Tapered wave-absorbing material and preparation method thereof

A technology of wave absorbing material and cone, applied in the field of cone wave absorbing material and its preparation, can solve problems such as poor wave absorbing performance, and achieve the effects of good wave absorbing performance, good broadband wave absorbing performance and good wave absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

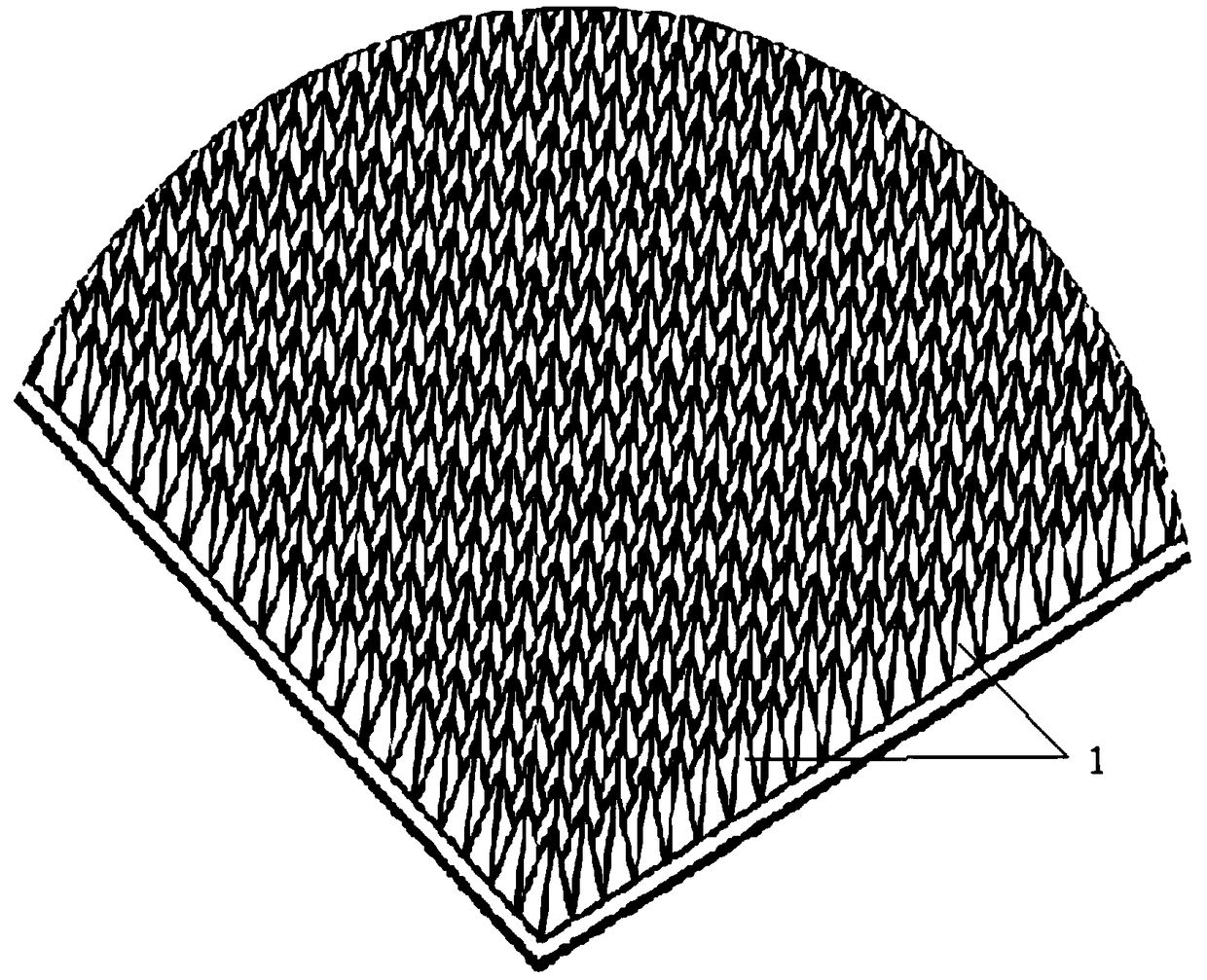

Image

Examples

Embodiment 1

[0025] In parts by mass, 100 parts of polyurethane rubber, 2 parts of stearic acid, 1 part of antioxidant N-phenyl-α-aniline, 2 parts of dicumyl peroxide, 3 parts of plasticizer o-phenyl Di-n-octyl diformate and 60 parts of carbonyl iron powder are mixed and banburyed evenly in a banbury mixer at a temperature of 65° C. to obtain a good polyurethane rubber of banbury;

[0026] In the flat vulcanizer, press-molded polyurethane rubber in a pyramid-shaped mold. During the press-forming process, vulcanize at a temperature of 160°C and the vulcanization time is 25 minutes, so as to obtain a conical wave-absorbing material. . Wherein, the pyramid-shaped mold includes a plurality of adjacent and repeatedly arranged quadrangular pyramid-shaped holes, the size of the pyramid-shaped mold is 330mm×330mm, and the height of the pyramid-shaped mold after removing the conical absorbing material is 22mm (including base).

Embodiment 2

[0028] With 100 parts of polyurethane rubber, 0.3 parts of stearic acid, 0.5 parts of antioxidant N-phenyl-β-naphthylamine, 2 parts of dicumyl peroxide, 5 parts of benzene polyester plasticizers and 70 parts of carbonyl iron powder are mixed and banburyed uniformly in an internal mixer at a temperature of 85° C. according to parts by mass to obtain a good polyurethane rubber of banburying;

[0029] In the plate vulcanizer, the polyurethane rubber that has been banburyed is pressed into a pyramid-shaped mold. During the press-forming process, it is vulcanized at a temperature of 170°C and the vulcanization time is 30 minutes, so as to obtain a conical wave-absorbing material. . Wherein, the pyramid-shaped mold includes a plurality of adjacent and repeatedly arranged quadrangular pyramid-shaped holes, the size of the pyramid-shaped mold is 330mm × 330mm, and the height of the pyramid-shaped mold after removing the conical absorbing material is 22mm (including base).

Embodiment 3

[0031] In parts by mass, 100 parts of polyurethane rubber, 3 parts of stearic acid, 1.5 parts of antioxidant N-phenyl-N'-cyclohexyl p-phenylenediamine, 1.5 parts of dicumyl peroxide, 2 parts The plasticizer diisobutyl phthalate and 50 parts of carbonyl iron powder are mixed and banburyed evenly in a banbury mixer at a temperature of 70° C. to obtain a good polyurethane rubber of banbury;

[0032] In the flat vulcanizer, press-molded polyurethane rubber in a pyramid-shaped mold. During the press-forming process, vulcanize at a temperature of 165°C and the vulcanization time is 38 minutes, so as to obtain a conical wave-absorbing material. . Wherein, the pyramid-shaped mold includes a plurality of adjacent and repeatedly arranged quadrangular pyramid-shaped holes, the size of the pyramid-shaped mold is 330mm × 330mm, and the height of the pyramid-shaped mold after removing the conical absorbing material is 22mm (including base).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com