Novel mould-pressing polyimide foamed plastic and preparation method thereof

A technology of molding polyimide and foam plastics, which is applied in the field of polyimide foam materials, can solve the problems of foam performance degradation, etc., and achieve the effects of uniform foaming, simple process, and convenience for mass production and popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

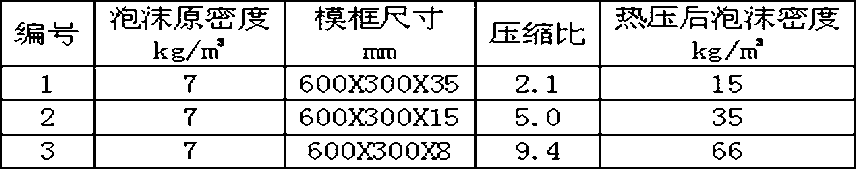

Image

Examples

Embodiment 1

[0026] In a 1000ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, put 129 grams (0.4mol) of 3,3 , ,4,4 , Benzophenone tetracarboxylic dianhydride (BTDA), 140 grams of anhydrous methanol and 80 grams of tetrahydrofuran were refluxed at 65° C. to form a clear solution, and cooled to room temperature. Add 79.5 g (0.4 mol) 4,4 , Diaminodiphenylmethane (MDA) and 0.2 grams of isoquinoline catalyst, continue to reflux reaction until clear and transparent, add 0.1% organic fluorine surfactant to prepare a foamable polyimide precursor solution, and put this solution in Vacuum dry in a rotary evaporator at 70°C to remove methanol and tetrahydrofuran. Cool to room temperature to obtain a loose solid-phase polyimide precursor, which is ground into powder to obtain a precursor powder.

Embodiment 2

[0028] In a 1000mL three-neck flask equipped with a stirrer, thermometer, constant temperature water bath and reflux condenser, put 129 grams (0.4mol) of 3,3 , ,4,4 , Benzophenone tetracarboxylic dianhydride (BTDA), 160 grams of anhydrous methanol and 20 grams of distilled water were refluxed at 65°C to obtain a clear solution, and cooled to room temperature. Add 65 g (0.32 mol) 4,4 , Diaminodiphenylmethane (MDA) reacts until the solid particles disappear, add 9 grams (0.08mol) of diaminopyridine and 0.5 grams of isoquinoline catalyst, continue the reflux reaction until the solution is clear and transparent, add 0.1% organic fluorine surfactant A foamable polyimide precursor solution was obtained, and the solution was vacuum-dried in a rotary evaporator at 70° C. to remove methanol. Cool to room temperature to obtain a loose solid-phase polyimide precursor, which is ground into powder to obtain a precursor powder.

Embodiment 3

[0030] In a 50L stainless steel reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, 1560 grams of 3,3 , ,4,4 , Benzophenone tetracarboxylic dianhydride (BTDA), 2500ml of anhydrous methanol and 1000ml of tetrahydrofuran were refluxed at 75°C to obtain a clear solution, and cooled to room temperature. Add 960g 4,4 , Diaminodiphenylmethane (MDA) and 15 grams of isoquinoline catalyst were reacted until the solid particles disappeared, and the reflux reaction was continued until the solution was clear and transparent, and 0.1% organic fluorine surfactant was added to prepare a foamable polyimide precursor Solution, the solution was vacuum-dried in batches at 70°C in a rotary evaporator to remove methanol and tetrahydrofuran. Cool to room temperature to obtain a loose solid-phase polyimide precursor, grind it into a polyimide precursor powder with a fineness of 43-35 μ with an ultrafine pulverizer,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com