New method for analyzing non-conductor material by utilizing glow discharge mass spectrum

A glow discharge mass spectrometry, non-conductor technology, applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of unsatisfactory signal-to-noise ratio, poor discharge stability, narrow application range, etc., and achieve good discharge stability and analysis repeatability, easy operation, and ideal signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

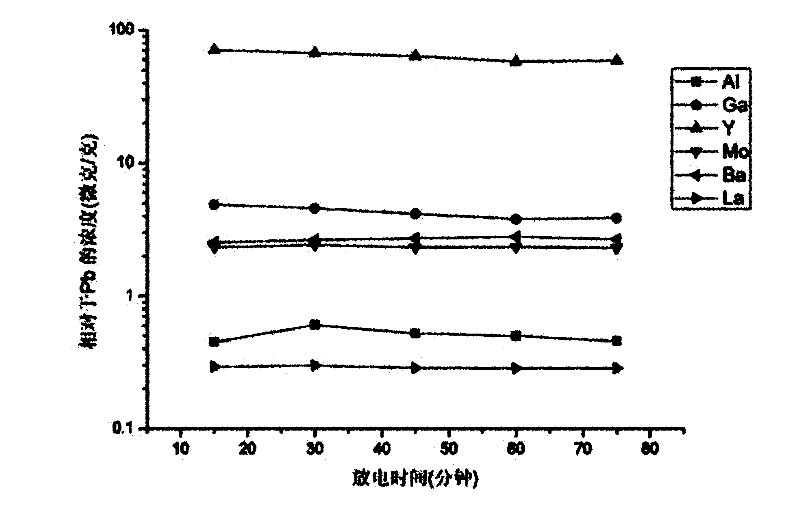

[0037] Under normal pressure, the lead tungstate (PWO) to be analyzed is processed into a small strip sample with a size of 18mm×2mm×2mm; 3 ) and ultrapure water, ultrasonically cleaned in a mixed solution of ultrapure water, then ultrasonically twice in ultrapure water, finally washed with ethanol, and dried; put metal indium into a quartz crucible and heat it to melt, and then keep it warm at 150°C to 155°C ℃; Use polytetrafluoroethylene tweezers or metal nickel tweezers to pick up the sample and put it into a quartz crucible filled with molten indium. After the molten indium forms a continuous smooth metal indium film on the outer layer of the sample (the film thickness is 10 μm, the film area is 2 / 3 of the surface area of the sample), take out the sample, and cool it down; 3 ) and ultrapure water for ultrasonic cleaning, then ultrasonically twice in ultrapure water, finally washed with ethanol, and dried; the sample was put into the dc-GD-MS needle sample cell for analys...

Embodiment 2

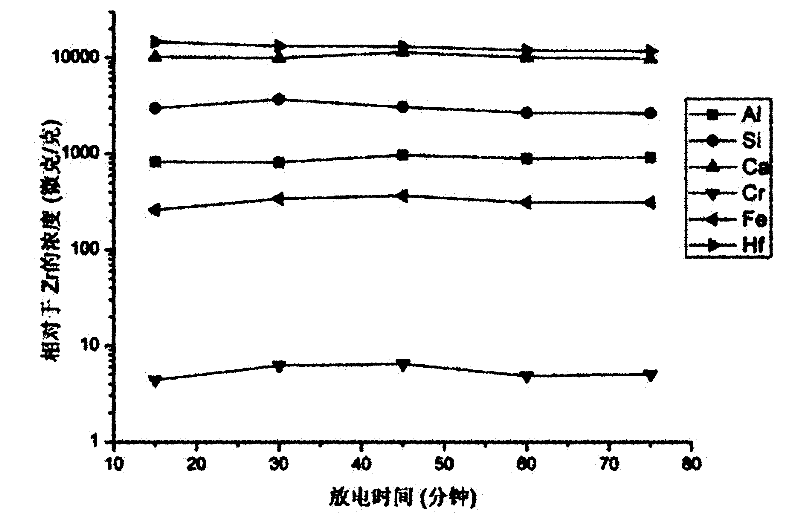

[0045] Under normal pressure, the zirconia (ZrO 2 ) processed into small strip samples with a size of 18mm×2mm×2mm; 3 ) and ultrapure water, ultrasonically cleaned in a mixed solution of ultrapure water, then ultrasonically twice in ultrapure water, finally washed with ethanol, and dried; put metal indium into a quartz crucible and heat it to melt, and then keep it warm at 150°C to 155°C ℃; Use polytetrafluoroethylene tweezers or metal nickel tweezers to pick up the sample and put it into a quartz crucible filled with molten indium. After the molten indium forms a continuous smooth metal indium film on the outer layer of the sample (the film thickness is 10 μm, the area is 2 / 3 of the surface area of the sample), take out the sample, and cool it down; 3 ) and ultrapure water, ultrasonically cleaned in ultrapure water twice, and finally washed with ethanol and dried; the sample was put into the dc-GD-MS needle sample cell for analysis, and the discharge voltage was 1.0kV, th...

Embodiment 3

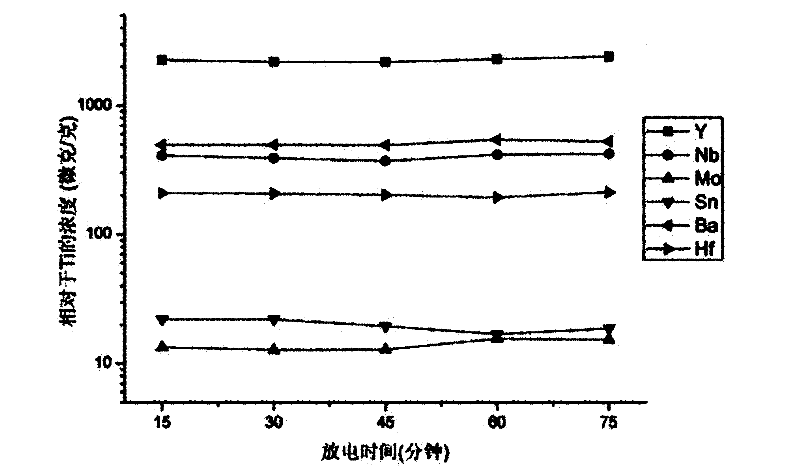

[0053] Under normal pressure, the lanthanum titanate (La 2 Ti 2 o 7 ) processed into small strip samples with a size of 18mm×2mm×2mm; 3 ) and ultrapure water, ultrasonically cleaned in a mixed solution of ultrapure water, then ultrasonically twice in ultrapure water, finally washed with ethanol, and dried; put metal indium into a quartz crucible and heat it to melt, and then keep it warm at 150°C to 155°C ℃; Use polytetrafluoroethylene tweezers or metal nickel tweezers to pick up the sample and put it into a quartz crucible filled with molten indium. After the molten indium forms a continuous smooth metal indium film on the outer layer of the sample (the film thickness is 10 μm, the film area is 2 / 3 of the surface area of the sample), take out the sample, and cool it down; 3 ) and ultrapure water for ultrasonic cleaning, then ultrasonically twice in ultrapure water, finally washed with ethanol, and dried; the sample was put into the dc-GD-MS needle sample cell for analysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com