Preparing method for magnesium alloy environment-friendly corrosion resisting type ceramic conversion film

A technology of ceramic transformation and magnesium alloy, applied in the direction of metal material coating process, etc., can solve the problems of limited substrate protection performance, unable to meet the needs of magnesium alloy industrial application, weak research foundation of magnesium alloy, etc., and achieve easy control and stable film formation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the present embodiment, the sample is a modified AZ80 magnesium alloy, and its specific steps are as follows:

[0039] (1) Pretreatment: the pretreatment solution is an aqueous solution of sodium hydroxide 50g / l and sodium silicate 20g / l, with a pH value of 12, soaked at room temperature for 5 minutes;

[0040] (2) Roughening treatment: the roughening treatment solution is an aqueous solution of citric acid 10g / l, DL-malic acid 10g / l, sodium fluoride 20g / l, pH value 3, soaking at room temperature for 1min;

[0041] (3) Homogenization treatment: the homogenization treatment solution is an aqueous solution of ammonium bifluoride 20g / l, alkylphenol polyoxyethylene ether 50mg / l, pH value 7, soaking at room temperature for 1min;

[0042] (4) Conversion treatment: the conversion treatment solution is potassium fluozirconate 5g / l, fluozirconate 5g / l, potassium manganate 8g / l, tannic acid 1g / l, γ-aminopropyltriethoxysilane 5g / l aqueous solution, temperature is 26°C, pH val...

Embodiment 2

[0044] In the present embodiment, the sample is a deformed AZ80 magnesium alloy, and its specific steps are as follows:

[0045] (1) Pre-treatment: the pre-treatment solution is an aqueous solution of 40 g / l sodium hydroxide and 40 g / l sodium silicate, with a pH value of 13, soaked at room temperature for 5 min;

[0046] (2) Roughening treatment: the roughening treatment solution is an aqueous solution of citric acid 10g / l, DL-malic acid 10g / l, hexamethylenetetramine 30g / l, pH value 4, soaking at room temperature for 1min;

[0047] (3) Homogenization treatment: the homogenization treatment solution is an aqueous solution of ammonium bifluoride 30g / l, alkylphenol polyoxyethylene ether 50mg / l, pH value 6, soaking at room temperature for 1min;

[0048] (4) Conversion treatment: the conversion treatment solution is potassium fluozirconate 10g / l, potassium fluotitanate 5g / l, ammonium molybdate 8g / l, phytic acid 1g / l, γ-aminopropyltriethoxysilane 1g / l aqueous solution, temperature...

Embodiment 3

[0050] In this embodiment, the sample is an extruded AZ31B magnesium alloy plate, and its specific steps are as follows:

[0051] (1) Pretreatment: the pretreatment solution is an aqueous solution of 40 g / l sodium hydroxide and 40 g / l sodium silicate, with a pH value of 11, soaked at room temperature for 5 minutes;

[0052] (2) Roughening treatment: the roughening treatment solution is an aqueous solution of 10 g / l of DL-malic acid, 10 g / l of lactic acid, and 20 g / l of sodium fluoride, with a pH value of 5, soaked at room temperature for 5 minutes;

[0053] (3) Homogenization treatment: the homogenization treatment solution is an aqueous solution of ammonium bifluoride 30g / l and sodium dodecylsulfonate 100mg / l, pH value 8, soaked at room temperature for 2min;

[0054] (4) Transformation treatment: The transformation treatment solution is 5g / l of fluozirconic acid, 5g / l of fluotitanic acid, 5g / l of potassium fluotitanate, 6g / l of potassium permanganate, 1g / l of cerium nitrate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

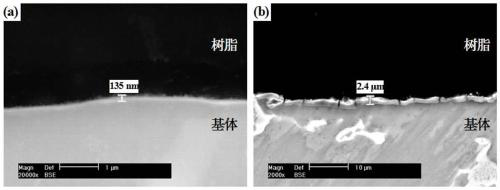

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com