Anticorrosion treatment process for converting/electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys

A technology of aluminum alloy surface and conversion treatment, which is applied in the coating process of metal materials, the device for coating liquid on the surface, the coating, etc., to achieve the effects of simple configuration, good corrosion resistance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

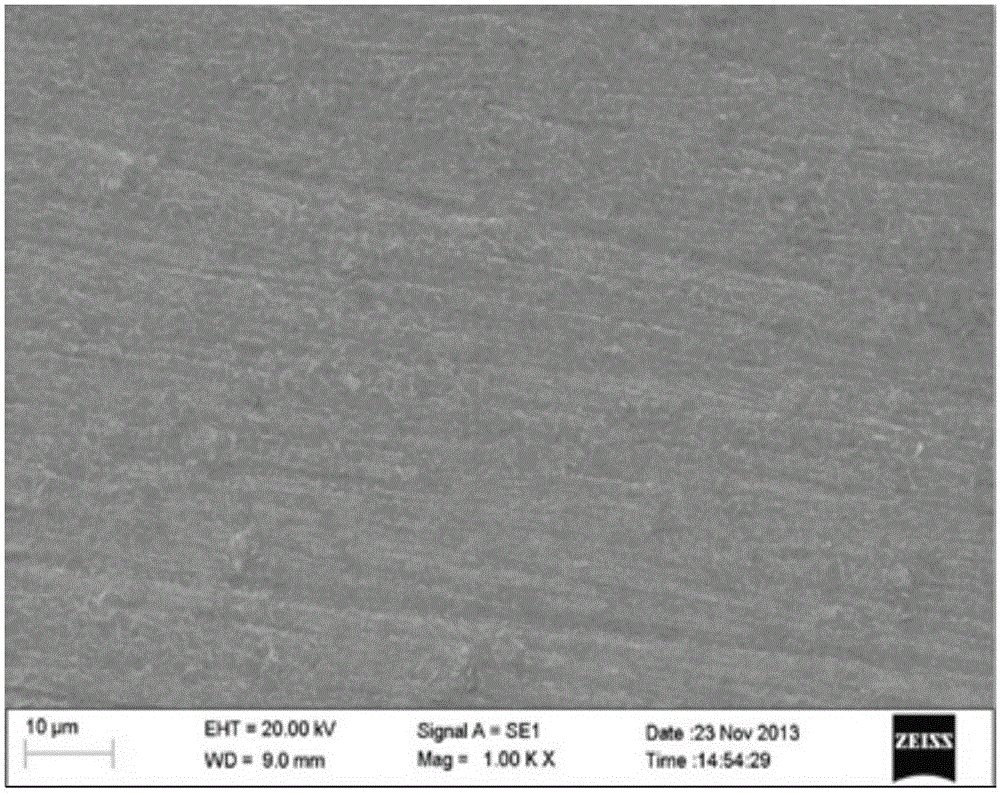

Image

Examples

Embodiment 1

[0037] An anticorrosion treatment process of an aluminum alloy surface (6063 aluminum alloy surface) environment-friendly titanium-zirconium conversion treatment / electrostatic spraying, comprising the following steps:

[0038] (1) Sample preparation: 30mm × 30mm × 2mm aluminum sheets were cut from the 6063 aluminum alloy on-line. Each sample was punched at the corner, and the aluminum alloy surface was polished to 1200# with sandpaper, and rinsed with tap water and blown. Dry, hang with a thin wire at the hole;

[0039] (2) Pretreatment: Suspend the 6063 aluminum alloy sample in industrial acid and soak for 1.5min to degrease, rinse with tap water, then soak in mixed acid for 3min for activation treatment, and rinse with tap water; The composition is 80g / LH 2 SO 4 , 25g / LH 3 PO 4 , 10g / LHF, 0.5g / LOP-10 emulsifying agent, solvent is water; The composition of described mixed acid is 15g / LHNO 3 , 20g / LH 3 PO 4 , 25g / LH 2 SO 4 , the solvent is water;

[0040] (3) Treatme...

Embodiment 2

[0051] An environmentally friendly titanium-zirconium conversion film is prepared on the surface of industrial pure aluminum, and electrostatic spraying is carried out after drying. The process of preparing conversion coating and spraying in this example is the same as that of Example 1, except that industrial pure aluminum is used instead of 6063 aluminum alloy in this example.

[0052] The titanium-zirconium film on the aluminum plate on the surface of industrial pure aluminum obtained in Example 2 presents a uniform yellow color, and the organic coating covering it is uniform and bright black, and the film thickness of the titanium-zirconium film measured by an eddy current thickness gauge is 2 ~3μm, coating thickness is 60μm. The organic coating on the aluminum plate on the surface of industrial pure aluminum obtained in Example 2 is resistant to neutral salt spray corrosion for 700 hours. Using a 100-grid knife to conduct cross-cut tests under dry conditions and boiling ...

Embodiment 3

[0054] An anticorrosion treatment process of an aluminum alloy surface (6063 aluminum alloy surface) environment-friendly titanium-zirconium conversion treatment / electrostatic spraying, comprising the following steps:

[0055] (1) Sample preparation: Cut the 6063 aluminum alloy into 100mm×100mm×2mm aluminum sheets, punch holes in the corners of each piece, rinse with tap water and dry them, and hang them with iron wires for later use;

[0056] (2) Pretreatment: Suspend the 6063 aluminum alloy sample in industrial acid and soak for 2min to degrease, rinse with tap water, then soak in mixed acid for 3min for activation treatment, and rinse with tap water; the composition of the industrial acid 100g / LH 2 SO 4 , 20g / LH 3 PO 4 , 6g / LHF, 0.3g / LOP-10 emulsifier, solvent is water; The composition of described mixed acid is 20g / LHNO 3 , 19g / LH 3 PO 4 , 20g / LH 2 SO 4 , the solvent is water;

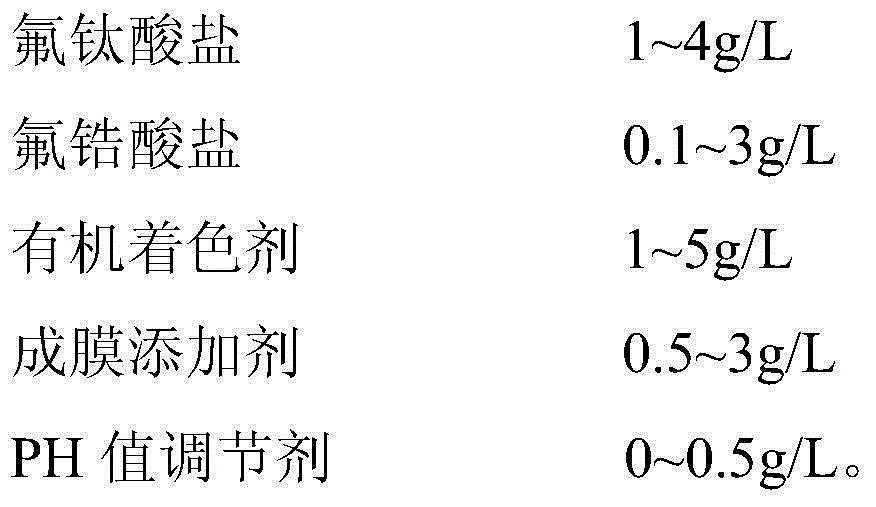

[0057] (3) Treatment solution preparation: prepare 200mL titanium-zirconium conversion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com