Overturned foaming clamping apparatus

A flip-up and fixture technology, applied in the field of foaming fixtures for refrigerator boxes, can solve problems such as uneven foaming, increased reject rate, and affect product quality, and achieve uniform foaming, flow promotion, and good thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

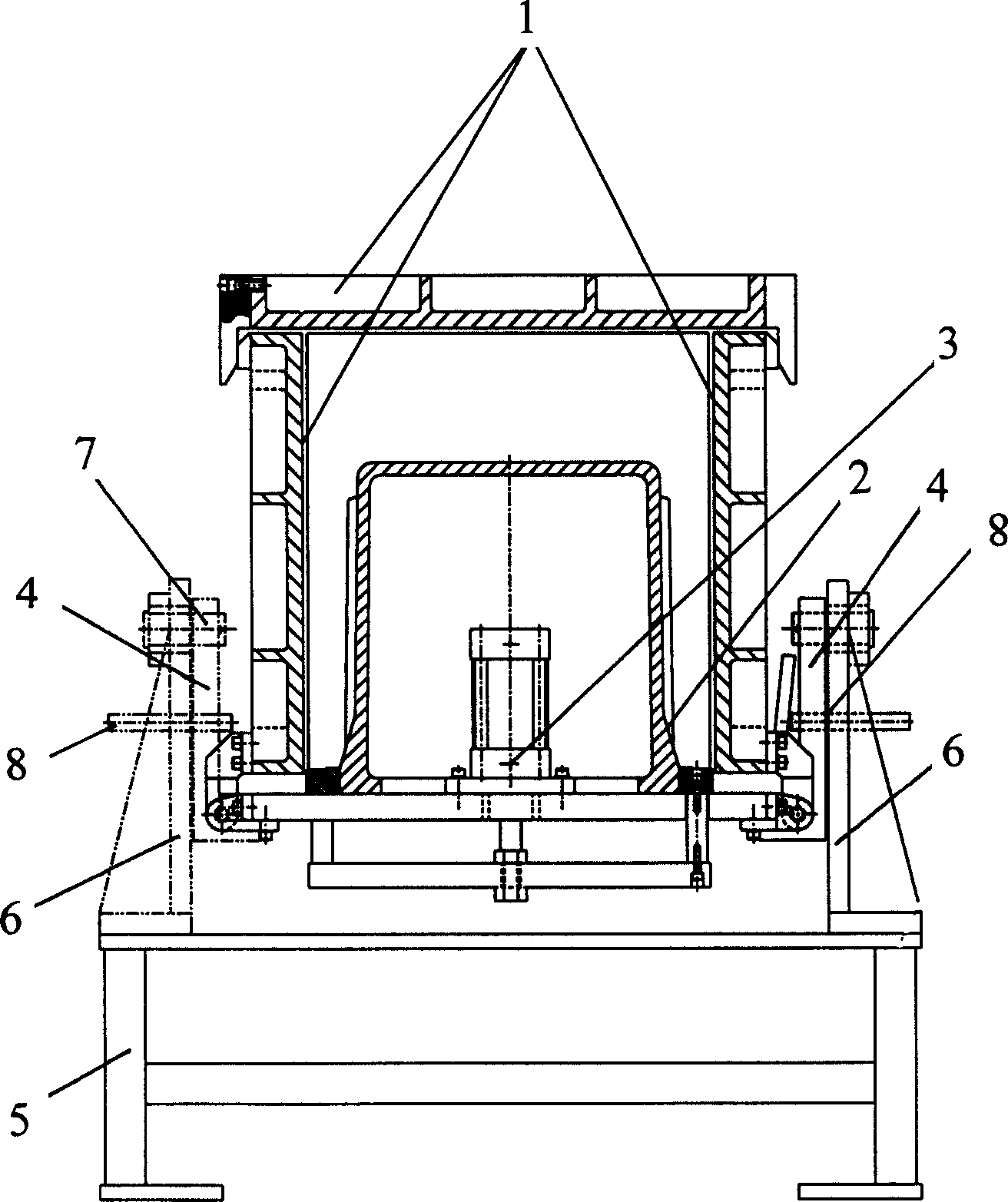

[0008] Referring to the accompanying drawings, the present embodiment is composed of the template part 1, the mold 2 and the ejector mechanism 3 as a turning mechanism, and the turning arms 4 are arranged symmetrically on both sides of the turning mechanism, and the supporting rods 6 on both sides of the turning arm 4 and the frame 5 Hinge with hinge axis 7.

[0009] In specific implementation, on the turning arm 4, a rotating handle 8 is provided, and the center of gravity of the turning mechanism is set slightly lower than the rotating shaft of the rotating handle 8. Turning the rotating handle 8, the manual turning of the turning mechanism can be implemented, and the dead point can be utilized. The position positioning is locked. Electric drive can also be used to turn over, and through the optimized electrical circuit design, the fixture can be controlled to turn over at different angles.

[0010] Properly set the length, width and depth of the frame 5 to ensure that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com