Patents

Literature

73 results about "Zirconium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

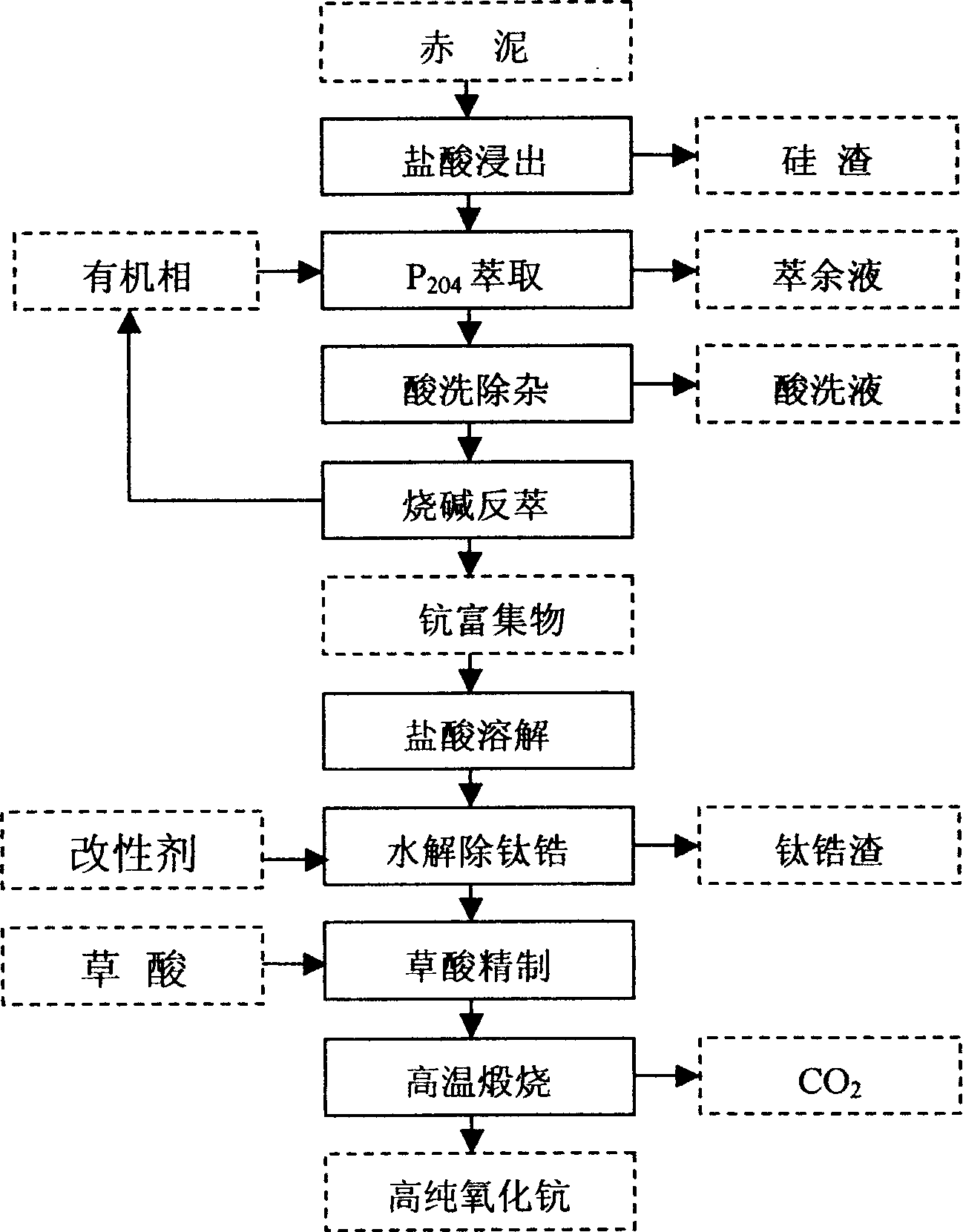

Method for extracting scandium from red mud

InactiveCN1844421AImprove protectionSimple processProcess efficiency improvementRed mudDecomposition

The invention relate to a method of extracting scandium from red mud, the method utilize the red mud that come from the process of producing aluminum oxide from alumyte, in accordance with specific characteristics of red mud, applying hydrochloric acid leach, P204 abstraction, acid-washing edulcoration, sodium-hydroxide back extraction, ammonia modifier hydrolytic decomposition zirconium and titanate in hydrochloric acid solution, oxalic acid precipitating scandium and medium temperature calcining technique, the purity of final production Sc2O3 is 99.9%. Extracting scandium from red mud change refuse into available material, save mineral resources, benefiting environmental conservation. The invention also fills up the study vacant of isolation technique in high-strength zirconium titanate and scandium.

Owner:汪友华

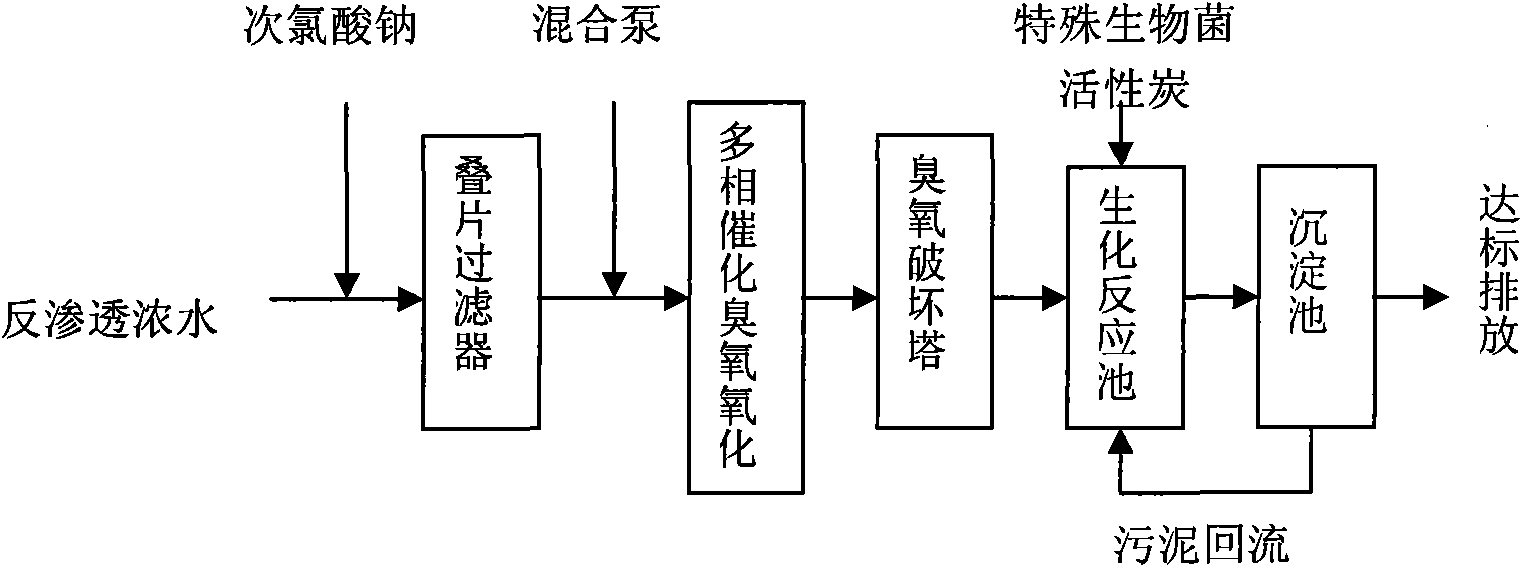

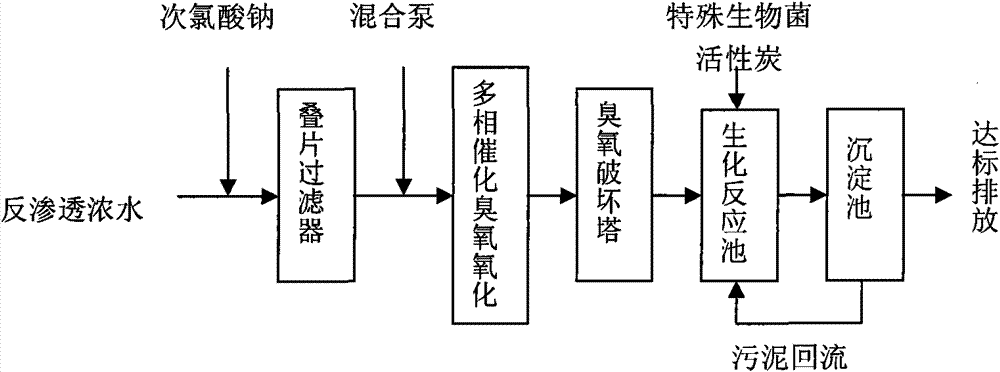

Method for treating reverse osmosis concentrated water

ActiveCN102040312AImprove biodegradabilityMultistage water/sewage treatmentSodium chlorateChemical oxygen demand

The invention provides a method for treating reverse osmosis concentrated water. In the method, the process flows of a laminated filter, heterogeneous catalytic ozone oxidation reaction, an ozone destruction tower and a biochemical reaction tank are adopted. The method comprises the following steps of: adding sodium hypochlorite into the reverse osmosis concentrated water produced in the recycling process of oil refining production wastewater subjected to biochemical treatment and membrane process treatment, sterilizing, filtering by using the laminated filter, fully mixing with ozone, adding into a reactor filled with a zirconium titanate catalyst and performing ozone oxidation; and performing biochemical treatment by using a biochemical reactor with special biological bacteria, wherein the chemical oxygen demand (COD) of effluent after the reverse osmosis concentrated water is treated is below 60mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment solution for preparing aluminum alloy surface amorphous composite passivation film, preparation method and application

InactiveCN101892477ASimple recipeSimple processMetallic material coating processesRare earthManganese

The invention discloses treatment solution for preparing an aluminum alloy surface amorphous composite passivation film, a preparation method and application. A formula of the treatment solution comprises 5 to 15g / L of corrosion inhibiting negative ion-containing rare earth salt, 3 to 10g / L of catalyst type composite oxidant, 1 to 3g / L of auxiliary oxidant, 0.1 to 0.5g / L of buffering film-forming accelerator and 0.5 to 1.5g / L of composite stabilizer. The treatment solution does not contain any toxic chromium or organic substances, does not need heating during conversion treatment of 2 to 5 minutes, and can prepare the golden amorphous 'rare earth-manganese' composite passivation film with excellent performance on the aluminum alloy surface. The treatment solution well solves environmental pollution and human harm caused by the present hexavalent chromium treatment, and can overcome the defects that a zirconium titanate series conversion film is colorless and field judgment cannot be realized. The preparation method has the advantages of simple process, simple and convenient operation and low cost, and is easy to realize industrialization.

Owner:SOUTH CHINA UNIV OF TECH

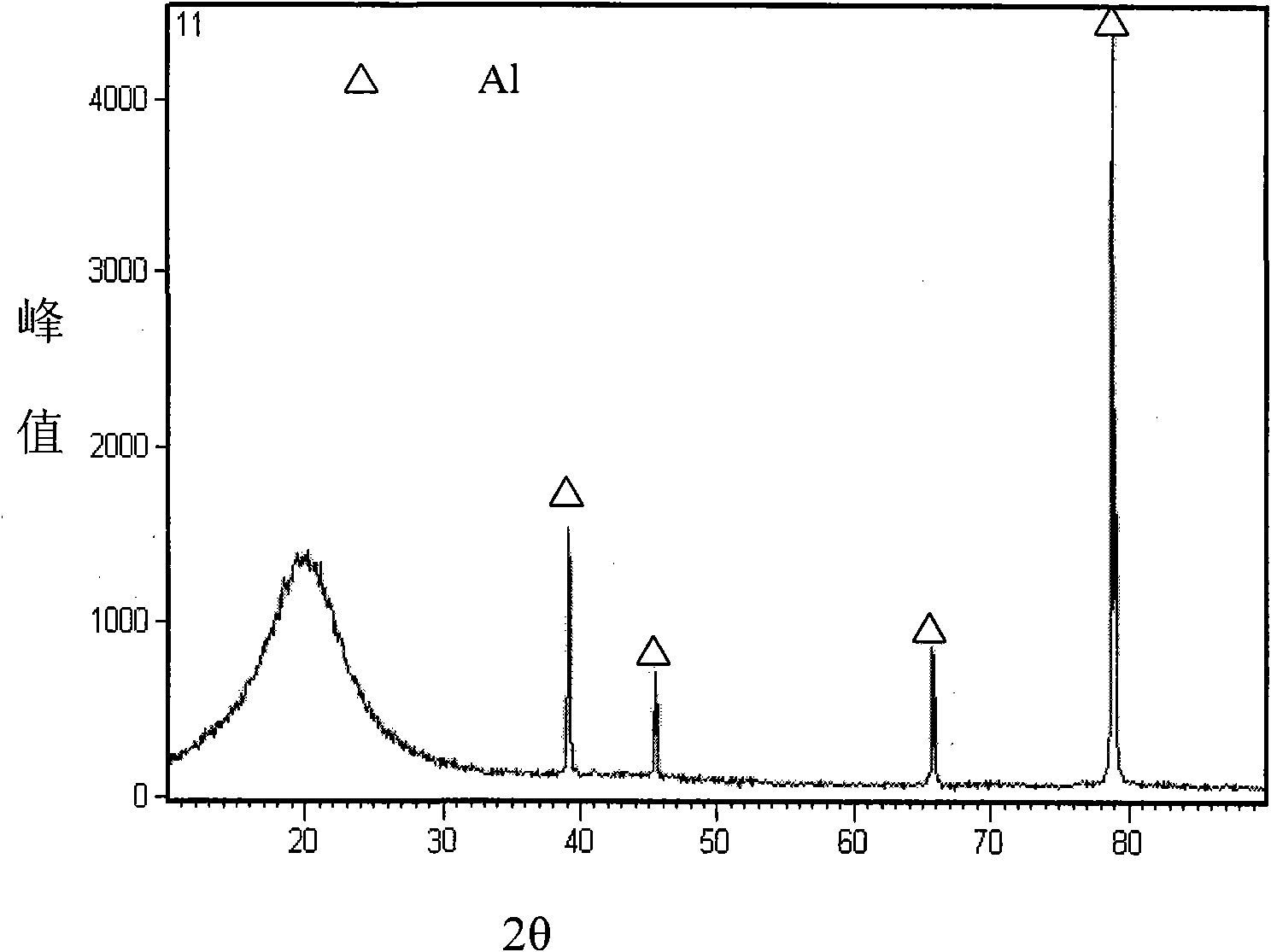

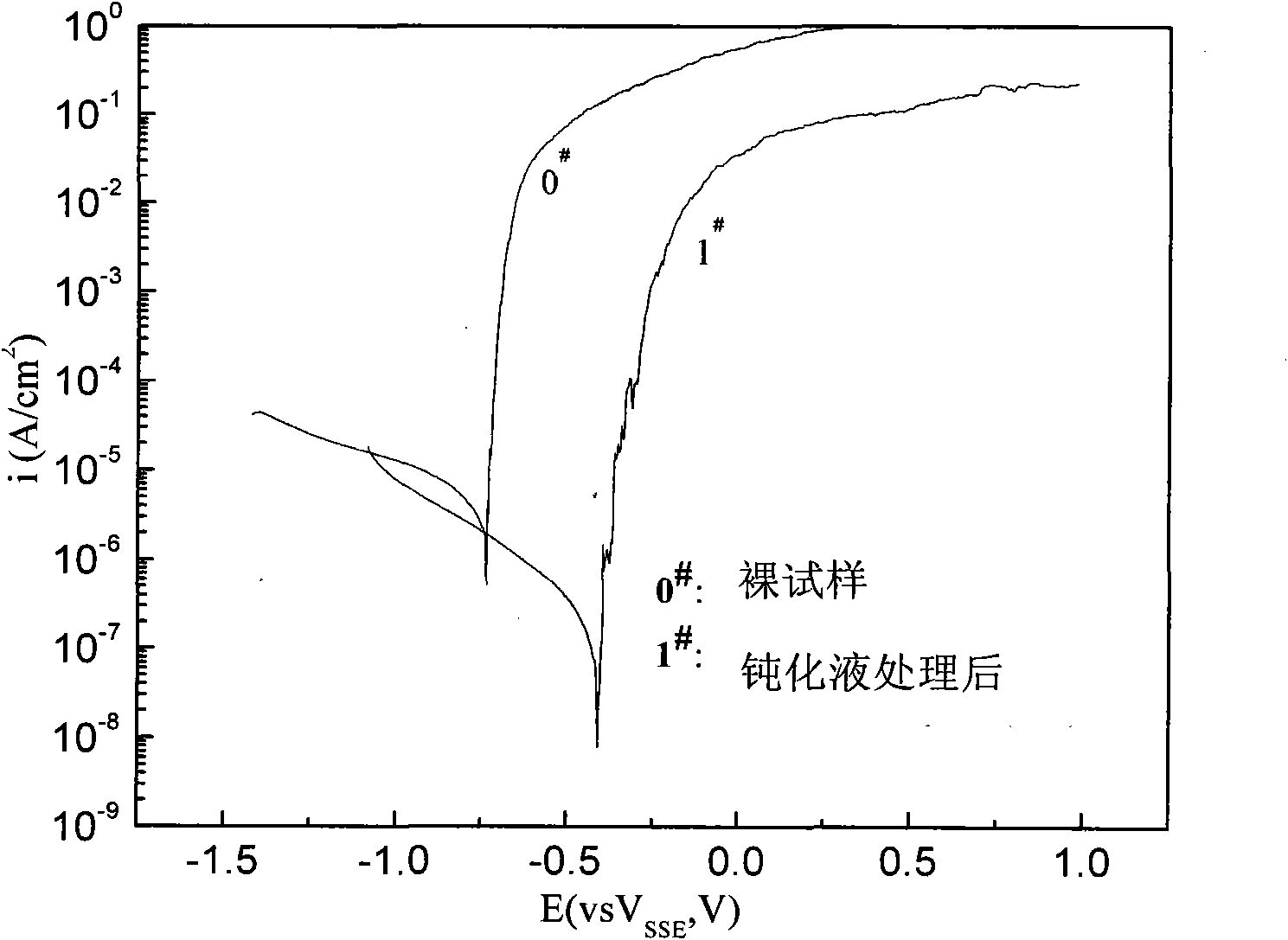

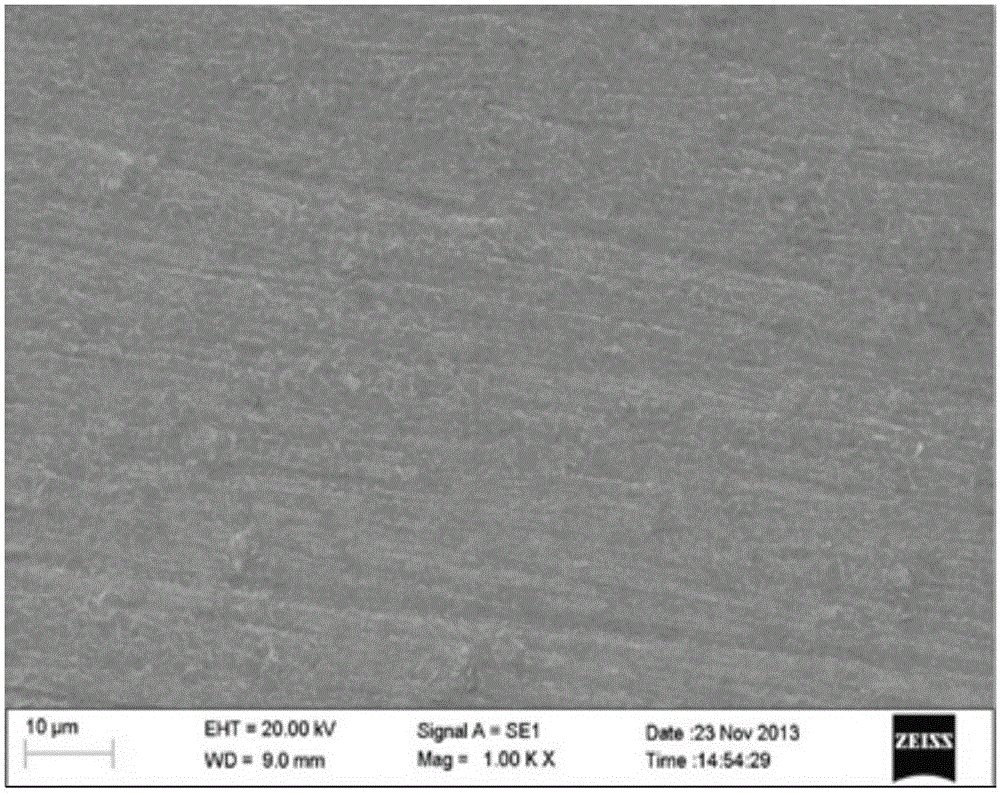

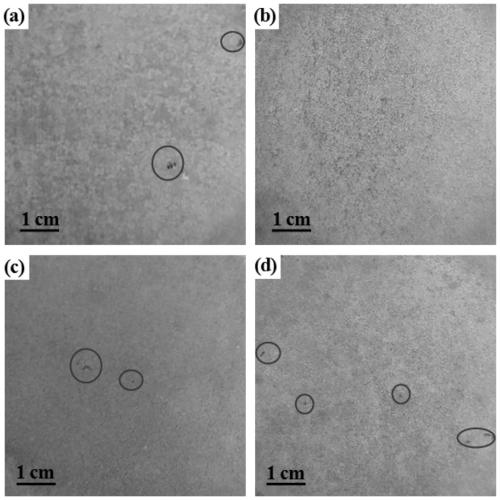

Anticorrosion treatment process for converting/electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys

ActiveCN105132900AEasy to operateLow film forming temperatureLiquid surface applicatorsMetallic material coating processesCompound (substance)Titanium

The invention belongs to the technical field of chemical materials and discloses an anticorrosion treatment process for converting / electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys. The anticorrosion treatment process comprises the following steps: (1) carrying out surface pretreatment on the aluminum alloys; (2) converting the surfaces of the aluminum alloys, putting the aluminum alloys subjected to surface pretreatment into a zirconium titanate converting solution, soaking, washing, standing and drying the aluminum alloys to obtain conversion films; (3) suspending the dried aluminum alloys in a powder spraying room and electro-statically spraying organic powder on the aluminum alloys; and (4) standing, preserving heat at 180-200 DEG C, then cooling to obtain anticorrosion coatings. According to the anticorrosion treatment process, the conversion treatment is low in film-forming temperature and short in film-forming time; the zirconium titanate treatment solution is stable, chromium-free and environmentally-friendly; through the treatment process, the surfaces of the aluminum alloys are high in corrosion resistance; the conversion films are excellent in combination with the aluminum alloys and the organic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Method for making fine and ultrafine spherical particles of zirconium titanate and other mixed metal oxide systems

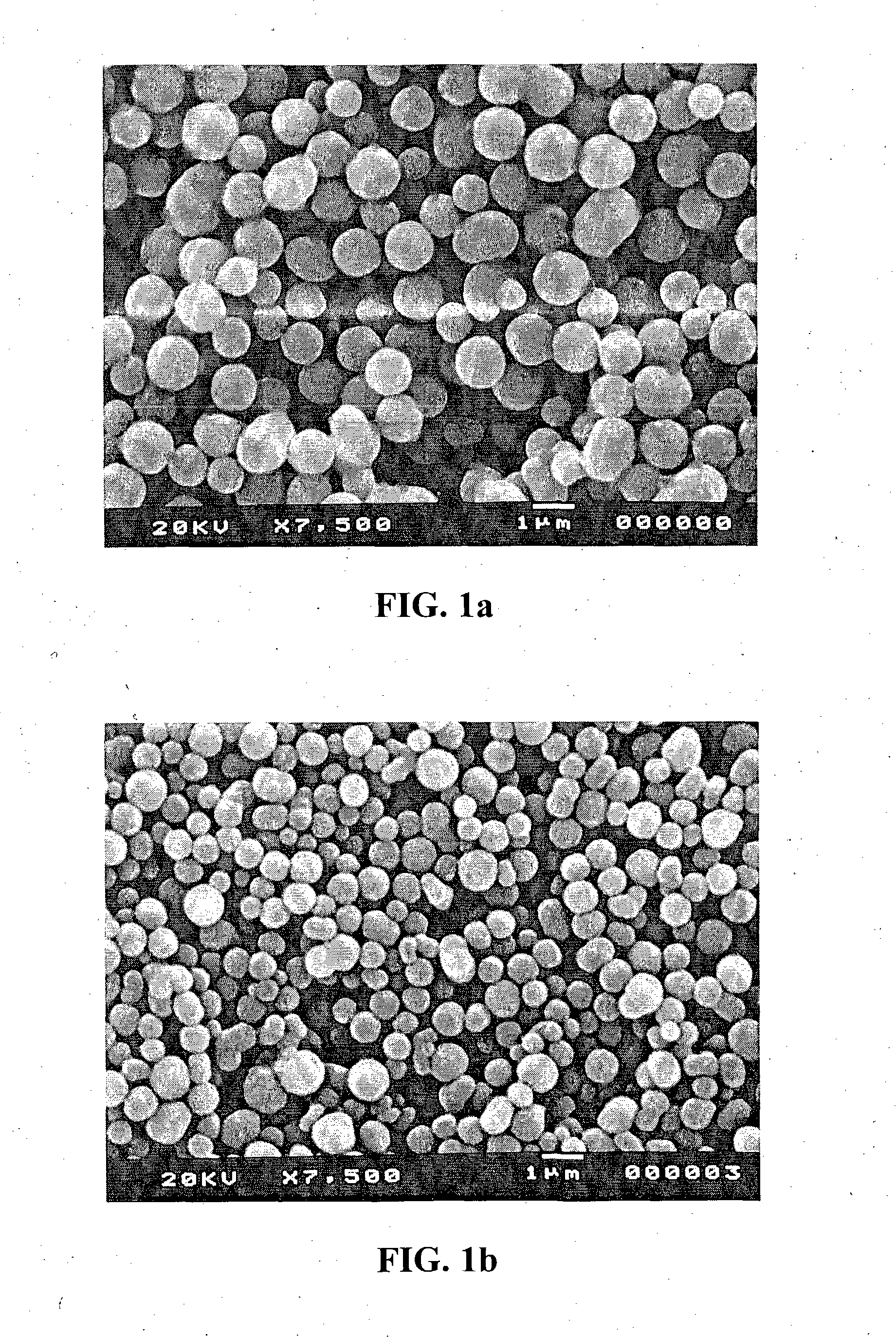

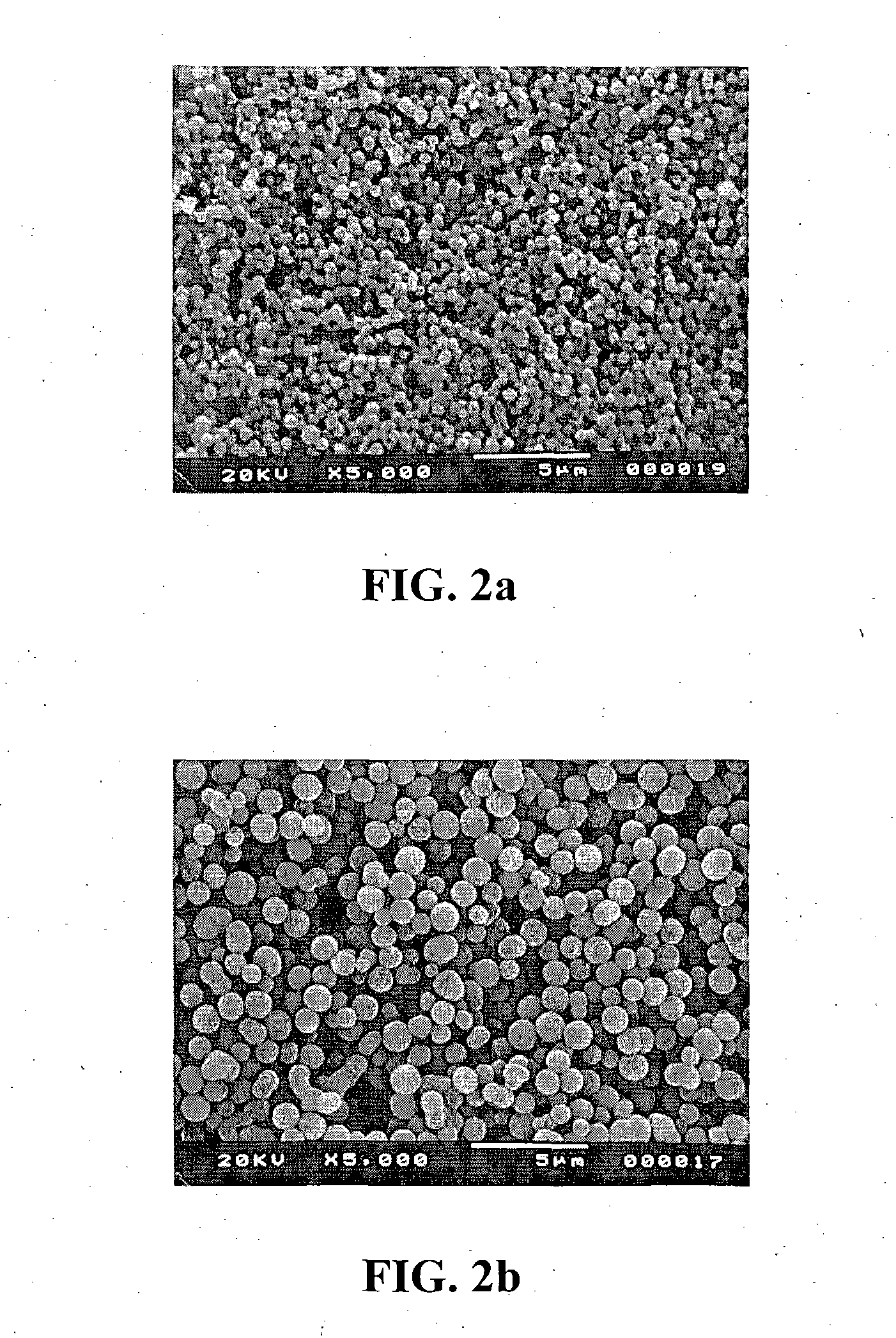

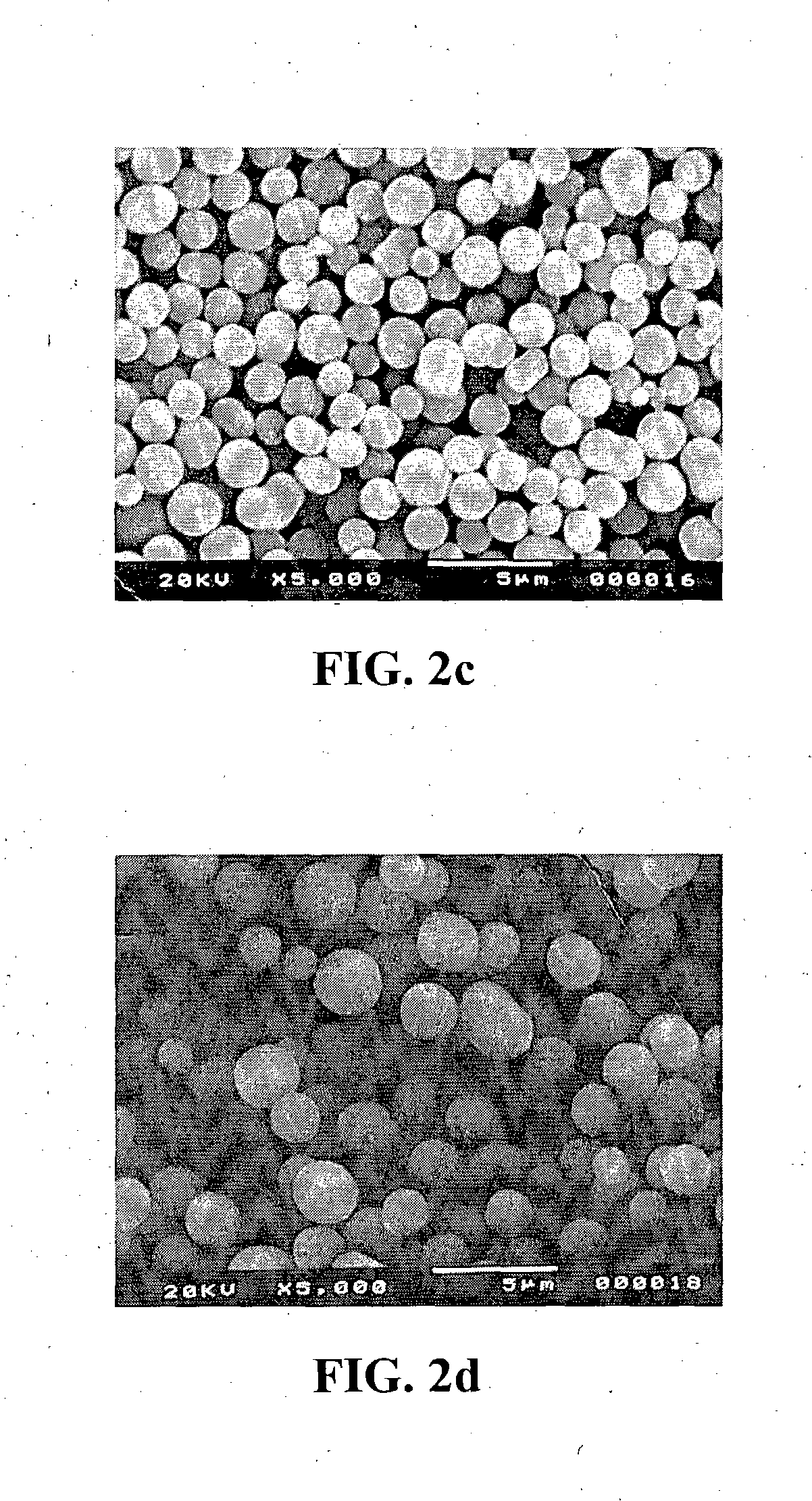

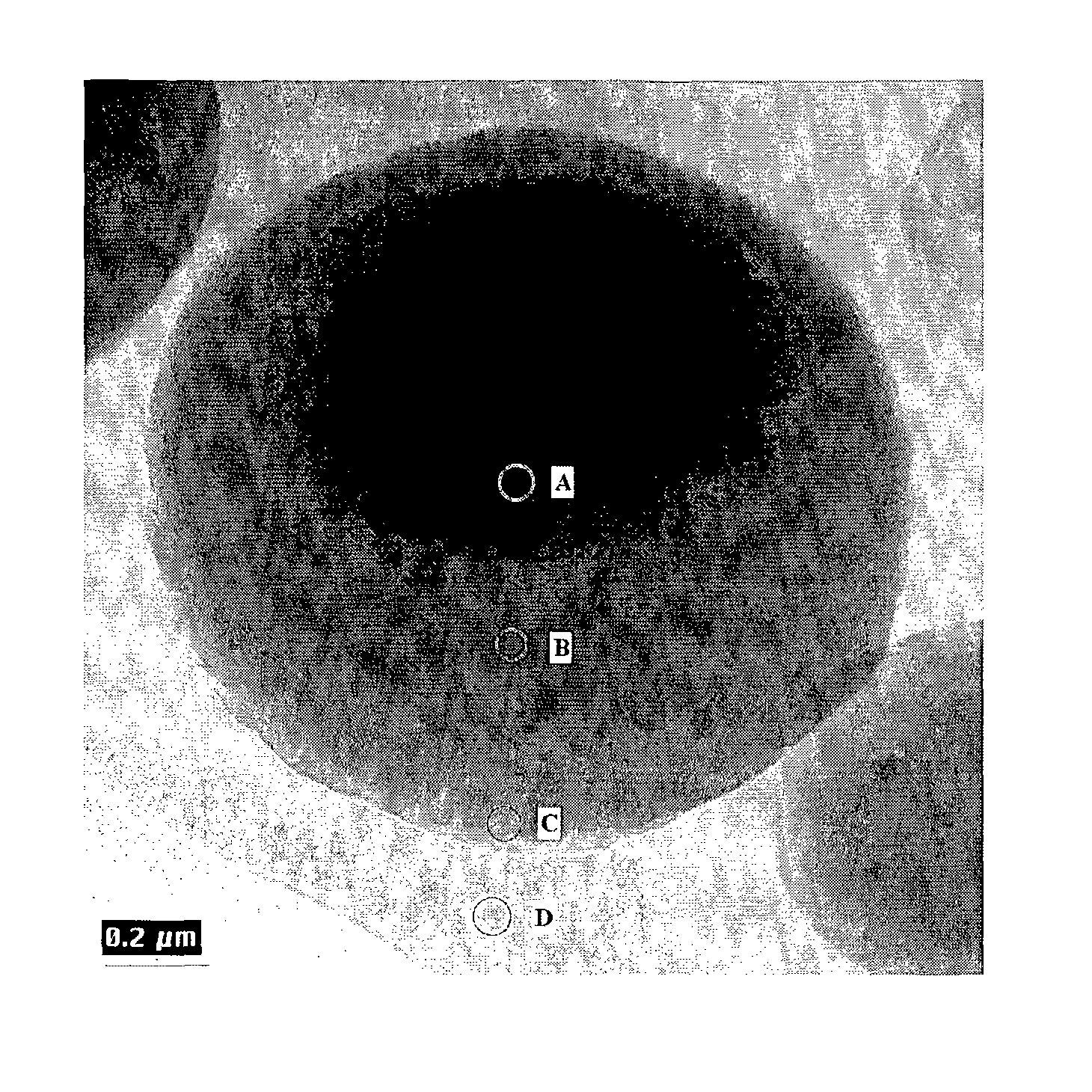

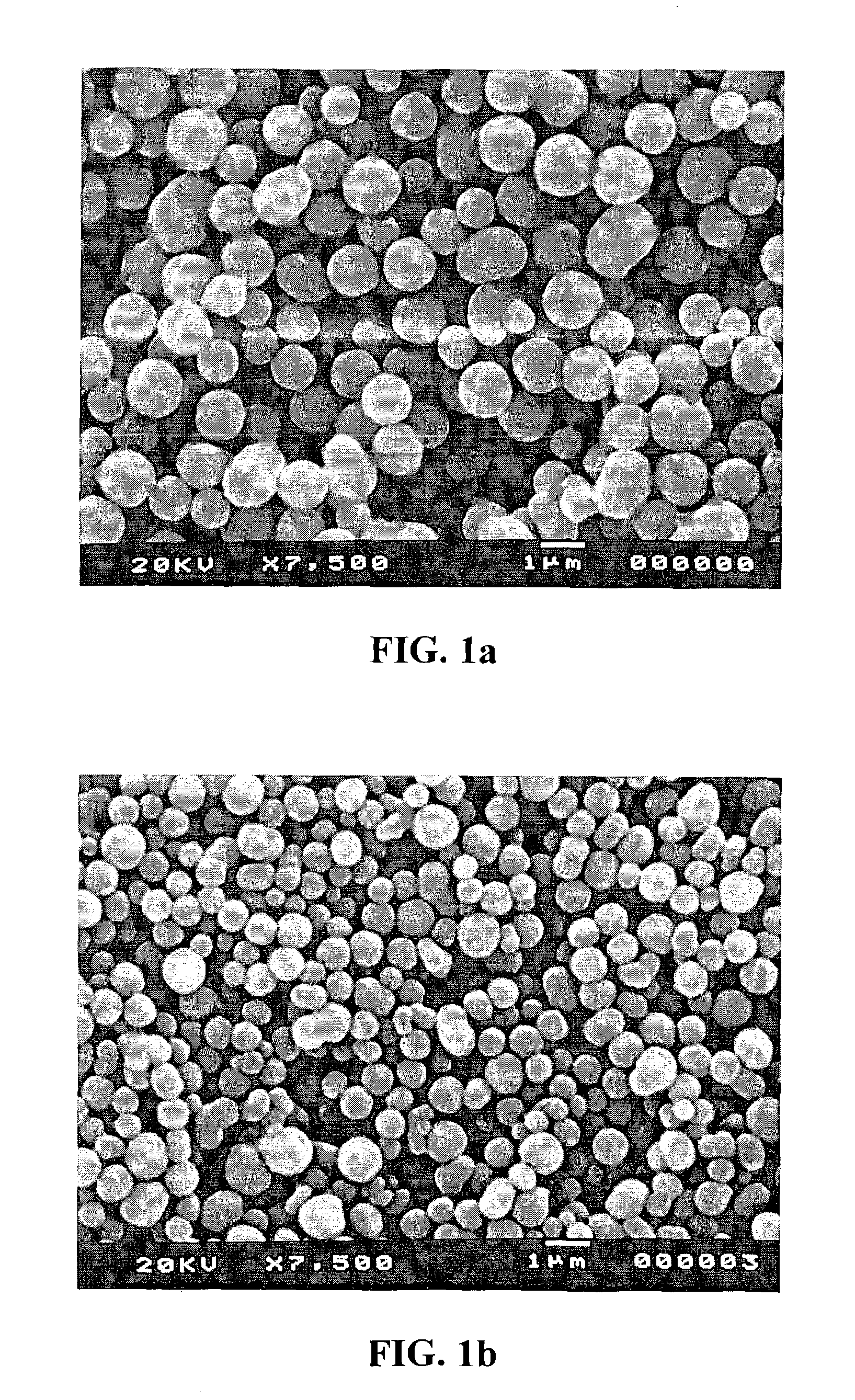

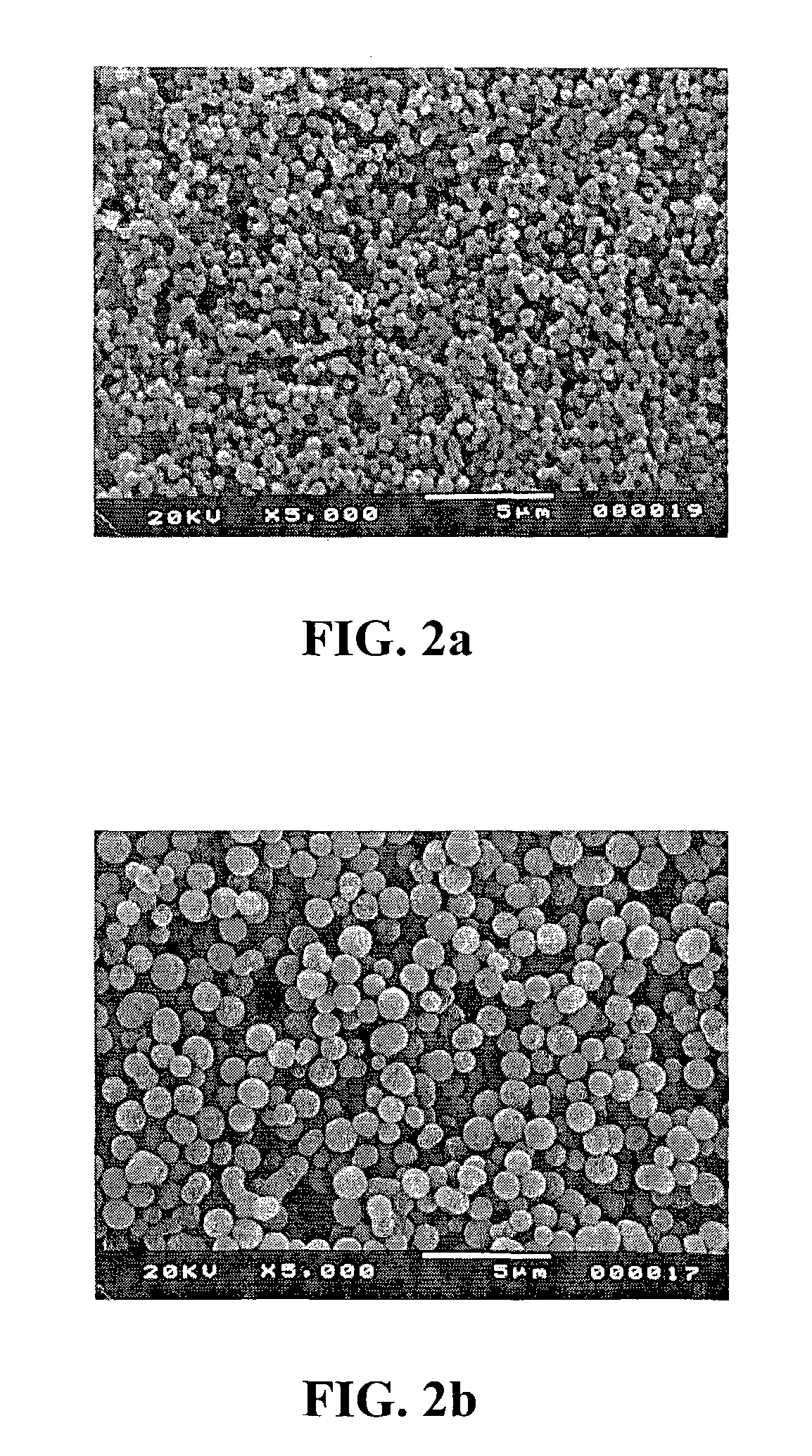

Disclosed is a method for making amorphous spherical particles of zirconium titanate and crystalline spherical particles of zirconium titanate comprising the steps of mixing an aqueous solution of zirconium salt and an aqueous solution of titanium salt into a mixed solution having equal moles of zirconium and titanium and having a total salt concentration in the range from 0.01 M to about 0.5 M. A stearic dispersant and an organic solvent is added to the mixed salt solution, subjecting the zirconium salt and the titanium salt in the mixed solution to a coprecipitation reaction forming a solution containing amorphous spherical particles of zirconium titanate wherein the volume ratio of the organic solvent to aqueous part is in the range from 1 to 5. The solution of amorphous spherical particles is incubated in an oven at a temperature ≦100° C. for a period of time ≦24 hours converting the amorphous particles to fine or ultrafine crystalline spherical particles of zirconium titanate.

Owner:UT BATTELLE LLC

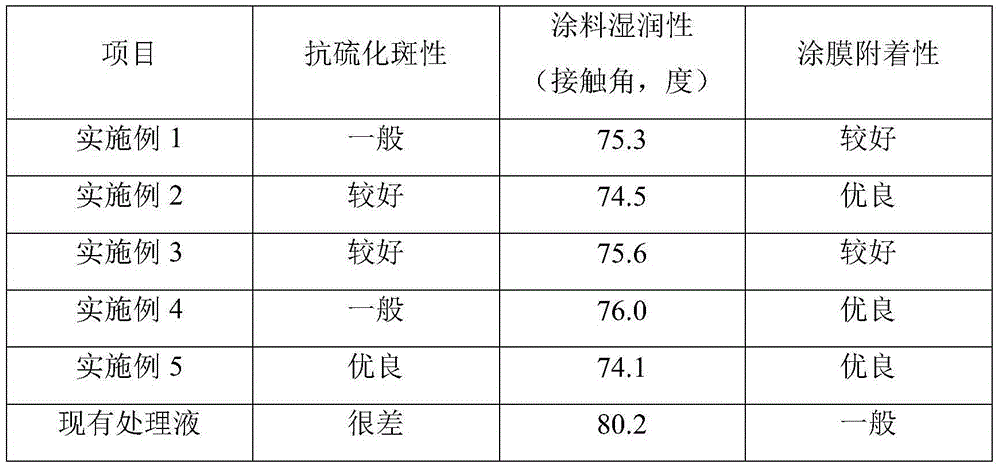

Tinned steel plate surface treatment solution and preparation method thereof

ActiveCN104357825AGuaranteed corrosion resistanceGood adhesionMetallic material coating processesChromium freePhosphate

The invention discloses a tinned steel plate surface treatment solution and a preparation method thereof. The surface treatment solution contains 2-25 g / L disodium hydrogen phosphate, 2-13 g / L sodium pyrophosphate, 1-15 g / L ammonium hydrofluotitanate, 1-10 g / L potassium fluosilicate, 2-14 g / L nickel nitrate, 1-12 g / L zirconium titanate, 1-10 g / L sodium metaaluminate, 5-12 g / L manganese dihydrogen phosphate, 2-5 g / L sodium phytate and 1-7 g / L oxalic acid. The preparation method comprises the following steps: a. adding the disodium hydrogen phosphate and sodium pyrophosphate into deionized water, and stirring; b. adding the ammonium hydrofluotitanate, potassium fluosilicate, nickel nitrate, zirconium titanate, sodium metaaluminate and manganese dihydrogen phosphate; and c. regulating the pH value of the solution to 3-5 with phosphoric acid. On the basis of chromium-free passivation, the surface treatment solution ensures the corrosion resistance of the tinned plate without degrading the sulfur resistance, and also has excellent paint adhesiveness.

Owner:深圳市九久电子科技有限公司

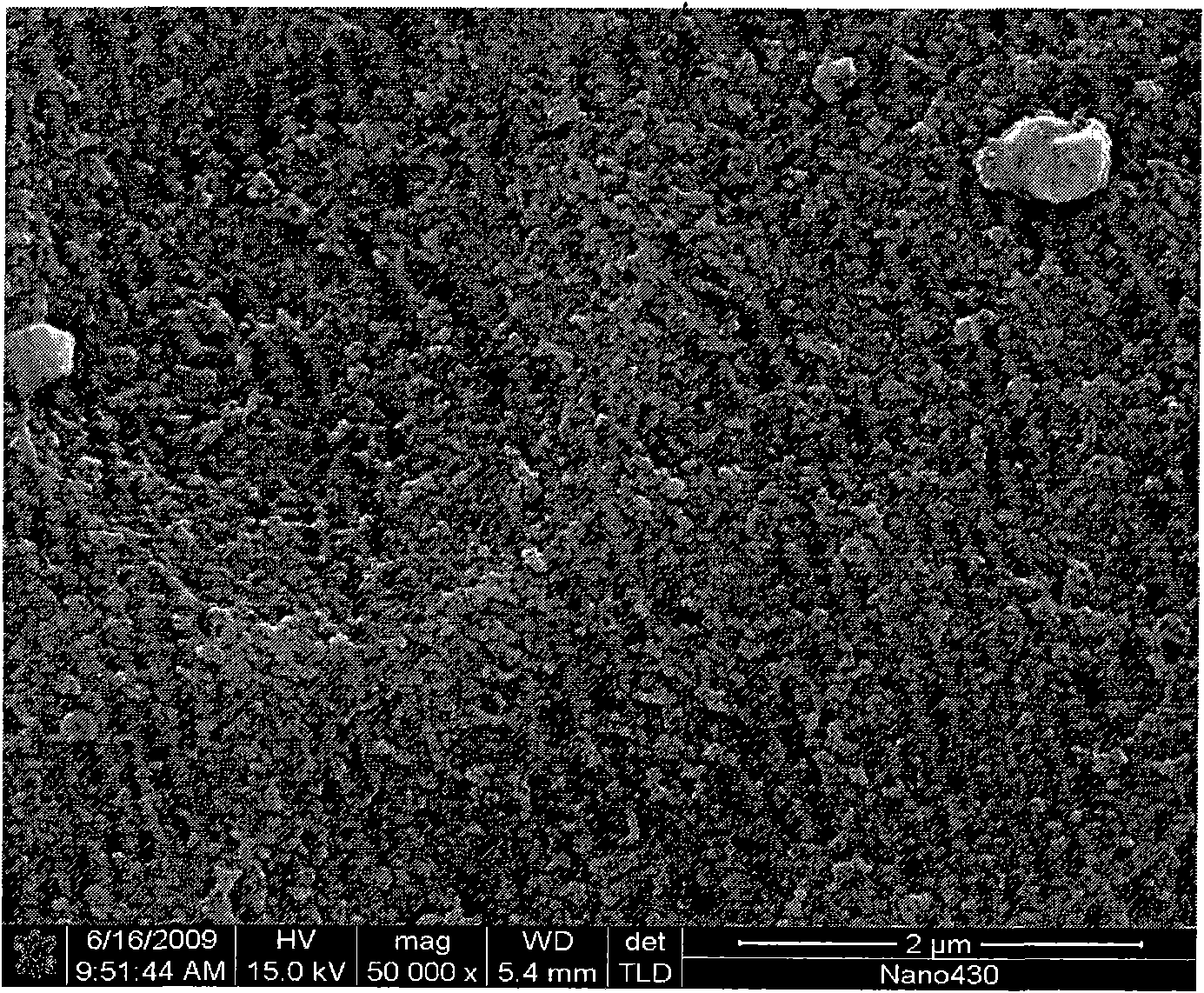

Fine-particulate lead zirconium titantes zirconium titanate hydrates and zirconium titanates and method for production thereof

ActiveUS20090060831A1Easily processableEasily economically producibleMaterial nanotechnologyConductive materialLead zirconate titanateFine particulate

The invention relates to fine-particulate zirconium titanates or lead zirconium titanates and a method for production thereof by reaction of titanium dioxide particles with a zirconium compound or a lead and zirconium compound. The titanium dioxide particles have a BET surface of more than 50 m2 / g. The lead zirconium titanates can be used for the production of microelectronic components.

Owner:TRONOX PIGMENTS GMBH

Method for making fine and ultrafine spherical particles of zirconium titanate and other mixed metal oxide systems

Disclosed is a method for making amorphous spherical particles of zirconium titanate and crystalline spherical particles of zirconium titanate comprising the steps of mixing an aqueous solution of zirconium salt and an aqueous solution of titanium salt into a mixed solution having equal moles of zirconium and titanium and having a total salt concentration in the range from 0.01 M to about 0.5 M. A stearic dispersant and an organic solvent is added to the mixed salt solution, subjecting the zirconium salt and the titanium salt in the mixed solution to a coprecipitation reaction forming a solution containing amorphous spherical particles of zirconium titanate wherein the volume ratio of the organic solvent to aqueous part is in the range from 1 to 5. The solution of amorphous spherical particles is incubated in an oven at a temperature ≦100° C. for a period of time ≦24 hours converting the amorphous particles to fine or ultrafine crystalline spherical particles of zirconium titanate.

Owner:UT BATTELLE LLC

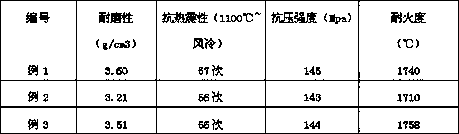

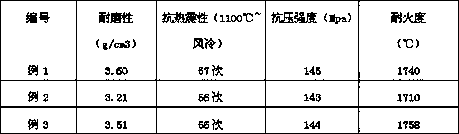

Aluminium titanate base high temperature structural composite material and preparation method thereof

InactiveCN101397207AHigh temperature resistantWith thermal shock resistancePolyvinyl alcoholHigh intensity

The invention relates to an aluminium titanate based high temperature structure composite material and a preparation method thereof, and pertains to the ceramic material field. The raw materials of the composite material and the weight percent thereof are: aluminium titanate powder, 90-98%; zirconium titanate powder, 2-10%. The grain diameter of the used raw material is less than 0.074 mm. The method for preparing the composite material is that: after being measured and proportioned, the raw materials are mixed in dryness for one minute, then 6% (weight percentage) of polyvinyl alcohol solution bonding agent with 0.5% of mass concentration is added, after being stirred for 5 minutes, the aging mixture is let stand for 5 hours so as to obtain the shaping blank; pressing and shaping are carried out on the blank by adopting a hydraulic press or a friction press, the shaping pressure of the blank is 70-100MPa; after shaping, heat retaining at more than or equal to 1500 DEG C for three hours and sintering are carried out on the blank, and the aluminium titanate based composite material with high temperature resistance, excellent thermal shock resistance and higher intensity is obtained. The composite material can be used in the fields such as metallurgy, automobile, aerospace, etc.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

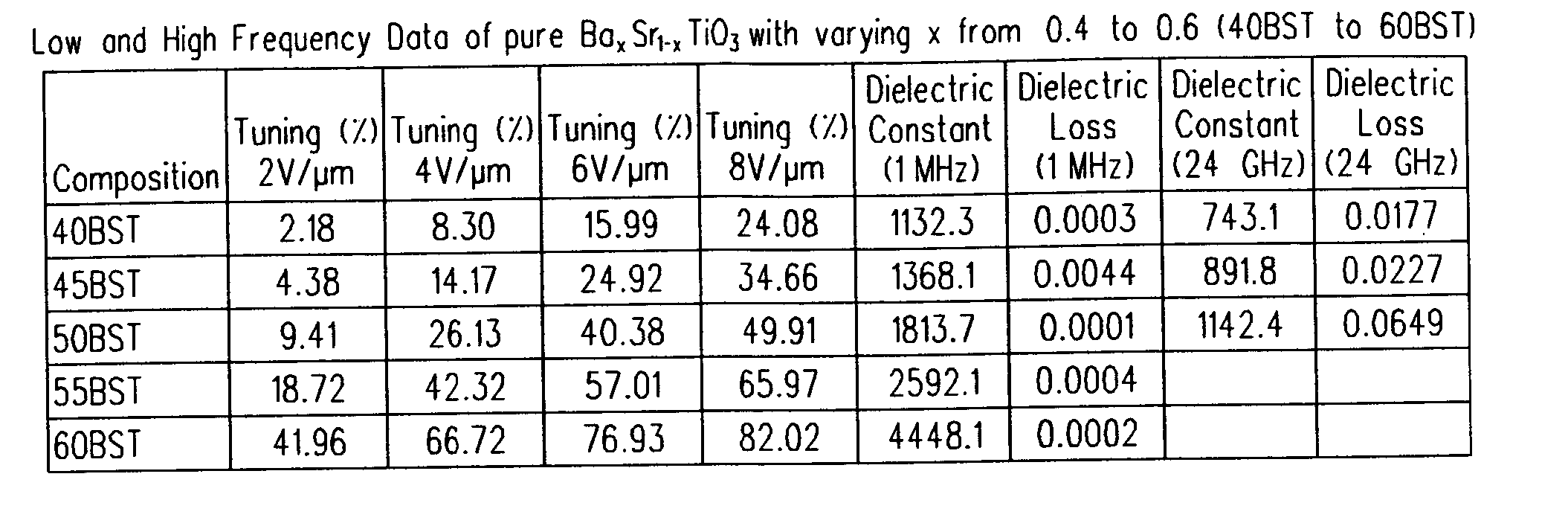

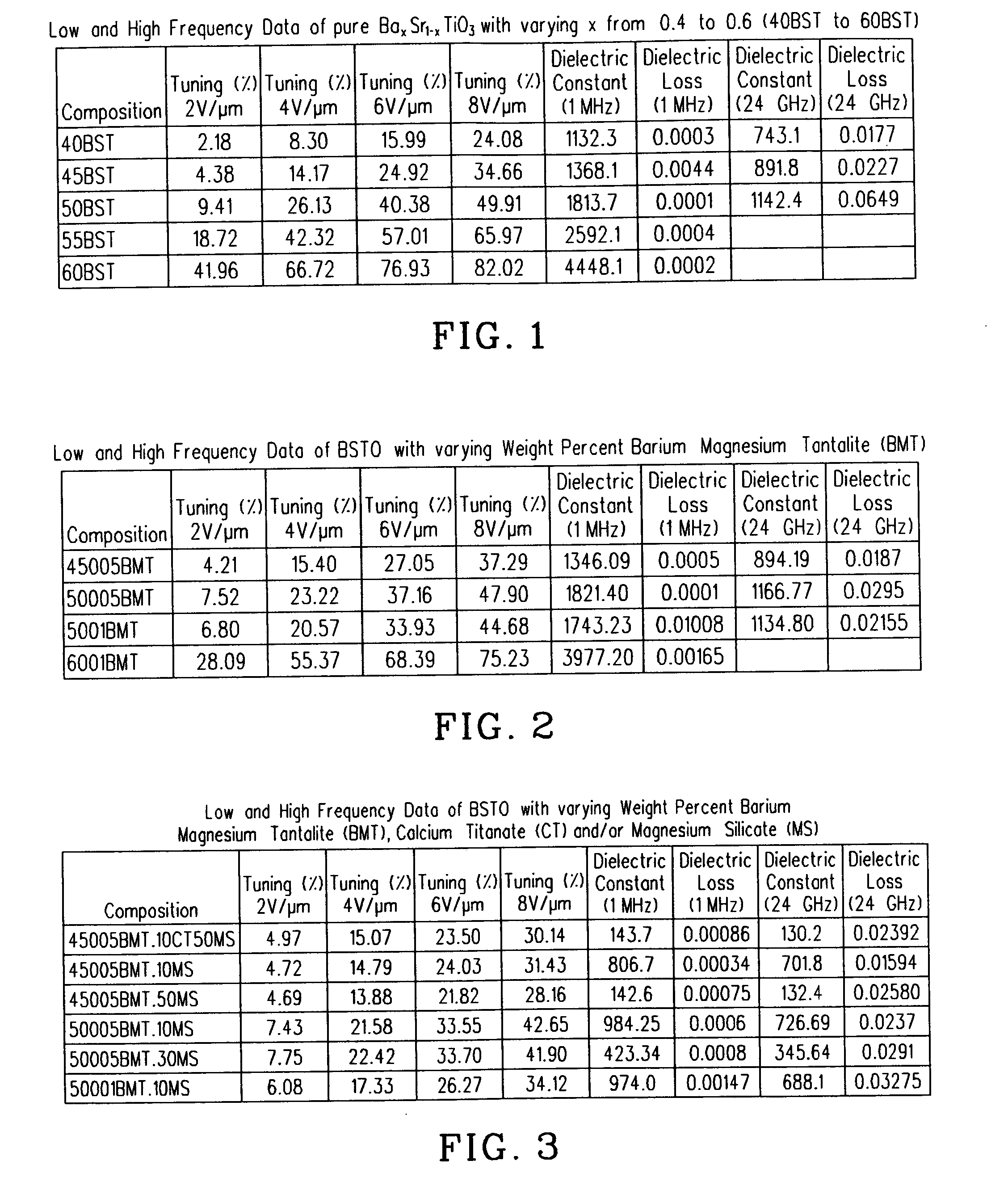

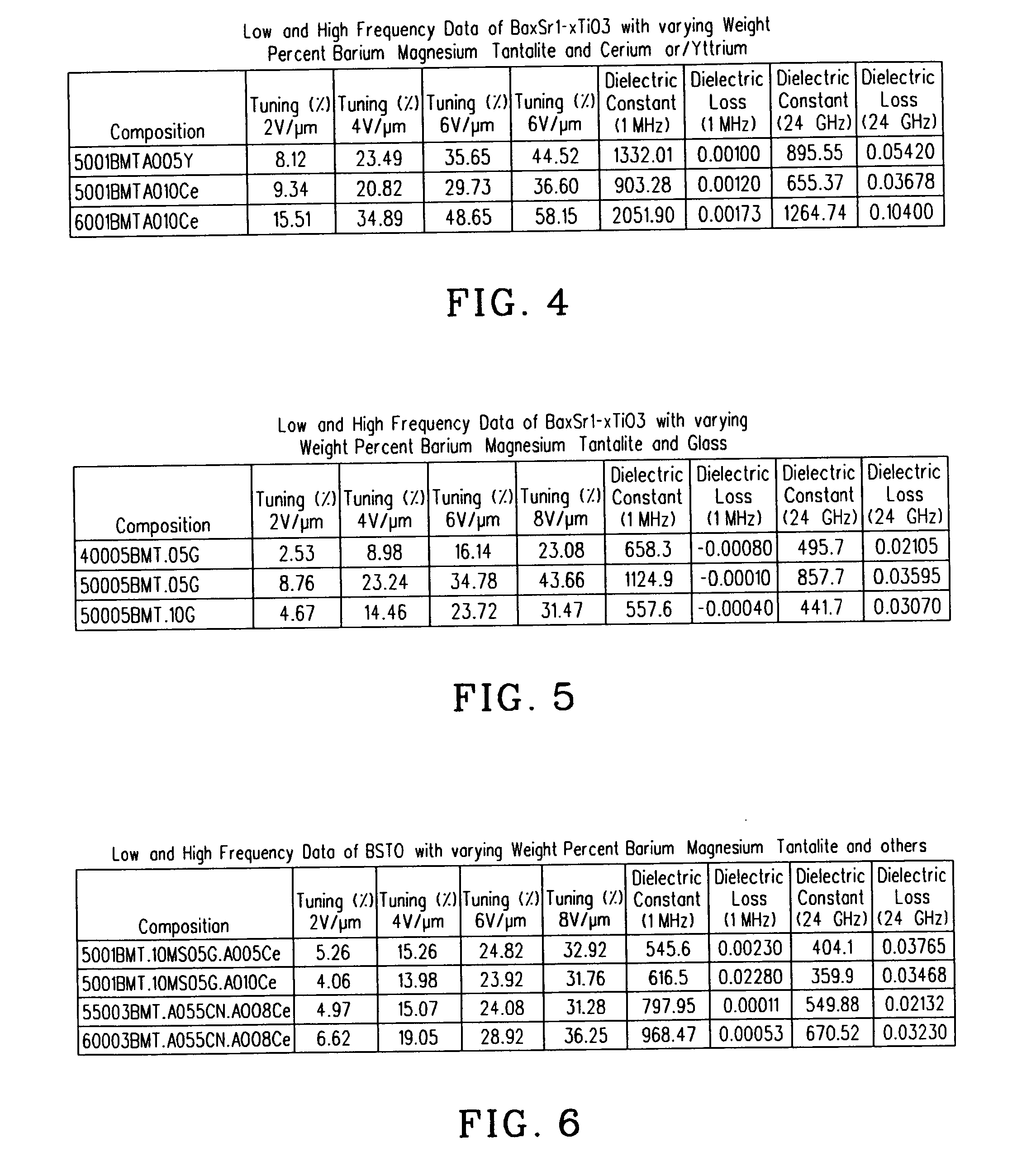

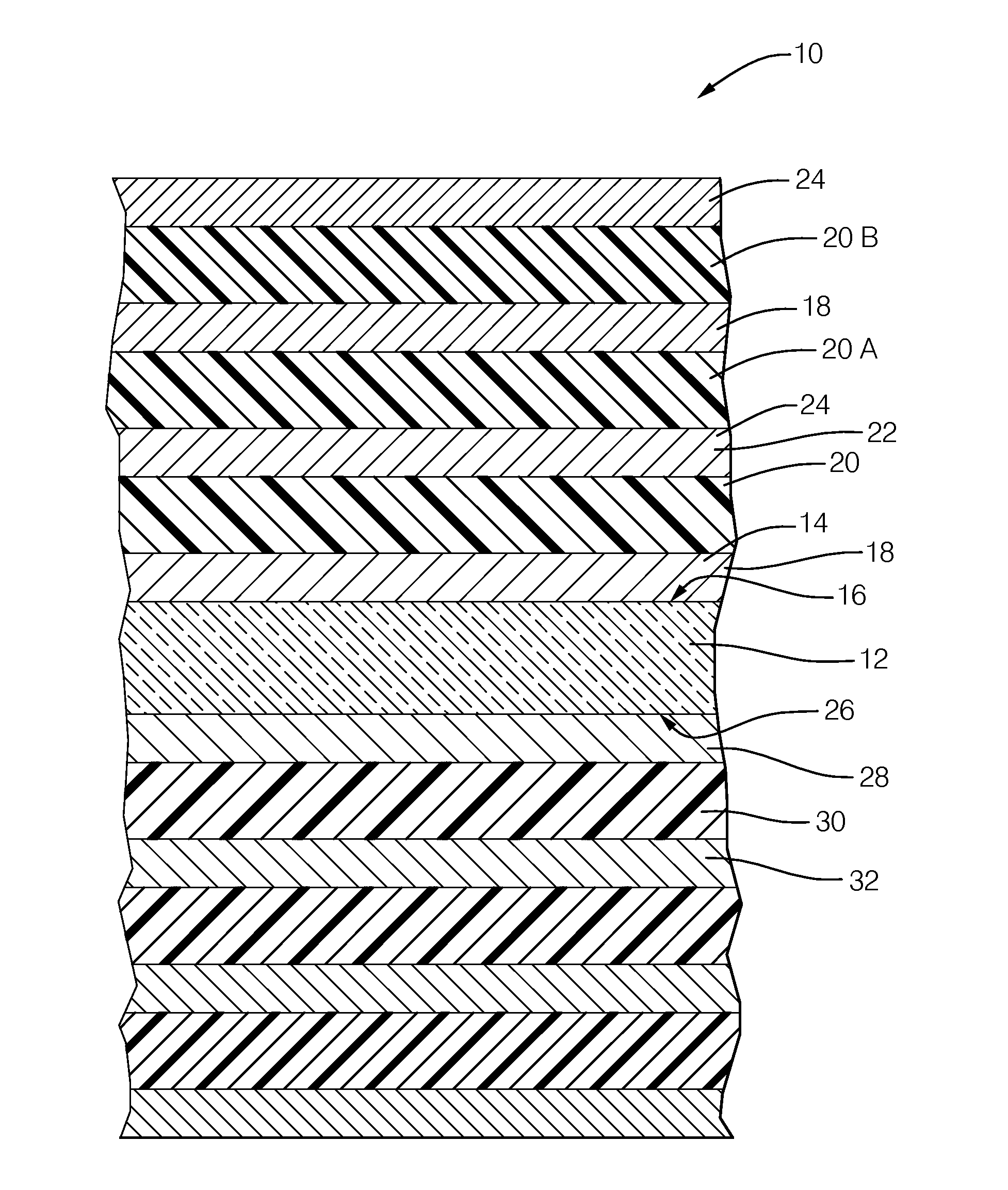

Tunable low loss material composition and methods of manufacture and use therefore

ActiveUS20060060900A1Semiconductor/solid-state device manufacturingSemiconductor devicesBarium strontium titanateBarium titanate

An embodiment of the present invention provides an electronically tunable dielectric material, comprising at least one electronically tunable dielectric phase and at least one compound of low loss complex perovskites. The at least one electronically tunable dielectric phase may be selected from the group consisting of barium strontium titanate, barium titanate, strontium titanate, barium calcium titanate, barium calcium zirconium titanate, lead titanate, lead zirconium titanate, lead lanthanum zirconium titanate, lead niobate, lead tantalate, potassium strontium niobate, sodium barium niobate / potassium phosphate, potassium niobate, lithium niobate, lithium tantalate, lanthanum tantalate, barium calcium zirconium titanate, sodium nitrate, and combinations thereof. Further, the barium strontium titanate may of the formula BaxSr1-xTiO3, where x is from about 0 to about 1, or more specifically, but not limited in this respect, may also be of the formula BaxSr1-xTiO3, where x may be from about 0.15 to about 0.65 or from about 0.25 to about 0.60.

Owner:NXP USA INC

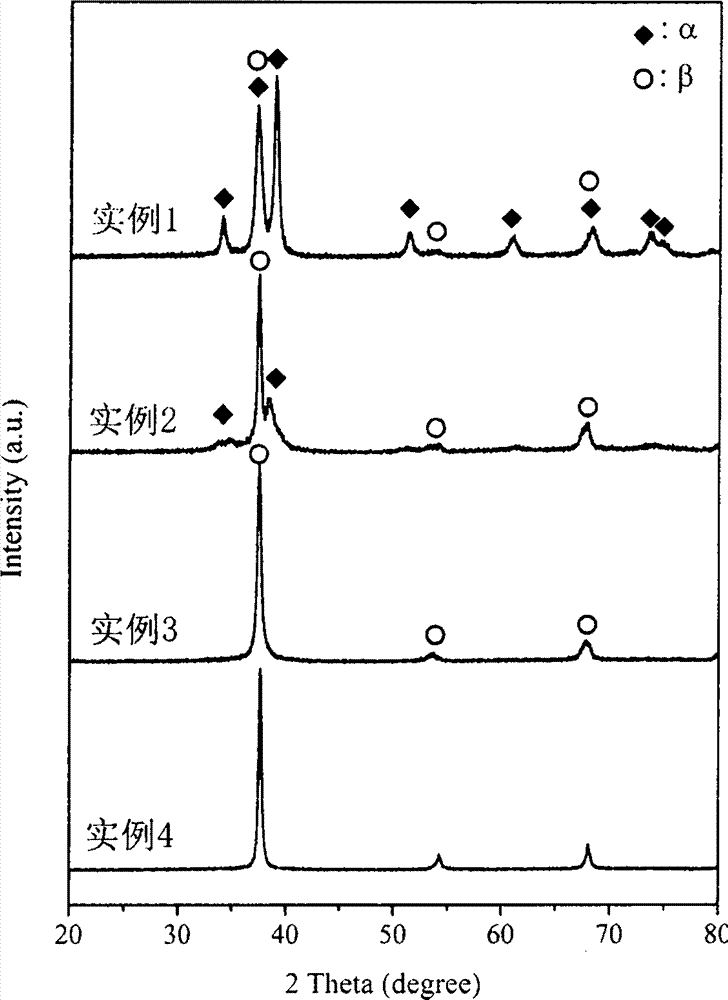

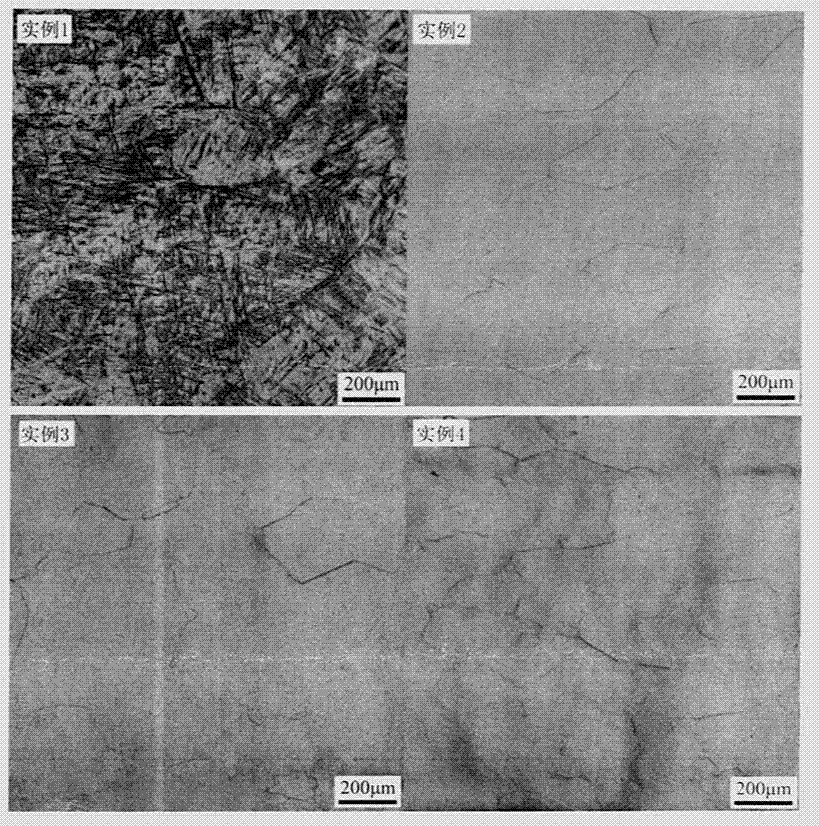

Low-cost and high-strength Ti-Zr-Al-F2 alloy

The invention discloses a zirconium titanate alloy which is low in cost and high in strength, relates to a Ti-Zr-Al-F2 serial alloy prepared by using cheap metal elements, and belongs to the technical field of novel materials. The alloy is characterized in that the alloy just contains low-cost Ti, Zr, Al and Fe elements and particularly comprises the following elements in percentage by weight: 4-5% of Al, 0.25-2.5% of Fe and the balance of Ti and Zr (respectively half) and inevitable impurities. The room-temperature tensile mechanical property indexes are as follows: the tensile strength sigmab is 1200-1500MPa, the yield strength sigma0.2 is 700-1350MPa, and the ductility delta is 7-15%. The alloy disclosed by the invention has the characteristics of being low in cost, high in strength, good in plasticity and free of toxic elements.

Owner:HEBEI UNIV OF ENG

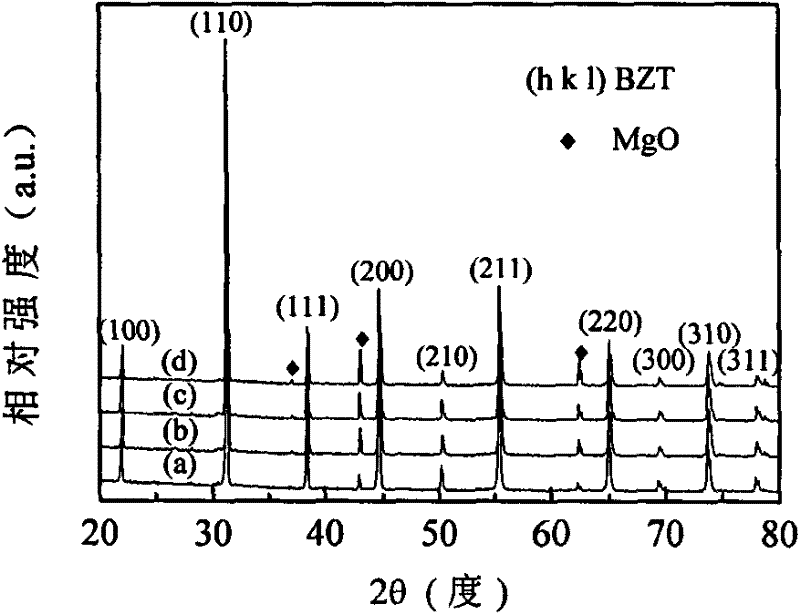

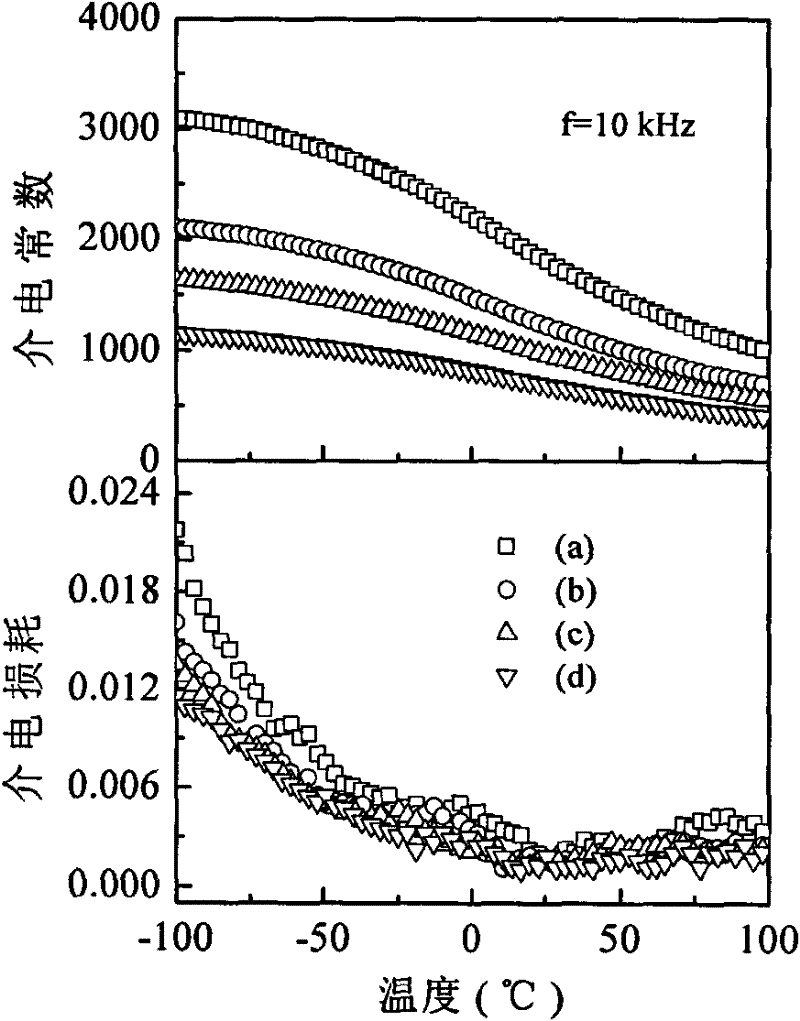

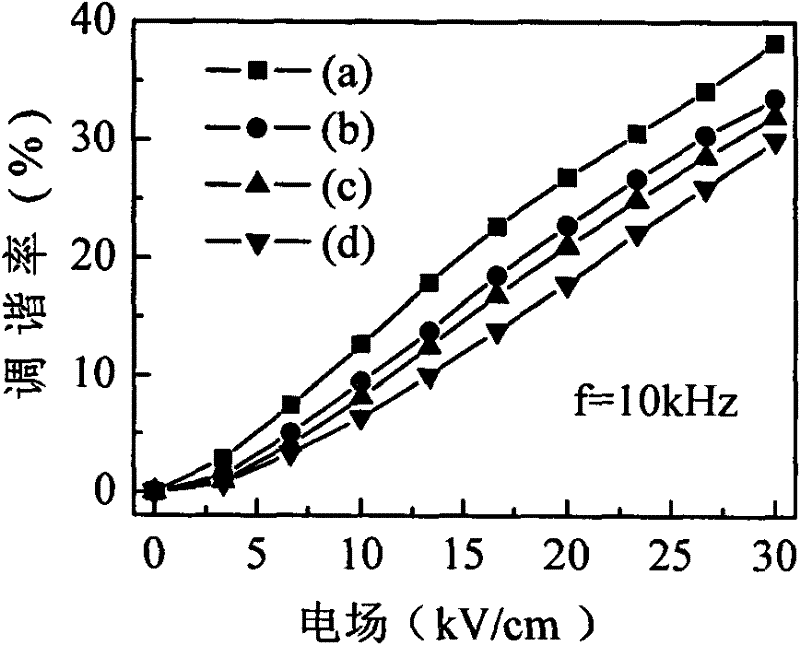

Dielectric adjustable magnesium oxide and barium zirconium titanate composite ceramic

InactiveCN102336568ALow dielectric constantLow dielectric lossHigh volume manufacturingComposite ceramic

The invention relates to a dielectric adjustable magnesium oxide and barium zirconium titanate composite ceramic, which is technically characterized in that: the chemical general formula of the magnesium oxide and barium zirconium titanate composite ceramic is BaZr0.25Ti0.75O3; the magnesium oxide and barium zirconium titanate composite ceramic is prepared by a ceramic preparation process; and at the room temperature and the frequency of 10kHz, the dielectric constant (672) of the ceramic is proper by component optimization, and low dielectric loss (0.0016) and high tuning rate (30 percent) are kept, so the magnesium oxide and barium zirconium titanate composite ceramic can meet the using requirement of a ferroelectric phase shifter, and the formula and the preparation method of the ceramic are suitable for industrialized popularization and large-batch production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for treating reverse osmosis concentrated water

ActiveCN102040312BImprove biodegradabilityMultistage water/sewage treatmentSodium chlorateChemical oxygen demand

Owner:CHINA PETROLEUM & CHEM CORP +1

Low wall quick change wear-resistant prefabricated part and preparing method thereof

InactiveCN108046818AGood resistance to acid and alkali corrosionStrong adaptability to the use environmentFurnace componentsAluminateFiber

The invention discloses a low wall quick change wear-resistant prefabricated part and a preparing method thereof, and belongs to the technical field of refractory materials. The wear-resistant prefabricated part is prepared from, by mass, 20-30 parts of titanium calcium aluminate aggregate, 20-30 parts of zirconium titanate aggregate, 5-10 parts of zirconium titanate calcium powder, 10-16 parts ofcalcium alumino-titanate powder, 5-9 parts of silica powder, 5-9 parts of alumina micro powder, 5-9 parts of aluminate cement, 6-10 parts of vitrified perlite, 0.15-0.18 part of sodium tripolyphosphate and 0.13-0.16 part of explosion-proof fiber, wherein sodium tripolyphosphate and the explosion-proof fiber are extra materials. The low wall quick change wear-resistant prefabricated part is used for replacing castable in the prior art and has the advantage of being convenient to construct, established cement kilns are good in thermal shock resistance and excellent in wear-resistant performance, the construction period is short, and the periodical maintenance cost is lower.

Owner:张静芬

High-strength and high-wearability prefabricated part and preparation method thereof

InactiveCN108249931AGood resistance to acid and alkali corrosionStrong adaptability to the use environmentAluminateFiber

The invention discloses a high-strength and high-wearability prefabricated part and a preparation method thereof and belongs to the technical field of refractory materials. The high-strength and high-wearability prefabricated part comprises the following components in part by mass: 20-30 parts of calcium titanate aggregates, 20-30 parts of calcium zirconium titanate, 5-10 parts of magnesium titanate powder, 10-16 parts of calcium titanium aluminate powder, 5-9 parts of silicon micro powder, 5-9 parts of alumina micro powder, 5-9 parts of aluminate cement, 6-10 parts of vitrified perlite; an admixture comprises 0.15-0.18 part of sodium tripolyphosphate and 0.13-0.16 part of explosion-proof fibers. The high-strength and high-wearability prefabricated part is used for replacing a casting material in the prior art and has the characteristic of being convenient to construct, and a built cement kiln is good in thermal shock resistance, excellent in wear resistance, short in construction period and relatively low in cycle maintenance cost.

Owner:张静芬

Low wall quick change wear-resistant prefabricated part

InactiveCN108046817AGood resistance to acid and alkali corrosionStrong adaptability to the use environmentFurnace componentsFiberWear resistant

The invention discloses a low wall quick change wear-resistant prefabricated part, and belongs to the technical field of refractory materials. The wear-resistant prefabricated part is prepared from, by mass, 20-30 parts of corundum aggregate, 20-30 parts of zirconium titanate aggregate, 5-10 parts of zirconium titanate calcium powder, 10-16 parts of calcium alumino-titanate powder, 5-9 parts of silica powder, 5-9 parts of alumina micro powder, 5-9 parts of aluminate cement, 6-10 parts of vitrified perlite, 0.15-0.18 part of sodium tripolyphosphate and 0.13-0.16 part of explosion-proof fiber, wherein sodium tripolyphosphate and the explosion-proof fiber are extra materials. The low wall quick change wear-resistant prefabricated part is used for replacing castable in the prior art and has the advantage of being convenient to construct, established cement kilns are good in thermal shock resistance and excellent in wear-resistant performance, the construction period is short, and the periodical maintenance cost is lower.

Owner:张静芬

A high-strength plastic case of a lead-acid storage battery

InactiveCN107746535AHigh mechanical strengthHigh impact strengthInorganic material artificial filamentsFiberPolymer science

The invention belongs to the technical field of lead-acid storage batteries, and discloses a high-strength plastic case of a lead-acid storage battery. The plastic case is prepared from ABS resin, PVCresin, nitrile butadiene rubber, reinforcing fibers, modified mica, modified white carbon black, an antioxidant, an antiager, stearic acid, a solvent and the like through injection molding. The reinforcing fibers are zirconium titanate fibers subjected to surface modification. The plastic case has high mechanical strength and impact strength, good toughness, high tensile strength and flexural modulus, good thermal stability, and good resistance to high voltages.

Owner:ZHEJIANG CHANGTONG SCI & TECH

Heat-resistant synthetic jewelry material

ActiveUS20160113363A1Improve thermal shock resistanceLow CTEPolycrystalline material growthNanotechnologyRare-earth elementApatite

A heat-resistant synthetic jewelry material having a transparent, semitransparent or nontransparent composite nanocrystalline material on the basis of nanosized oxide and silicate crystalline phases. The material includes at least one of the following crystalline phases: spinel, quartz-like phases, sapphirine, enstatite, petalite-like phase, cordierite, willemite, zirconium, rutile, zirconium titanate, zirconium dioxide with a content of ions of transition elements, rare-earth elements and precious metals of from 0.001 to 4 mol %. One of the crystalline phases is additionally quartz-like solid solutions of lithium magnesium zinc aluminosilicates with a virgilite or keatite structure. The composition is selected from the following components, SiO2, Al2O3, MgO, ZnO, Li2O, PbO, ZrO2, TiO2, NiO, CoO, CuO, Cr2O3, Bi2O3, Fe2O3, MnO2, CeO2, Nd2O3, Er2O3, Pr2O3 and Au.

Owner:AVAKYAN KAREN KHORENOVICH

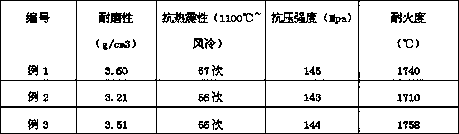

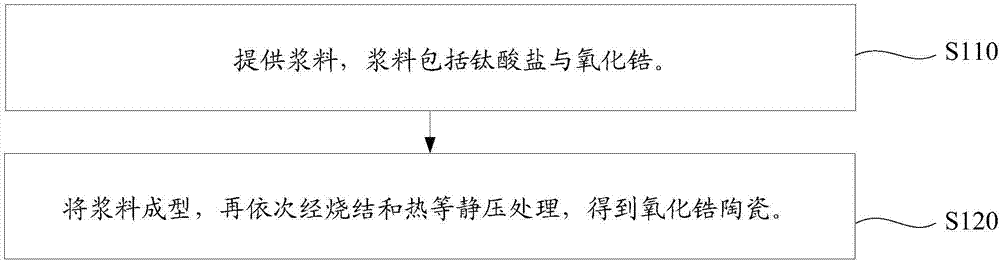

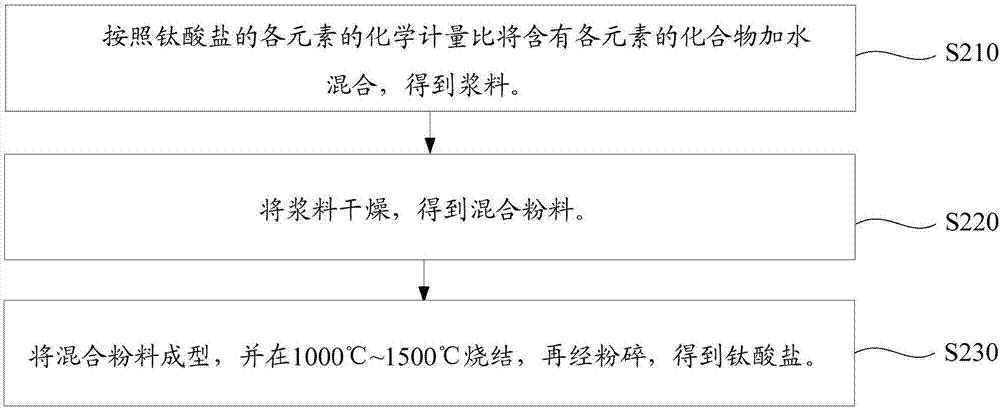

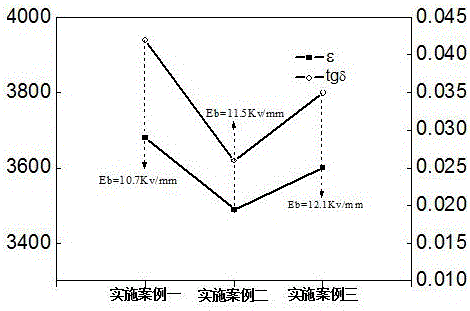

Zirconia ceramic and preparation method thereof

The invention relates to a zirconia ceramic and a preparation method thereof. The preparation method of the zirconia ceramic comprises the following steps: providing slurry, wherein the slurry comprises titanate and zirconia, the mass ratio of the titanate to the zirconia is (0.01-0.25):1, and the titanate is selected from at least one of zirconium titanate, calcium titanate, strontium titanate, copper calcium titanate and strontium barium titanate; and shaping the slurry, and sequentially performing sintering and hot isostatic pressing treatment to obtain the zirconia ceramic. The zirconia ceramic prepared by the above zirconia ceramic preparation method has a high dielectric constant.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Method for preparing high-performance ceramic capacitor material by preparing multi-variant synergetic doped barium strontium titanate

ActiveCN105777115AFlexible designHigh dielectric low loss high withstand voltage characteristicsFixed capacitor dielectricStrontium titanateBarium strontium titanate

The invention relates to a method for preparing a high-performance ceramic capacitor material by preparing multi-variant synergetic doped barium strontium titanate. Dielectric properties of a BST ceramic material in a room temperature range are realized by utilizing strontium titanate, barium titanate and zirconium titanate; the performance of a product is improved by adopting multi-variant doping and synergetic compensation. Results show that the material has the characteristics of high dielectricity, low loss and voltage resistance; moreover, the product is easy to design, and cost is saved.

Owner:江苏省陶瓷研究所有限公司

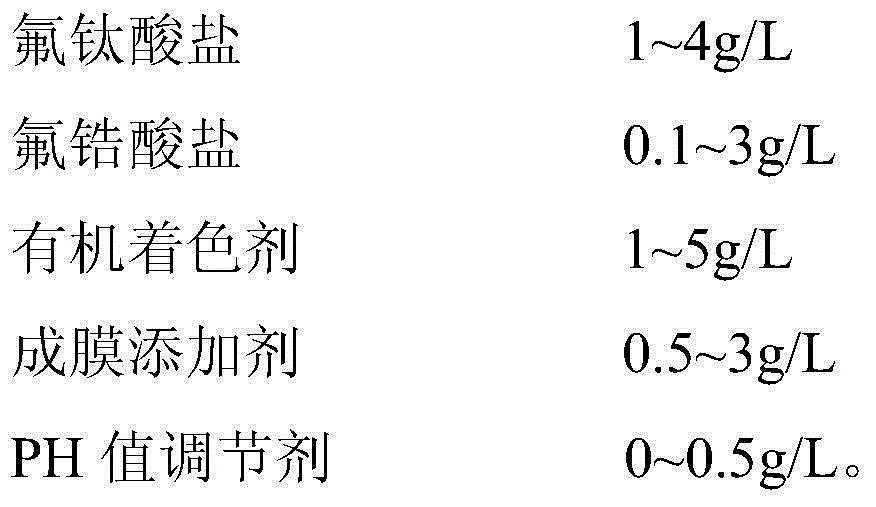

Preparing method for magnesium alloy environment-friendly corrosion resisting type ceramic conversion film

InactiveCN111139463AReduce pollutionCompliance with emission standardsMetallic material coating processesPhosphateOxidizing agent

The invention relates to the field of magnesium alloy surface treatment, in particular to a preparing method of an environment-friendly corrosion resisting type ceramic conversion film applied to a magnesium alloy. The method comprises front treatment, roughening treatment, homogenizing treatment and conversion treatment. A conversion treatment solution comprises 2-20 g / l of zirconium titanate (salt), 2-20 g / l of an oxidizing agent and 0.5-10 g / l of a film forming addition agent, 0.1-5 g / l of a silane coupling agent is added, the balance is water, and the pH value of the conversion treatment solution needs to be adjusted to 2-5 before usage. Base body surface uniform film forming can be achieved under the normal temperature condition in a dipping or spraying manner, the corrosion resistingperformance of the environment-friendly corrosion resisting type ceramic conversion film is equivalent to a traditional phosphate conversion film, and the environment-friendly corrosion resisting type ceramic conversion film can be directly used or used for coating pretreatment and has good adhesive force with an organic coating. The technology operation is simple, cost is low, emission of phosphate, chromium, nickel and other pollution ions is avoided, and the preparing method is an environment-friendly surface treatment new method suitable for magnesium alloy industry production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

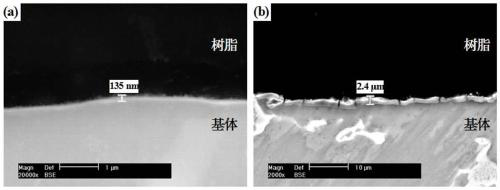

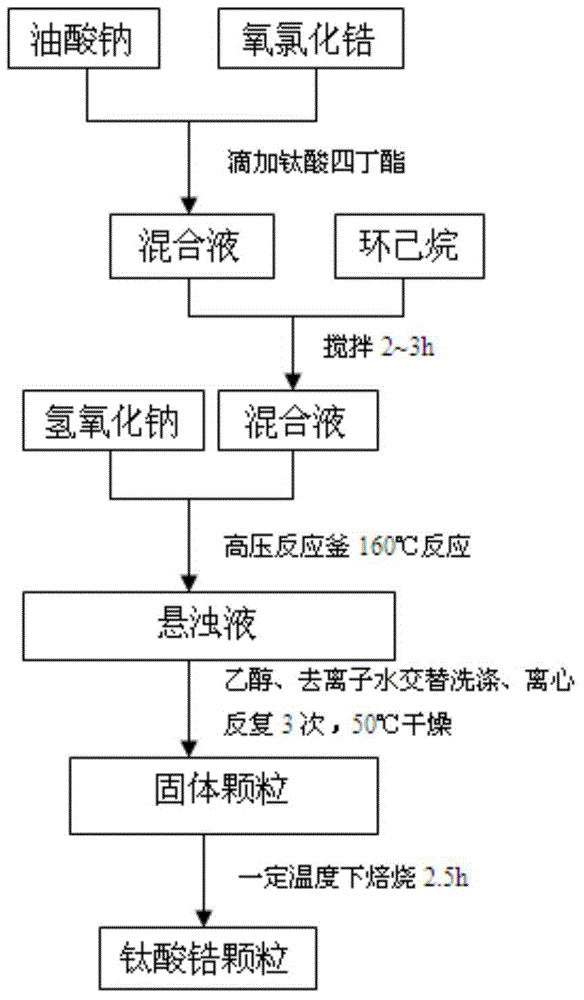

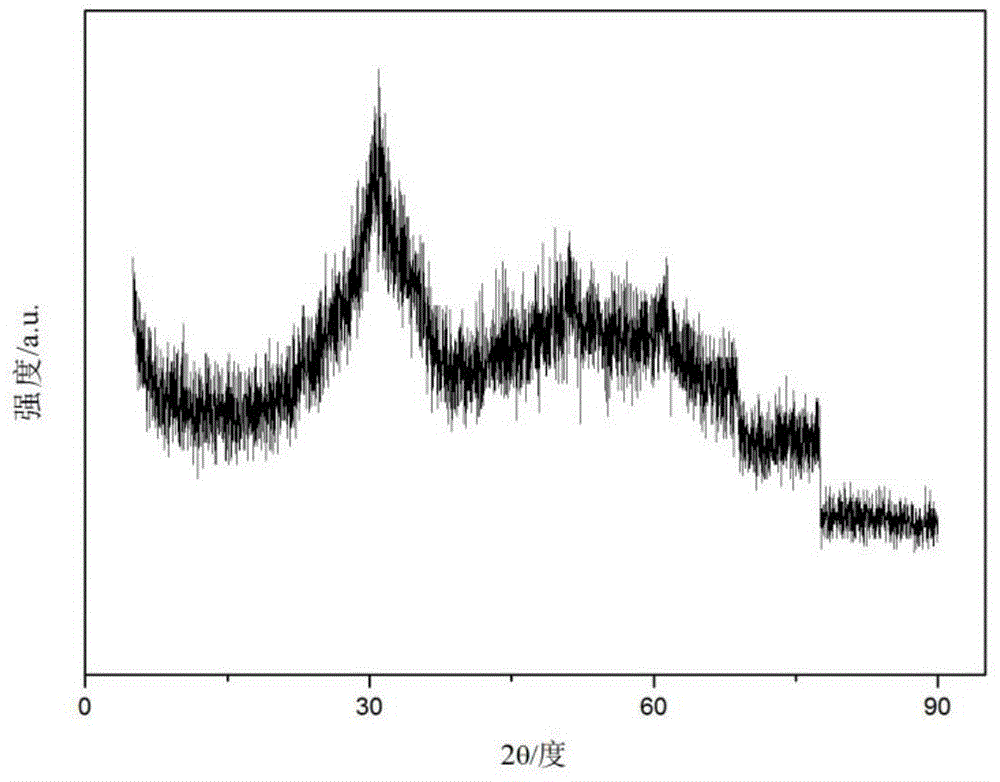

Method for preparing zirconium titanate by oil-water interface process

The invention relates to a method for preparing zirconium titanate by an oil-water interface process, which comprises the following steps: (1) under room temperature conditions, dropwisely adding a zirconium oxychloride solution and tetrabutyl titanate into a sodium oleate water solution, adding cyclohexane, and stirring to obtain a mixed solution; (2) pouring the mixed solution into a reaction kettle, adding a NaOH solution to regulate the pH value, keeping the oil-water ratio at 1:1, reacting at 160-180 DEG C for 24-18 hours, washing, separating the oil phase, washing, centrifuging, drying to obtain a primary product, and roasting to obtain the zirconium titanate ZrTiO4. The method is simple to operate, and has the characteristics of favorable repetitiveness, controllable reaction conditions, lower temperature requirements and the like.

Owner:DONGHUA UNIV +1

Fine-particulate lead zirconium titantes zirconium titanate hydrates and zirconium titanates and method for production thereof

ActiveUS8080230B2Easy to processSimple and economical processMaterial nanotechnologyConductive materialZirconium compoundsPhysical chemistry

Owner:TRONOX PIGMENTS GMBH

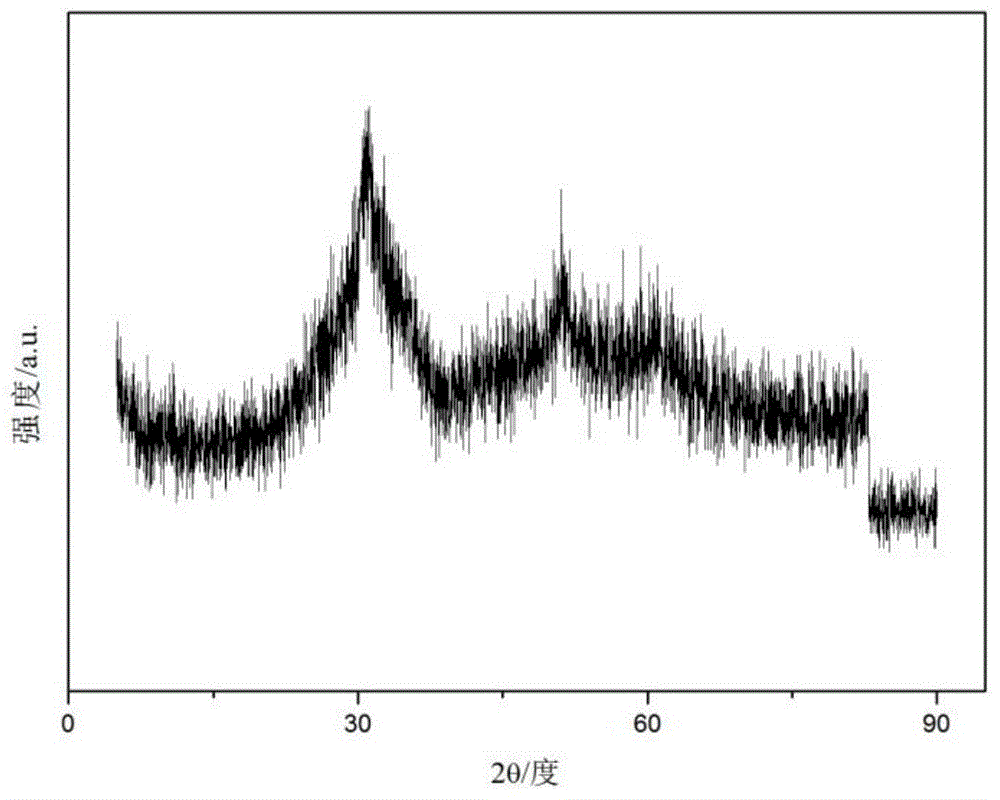

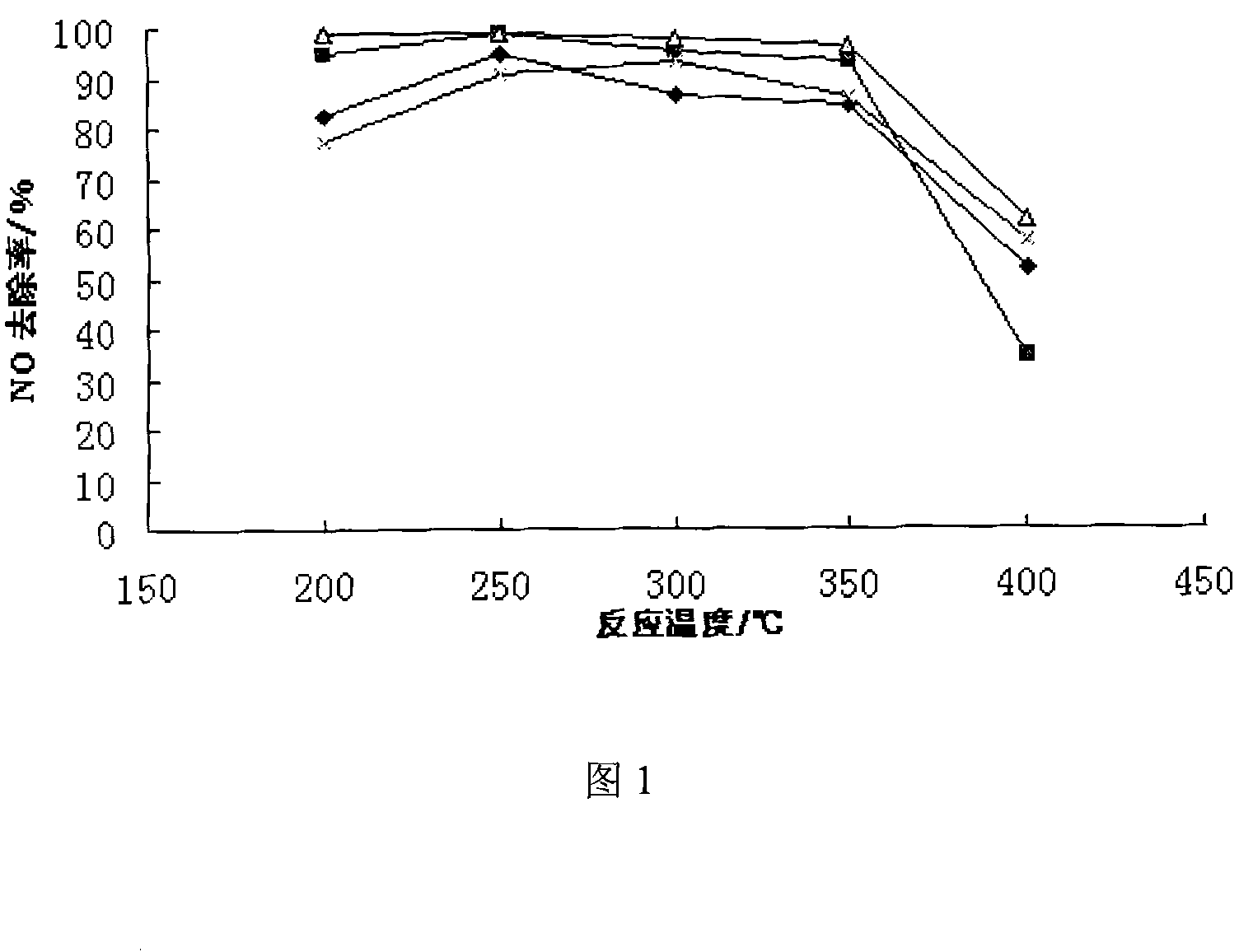

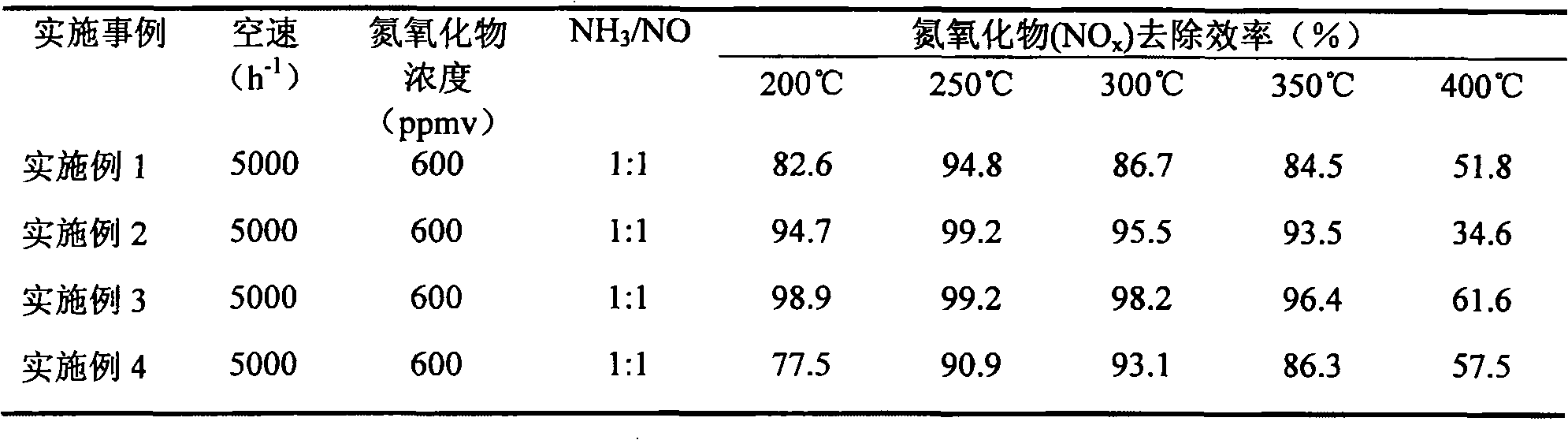

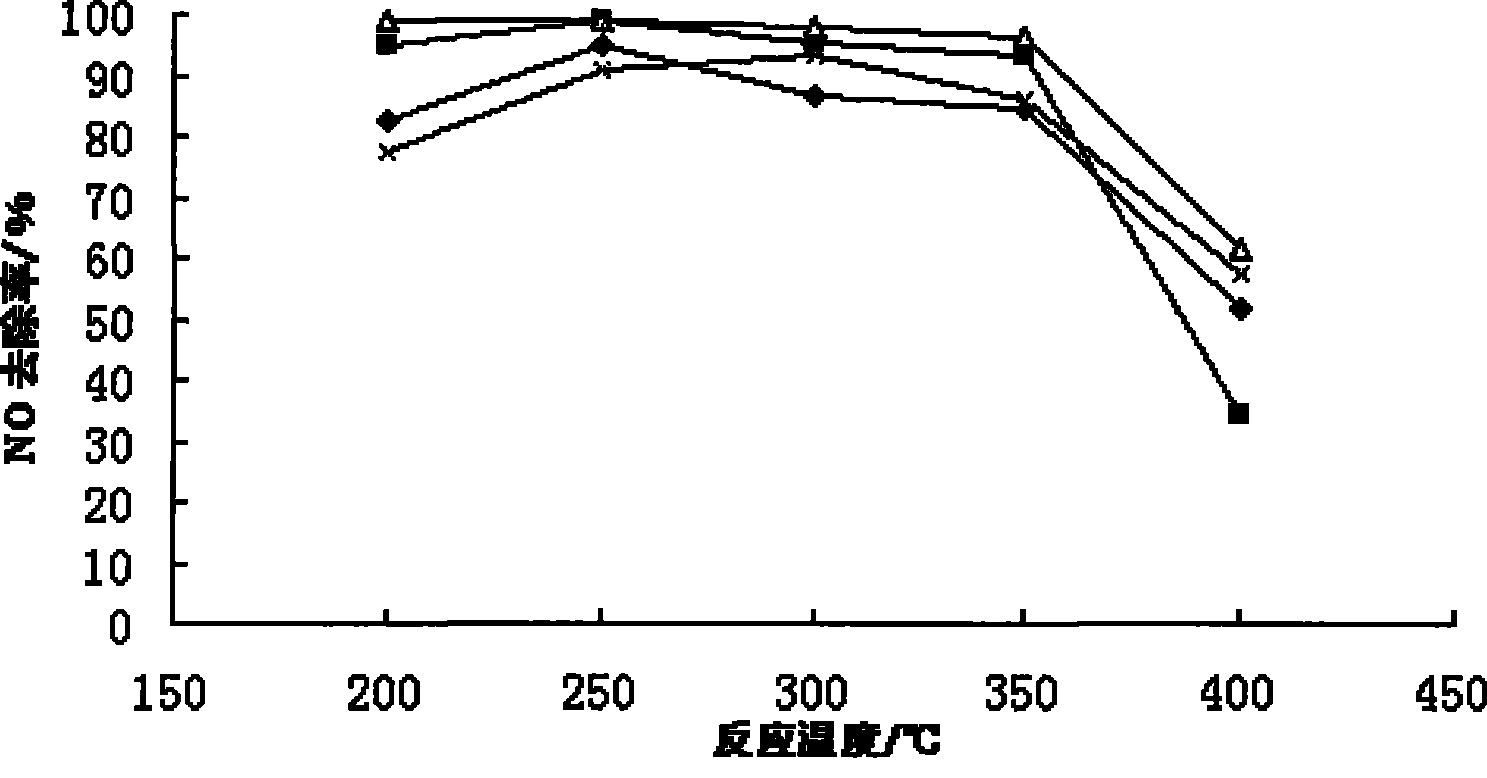

Flue gas denitrating integral catalyst with titanium base ceramic as carrier and preparation thereof

ActiveCN101234346BGood activity at low temperatureImprove thermal stabilityDispersed particle separationCatalyst activation/preparationPtru catalystTitanium zirconium

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

Cordierite ceramic and method for manufacturing the same

InactiveUS20080124515A1No heterogeneous appearancePromote generationLayered productsThin material handlingCordieriteHafnium

The present invention provides a cordierite ceramic containing at least either of zirconium oxide and hafnium oxide and also containing titanium oxide, wherein the molar ratio of zirconium (Zr), hafnium (Hf) and titanium (Ti) in terms of the moles in the form of the dioxides, respectively which is given by the formula [(ZrO2+HfO2) / TiO2] is in a range of 0.1 to 5; and a honeycomb structure made of the cordierite ceramic. In this cordierite ceramic, the phases of the above components are contained mainly as zirconium titanate or hafnium titanate, and there occurs no heterogeneity in appearance, caused by change in color and generation of spots or the like.

Owner:NGK INSULATORS LTD

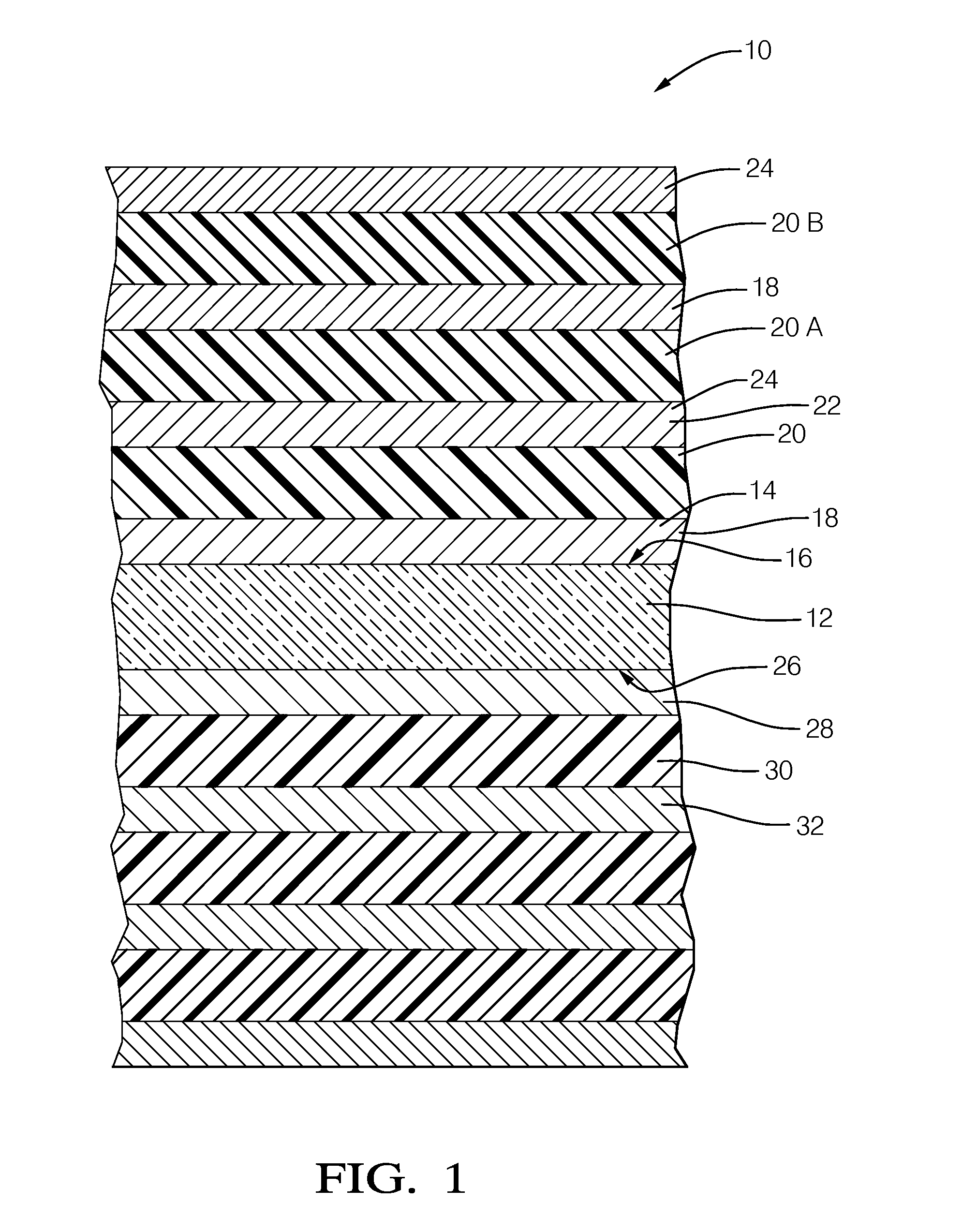

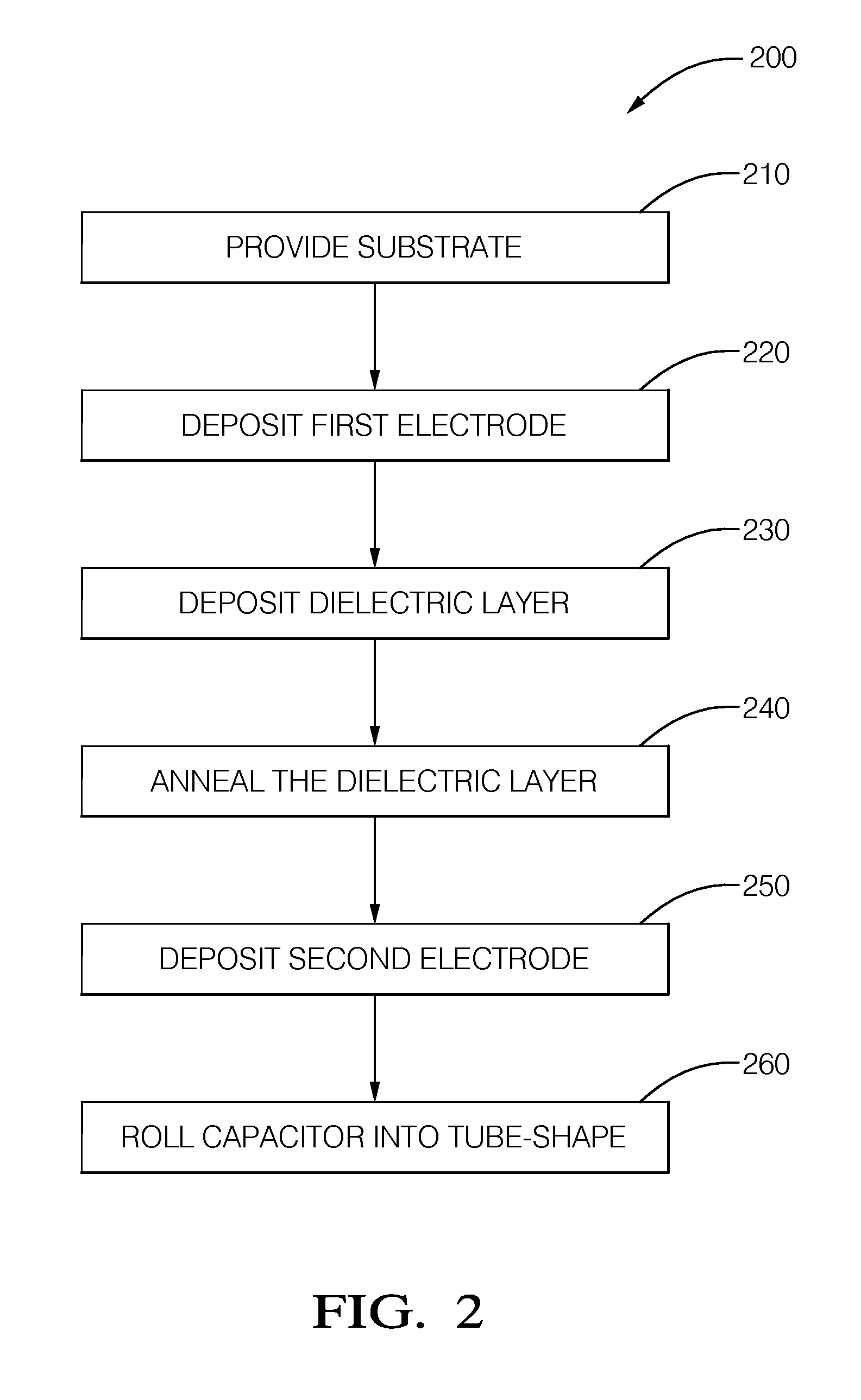

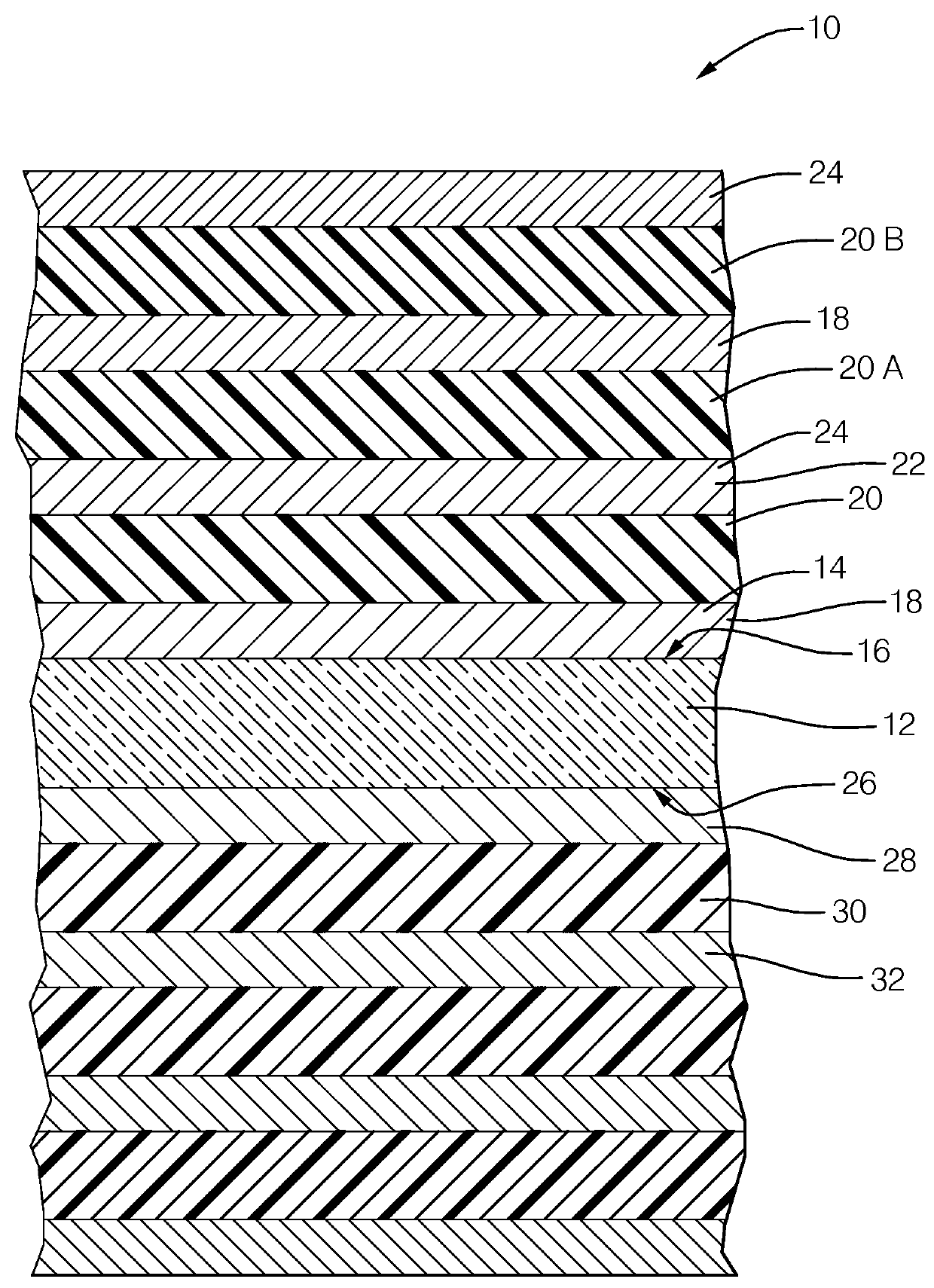

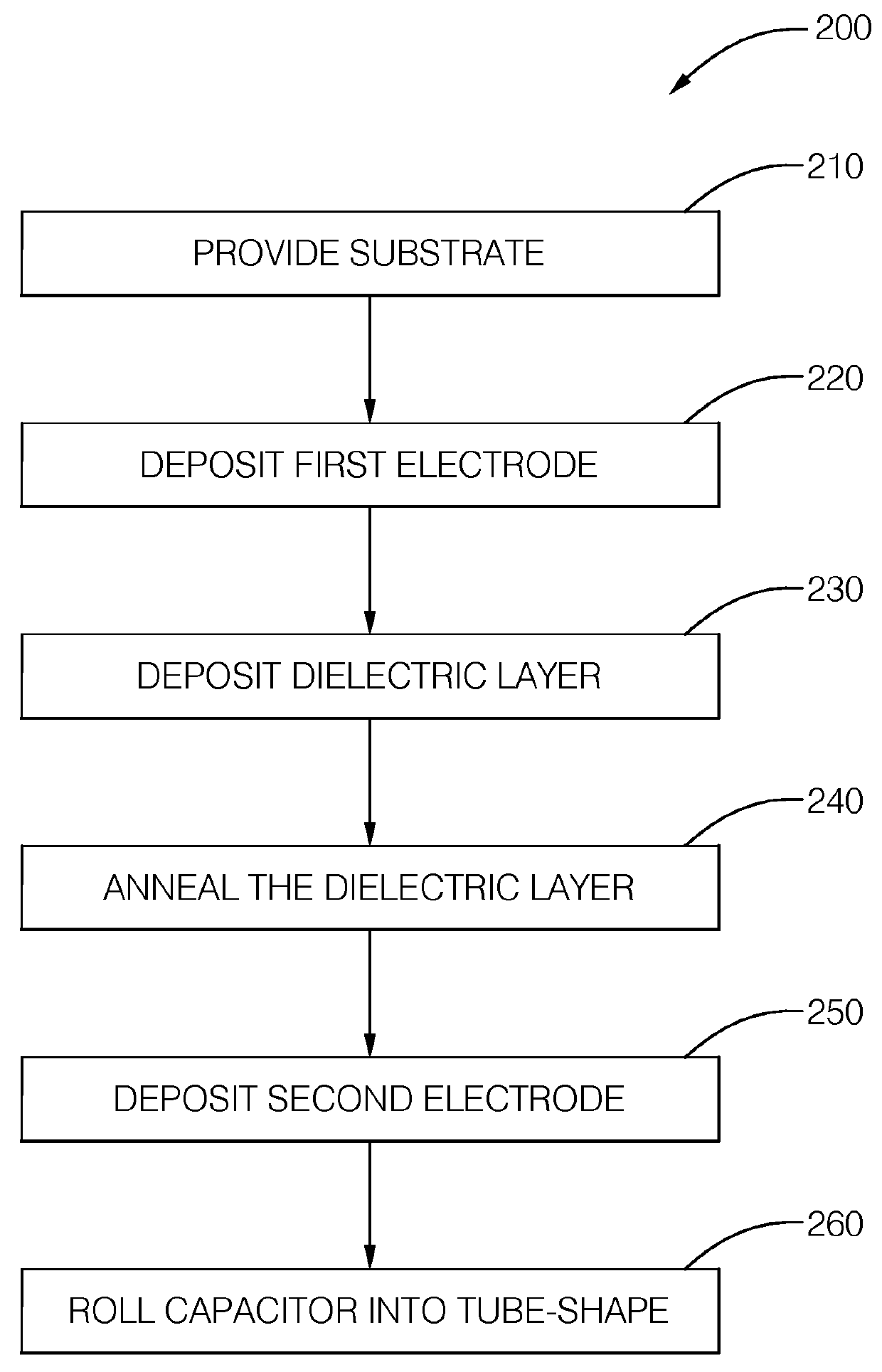

Plzt capacitor on glass substrate

A lead-lanthanum-zirconium-titanate (PLZT) capacitor on a substrate formed of glass. The first metallization layer is deposited on a top side of the substrate to form a first electrode. The dielectric layer of PLZT is deposited over the first metallization layer. The second metallization layer deposited over the dielectric layer to form a second electrode. The glass substrate is advantageous as glass is compatible with an annealing process used to form the capacitor.

Owner:DELPHI TECH IP LTD +1

Zirconium titanate-based high temperature structure composite material and preparation thereof

InactiveCN101407416AHigh temperature resistantImprove thermal shock resistancePolyvinyl alcoholTemperature resistance

The invention relates to a zirconia titanate based high-temperature structured composite material and a preparation method thereof, which belongs to the field of ceramic materials. The composite material adopts the raw materials with the weight percent of 90-98 percent of zirconia titanate powder and 2-10 percent of aluminum titanate powder, wherein, the grain diameter of the adopted raw material is less than 0.074mm. The preparation method of the composite material comprises: measuring and batching the raw materials, dry-blending for 1 minute, adding 6 percent (weight percent) of polyvinyl alcohol solution bonding agent with 0.5 percent of mass concentration, stirring for 5 minutes, standing and ageing mixture for 5h to obtain the formed stock; adopting a hydraulic press or a friction press to press and form the stock on the condition that the forming pressure of the green body is between 70-100MPa; and sintering the formed green body on the condition of insulating heat for 3 hours at 1500 DEG C or higher temperature to obtain the zirconia titanate based composite material with high temperature resistance, high strength and favorable thermal shock resistance. The composite material can be used in the fields of metallurgy, automobile, aerospace, and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminium titanate-zircite-zirconium titanate composite material and preparation method thereof

The invention relates to a composite material of aluminium titanate, zirconia and zirconium titanate, and a method for preparing the same, which belongs to the field of ceramic materials. The raw materials used by the composite material in weight percentage are: 91 to 94.5 percent of aluminium titanate powder the grain size of which is less than 0.03 millimeter, 4.5 to 8 percent of nano-zirconia powder the grain size of which is less than 100 nanometers, and 1 to 1.5 percent of nanometer titanium dioxide powder the grain size of which is less than 100 nanometers. The method comprises the following steps: after the dry mixing of the raw materials, mixing the mixture with adequate amount of diluent of phenolic resin and ethanol and stirring the mixture for 10 minutes, and removing the ethanol from the slurry after the stirring to obtain a blank for molding, wherein the molding pressure of the blank is between 100 and 150 MPa; drying the blank after molding at a temperature of 110 DEG C for 2 hours; and keeping the temperature of the blank after the drying between 1,500 and 1,550 DEG C for 2 to 3 hours, and sintering the blank to obtain the composite material of the aluminium titanate, the zirconia and the zirconium titanate. The strength of the composite material is far higher than that of the common aluminium titanate material, thus the composite material is a promising updating material in the fields of the metallurgy, glass, automobile, aerospace and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

PLZT capacitor on glass substrate

A lead-lanthanum-zirconium-titanate (PLZT) capacitor on a substrate formed of glass. The first metallization layer is deposited on a top side of the substrate to form a first electrode. The dielectric layer of PLZT is deposited over the first metallization layer. The second metallization layer deposited over the dielectric layer to form a second electrode. The glass substrate is advantageous as glass is compatible with an annealing process used to form the capacitor.

Owner:DELPHI TECH IP LTD +1

Zirconium titanate-based solid solution carrier material for motorcycle exhaust catalyst carrier

InactiveCN101698156ALow costWell mixedCatalyst carriersDispersed particle separationZirconium hydrideCerium(IV) oxide

The invention relates to a zirconium titanate-based solid solution carrier material for a motorcycle exhaust catalyst carrier, which mainly consists of titanium oxide, zirconium oxide and a stabilizer; the mixing ratio by parts by weight is as follows: 10-45 parts of the zirconium oxide, 10-45 parts of the titanium oxide and 1-10 parts of the stabilizer; and the stabilizer is one or two of yttrium oxide, lanthanum oxide, cerium oxide, copper oxide and barium oxide, and the stabilizer exists in the form of zirconium titanate solid solution. The zirconium titanate-based solid solution carrier material has the advantages that as a metal oxide-doped zirconium titanate composite oxide with cheap price is used as the carrier material of a three-way catalyst, a valuable Rh metal can be saved and the cost of the product can be reduced. The using effect proves that the transformation efficiency of a catalyst prepared by the carrier material to main pollutants of NOx, HC and CO can be more than 90%.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com