Patents

Literature

126 results about "Square pyramid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a square pyramid is a pyramid having a square base. If the apex is perpendicularly above the center of the square, it is a right square pyramid, and has C₄ᵥ symmetry. If all edges are equal, it is an equilateral square pyramid, the Johnson solid J₁.

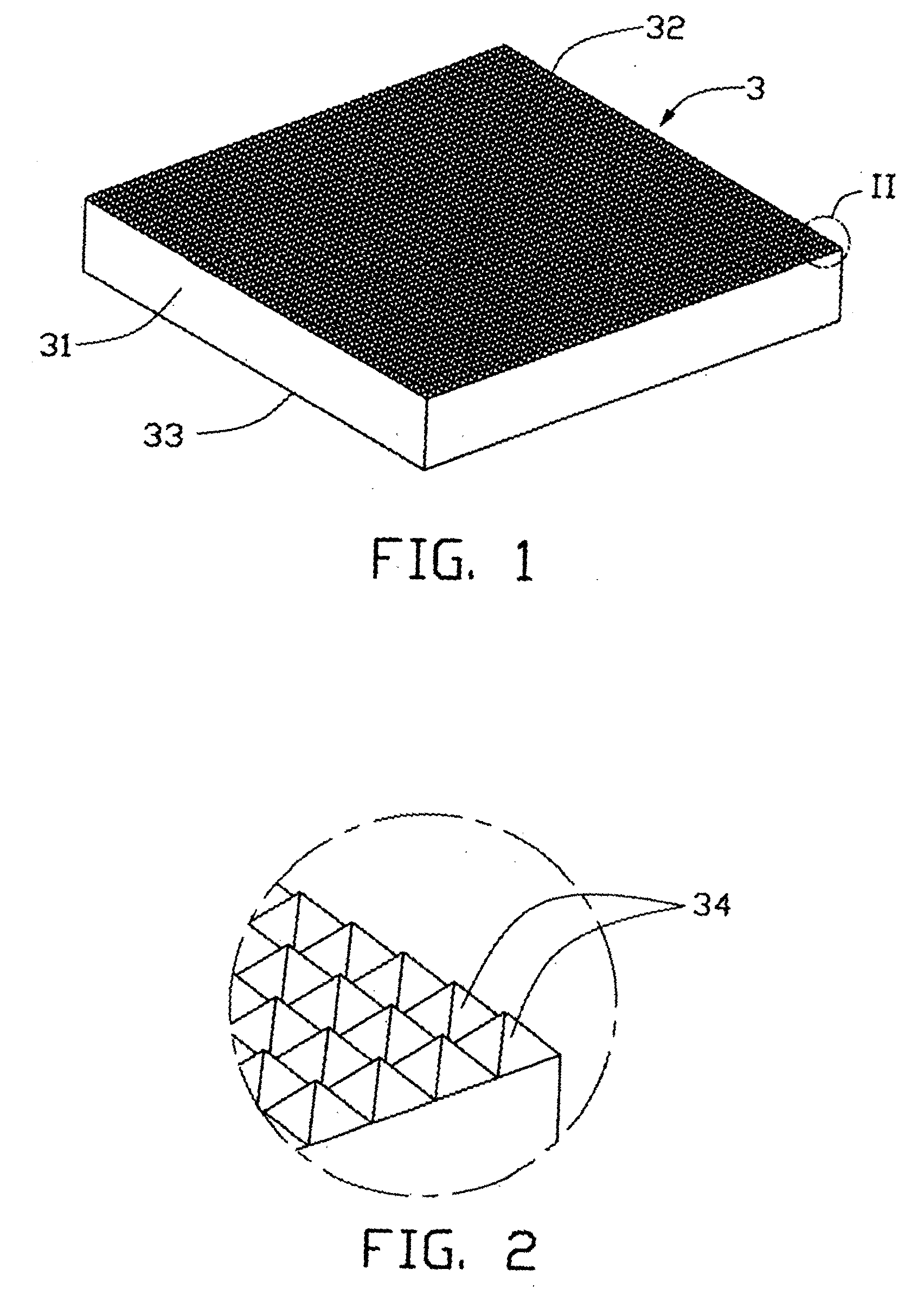

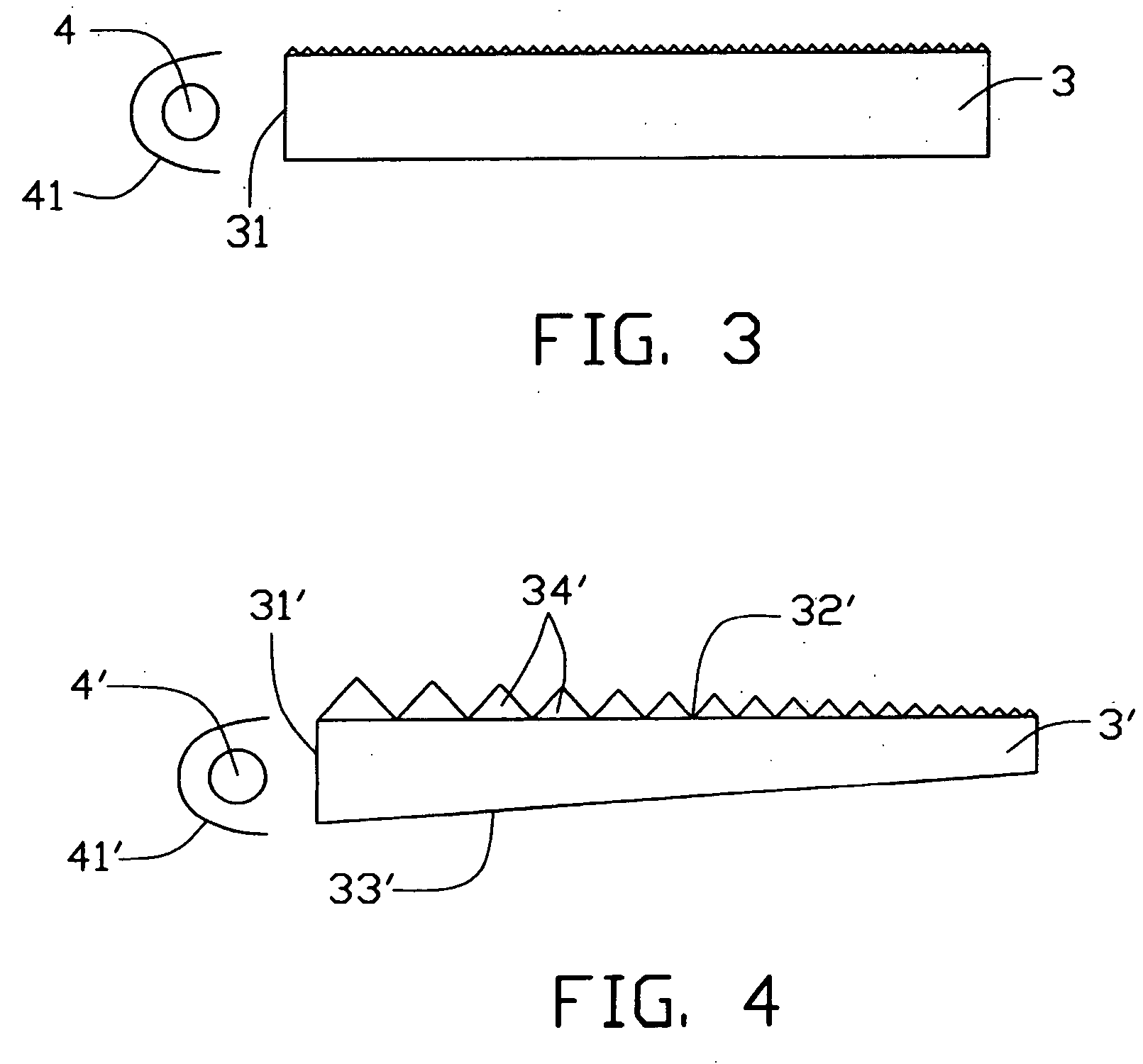

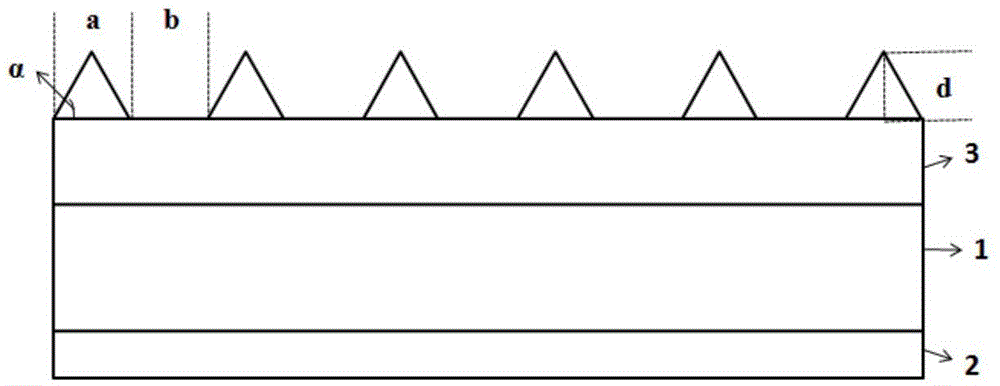

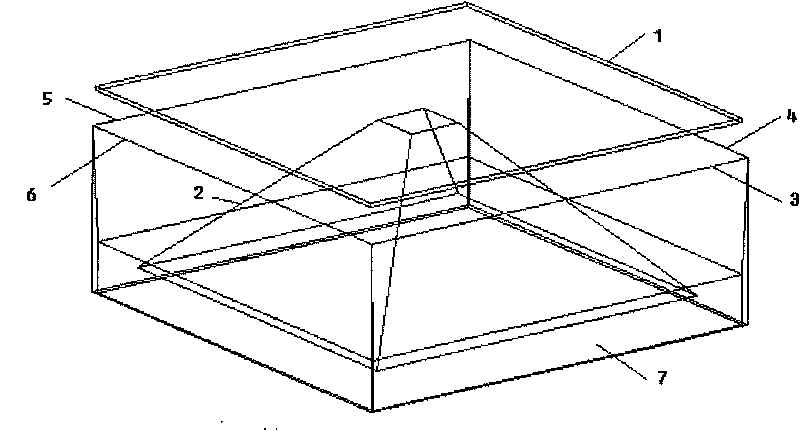

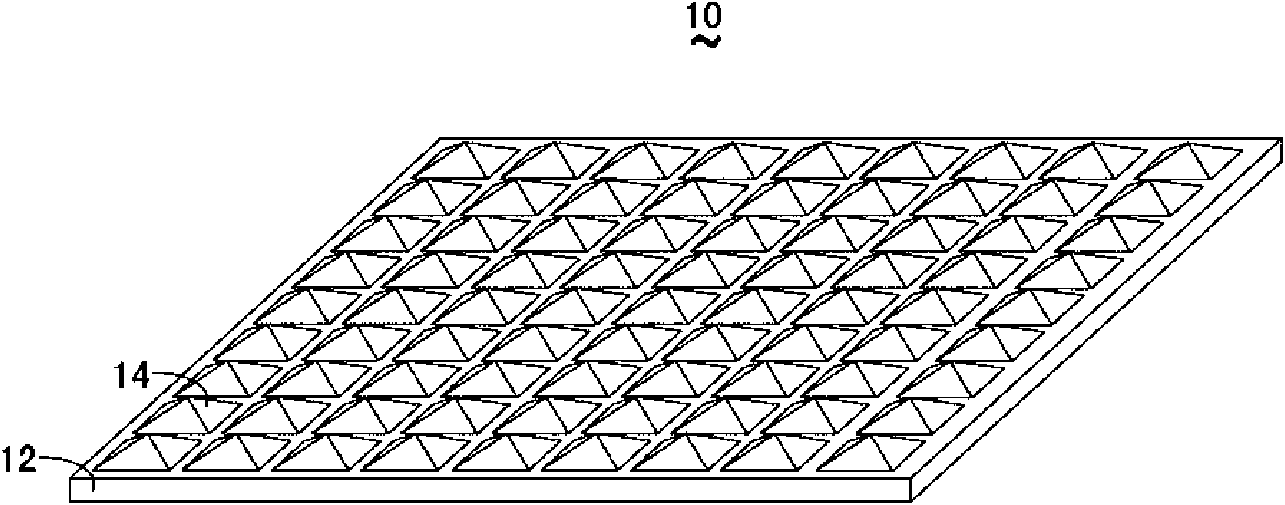

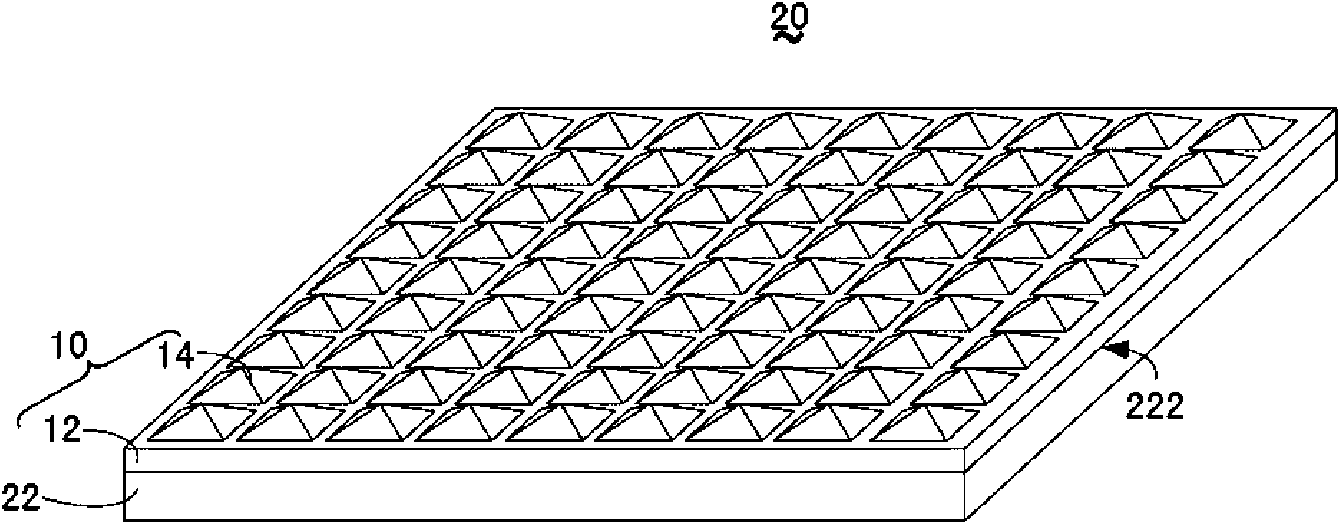

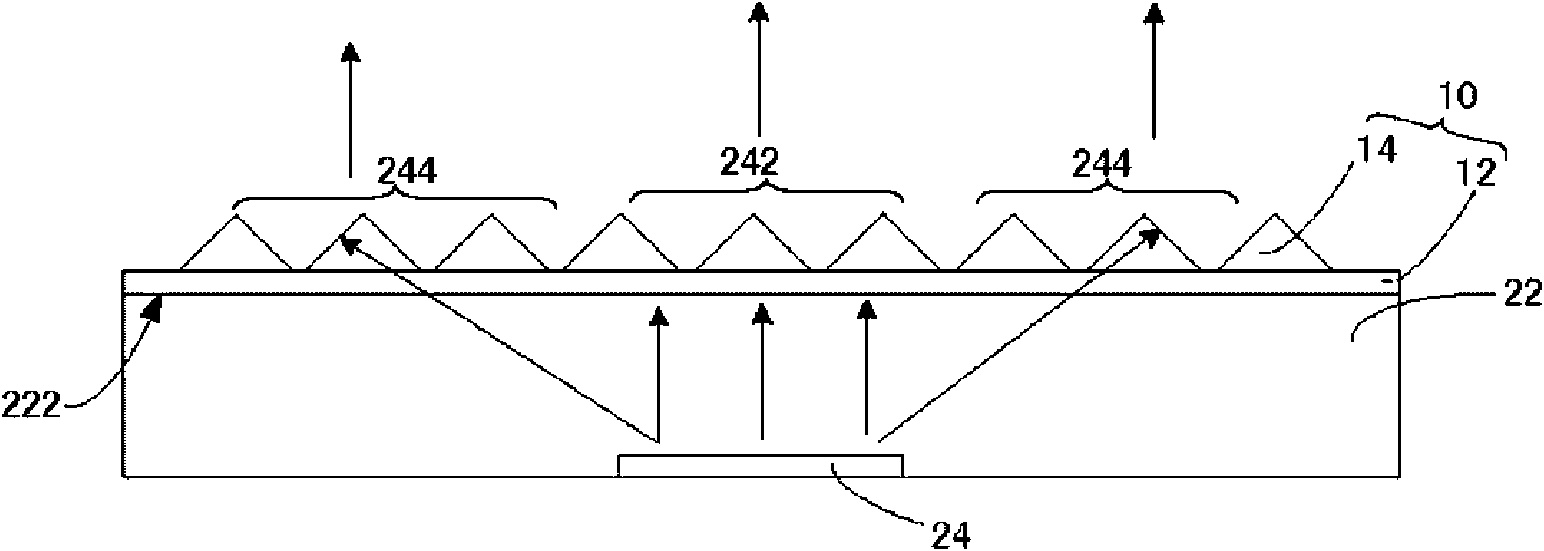

Light guide plate for liquid crystal display

InactiveUS7018088B2Reduce manufacturing costImprove uniformityMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

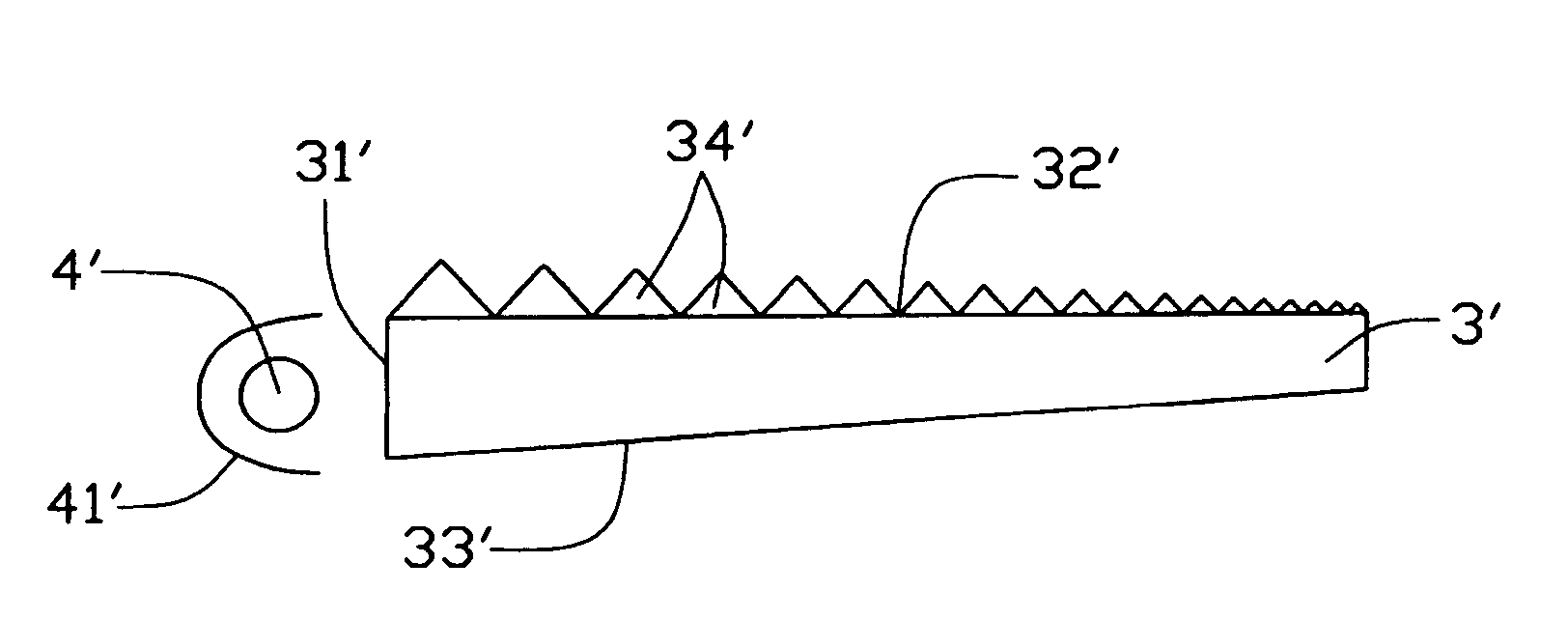

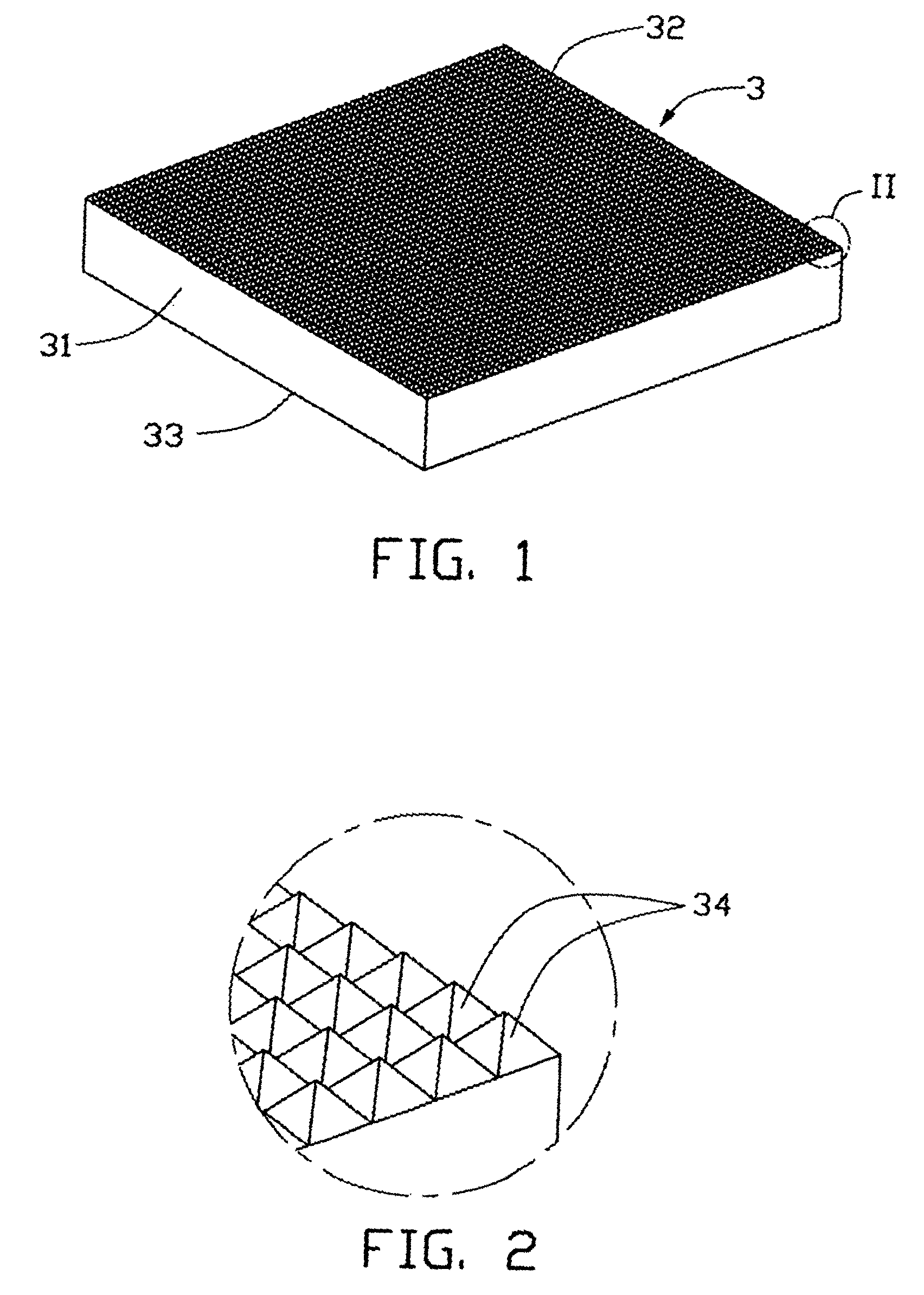

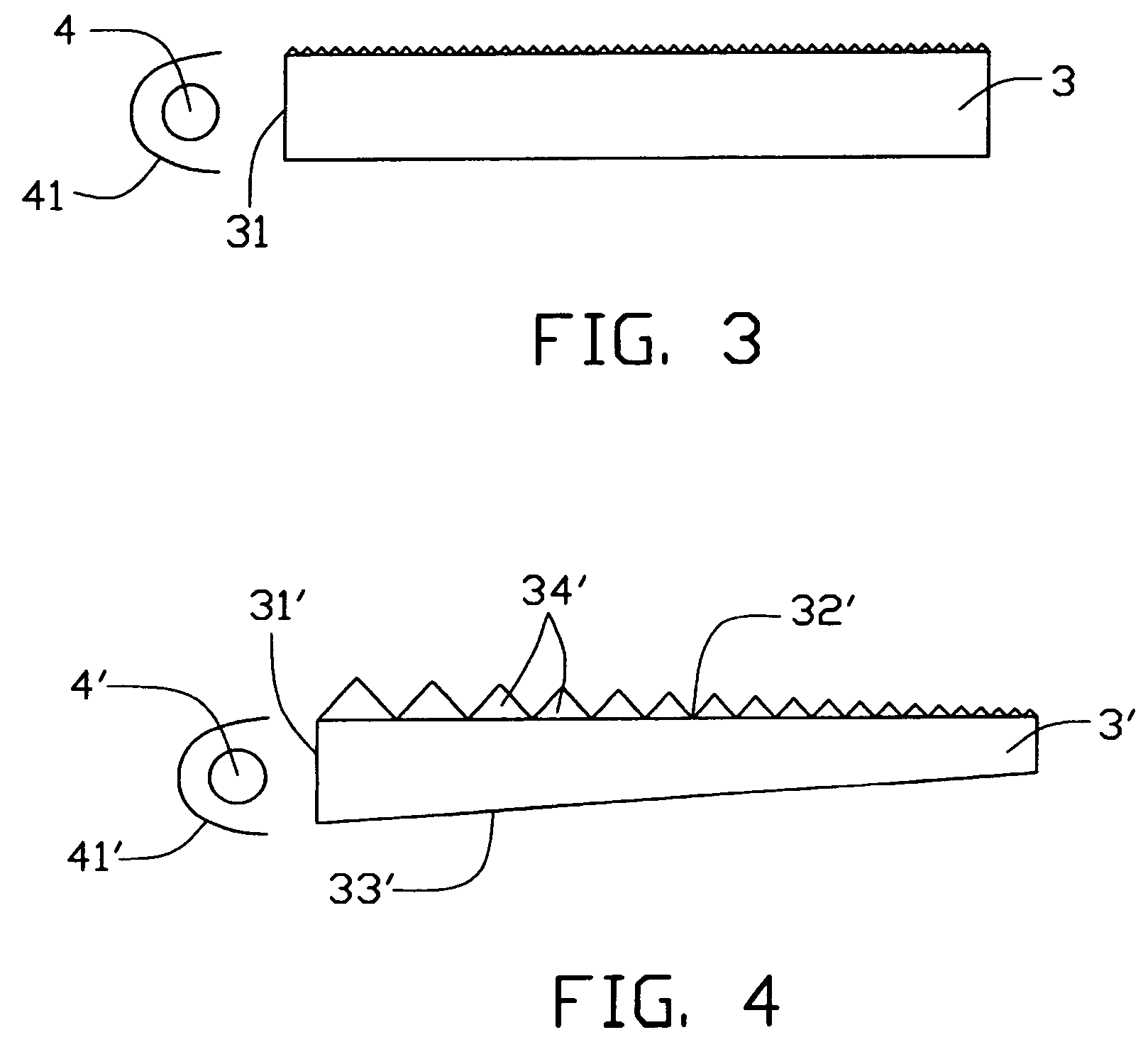

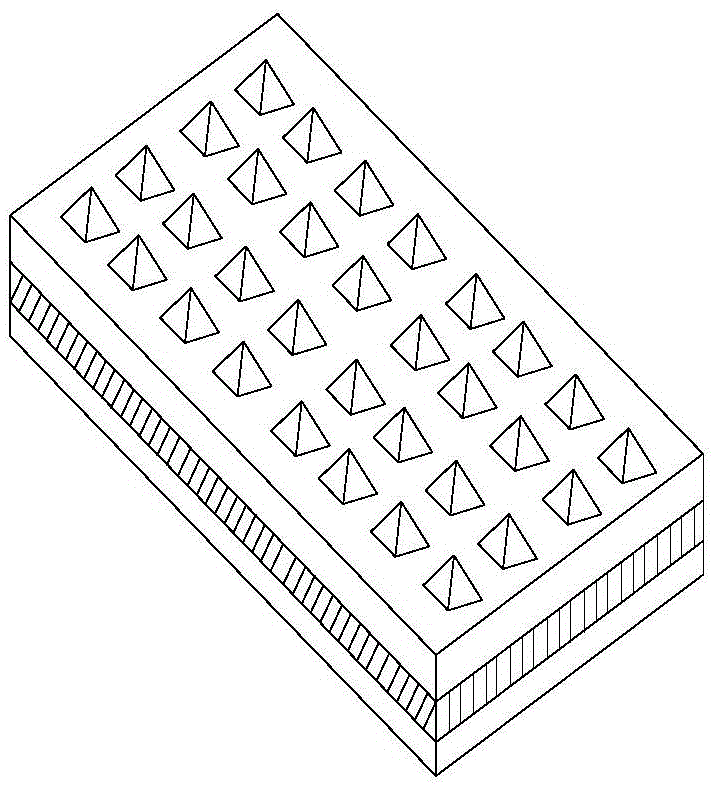

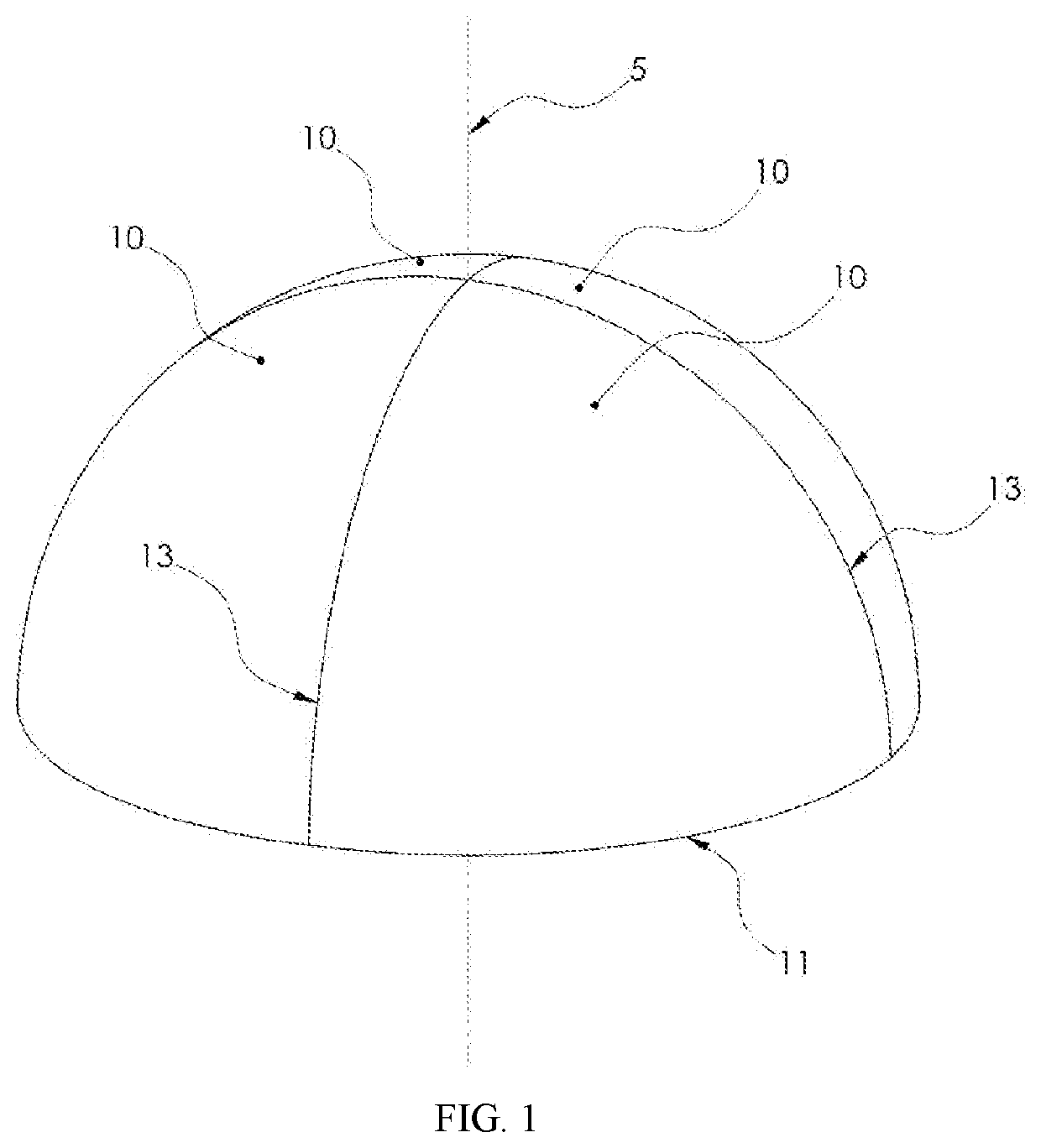

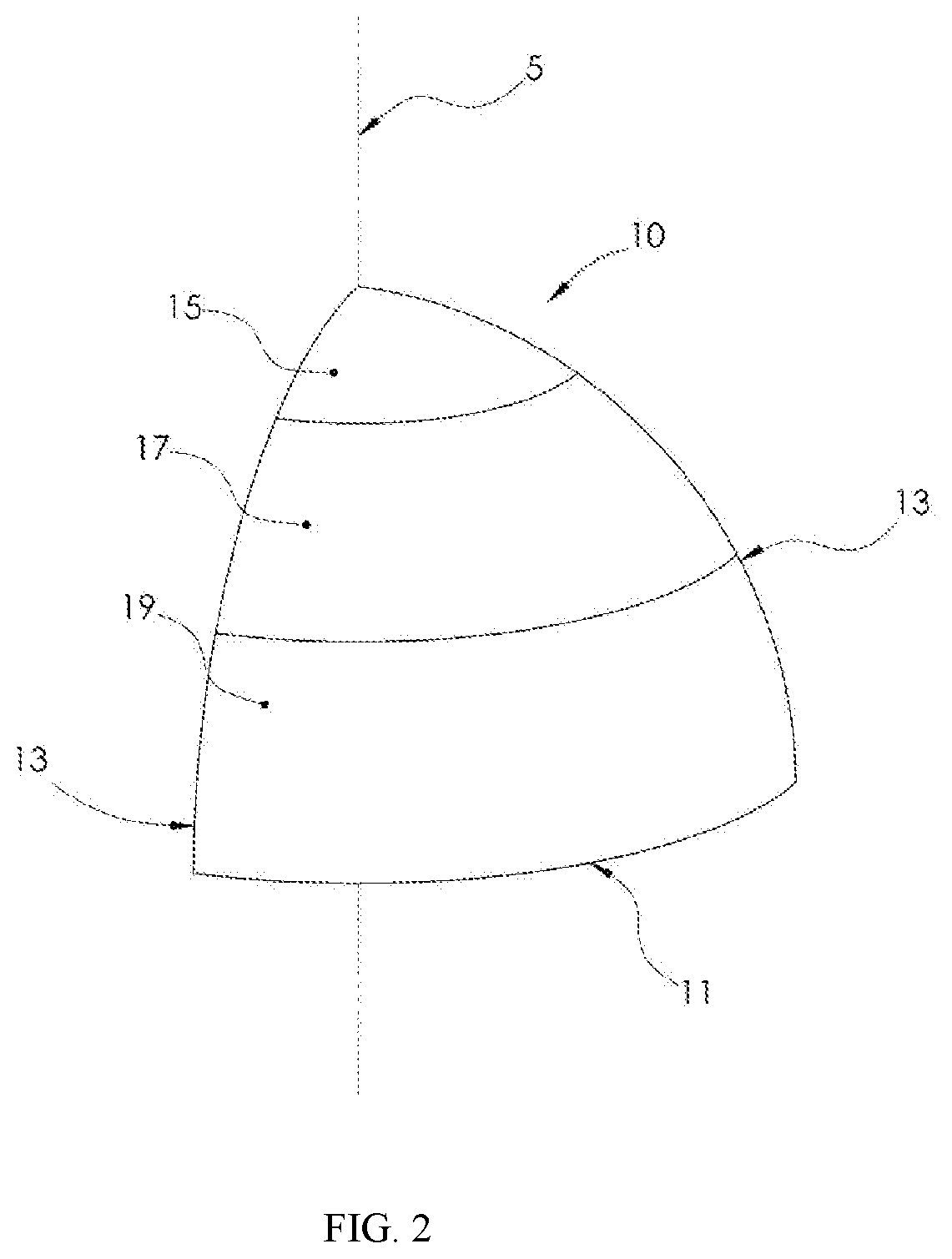

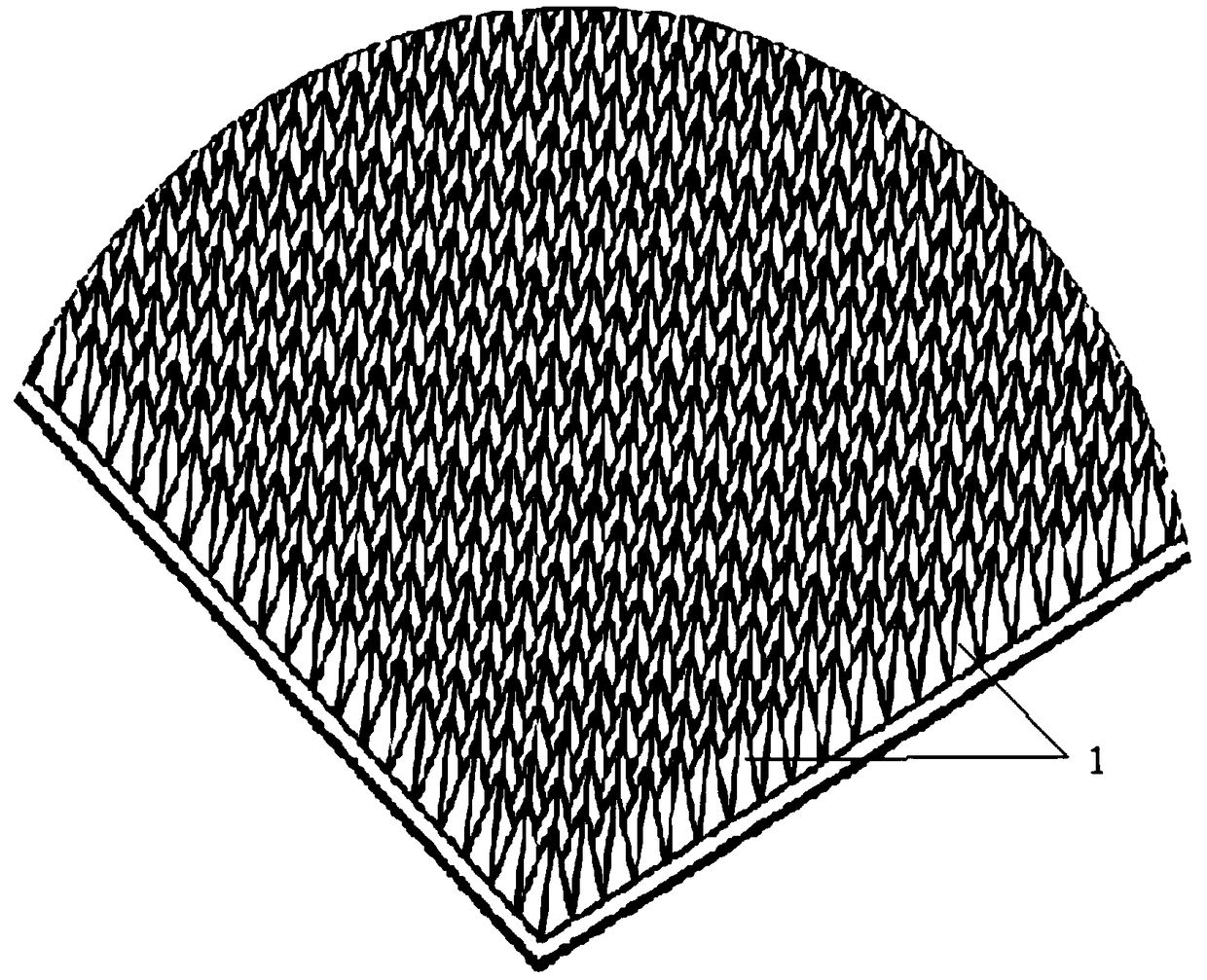

A light guide plate (3) includes a parallelepiped block. The block includes an input surface (31) for receiving light beams irradiated from a light source; two side surfaces perpendicularly adjoining the incident surface; an output surface (32) perpendicularly adjoining the incident surface and the side surfaces; and a bottom surface (33) opposing to the output surface. An array of prisms (34) is integrally formed on the output surface. Each prism is shaped as a square pyramid. All the prisms have a same size and are arranged contiguously with each other. Alternatively, the light guide plate may be a wedge-shaped block (3′). A rectangular array of prisms (34′) is integrally formed on an output surface (32′) thereof. Each prism is shaped as a square pyramid. The prisms are arranged contiguously with each other, and sizes of the prisms gradually decrease from a thick end to a thin end of the block.

Owner:HON HAI PRECISION IND CO LTD

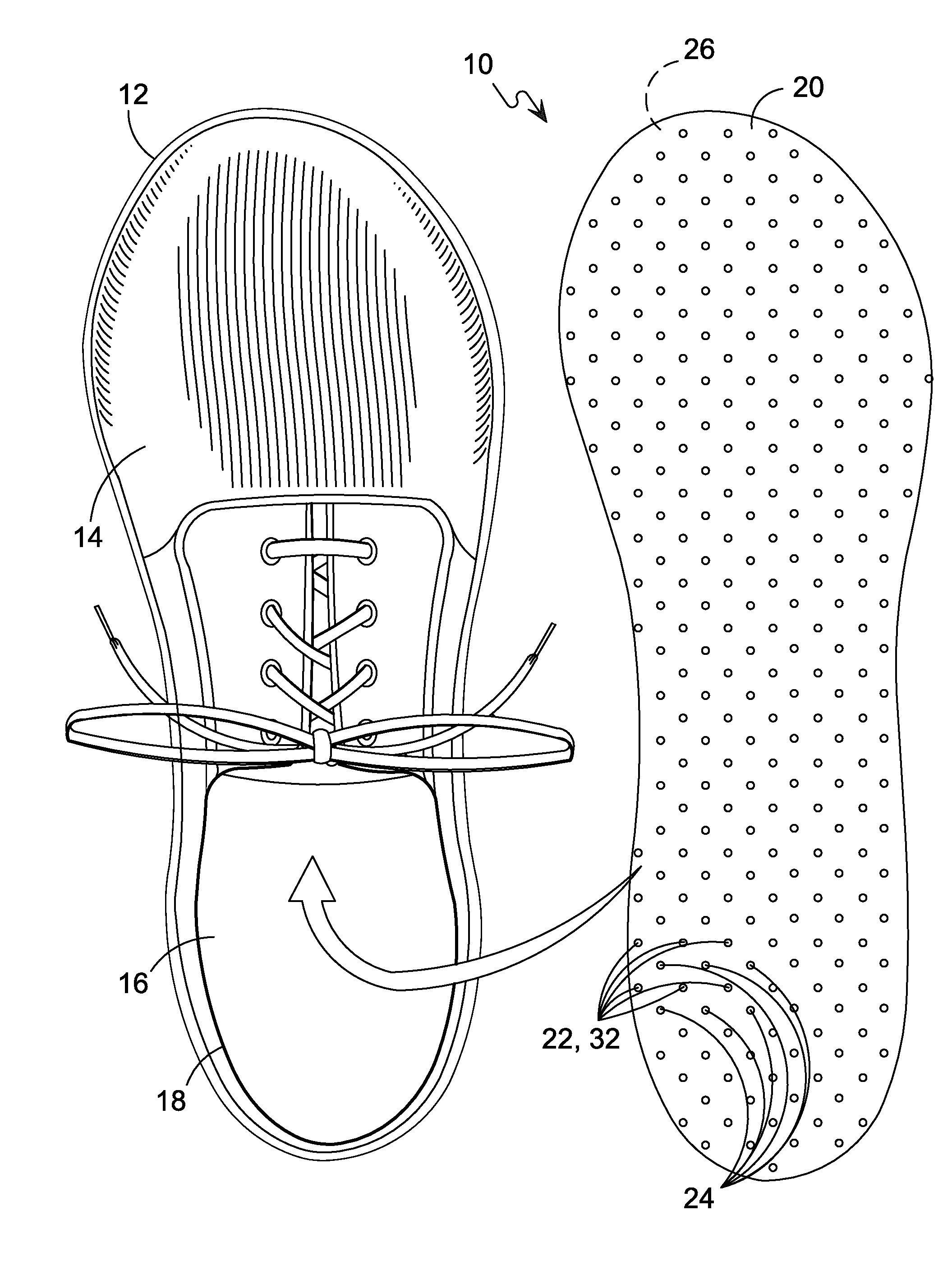

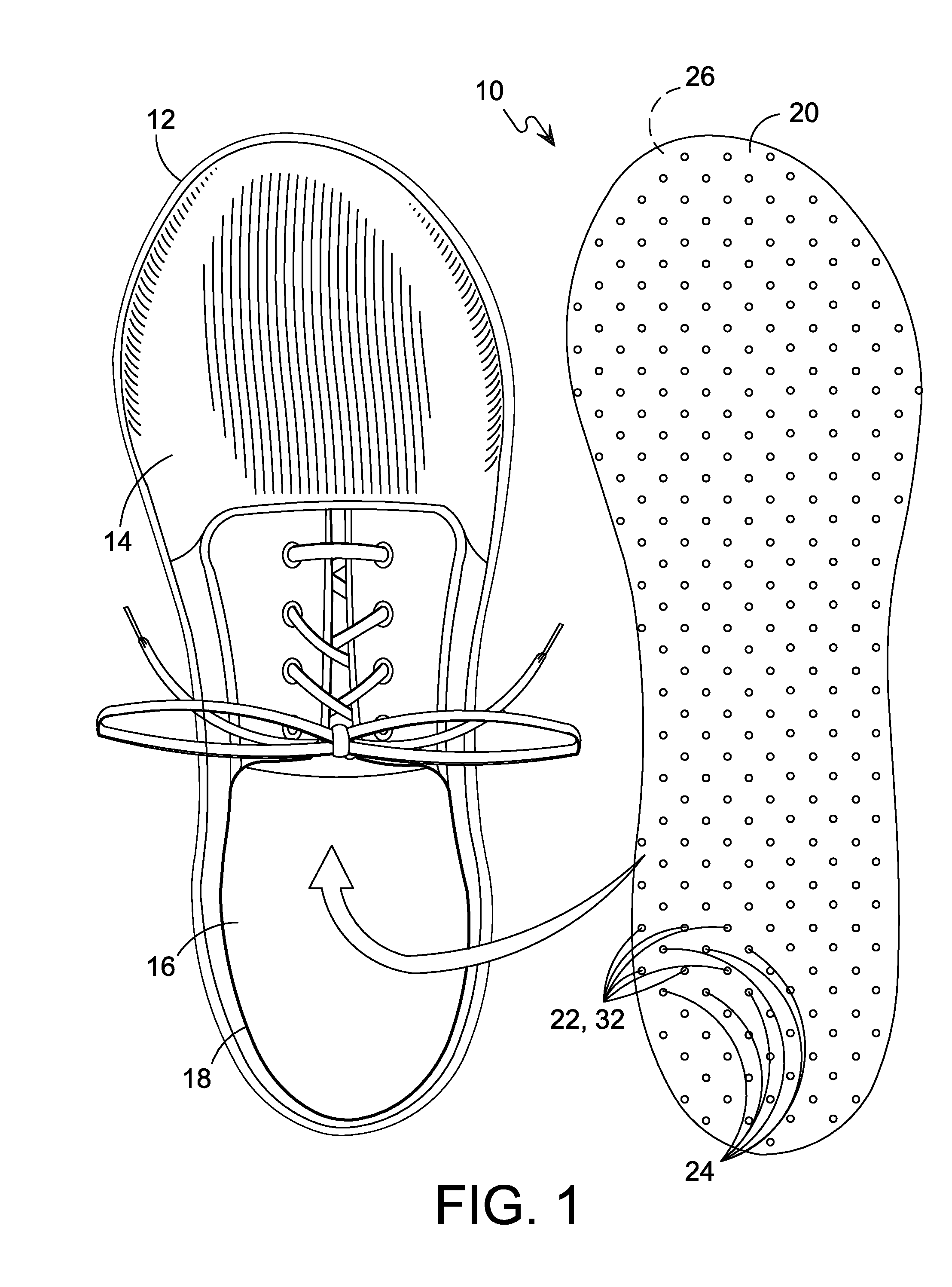

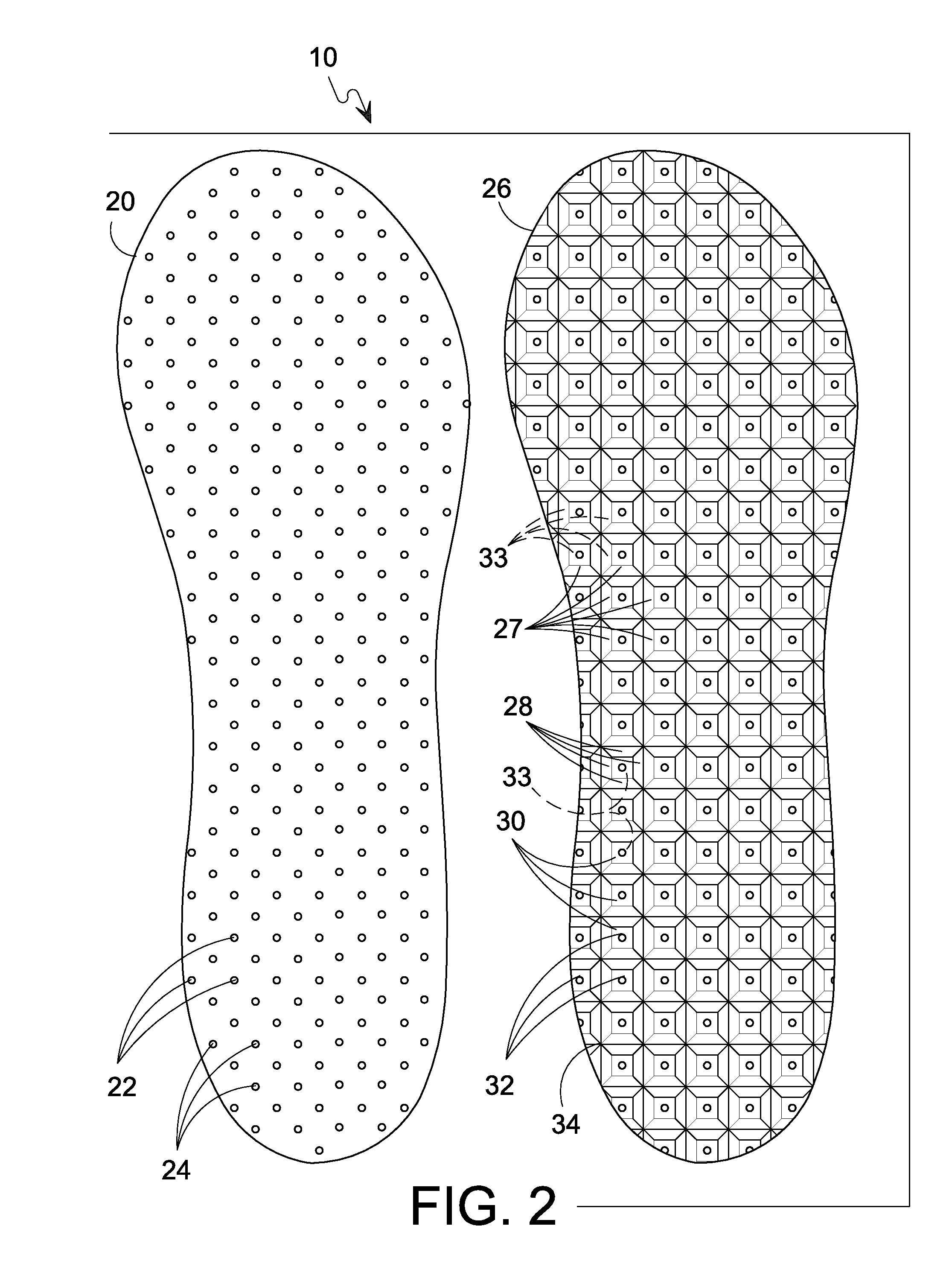

Disposable Cushion Shoe Insert

The present invention is a disposable cushion inserts for shoes designed to temper forces imparted on a foot during activities such as walking and running. The cushion insert in one embodiment has first and second layers conjoined by a bonding method taken from the group of adhesive and ultrasonics. The first layer is constructed of fibrous material taken from the group of fiber crops and polymers that will be treated to have a low moisture content and absorbency with a plurality of air passages apertures passing between the second layer and the cushioned insert exterior. The second layer is manufactured from a cross-linked open cell silicone material having a plurality of conjoined truncated-apex square pyramids where the walls enclose a central cavity with open bottoms providing a structure that is mostly ambient air-filled space that when released from a compressed state returns to its original form. Each of the truncated-apex surfaces has an aperture placed therethrough providing passage for air between each of the pyramid-shaped cavities and the cushioned-insert exterior. Also provides is an embodiment having a base layer conjoined to the second layer manufactured from a frictional material to prevent slippage of the cushioned insert during use.

Owner:KIM ERIC BYEUNG

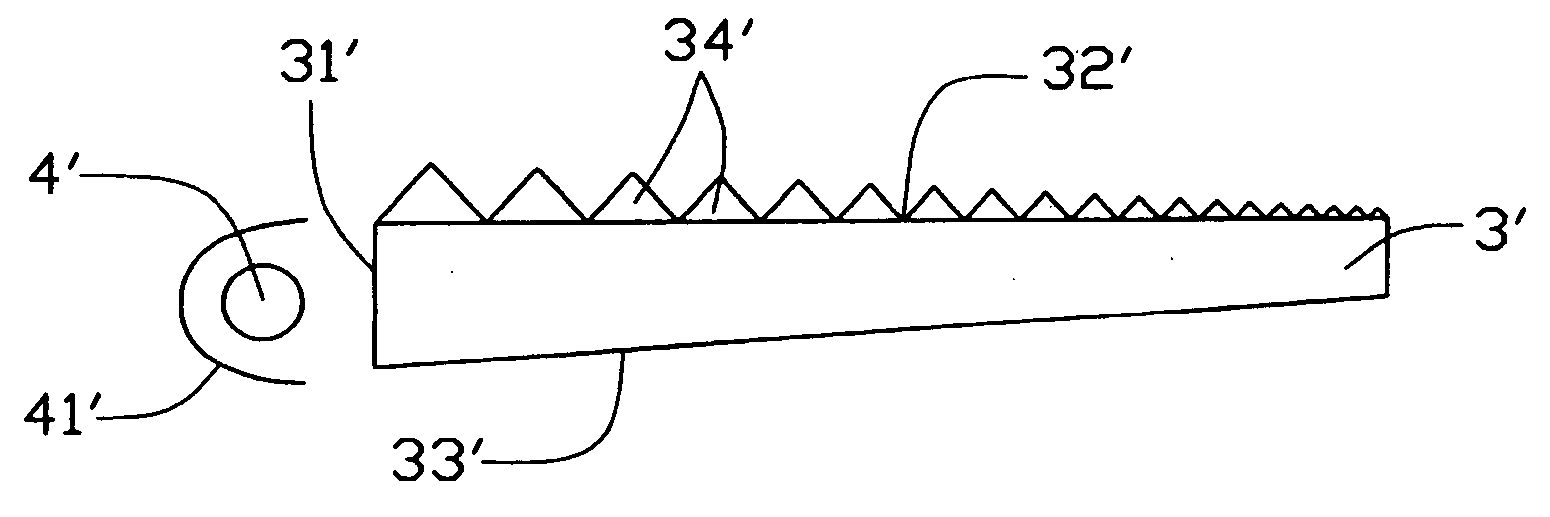

Light guide plate for liquid crystal display

A light guide plate (3) includes a parallelepiped block. The block includes an input surface (31) for receiving light beams irradiated from a light source; two side surfaces perpendicularly adjoining the incident surface; an output surface (32) perpendicularly adjoining the incident surface and the side surfaces; and a bottom surface (33) opposing to the output surface. An array of prisms (34) is integrally formed on the output surface. Each prism is shaped as a square pyramid. All the prisms have a same size and are arranged contiguously with each other. Alternatively, the light guide plate may be a wedge-shaped block (3'). A rectangular array of prisms (34') is integrally formed on an output surface (32') thereof. Each prism is shaped as a square pyramid. The prisms are arranged contiguously with each other, and sizes of the prisms gradually decrease from a thick end to a thin end of the block.

Owner:HON HAI PRECISION IND CO LTD

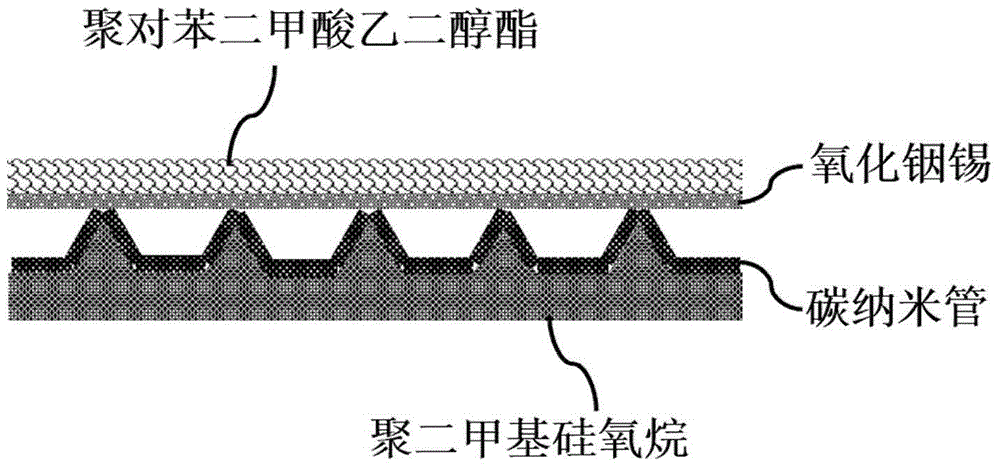

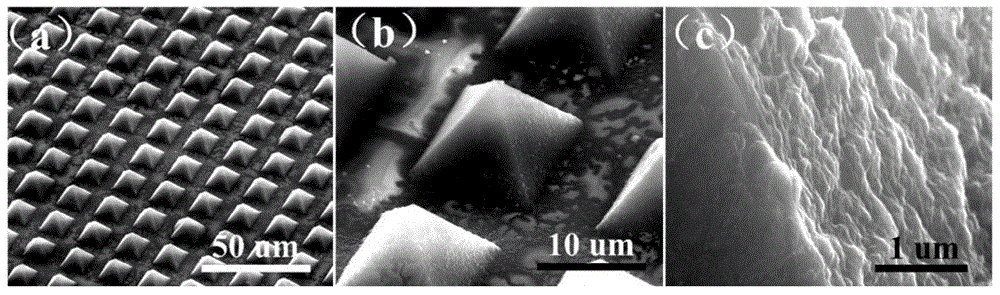

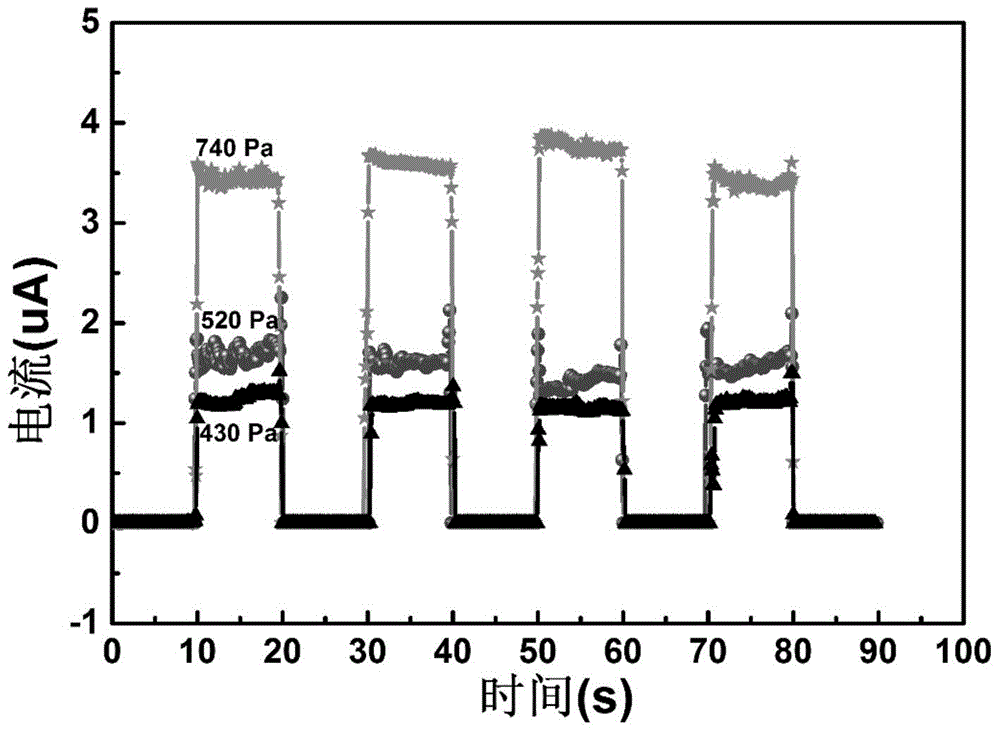

Flexible micro pressure sensor and preparation method thereof

InactiveCN104803339AResponsiveEasy to shapeDecorative surface effectsSolid-state devicesMicro structureCoupling

The invention provides a flexible micro pressure sensor and a preparation method thereof, and belongs to the field of micro pressure sensor preparation. The flexible micro pressure sensor comprises a flexible substrate, a conducting layer and a flexible coupling electrode, wherein the flexible substrate is of a right square pyramid micro structure, the conducting layer is positioned on the flexible substrate, the flexible substrate is polydimethylsiloxane dimethyl silicone polymer with the right square pyramid micro structure, the conducting layer is a single-wall carbon nanometer tube, and the flexible coupling electrode is polyethylene glycol terephthalate with an indium tin oxide conducting layer. A lower electrode with the right square pyramid micro structure is adopted, and the deformation of the right square pyramid micro structure is very obvious under the pressure effect, so that the response of the sensor to micro pressure is more sensitive; the single-wall carbon nanometer tube is adopted as the conducting layer, and is transparent for visible light, in addition, the sensor cannot be easily damaged in the stretching or bending process, and the stability is good; the polydimethylsiloxane dimethyl silicone polymer is used as a lower electrode substrate, the flexibility is good, and the bending and the stretching can be realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

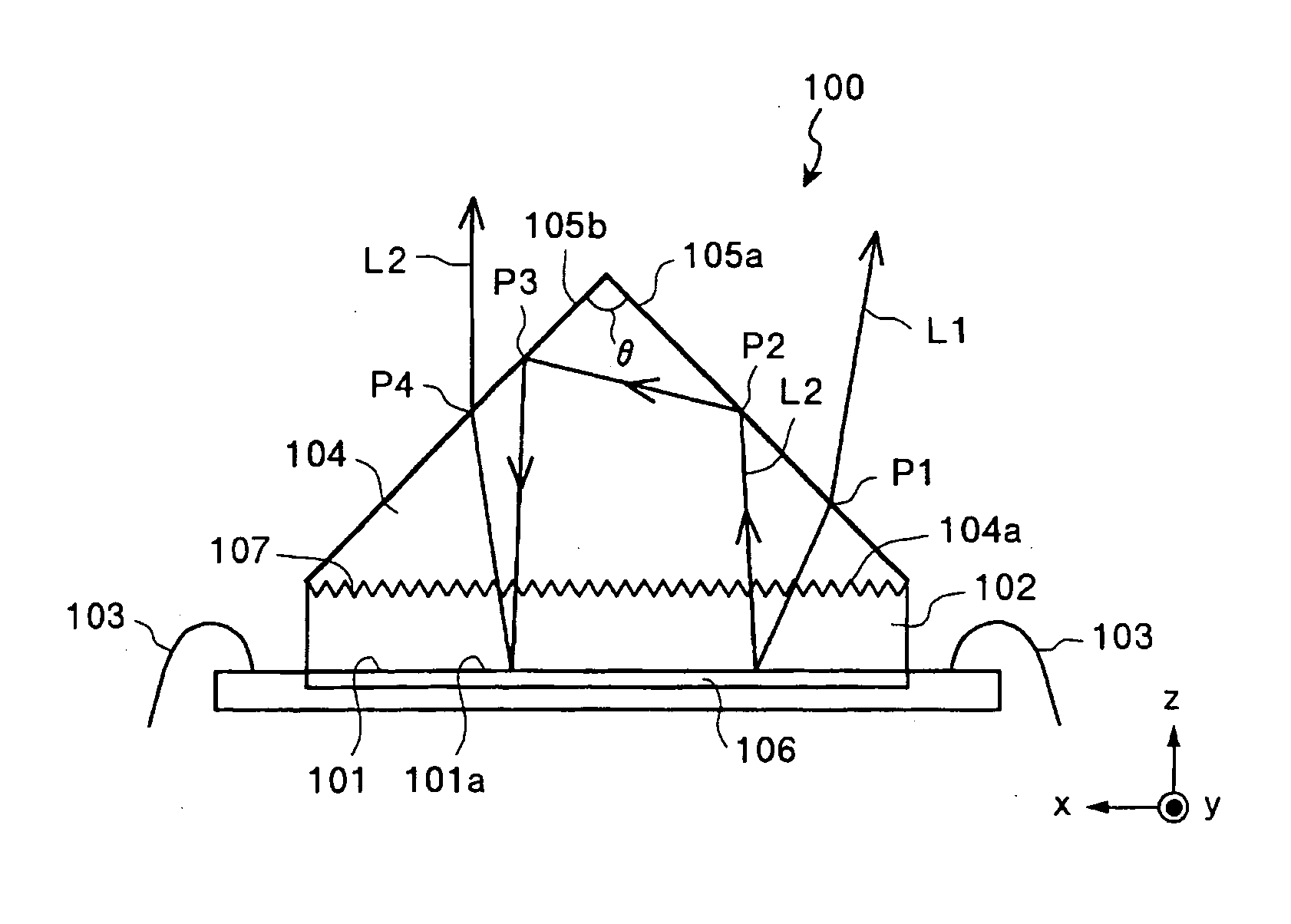

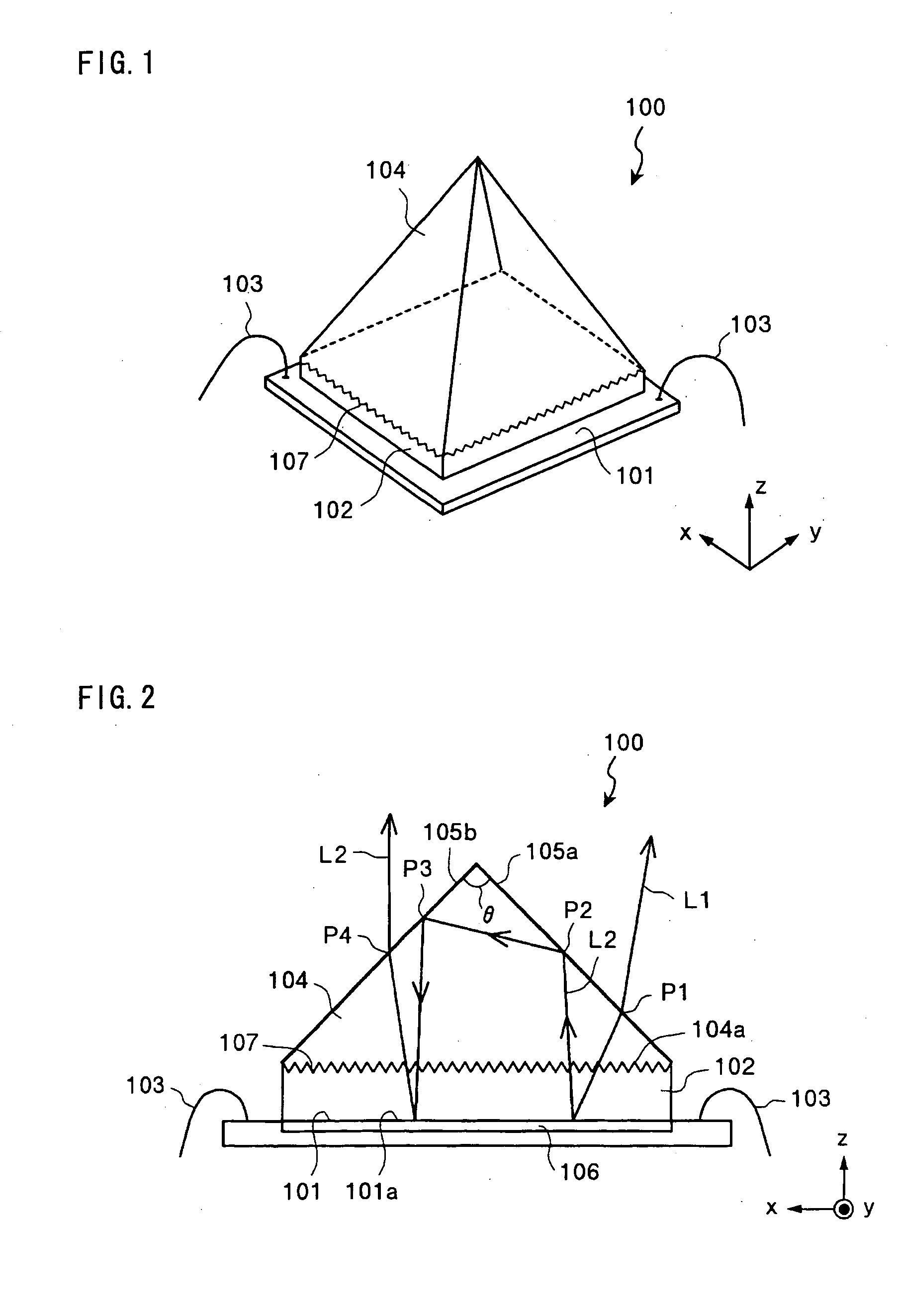

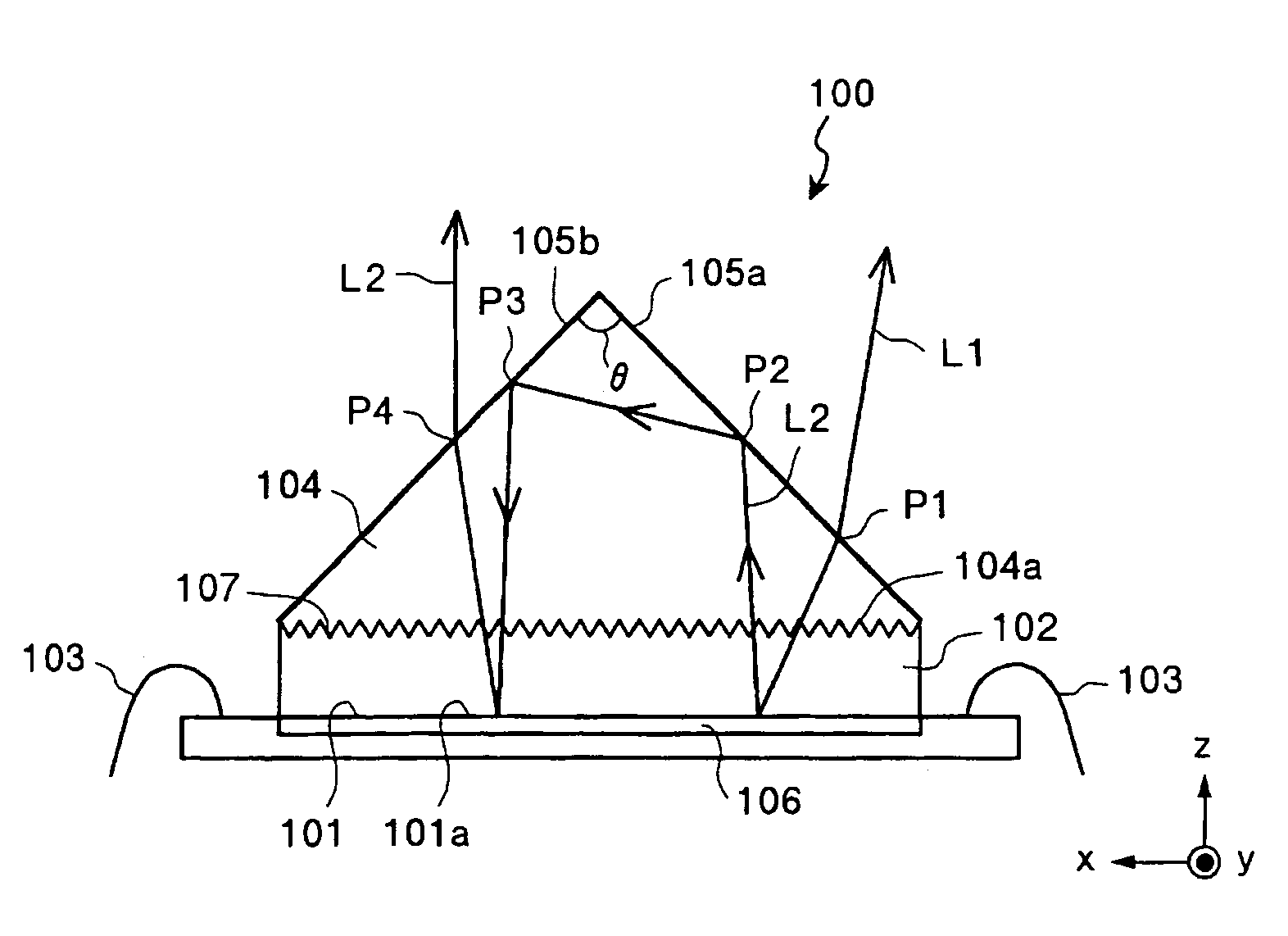

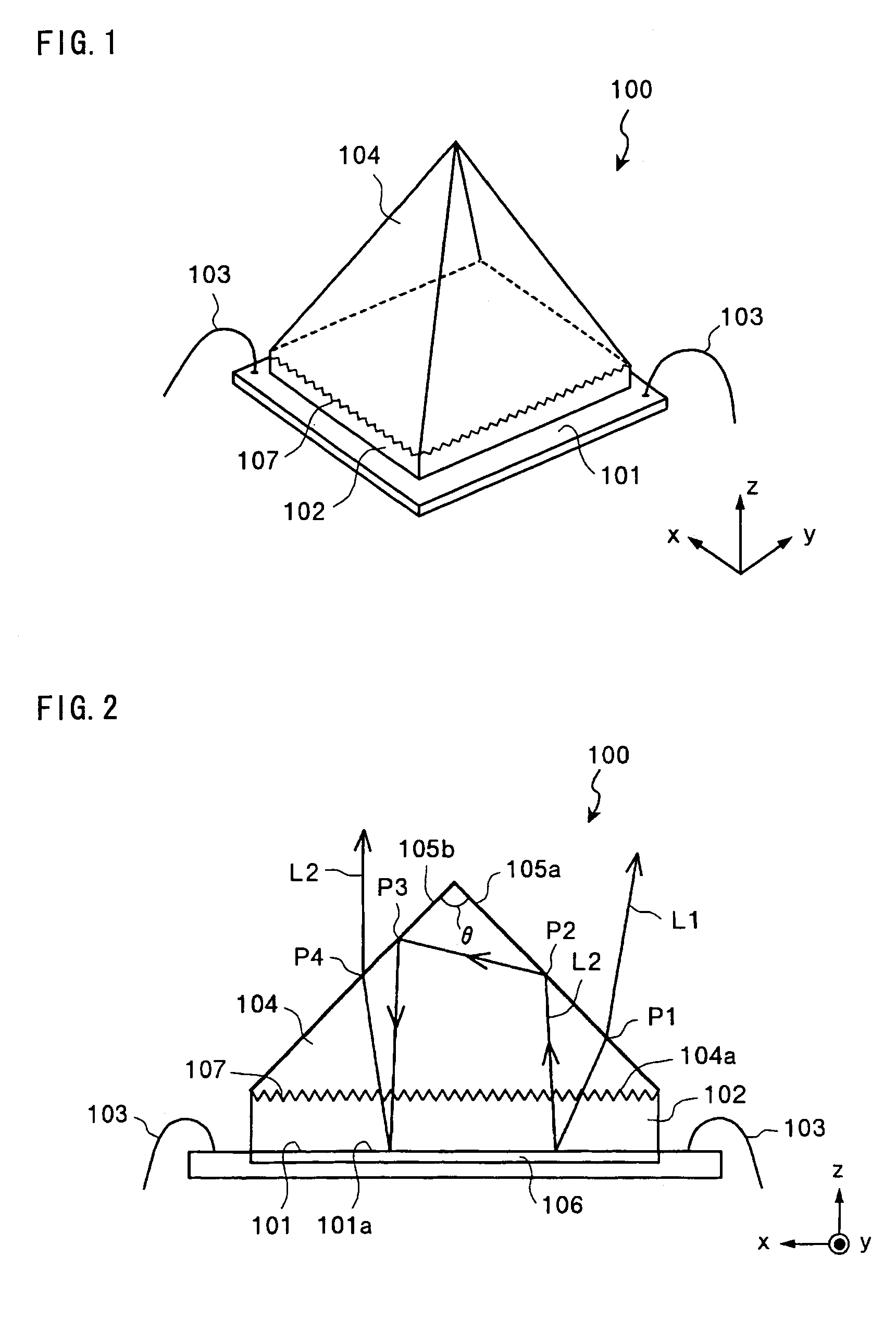

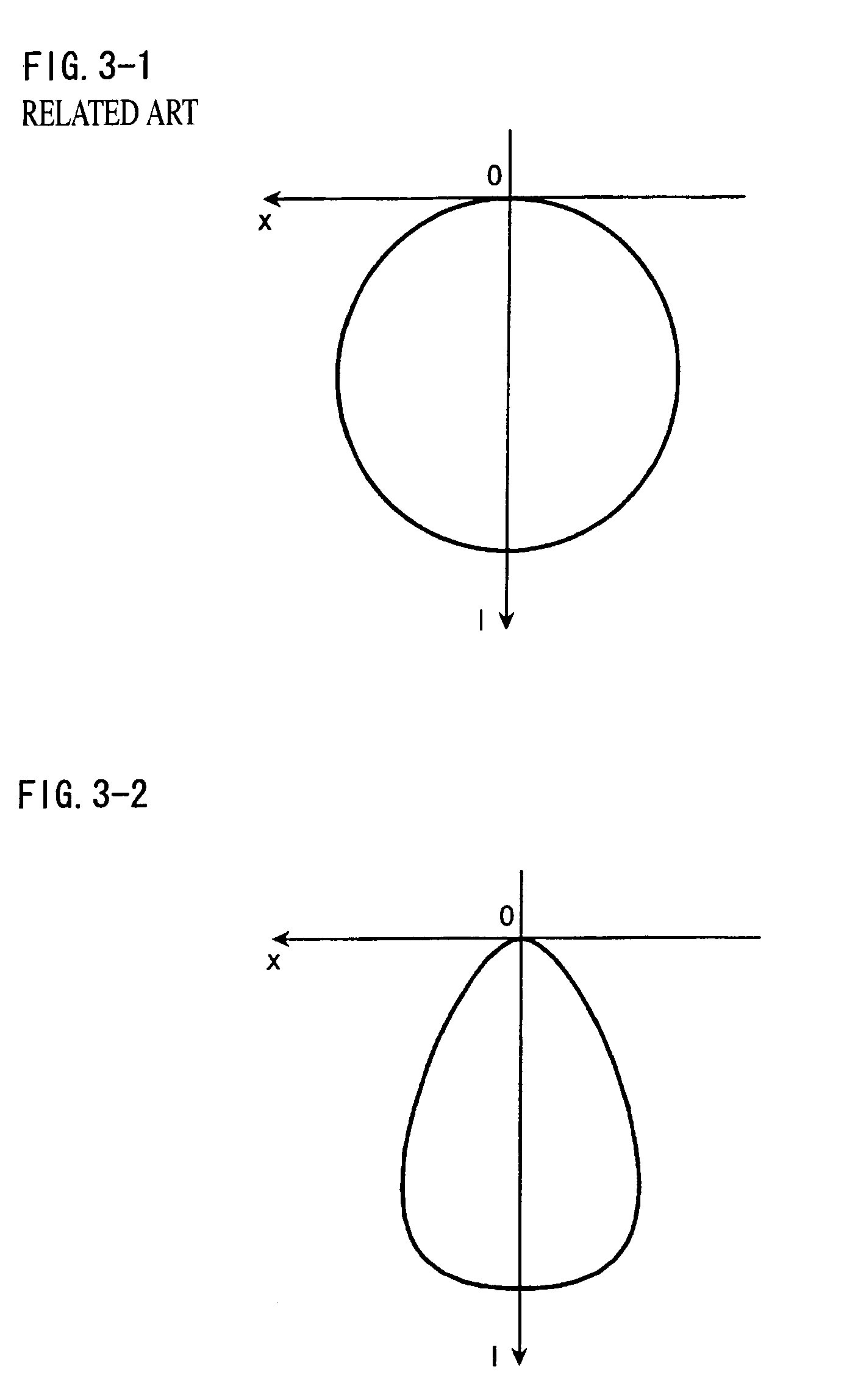

Light source unit and projector

To provide a light source unit and a projector with high light utilization efficiency, the unit has a surface emitting part to emit light from a planer emitting region, a reflecting metal electrode provided on one surface side of the surface emitting part, a square pyramid prism on the other surface side of the surface emitting part 101 and including glass. A bottom surface of the square pyramid prism 104 has substantially the same size and shape as the planer emitting region 101a. Inclined surfaces of the square pyramid prism output the light refracted by the inclined surfaces of the light that has entered the square pyramid prism from the bottom surface in a specific direction and guide the light reflected by the inclined surfaces toward the bottom surface. The reflecting metal electrode reflects the light that has been reflected by the inclined surfaces and transmitted through the bottom surface and the surface emitting part toward the square pyramid prism again.

Owner:SEIKO EPSON CORP

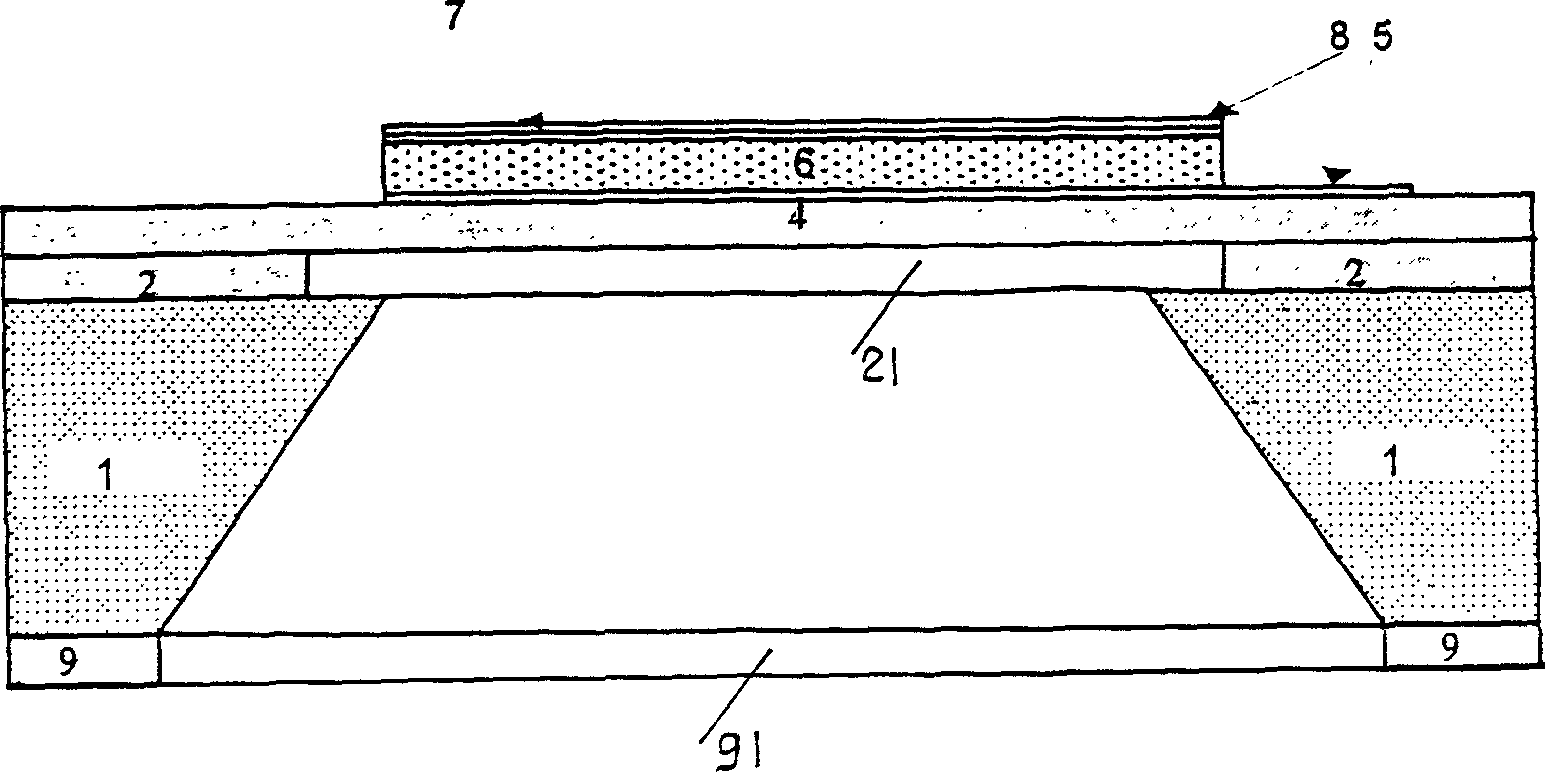

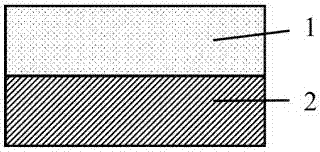

High-reflectivity backplate material of photovoltaic module

ActiveCN105609575AHigh light reflectivityHigh partial discharge voltageSynthetic resin layered productsElectrical equipmentPolyolefinOptoelectronics

The invention discloses a high-reflectivity backplate material of a photovoltaic module. The backplate material sequentially comprises a weather resistant layer, a polymer basic membrane layer, a polyolefin layer and a plurality of right square pyramid structures, wherein the plurality of right square pyramid structures are uniformly arranged on the upper surface of the polyolefin. The backplate material of the photovoltaic module, fabricated according to the invention is cheap in raw materials and simple in production process, also has the characteristics of high reflectivity, moisture blocking performance, local discharging voltage, relatively wide temperature application range, favorable mechanical property, high bonding strength and excellent outdoor weather resistance, and is the backplate material which has excellent comprehensive performance and is suitable for the photovoltaic module.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

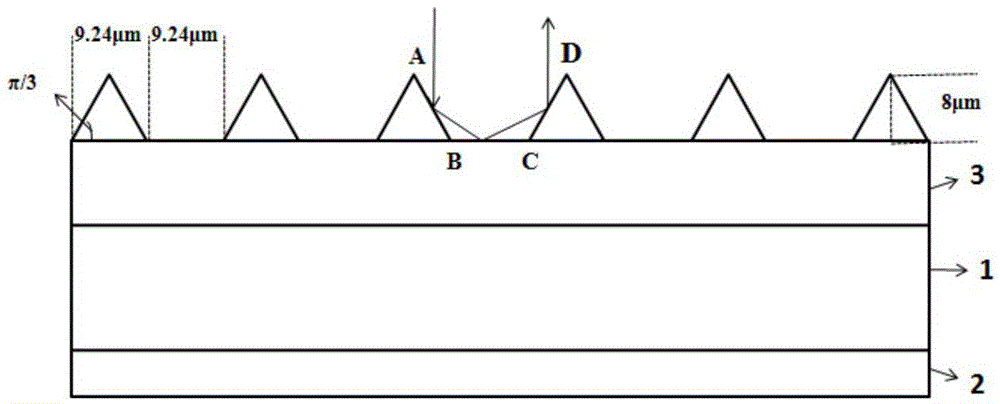

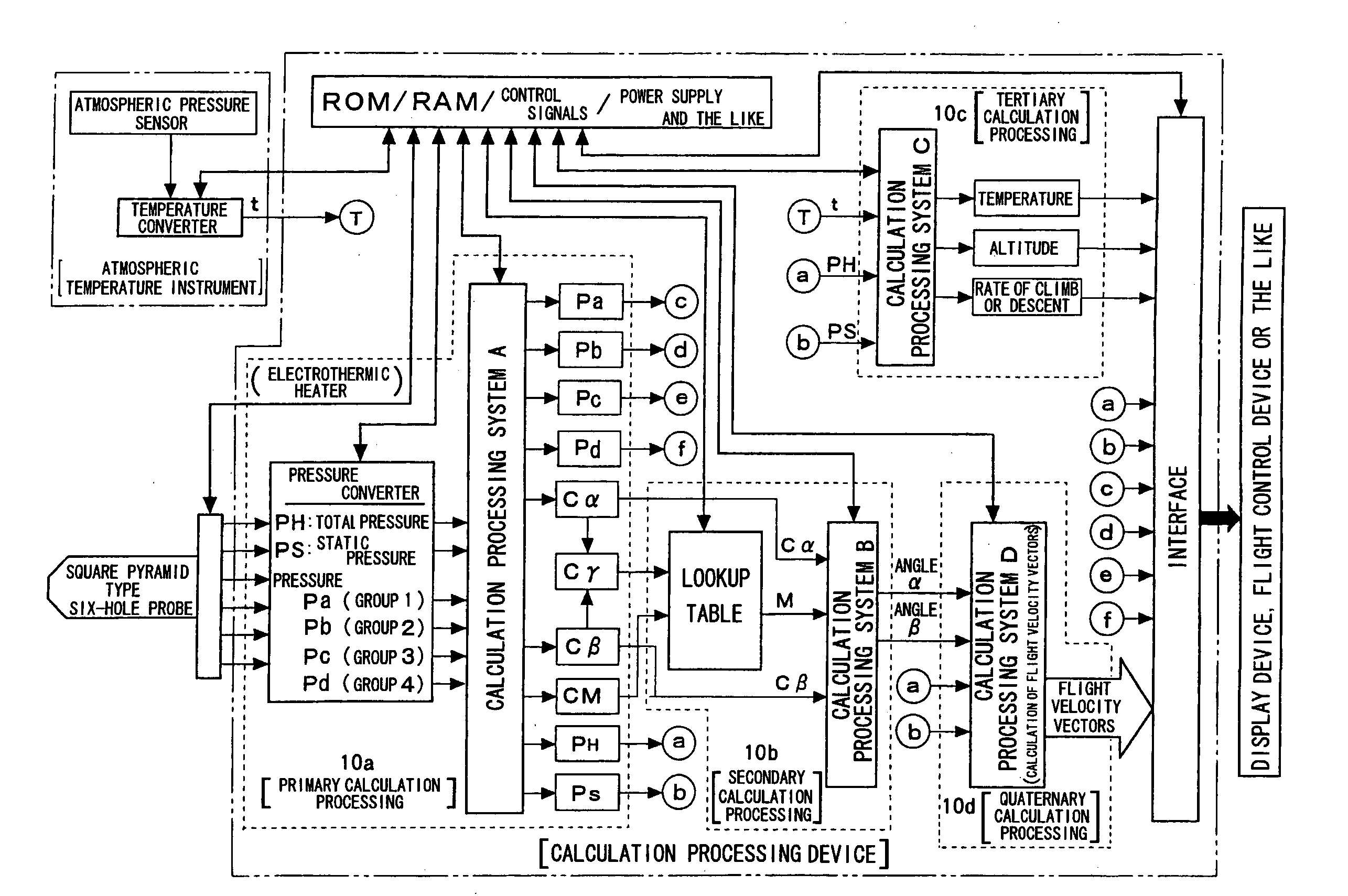

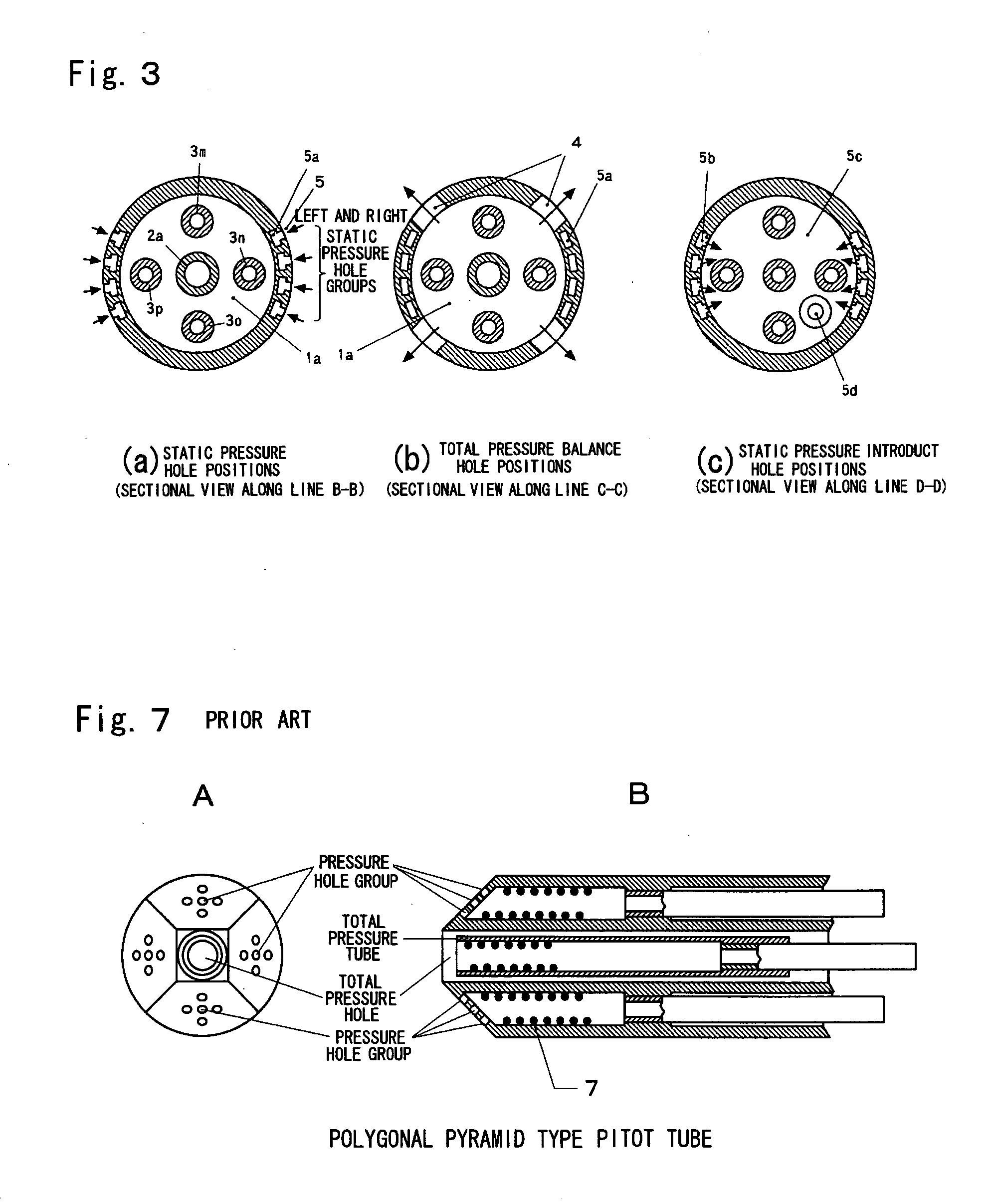

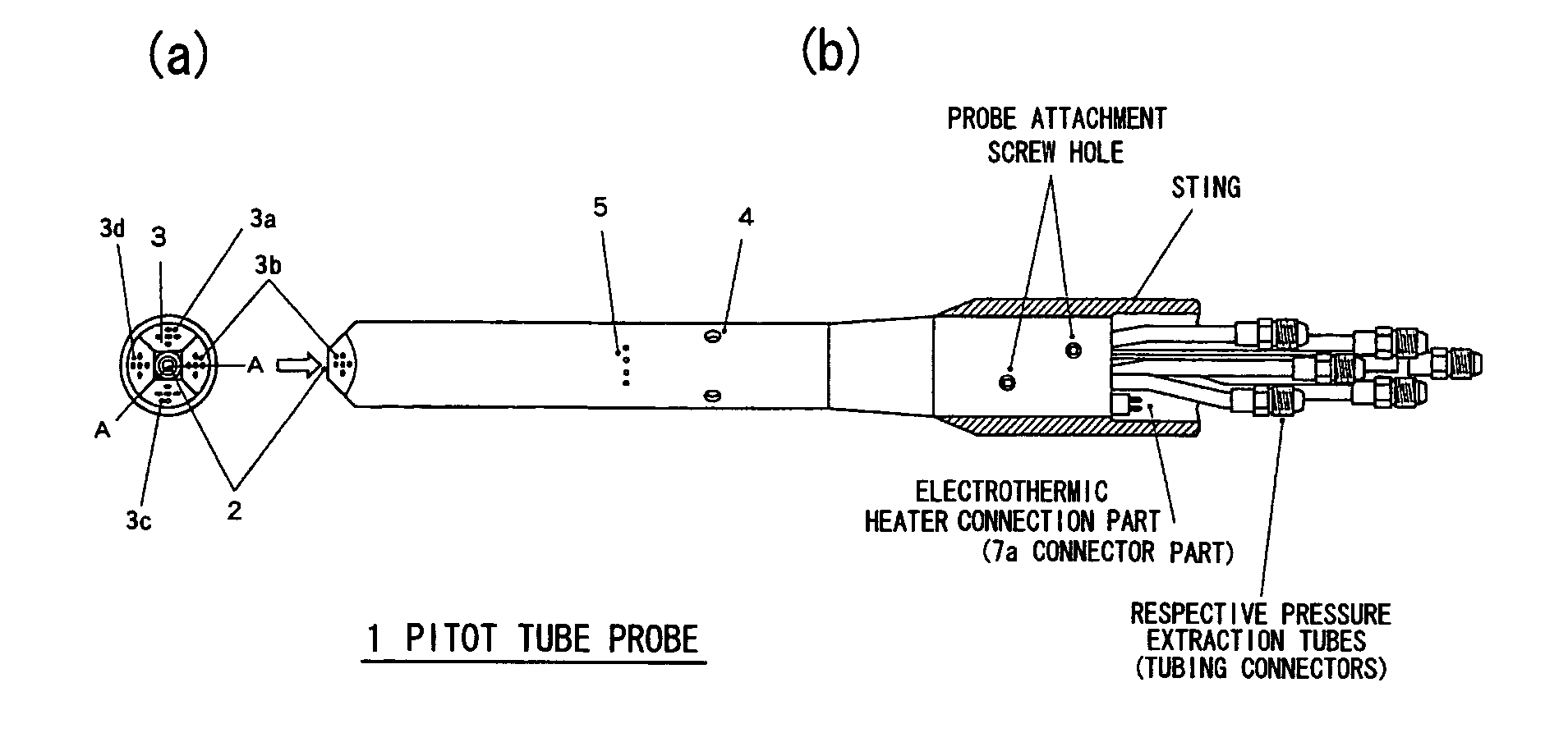

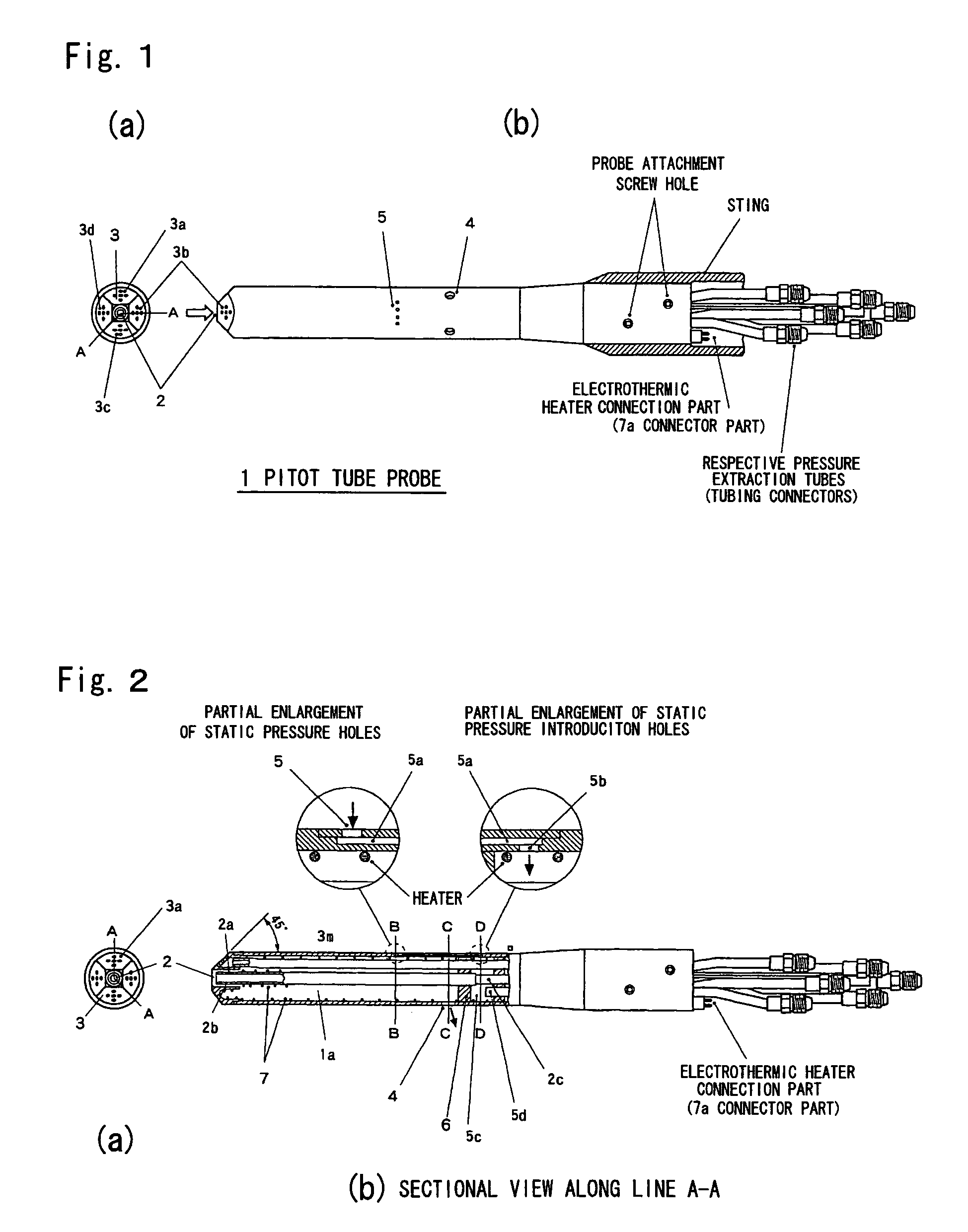

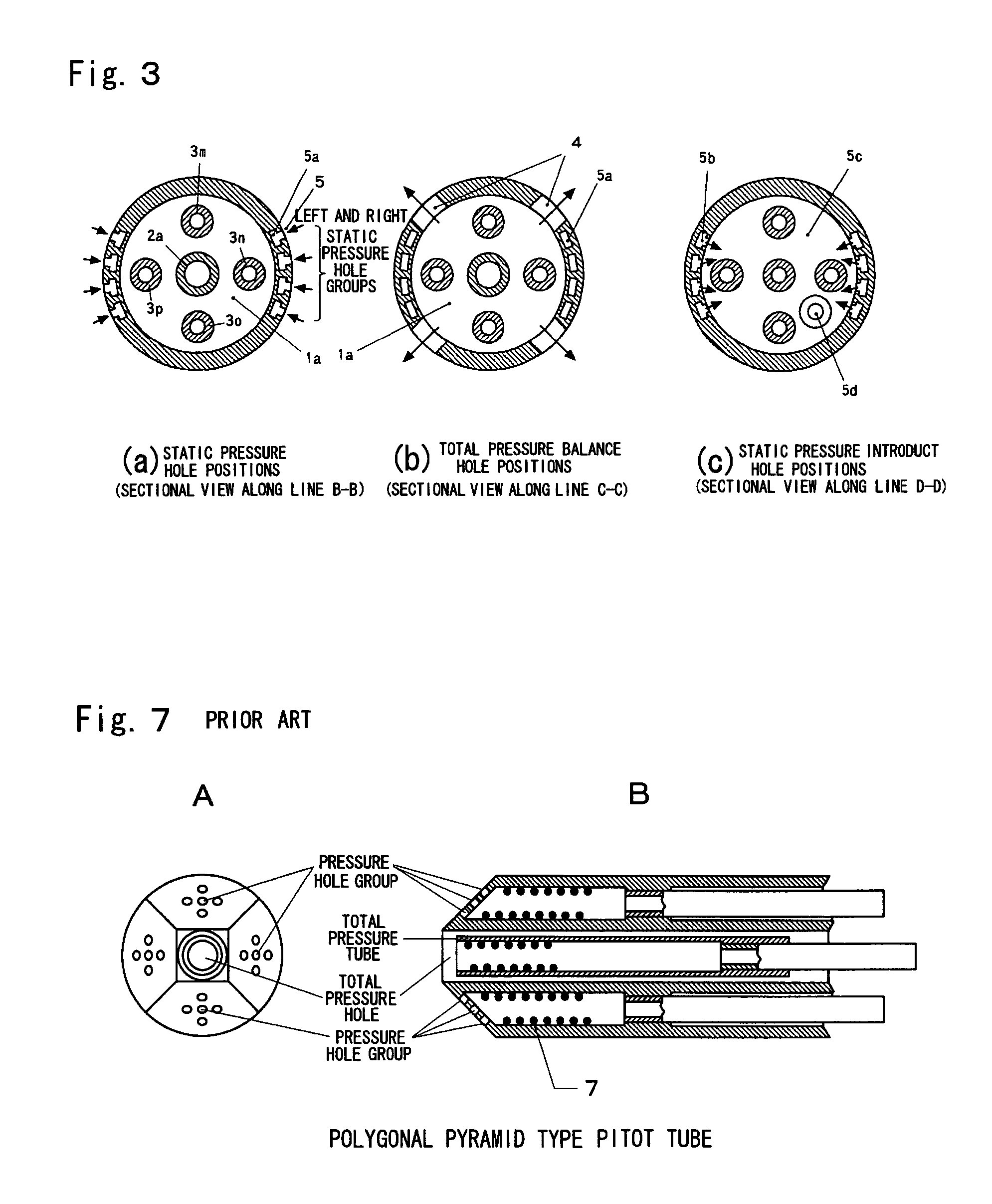

High-altitude capable wide velocity range flight velocity vector measurement probe and measurement system

InactiveUS20060178790A1Erroneous detectionPrevent fallingDigital data processing detailsFluid speed measurement using pressure differenceAnomaly detectionFlight velocity

It is an object of the present invention to solve the problem of a drop in precision in conventional systems using a square pyramid type five-hole probe due to the drop in atmospheric pressure in high altitude ranges, and to provide a wide velocity range flight velocity vector measurement system that can prevent a drop in measurement precision. Furthermore, it is also an object of the present invention to provide a method for eliminating the effects of detection fluctuations caused by adhering water droplets, ice particles or dust in a wide velocity range flight velocity vector measurement system. The flight velocity vector measurement probe of the present invention comprises means in which a static pressure hole is formed in the tube wall surface of the probe, so that a static pressure value is obtained from the pressure detected by this static pressure hole, the Mach number M is calculated on the basis of an equation approximated by a fourth-order polynomial of the static pressure / total pressure signal and the angle of attack, and in cases where an abnormal detection value is detected, this is replaced by the preceding detection value.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

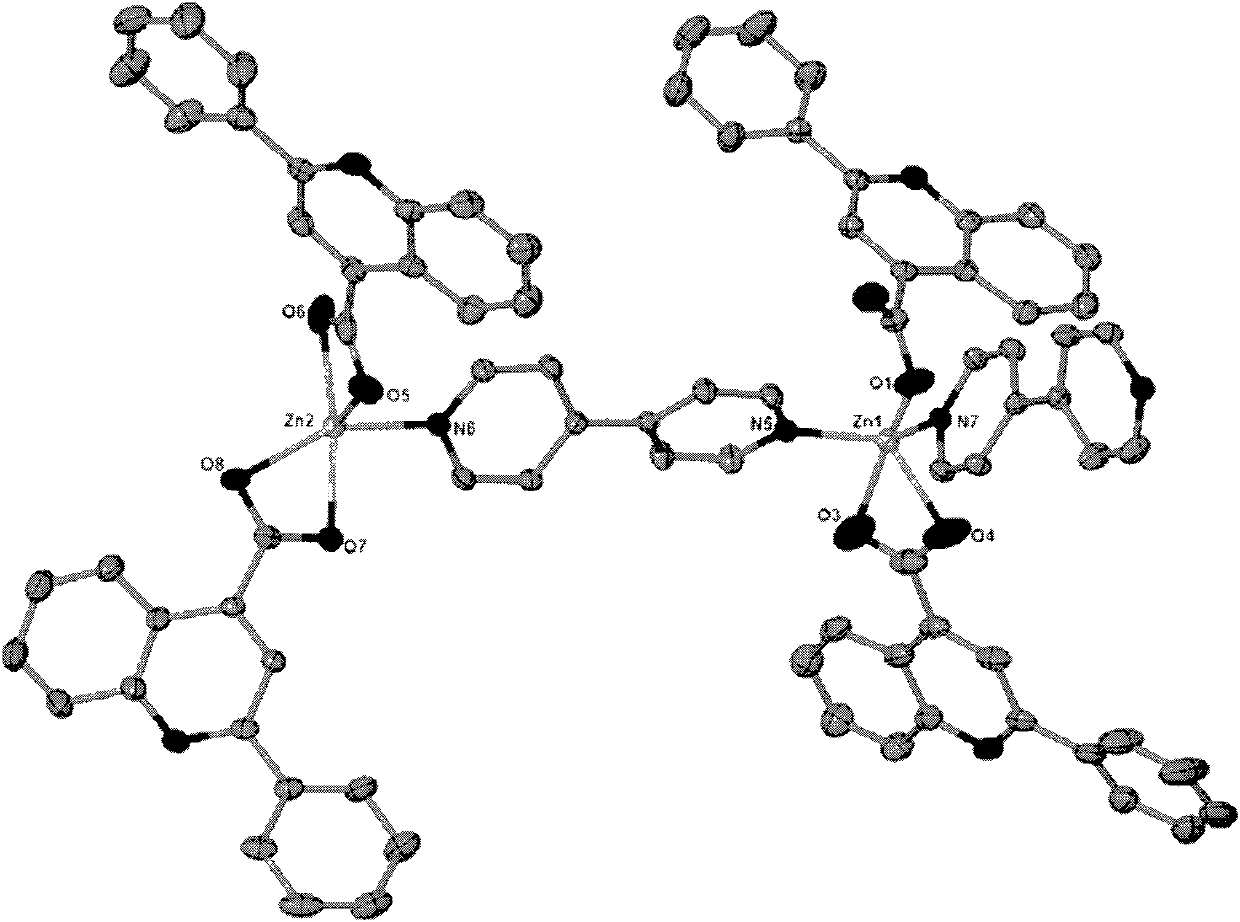

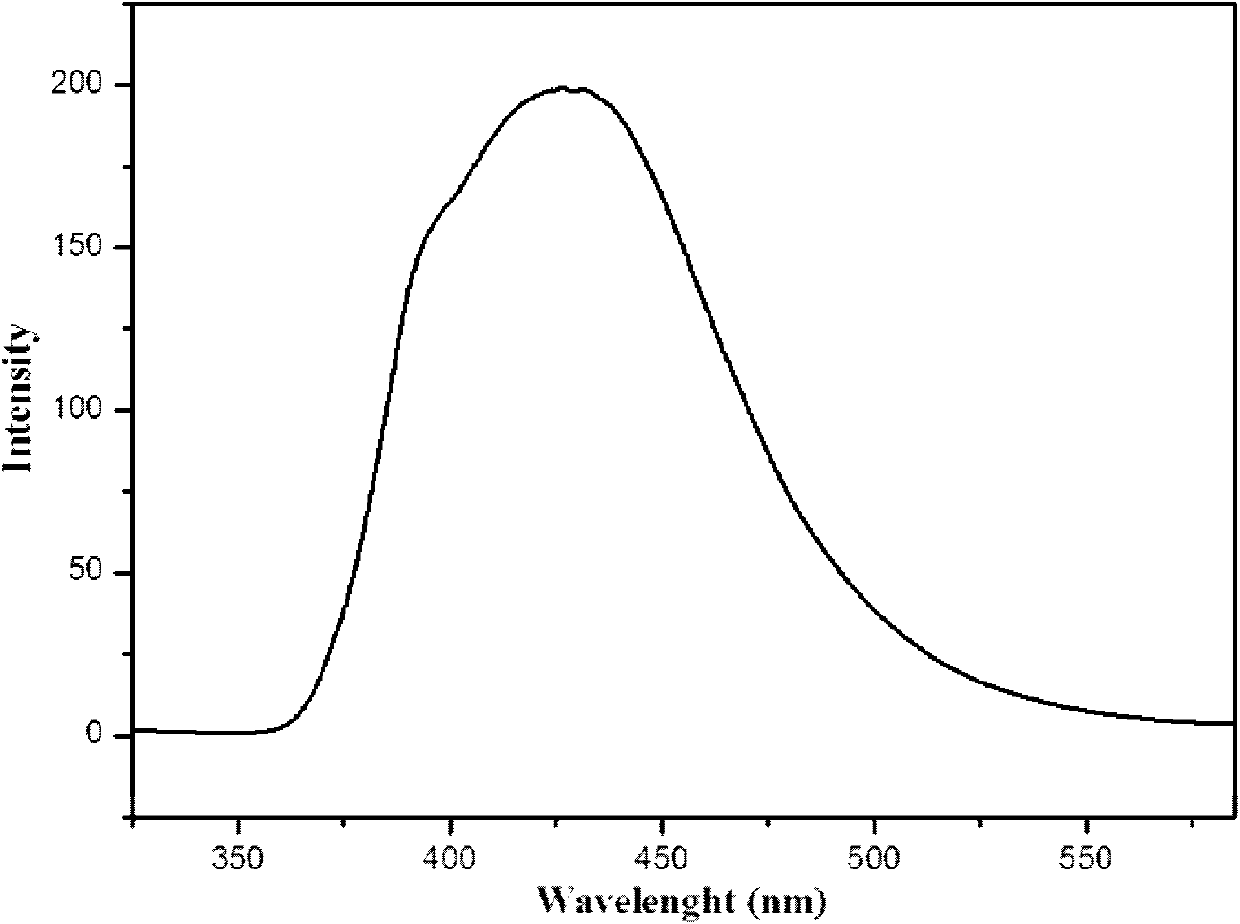

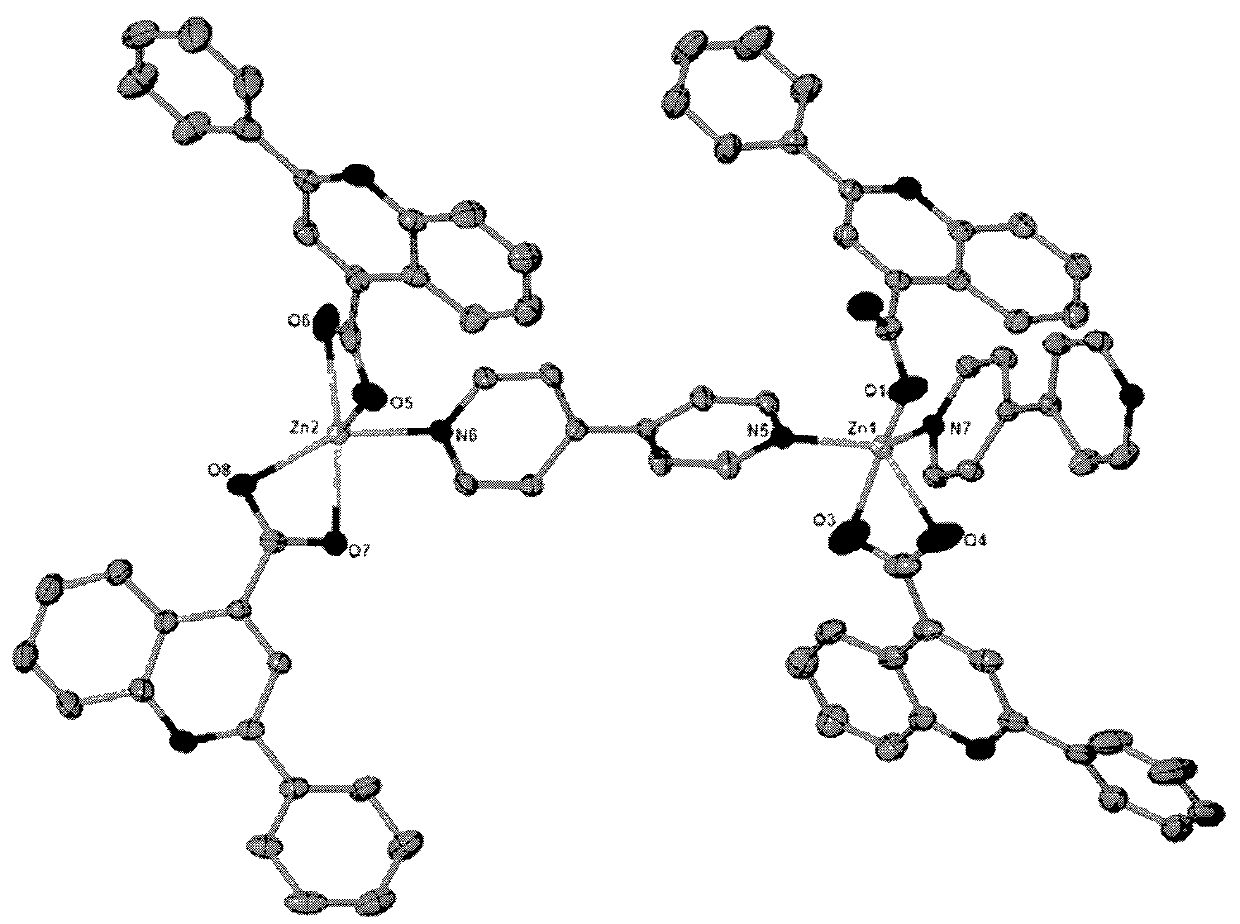

Near blue fluorescent material and preparation method thereof

InactiveCN102241974AAccurate spatial structureGood photoelectric activityLuminescent compositionsZinc organic compoundsCrystal systemSpace group

The invention discloses a near blue fluorescent material and a preparation method thereof. The material is prepared through chemical reactions of quinoline carboxylic acid and 4,4'-bipyridine with conjugated extended pi bonds, and zinc ions with optical activity. The fluorescent material is a zinc quinoline carboxylic crystal with a molecular formula of C84H56N8O8Zn2. The crystal belongs to a crystal system of triclinic system, and a space group of P-1. Cell parameters of the crystal are that: alpha= 91.357 DEG, gamma=106.573 DEG, and beta=101.953DEG. The zinc ions have two coordination modes, one is a square pyramid coordination mode, wherein two nitrogen coordinating atoms come from two different 4,4'-bipyridines, and three oxygen coordinating atoms come from two different quinoline carboxylic acid ligands; the other is a octahedral coordination mode, wherein two nitrogen coordinating atoms come from two different 4,4'-bipyridines, and four oxygen coordinating atoms come from two different quinoline carboxylic acid ligands. The material is advantaged in that: the fluorescent material contains abundant optically active Zn (II) ions and conjugated extended bonds, and has good near blue light emission performance.

Owner:NINGBO UNIV

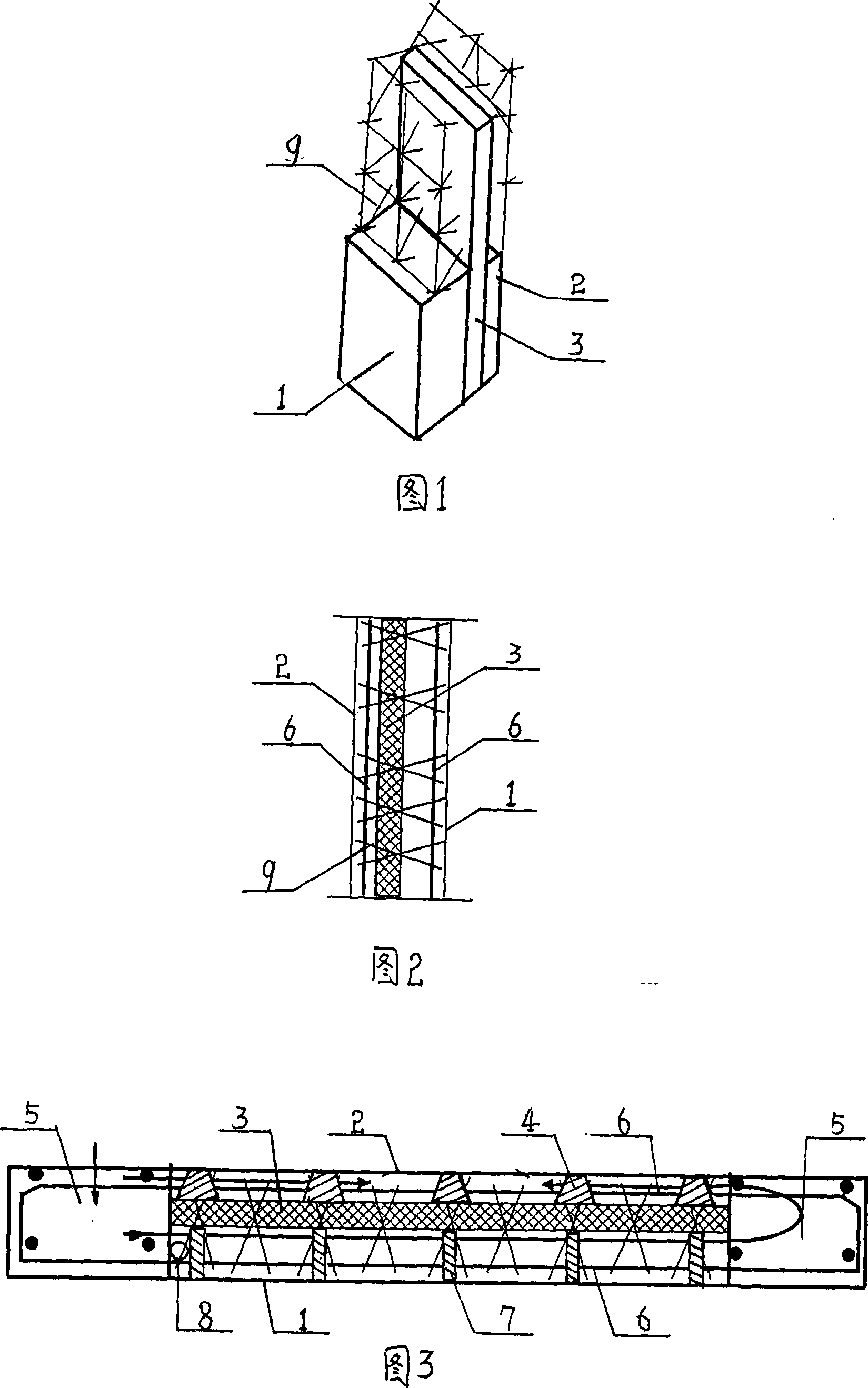

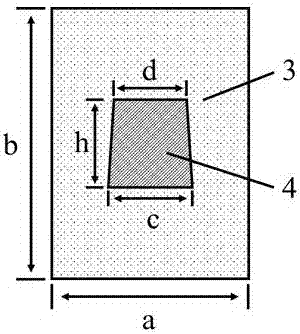

Double-side in-situ placing construction method for CL structure system composite wall board concrete

The present invention relates to the building construction technique filed, concretely to a construction method for two-side in-place-casting the CL structure system composite wall plate concrete, the invention settles the problems of high construction and transportation cost, large installing difficulty, weak wholeness and hard guaranteeing the construction quality caused by that the existing CL structure system composite wall plate adopts single-side prefabricating and single-side casing-in-place, and the method comprises the steps of CL rack board manufacturing and baiting; directly prefabricating the square pyramid concrete cushion block on the polystyrene board of the inner wall side CL rack board; CL rack board installing and tying to the steel bar of the edge component; arranging the formwork of the wall; prefabricating the rectangular concrete cushion block, before the closing of the formwork inserting a rectangular concrete block with position corresponding with the square pyramid concrete cushion block at the side of the CL rack board of the exterior wall side, and the concrete of inner wall and exterior wall is simultaneously casted. The invention has the advantages of simplifying the construction working procedure, reducing the quality control point, guaranteeing the quality, shortening the construction time for a large scale, increasing the economic benefit, and the wall concrete has the advantages of compactness, good whole structural property and smooth external appearance.

Owner:CHINA RAILWAY 12TH BUREAU GRP

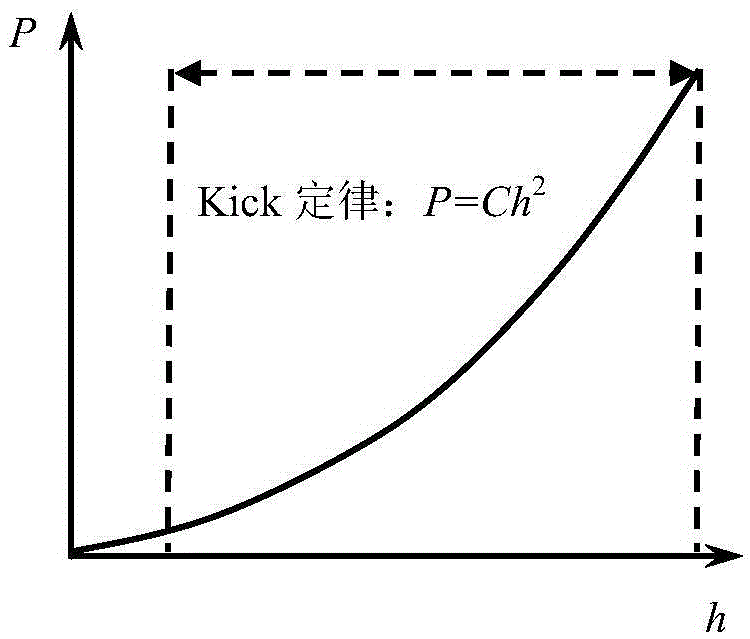

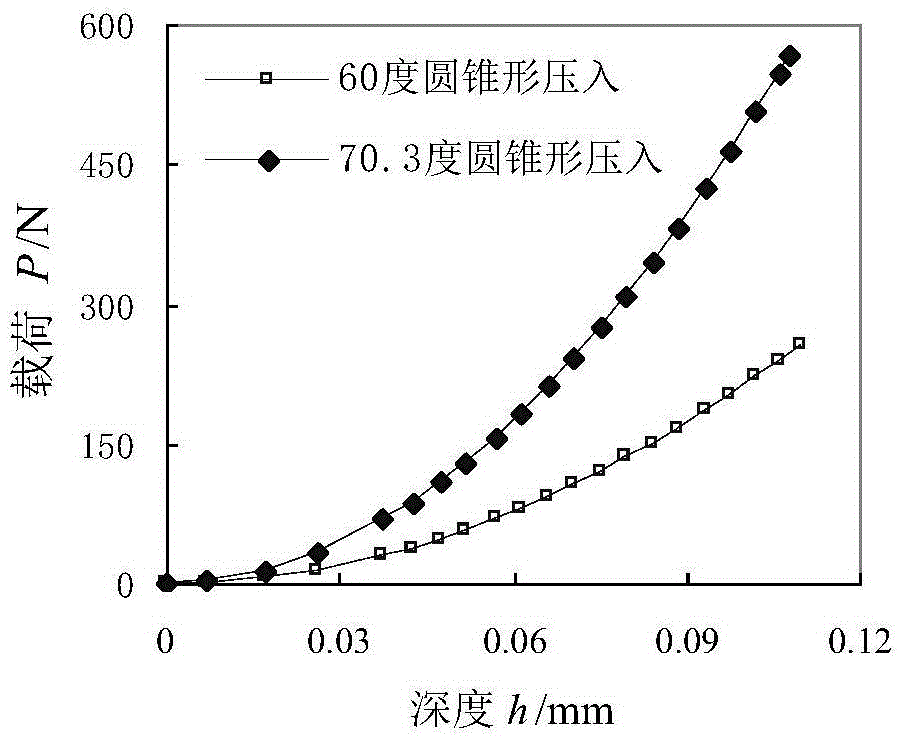

Determination method of material's uniaxial constitutive relation through biconical indentation prediction

InactiveCN105675419AAchieve acquisitionGood effectInvestigating material hardnessNuclear powerSquare pyramid

The invention discloses a determination method of a material's uniaxial constitutive relation through biconical indentation prediction. By the use of two different diamond cone indenters (shaped as a cone or a right square pyramid), a smooth material's surface undergoes quasi-static indentation loading so as to obtain a continuous loading P-depth h curve; loading curvature C is obtained through the curve loading section; and through simple treatment, the material's uniaxial constitutive relation is predicted. By the method, the defect that existing cone indentation technology requires long-range finite element calculation and depends on multistage regression fitting to obtain complex numerical relationship and the like is overcome, and harsh technological requirements for solution to constitutive relation in the prior art are avoided. The method of the invention can be used in mechanical effects analysis of material's constitutive relation and relevant factors under loading conditions such as creep deformation, impact and the like. The invention is of great significance for acquisition of uniaxial mechanical properties of materials with a small structure or a welding structure widely existing in key projects such as micro electro mechanical system, aerospace, nuclear power, high-speed railway, oil and gas transportation, biomedical engineering and the like.

Owner:SOUTHWEST JIAOTONG UNIV

High-altitude capable wide velocity range flight velocity vector measurement probe and measurement system

InactiveUS7480548B2Prevent fallingEliminate the effects ofDigital data processing detailsFluid speed measurement using pressure differenceAnomaly detectionFlight velocity

It is an object of the present invention to solve the problem of a drop in precision in conventional systems using a square pyramid type five-hole probe due to the drop in atmospheric pressure in high altitude ranges, and to provide a wide velocity range flight velocity vector measurement system that can prevent a drop in measurement precision. Furthermore, it is also an object of the present invention to provide a method for eliminating the effects of detection fluctuations caused by adhering water droplets, ice particles or dust in a wide velocity range flight velocity vector measurement system. The flight velocity vector measurement probe of the present invention comprises means in which a static pressure hole is formed in the tube wall surface of the probe, so that a static pressure value is obtained from the pressure detected by this static pressure hole, the Mach number M is calculated on the basis of an equation approximated by a fourth-order polynomial of the static pressure / total pressure signal and the angle of attack, and in cases where an abnormal detection value is detected, this is replaced by the preceding detection value.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

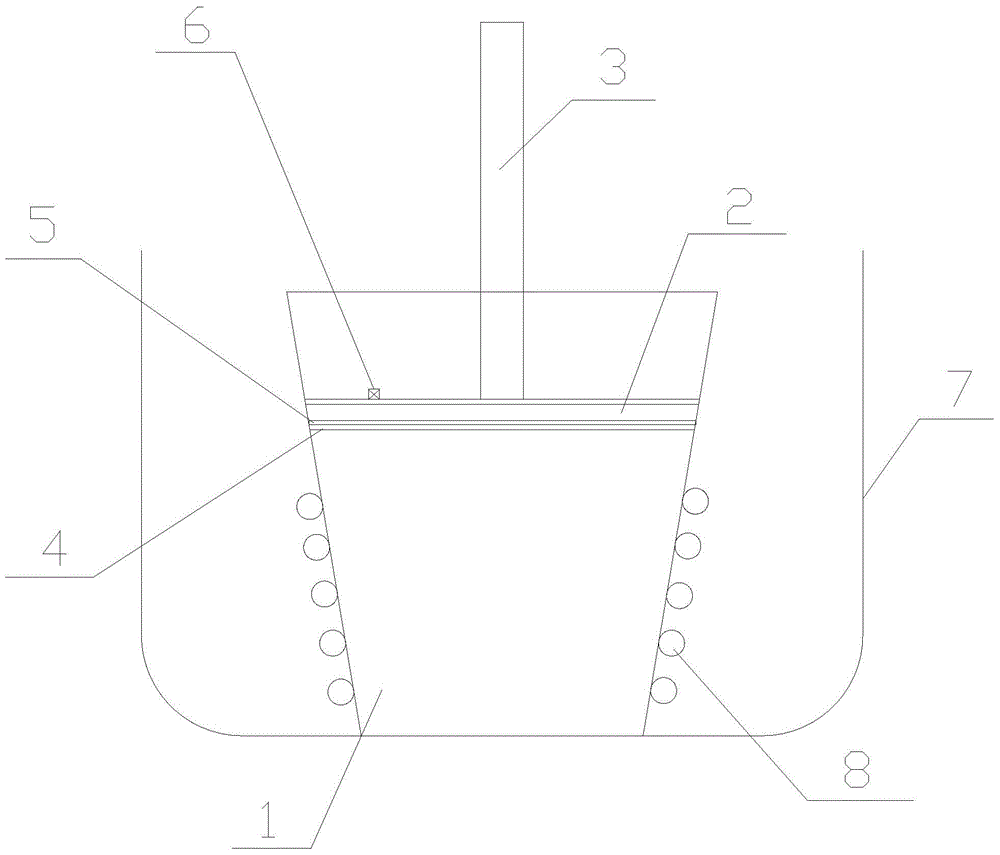

Device for improving foaming uniformity of foamed aluminum and foaming technology

Provided is a device for improving a foaming uniformity of foamed aluminum. The device comprises a mould case provided with a foaming cavity. The mould case is designed into a big-end-up platform or a square pyramid opening cavity structure. The mould case is provided a pressurizing cover plate with multiple dimensions in a matched mode. The center portion of the pressurizing cover plate is connected with a hydraulic piston rod. The peripheral edge of the pressurizing cover plate is provided with a sealing ring. The pressurizing cover plate is further provided with an electric heater unit and one or more exhaust valves. A mould case body is arranged inside a thermal insulating chamber, and a melt is prevented from solidifying in a excessively fast mode. The outer wall of the mould case is provided with cooling pipelines. Cooling treatment is carried out on the melt according to needs. The structure is simple, the design is novel, by adopting pressurizing and cooling, after the melt is cooled to a semi-solid state and thickened, natural foaming or decompression foaming is carried out, and bubbles are prevented from floating upwards. The up and down consistency of the foamed melt density can be guaranteed, it is guaranteed that foaming is even, the product yield is improved, and the problem that a traditional melt foaming method is uneven in foaming is solved.

Owner:ANHUI NEOFOUND TECH

Silicon micro piezoelectric sensor chip and its preparing method

InactiveCN1790765AAchieve good process compatibilityReduce corrosion defectsImpedence networksPiezoelectric/electrostrictive devicesSilicon oxideProtection layer

The invention relates to a silicon micro piezoelectric sensor chip, which comprises: big-end-down square-pyramid holes on center of N-type silicon substrate, a deposited silicon nitride base film layer and mask layer on front and reverse surface of substrate, a circular hole on center of base film layer, a square hole on mask layer center with same size as the one on silicon substrate reverse surface, a silicon nitride vibration film on top surface of base film layer with circular upper electrode and lower electrode that has circular piezoelectric film on its top surface with circular low-temperature silicon oxide film protection layer by photo etching. Wherein, the silicon nitride or multicrystal silicon vibration film and piezoelectric film form circular piezoelectric film / silicon nitride or multicrystal silicon composite bending vibration film. This invention can reduce the unevenness of vibration stress to prevent film breakage, and improves sensitivity of sensor.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

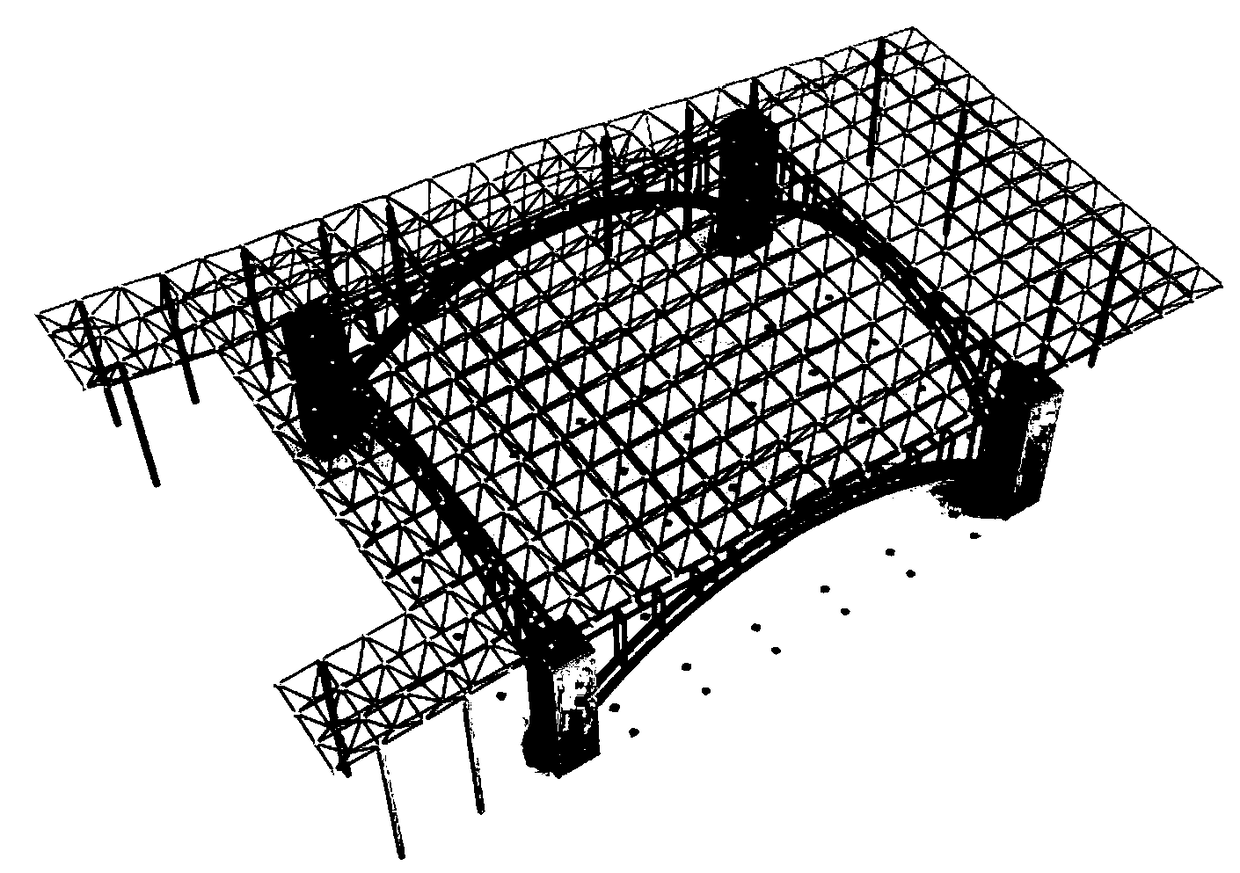

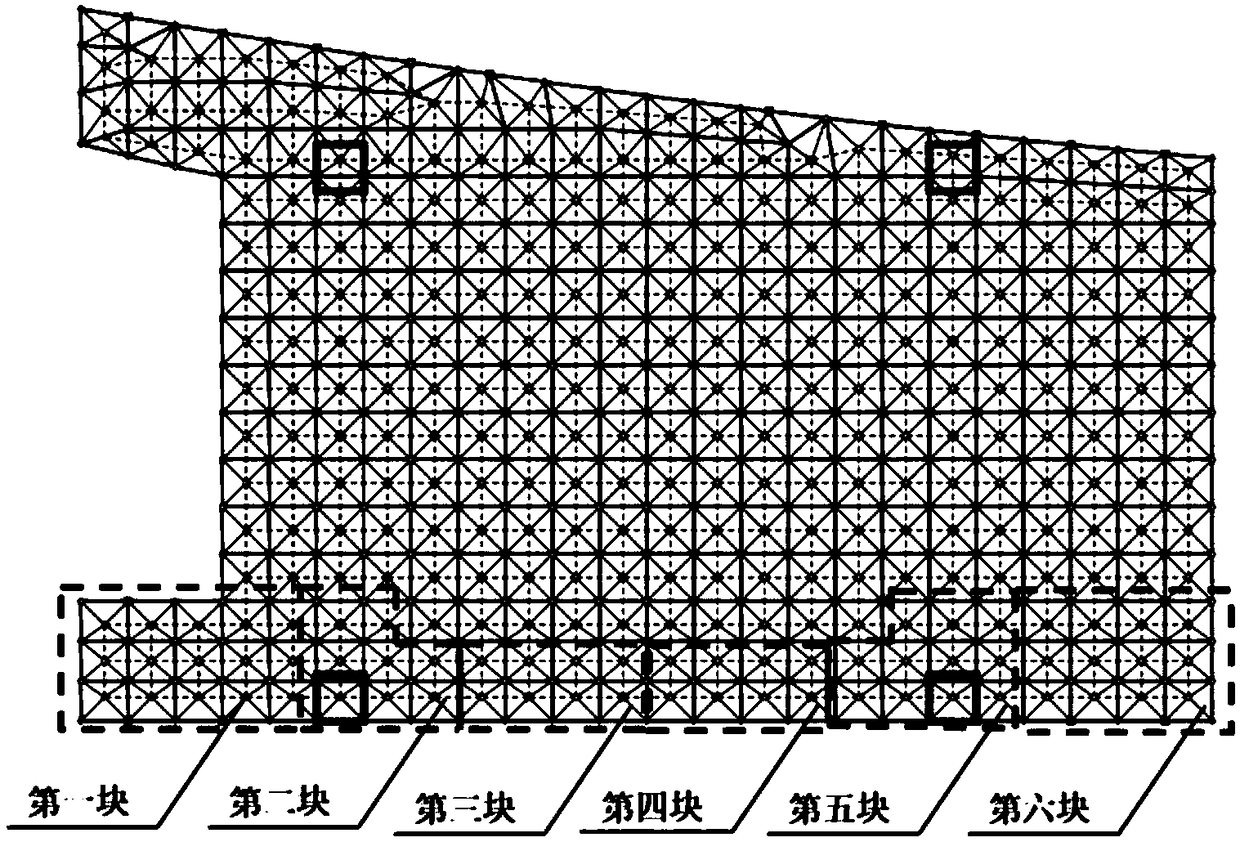

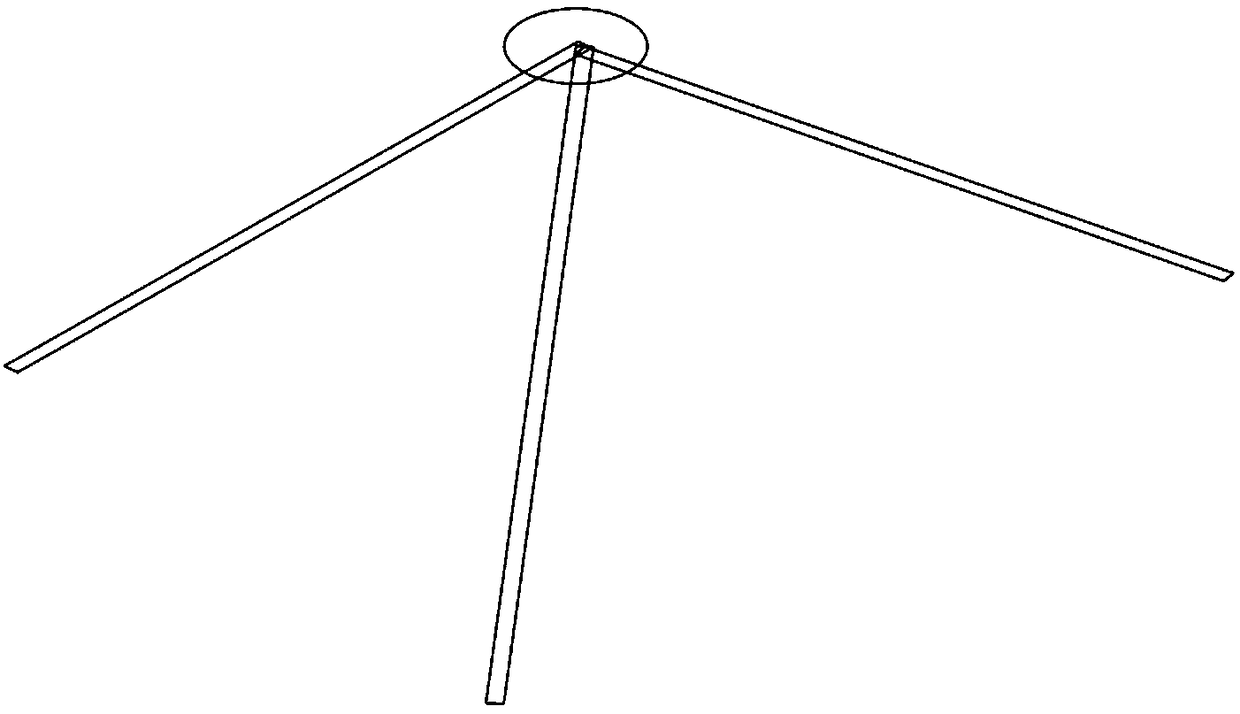

Rectangular square pyramid bolt ball grid multi-point supporting high-altitude separate assembling method

InactiveCN109235902ASolve the installationCutting costsBuilding material handlingSquare pyramidMechanical engineering

The invention discloses a rectangular square pyramid bolt ball grid multi-point supporting high-altitude separate assembling method. A starting frame of a net rack is lifted by a small lifting unit formed by separate assembling on the ground; after the starting frame is installed, the other portions are separately assembled in the air; before high-altitude separate assembling, a net rack wire moldis subjected to acceptance analysis through MIDAS, the place where deformation is possibly large in the assembling process is found, a support is arranged at the place, and the support is designed into the structure capable of adjusting the level at any time. According to the net rack construction method adopting starting frame blocking lifting, net rack high-altitude separate assembling and multi-point supporting, the small-area and small-tonnage net rack structure installing purpose is well achieved, for the space net rack structure with the wide development prospect, the requirements for lowering the cost, improving the efficiency, and achieving high quality and high-precision positioning can be met, and the method is applicable to most small-area low-weight net rack structure systems.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

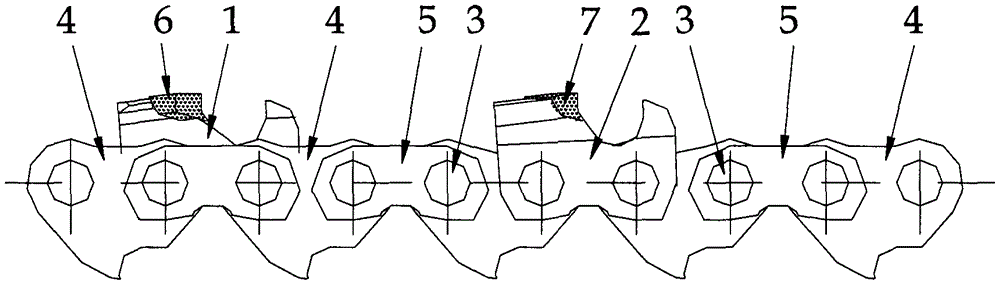

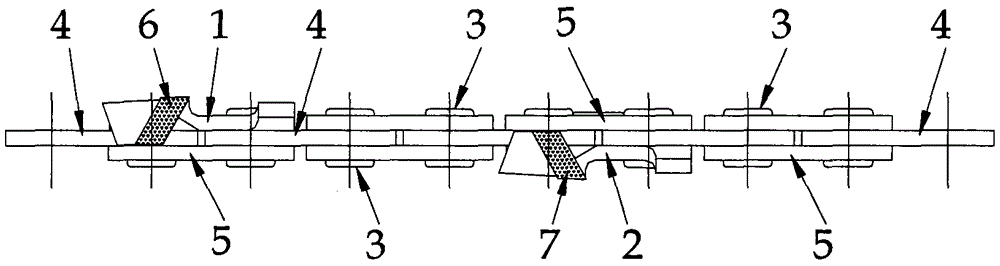

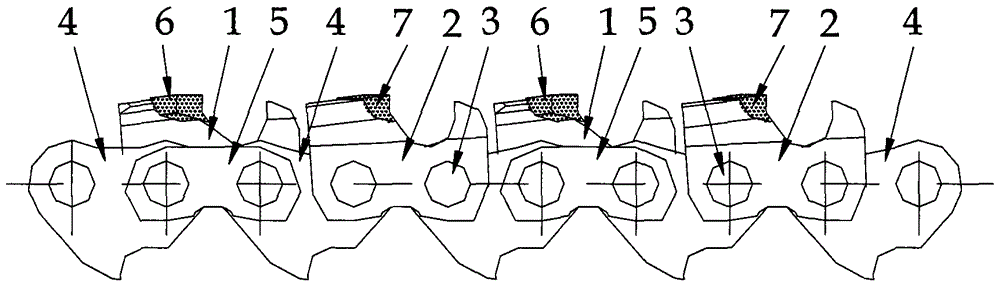

Hard alloy saw chain

ActiveCN103331487AEliminates solder brittlenessAvoid brittle fractureMetal sawing toolsButt weldingCarbide saw

The invention relates to a hard alloy saw chain of a chain saw. The welding face of a hard alloy tooth block and cutting teeth is made to be a cylindrical face, the arc radius of the cylindrical face is 2 to 5mm, and the optimal arc radius is 2.5 to 4mm. The shape of the tooth block is made to be similar to a frustum of a square pyramid, and the height of inner side face of the teeth block is lower than the height of outer side face of the tooth block. The tooth side face of the tooth block concaves inwards and perpendicularly, and a concave angle is 1 degree to 3 degrees. The intersection of the tooth top face of the tooth block and the tooth side face of the tooth block is made to be a circular bead, the tooth tip of the tooth block is made to be a section of arc line, the arc radius of the tooth tip is 0.2 to 0.8mm, and the optimal arc radius of the tooth tip is 0.3 to 0.4mm. According to the hard alloy saw chain, due to the adoption of butt welding, the hard alloy tooth block is welded with the cutting teeth, after the tooth block is welded, local high-temperature tempering is conducted, the joining strength of a welding line is 4 times higher than the jointing strength of brazing, the hard alloy saw chain is very firm, and no teeth drop during saw cutting.

Owner:缙云县鼎盛工具制造厂(普通合伙)

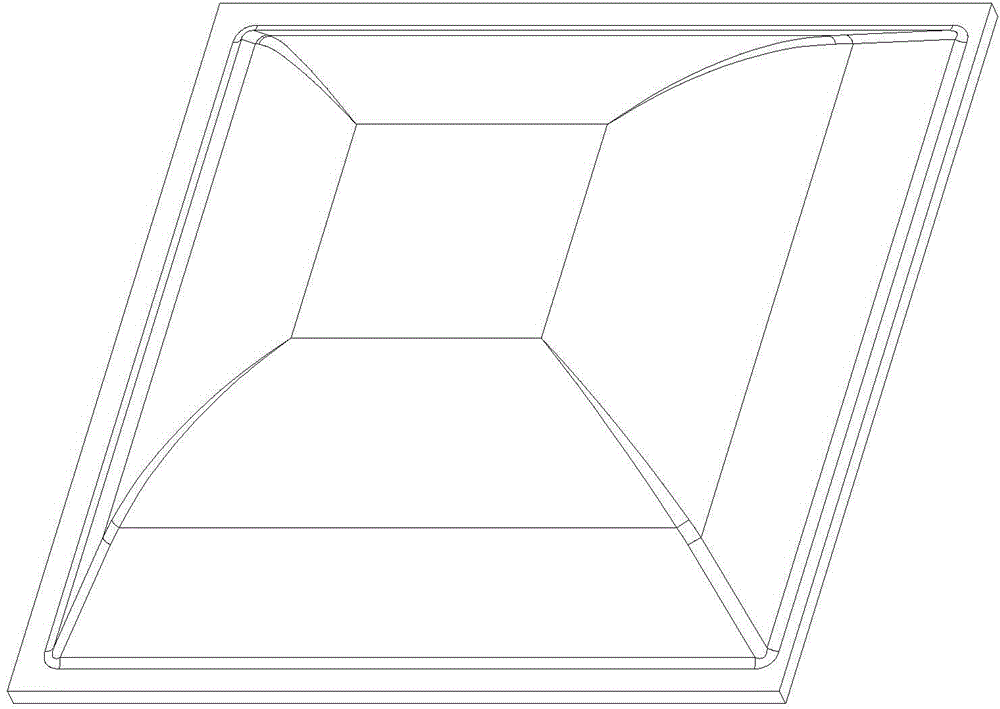

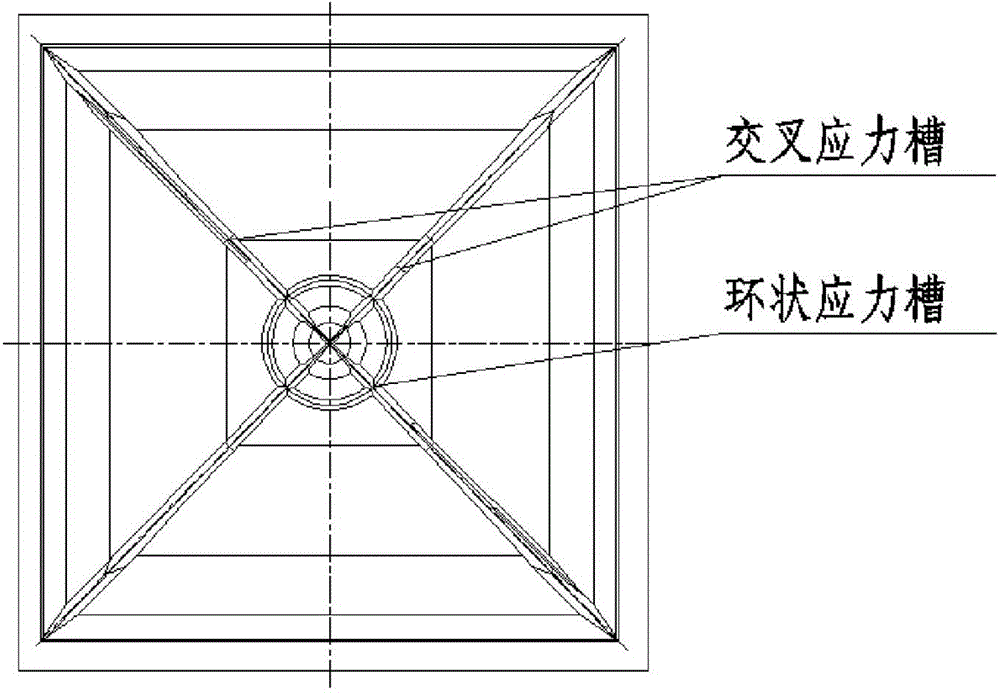

Fragile cap

ActiveCN104913692ABroken in timeGuaranteed crushing effectAmmunition storageEngineeringSquare pyramid

The invention discloses a fragile cap. The fragile cap is characterized in that the external appearance is a housing in the shape of a square pyramid; the periphery of the top surface of the outer wall is in the shape of an arc inverted angle; the center of the top surface of the inner wall is provided with an annular stress groove; stress grooves, in the cross-shaped shapes, are arranged at four corners of the inner side wall; and centers of the cross-shaped stress grooves and the center of the annular stress groove are overlapped. The fragile cap has following beneficial effects: the fragile cap can be regularly broken in a forward direction according to the cross-shaped stress grooves; a missile warhead is not damaged; and the breaking process goes on stably and reliably.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Light source unit and projector

The enclosed embodiments provide a light source unit and a projector with high light utilization efficiency. The unit has a light emitting part for emitting light from a planer emitting region, a reflecting metal electrode provided on one side of the light emitting part, a square pyramid prism on the other side of the light emitting part, and a bottom surface of the prism that has substantially the same size and shape as the planer emitting region. The inclined surfaces of the square pyramid prism output light that has entered the square pyramid prism from the bottom surface in a specific direction. The reflecting metal electrode reflects the light that has been reflected by the inclined surfaces and transmitted through the bottom surface of the square pyramid prism.

Owner:SEIKO EPSON CORP

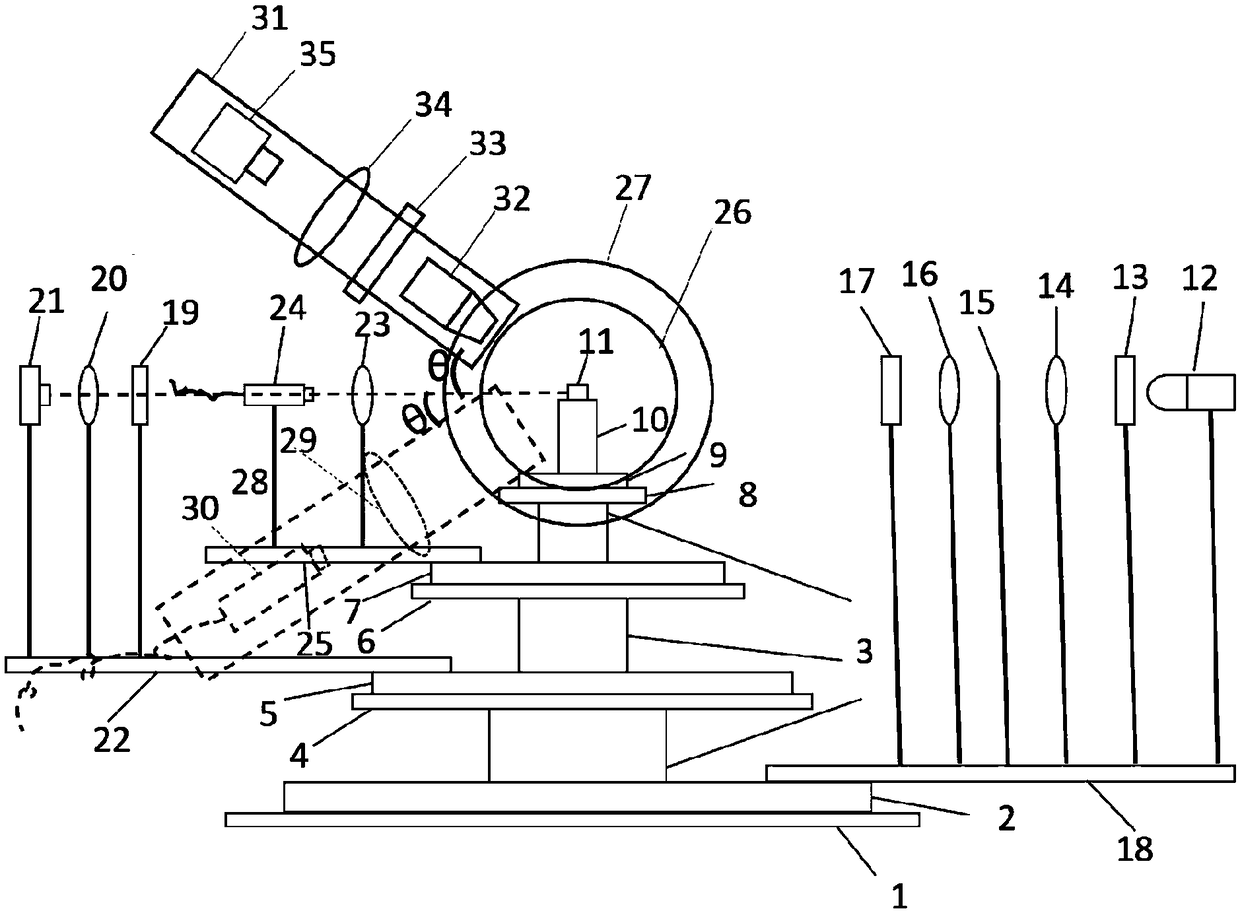

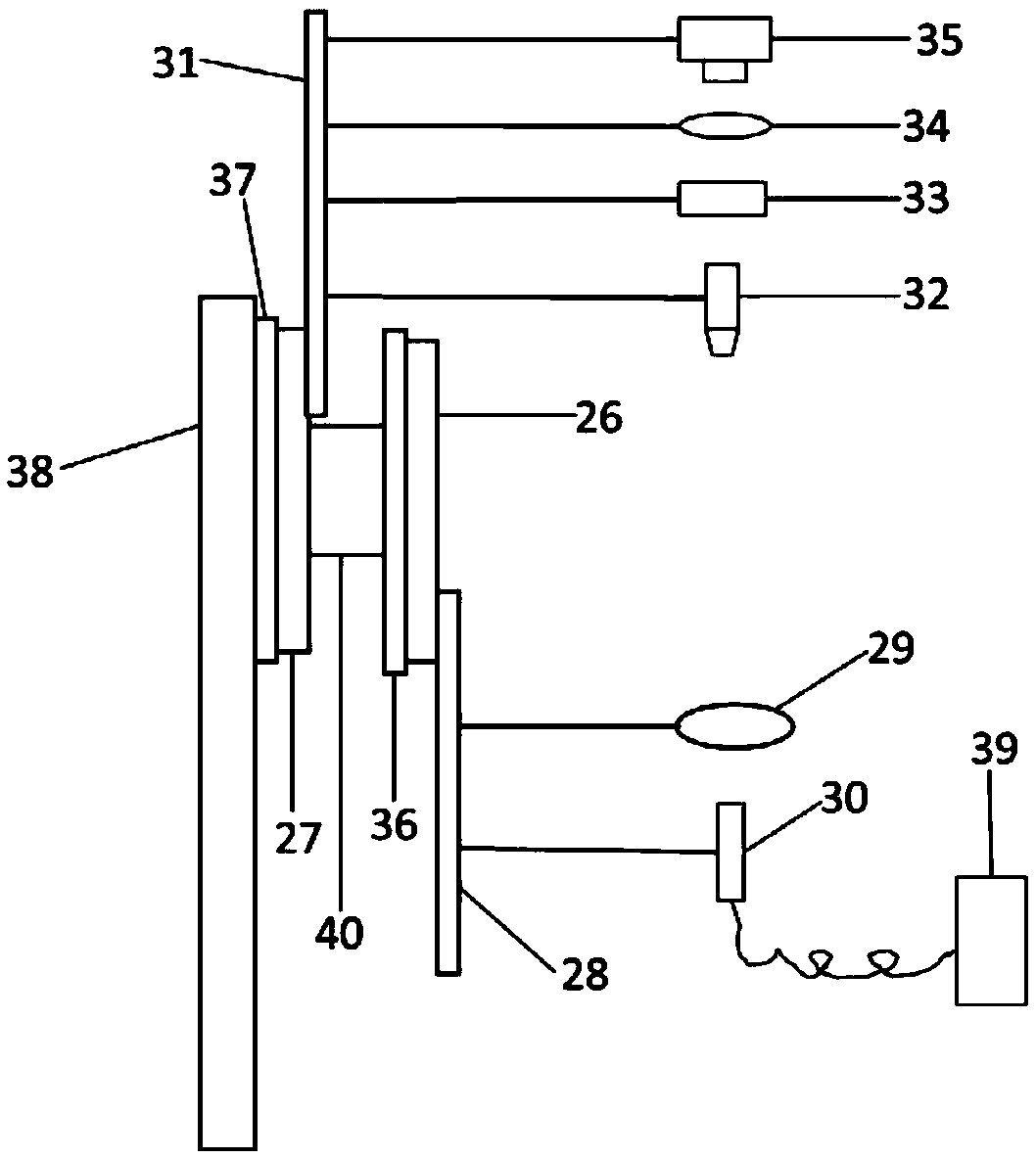

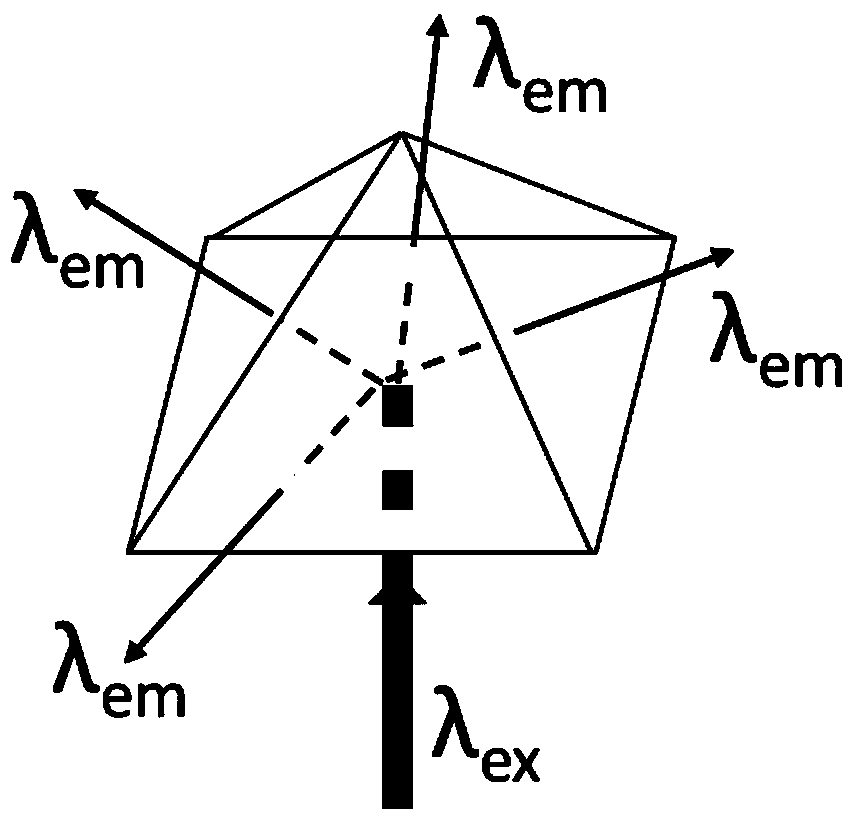

Multifunctional surface plasma coupled emission fluorescence and Raman detector and detection method thereof

ActiveCN108645831AAvoid the influence caused by local unevenness, etc.Raman scatteringFluorescence/phosphorescenceMicroscopic imageImage detection

The invention discloses a multifunctional surface plasma coupled emission fluorescence and Raman detector and a detection method thereof, relating to detection of fluorescent spectrum, Raman spectrum,fluorescent imaging and fluorescent microscopic imaging. The detector comprises an angle distinguishing module, an excited light path module, a fluorescent spectrum detection module, a Raman spectrumdetection module, an imaging detection module and a microscopic imaging detection module, wherein the modules are separately fixed on corresponding rotary tables through optical guide rails, and canrotate simultaneously or independently around a prism and a membrane sample on the prism, excitation signals of different angles and emission signals of different angles can be generated by rotating the modules, and a square pyramid mirror is used as a coupling element and combines with the detection modules so as to enable the detector to acquire surface enhanced fluorescence and Raman, spectrumand imaging information and so on of the same sample simultaneously without using a light splitting system. The detector has a simple structure, is low-cost, is easy to operate, and is easy to promote.

Owner:XIAMEN UNIV

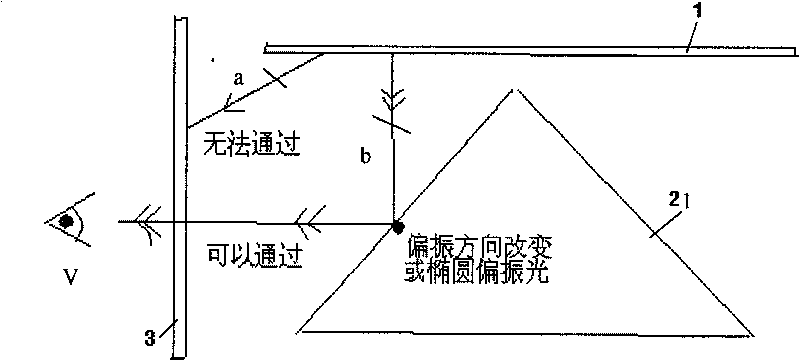

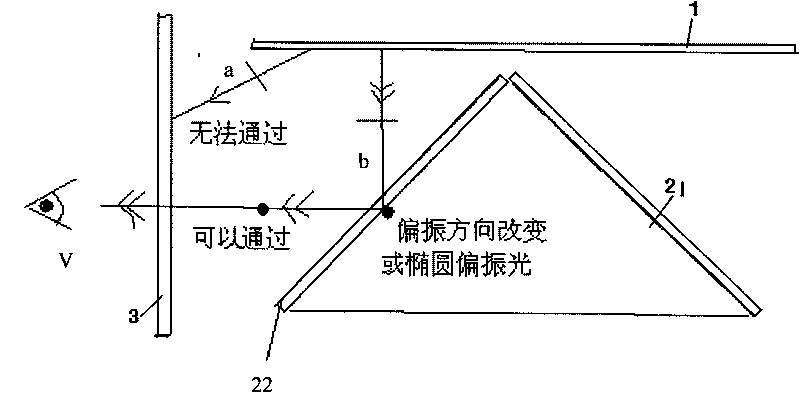

Floated quasi-three dimensional display device sheltered by display screen

The invention discloses a floated quasi-three dimensional display device sheltered by a display screen, comprising a polarized display, a pyramid polarized rotating mirror, a first polaroid, a second polaroid, a third polaroid, a fourth polaroid and a base. The center of the base is provided with the pyramid polarized rotating mirror above which the polarized display is arranged; the pyramid polarized rotating mirror is a square pyramid or a square prismaid, each of the four lateral sides of the square pyramid or the square prismaid has an included angles of 45 degrees with the bottom surface; and the periphery of the bottom surface is vertically provided with the first polaroid, the second polaroid, the third polaroid and the fourth polaroid. The invention has simple structure, can be observed by encircling of 360 degrees and by multiple angles in a close distance, and can realize large-area quasi-three dimensional display in tens of square meters and miniature portable three-dimensional display.

Owner:ZHEJIANG UNIV

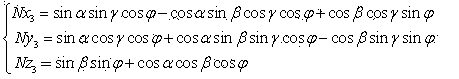

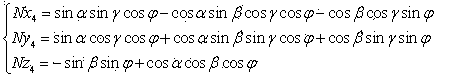

Three-dimensional small-angle measuring device and three-dimensional small-angle measuring method

InactiveCN103471561AImprove anti-interference abilityStrong ability to suppress noiseAngle measurementBeam expanderBeam splitter

The invention discloses a three-dimensional small-angle measuring device and a three-dimensional small-angle measuring method. The three-dimensional small-angle measuring device comprises a laser, a beam expander, a beam splitter, a measuring camera, a rectangular square pyramid reflector and a data processing computer, wherein a planar reflector is arranged between the beam expander and the beam splitter, the beam splitter is positioned between the measuring camera and a light path of the rectangular square pyramid reflector, laser emitted by the laser is expanded through the beam expander, enters the rectangular square pyramid reflector through the planar reflector and the beam splitter, then returns the beam splitter after being reflected by the rectangular square pyramid reflector, and enters the measuring camera; the data processing computer is connected with the measuring camera. The invention also discloses a method for measuring the three-dimensional small-angle change amount by using the three-dimensional small-angle measuring device further comprises the steps of establishing a coordinate system; acquiring position data of the center of mass of a lasing image spot; and solving the angle. The three-dimensional small-angle measuring device is high in accuracy and measurement resolution ratio due to the adoption of a non-contact optical small-angle precision measurement technology. Compared with a conventional method, the three-dimensional small-angle measuring method has the advantages that the small change amount of a rolling angle can be distinguished, and the spatial three-dimensional small-angle measurement is realized.

Owner:UNIT 63680 OF PLA

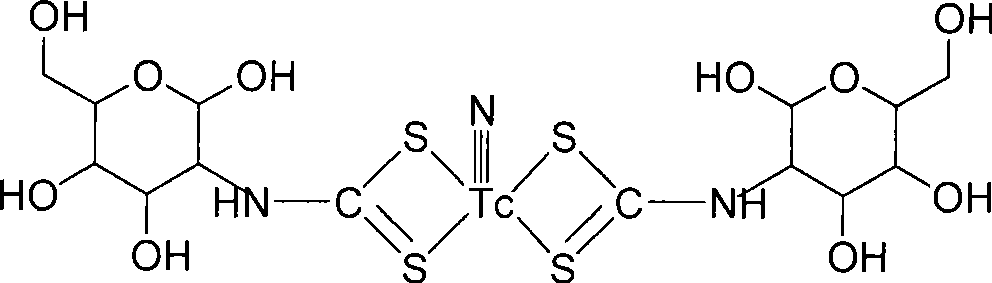

TcN(DGDTC)2 complexes as well as preparation method and use thereof

The invention discloses a <99m> TcN(DGDTC)2 complex, a preparation method and application thereof. Taking the [<99m>Tc 3N] <2+> core as a central core, the complex has an irregular geometric configuration of square pyramid, wherein the N atom in the Tc3N triple bond is located at the acme, and the four sulphur atoms provided by two ligand CPFXDTC molecules are located at the four points on the bottom surface. The complex has the advantages of high radiochemical purity, good stability, simple preparation and low price, a higher uptake value and good residence in a tumor, and good target organ / non-target organ ratio such as tumor / blood ratio and tumor / muscle ratio. The complex is a novel tumor developer with high popularization and application value.

Owner:BEIJING NORMAL UNIVERSITY +1

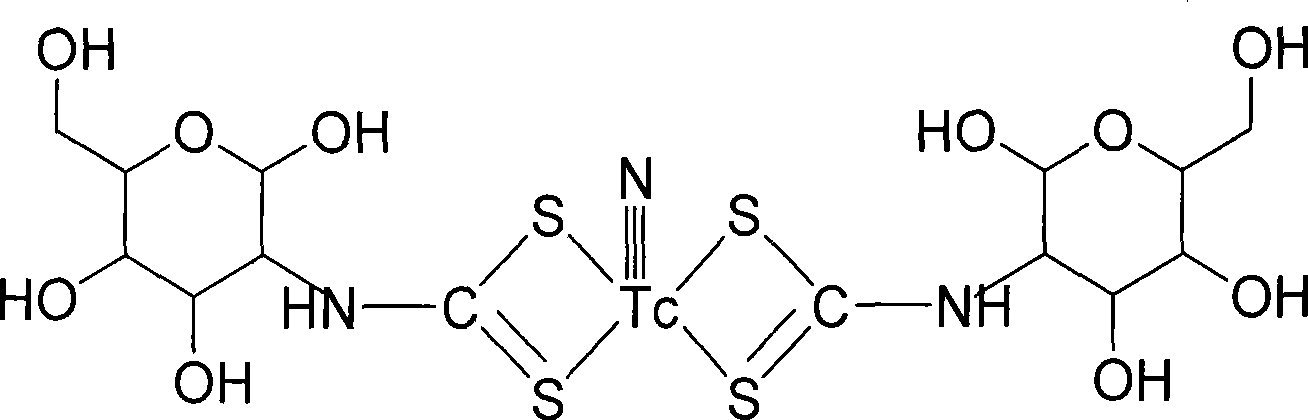

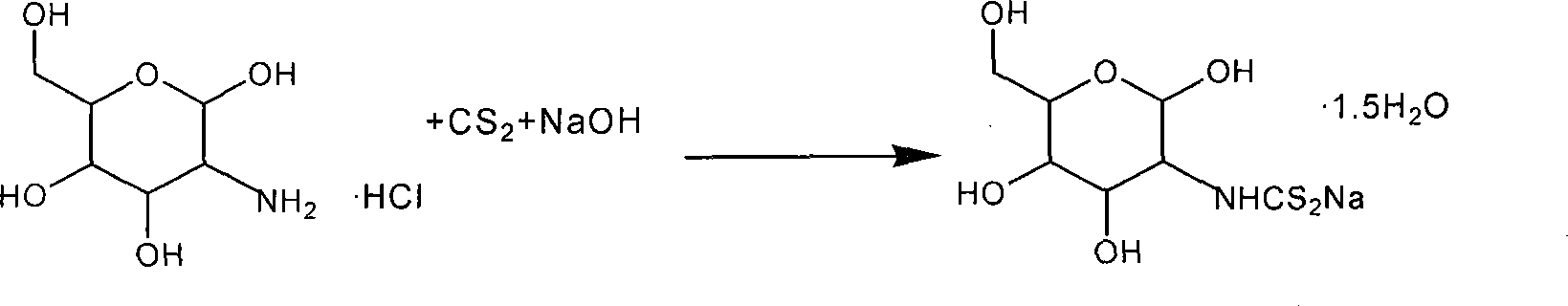

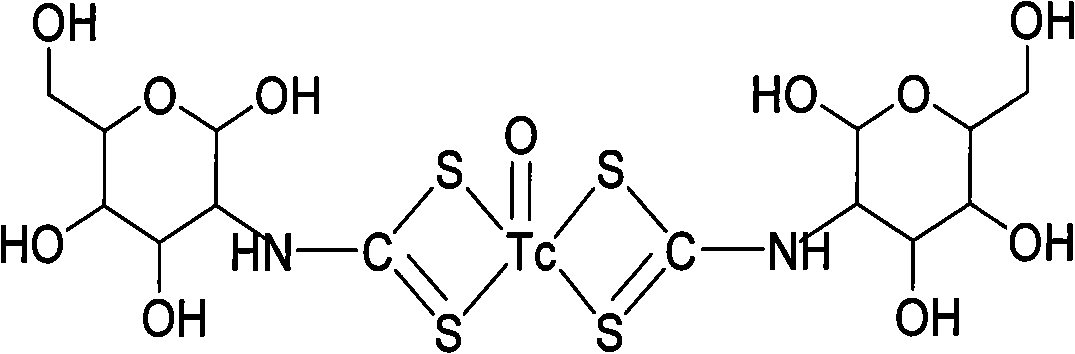

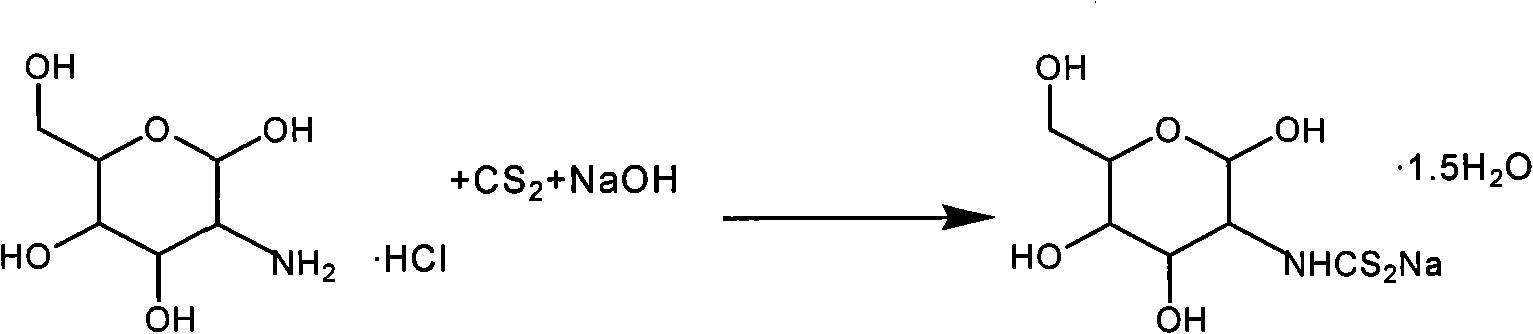

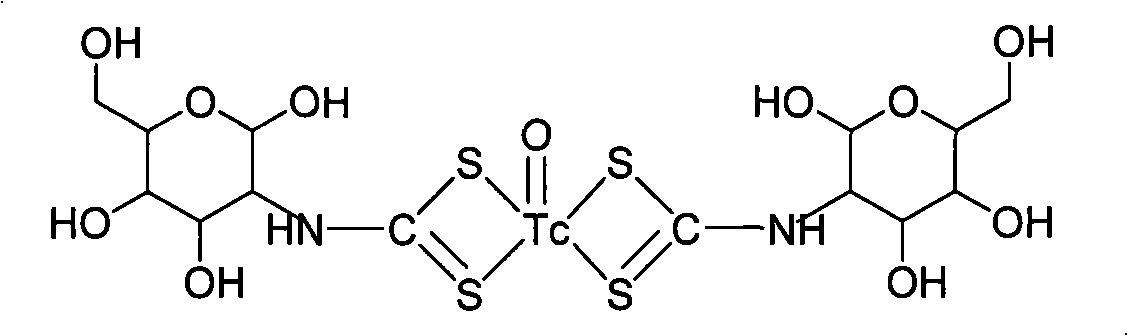

D-glucose dithiocarbamate complex marked by TcO, preparation method and applications thereof

The invention discloses a D-glucose dithiocarbamate complex marked by TcO, a preparation method and applications thereof; the formula of the complex is TcO(DGDTC)2, takes Tc(V)O as a central nucleus and has a geometric configuration with the shape of an irregular square pyramid, wherein O atom in Tc=O bond is positioned at the top point and four sulphur atoms provided by two DGDTC ligand molecules are positioned at the four points of the bottom surface. By the technical steps of synthesis of ligand DGDTC and preparation of TcO (DGDTC)2 complex, the TcO (DGDTC)2 complex is obtained. The D-glucose dithiocarbamate complex has high radiochemical purity and good stability, has higher uptake value and good detention in tumor and higher ratio of tumor / muscle, and is suitable for being promoted and applied as a novel tumor imaging agent.

Owner:BEIJING NORMAL UNIVERSITY +1

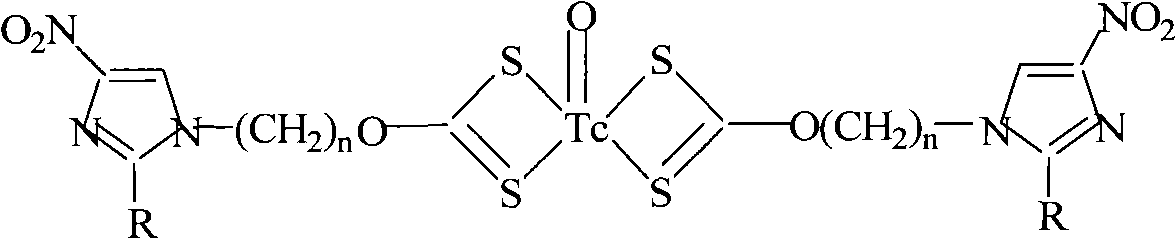

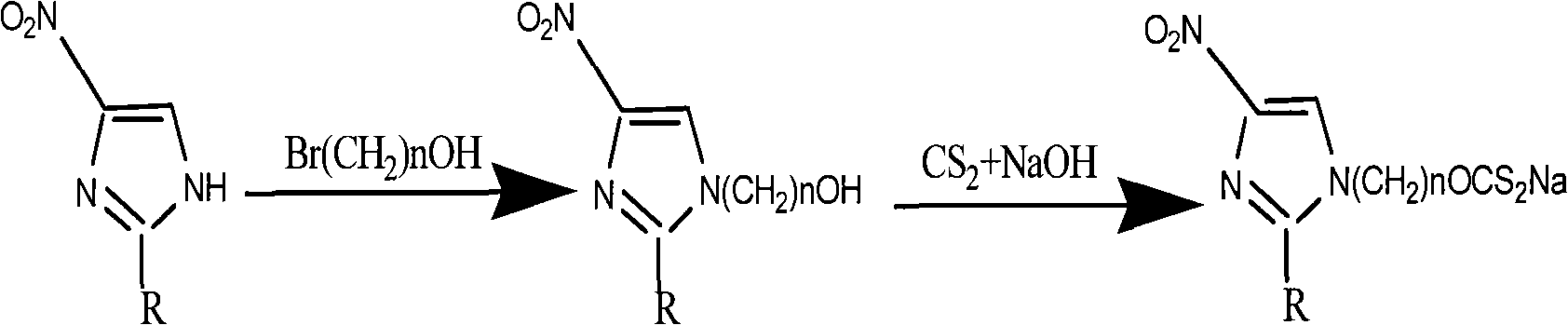

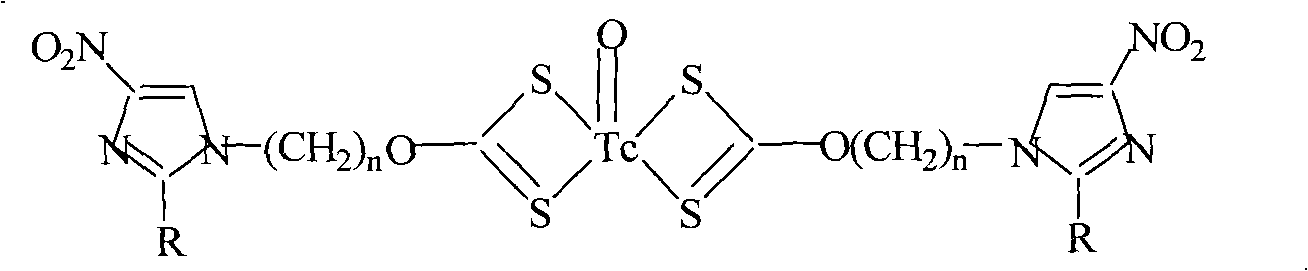

Nitro imidazole xanthogenate complex marked by TcO, preparation method and applications

InactiveCN101555229ARadioactive preparation carriersGroup 7/17 element organic compoundsNitroimidazoleHuman body

The invention discloses a nitro imidazole xanthogenate complex marked by TcO with the formula of TcO (NMXT)2; in the formula, NMXT represents a compound containing nitro imidazole xanthogenate. The complex adopts Tc(V)O as a central nucleus and has a geometric configuration with the shape of an irregular square pyramid, wherein O atom in Tc=O bond is positioned at the top point and four sulphur atoms provided by two xanthogenate ligand molecules are positioned at the four points of the bottom surface. By the technical steps of synthesis of ligand NMXT and preparation of TcO (NMXT)2 complex, the TcO (NMXT)2 complex is obtained. The nitro imidazole xanthogenate complex has high radiochemical purity and good stability, has higher uptake value and good detention through in tumor and higher ratio of tumor / muscle, is widely applied to tumor imaging of human body and animal organs and is a novel tumor hypoxia imaging agent which is conveniently promoted and applied.

Owner:BEIJING NORMAL UNIVERSITY +1

Tapered wave-absorbing material and preparation method thereof

PendingCN108084694AExcellent broadband absorbing performanceImprove absorbing performanceOther chemical processesThermal energyStearic acid

The invention discloses a tapered wave-absorbing material and a preparation method thereof. The method comprises the following steps: mixing polyurethane rubber, stearic acid, an antioxidant, dicumylperoxide, a plasticizer and carbonyl iron powder in proportion for blending evenly to obtain blended polyurethane rubber; and pressing the blended polyurethane rubber in a pyramidal mold to form the tapered wave-absorbing material. The prepared tapered wave-absorbing material includes a plurality of adjacent and repetitively-arranged square-pyramid pieces and is added with the carbonyl iron powderas a wave absorber, so that the prepared tapered wave-absorbing material has a good wide-band wave absorbing performance and can realize a good wave absorbing performance in a wide-band range from microwave to millimeter wave, and by multiple reflections between wedges of the plurality of square-pyramid pieces and conversion of energy of electromagnetic waves into thermal energy by use of the wave absorber for consumption, the tapered wave-absorbing material has a good absorbing effect at specific wavelength bands. The tapered wave-absorbing material can be applied to many fields such as aerospace, high-speed locomotives, warships, radar antennas, and electronics.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Adiabatic suspension

InactiveCN103591411AThermal insulationPipe protection by thermal insulationThermal engineeringCopper foil

The invention relates to an adiabatic suspension, and discloses a super adiabatic technology based on the structural adiabatic principle. A super adiabatic structure with sufficient mechanical strength is realized through collaborative design of adiabatic material, thermal structure, mechanical structure and applicable functions. The adiabatic suspension is characterized by comprising super adiabatic material (silica aerogel or aluminum oxide aerogel or the like), an adiabatic suspending line (aramid or acrylic fibers, silica cantilevers, metal springs and the like), an adiabatic suspension structure (a right square pyramid suspension, a cube suspension and the like), a rigid suspension bucket (an aluminum alloy casing with the surface provided with an aluminum oxide cladding) and a thermal short circuit structure (a graphite particle painting layer with high thermal conductivity or a soaking film formed by copper foils or silver foils ). The adiabatic suspension can serve as a fundamental paradigm for the thermal engineering technology and the packaging technology, and can be used for designing various new concept products, which can operate under super low temperature or super high temperature, such as adiabatic suspension batteries, adiabatic levitation batteries and adiabatic temperature sensing chips, with super adiabatic performances.

Owner:SUZHOU YUANZHENG HOT VOLT

Double-layer heterostructure mold, its manufacturing method and application in micro nano material preparation

InactiveCN106744668AControl self-harvesting characteristicsControl of droplet condensation characteristicsSpecific nanostructure formationMaterial nanotechnologyMicro structureMaterials preparation

The invention provides a double-layer heterostructure mold, its manufacturing method and application in micro nano material preparation. The mold includes a silicon lining plate, multiple micro groove sets are formed in the upper surface layer of the silicon lining plate in the axial direction of the silicon lining plate, each micro groove set includes a number of micro grooves formed at equal intervals, and the gradient of the axial spacing between every two adjacent groove sets is gradually increased; nanoscale holes are formed in the upper surface of the whole silicon lining plate, and the micro grooves and the nanoscale holes formed in the surfaces of the micro grooves form a secondary structure. The manufacturing method includes the steps that a specific concave square-pyramid-frustum micro structure is etched by means of a chemical method, and a uniform and ordered concave semispherical nano structure is indirectly generated on a silicon substrate by means of a porous AAO film. The mold has the advantages that a concave square pyramid frustum can be directly manufactured, the manufacture is simple and direct, the nano structure is uniform, small in size and high in precision, PDMS is injected into the mold, a specific dropwise condensed self-water-collected micro nano material can be obtained through simple processing, large scale production is easily achieved, and the reuse rate is high.

Owner:ZHEJIANG UNIV OF TECH

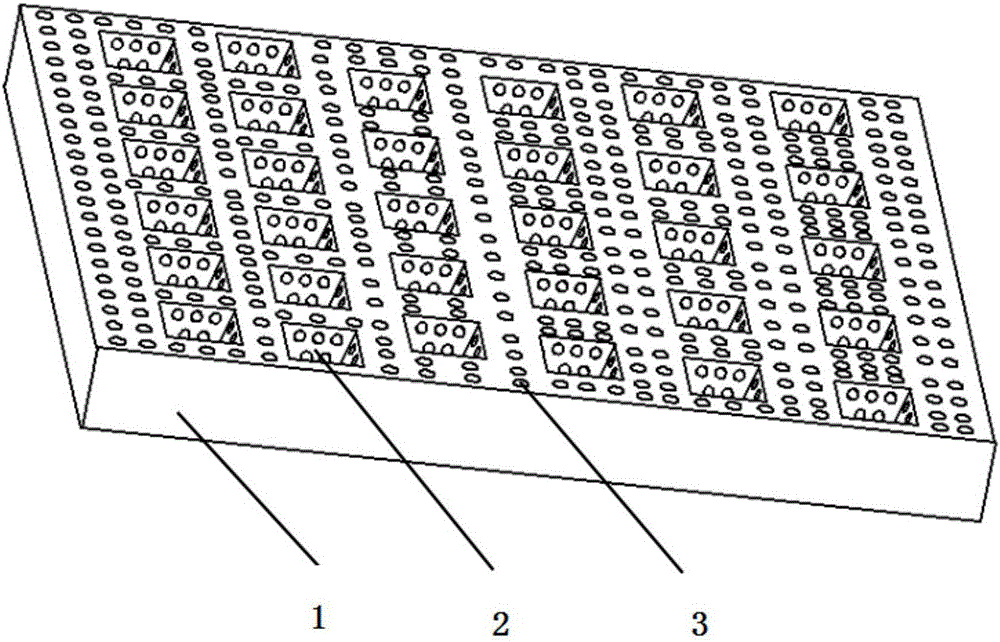

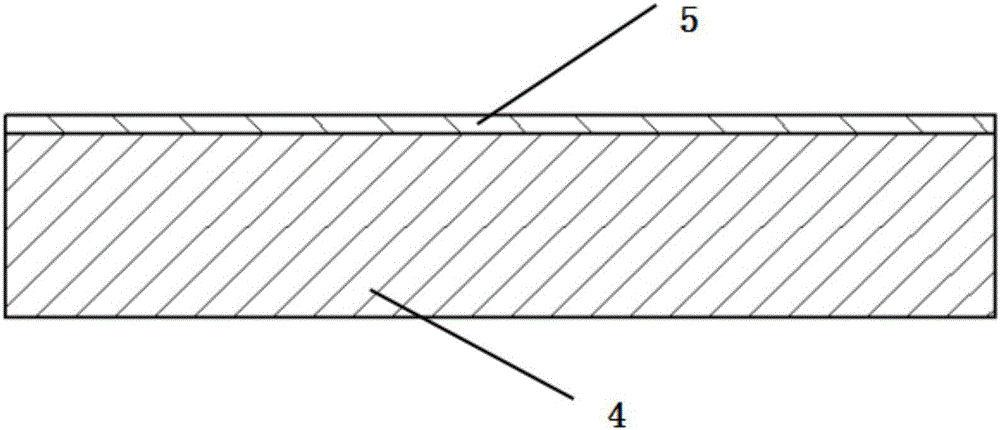

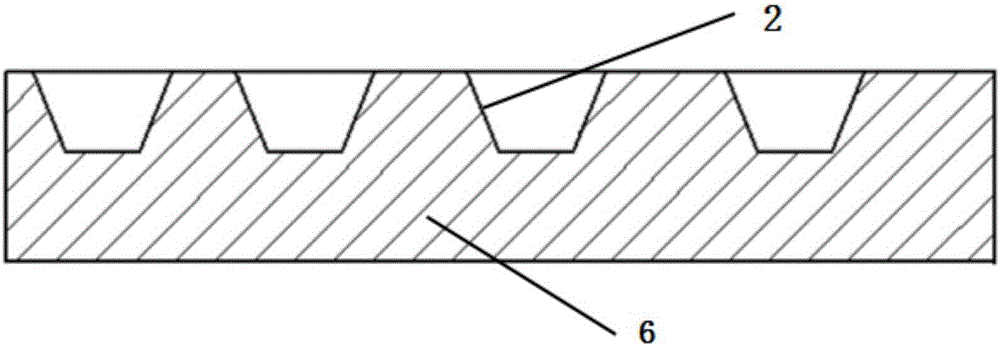

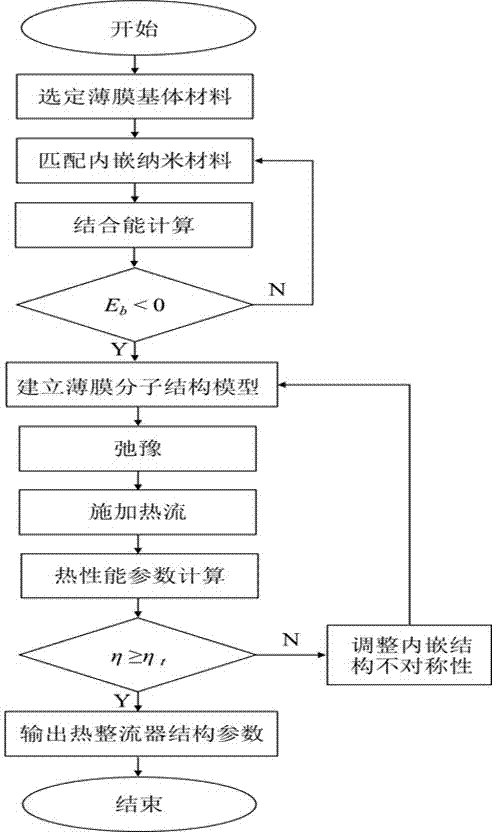

Design method for nano-film thermal rectifier with asymmetric embedded structure

ActiveCN107194037AWith normal thermal rectification characteristicsWith normal thermal rectification performanceDesign optimisation/simulationSpecial data processing applicationsPrismEngineering

The invention discloses a design method for a nano-film thermal rectifier with an asymmetric embedded structure. The method comprises the steps of embedding a square pyramid frustum-shaped asymmetric embedded structure into a right square prism-shaped nano-film; enabling the height of the asymmetric embedded structure to have gradient change along the thickness direction of the nano-film; establishing an initial molecular structure model; carrying out relaxation on the initial molecular structure model; calculating thermal rectification efficiency of the relaxed molecular structure model; and comparing the rectification efficiency with a preset target thermal rectification efficiency to obtain a structure design parameter of the nano-film thermal rectifier with the asymmetric embedded structure. Thermal characteristics of thermal rectification of the asymmetric embedded structure are combined with ultrathin and regular geometrical characteristics of the nano-film, the thermal rectification performance of the nano-film thermal rectifier is adjusted and controlled through parameter adjustment for the embedded asymmetric structure, and the flexibility and the controllability for design of the thermal rectifier are improved.

Owner:平邑仁安中医药产业发展有限公司

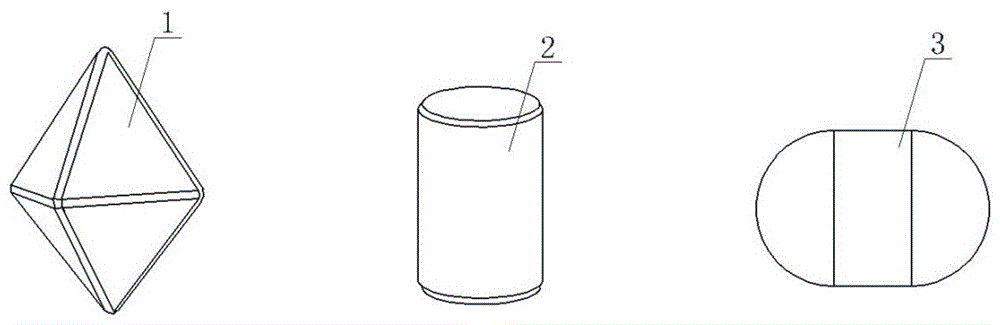

Ceramic grinding section for cement ball mill, and preparation method thereof

InactiveCN105859261AHigh mechanical strengthHigh hardnessCement productionGrain treatmentsHigh resistanceTitanium nitride

The invention discloses a ceramic grinding section for a cement ball mill, and a preparation method thereof. The ceramic grinding section for the cement ball mill comprises the following raw materials in weight percentage: 92-95% of alumina, 0.5%-2% of silicon nitride, 0.8-3% of kaolin, 0.2-2% of titanium carbide, 1.5-2% of nano boron carbide, 0.8-1% of titanium nitride, and 0.3-2% of tantalum carbide. The ceramic grinding section is in the shape of a ball-column combination body, a corner-rounded cylinder or an up-and-down symmetrical type regular square pyramid. The ceramic grinding section is prepared through the compression moulding and high-temperature sintering process. The preparation method comprises the steps of burdening, ball-milling, spray granulation, ageing in a stock bin, compression processing, high-temperature sintering, powder removing, polishing, finished product drying, and the like. The ceramic grinding section for the cement ball mill has the advantages of high hardness, high wear resistance, high temperature resistance and the like. Meanwhile, the ceramic grinding section is extremely excellent in shock resistance, wear resistance and anti-impact performance.

Owner:山东天汇科技有限公司 +1

Display

InactiveCN101620325AIncrease lighting brightnessNon-linear opticsLensComputer graphics (images)Display device

The invention relates to a display, comprising a display screen and a brightening slice. The display screen is provided with a surface for emergent rays; the brightening slice consists of a transparent substrate with two opposite surfaces, one surface is provided with a plurality of square pyramid-shaped micro lenses, and the other surface is attached on the surface of the display screen for emergent rays. The multiple square pyramid-shaped micro lenses can destroy the total reflection condition of the display screen emergent rays to outside, so that more rays can be emerged to the outside, thus increasing the emergent ray brightness of the display screen.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com