A high-temperature-resistant wave-absorbing wedge and its preparation method

A technology of high temperature resistance and high temperature sintering, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of poor microwave absorption performance, poor temperature resistance, and internal energy can only reach -7~-12dB, and achieve easy preparation, Good high temperature resistance and oxidation resistance, the effect of excellent broadband absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

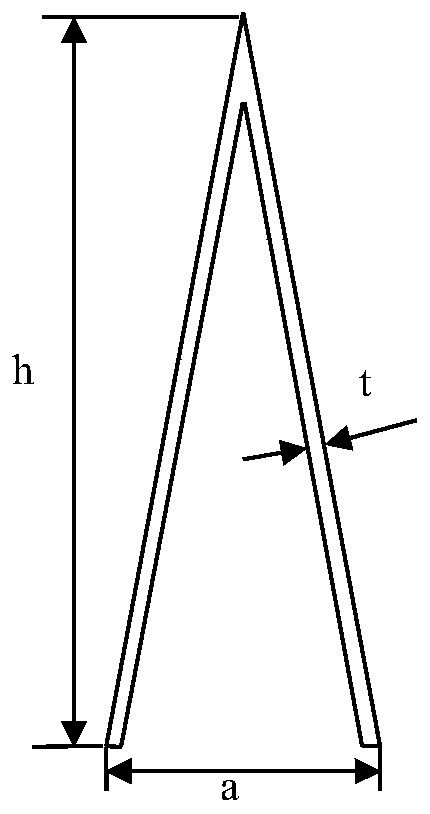

[0038] Kind of like figure 1 , figure 2 The high-temperature-resistant wave-absorbing material wedge shown is a square pyramid with a hollow structure. The wave-absorbing wedge includes a substrate layer and a high-temperature resistance coating uniformly coated and sintered on the surface of the substrate layer. The substrate layer adopts Hollow alumina square pyramid, resistance coating is Bi 2 O 3 -Al 2 O 3 -SiO 2 Glass is the binder phase, with RuO 2 For the conductive phase. The base length of the regular quadrangular pyramid is a=20mm, the side plate thickness t=1.5mm, the side plate vertical height h=150mm, and the average square resistance of the resistive coating is about 190Ω / □.

[0039] The preparation method of the high-temperature-resistant wave-absorbing material wedge of this embodiment includes the following steps:

[0040] (1) Preparation of hollow alumina square pyramid substrate layer: the prepared alumina powder slurry is injected into the mold by the slurry in...

Embodiment 2

[0054] Kind of like figure 1 , image 3 The high-temperature-resistant wave-absorbing material wedge shown is a square pyramid with a hollow structure. The wave-absorbing wedge includes a substrate layer and a high-temperature resistance coating uniformly coated and sintered on the surface of the substrate layer. The substrate layer adopts Hollow mullite fiber reinforced mullite square pyramid, the resistance coating is Bi 2 O 3 -Al 2 O 3 -SiO 2 Glass is the binder phase, with RuO 2 For the conductive phase. The base length of the regular quadrangular pyramid is a=30mm, the side plate thickness t=2mm, the side plate vertical height h=300mm, and the average square resistance of the resistive coating is about 150Ω / □.

[0055] The preparation method of the high-temperature-resistant wave-absorbing material wedge of this embodiment includes the following steps:

[0056] (1) Preparation of hollow mullite fiber-reinforced mullite square pyramid substrate layer: firstly, mullite fiber-rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com