A high-temperature composting pretreatment equipment for urban environmental protection garbage

A high-temperature composting and pretreatment technology, applied in grain treatment, organic fertilizer, climate change adaptation, etc., can solve the problems of long processing time, large labor force, no graded treatment, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

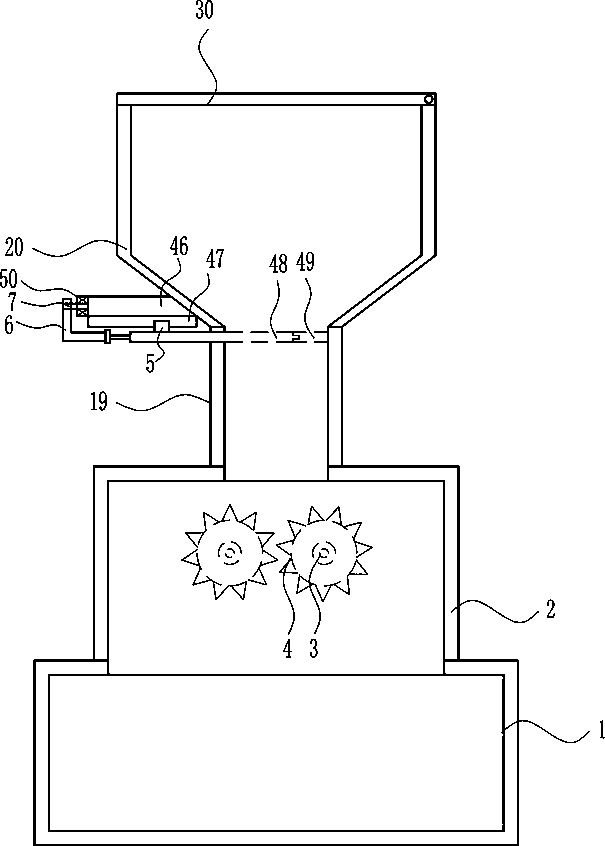

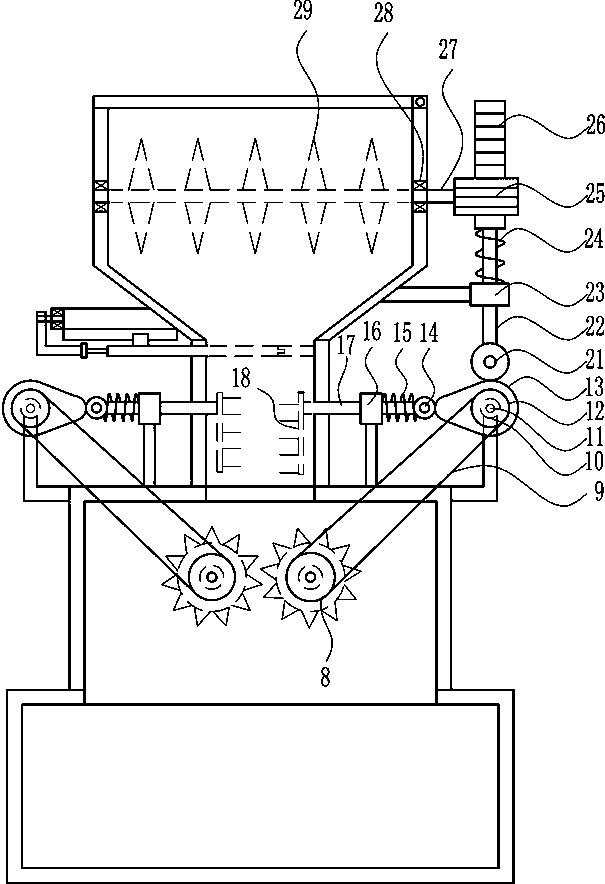

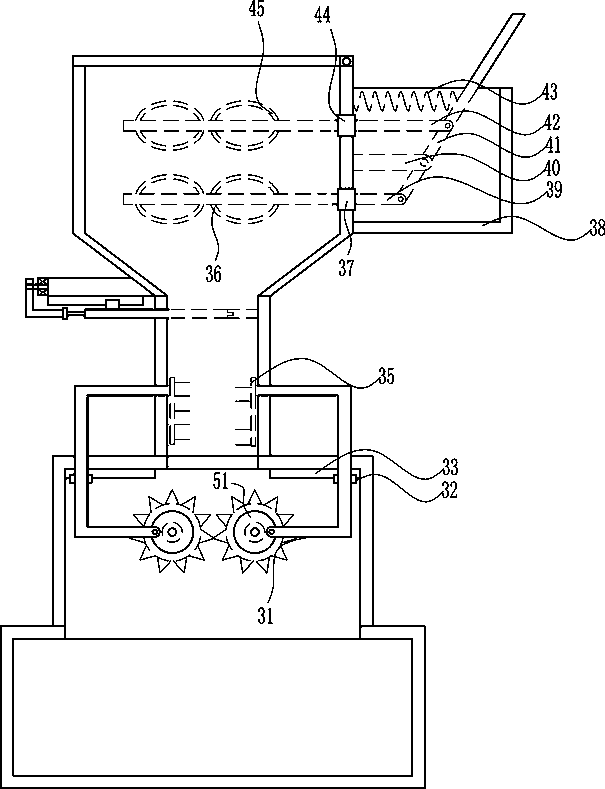

[0028] A kind of high-temperature composting pretreatment equipment for urban environmental protection garbage, such as Figure 1-3 As shown, it includes a collection box 1, a crushing tank 2, a motor 3, a crushing gear cylinder 4, a second slider 5, a clamping plate 6, a first rotating shaft 7, a cutting groove 19, a groove cover 30, a second slide rail 47, Baffle plate 48, fixed plate 49 and first bearing 50, collection box 1 upper part is equipped with broken tank 2, broken tank 2 upper part is equipped with cutting tank 19, and cutting tank 19 upper part is equipped with soaking tank 20, soaking tank 20 is connected by hinges The tank cover 30 is connected in the same way, the motor 3 is installed from the left and right sides at the rear of the crushing tank 2, the crushing gear cylinder 4 is installed on the motor 3, the crushing gear cylinder 4 is located in the crushing tank 2, and the left side of the soaking tank 20 is installed with a support Plate 46, a second slid...

Embodiment 2

[0030] A kind of high-temperature composting pretreatment equipment for urban environmental protection garbage, such as Figure 1-3 As shown, it includes a collection box 1, a crushing tank 2, a motor 3, a crushing gear cylinder 4, a second slider 5, a clamping plate 6, a first rotating shaft 7, a cutting groove 19, a groove cover 30, a second slide rail 47, Baffle plate 48, fixed plate 49 and first bearing 50, collection box 1 upper part is equipped with broken tank 2, broken tank 2 upper part is equipped with cutting tank 19, and cutting tank 19 upper part is equipped with soaking tank 20, soaking tank 20 is connected by hinges The tank cover 30 is connected in the same way, the motor 3 is installed from the left and right sides at the rear of the crushing tank 2, the crushing gear cylinder 4 is installed on the motor 3, the crushing gear cylinder 4 is located in the crushing tank 2, and the left side of the soaking tank 20 is installed with a support Plate 46, a second slid...

Embodiment 3

[0033] A kind of high-temperature composting pretreatment equipment for urban environmental protection garbage, such as Figure 1-3 As shown, it includes a collection box 1, a crushing tank 2, a motor 3, a crushing gear cylinder 4, a second slider 5, a clamping plate 6, a first rotating shaft 7, a cutting groove 19, a groove cover 30, a second slide rail 47, Baffle plate 48, fixed plate 49 and first bearing 50, collection box 1 upper part is equipped with broken tank 2, broken tank 2 upper part is equipped with cutting tank 19, and cutting tank 19 upper part is equipped with soaking tank 20, soaking tank 20 is connected by hinges The tank cover 30 is connected in the same way, the motor 3 is installed from the left and right sides at the rear of the crushing tank 2, the crushing gear cylinder 4 is installed on the motor 3, the crushing gear cylinder 4 is located in the crushing tank 2, and the left side of the soaking tank 20 is installed with a support Plate 46, a second slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com