Silicon micro piezoelectric sensor chip and its preparing method

A sensor chip, micro-piezoelectric technology, applied in the direction of piezoelectric devices/electrostrictive devices, electrical components, impedance networks, etc., can solve the problems of reducing the sensitivity and yield of micro-sensors, the decrease of sensor sensitivity, and the stress of vibrating membrane. , to achieve the effect of reducing corrosion defects, reducing stress inhomogeneity, and fast corrosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

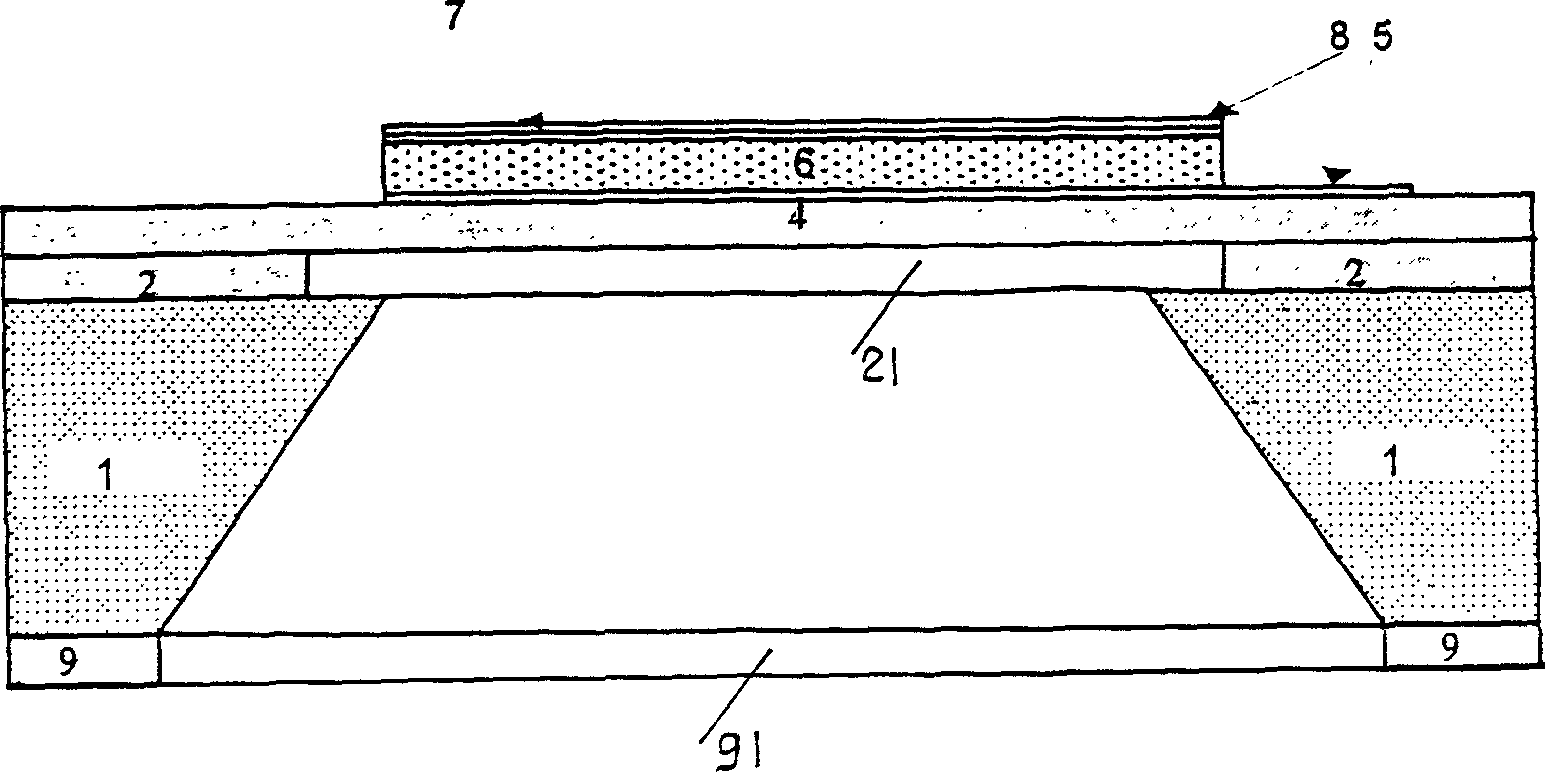

[0047] Embodiment 1, using the preparation method of the present invention to prepare a novel piezoelectric sensor chip, the steps are as follows:

[0048] 1) Clean n-type silicon substrate 1

[0049] Cleaning the n-type silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

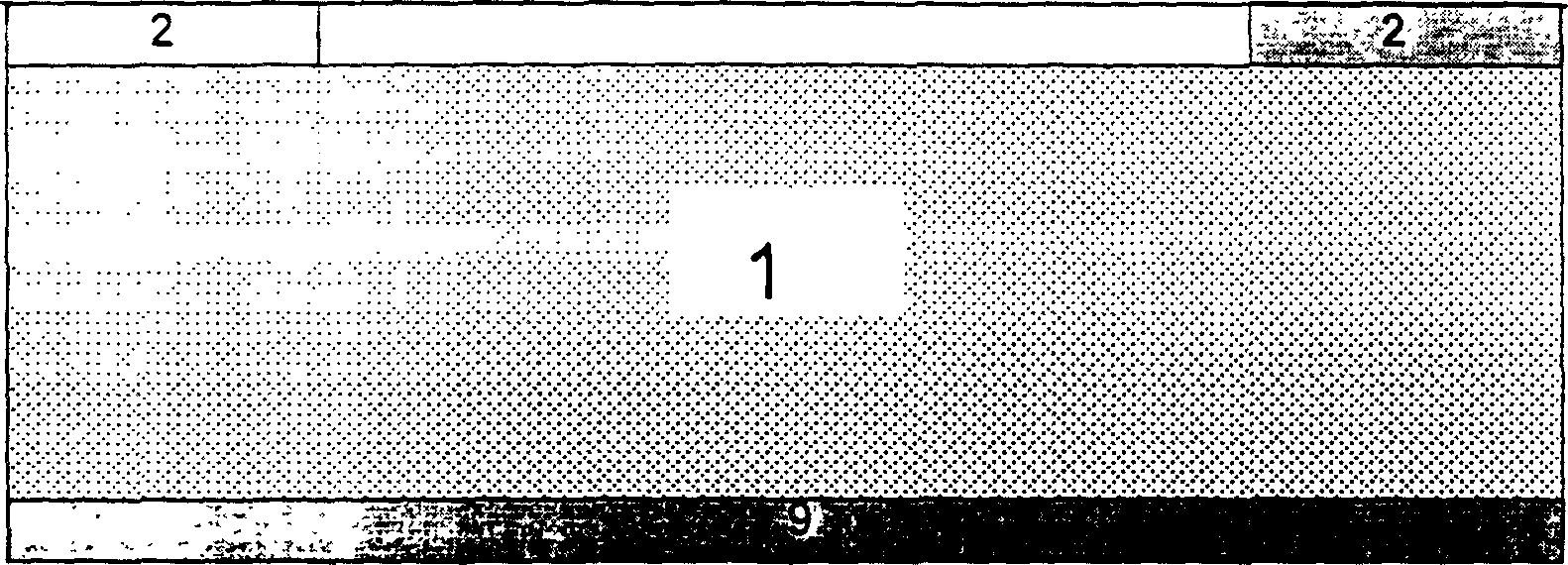

[0050] 2) On the front and back surfaces of the n-type silicon substrate 1, respectively deposit a silicon nitride base film layer 2 with a thickness of 0.2 μm and a silicon nitride mask layer 9 with a thickness of 0.2 μm by using a low-pressure chemical vapor deposition equipment ;

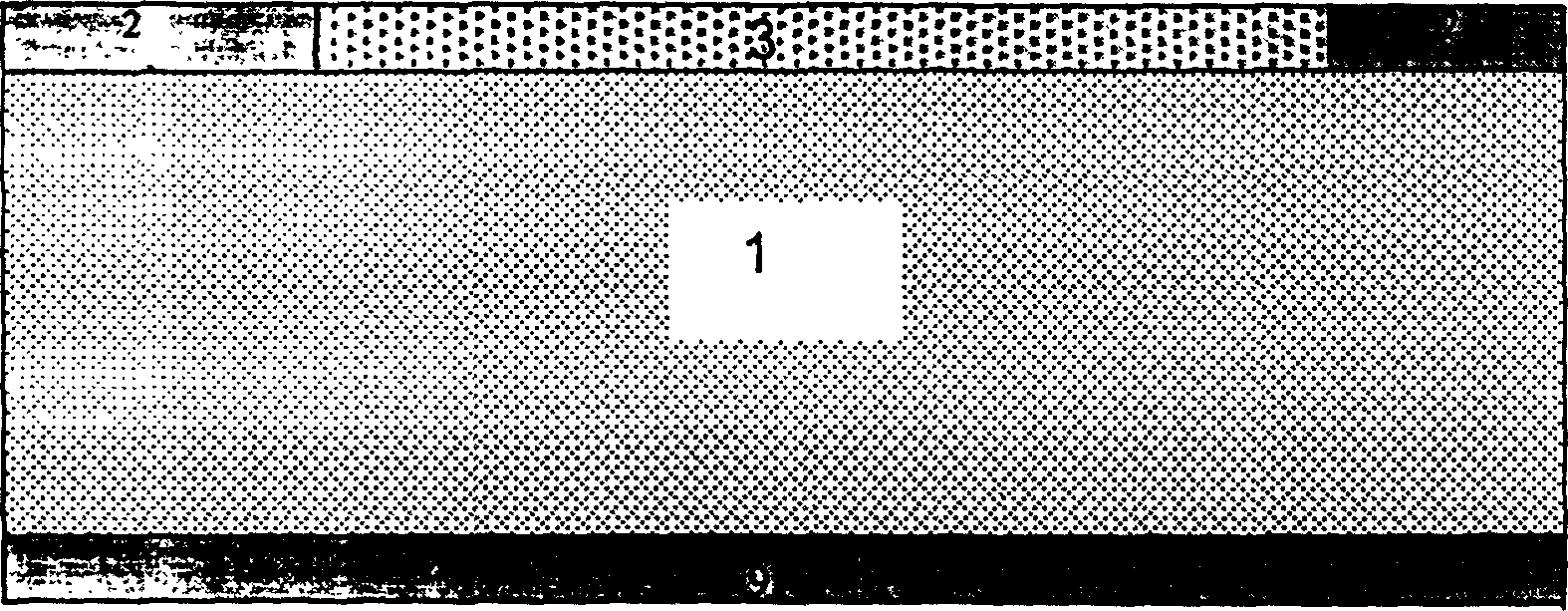

[0051] 3) Preparation of zinc oxide sacrificial layer 3

[0052] Coating a positive photoresist on the surface of the silicon nitride base film layer 2, and exposing by photolithography to form a circular sacrificial layer inverted film photolithographic pattern;

[0053] Then use a high-density plasma etching machine to photoetch the sil...

Embodiment 2

[0067] Embodiment 2, using the preparation method of the present invention to prepare a novel piezoelectric sensor chip, the steps are as follows:

[0068] 1) Clean n-type silicon substrate 1

[0069] Cleaning the n-type silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0070] 2) On the front and back surfaces of the n-type silicon substrate 1, respectively deposit a silicon nitride base film layer 2 with a thickness of 2 μm and a silicon nitride mask layer 9 with a thickness of 2 μm by using low-pressure chemical vapor deposition equipment;

[0071] 3) Preparation of phosphosilicate glass sacrificial layer 3

[0072] Coating a positive photoresist on the surface of the silicon nitride base film layer 2, and exposing by photolithography to form a circular sacrificial layer inverted film photolithographic pattern;

[0073] Then use a high-density plasma etching machine to photoetch th...

Embodiment 3

[0087] Embodiment 3, using the preparation method of the present invention to prepare a novel piezoelectric sensor chip, the steps are as follows:

[0088] 1) Clean n-type silicon substrate 1

[0089] Cleaning the n-type silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0090] 2) On the front and back surfaces of the n-type silicon substrate 1, respectively deposit a silicon nitride base film layer 2 with a thickness of 1 μm and a silicon nitride mask layer 9 with a thickness of 1 μm by using low-pressure chemical vapor deposition equipment;

[0091] 3) Preparation of zinc oxide sacrificial layer 3

[0092] Coating a positive photoresist on the surface of the silicon nitride base film layer 2, and exposing by photolithography to form a circular sacrificial layer inverted film photolithographic pattern;

[0093] Then use a high-density plasma etching machine to photoetch the silicon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com