Food waste hydrolysis acidifying reactor

A technology for hydrolyzing acidification and kitchen waste, which is applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc. It can solve the problems that cannot meet the requirements of acidification and hydrolysis reaction, so as to simplify the pretreatment process and reduce equipment investment , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

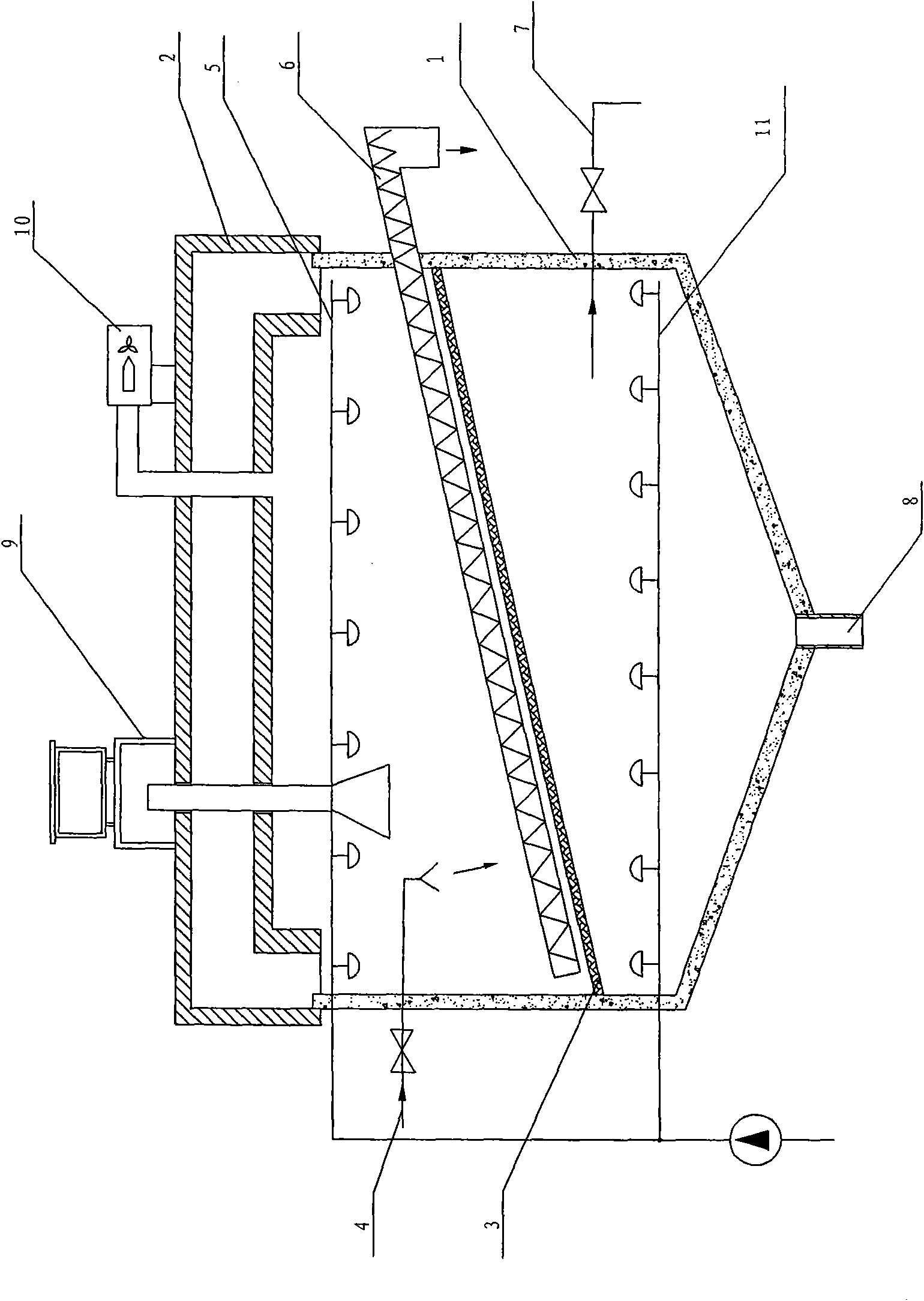

[0016] refer to figure 1 , a food waste hydrolysis acidification reactor, comprising a hydrolysis pool 1 and a top cover 2 arranged thereon. A mesh screen 3 is arranged obliquely in the hydrolysis tank 1, a feeding device 4 is arranged on the top of the hydrolysis tank 1, and a slag discharge device 6 and a liquid discharge device 7 are respectively arranged on the upper and lower sides of the hydrolysis tank corresponding to the mesh screen 3; 1 has a funnel-shaped bottom, and is provided with a sand outlet 8 at the bottom; a water filling device 11 is provided at the bottom of the hydrolysis tank. The top cover 2 has an inner and outer double-layer structure, and an oil collector 9 and an exhaust device 10 are arranged between the inner and outer layers; the lower part of the top cover 2 and the upper part of the hydrolysis tank 1 are provided with a spray device 5 .

[0017] Among them, the body of the hydrolysis tank 1 is a rectangular reinforced concrete structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com