Carbon fiber honeycomb reinforced polyimide foam material and preparation method thereof

A technology of polyimide and foam materials, which is applied in the field of modified polyimide foam materials and its preparation, can solve the problems of high production cost and poor mechanical properties of polyimide foam materials, and achieve good sound absorption , good flame retardancy and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of carbon fiber honeycomb material.

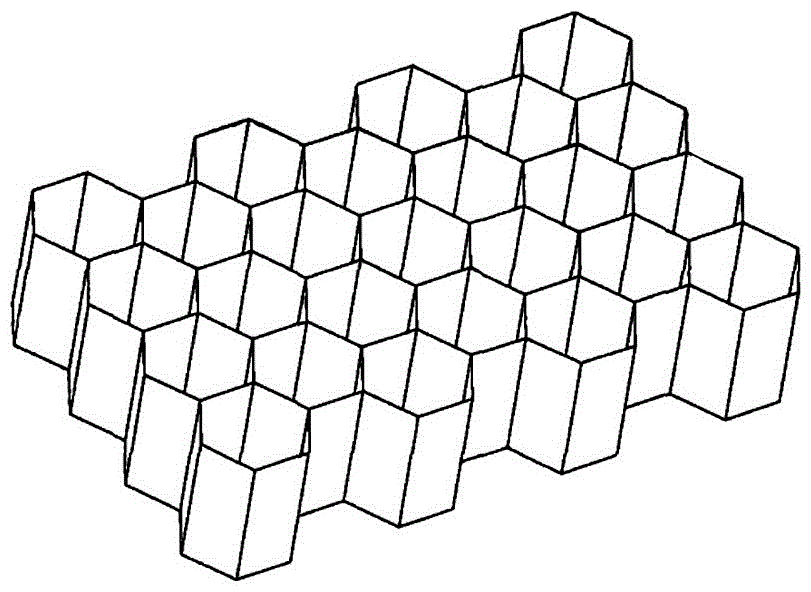

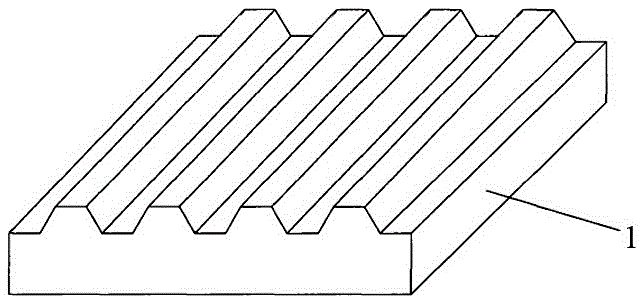

[0032] The carbon fiber honeycomb material used in the present invention is formed by laying carbon fiber prepreg in a mold and pressing it once, and its structure is as follows: figure 2 shown. The mold used comprises a semi-hexagonal mold 1 and a hexagonal core mold 2 for forming honeycomb holes, such as image 3 with Figure 4 shown. The hexagonal prism mandrel 2 is a prism whose end face is a regular hexagon, and its material is aluminum alloy or stainless steel. The semi-hexagonal mold 1 is provided with several identical strip-shaped convex ribs on its upper surface, and the end face of the convex ribs is trapezoidal. The same two parts are called half hexagonal prisms, and the shape and size of the convex ribs are the same as those of the half hexagonal prisms. A groove is formed between two adjacent ribs, the groove matches the half hexagonal prism, and is used for embedding the lower half of the...

Embodiment 2

[0040] Example 2: Preparation of carbon fiber honeycomb reinforced polyimide foam material.

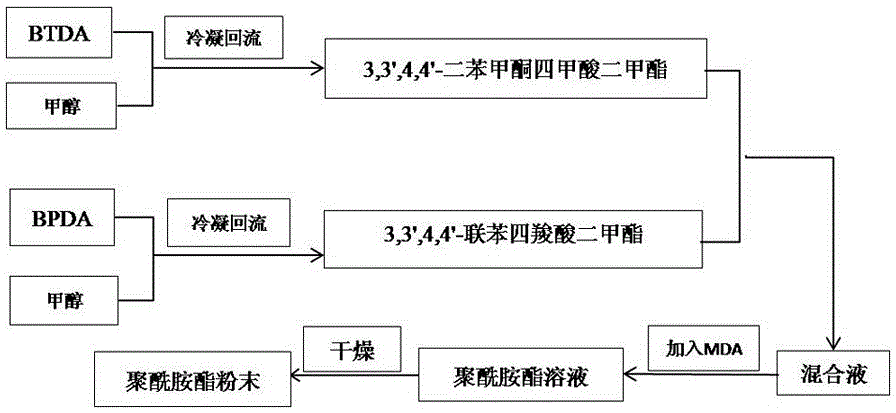

[0041] Preparation of polyimide prepolymer powder: the molar ratio of BTDA to BPDA is 6:4.

[0042]Add 120g of methanol into a four-neck flask equipped with a stirrer, reflux condenser and thermometer, and heat it under stirring until the methanol begins to reflux, then slowly add 30g of BTDA to make BTDA and methanol react for 1.5 hours under reflux, and the system is formed by suspension The solution gradually turned into a transparent light yellow solution, that is, a dimethyl 3,3',4,4'-benzophenone tetracarboxylate solution was obtained.

[0043] Add 73.04g of methanol into a four-neck flask equipped with a stirrer, reflux condenser and thermometer, and heat it under stirring until the methanol begins to reflux, then slowly add 18.26g of BPDA to react BPDA and methanol for 10.0h under reflux, and the system The suspension gradually turns into a transparent light yellow solution, ...

Embodiment 3

[0048] Example 3: Preparation of carbon fiber honeycomb reinforced polyimide foam material.

[0049] Preparation of polyimide prepolymer powder: The molar ratio of BTDA to BPDA is 2:1.

[0050] Add 80g of methanol into a four-neck flask equipped with a stirrer, reflux condenser and thermometer, and heat it under stirring until the methanol begins to reflux, then slowly add 20g of BTDA to make BTDA and methanol react for 1.5 hours under reflux, and the system starts to reflux. The solution gradually turned into a transparent light yellow solution, that is, a dimethyl 3,3',4,4'-benzophenone tetracarboxylate solution was obtained.

[0051] Add 36.5g of methanol into a four-necked flask equipped with a stirrer, reflux condenser and thermometer, and heat it under stirring until the methanol begins to reflux, then slowly add 9.13g of BPDA to react BPDA and methanol for 10.0h under reflux, and the system The suspension gradually turns into a transparent light yellow solution, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com