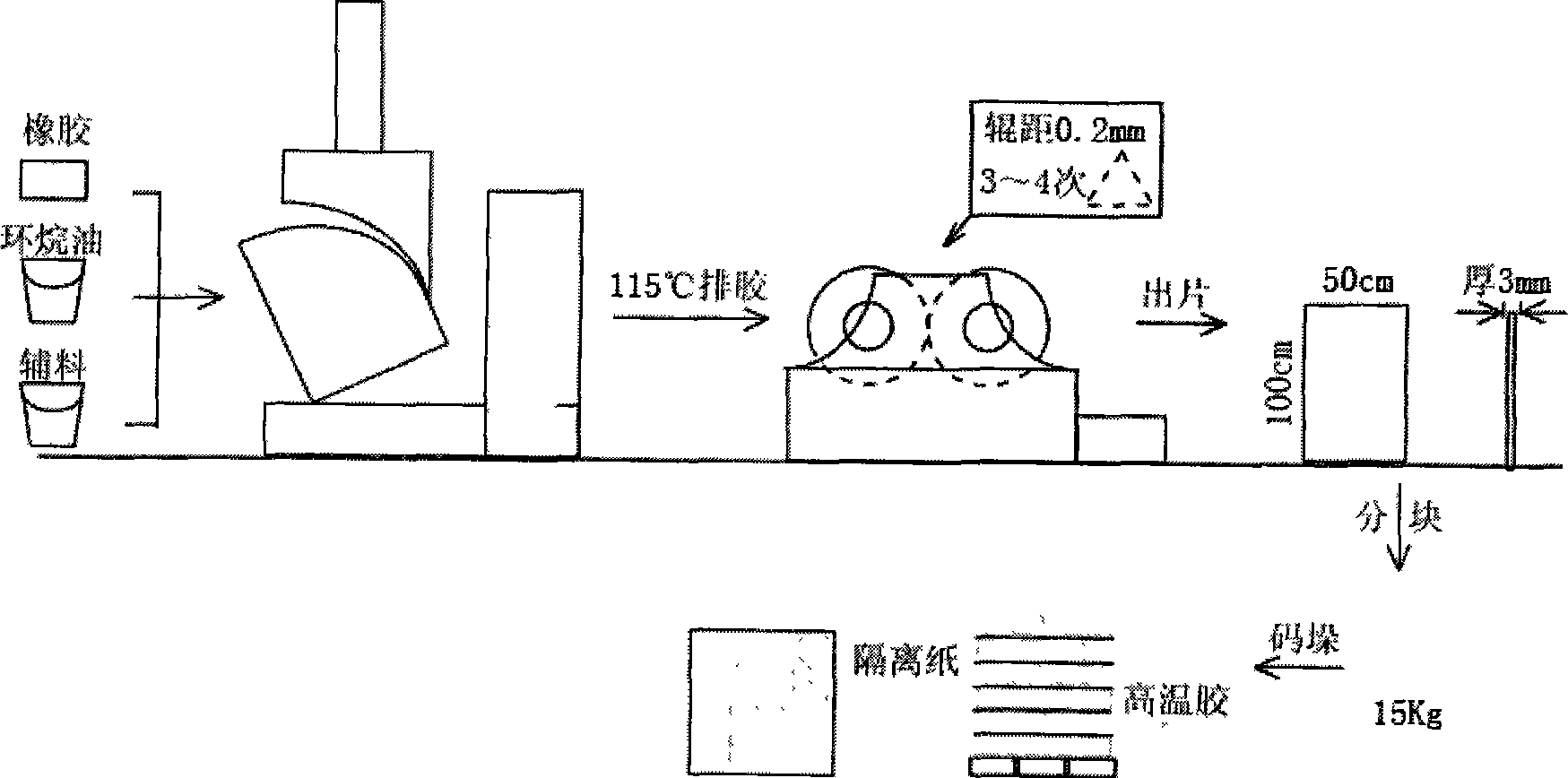

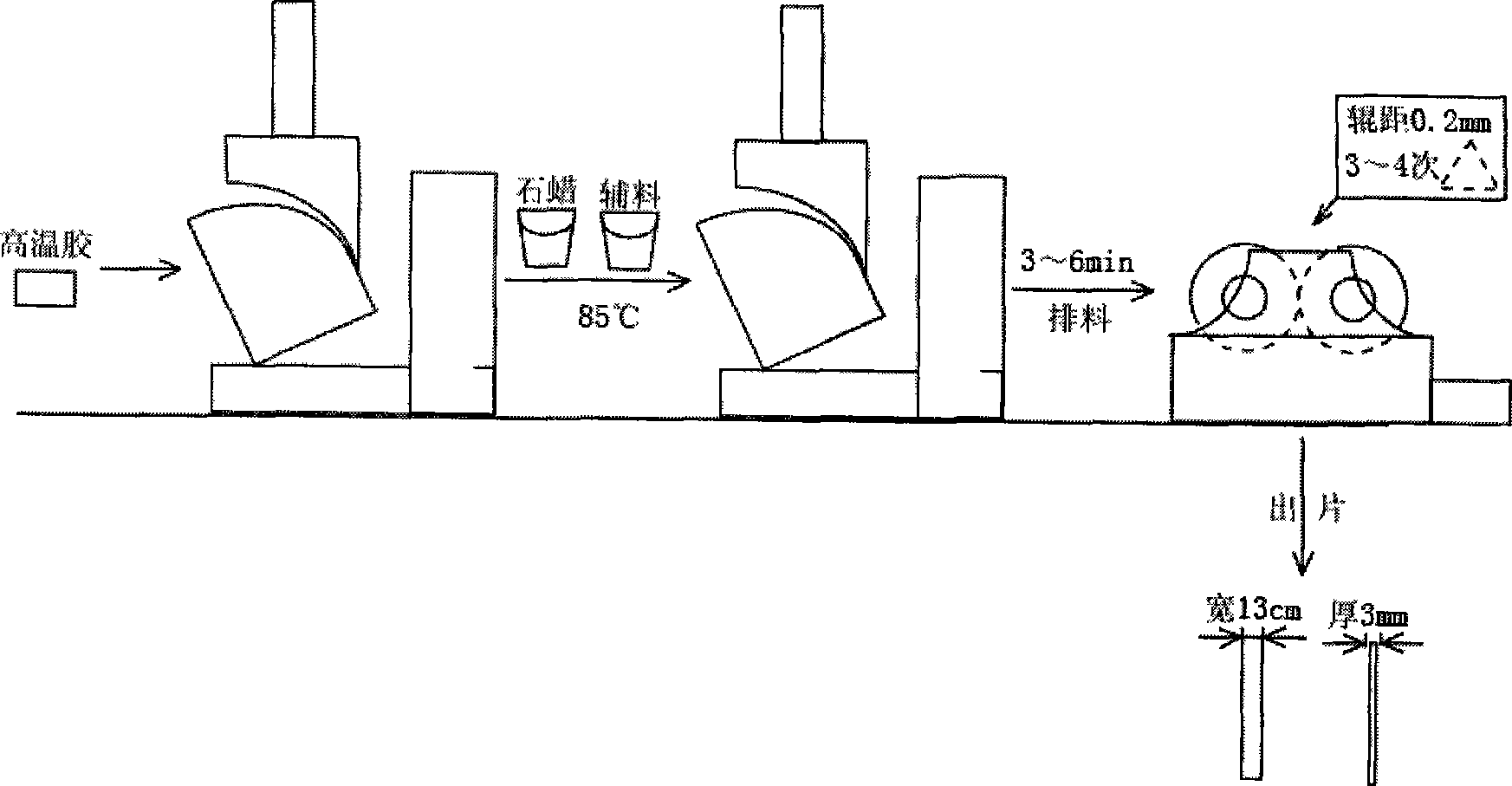

Foam material and moulding method thereof

InactiveCN101497721AUniform foamingLow compression setPolymer scienceEthylene-propylene-diene-monomer

The invention relates to a foaming material and a molding method thereof, in particular to an ethylene propylene diene monomer (EPDM) and chlorinated polyethylene (CPE) foaming material and a molding method thereof. The material is prepared in the following steps that: firstly, high-temperature mixed rubber containing ethylene propylene diene monomer (EPDM) and chlorinated polyethylene (CPE) is mixed in an internal mixer according to a formula; after piece output and placing, high-temperature mixed rubber is mixed into low-temperature rubber according to a mixture radio; after the low-temperature rubber is cut into pieces, foaming is extruded on an extruding machine; and secondary sulfuration and shaping are carried out in a drying tunnel after the extruding so as to manufacture the foaming material. The invention has the characteristics of favorable season durability, temperature durability, aging durability, damping seal, and the like, and can be applied to the fields of heat insulation of a central air conditioner and a pipeline of a refrigeration set, buffer pad, sound absorption, voice reduction, and the like.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

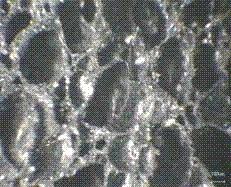

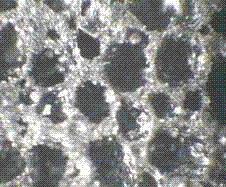

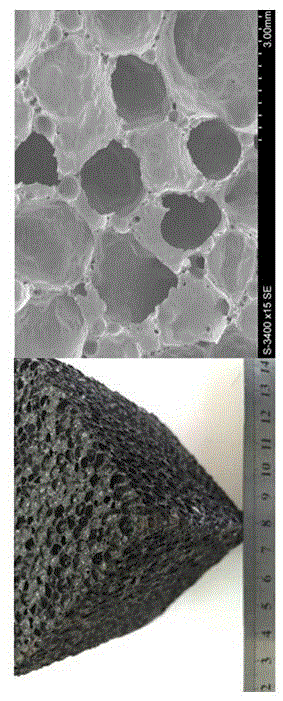

Super-light aluminum oxide foam ceramic and preparation method thereof

The invention relates to super-light aluminum oxide foam ceramic and a preparation method thereof. According to the technical scheme, sugar and aluminum oxide fine powder are used as raw materials, wherein the mass ratio of the sugar to the aluminum oxide fine powder is 1 to (0.4-1.6); and a combustion-supporting agent which is 0.1wt%-0.5wt% of the raw materials is additionally added and then is uniformly mixed with the raw materials to obtain a mixture; the mixture is heated to 100-200 DEG C and the heat is preserved for 1-3 hours to obtain a dispersion system in which the aluminum oxide fine powder and the combustion-supporting agent are dissolved into a sugar solution; then the dispersion system is foamed and cured for 8-25 hours under a continuous temperature condition of 120-180 DEG C; and a cured blank is heated to 1400-1600 DEG C and the heat preservation is performed for 3-9 hours to obtain the super-light aluminum oxide foam ceramic. The preparation method has a simple process and is environmentally friendly; and the product has low volume density, high porosity and high strength and has no cracks.

Owner:WUHAN UNIV OF SCI & TECH

Ultra-thin electron radiation crosslinked polyolefin foamed sheet and preparation method thereof

The invention relates to an ultra-thin electron radiation crosslinked polyolefin foamed sheet and a preparation method thereof. The preparation method comprises the following steps: step 1: adding LLDPE (Linear Low Density Polyethylene), EPDM (Ethylene-Propylene-Diene Monomer), EVA (Ethylene Vinyl Acetate), A171, DCP (Dibasic Calcium Phosphate), PE (Polyethylene) wax and an antioxidant 1010 to an internal mixer for fully internal mixing for 8-10 minutes at the internal mixing temperature of 70-100 DEG C, and then discharging the mixture into a double-stepped mixing granulator for mixing, grafting and granulation to obtain a grafting base material; step 2: adding the grafting base material, an AC foaming agent, a crosslinking agent, zinc stearate and talcum powder into a high-speed mixer for mixing, and then discharging the mixture into a single screw extruder to be extruded into a sheet; step 3: adding the extruded sheet in the step 2 to an electronic accelerator for radiation crosslinking; step 4: adding the sheet subjected to radiation crosslinking to a foaming furnace for foaming; and step 5: directly adding the formed sheet to a double-roll calender for calendering to obtain the electron radiation crosslinked polyolefin foamed sheet with the thickness of 0.1-0.3mm.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

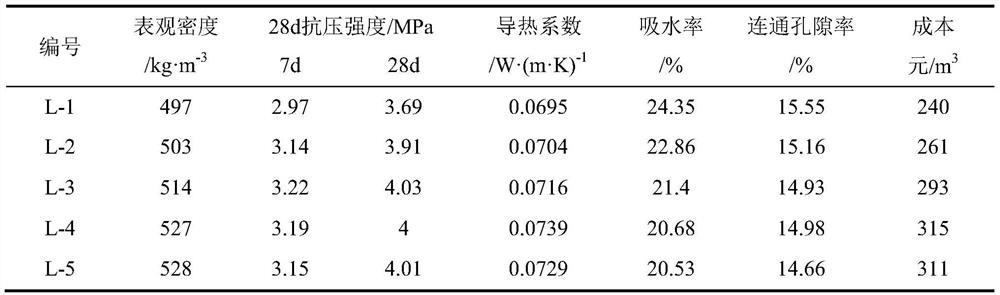

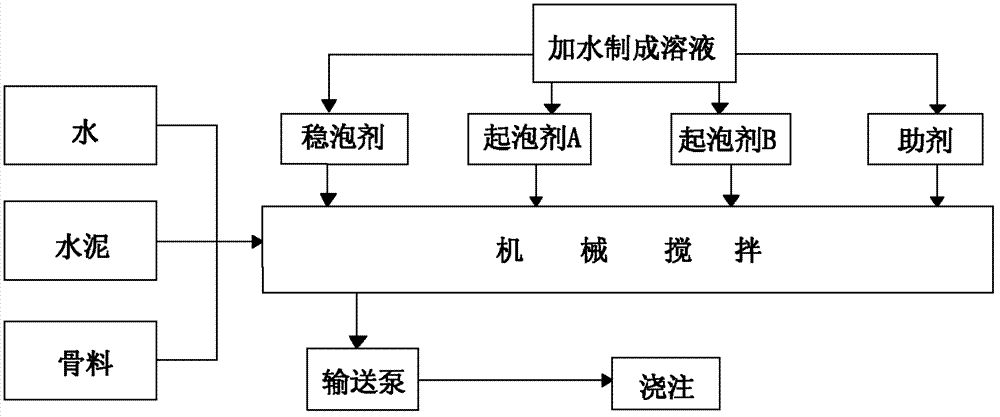

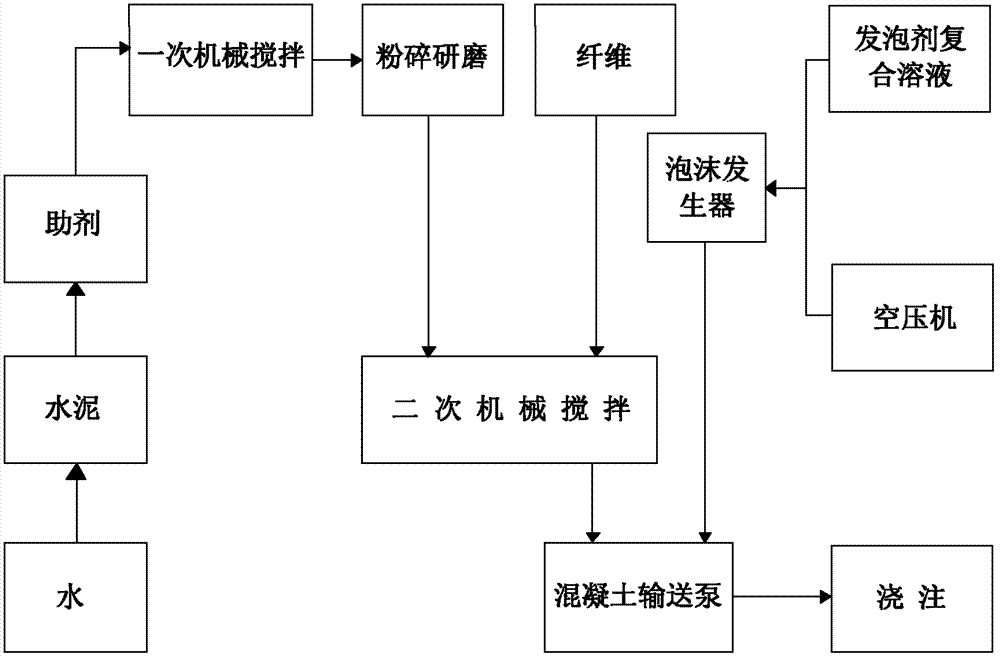

Non-autoclaved lightweight thermal insulation particle aerated concrete block and preparation method thereof

The invention discloses a non-autoclaved lightweight thermal insulation particle aerated concrete block and a preparation method thereof. The aerated concrete block comprises the following components:50 to 100 parts of cement, 0 to 37.5 parts of fly ash, 0 to 12.5 parts of superfine slag powder, 0 to 50 parts of light particles, 2 to 8 parts of a foaming agent, 0 to 5 parts of a coagulation accelerator, 0.025 to 0.175 part of a foam stabilizer, 0.2 to 1.4 parts of a water reducing agent, 0.1 to 0.7 part of a water repellent, 0 to 0.6 part of fibers and 30 to 60 parts of water. The aerated concrete block has the advantages of light weight, heat preservation and insulation, energy conservation, high strength, simple maintenance process and low cost, and solves the problems of non-ideal heatpreservation and insulation performance and complex maintenance process of the existing aerated concrete block.

Owner:CENT SOUTH UNIV +3

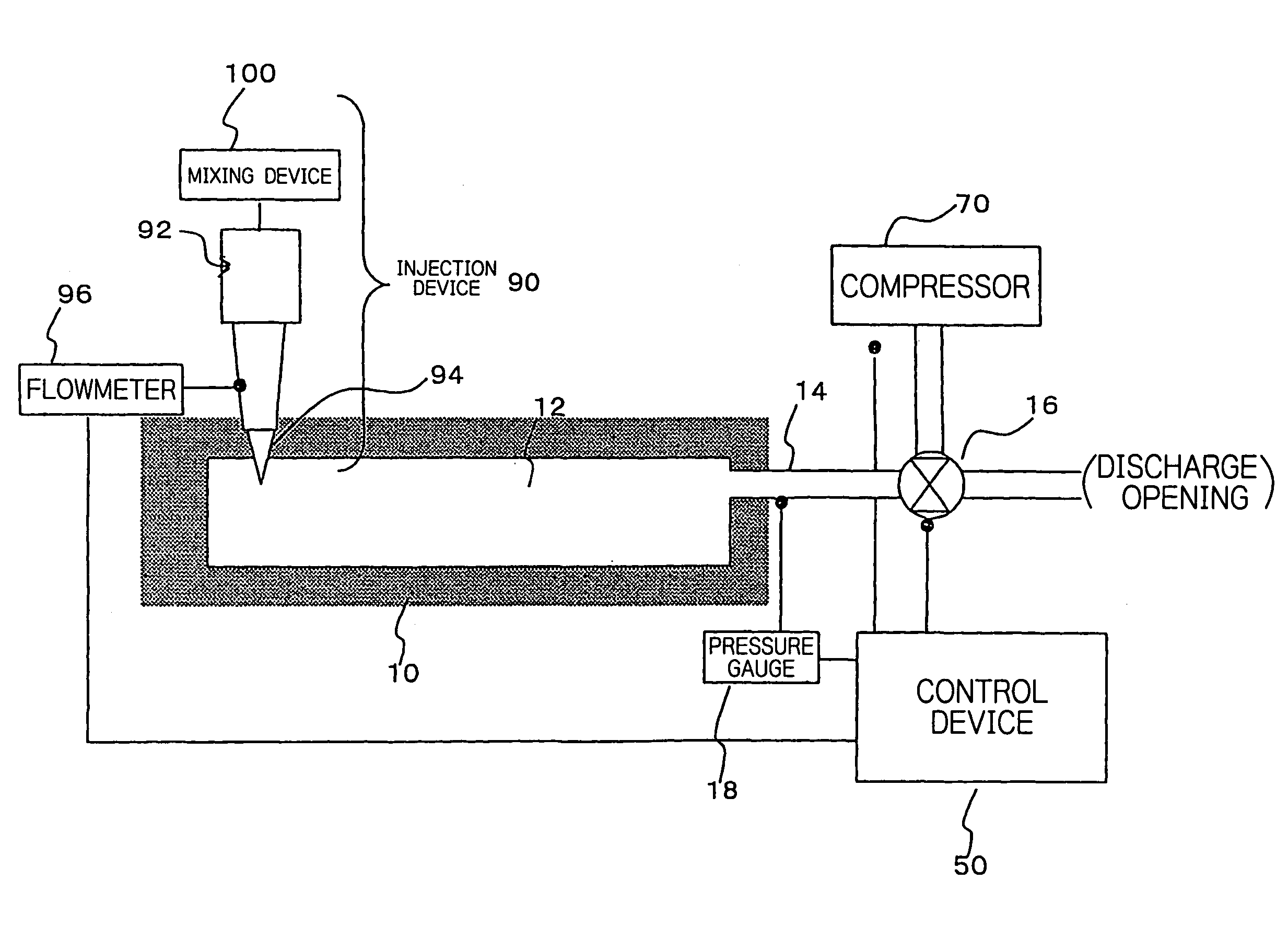

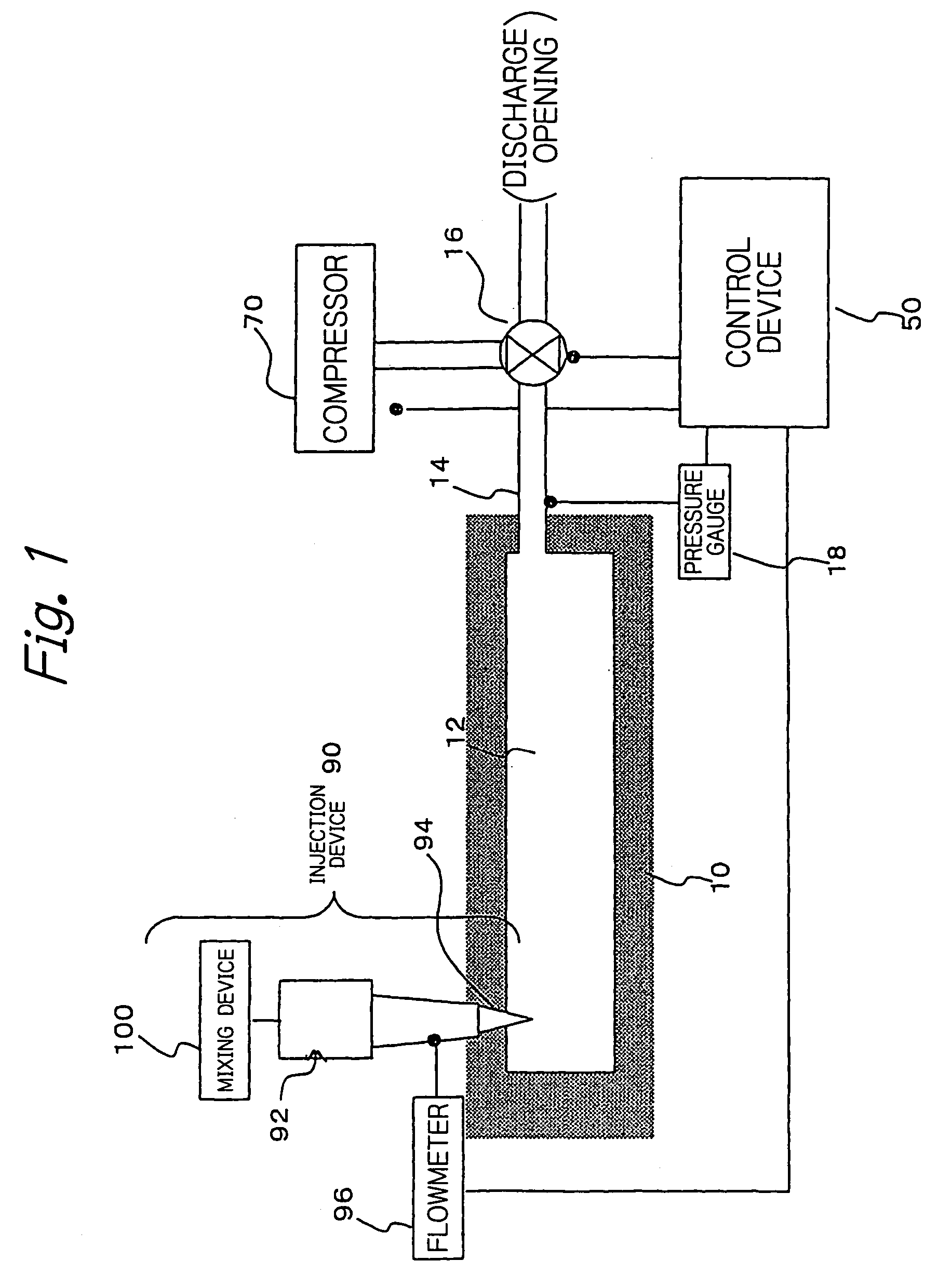

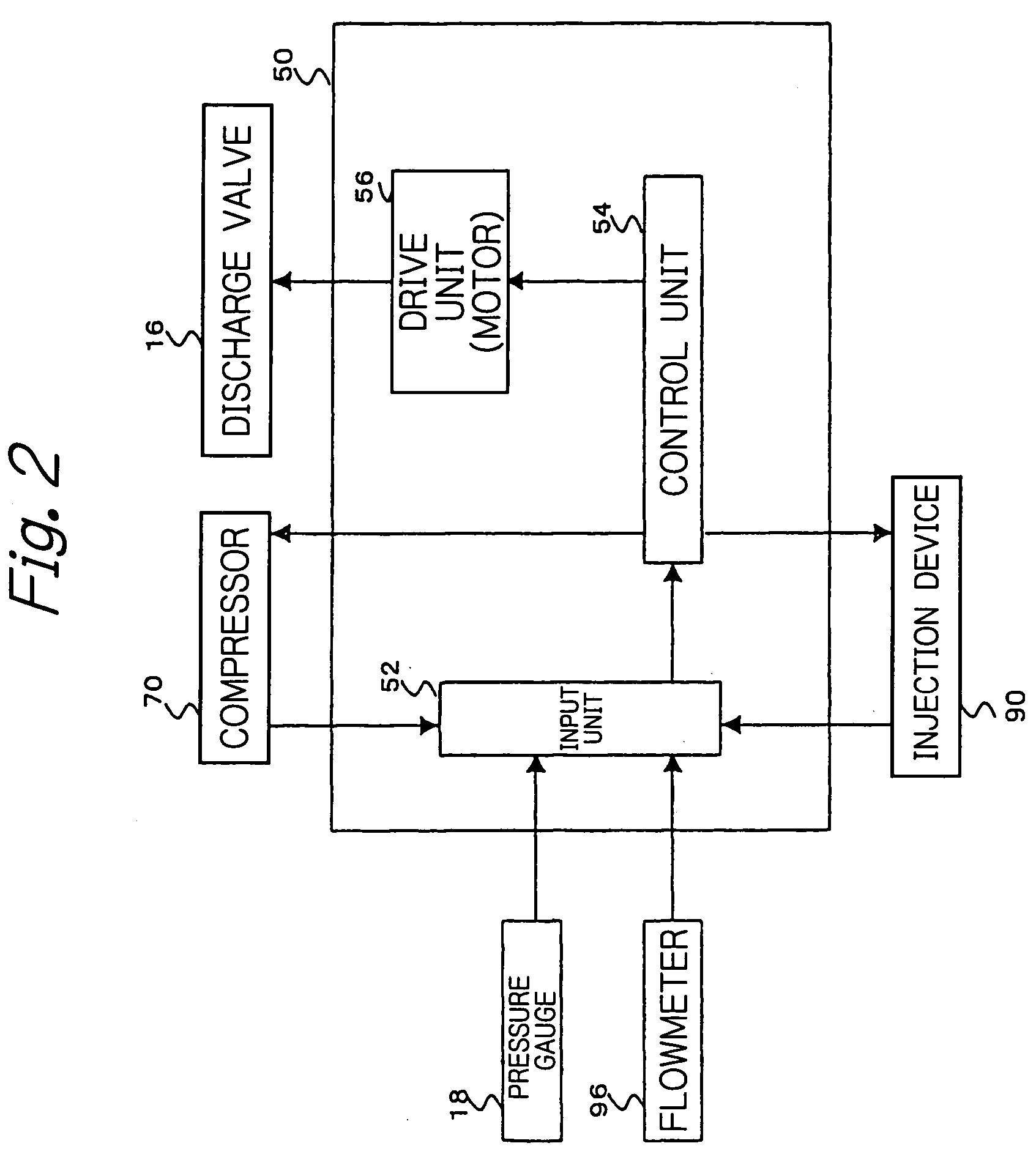

Method and apparatus for foam molding

It is an object of the present invention to provide a foam molding method for foaming and molding a foamable material, which is free from problems, such as deformation of or continuation between closed cells. To achieve this object, there is provided a foam molding method for foaming a foamable material, comprising the steps of providing a mold having a cavity, placing the cavity of the mold under a pressurized condition, foaming the foamable material in the cavity of the mold under the pressurized condition, thus appropriately controlling foaming of the foamable material, and releasing the pressurized condition of the cavity of the mold.

Owner:SUNSTAR GIKEN KK +1

Exterior wall board insulation material with excellent mechanical properties

The invention discloses an exterior wall board insulation material with excellent mechanical properties. The exterior wall board insulation material comprises the following raw materials in parts by weight: 30-60 parts of expanded polystyrene, 25-35 parts of polyurethane-modified epoxy resin, 35-45 parts of organosilicon-modified phenolic resin, 8-12 parts of modified graphite powder, 1.5-2.5 parts of bis-tributylphenol polyoxyethylene ether, 3-4 parts of epoxidized soybean oil, 4-8 parts of mica powder, 8-12 parts of graphene nanosheet, 6-10 parts of calcium silicate, 2-4 parts of aluminum oxide, 3-5 parts of sodium silicate, 2-3 parts of magnesium oxide, 4-12 parts of calcined clay, 1.5-2.5 parts of phosphoric acid, 1.5-2.5 parts of p-methylsulfonic acid, 2-3 parts of a physical foaming agent and 35-55 parts of water. The exterior wall board insulation material with the excellent mechanical properties, provided by the invention, is uniformly foamed, has excellent heat insulation and the excellent mechanical properties, and has very good fire resistance.

Owner:芜湖雪丛林建材有限公司

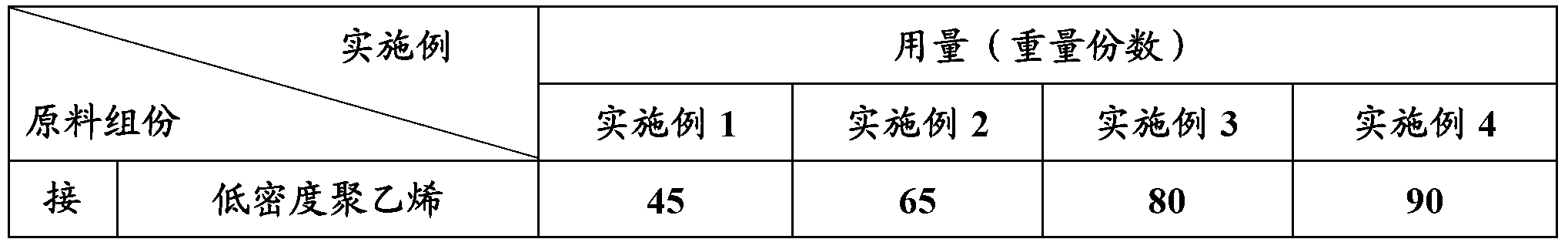

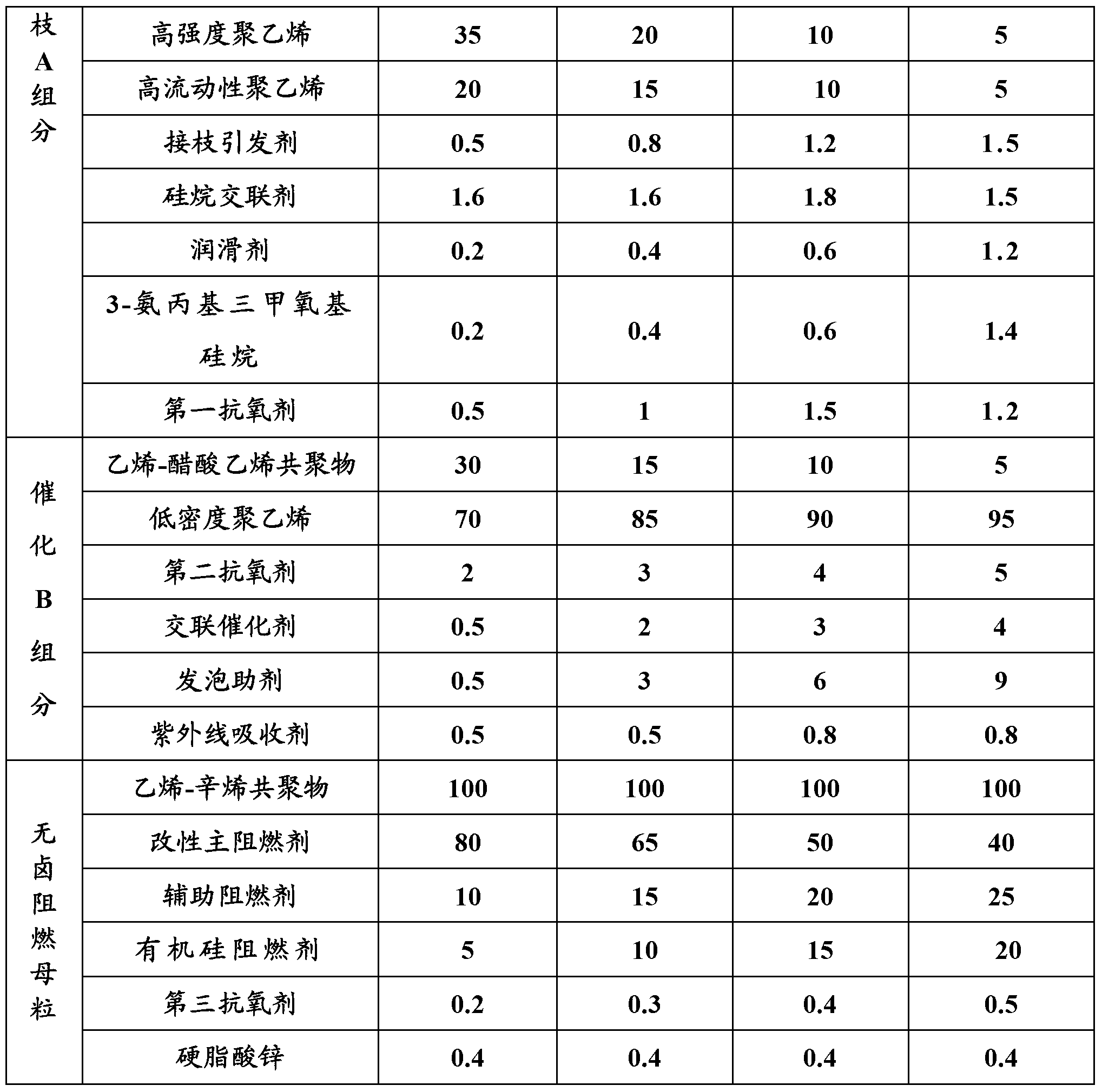

Silicane self-crosslinked halogen-free flame retardant polyolefin foamed composite and preparation method thereof

ActiveCN103224681ADifferent expansion ratioDifferent Flame RetardancyLow-density polyethylenePolyolefin

The invention relates to a silicane self-crosslinked halogen-free flame retardant polyolefin foamed composite and a preparation method thereof. The composite comprises a grated component A, a catalytic component B and halogen-free flame retardant masterbatch according to a weight proportion of 100: (3-10): (10-60), wherein the grated component A comprises low-density polyethylene, high-strength polyethylene, high-flow polyethylene, a silane crosslinking agent, a grafting initiator, a first antioxidant, a lubricating agent and 3-aminopropyl trimethoxy silane; the catalytic component B comprises an ethylene-vinyl acetate copolymer, low-density polyethylene, a second antioxidant, a crosslinking catalyst, a foaming aid and an ultraviolet light absorber; and the halogen-free flame retardant masterbatch comprises an ethylene-octylene copolymer, a modified main flame retardant, an auxiliary flame retardant, zinc stearate and a third antioxidant. The silicane self-crosslinked halogen-free flame retardant polyolefin foamed composite has the characteristics of excellent flame retardance, low smoke and toxicity, uniformity in foaming, natural crosslinking property, high temperature resistance and the like.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Coextruded polyethylene film

ActiveUS20160059515A1Less undulationLow viscositySynthetic resin layered productsDomestic containersPolymer chemistryPolymer

A coextruded polyethylene blown film, particularly for packaging, has a thickness between 20 μm and 250 μm and is formed by a foamed, particle-containing core layer between a first unfoamed weldable outer layer and a second unfoamed outer layer. The core layer has a polyethylene or a polyethylene-based mixture as a polymer component having a melt mass-flow rate (MFR) per DIN ISO EN 1133 of greater than 5 g / 10 min at 190° C. and 2.16 kg.

Owner:MONDI GROUP

Light environment-friendly brick prepared from waste brick powder, and preparation method for light environment-friendly brick

InactiveCN102515691ASolve the problem of foaming rate controlUniform foamingSolid waste managementBrickFoaming agent

The invention discloses a light environment-friendly brick prepared from waste brick powder, and a preparation method for the light environment-friendly brick. The light environment-friendly brick prepared by the method comprises the following raw materials in percentage by weight: 50 to 60 percent of polishing brick waste mud, 10 to 15 percent of waste brick powder, 10 to 15 percent of Qidao clay, 10 to 15 percent of aluminum ore, 5 to 10 percent of mung bean mud, 0.3 percent of foaming agent, 0.5 percent of water reducing agent and 0.08 percent of green body intensifier, wherein the polishing brick waste mud is waste mud which is wasted when a polishing brick is produced; and the waste brick powder is brick powder which is wasted when a common brick is produced. The problems about control over foaming rate and flatness of a product in a drying and calcination process can be solved, the prepared finished product is smooth and flat in surface, and closed air holes in the brick are ideal. Meanwhile, the waste brick powder and the waste mud in a ceramic production enterprise are used as raw materials, so industrial waste is treated, production cost is saved, environment is protected, and energy consumption is reduced.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

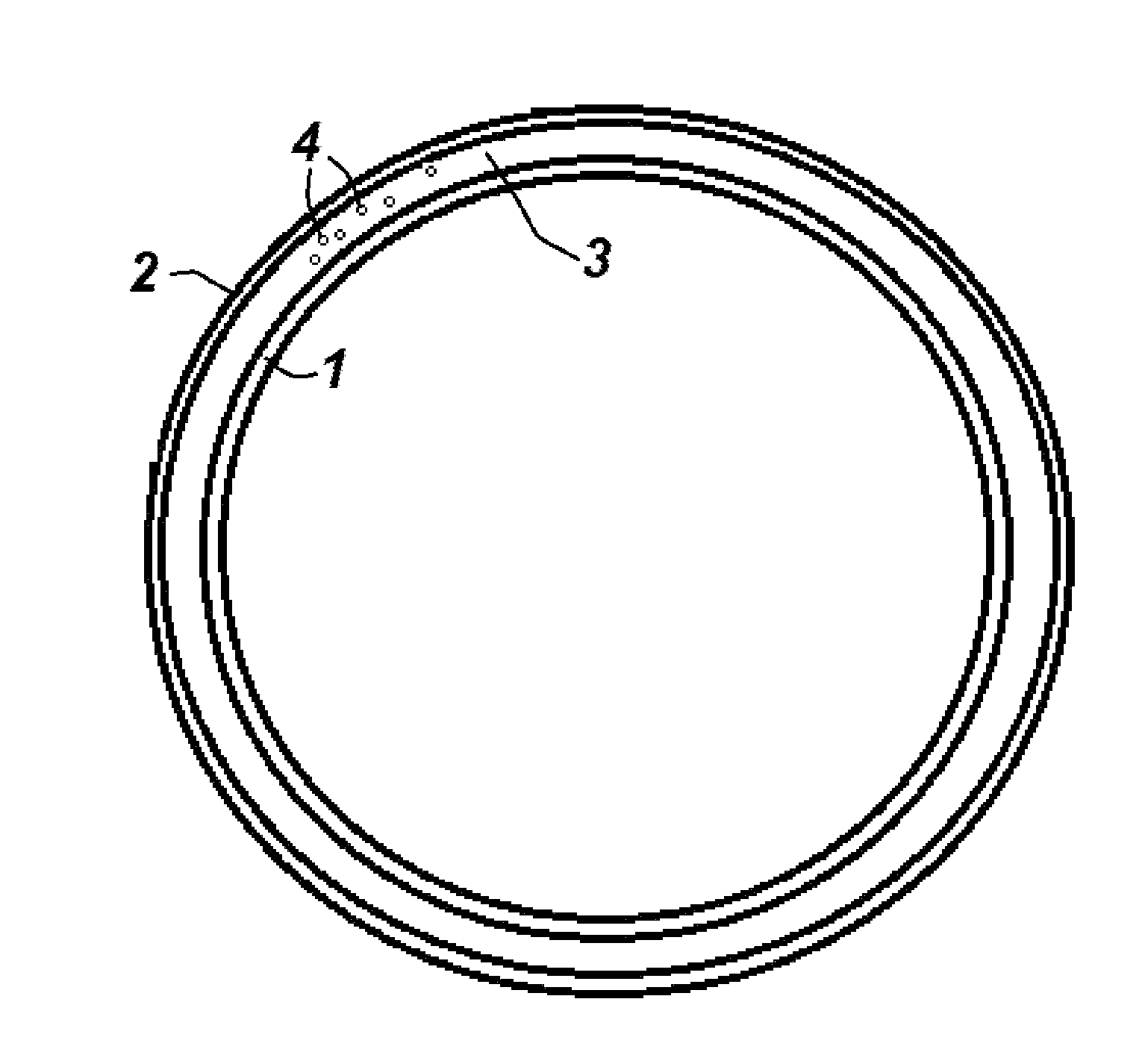

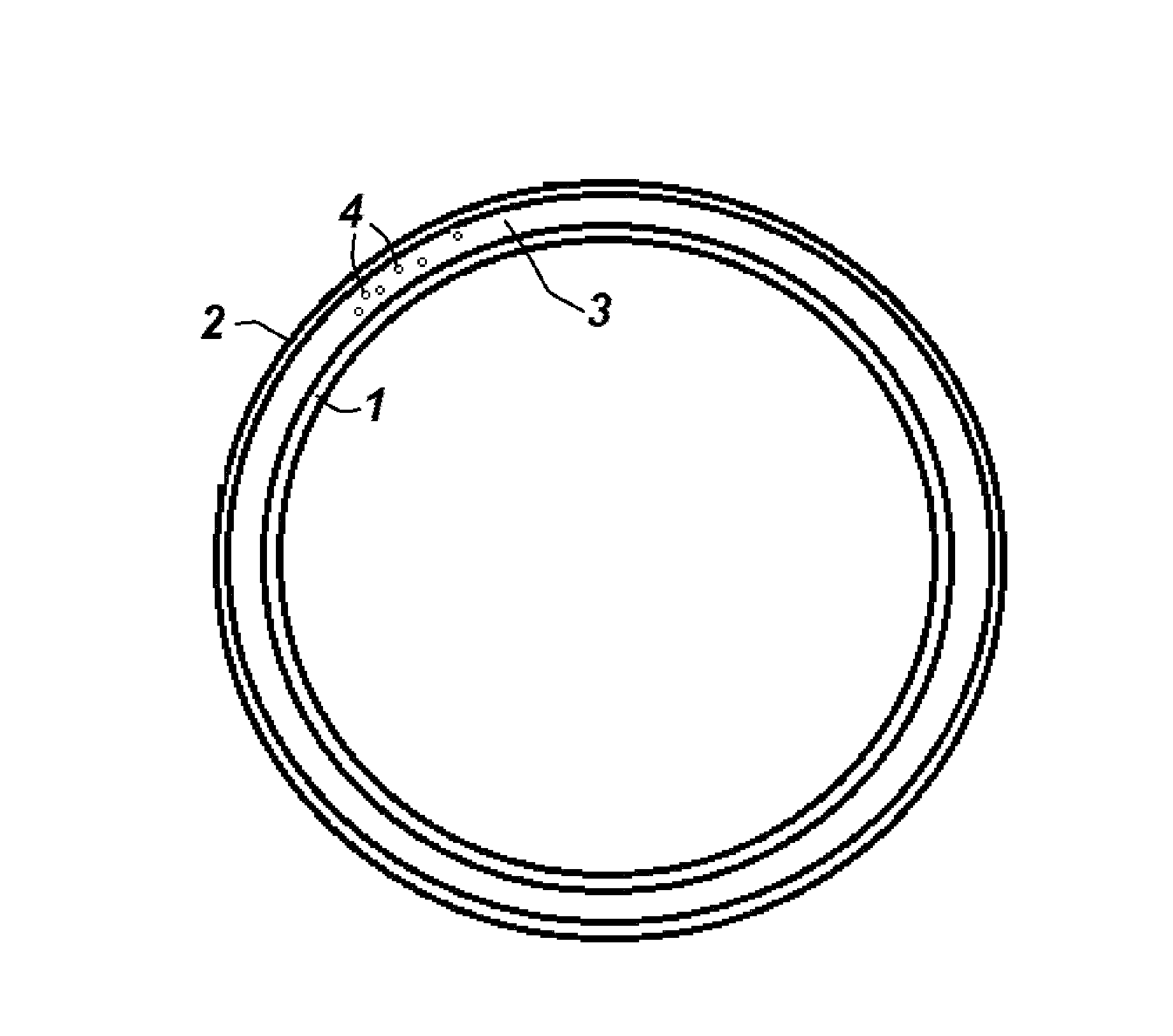

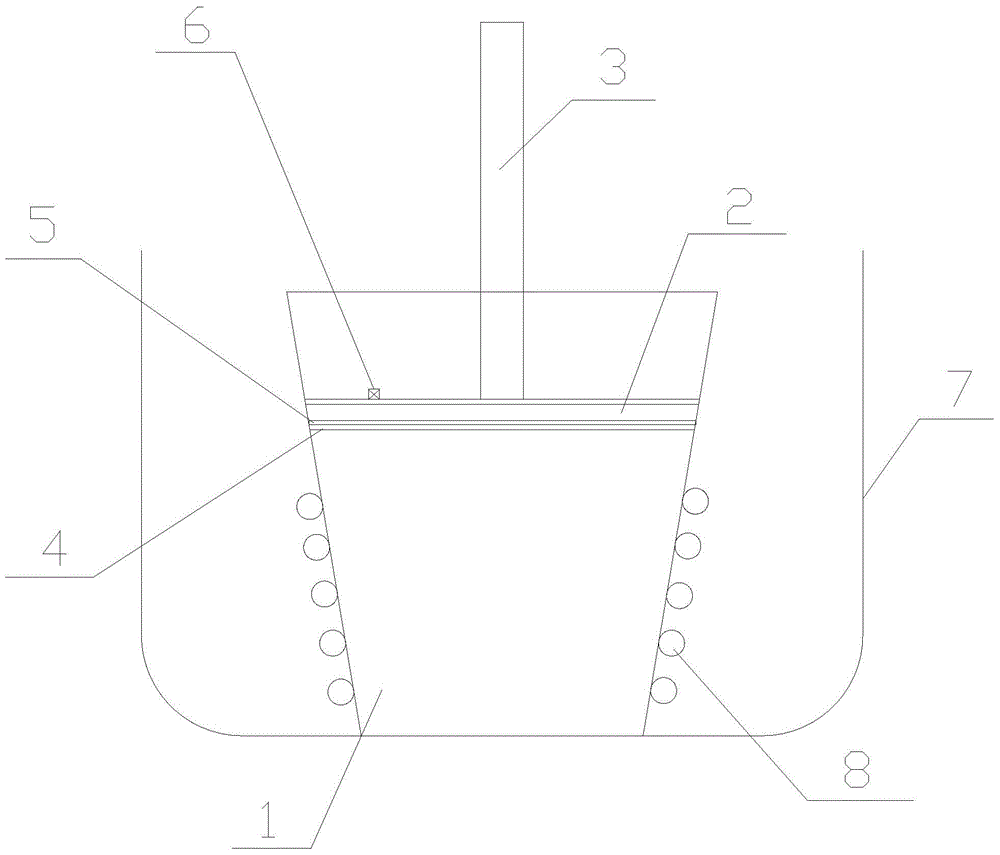

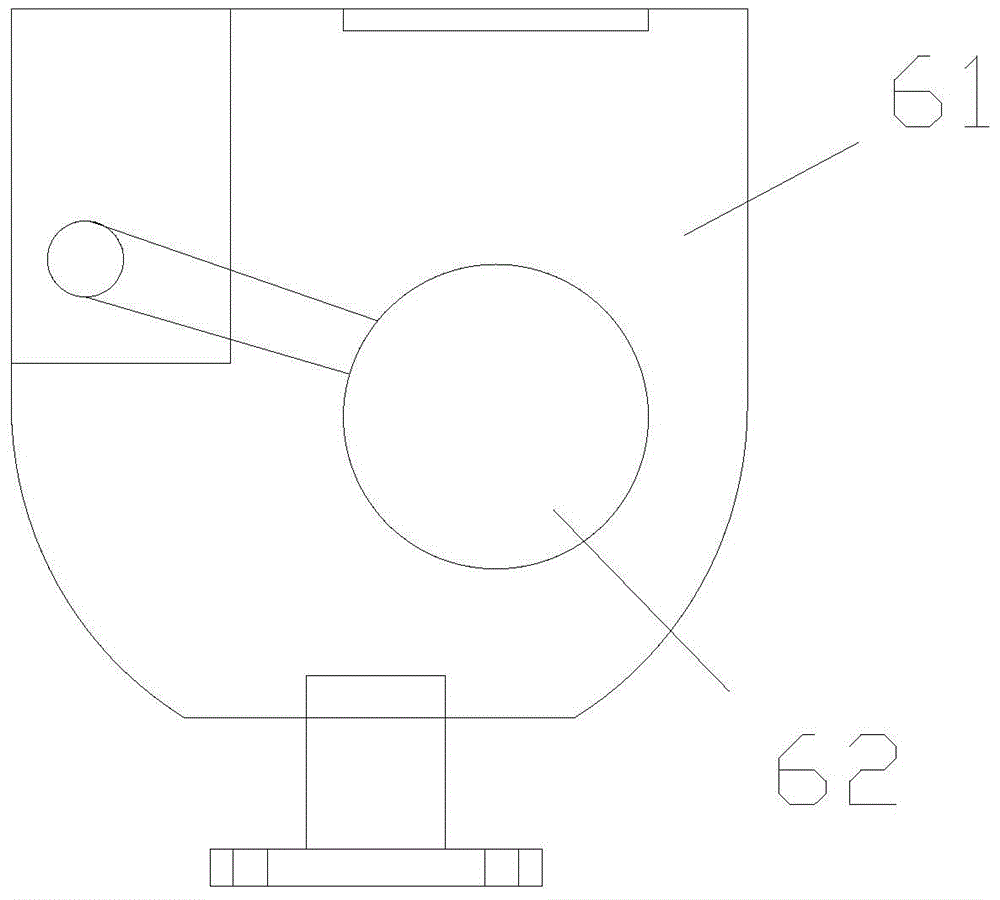

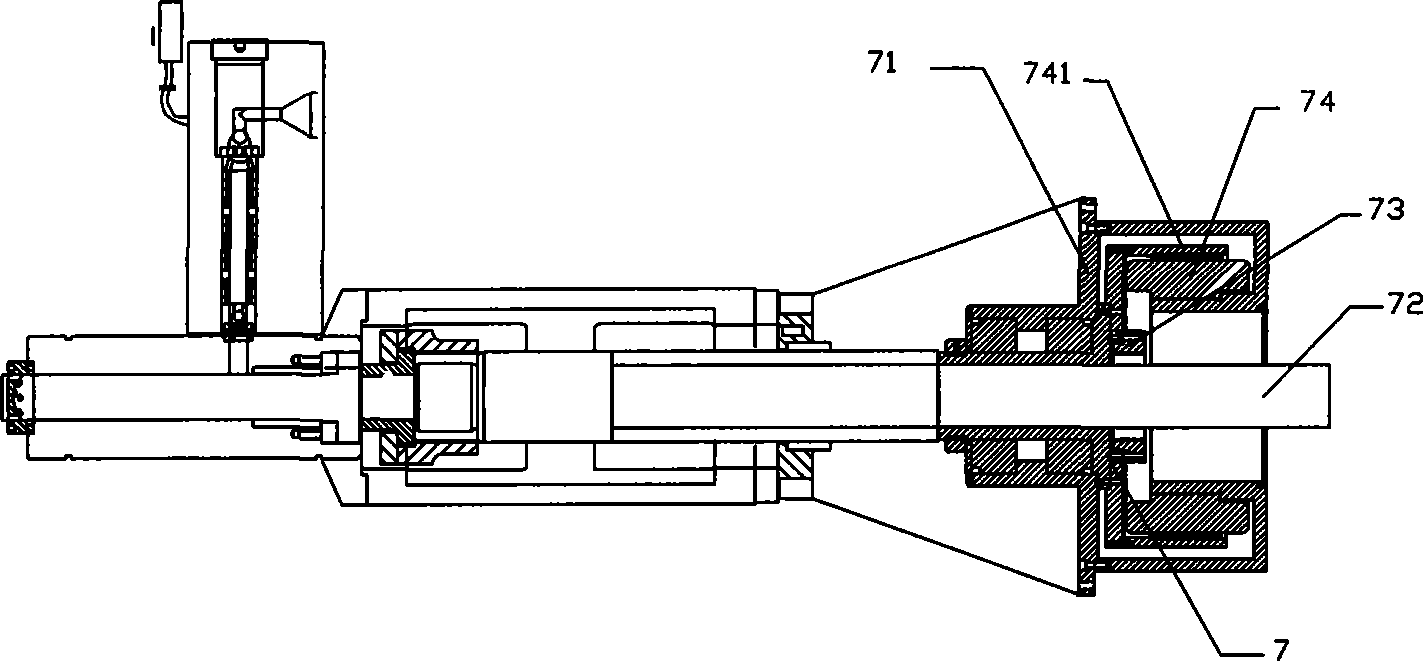

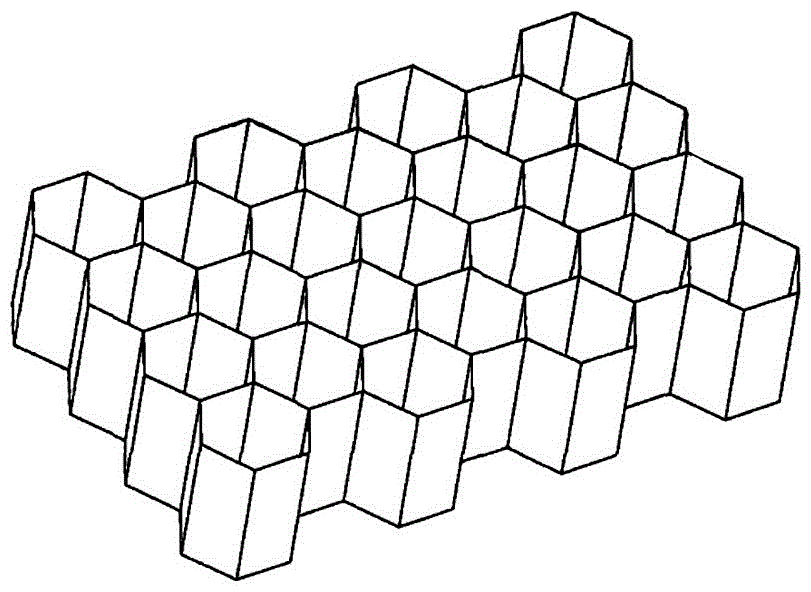

Device for improving foaming uniformity of foamed aluminum and foaming technology

Provided is a device for improving a foaming uniformity of foamed aluminum. The device comprises a mould case provided with a foaming cavity. The mould case is designed into a big-end-up platform or a square pyramid opening cavity structure. The mould case is provided a pressurizing cover plate with multiple dimensions in a matched mode. The center portion of the pressurizing cover plate is connected with a hydraulic piston rod. The peripheral edge of the pressurizing cover plate is provided with a sealing ring. The pressurizing cover plate is further provided with an electric heater unit and one or more exhaust valves. A mould case body is arranged inside a thermal insulating chamber, and a melt is prevented from solidifying in a excessively fast mode. The outer wall of the mould case is provided with cooling pipelines. Cooling treatment is carried out on the melt according to needs. The structure is simple, the design is novel, by adopting pressurizing and cooling, after the melt is cooled to a semi-solid state and thickened, natural foaming or decompression foaming is carried out, and bubbles are prevented from floating upwards. The up and down consistency of the foamed melt density can be guaranteed, it is guaranteed that foaming is even, the product yield is improved, and the problem that a traditional melt foaming method is uneven in foaming is solved.

Owner:ANHUI NEOFOUND TECH

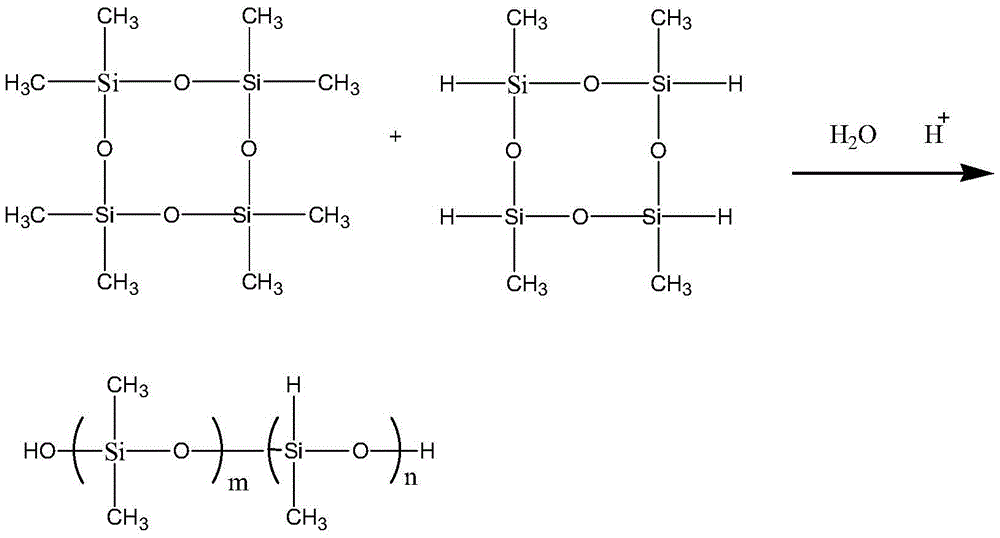

Organic foaming silicone rubber

The invention discloses organic foaming silicone rubber. The organic foaming silicone rubber is prepared by mixing, by weight, 100 parts of hydroxy-terminated hydrogen-containing polysiloxane, 5-50 parts of vinyl silicone oil, 5-40 parts of white carbon black, 0.2-2 parts of a reaction inhibitor and 0.1-1 part of a platinum catalyst. The foaming ratio can be controlled flexibly, reaction cross-linking points are increased, stability is good, foaming is uniform, and a foaming agent does not need to be used.

Owner:浙江凌志新能源科技有限公司

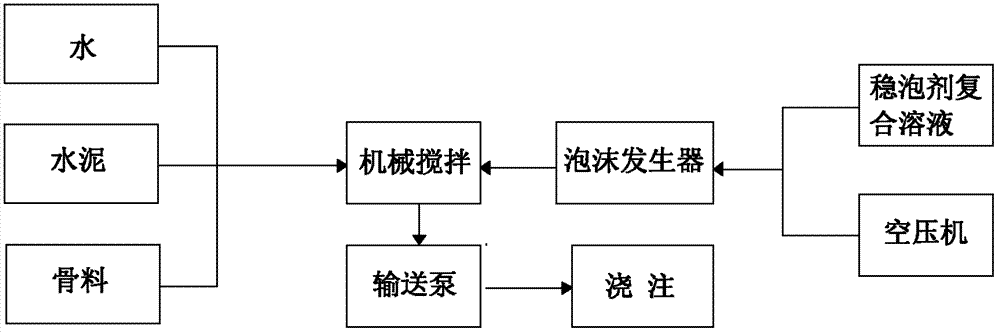

Inorganic foamed concrete insulation board and preparation method thereof

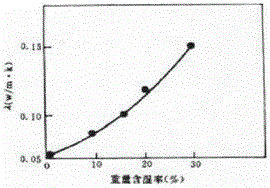

InactiveCN103086734AImprove compressive strengthSolve subsidence and subsidenceCeramicwareThermal conductivityFoam concrete

The invention provides an inorganic foamed concrete insulation board and a preparation method thereof. The insulation board comprises foamed concrete, and has density of 160-250kg / m<3>, compressive strength of 0.3-0.5 MPa, and coefficient of thermal conductivity of 0.05-0.062 W / m.K. The prepared insulation board has the characteristics of low unit weight and good heat insulation effect, and can be widely used as an insulation material in the field of construction.

Owner:杨奎利

Helmet manufacture method and products thereof

InactiveCN101417489AAppearance crispImprove waterproof performanceLayered productsHelmetsCheck valveGas bubble

The invention relates to a manufacturing method of a helmet, comprising the following steps: manufacturing an injection mold of a plastic helmet; manufacturing mixed foamed plastic liquid, leading the liquid into a first storage machine barrel, extruding the liquid out of the first storage machine barrel, then leading the liquid into an injection machine barrel by a first check valve, simultaneously feeding materials into the first storage machine barrel by a feeding machine barrel, pressurizing the injection machine barrel, carrying injection until the mold is molded, firstly cooling the surface of the plastic liquid, measuring the current amount of injection of the injection machine barrel and the current output speed of the feeding machine barrel, adjusting the output speed of the feeding machine barrel, adjusting the rotating speed of a screw of the feeding machine barrel so as to control the feeding speed of the plastics and simultaneously adjusting the admission speed so as to match the feeding speed of the plastics. The product obtained according to the method comprises a lining which is coated by an outer layer; the helmet product obtained according to the method comprises the outer layer which does not contain bubbles or contains few bubbles and an inner core containing bubbles; and the inner core is coated by the outer layer.

Owner:UNION PLASTIC HANGZHOU MACHINERY

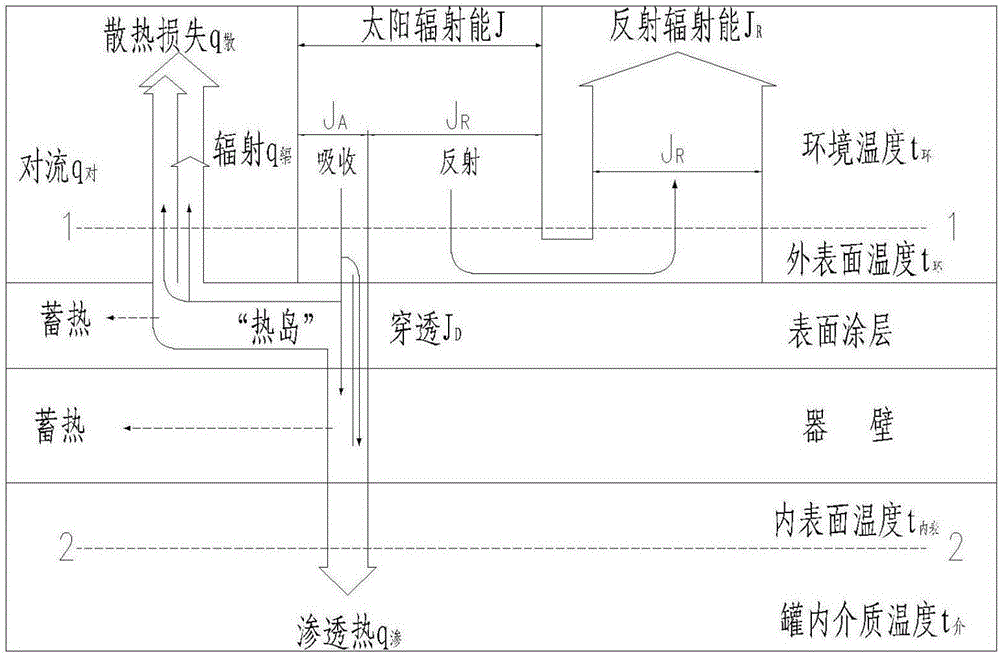

Energy saving fireproof paint and preparation method thereof

The invention provides energy saving fireproof paint and a preparation method thereof. The energy saving fireproof paint comprises the following components in parts by weight: 20-30 parts of a fire retardant, 7-12 parts of a carburization agent, 7-12 parts of a foaming agent, 9-15 parts of an inorganic hollow material, 10-22 parts of titanium dioxide, 31-43 parts of a cross-linking agent, 3-5 parts of an anti-aging agent, 2-5 parts of magnesium hydroxide, and 2-5 parts of diatomite. The energy saving fireproof paint has the advantages of solar heat reflection, heat insulation, water resistance, and corrosion resistance, and the advantages are identical to the advantages of energy saving paint; at the same time the energy saving fireproof paint has the advantages of self-extinguishing, flame retardation, formation of a compact heat insulating protective layer by expansion during fire hazard, and the like, and the advantages are identical to the advantages of fireproof paint.

Owner:广州市环康机电工程安装有限公司 +2

Overturned foaming clamping apparatus

Owner:CHANGHONG MEILING CO LTD

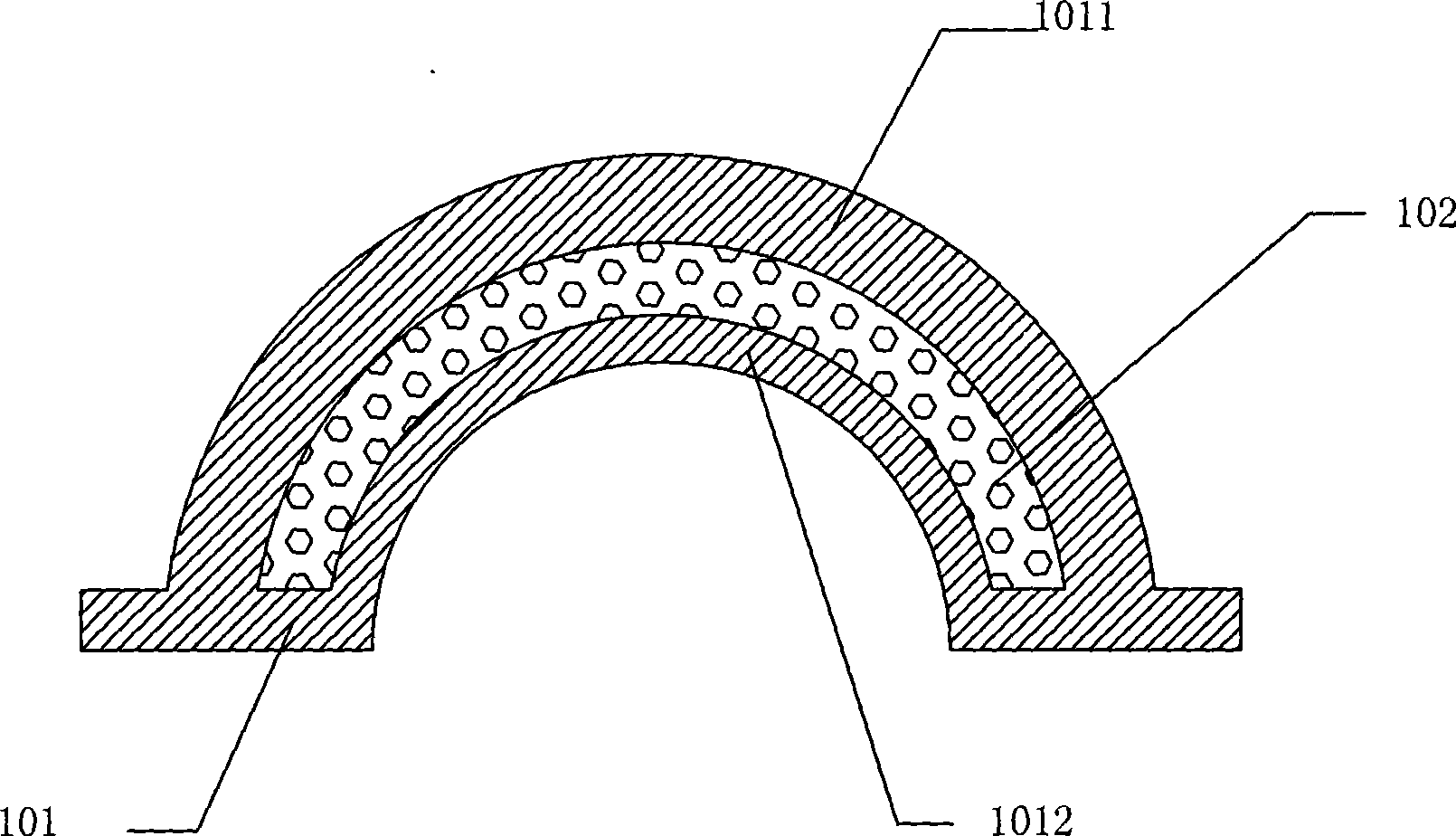

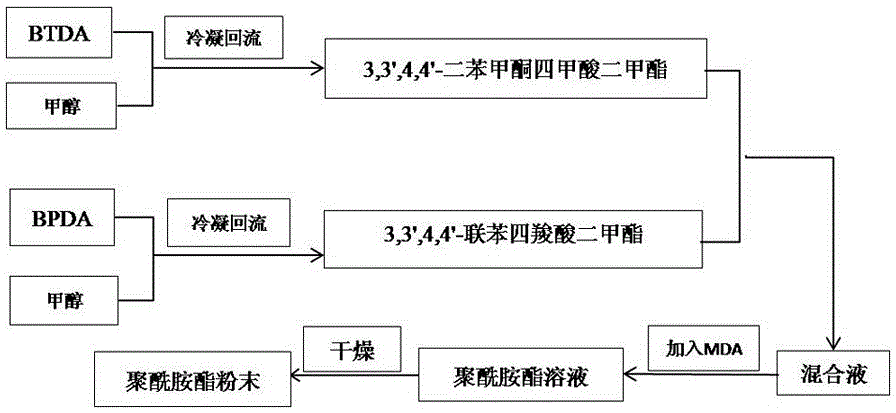

Carbon fiber honeycomb reinforced polyimide foam material and preparation method thereof

The invention provides a carbon fiber honeycomb reinforced polyimide foam material and a preparation method thereof. The foam material is obtained through a reaction of polyimide prepolymer powder and a carbon fiber honeycomb material. A preparation method of the polyimide prepolymer powder comprises the steps that BTDA and methyl alcohol are reacted for 1.5-2.5 h in a backflow state to prepare a 3,3',4,4'-benzophenone tetramethyl acid dimethyl ester solution, BPDA and methyl alcohol are reacted for 10-11 h in a backflow state to obtain a 3,3',4,4'-biphenyl tetracarboxylic acid dimethyl ester solution, the obtained 3,3',4,4'-benzophenone tetramethyl acid dimethyl ester solution and the obtained 3,3',4,4'-biphenyl tetracarboxylic acid dimethyl ester solution are mixed, MDA is added into the mixture, stirring is performed at room temperature for 0.5-1 h, a foam stabilizer is added, stirring continues to be performed for 0.5-3 h, a polyimide prepolymer solution is prepared, and the polyimide prepolymer solution is dried to obtain the polyimide prepolymer powder, wherein the mole ratio of the BTDA to the BPDA is (6-8):(2-4). The carbon fiber honeycomb reinforced polyimide foam material has uniform foam holes and quite high mechanical property and is low in production cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

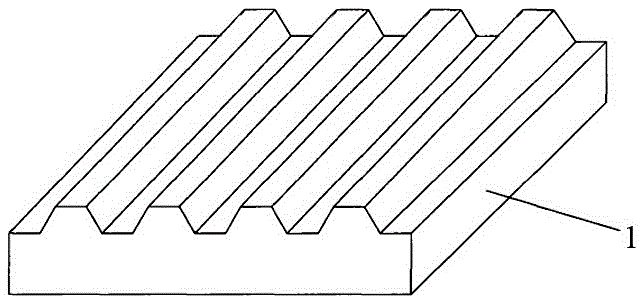

Polyvinyl chloride co-extrusion foaming furniture board and manufacturing method thereof

ActiveCN108384156AHigh hardnessHigh surface hardnessSynthetic resin layered productsPolyvinyl chlorideTriple superphosphate

The invention discloses a polyvinyl chloride co-extrusion foaming furniture board and a manufacturing method thereof, belongs to the technical field of polyvinyl chloride boards, and aims at solving the problems of high density, low hardness and toughness, and rough surface of the conventional product. The polyvinyl chloride co-extrusion foaming furniture board comprises a core layer and a surfacelayer, wherein the core layer comprises 60-80 parts of polyvinyl chloride SG8 type resin, 45-60 parts of triple superphosphate, 35-50 parts of recovery material, 5-6 parts of foaming conditioner P, 2.8-3.2 parts of a calcium-zinc stabilizer, 0.5-0.6 parts of an inner lubricating agent SP-60, 0.1-0.25 part of micronized polyethylene wax N-14P, 0.4-0.5 part of a plasticizer OA, a foaming agent anda pigment. The method comprises the following steps: preheating a heat mixing pot; sequentially adding chloroethylene resin, recovery material, calcium powder and the lubricating agent in sequence; heating; sequentially adding the foaming agent, the foaming conditioner and the rest materials; heating; cooling; extruding the materials to obtain the finished product through an extruder. The method is carried out to manufacture the furniture board.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com