Novel honeycomb structure wave-absorbing material and preparation method thereof

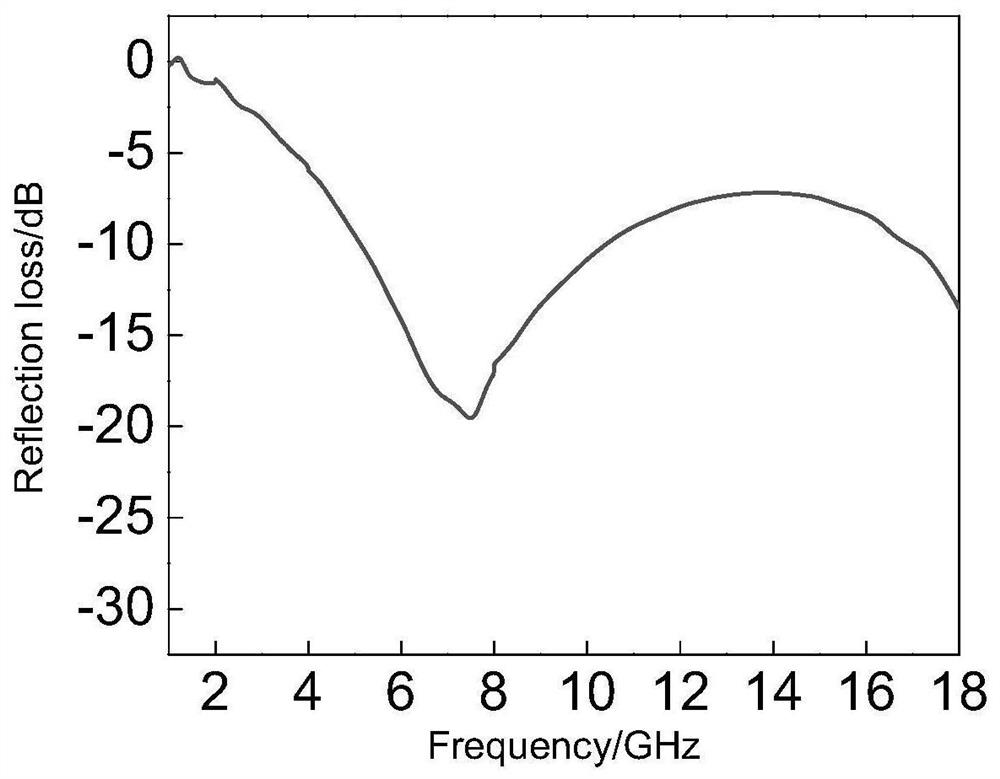

A honeycomb structure and wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve problems such as unstable product consistency, difficult process control, and additional honeycomb load, and achieve excellent broadband wave-absorbing performance, poor product uniformity, Reduce the effect of surface reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) First soak 10 aramid fibers in a mixed solution of 10g / L potassium permanganate and 20mL / L sulfuric acid for 1 minute, then soak them in 10g / L oxalic acid solution for 1 minute, and then put the fibers into the sensitized Liquid (10g / L SnCl 2 ; Soak in 40ml / L HCl (38%) at 40°C for 5 minutes, then in activation solution (1.5g / L PdCl 2 ; Activation treatment in 20ml / L HCl (38%) for 5 minutes.

[0024] Disperse the sensitized and activated fibers in the electroless plating solution for nickel plating, adjust the pH to 9 with 1mol / L sodium hydroxide, and plate the metal layer at a temperature of 65°C for 30 minutes, then take out the fibers and place them in a vacuum Dry in an oven at 70°C for 2 hours, and the plating solution is composed of: 15g potassium sodium tartrate, 8g (NH 4 ) 2 SO 4 , 6.7g NiSO 4 ·6H 2 O and 5g of sodium hypophosphite were dissolved in 200ml of distilled water.

[0025] (2) Crushing the metallized aramid fibers into chopped fibers with a ...

Embodiment 2

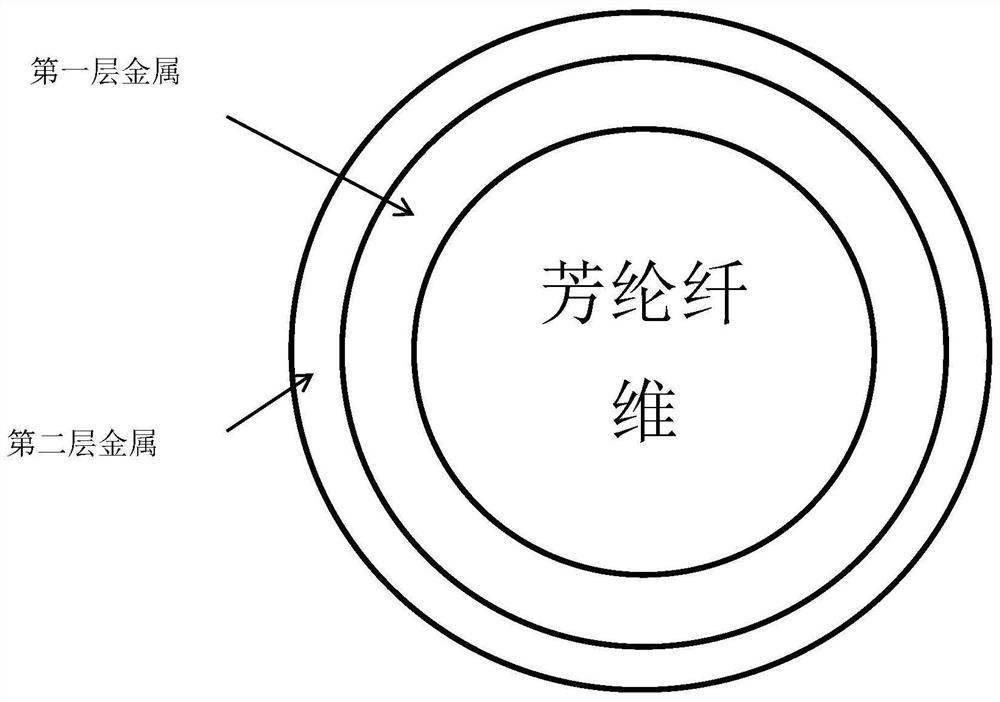

[0027] (1) In embodiment 2, a double-layer metal is plated on the aramid fiber, and then it is applied to the wave-absorbing honeycomb. The activation and sensitization step of the fiber is the same as in Example 1, and the plating process is as follows:

[0028] Disperse 100g of sensitized and activated fibers in the chemical plating solution to plate the first layer of nickel, adjust the pH to 9 with 1mol / L sodium hydroxide, and plate the metal layer at a temperature of 65°C for 20 minutes. Take out the fiber, and the plating solution is composed of: 10gNiSO 4 ·6H 2 O, 5g potassium sodium tartrate, 5g sodium citrate, 4g boric acid, 8g (NH 4 ) 2 SO 4 and 2g of sodium hypophosphite were dissolved in 200ml of distilled water.

[0029] Put the aramid fiber coated with metal nickel into the plating solution again to plate the second layer of metal copper, adjust the pH to 9 with 1mol / L sodium hydroxide, and plate the metal layer at a temperature of 65°C for 5 Minutes later,...

Embodiment 3

[0032] (1) In embodiment 3, a double-layer metal is plated on the aramid fiber, and then it is applied to the wave-absorbing honeycomb. The activation and sensitization step of the fiber is the same as in Example 1, and the plating process is as follows:

[0033] Disperse 40g of sensitized and activated fibers in the chemical plating solution to plate the first layer of cobalt metal, adjust the pH to 9 with 1mol / L sodium hydroxide, and plate the metal layer at a temperature of 65°C for 30 minutes , take out the fiber, the bath composition is: 20gCoCl 2 , 10g sodium potassium tartrate, 8g sodium citrate, 2g boric acid and 8g sodium hypophosphite were dissolved in 200ml distilled water.

[0034] Put the aramid fiber coated with metal cobalt into the plating solution again to coat the second layer of metal nickel, adjust the pH to 9 with 1mol / L sodium hydroxide, and coat the metal layer at a temperature of 65°C for 10 Minutes later, the fibers were taken out and dried at 70°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com