Patents

Literature

33results about How to "Broken in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

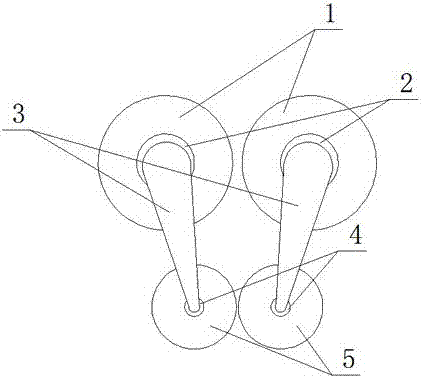

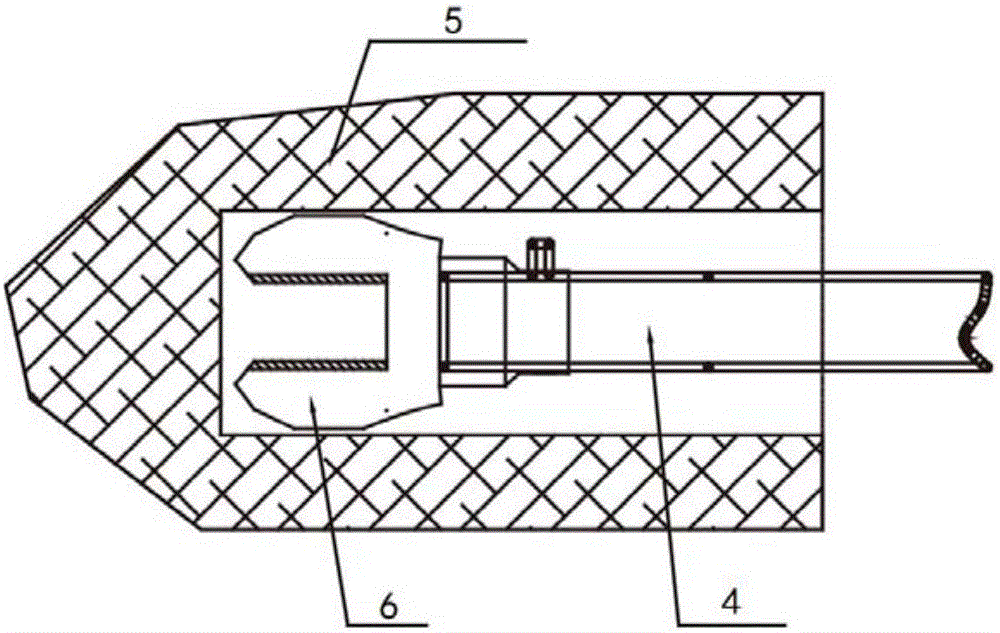

Fragile cap

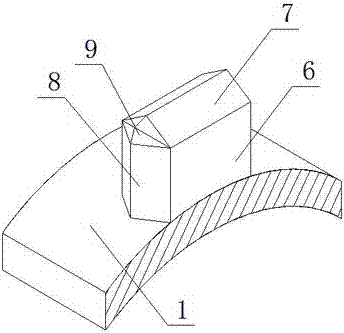

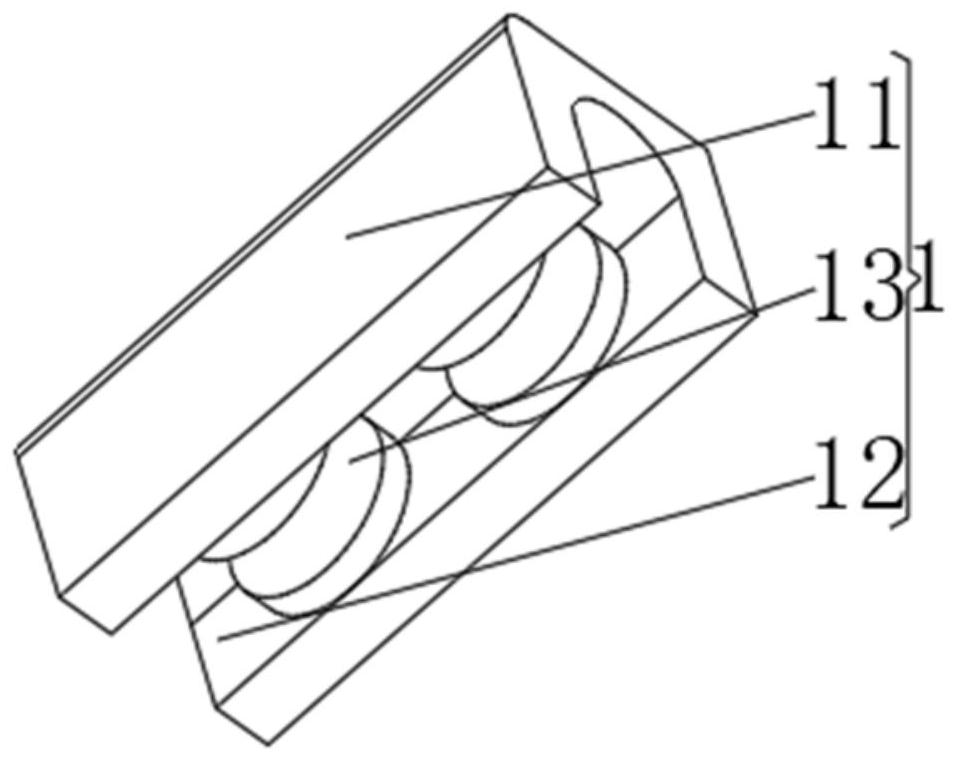

ActiveCN104913692ABroken in timeGuaranteed crushing effectAmmunition storageEngineeringSquare pyramid

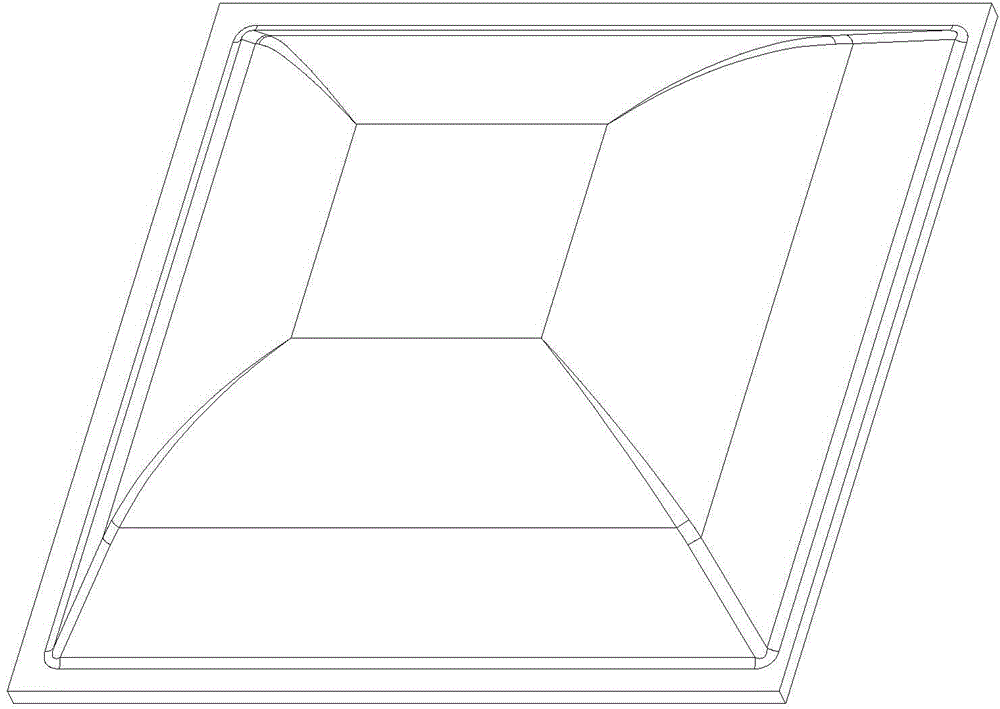

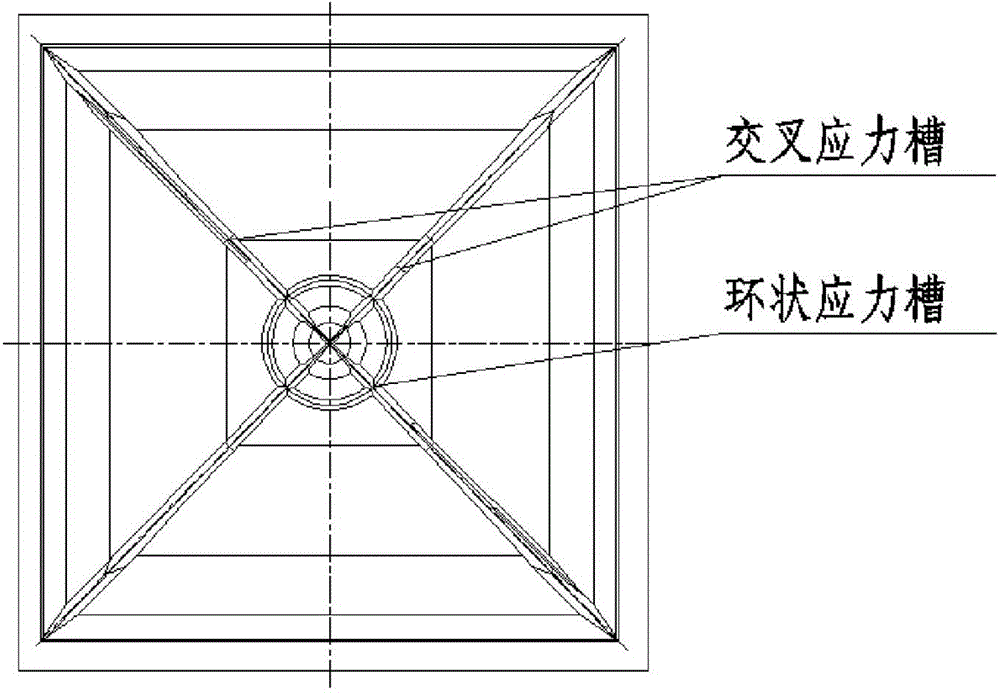

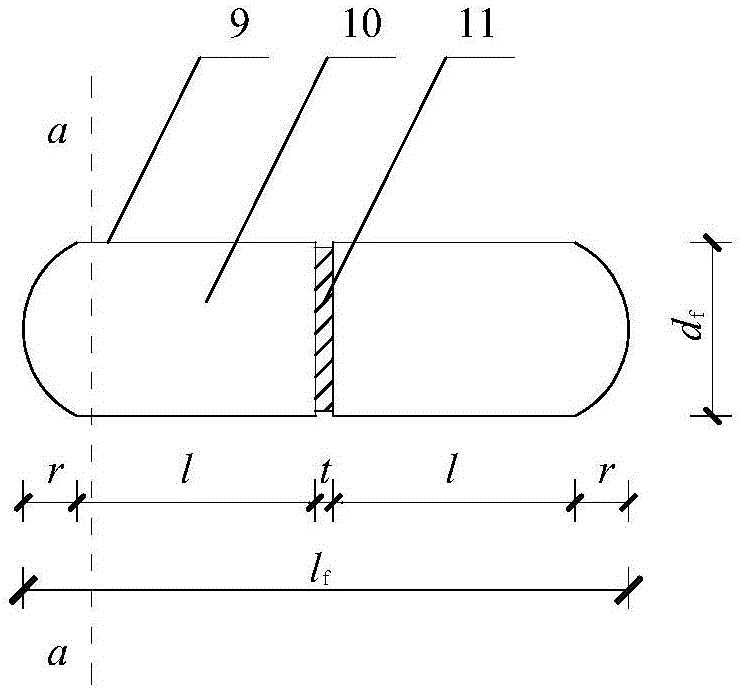

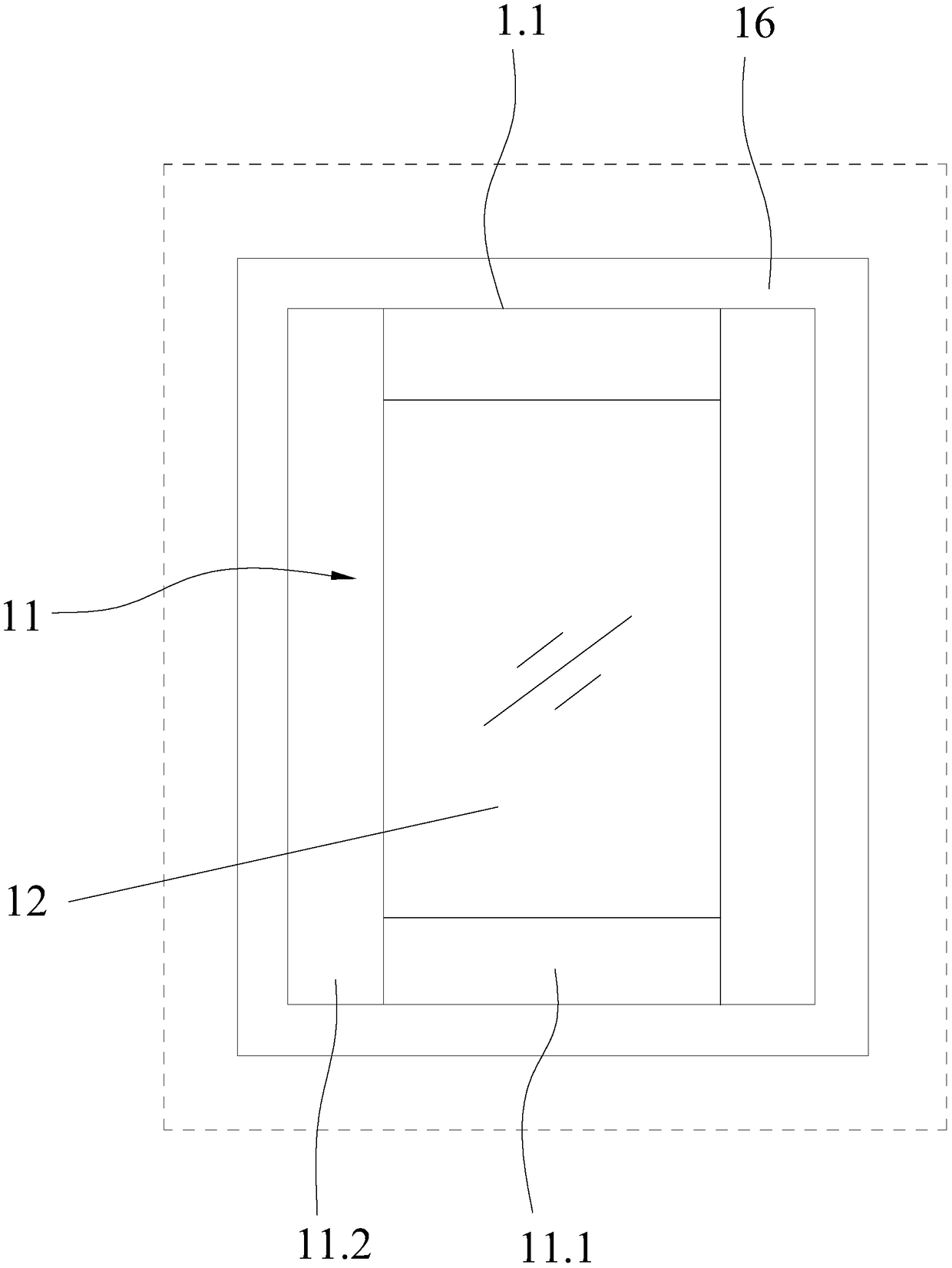

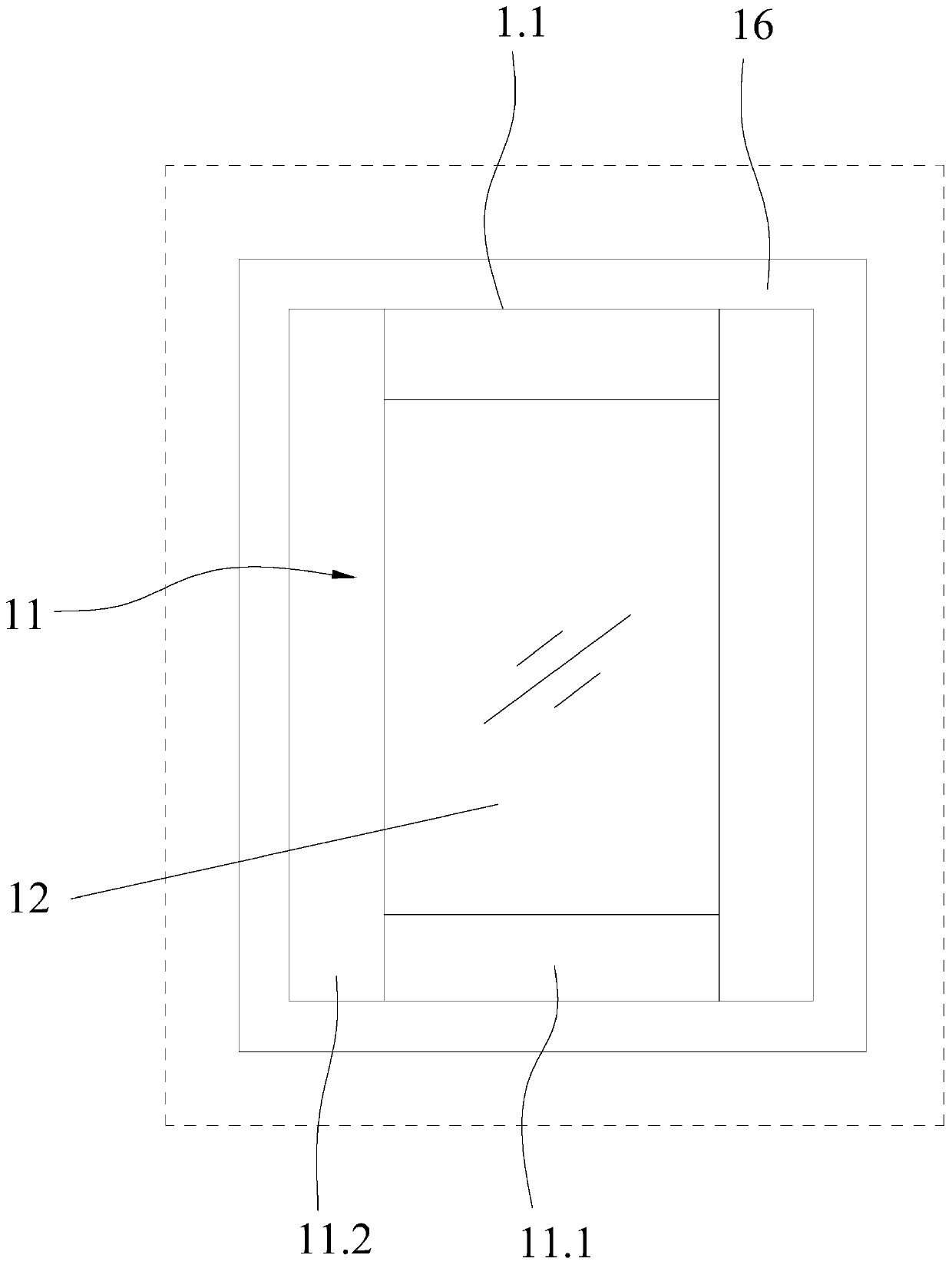

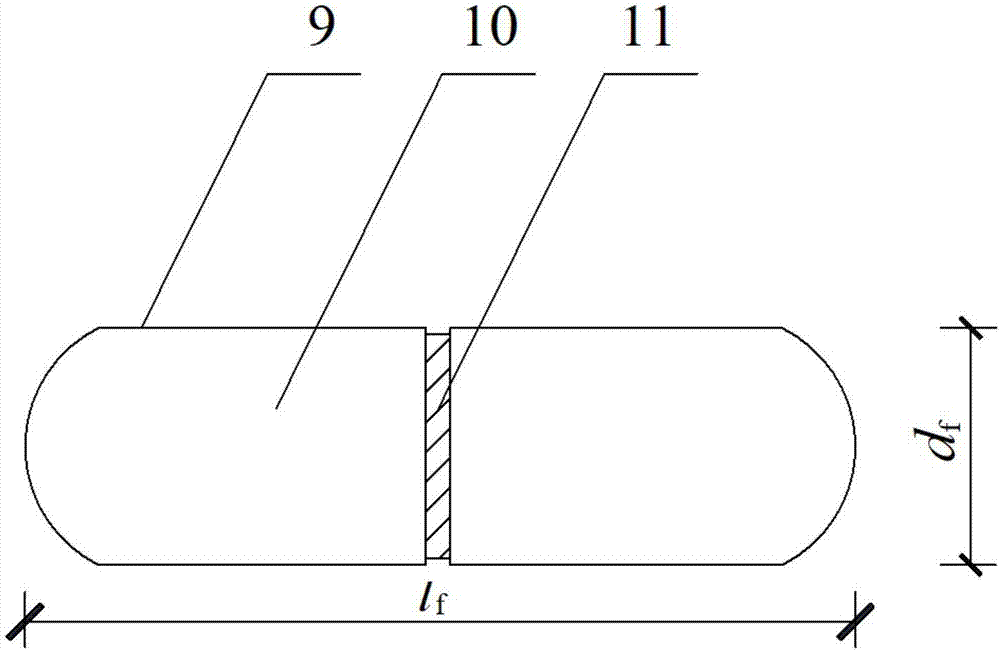

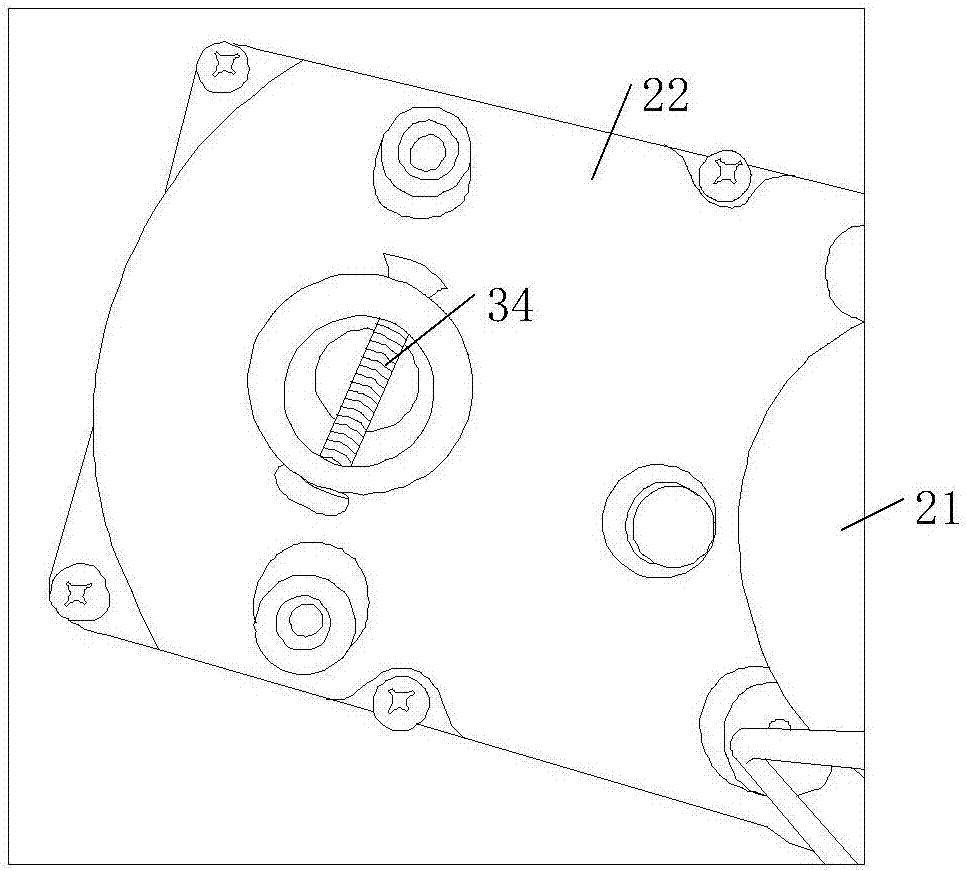

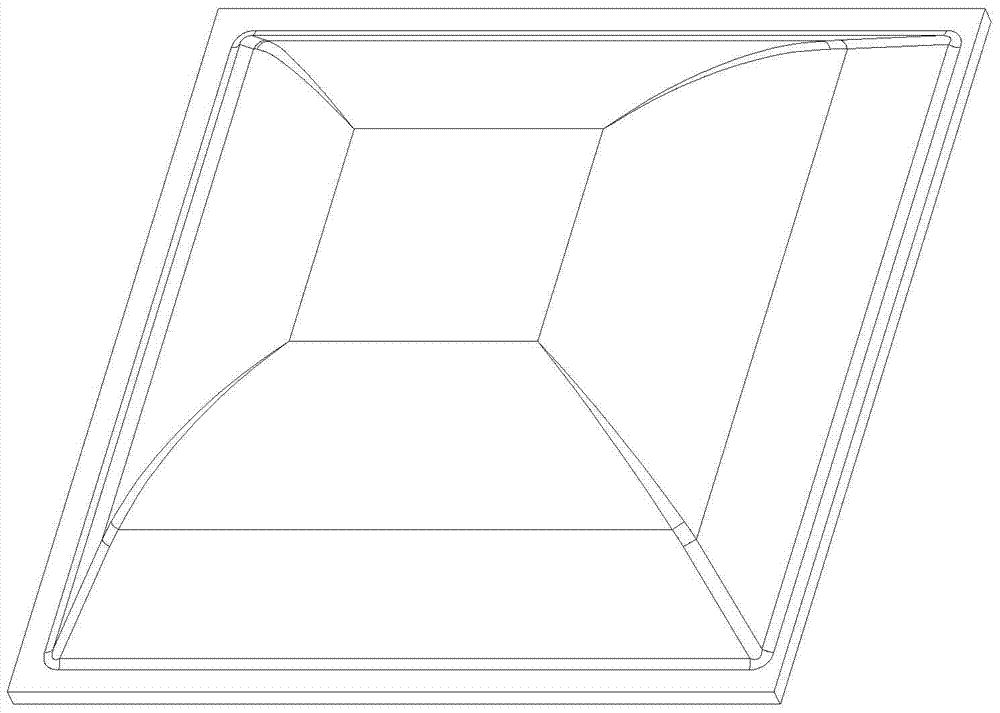

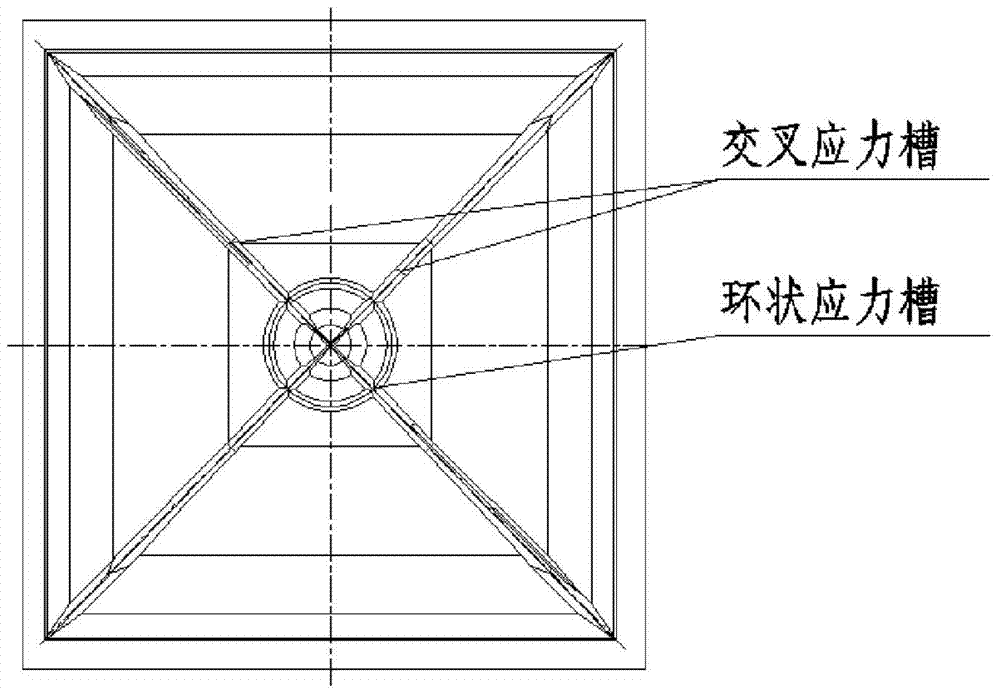

The invention discloses a fragile cap. The fragile cap is characterized in that the external appearance is a housing in the shape of a square pyramid; the periphery of the top surface of the outer wall is in the shape of an arc inverted angle; the center of the top surface of the inner wall is provided with an annular stress groove; stress grooves, in the cross-shaped shapes, are arranged at four corners of the inner side wall; and centers of the cross-shaped stress grooves and the center of the annular stress groove are overlapped. The fragile cap has following beneficial effects: the fragile cap can be regularly broken in a forward direction according to the cross-shaped stress grooves; a missile warhead is not damaged; and the breaking process goes on stably and reliably.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

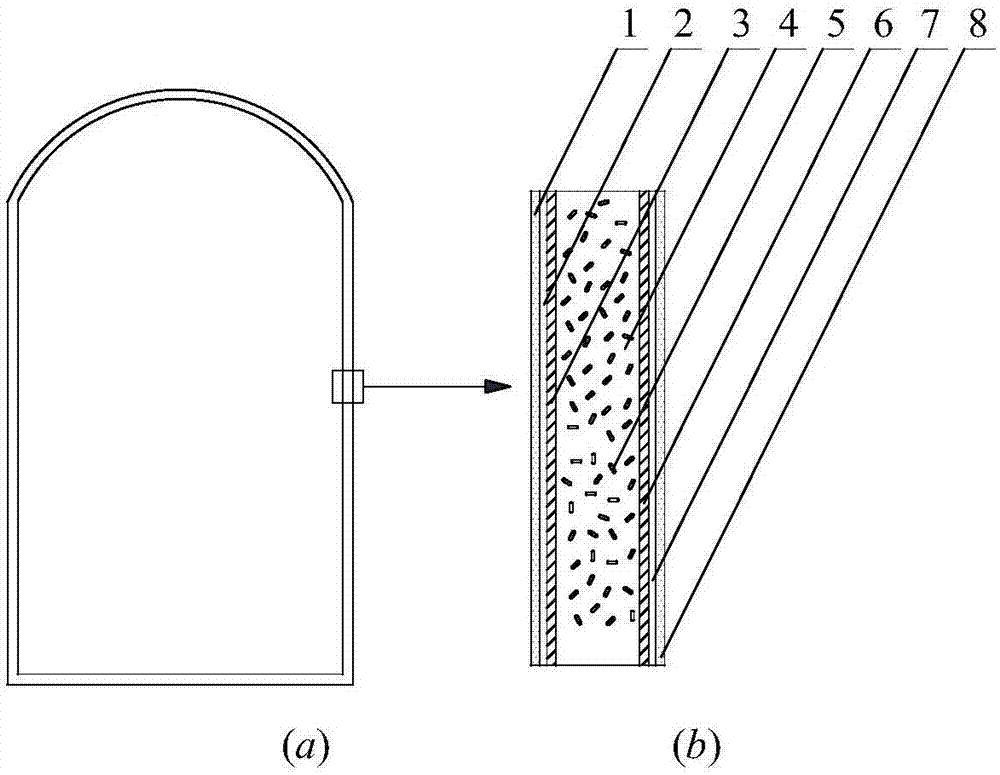

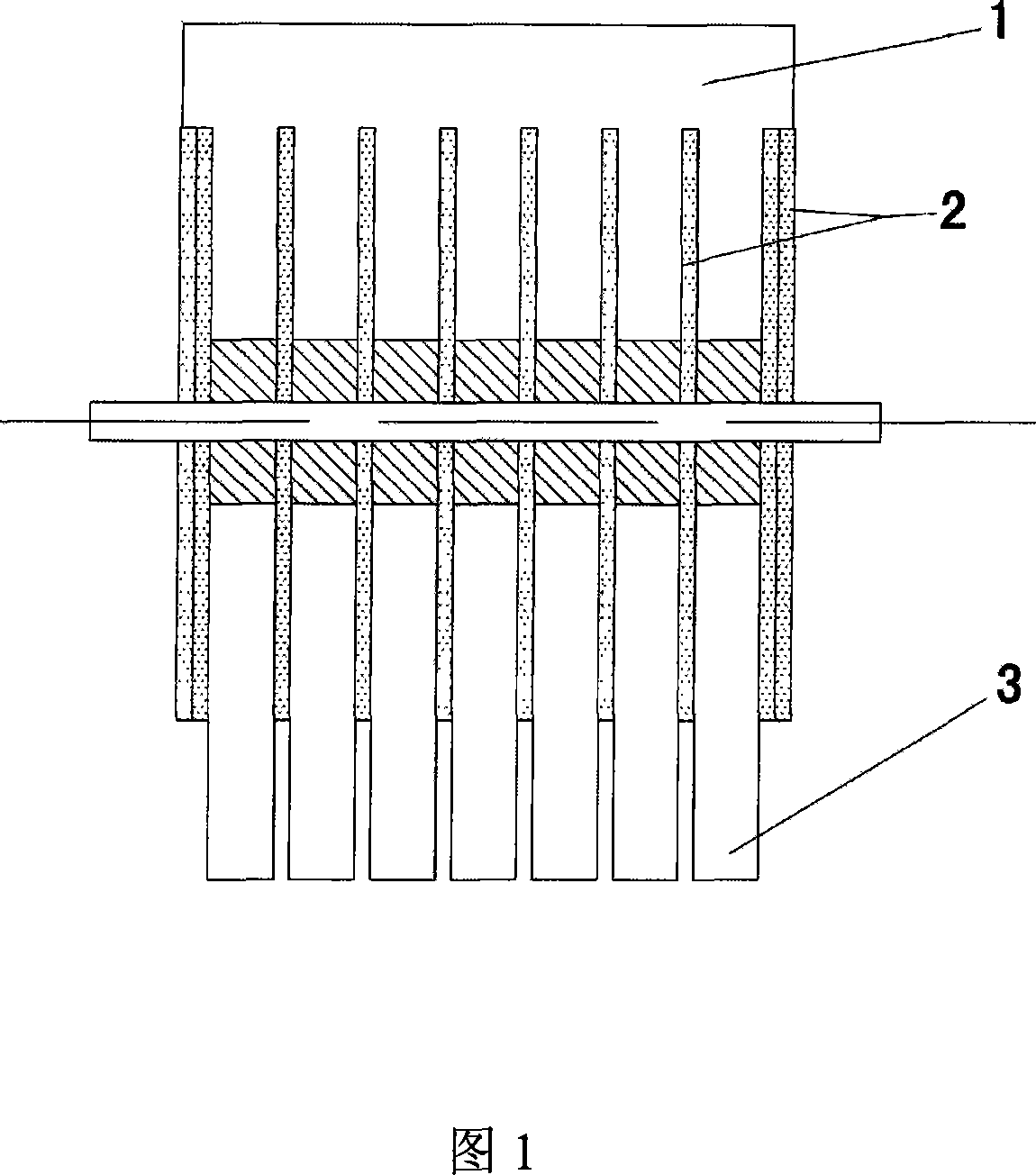

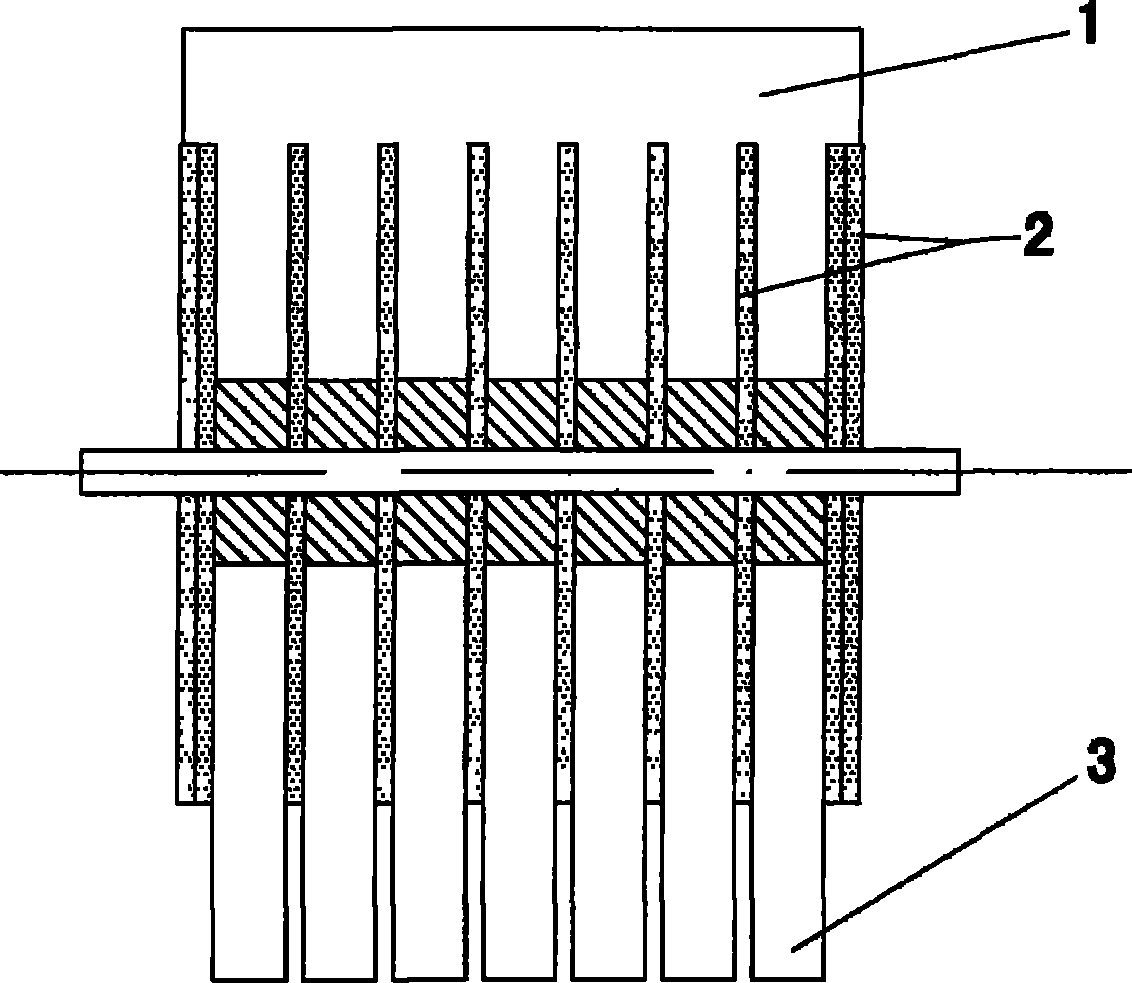

Nuclear radiation resistant self-healing concrete containment vessel

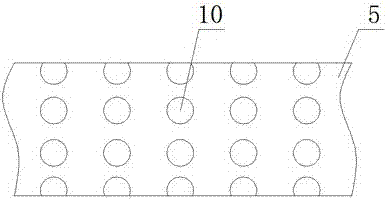

InactiveCN105835466AHigh strengthIncrease elasticityNuclear energy generationSynthetic resin layered productsNuclear radiationSelf-healing

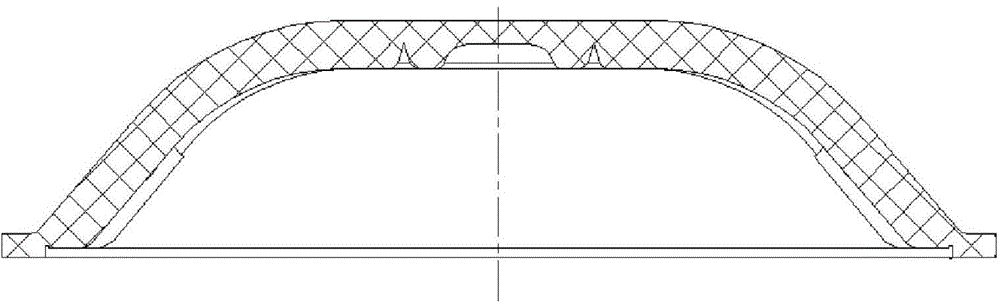

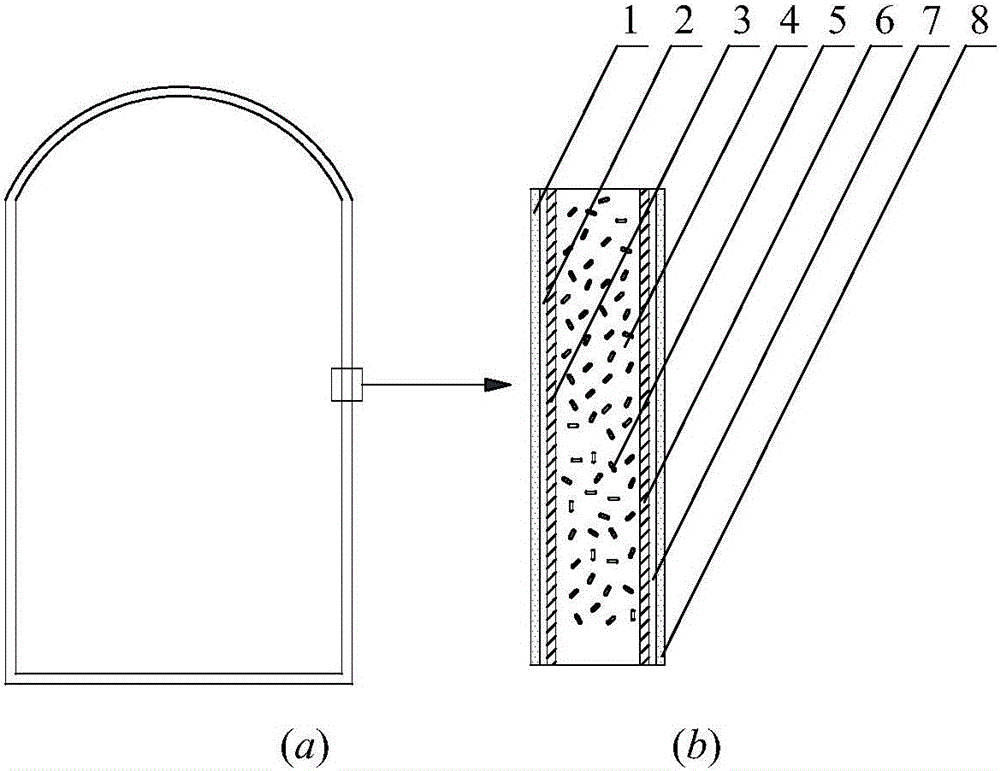

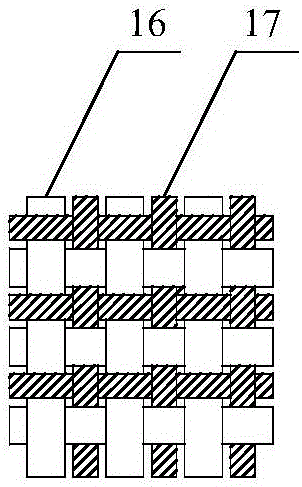

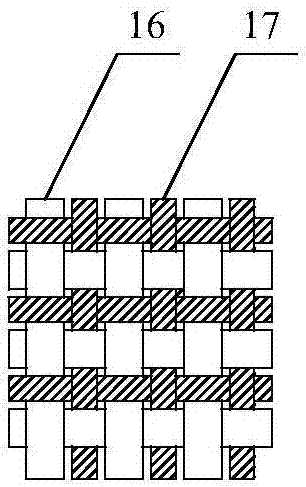

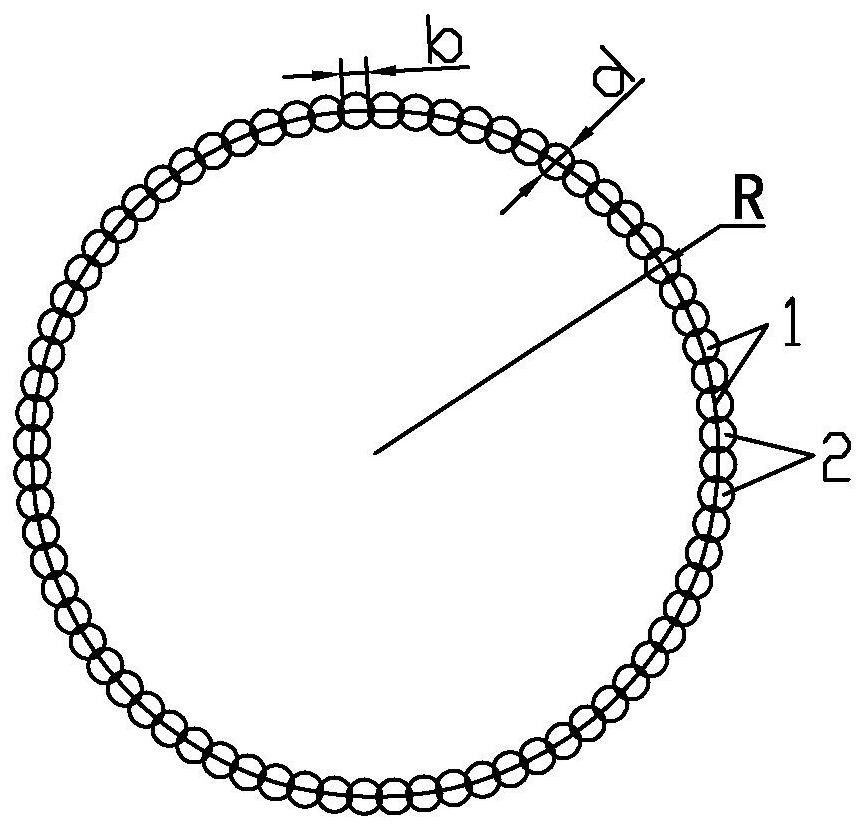

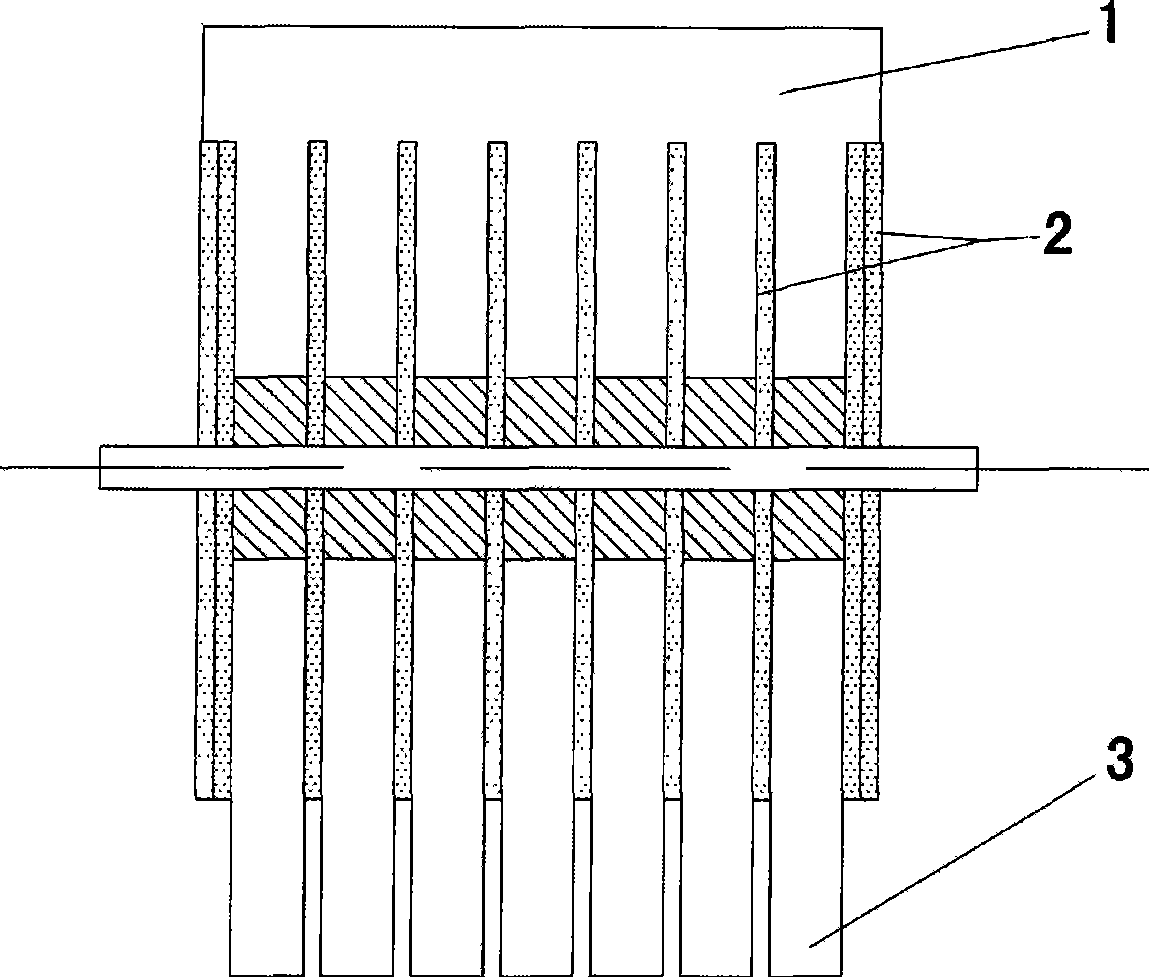

The invention discloses a nuclear radiation resistant self-healing concrete containment vessel. The containment vessel body is composed of a first steel deck, a first structural adhesive layer, a first compound fabric layer, a leaded steel capsule concrete layer, a second compound fabric layer, a second structural adhesive layer and a second steel deck successively from inside out, wherein the leaded steel capsule concrete layer is prepared by mixing concrete and leaded steel capsules. The product can effectively absorb rays so as to raise radiation resistance of the containment vessel. In addition, leakage of radioactive substances can be prevented, and strength and toughness of the product are also enhanced so as to further raise anti-seismic property.

Owner:WUHAN UNIV

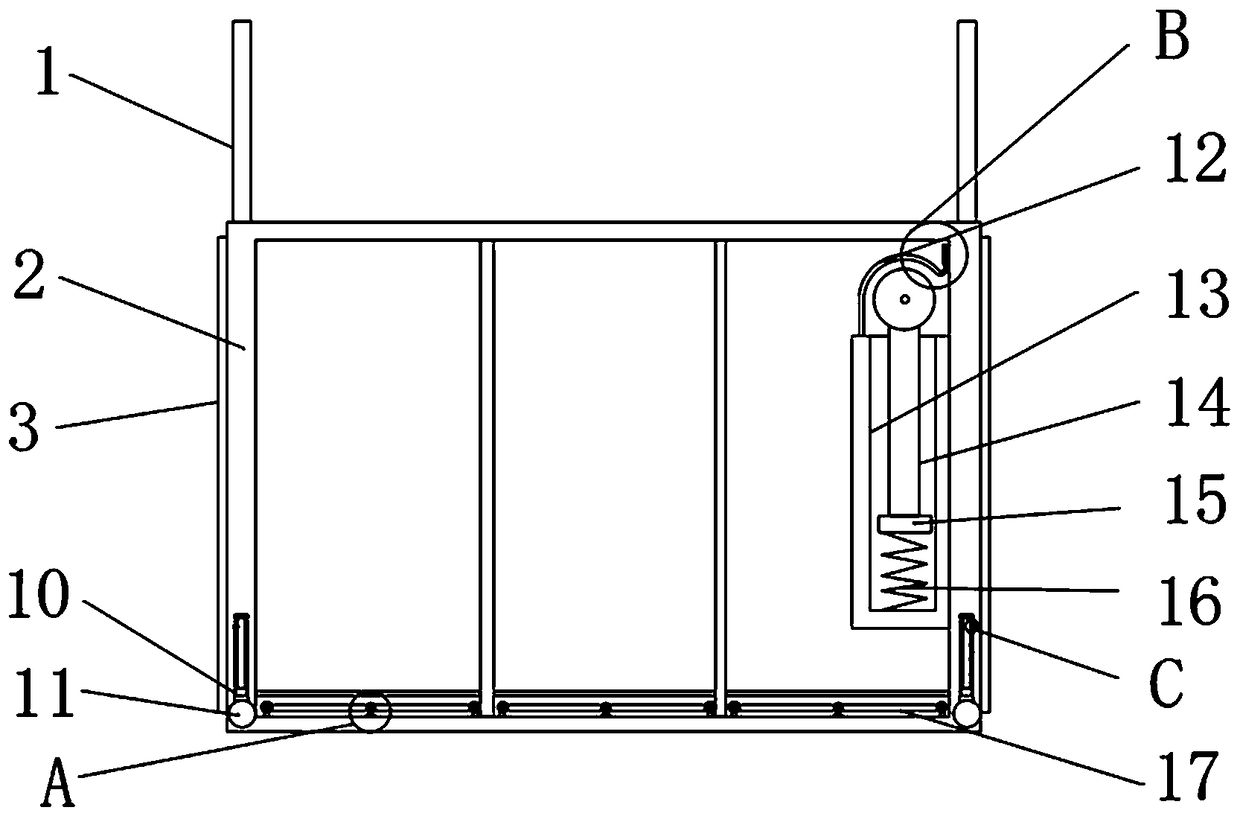

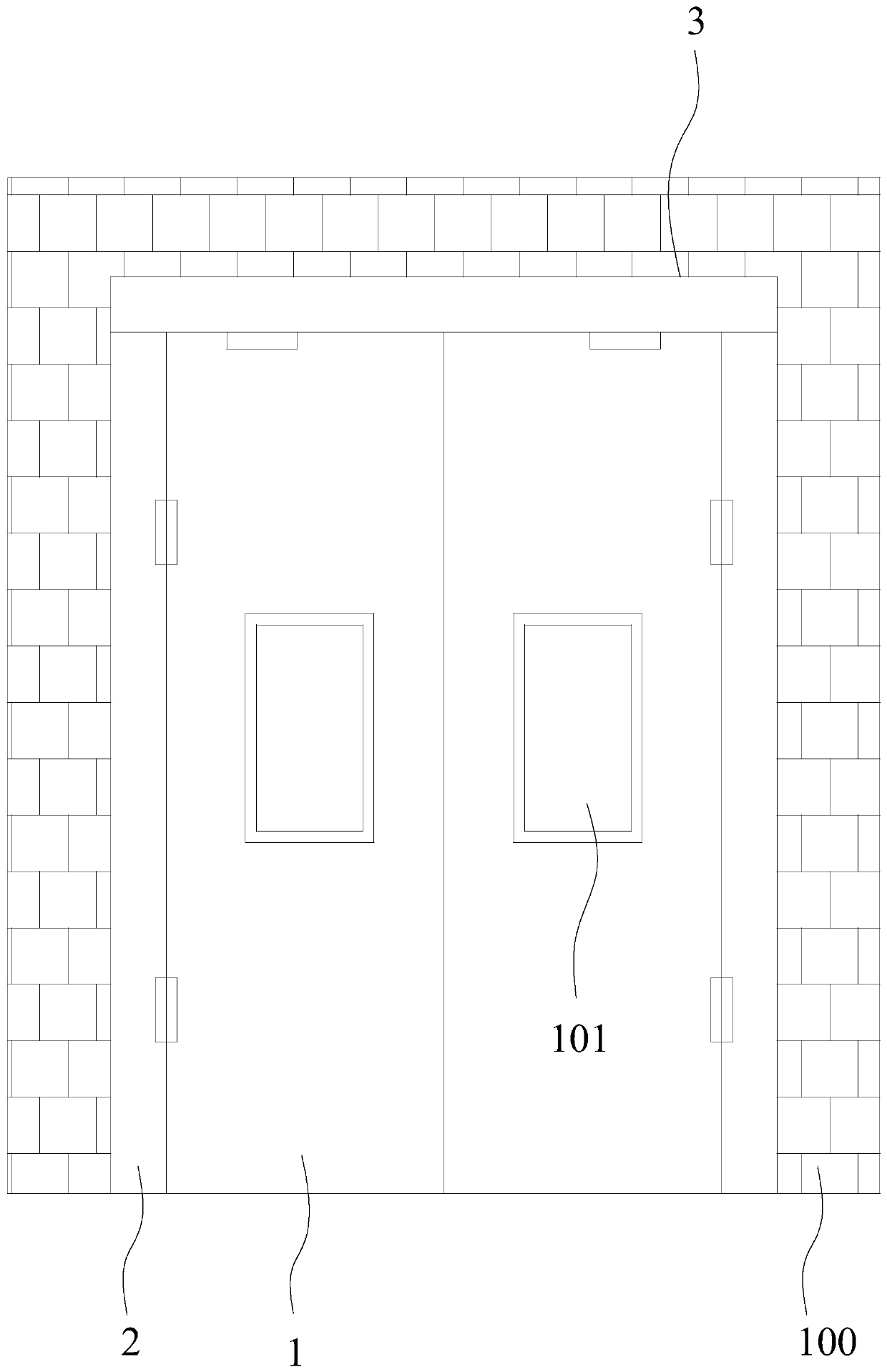

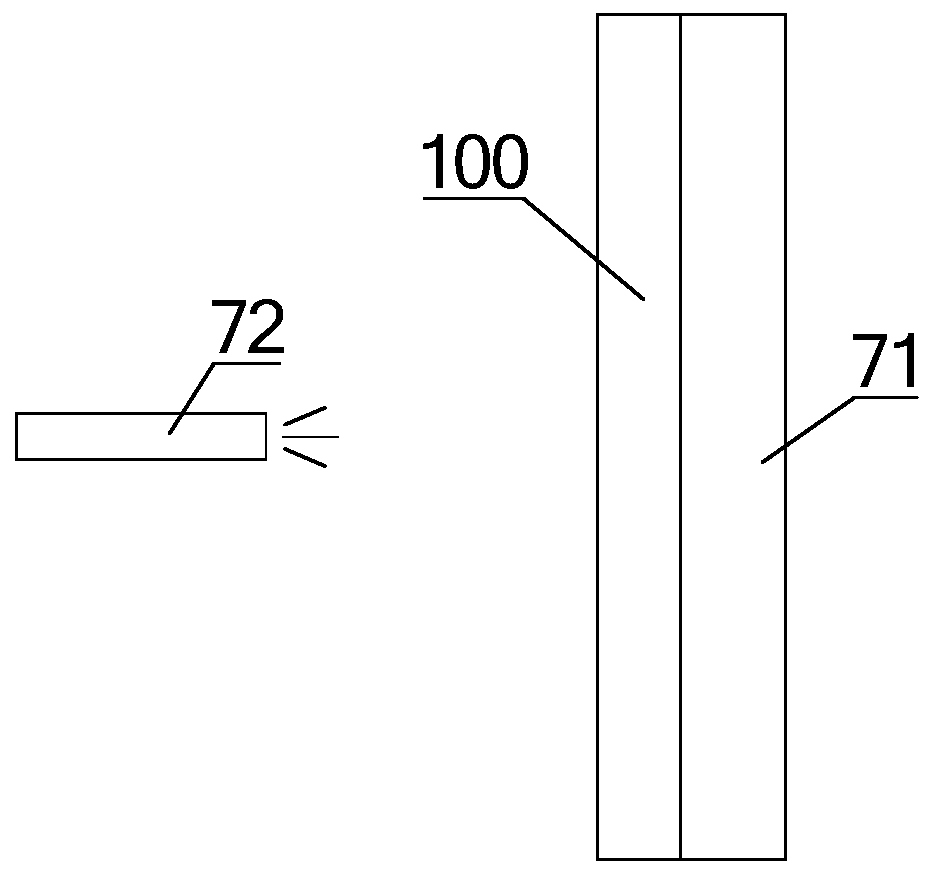

Fire-proof door structure

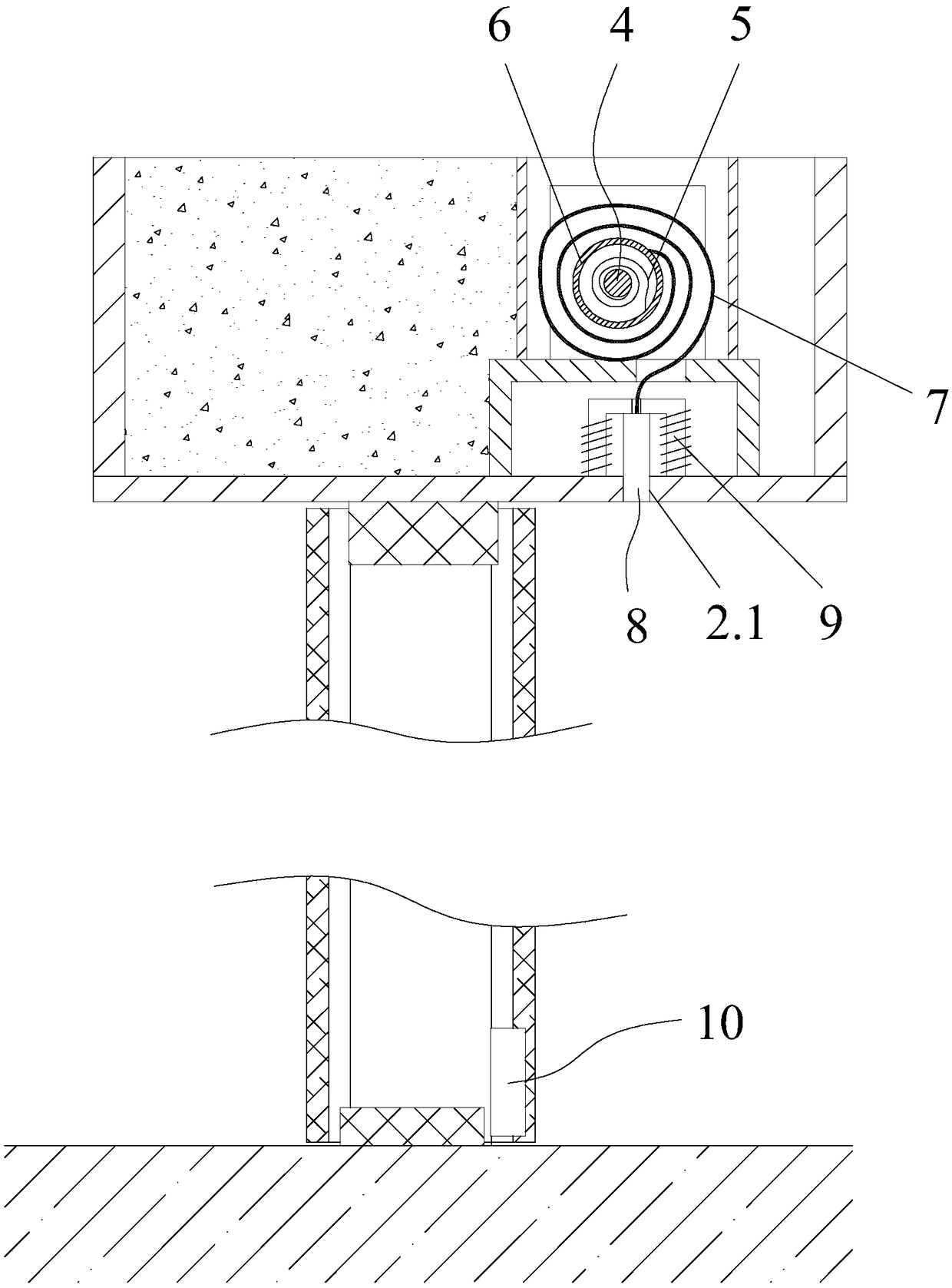

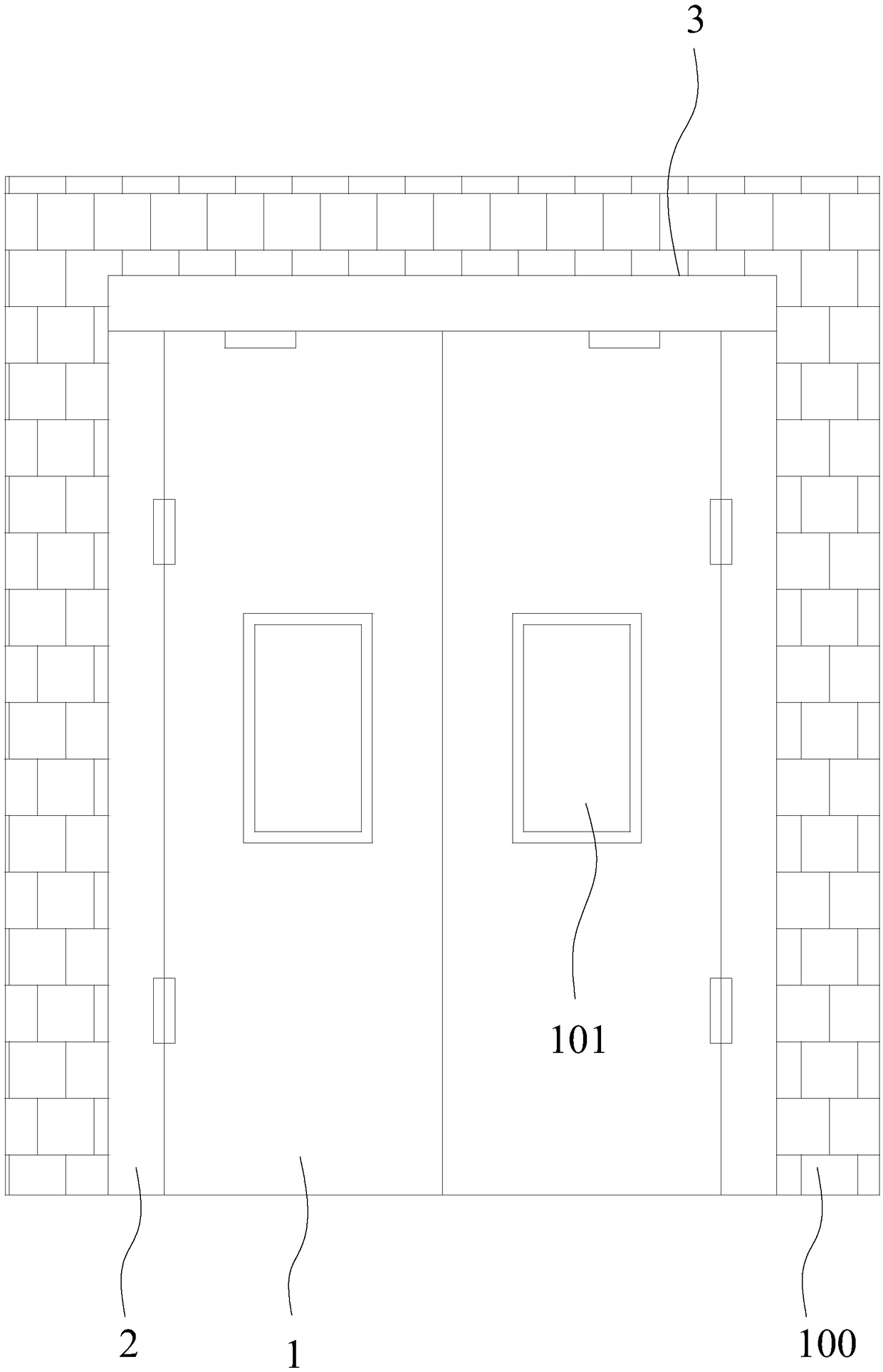

ActiveCN109372401AWon't touchAvoid spreadingFireproof doorsWing fastenersEngineeringUninterruptible power supply

The invention discloses a fire-fighting door device. The fire-fighting door device comprises a door plate and a door frame arranged in the circumferential direction of the door plate, the outer side of the door frame is arranged in a pre-arranged installation door hole on a wall in a matched mode, and one side of the door plate is hinged to the side wall of the door frame. A rotating shaft is arranged at the position, near the door plate, in the top cavity of the door frame in the width direction of the door frame, a reset spring and an mounting cylinder sleeve the rotating shaft in sequence,one end of the reset spring is connected with the rotating shaft, and the other end of the reset spring is connected with the mounting cylinder. A fire-proof screen is arranged on the outside of the mounting cylinder in a rolling mode, an iron block is arranged at the end part of the outermost layer of the fire-proof screen, and a passageway for the iron block to pass through is arranged at the top of the door frame. An electromagnetic coil is arranged in the top cavity of the door frame, and the electromagnetic coil is electrically connected with preset uninterruptible power supply in the wall. According to the fire-proof door structure, the fire-proof screen is additionally arranged on the outside of the door plate, and the transfer of fire can be blocked for a longer time.

Owner:宁波新万泰消防设备有限公司

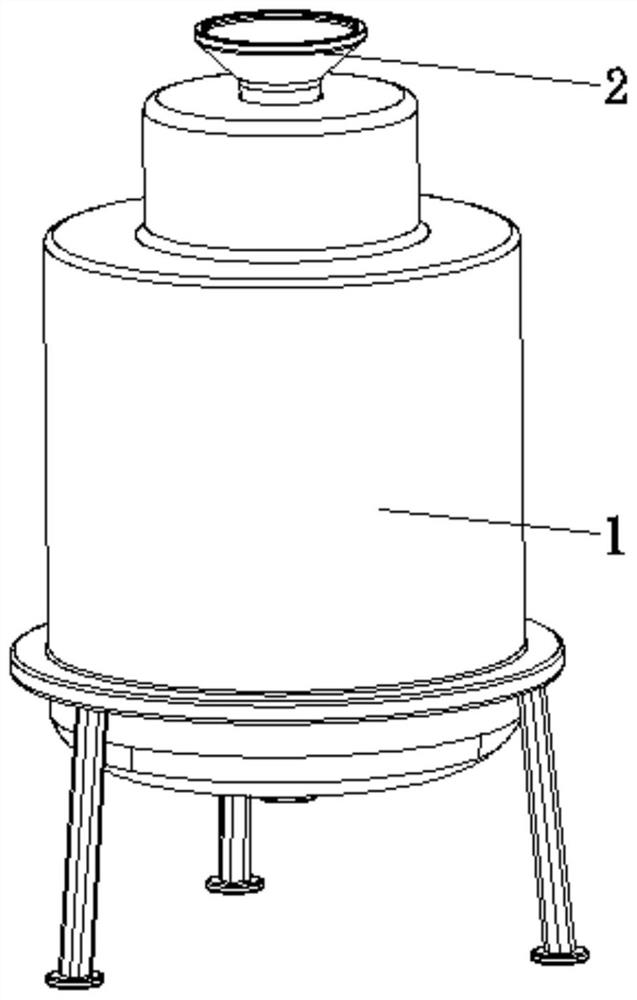

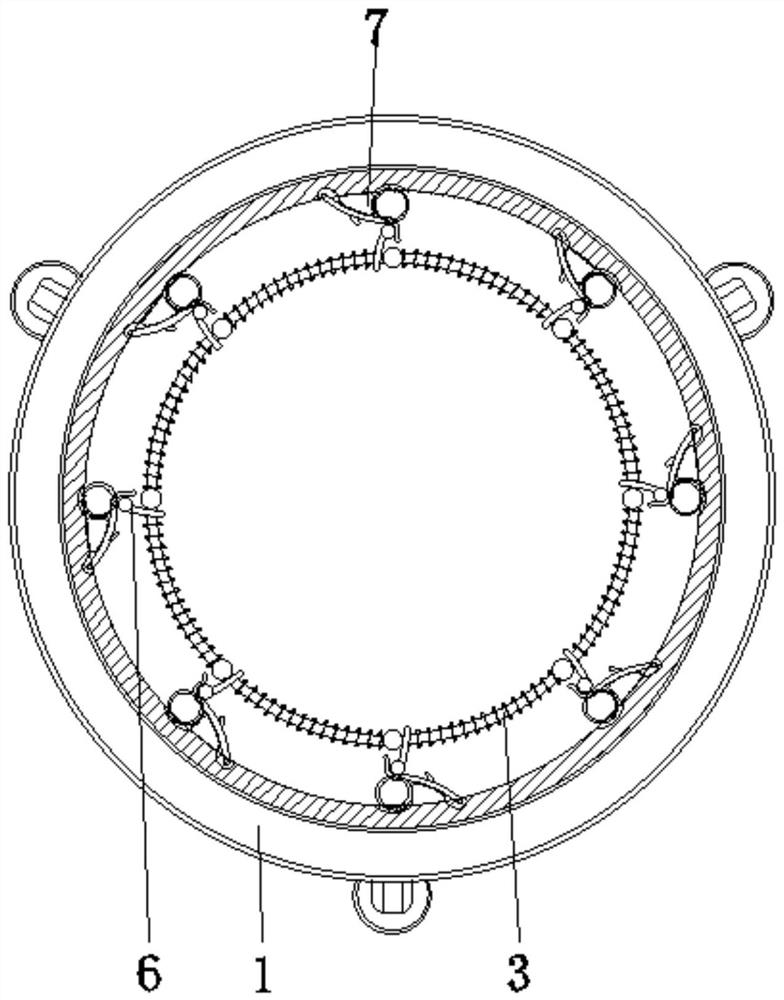

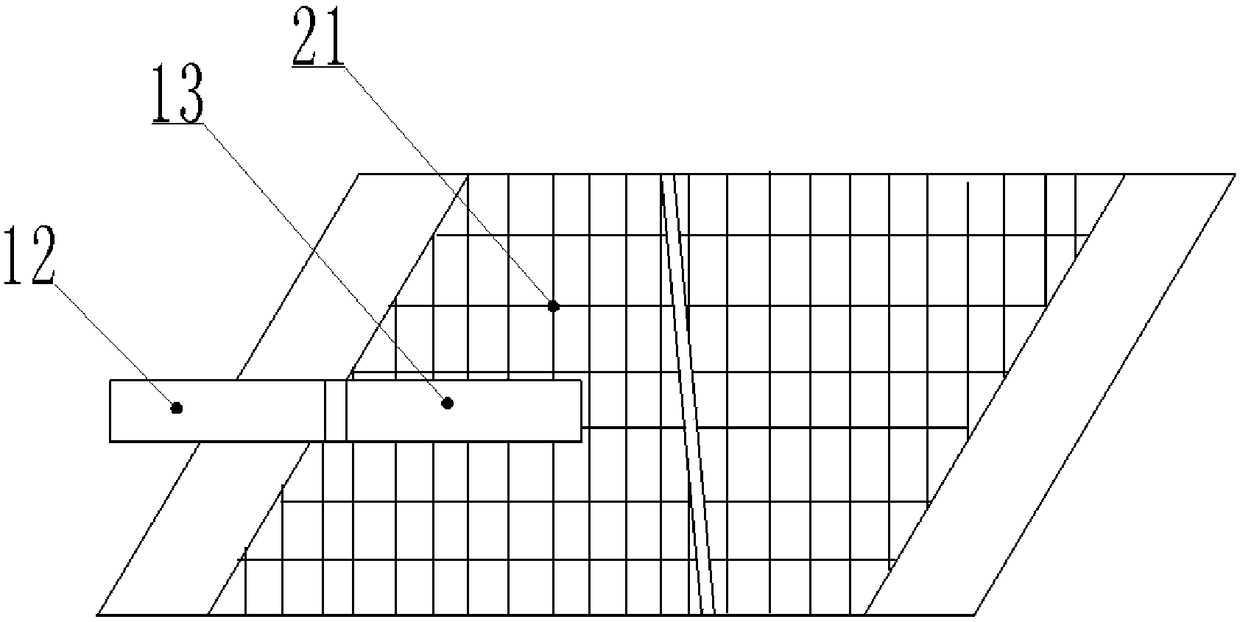

Novel soybean oil pressing device capable of improving oil yield

PendingCN111748406AImprove oil yieldIncrease profitFatty-oils/fats refiningFatty-oils/fats productionMechanical engineeringMaterials science

The invention discloses a novel soybean oil pressing device capable of improving the oil yield. The device comprises a material receiving box and a processing table, three supporting columns are fixedly mounted at the bottom of the material receiving box, the three supporting columns are distributed at the bottom of the material receiving box in an equilateral triangle shape, antiskid gaskets arefixedly mounted at the bottoms of the three supporting columns, the outer surface of the right inner wall, close to a treatment box, of a second rotating rod is sleeved with a sealing ring, a lower grinding disc is fixedly mounted on the inner bottom wall of the material receiving box, a first bearing seat is fixedly embedded in the lower grinding disc, a supporting cylinder is rotationally connected into the first bearing seat, the diameter of the supporting cylinder is five centimeters, the supporting cylinder is matched with the first bearing seat, an upper grinding disc is fixedly installed at the top of the supporting cylinder, two symmetrical material holes are formed in the surface of the upper grinding disc, and two brush strips and an annular baffle are fixedly installed on the outer circle face of the bottom of the upper grinding disc and the outer circle face of the top of the upper grinding disc respectively. Steam is used for heating soybeans to remove impurities, stirringradiating and grinding disc grinding are carried out, and the oil yield is increased.

Owner:泉州台商投资区国进信息技术有限公司

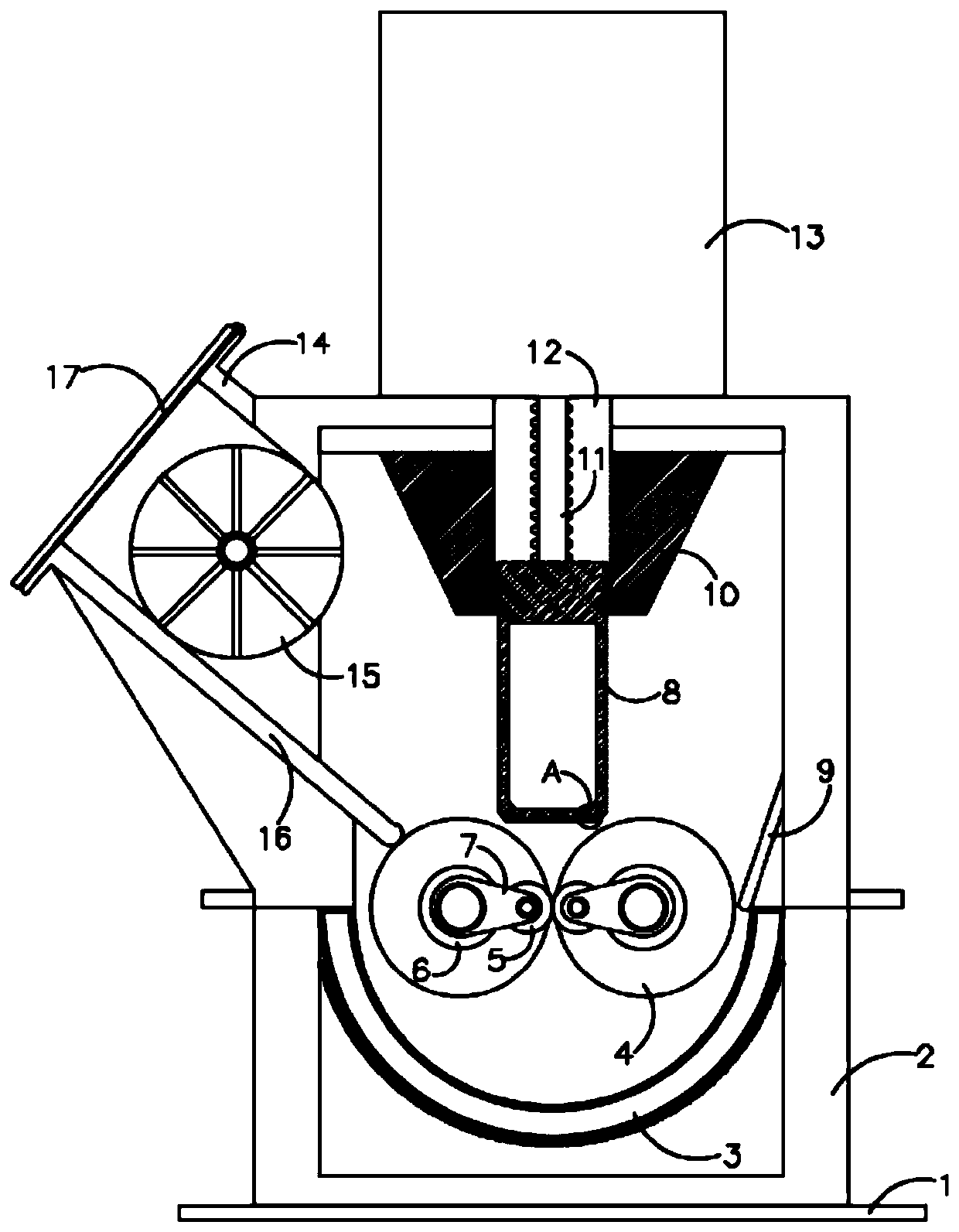

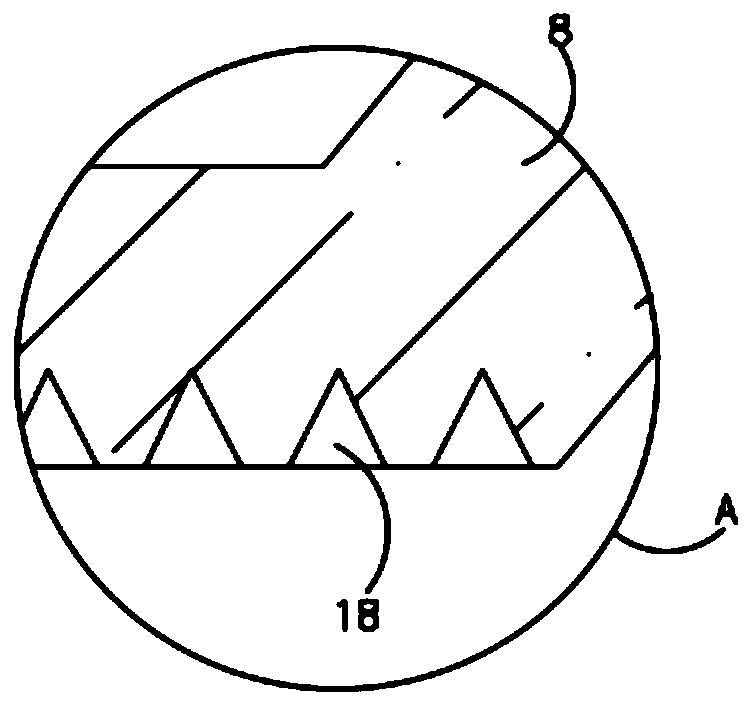

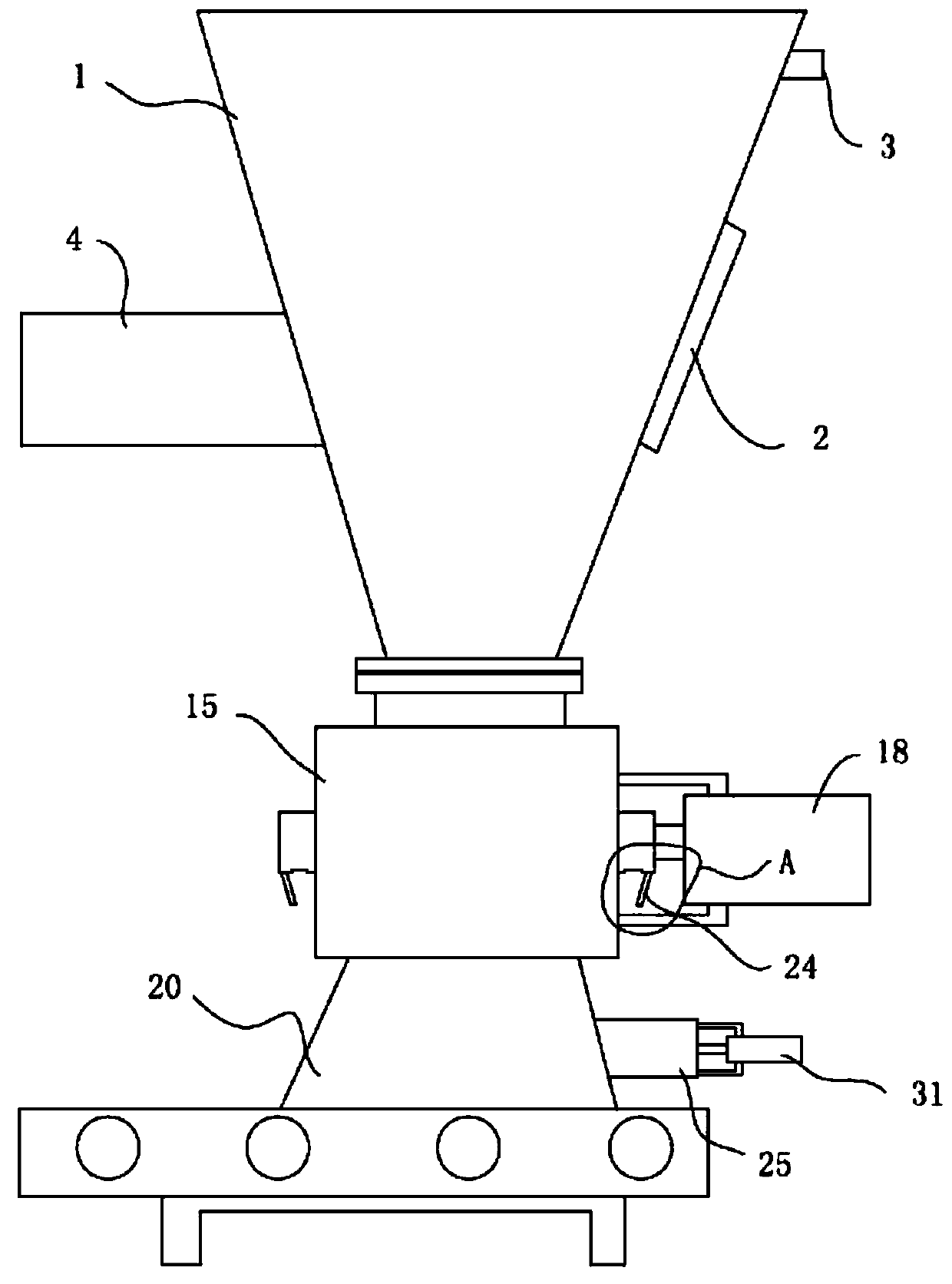

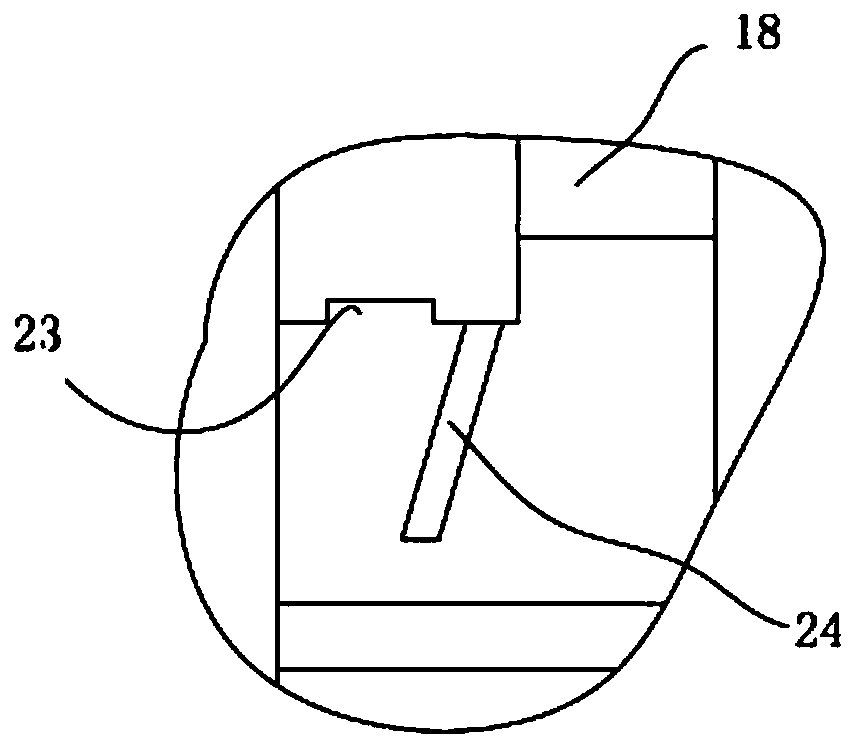

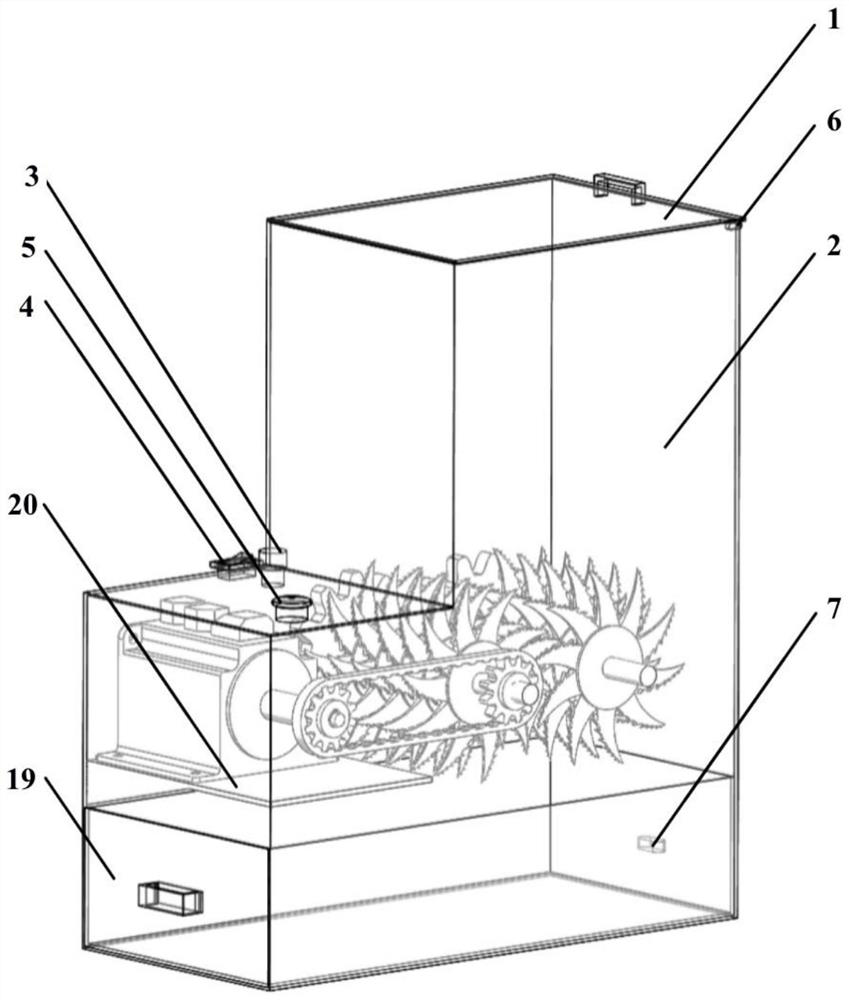

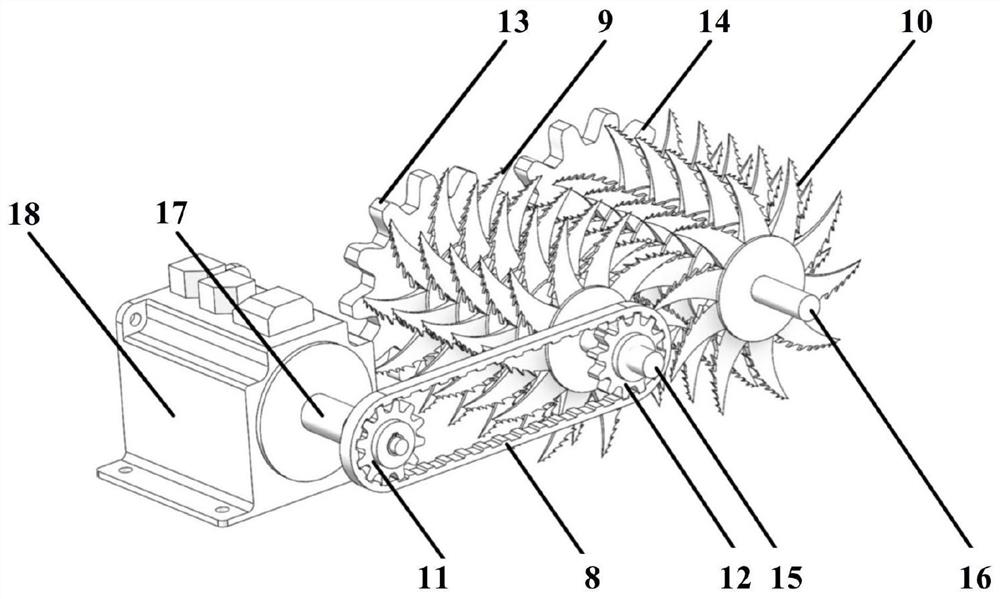

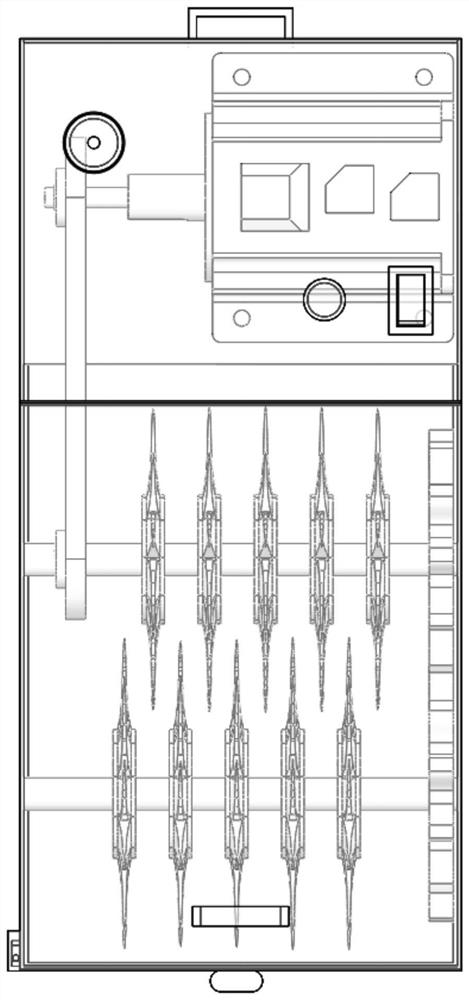

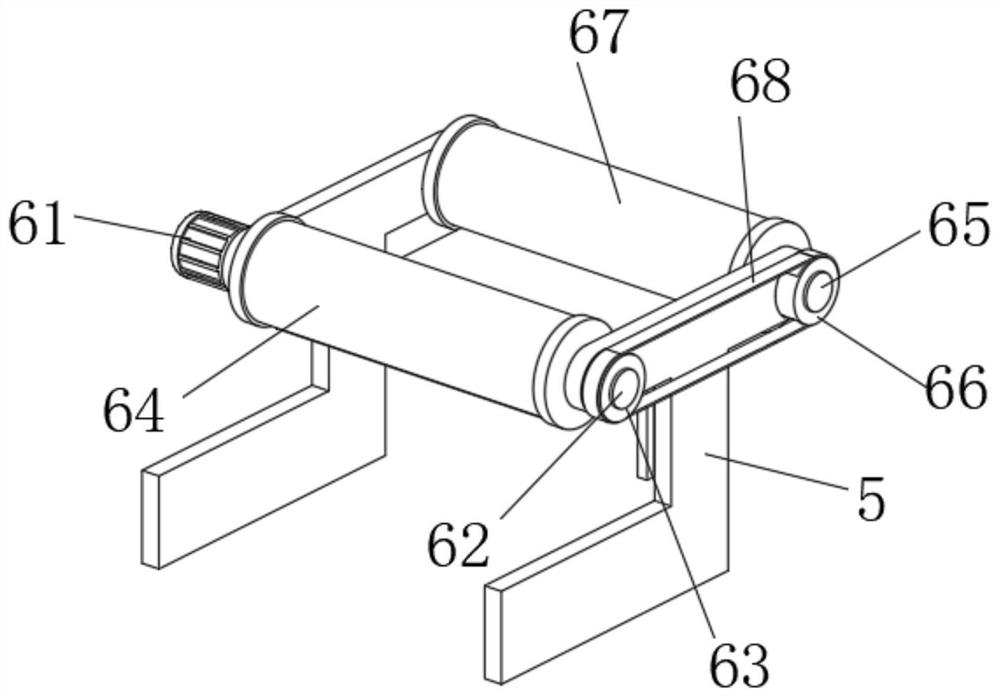

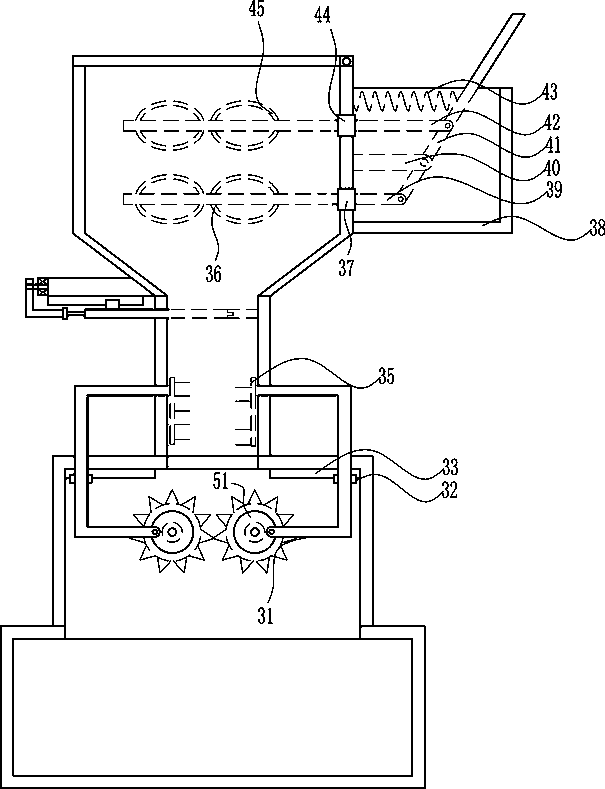

Crusher capable of efficiently crushing and easily discharging materials

PendingCN110052305APromote fragmentationBroken in timeGrain treatmentsDischarge efficiencyInstability

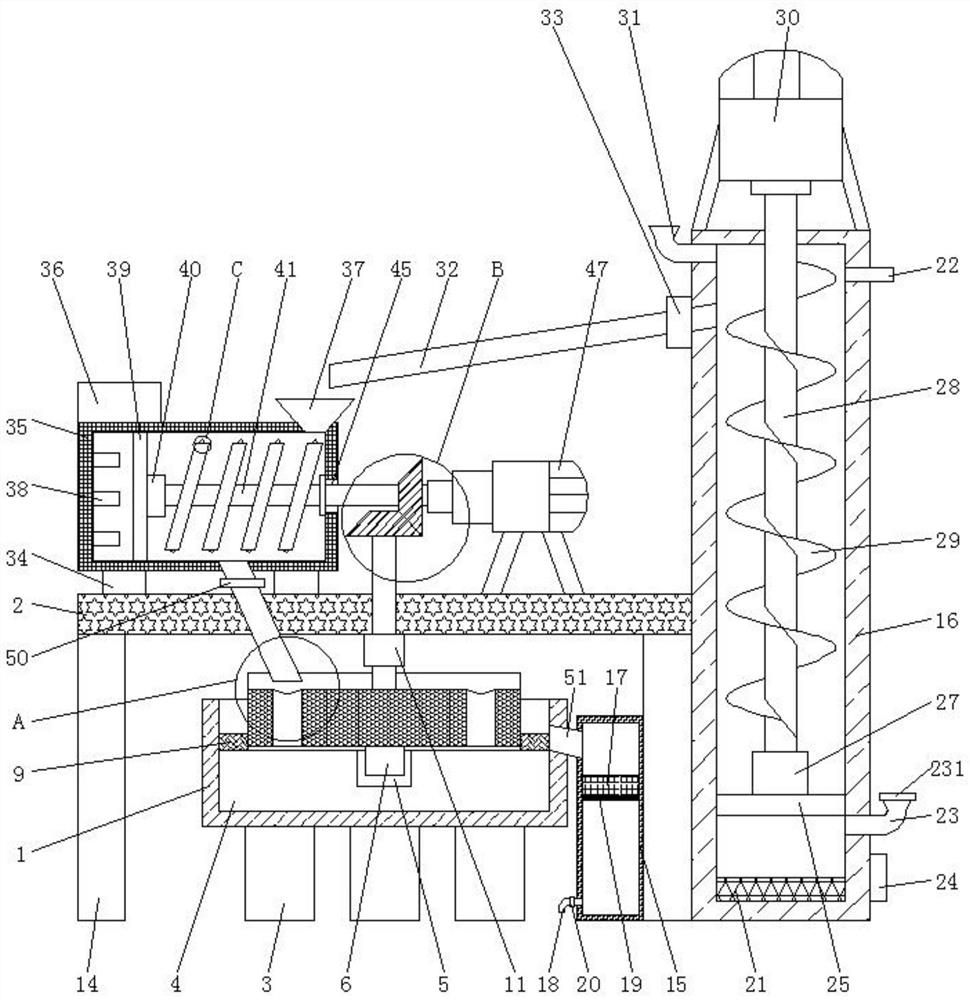

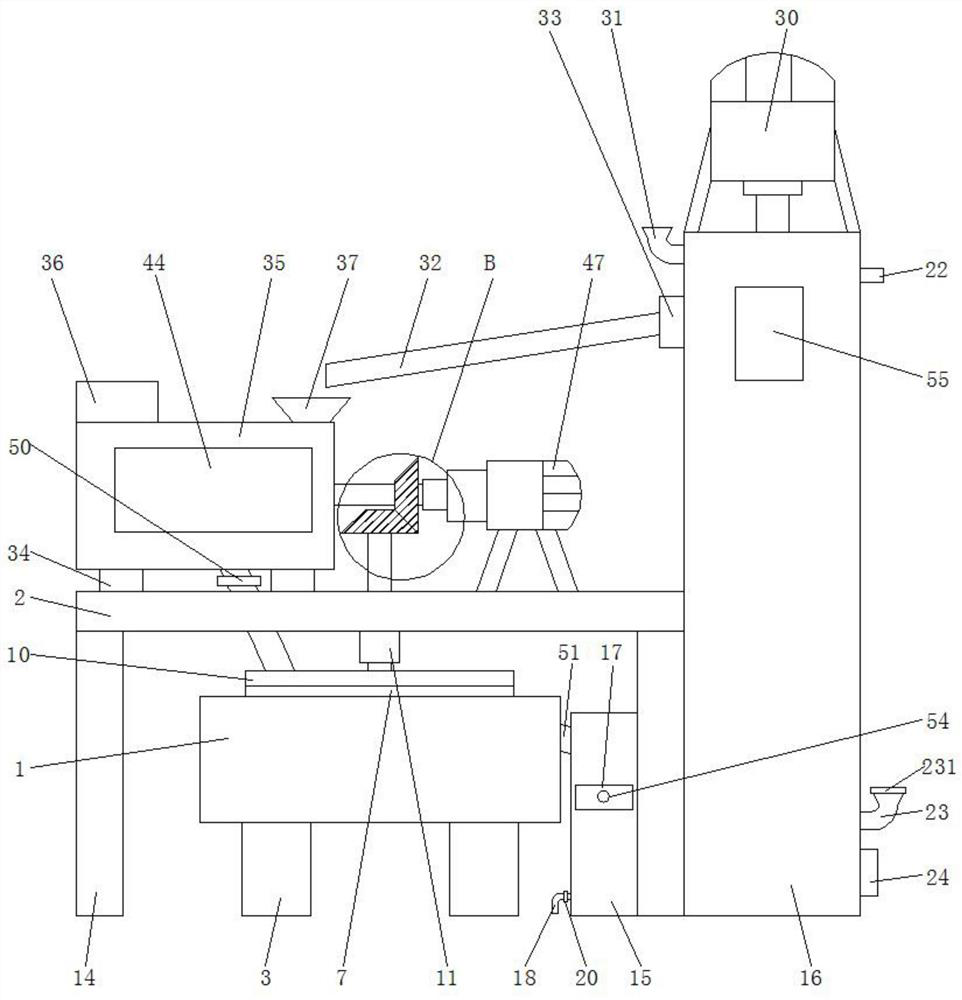

The invention discloses a crusher capable of efficiently crushing and easily discharging materials. The crusher comprises a machine body, wherein a base is fixedly connected to the bottom part of themachine body; a case is arranged above the machine body; a crushing mechanism is arranged on the lower part of the inner part of the machine body; a collecting groove is formed in the lower part of the crushing mechanism; a conveying pipe is arranged on one side of the machine body; a guiding plate is arranged on the inner wall of the conveying pipe; a roller is rotatably arranged in the conveyingpipe; a fixator is fixedly arranged on the top part of the inner part of the machine body; a lower movable cavity is arranged in the fixator; an upper movable cavity is arranged in the case; and thelower movable cavity communicates with the upper movable cavity. According to the crusher capable of efficiently crushing and easily discharging materials, extruding is carried out appropriately during discharging, so that materials are promoted to be ground and crushed, and the occurrence of the phenomenon that the materials cannot be crushed due to the instability of the materials is avoided; and the materials are extruded through an extruding block so as to be timely crushed through a crushing roller, so that the discharging efficiency is improved, and the occurrence of the phenomenon thatthe materials are too less to grind in the later period is avoided.

Owner:JIANGMEN XIECHENG MACHINERY

Sand filtering device for building

PendingCN112791928AAvoid shockExtended service lifeSievingScreeningSand filterStructural engineering

The invention discloses a sand filtering device for a building. The sand filtering device for the building comprises a machine body, a feeding hopper is rotationally connected to the top of the machine body, a conical screen is fixed to the bottom of the feeding hopper, an impurity storage cavity is fixed to the bottom of the conical screen, the surface of the impurity storage cavity is rotationally connected with the bottom of the machine body, a spiral blade is located in the conical screen and fixed to the bottom of the feeding hopper, a cleaning device is arranged on the surface of the conical screen, a pressing device is arranged on the inner wall of the machine body, a flow guide plate is fixed to the inner wall of the machine body and close to the bottom of the machine body, and a filter sieve is fixed to the bottom of the inner wall of the machine body. The invention relates to the technical field of building equipment. According to the sand filtering device for the building, the purpose of removing impurities in time is achieved, the impurities can be removed in time, impact generated after the impurities are thrown out is avoided, the service life of equipment is prolonged, meanwhile, wet sand balls are scattered in time, filtering is facilitated, and the working efficiency and the using performance are improved.

Owner:王长桂

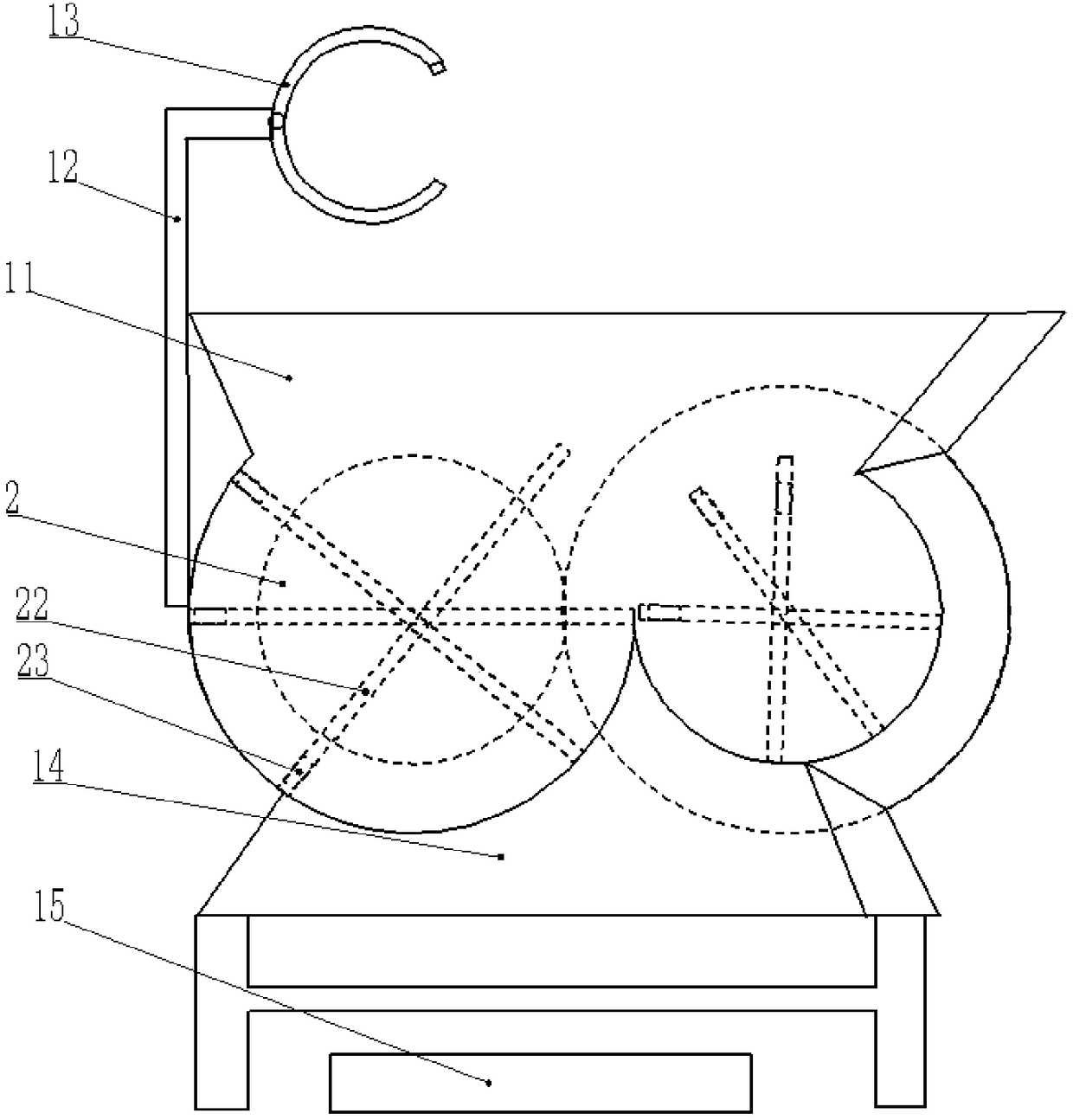

Gate material breaking type separating and discharging device

ActiveCN110745582ASuccessful deliveryAvoid clog buildupConveyorsLoading/unloadingControl systemEngineering

The invention discloses a gate material breaking type separating and discharging device which comprises a control system, a discharging hopper system, a pneumatic gate system, a separating wheel system and a temporary material push system. The discharging hopper system, the pneumatic gate system, the separating wheel system and the temporary material push system are electrically connected with thecontrol system. The discharging hopper system is used for bearing materials conveyed by a feeding system on the upper side, and the materials are transferred to a material machining and conveying system through the separating wheel system on the lower side. A pneumatic gate system is transversely installed on the discharging hopper system, when block-shaped materials exist in the discharging hopper system and affect discharging, the pneumatic gate system is used for smashing the block-shaped materials, and it is ensured that the materials slide normally in detail. The temporary material pushsystem is transversely arranged on the lower rear side of the separating wheel system, when the block-shaped materials in the discharging hopper system are broken by the pneumatic gate system, the material accumulating and falling phenomenon can inevitably happen; and after the materials are smashed, the temporary material push system is used for accelerating transferring of the materials below the separating wheel system, and the materials are prevented from being accumulated below the separating wheel system.

Owner:ZHANGQIU HUAMING CEMENT

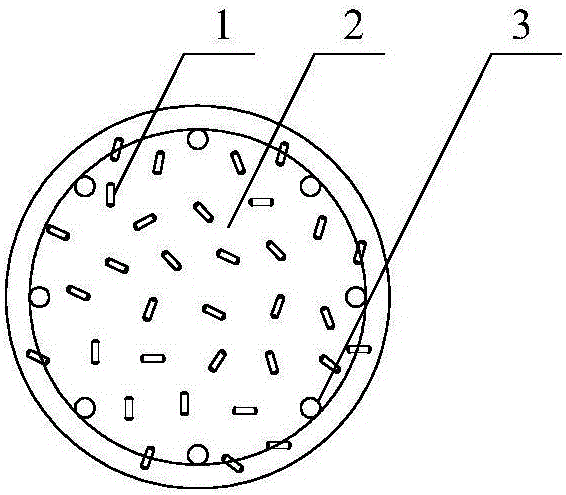

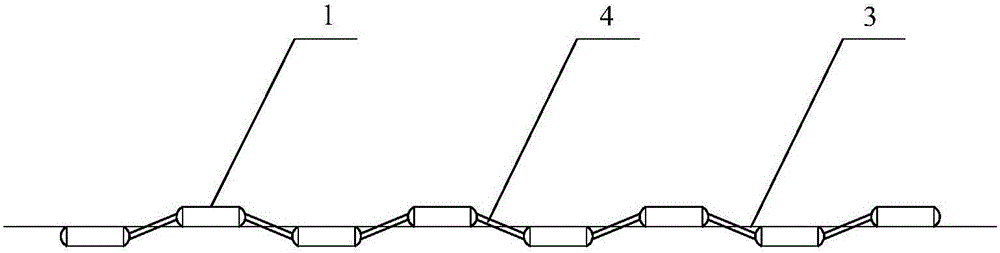

Self-healing concrete pile preventing frost heaving and bonding weakening

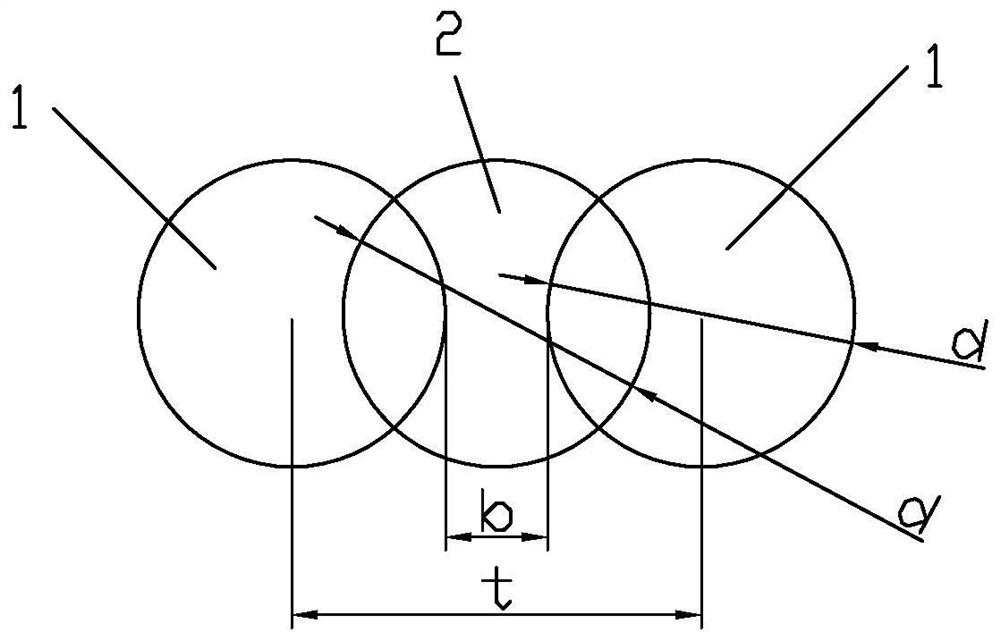

InactiveCN105821832AImprove tensile and shear strengthImprove toughnessProtective foundationBulkheads/pilesRebarPolypropylene

The invention discloses a self-healing concrete pile preventing frost heaving and bonding weakening. In order to improve the bonding performance between steel bars and concrete, a steel capsule string formed by connecting steel capsules through strip-shaped polypropylene fabrics in series is twined on each steel bar. By adopting the self-healing concrete pile, the tensile strength and shear strength of concrete can be remarkably improved, roughness of the concrete can be greatly enhanced, and accordingly the anti-seismic performance of the concrete is improved. The critical bonding stress between the steel bars and the concrete can be remarkably increased. As polypropylene has good plasticity, roughness and temperature adaptability, the polypropylene can have extremely strong resisting capacity on heaving stripping and degradation between the steel bars and the concrete in the freezing-thawing process. Because the positions and orientations of the steel capsules are distributed randomly in the concrete, the steel capsules can break to conduct repairing and heeling on cracks in all directions. Self-compacting concrete is adopted as the concrete in the pile, and accordingly the steel capsules in the concrete can be prevented from breaking during vibrating.

Owner:WUHAN UNIV

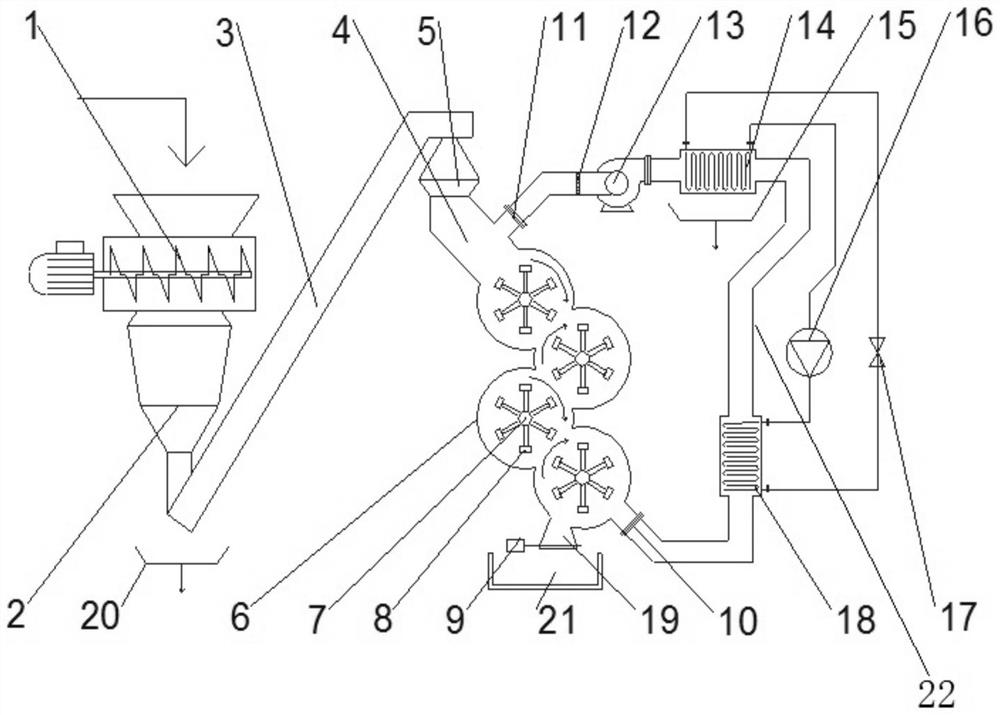

Carbon dioxide heat pump sludge drying system

PendingCN112897846AImprove drying efficiencyIncrease contact areaSludge treatment by de-watering/drying/thickeningCompression machinesSludgeProcess engineering

The invention discloses a carbon dioxide heat pump sludge drying system, which comprises: a sludge drying unit, which is used for drying sludge to obtain dried sludge and wet and hot air; a carbon dioxide heat pump unit, which is used for enabling the damp and hot air flowing into the carbon dioxide heat pump unit from the sludge drying unit to form dry high-temperature air and then returning the dry high-temperature air to the sludge drying unit, wherein the dried high-temperature air is used as a heat source for drying the sludge. By using the supercritical CO2 heat pump unit, the exhaust temperature of a compressor is high, CO2 latent heat is high, and condensation is avoided, so that the temperature of a hot air outlet can reach 100 DEG C or above, and the drying efficiency is greatly improved.

Owner:CITIC CONSTR +1

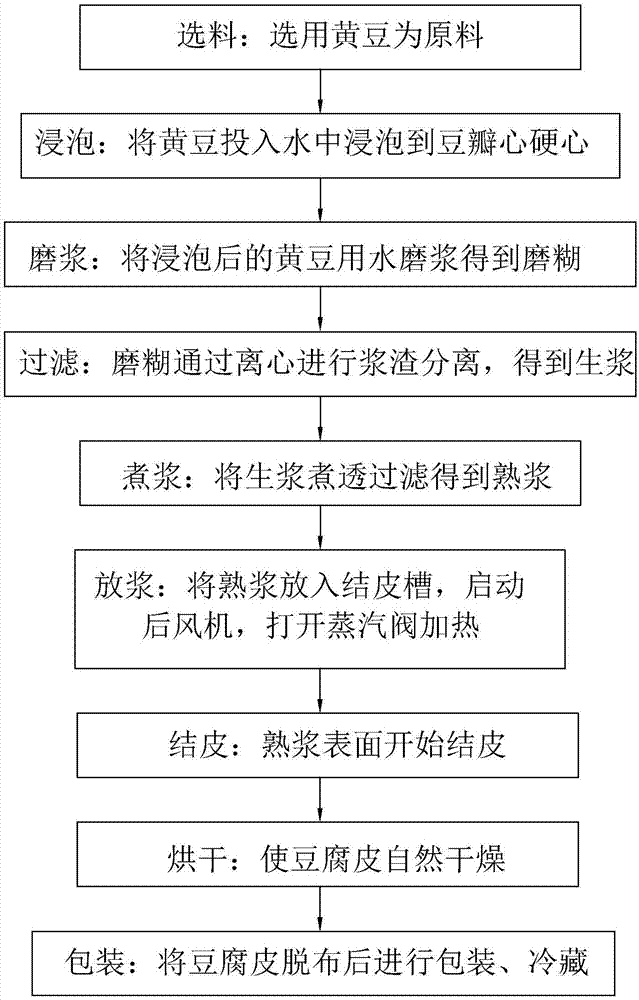

Preparation method of bean curd skin

InactiveCN107950675AUniform distribution of solid contentUniform thicknessFood preservationCheese manufactureWrinkle skinSteam pressure

The present invention discloses a preparation method of bean curd skin. The preparation method comprises the following steps: (1) selecting raw materials; (2) soaking soya beans; (3) grinding pulp; (4) performing centrifugal filtration; (5) boiling pulp; (6) discharging boiled pulp: putting the boiled pulp into a skin-forming groove, controlling the temperature of the boiled pulp at 95-98 DEG C and the solid content of the boiled pulp at 10-11%, running a rear fan when 1 / 3 of the skin-forming groove is filled with the boiled pulp, and opening all steam valves to heat, with the steam pressure not more than 0.2 MPa and the heating temperature controlled at 95-97 DEG C; (7) forming skin: pulling the bean curd skin to a conveyor belt when the surface of the boiled pulp begins to form skin andsmall wrinkles appear in the skin, opening the pulp-returning pump when the formed skin is uneven and the skin forming is slow, controlling the speed of pulp returning through the valves, and using the recovered soya bean milk to produce other products; (8) drying the bean curd skin; and (9) packing products. The prepared bean curd skin is delicate, uniform in thickness and not easy to break. In addition, the preparation method improves the utilization rate and production efficiency of the soya beans, and prolongs the shelf life of the bean curd skin by spraying table salt water and spirit.

Owner:安吉祖名豆制食品有限公司

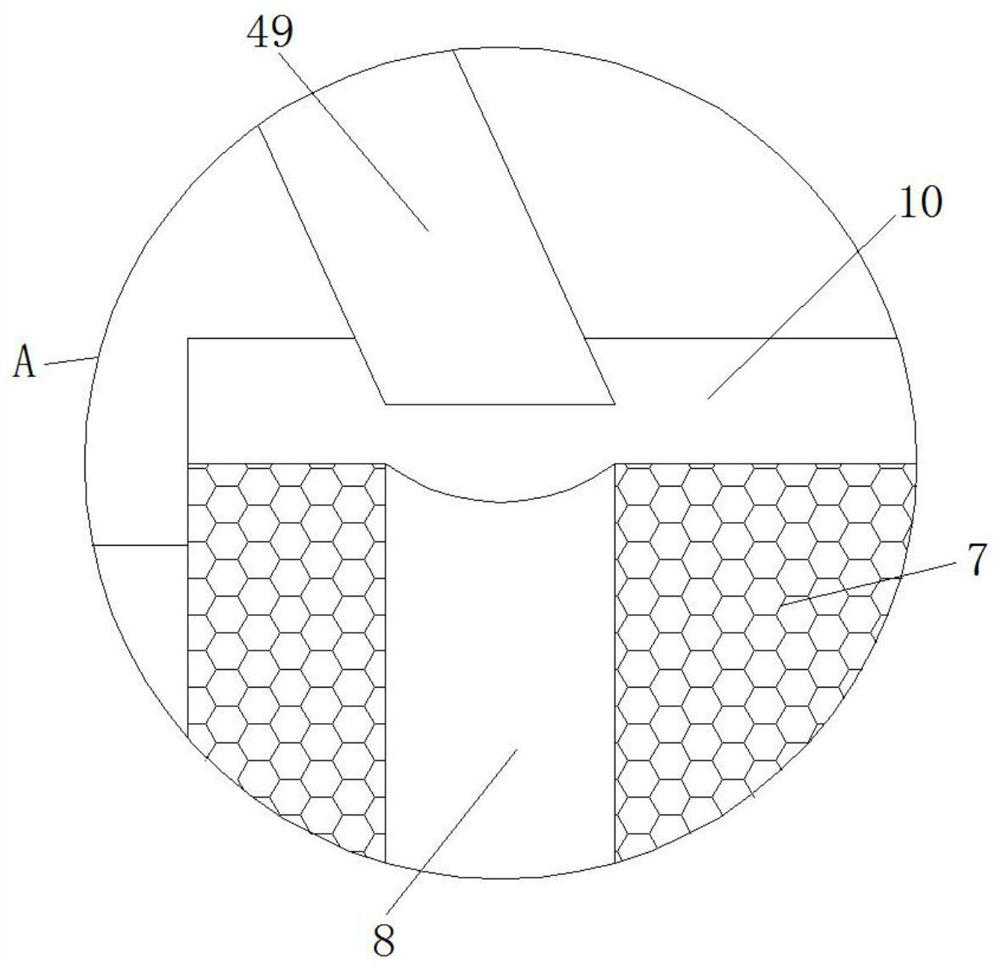

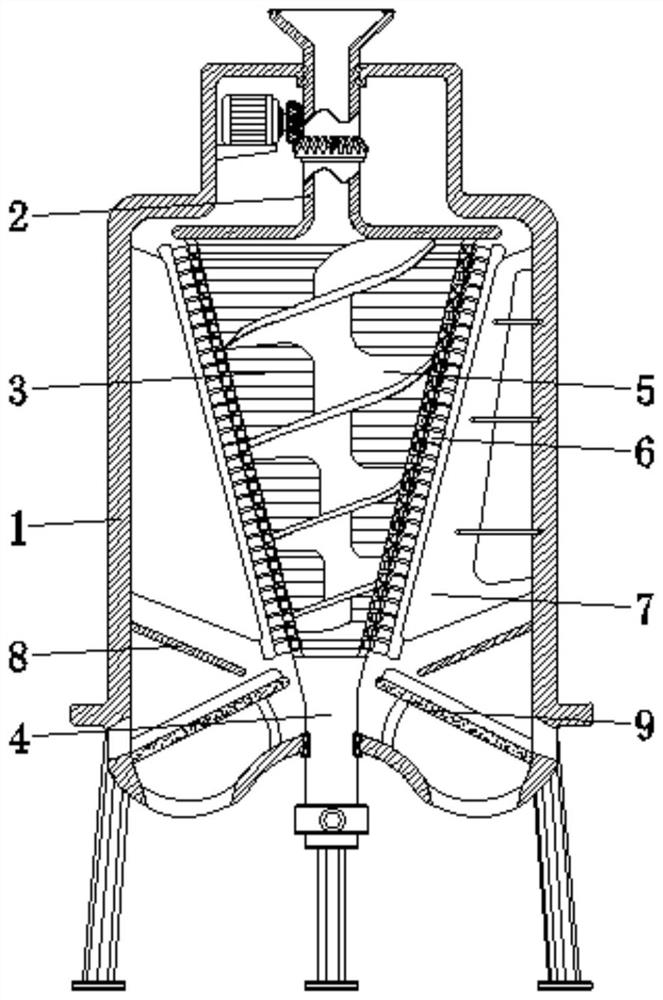

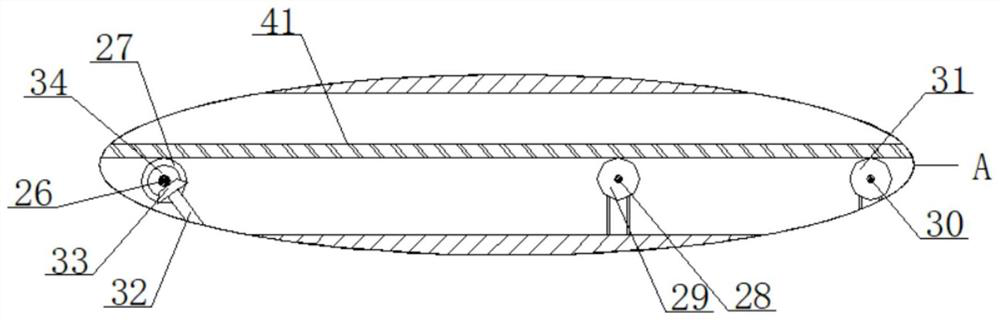

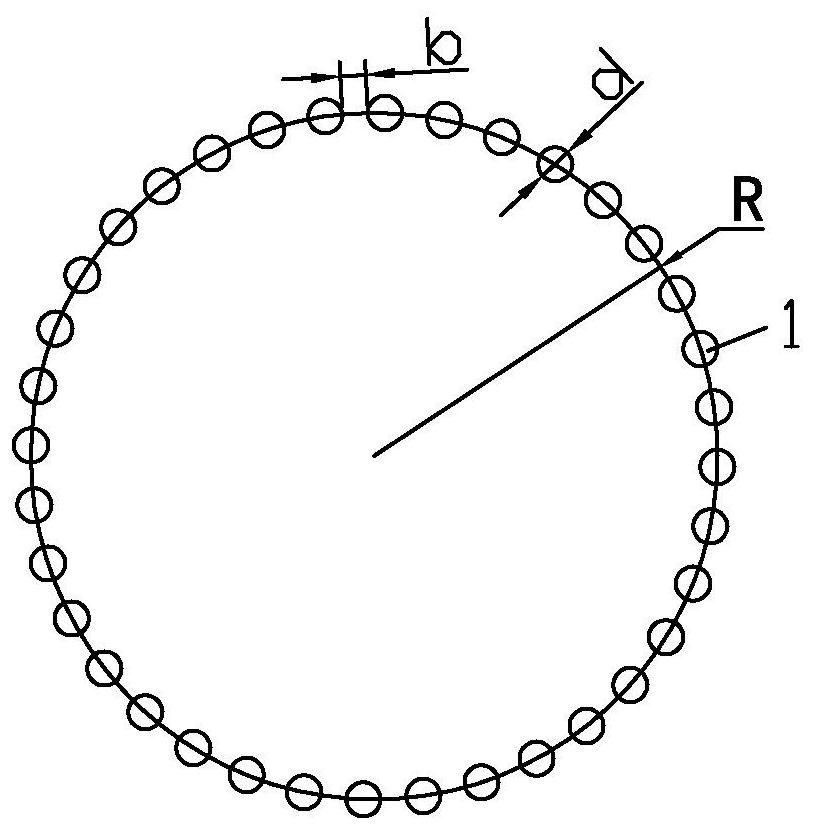

Progressive crushing device for petroleum coke

A progressive crushing device for petroleum coke, including a shearing and crushing mechanism and a crushing and crushing mechanism arranged up and down; the shearing and crushing mechanism includes two shearing and crushing rollers arranged side by side, and the two shearing and crushing rollers are driven by two motors Driven by two first rotating shafts respectively, several shearing and crushing teeth are evenly arranged on the shearing and crushing roller; a triangular prism-shaped shearing block is arranged on the shearing and crushing teeth, and the length direction of the shearing block is in line with the shearing and crushing The roller surface of the roller is tangent, and a triangular prism-shaped material distribution block is also arranged on the shearing and crushing teeth. The extrusion crushing mechanism includes two extrusion crushing rollers arranged side by side, and the two extrusion crushing rollers respectively follow the two second rotating shafts, and the two second rotating shafts are respectively connected with the two first rotating shafts through the transmission device and rotate synchronously , Several extrusion crushing teeth are evenly arranged on the peripheral side of the extrusion crushing roller. The present invention not only has a good crushing effect, but also can effectively prevent the petroleum coke from being stuck on the crushing roller.

Owner:卢晓鹏

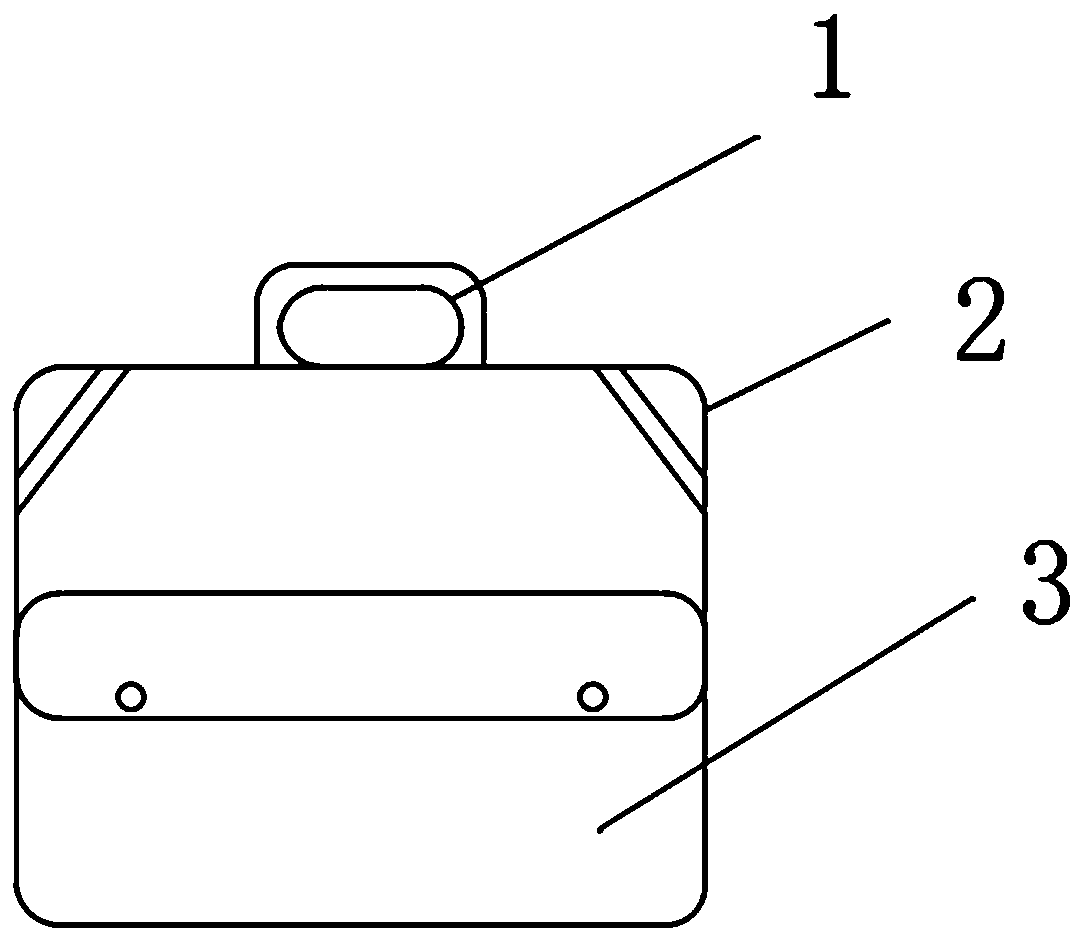

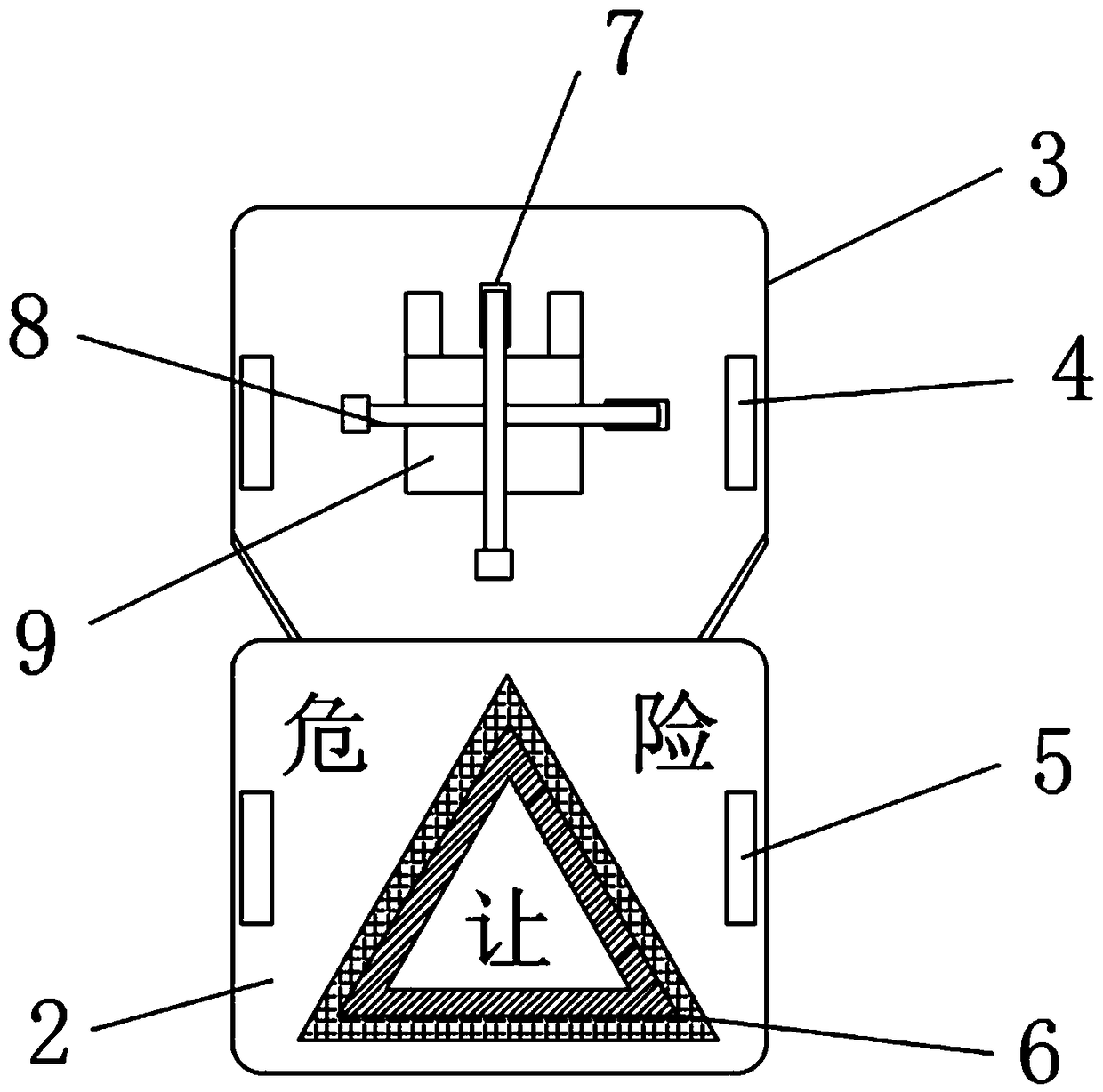

Vehicular multifunctional traveling storage bag

The invention discloses a vehicular multifunctional traveling storage bag. The vehicular multifunctional traveling storage bag comprises handles, a storage bag body, a reflecting plate, a reflecting waistcoat, a fixing barrel, a safe hammer, a push plate, a first spring, a first folding plate, a buckle box, a buckle, a second folding plate, a fixing block, a second spring, a fixing groove, a thirdspring, a fixing latch, a second fixing rod and a fifth spring. The vehicular multifunctional traveling storage bag is provided with the fixing barrel, the safe hammer is placed in the fixing barrel,after an accident happens, the safe hammer can be taken out in time, and can be used for breaking a vehicle window in time, thus, a user can save himself in time, the first folding plate and the second folding plate are arranged on the bottom of the storage bag, when articles are placed, the first folding plate and the second folding plate extend, the space of the storage bag is expanded, after the articles are taken out, the first folding plate and the second folding plate contract under the effect of the third spring, and a proper accommodating space is provided.

Owner:四川四海鹏飞科技有限责任公司

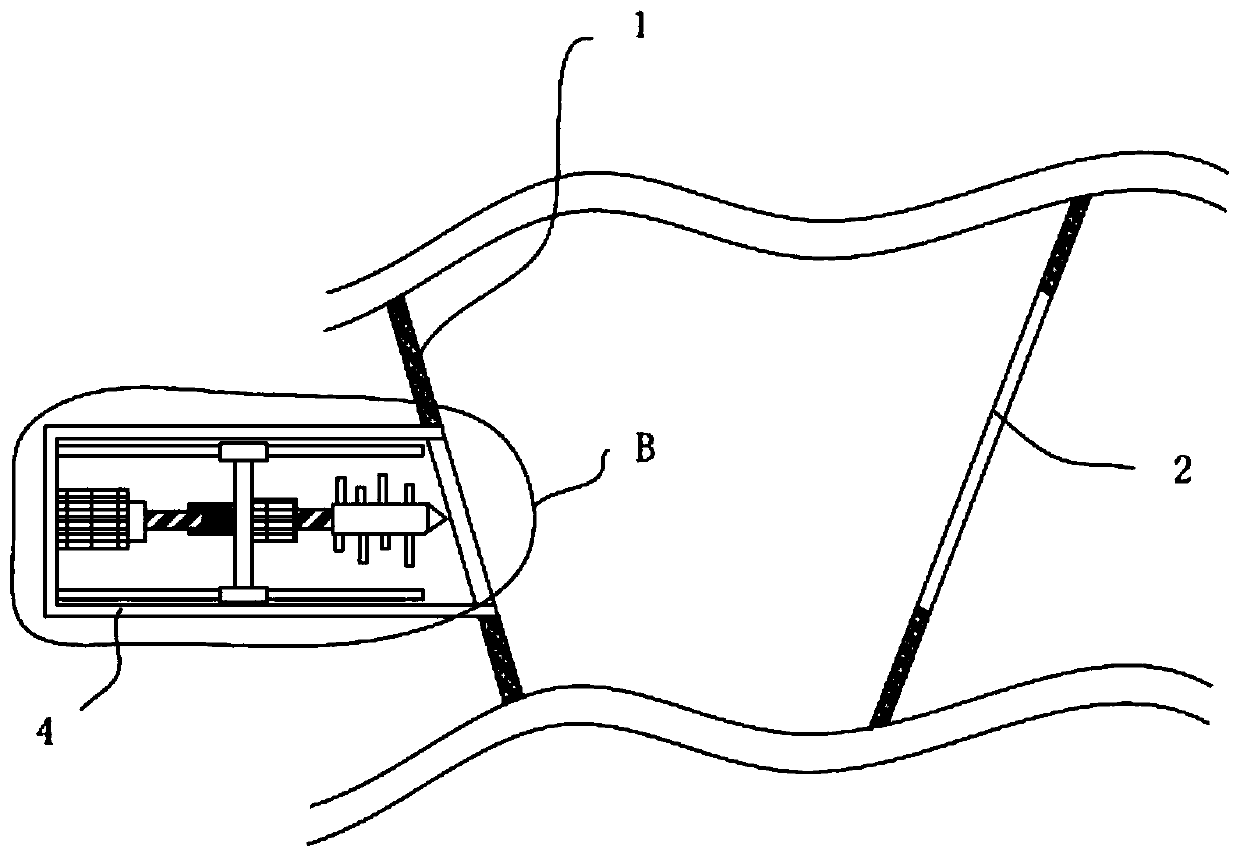

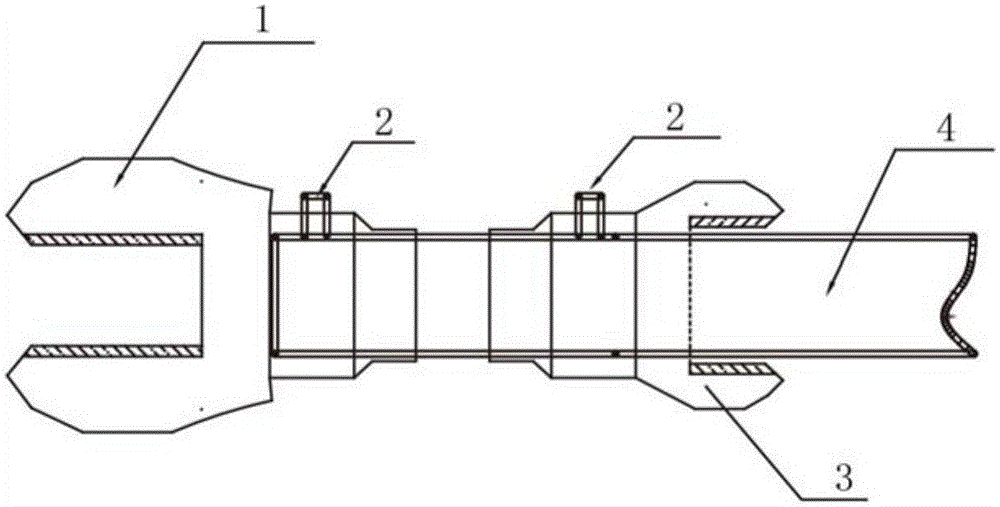

Anti-sloughing drilling tool for surrounding rocks of tunnel

InactiveCN105041217AReduce adverse effectsIncrease profitDrill bitsUnderground chambersSloughingDrill bit

The invention relates to the field of mine support technology, and discloses an anti-sloughing drilling tool for surrounding rocks of a tunnel. The anti-sloughing drilling tool comprises a first drill, a second drill and a drilling rod. The first drill is mounted, facing to a forward direction relative to a hole, at the front end of the drilling rod, the second drill sleeves, facing to a backward direction relative to the hole, the drilling rod, the second drill and the first drill are arranged at an interval, and the external diameter of the first drill is larger than the external diameter of the second drill. The anti-sloughing drilling tool for surrounding rocks of the tunnel is simple in structure, convenient to operate, normal drilling can be ensured, and unfavorable influence on drilling tools caused by rear collapse can be prevented.

Owner:TIANDI SCI & TECH CO LTD +1

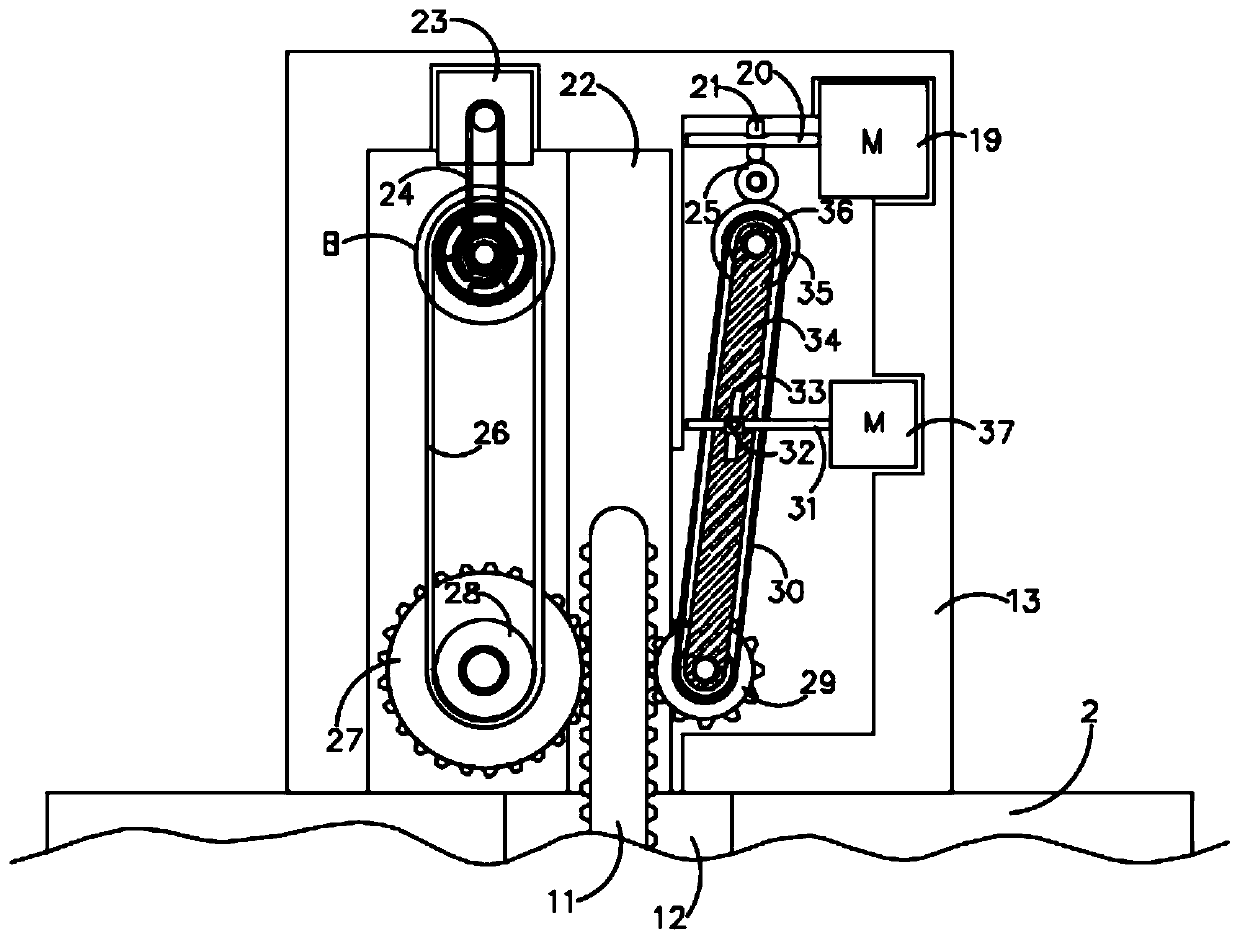

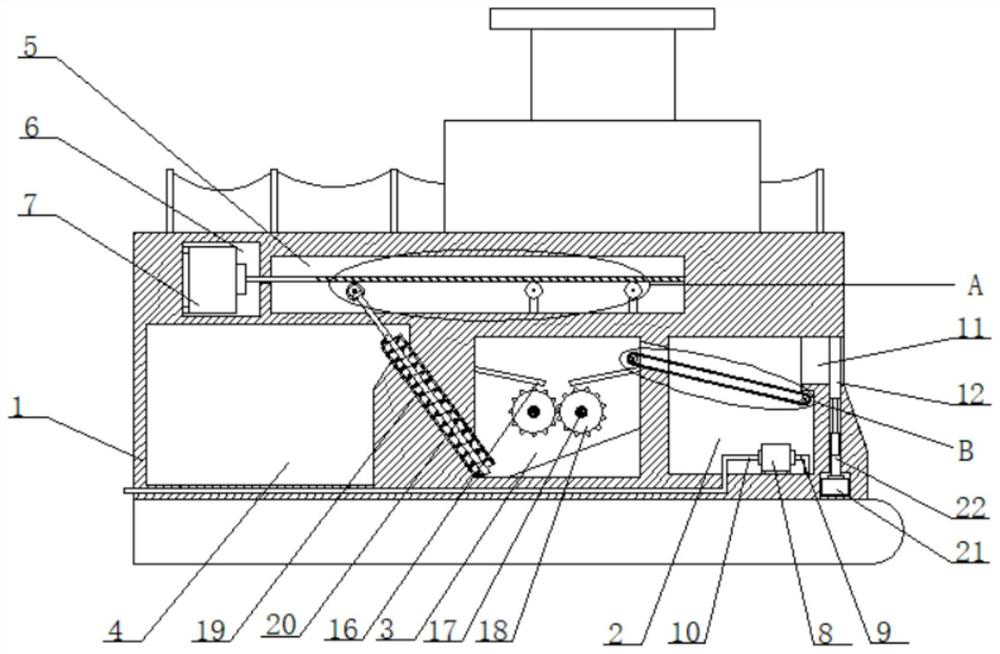

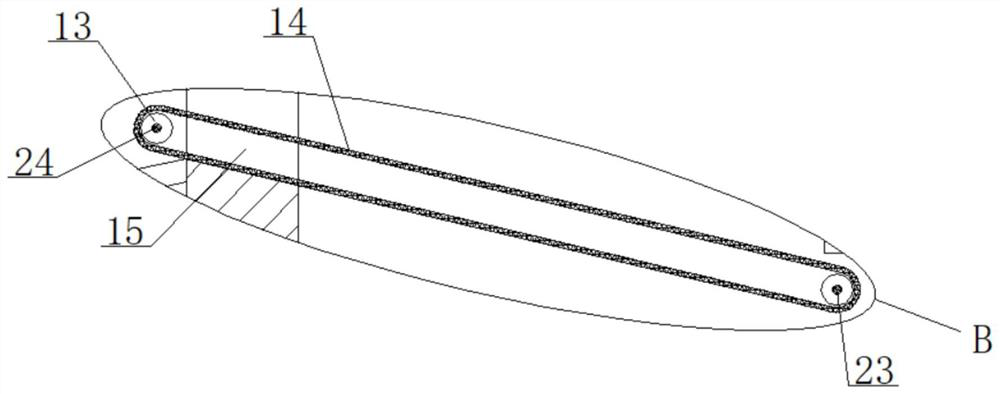

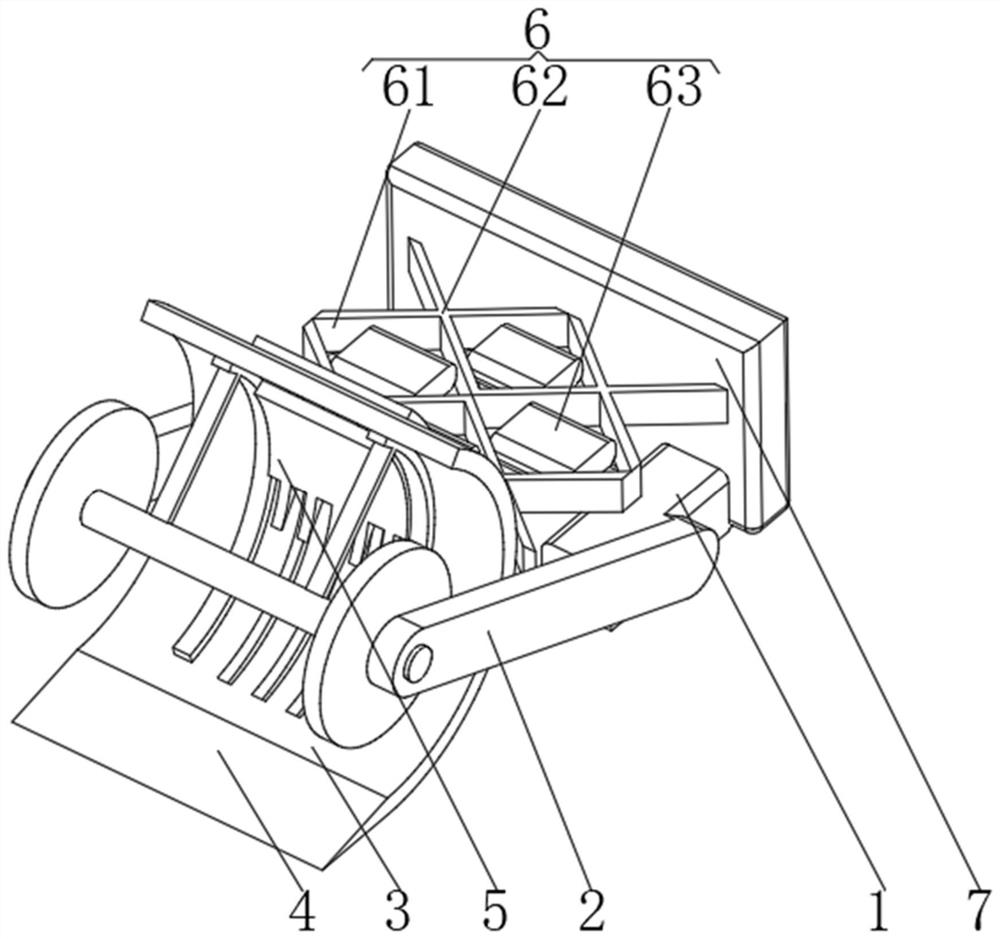

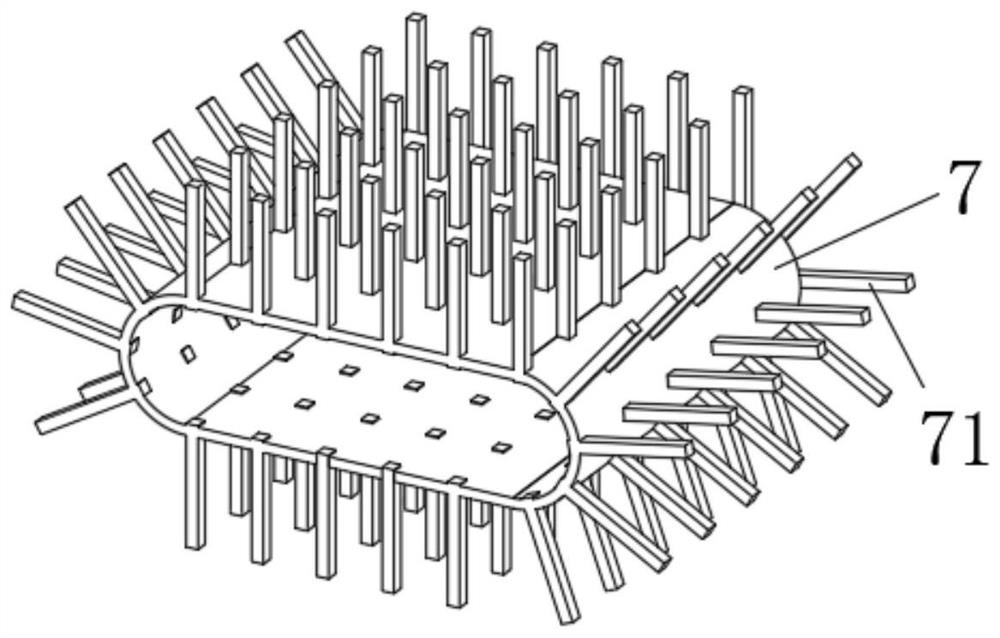

Marine floating garbage treatment equipment

InactiveCN113227502ABroken in timeEasy to salvageWater cleaningGrain treatmentsElectric machineryRefuse Disposals

The invention belongs to the field of marine environment, particularly relates to marine floating garbage treatment equipment, and aims to solve the problems that existing marine floating garbage is often salvaged manually, the salvage efficiency is low, time and labor are wasted, the salvaged garbage needs to be transferred to a specific place to be transferred and crushed, the whole process is complicated and strenuous, and the working efficiency is high. According to the technical scheme, the marine floating garbage treatment equipment comprises a ship body; a collecting cavity, a crushing cavity, a storage cavity, a transmission cavity and a motor cavity are formed in the ship body; a motor is fixedly installed on the inner wall of one side of the motor cavity; and a worm is rotatably installed in the transmission cavity. When the equipment is in use, the equipment salvages marine garbage conveniently and quickly, discharges seawater, and improves the salvage efficiency. Meanwhile, after salvaging is finished, the salvaged marine garbage can be crushed in time, and thoroughly crushed marine garbage can be transferred and temporarily stored. The whole process is simple and convenient, and the treatment efficiency of the marine garbage is effectively improved.

Owner:TANGSHAN HARBIN SHIP TECH CO LTD

A fire door structure

ActiveCN109372401BWon't touchAvoid spreadingFireproof doorsWing fastenersUninterruptible power supplyMechanical engineering

The invention discloses a fire-fighting door device. The fire-fighting door device comprises a door plate and a door frame arranged in the circumferential direction of the door plate, the outer side of the door frame is arranged in a pre-arranged installation door hole on a wall in a matched mode, and one side of the door plate is hinged to the side wall of the door frame. A rotating shaft is arranged at the position, near the door plate, in the top cavity of the door frame in the width direction of the door frame, a reset spring and an mounting cylinder sleeve the rotating shaft in sequence,one end of the reset spring is connected with the rotating shaft, and the other end of the reset spring is connected with the mounting cylinder. A fire-proof screen is arranged on the outside of the mounting cylinder in a rolling mode, an iron block is arranged at the end part of the outermost layer of the fire-proof screen, and a passageway for the iron block to pass through is arranged at the top of the door frame. An electromagnetic coil is arranged in the top cavity of the door frame, and the electromagnetic coil is electrically connected with preset uninterruptible power supply in the wall. According to the fire-proof door structure, the fire-proof screen is additionally arranged on the outside of the door plate, and the transfer of fire can be blocked for a longer time.

Owner:宁波新万泰消防设备有限公司

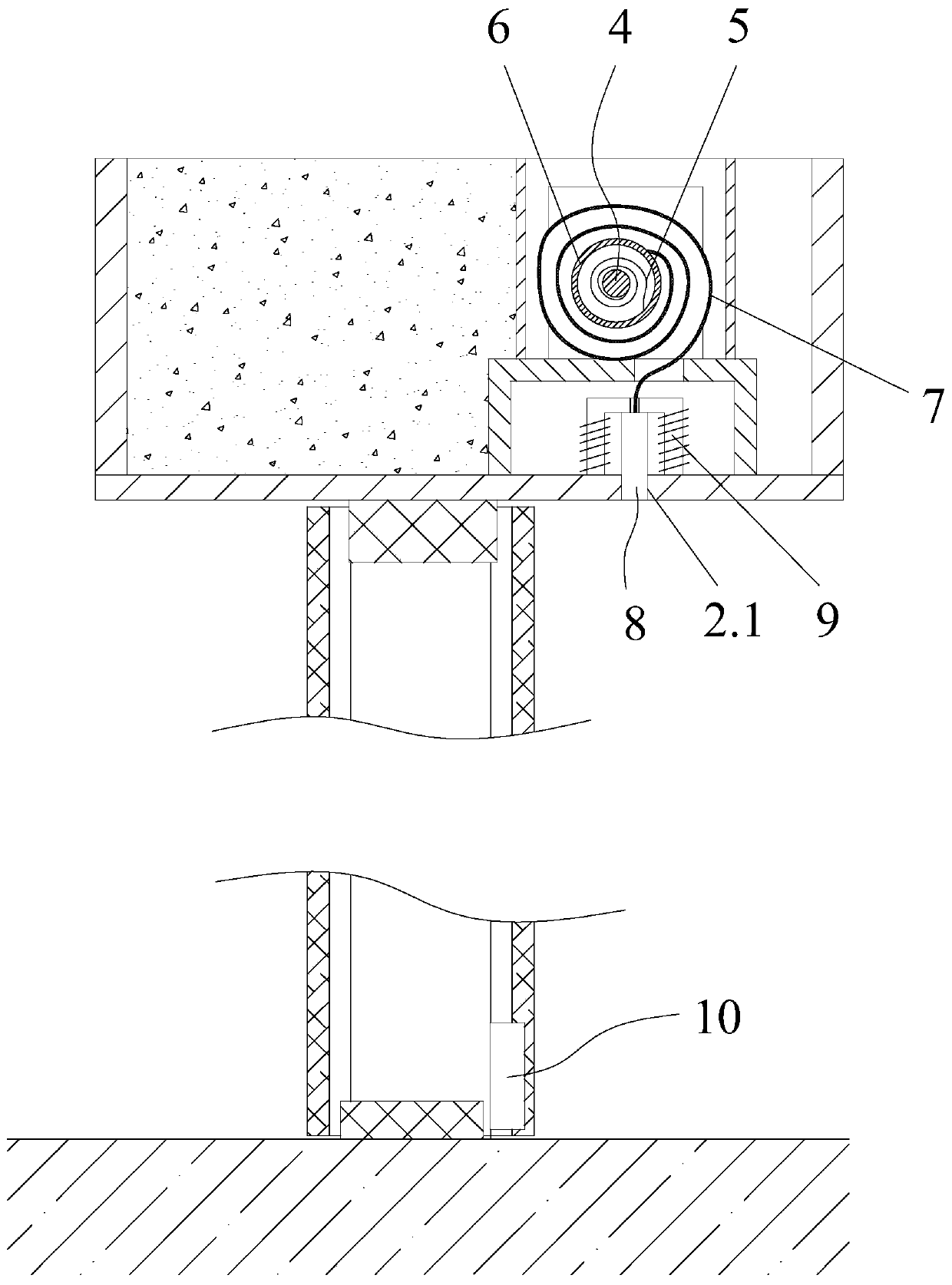

Tempered glass breaking device

ActiveCN104442672BBroken in timeTimely useVehicle arrangementsPedestrian/occupant safety arrangementEngineeringMechanical drive

The invention relates to improvement of a tempered glass breaking device. The tempered glass breaking device comprises a base relatively fixed with tempered glass to be broken, a breaking column used for exerting static pressure on a breaking face of the tempered glass is arranged on the base, the end, close to the tempered glass, of the breaking column is a working end, and a mechanical drive mechanism driving the breaking column to exert static pressure on the breaking face of the tempered glass is further arranged on the base. The mechanical structure is adopted, static pressure is used for quickly breaking the tempered glass, and strength for operating the device is little; in addition, the device and the tempered glass before breaking are relatively fixed, and the tempered glass can not be easily stolen.

Owner:黄志华

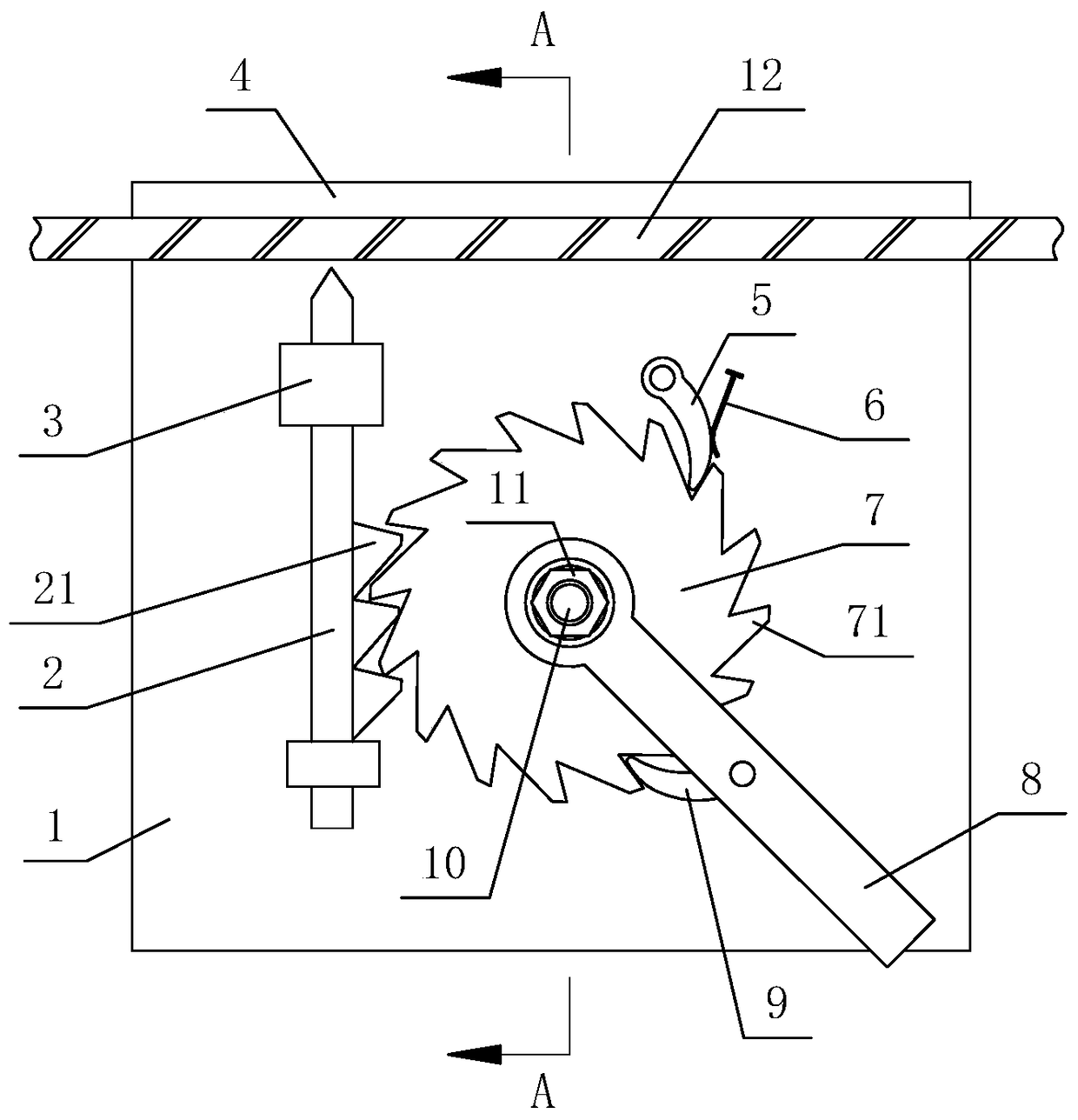

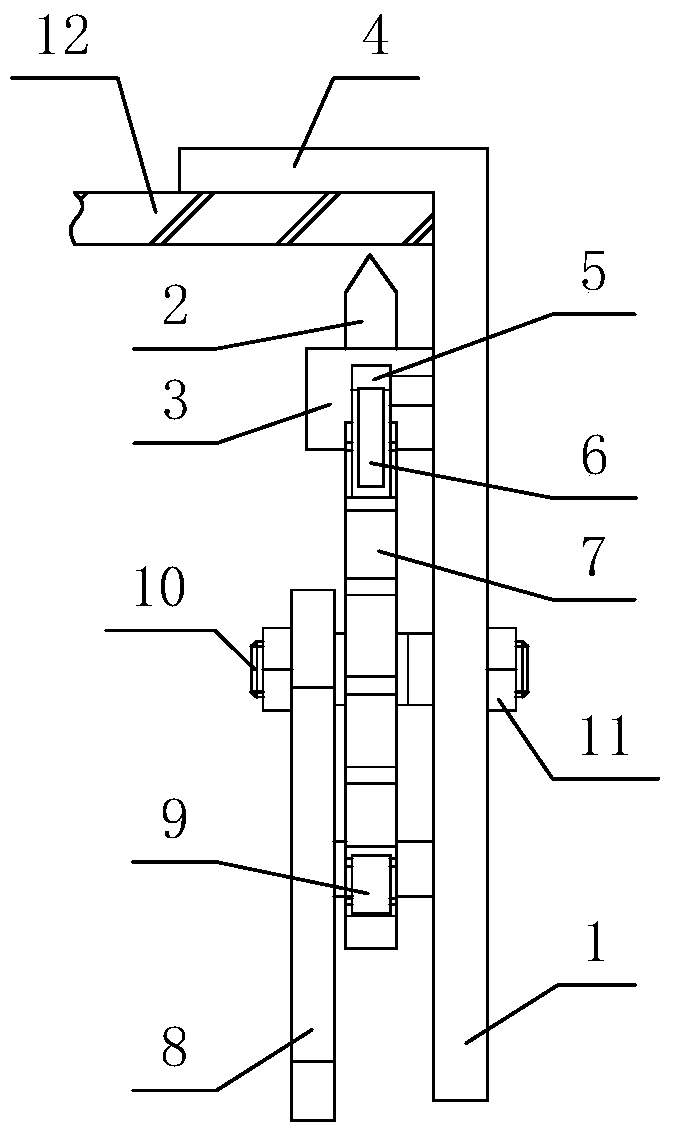

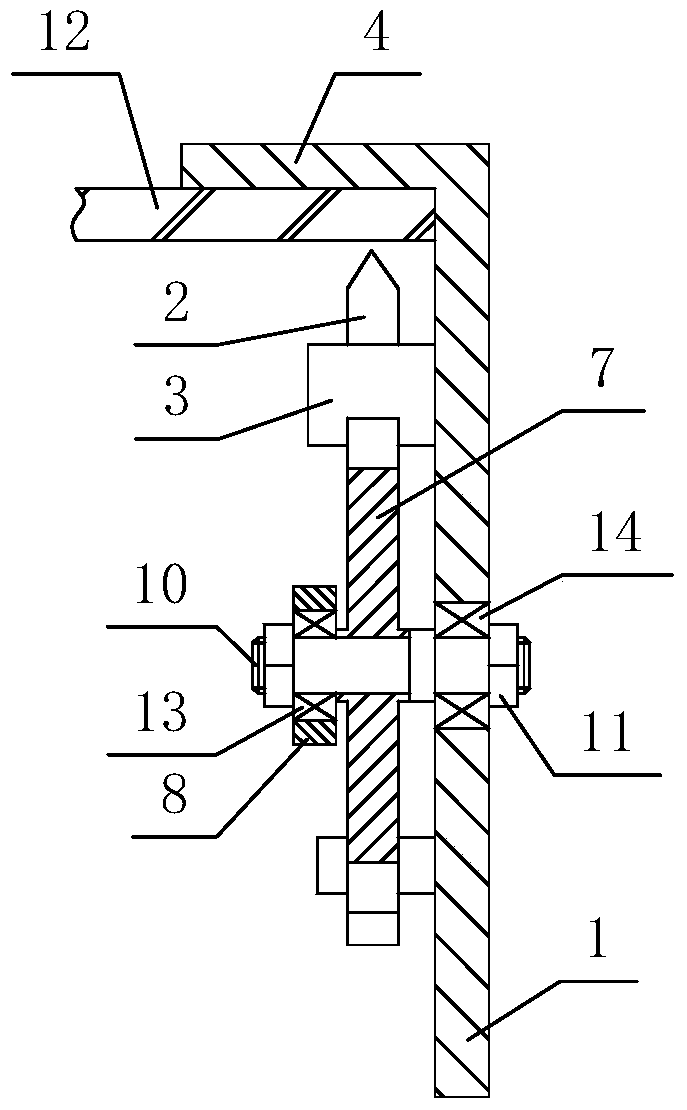

Garbage can with carton crushing function

PendingCN111634582ABroken in timeBroken stop in timePaper recyclingRefuse receptaclesSoftware engineeringCarton

The invention discloses a garbage can with a carton crushing function, and relates to the field of garbage crushers. The system comprises a box structure, a start mechanism and a power transmission mechanism. The arrangement of microswitches in the start mechanism can ensure that only when a garbage can cover and a carton scrap collection box are closed, can the garbage can perform crushing, so that high safety is achieved. The garbage can is relatively easy to operate, the masses can perform carton crushing on their own, the space occupied by cartons is reduced, and the collection rate is effectively increased. While the cost of subsequent recovery processing of carton garbage is reduced, personal information security is ensured, people's awareness of garbage classification and recovery is improved, and the progress of garbage classification in China is promoted.

Owner:CHINA JILIANG UNIV

A Self-healing Concrete Containment Shell Against Nuclear Radiation

InactiveCN105835466BHigh strengthIncrease elasticityNuclear energy generationSynthetic resin layered productsNuclear radiationSelf-healing

Owner:WUHAN UNIV

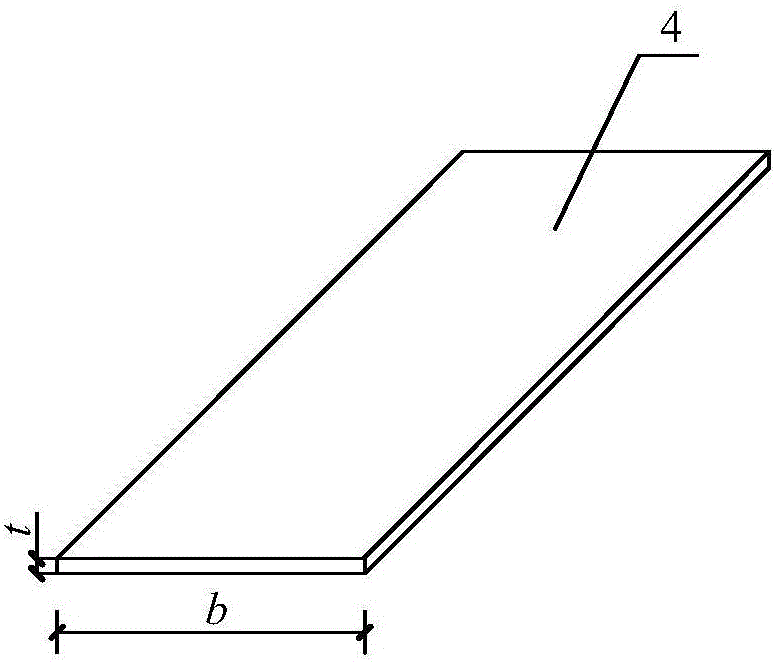

Anti-permeable tipping paper

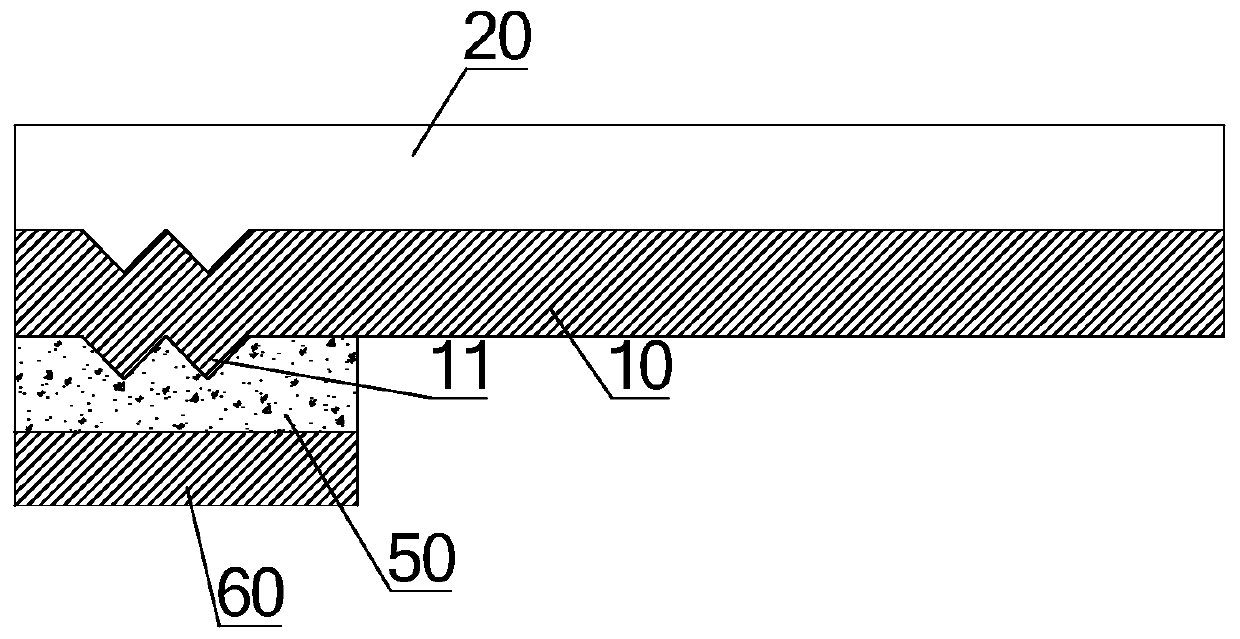

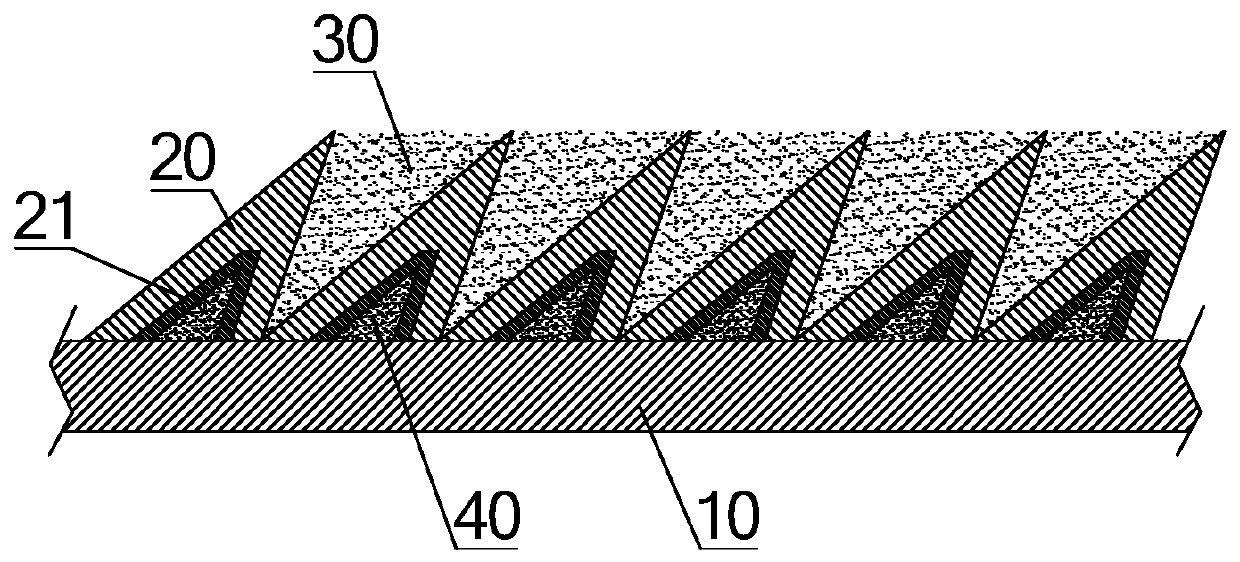

PendingCN110859319APrevent leakageBalance of abilitiesSurface covering paperCigar manufactureMechanical engineeringComposite material

The invention discloses an anti-permeable tipping paper. The anti-permeable tipping paper comprises a base layer prepared from tipping base paper, wherein a plurality of convex strips which extend inthe left-right direction are adhered to the upper surface of the base layer; the cross sections of the convex strips are triangular; at the same time, an upper sponge layer is filled in the upper gapsof the convex strips; a lower sponge layer is filled in the convex strips; the density of the upper sponge layer is smaller than that of the lower sponge layer; and the lower surfaces of the convex strips are coated with an anti-permeation resin layer. The anti-permeable tipping paper has the advantages of being suitable for being used in cooperation with a bead filter.

Owner:ANHUI TIANXIANG HIGH TECH SPECIAL PACKAGING MATERIALS GRP CO LTD

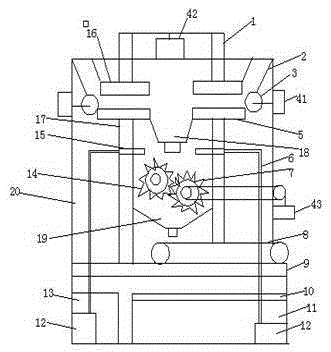

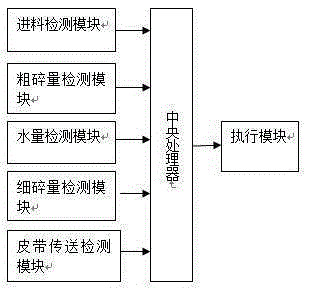

Control system of mine crusher

InactiveCN106807534ASmooth crushing processPrevents channel blockageGrain treatmentsControl systemEngineering

The invention discloses a control system of a mine crusher. The control system comprises detection modules, a central processing unit and an execution module. The detection modules comprise a feeding detection module for detecting the feeding amount, a coarse crushing amount detection module for detecting the coarse crushing amount of an outlet of a coarse crushing hopper, a water amount detection module for detecting the water spraying amount of cooling water, a fine crushing amount detection module for detecting the fine crushing amount of an outlet of a fine crushing hopper, and a belt conveying detection module for detecting the conveying speed of a conveyor belt. The central processing unit receives digital signals sent by the detection modules, processes the digital signals and sends execution signals to the execution module. The execution module receives the execution signals sent by the central processing unit, and controlling is carried out through an executer. The control system can detect the feeding speed and the discharging amount after two times of crushing in the use process of the crusher and can carry out controlling so that the crushing process can be smoothly carried out, the situation that crushing is insufficient and materials are stacked together is prevented, and the crushing efficiency is improved.

Owner:CHENGDU DESHANNENG TECH CO LTD

Rail road surface obstacle cleaning equipment

InactiveCN112376486APrevent deviationConducive to full protectionRailway cleaningGrain treatmentsStructural engineeringRoad surface

The invention discloses rail road surface obstacle cleaning equipment which comprises a positioning mechanism, a protection mechanism is fixedly connected to the middle of the sides, away from each other, of the positioning mechanism, a pocket plate is movably connected to the side, close to the positioning mechanism, of the protection mechanism, and an inclined guide block is arranged on the side, away from the protection mechanism, of the bottom of the pocket plate. A crushing mechanism is arranged in the middle of the pocket plate, a driving mechanism is movably connected to the side, closeto the positioning mechanism, of the crushing mechanism, and a mounting plate is movably connected to the side, away from the crushing mechanism, of the driving mechanism. The invention relates to the technical fields of rail road cleaning. Position change is carried out on small substances through flow guiding, equipment triggering is carried out through current generated by the deformation of the equipment, large substances are crushed and cleaned, the whole is driven through magnetic force and isolated from one another, the damage to a vehicle is avoided, and the whole safety of the equipment is protected.

Owner:殷欣澜

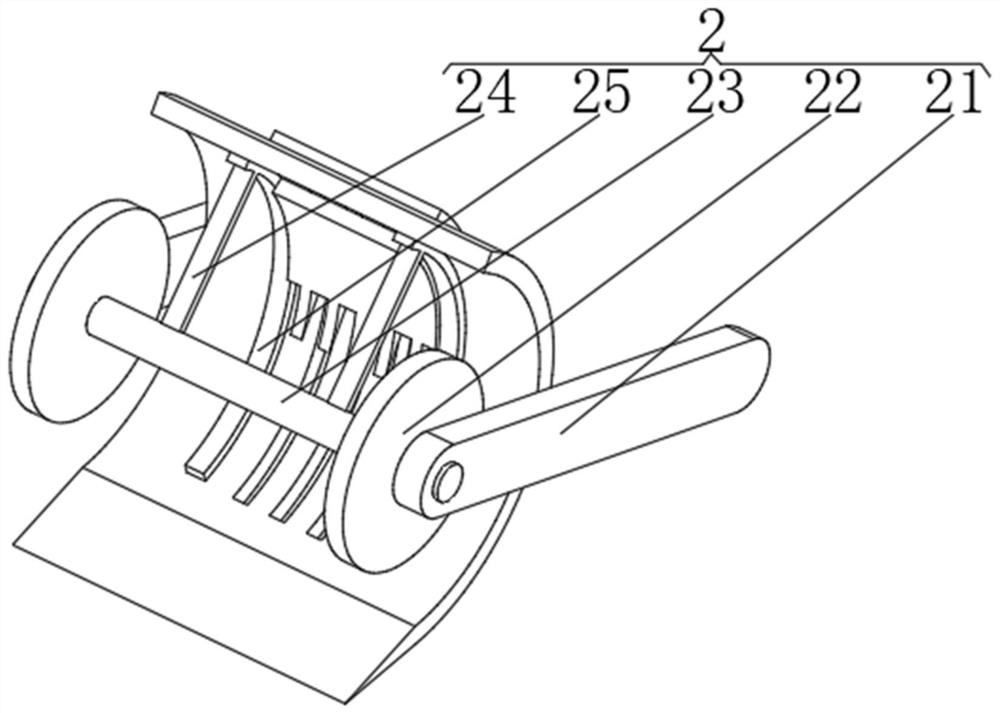

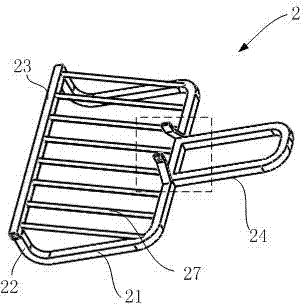

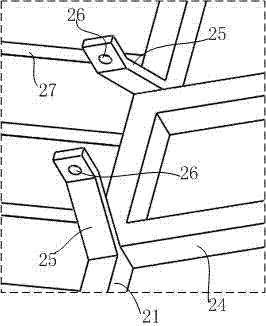

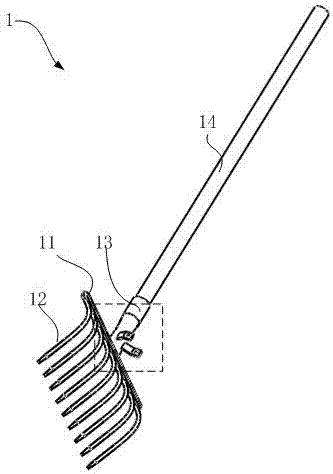

Soil loosener

InactiveCN107371388AReduce the force of entry into the groundSimple structureHand equipmentsStructural engineering

Owner:李欣泽

No-alburn rockwool sliver processing technique

ActiveCN101422935BTimely processingBroken in timeStone-like material working toolsPulp and paper industryMaterial resources

Owner:上海新型建材岩棉大丰有限公司 +1

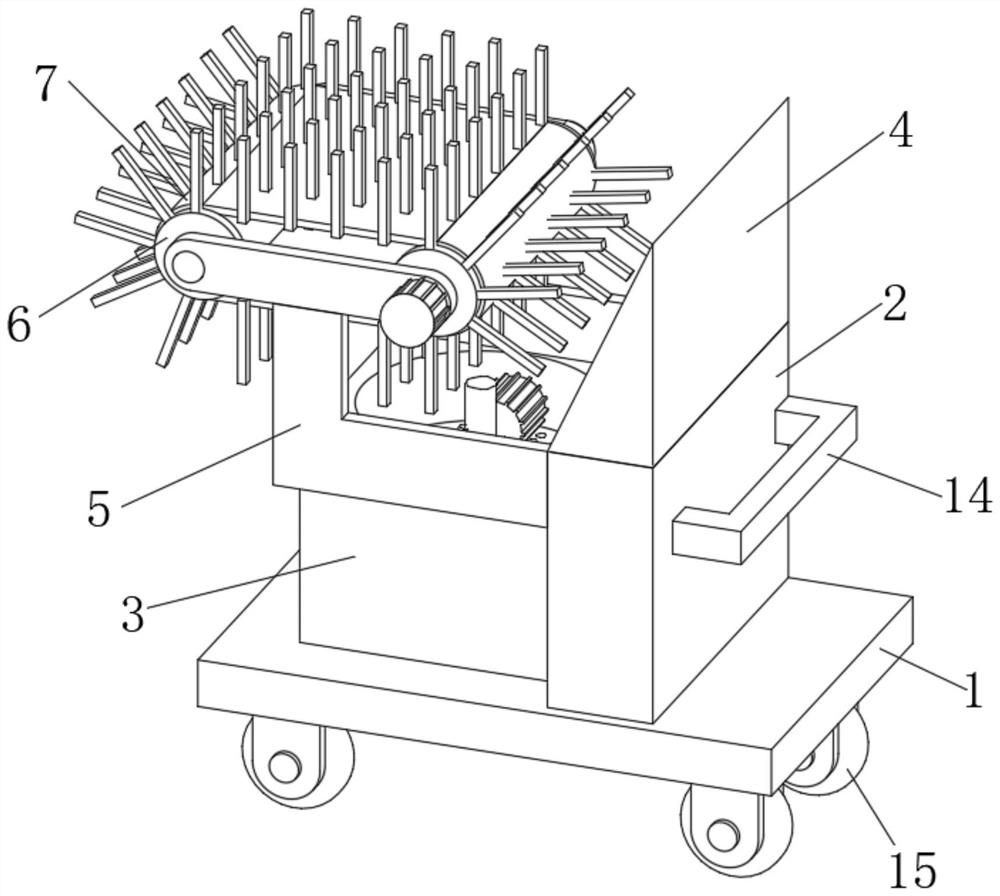

Aquatic plant treatment device for hydraulic engineering

InactiveCN112352773ABroken in timeSave storage spaceWeed killersGrain treatmentsFisheryHydraulic engineering

The invention discloses an aquatic plant treatment device for hydraulic engineering. The device comprises a base, a supporting plate and a crushing box are fixedly installed at the upper end of the base, a baffle is fixedly welded to the upper end of the supporting plate, the left end of the baffle is of a slope structure, and the two sides of the left end of the supporting plate are each fixedlyconnected with a supporting frame; a driving mechanism is jointly and movably connected between the two supporting frames, the outer surface of the driving mechanism is sleeved with a conveying sleeve, a handle is fixedly installed at the right end of the supporting plate, movable wheels are fixedly connected to the four corners of the lower end of the base correspondingly, and a crushing disc anda material guiding plate are fixedly connected in the crushing box; and a crushing mechanism is fixedly connected to the lower box wall in the crushing box, the crushing mechanism is movably connected with the crushing disc and the material guiding plate through bearings, and a material guiding groove is connected to one end of the crushing box in a penetrating manner. The aquatic plant treatmentdevice for the hydraulic engineering is high in stability, thorough in cleaning and capable of crushing aquatic plants in time, the storage space is reduced, and discharging is smooth.

Owner:周宁

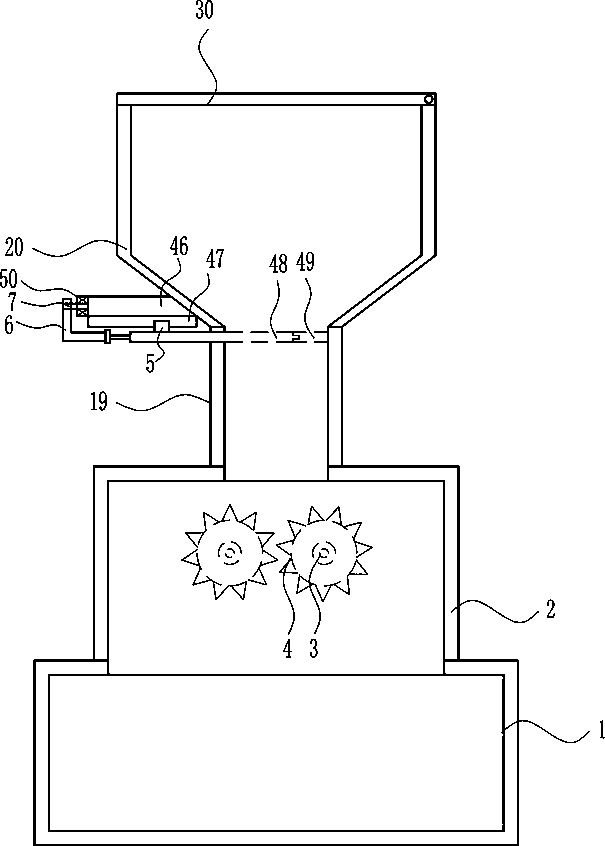

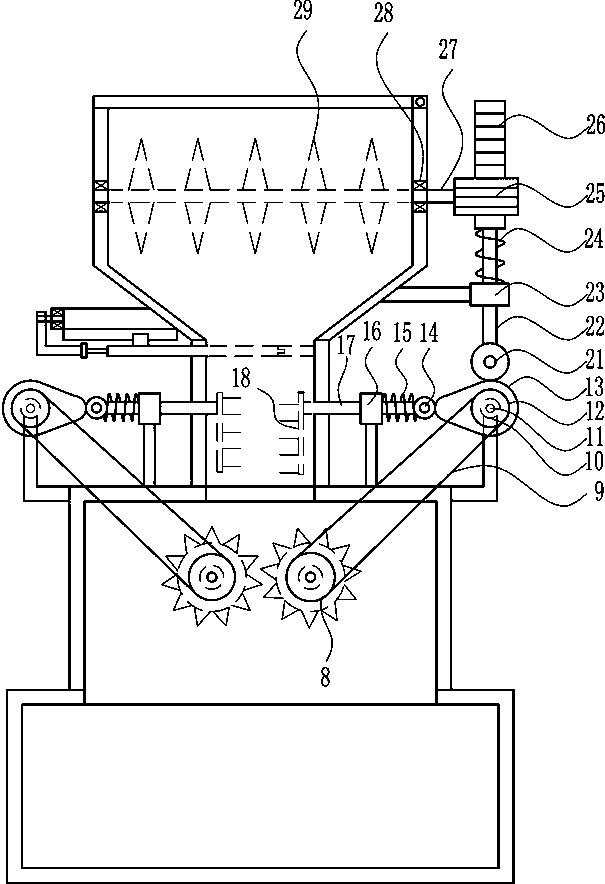

A high-temperature composting pretreatment equipment for urban environmental protection garbage

InactiveCN108212405BHigh pretreatment efficiencyThe pre-processing process is simpleClimate change adaptationOrganic fertilisersElectric machineryEnvironmental engineering

The invention relates to compost pretreatment equipment, in particular to rubbish high-temperature compost pretreatment equipment for city environmental protection. According to the technical aims, the rubbish high-temperature compost pretreatment equipment for city environmental protection is high in rubbish pretreatment efficiency, high in rubbish pretreatment degree and good in stage treatmenteffect. In order to achieve the above technical aims, the rubbish high-temperature compost pretreatment equipment for city environmental protection comprises a collecting box, a smashing groove, a motor, a smashing tooth barrel, a second sliding block, a clamping plate, a first rotating shaft, a cutting groove, a groove cover, a second sliding rail, a baffle and the like; and the smashing groove is installed at the upper portion of the collecting box, the cutting groove is installed at the upper portion of the smashing groove, and a soaking groove is installed at the upper portion of the cutting groove. The rubbish high-temperature compost pretreatment equipment achieves the effects that the rubbish pretreatment efficiency is high and the rubbish pretreatment degree is high, the follow-uprubbish composting is facilitated, and the composting effect is better.

Owner:JINAN JINNIU BIOTECH CO LTD

Tire smashing device

InactiveCN108527728AProtection lifetimeLow input costPlastic recyclingMechanical material recoveryElectric machineryInvestment cost

The invention discloses a tire smashing device. The device comprises a shell, a feeding port is formed in the upper part of the shell, a clamp is arranged above the feeding port, is connected with a third motor, and is connected with a rotating arm, the rotating arm is connected on the shell, a second motor is connected on the rotating arm, and is electrically connected with a button, and the button is located at the end parts of clamping jaws, and is used for controlling the second motor to stop the rotating arm from rotating; a plurality of smashing cylinders which are transversely arrangedside by side are rotationally connected in the shell, each smashing cylinder is in a circular truncated cone shape, the directions of the small-diameter ends on the adjacent smashing cylinders are opposite, criss-cross cutting edges are arranged on the outer walls of the smashing cylinders, and each smashing cylinder is hollow; and hollow supporting rods are arranged in the smashing cylinders, thetwo ends of the supporting rods are connected with the inner walls of the smashing cylinders, and impact pieces with the weak magnetism are arranged in the supporting rods. By adopting the technicalscheme, the service period of each smashing cylinder can be protected, the equipment investment cost can be reduced, a tire can also be fully smashed, and the working efficiency can be improved.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

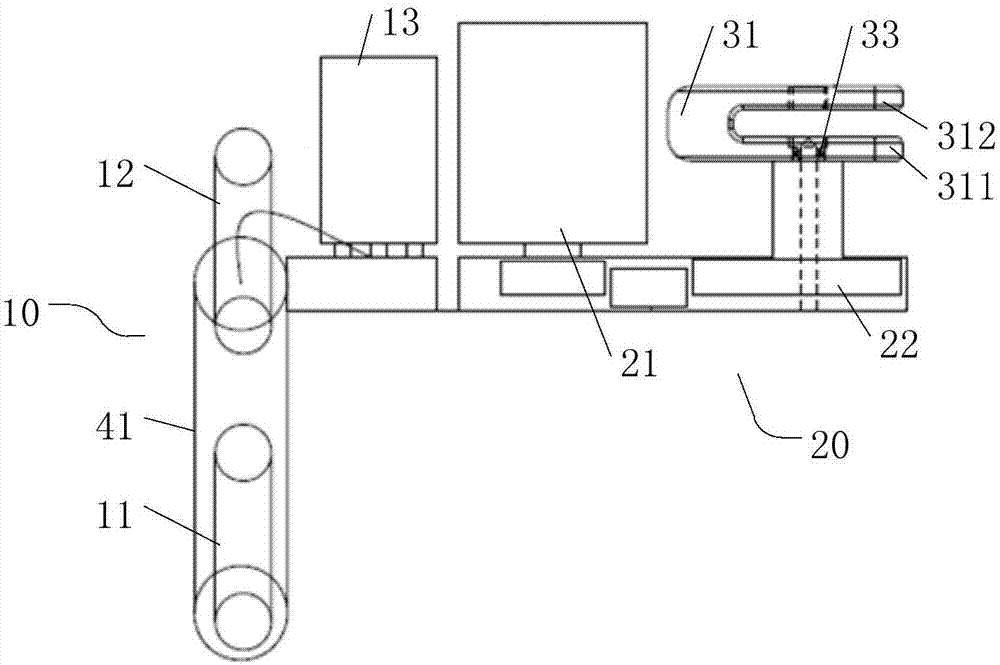

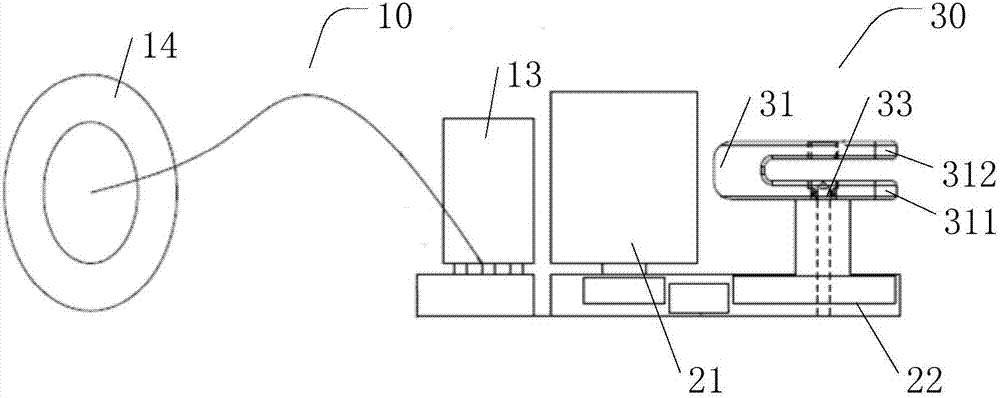

A rapid construction method for mechanical excavation of urban hard rock tunnels

ActiveCN108729924BSolve non-explosive construction problemsImprove applicabilityTunnelsRock tunnelMechanical engineering

The invention discloses a mechanical excavation and rapid construction method for an urban hard rock tunnel. The mechanical excavation and rapid construction method comprises the steps that accordingto the cross section shape of a tunnel, a multi-hole combined water-milling drilling machine is adopted for drilling and coring along the tunnel excavation contour line periphery so as to form a peripheral continuous free face of a tunnel contour line; the multi-hole combined water-milling drilling machine is continuously adopted for face drilling and coring in the sequence from periphery to center so as to make residual rock bodies in the tunnel face in shapes of sifters or multiple islets; an impact hammer device is adopted to impact and break the residual rock bodies in the tunnel face; anexcavating-shoveling work head is adopted to conduct mechanical residue removal and output on broken scattered rock blocks and rock residues. Preferably, the multi-hole combined water-milling drillingmachine and the impact hammer device are integrated on the same self-walking device. The mechanical excavation and rapid construction method has the advantages of achieving multi-hole drilling and coring, hydraulic impact and crushing and mechanical residue removal and output through the combined self-walking device, being high in mechanical degree, high in tunneling speed, high in tunneling efficiency and low in safety risk and needing few construction operators.

Owner:CRRC CONSTR ENG CO LTD

Glass breaking mechanism and automobile

PendingCN107985243AControl movementBroken in timePedestrian/occupant safety arrangementBuilding rescueElectrical and Electronics engineeringBreak the glass

The invention relates to a glass breaking mechanism and an automobile. The glass breaking mechanism can break a glass through an automatic sensing method so that people in a car can rescued by himselfor herself. The glass breaking mechanism comprises a sensing component, a driving component and a breaking component which are connected in order, wherein the sensing component is used for automatically sensing to open and control the driving component to drive the breaking component to move along the thickness direction of the glass, so as to break the glass.

Owner:王林中

No-alburn rockwool sliver processing technique

ActiveCN101422935ABroken in timeEasy to operateStone-like material working toolsPulp and paper industryMaterial resources

The invention provides a non-waste rock wool processing cutting technology, which is characterized in that the two ends of a cutting knife adopted in the processing technology are double blades; and when cutting is carried out, the double blades directly break the scrap into powder. The scrap produced in the processing is treated in time, the operation is simple and the manpower and the material resources are saved.

Owner:上海新型建材岩棉大丰有限公司 +1

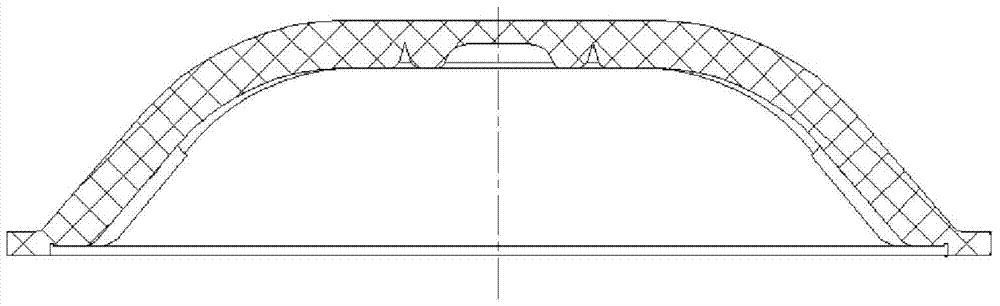

a breakable cover

ActiveCN104913692BBroken in timeGuaranteed crushing effectAmmunition storagePetroleum engineeringMissile

The invention discloses a frangible cover, the shape of which is a shell similar to the shape of a regular square prism, and the top surface of the outer wall is rounded in an arc-shaped chamfer shape, and the center of the top surface of the inner wall is provided with a ring-shaped stress groove. The four corners of the inner wall are provided with overall cross-shaped stress grooves, and the centers of the cross-shaped stress grooves and the ring-shaped stress grooves coincide. The friable cover of the invention can be broken according to the regular positive center of the cross-shaped stress grooves, without damaging the warhead of the missile, and the breaking process is stable and reliable.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com