Patents

Literature

642 results about "Ammonium bifluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium hydrogen fluoride is the inorganic compound with the formula NH₄HF₂ or NH₄F·HF. It is produced from ammonia and hydrogen fluoride. This colourless salt is a glass-etchant and an intermediate in a once-contemplated route to hydrofluoric acid.

Acidizing block remover suitable for complex lithologic reservoir

ActiveCN102775980ASuppressed ionizationRestore permeabilityDrilling compositionSolventFluoboric acid

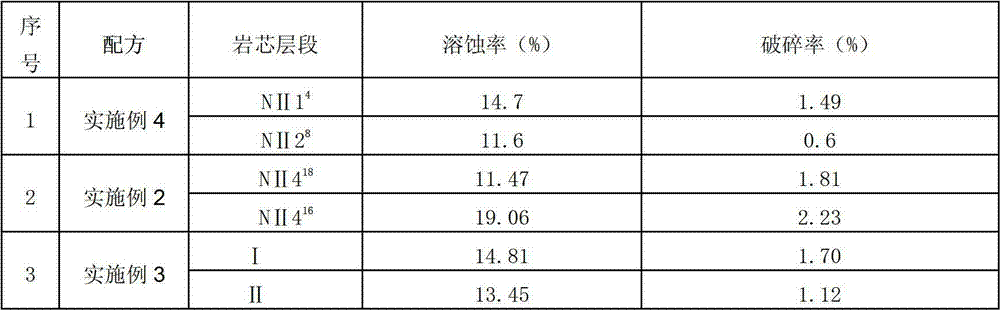

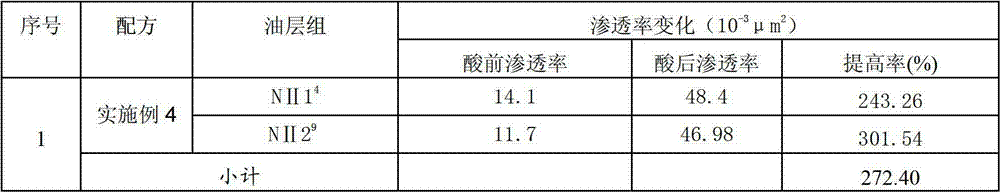

The invention relates to an acidizing block remover suitable for a complex lithologic reservoir. The acidizing block remover suitable for the complex lithologic reservoir comprises the following components by weight: 0-12% of hydrochloric acid, 0-3% of ammonium bifluoride, 0-10% of sulfamic acid, 0-5% of fluoboric acid, 0-3% of boric acid, 0-4% of alcohol, 0-2% of triethanolamine, 3% of glacial acetic acid, 4.0-6.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 0.5-1.0% of penetrating agent, 2.0% of clay stabilizer and 45-88.5% of water. The problems that the lithologic and physical property differences of oil fields are large, the oil fields are in staggered distribution, and the acidizing debugging construction effect of a common water injection well is not ideal are mainly solved. The acidizing block remover suitable for the complex lithologic reservoir can effectively corrode the strata minerals and obstruent, does not destroy a rock skeleton, can prevent secondary precipitation caused by sensitive mineral, improves the water absorbing capacity of the reservoir, and increases the daily increasing water injection rate of an average single-well measure.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

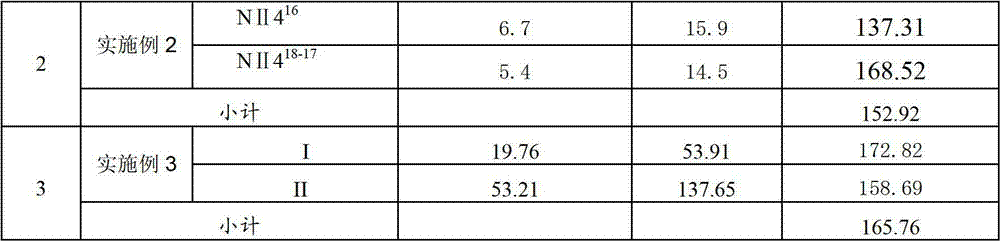

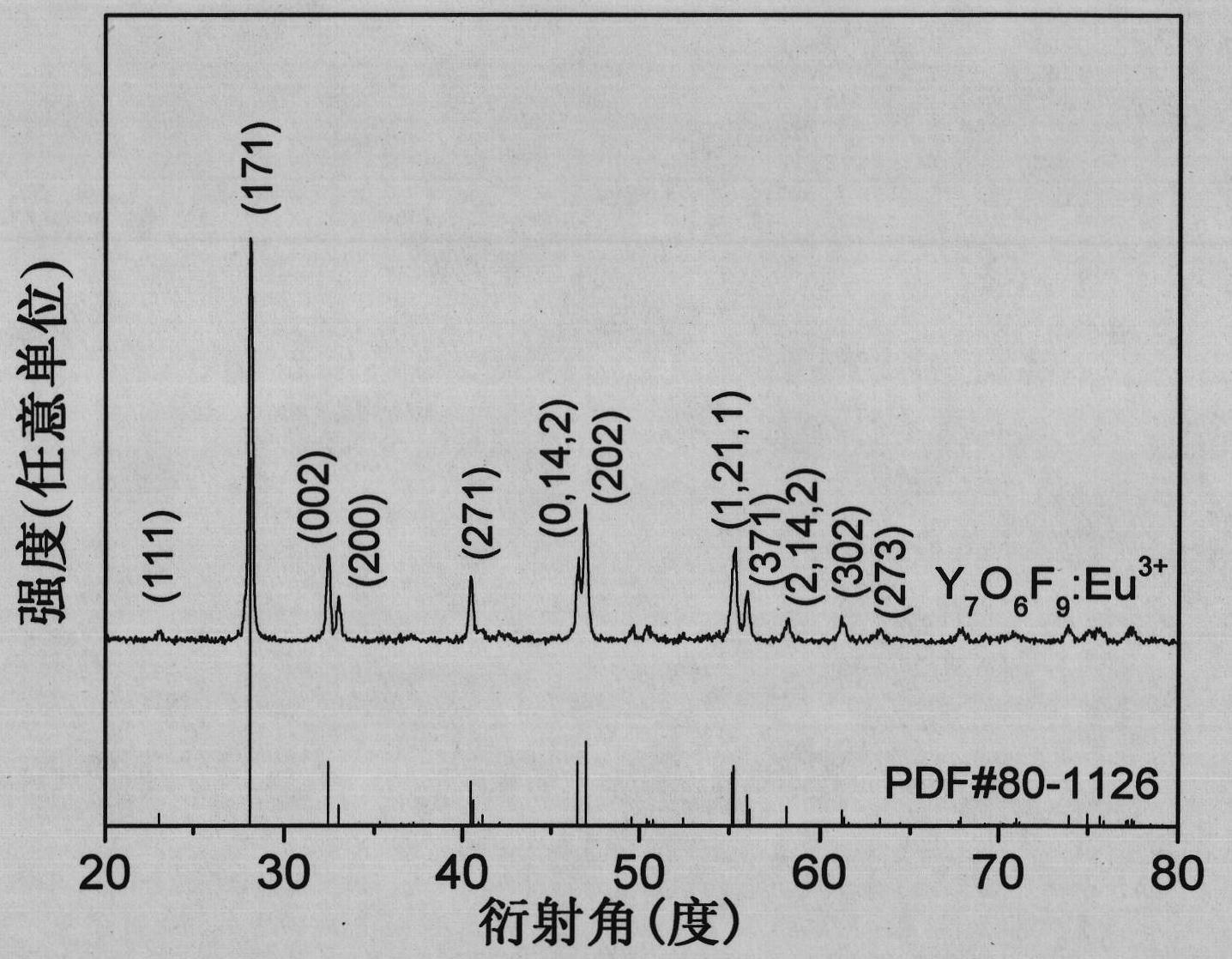

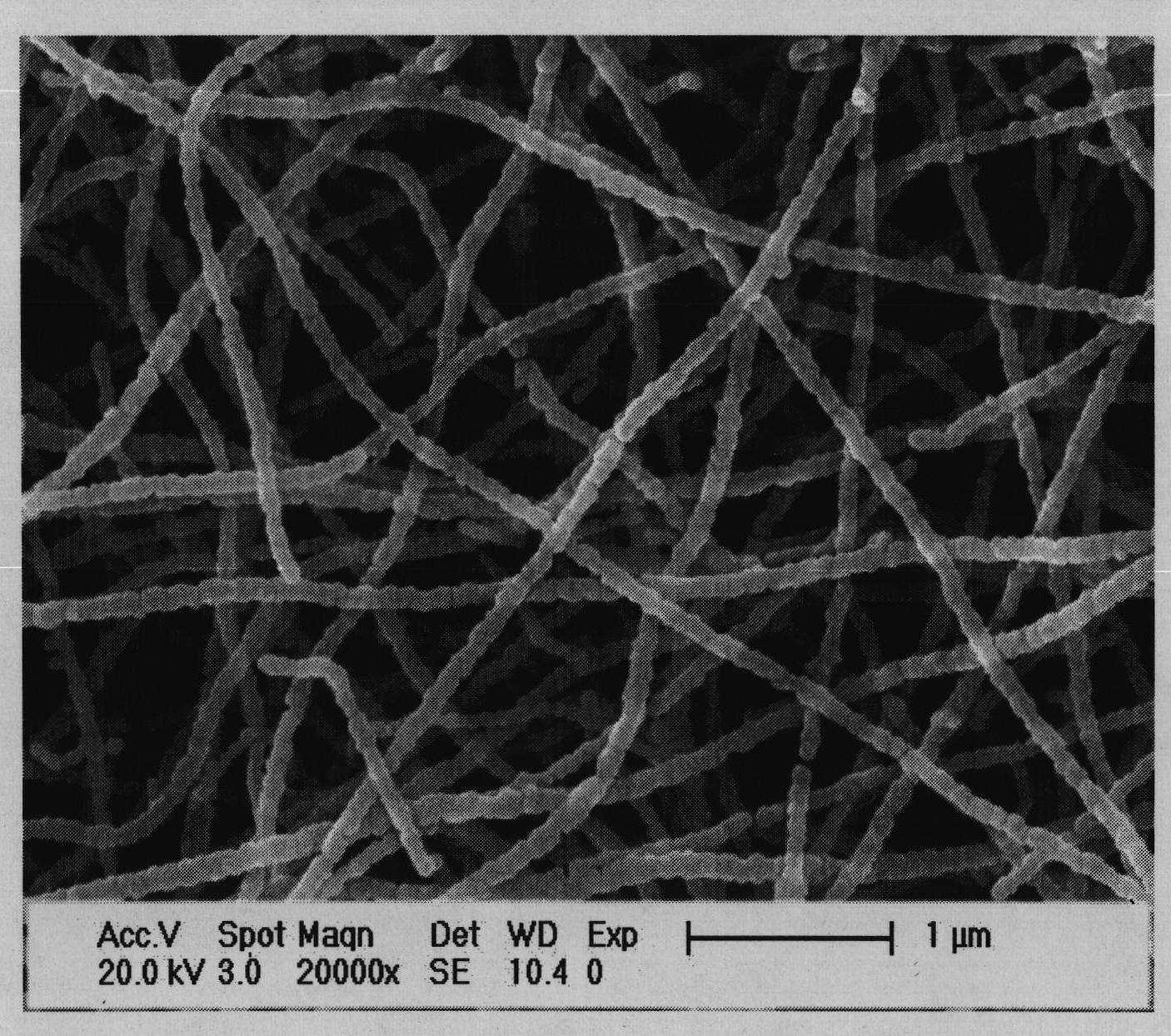

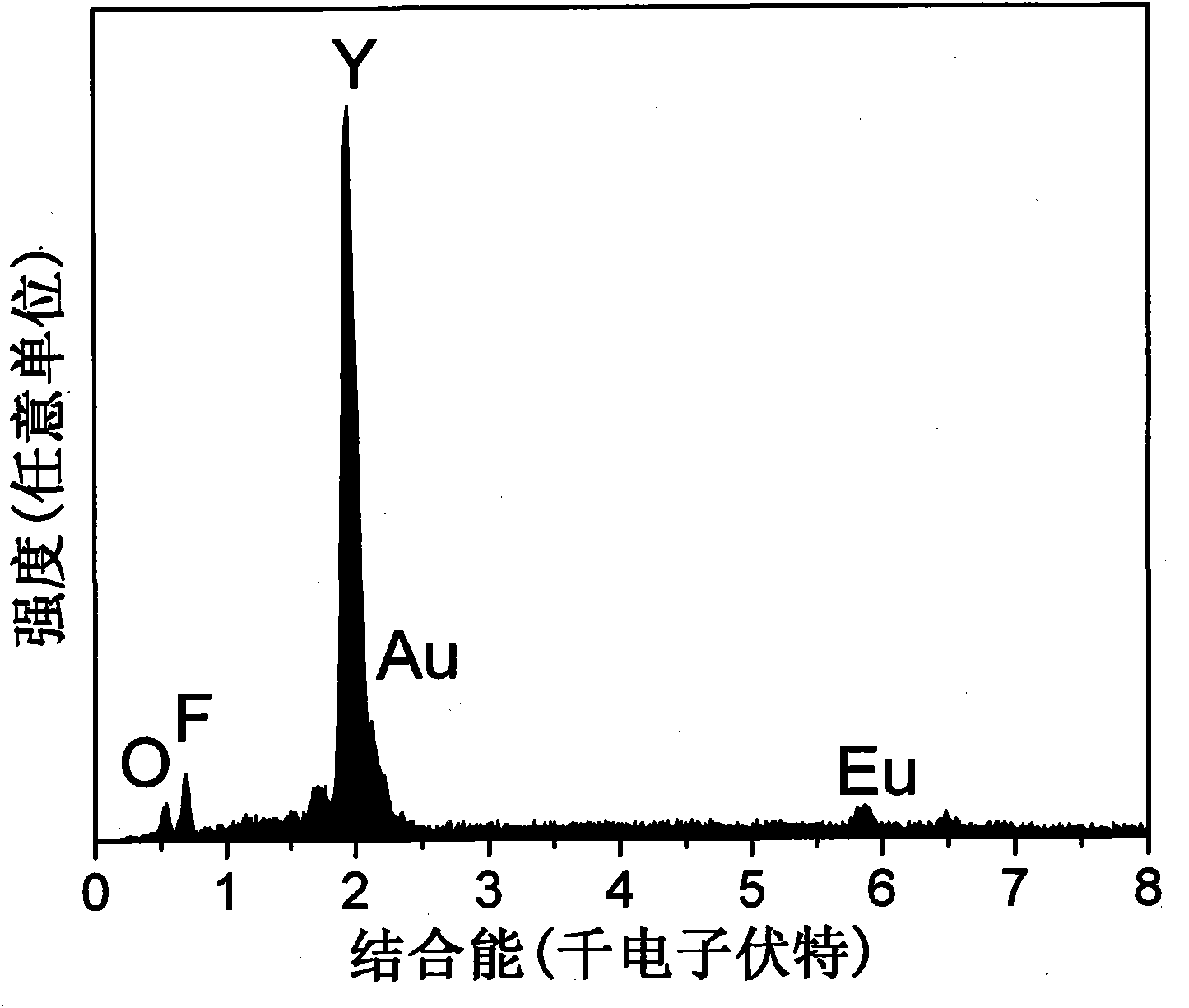

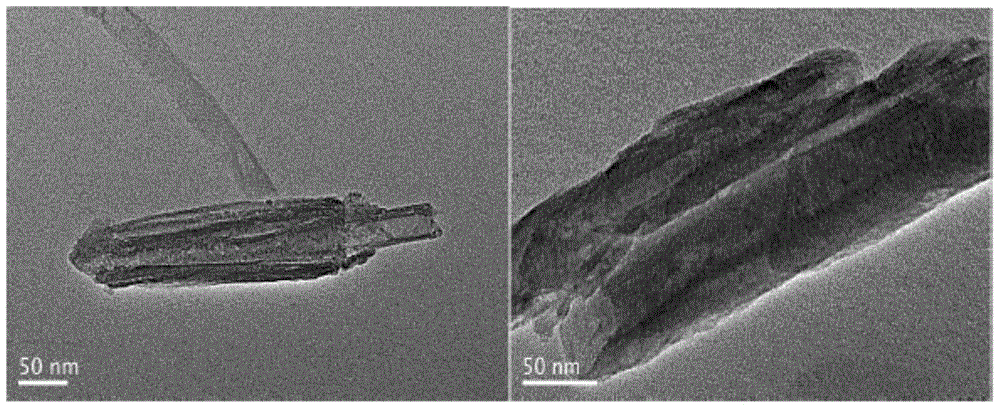

Europium-doped Y7O6F9 nano fiber and preparation method thereof

The invention relates to a europium-doped Y7O6F9 nano fiber and a preparation method thereof, belonging to the technical field of the preparation of nano materials. A rare earth fluoride / rare earth oxyfluoride composite nano fiber is prepared by the traditional electrostatic spinning technology. The preparation method provided by the invention comprises the following three steps: (1) preparation of a Y2O3:5%Eu<3+> nano fiber: preparing a PVP / [Y(NO3)3+Eu(NO3)3] composite nano fiber by adopting the electrostatic spinning technology, and then, carrying out heat treatment to obtain the Y2O3:5%Eu<3+> nano fiber; (2) preparation of a YF3:5%Eu<3+> nano fiber: fluorinating the Y2O3:5%Eu<3+> nano fiber by a double-crucible method to obtain the YF3:5%Eu<3+> nano fiber, wherein the fluorinating reagent is ammonium bifluoride; and (3) preparation of a Y7O6F9:5%Eu<3+> nano fiber: placing the YF3:5%Eu<3+> nano fiber in a muffle furnace, heating at 580 DEG C under the air atmosphere for 9 hours to obtain the Y7O6F9:5%Eu<3+> nano fiber, wherein the diameter is 181-241 nm, and the length is greater than 300 mu m. The europium-doped Y7O6F9 nano fiber is a novel important red nano fluorescent material having wide application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

Stainless steel etching technique

The invention provides an etching process for stainless steel, which comprises a plurality of steps: a. pre-processing, used to do surface cleaning operations like cleaning and deoiling of the initial stainless steel workpiece; b. coating, in which the surface of the stainless steel is applied with photosensitive glue, and the operations of exposure, development and hardening are conducted; c. etching, in which stainless steel etching solution is used to erode the exposed metal part of the stainless steel workpiece; wherein, the stainless steel etching solution is mainly composed of: ferric trichloride 400 to 600 g / L, hydrochloric acid 2 to 5 g / L, ammonium bifluoride 1 to 2 g / L, thioureas 2.5 to 5 g / L, etching promoter 1 to 5 g / L and regenerator 2 to 5 g / L; d. demoulding, when the etching is done to a certain extent, the remaining glue on the surface of the workpiece can be removed by means of dissolving liquid, and thus the intended product can be obtained after cleaning. The invention has the advantages of good etching speed, high precision, regenerating capacity of the etching solution, simple manufacturing process and broad market prospect.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Etching liquid composition and etching method

The invention relates to an etchant composition and an etching method, wherein, the etchant composition comprises any two components of oxidants, acid and salt, and the pH value of the etchant composition is between 1 and 7. The oxidant components are selected from hydrogen peroxide, ammonium persulfate, potassium persulfate and ceric ammonium nitrate; the acid components are selected from chloric acid, perchlorate, acetic acid, nitric acid, hydrofluoric acid, sulfuric acid and oxalic acid, and the salt components are selected from ammonium fluoride, ammonium bifluoride, diammonium phosphate, ammonium phosphate, ammonium chloride and perfluorinated octyl sulfanilic acid (C8F17SO3NH4).

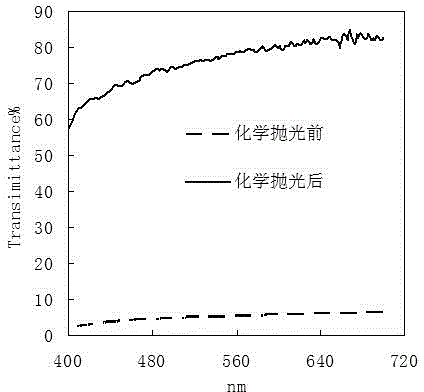

Method for preparing anti-dazzle glass

The method relates to a method for preparing antiglare glass. The method comprises the following steps that: (1) an etching solution comprises the following compositions in portion by weight according to a formula: 10 to 15 portions of ammonium bifluoride, 20 to 30 portions of ammonium fluoride, 5 to 7.5 portions of calcium fluoride, 10 to 15 portions of barium sulphate, 5 to 7.5 portions of ammonium sulphate, 5 to 10 portions of sodium fluosilicate or 5 to 10 portions of sodium fluoborate, 5 to 10 portions of zinc chloride, 10 to 20 portions of concentrated sulphuric acid and 70 to 100 portions of water; raw materials are weighed, mixed, evenly stirred and matured for 6 to 10 hours at room temperature to prepare the etching solution; (2) the surface of a glass sample is cleaned and dried by absolute ethyl alcohol; (3) one surface of the glass sample which does not need to be etched is covered; and (4) the glass sample is put into the etching solution, marinated, taken out, washed by clean water and dried to produce a finished product of the antiglare glass. The method has simple process and easy operation; the prepared glass sample has the advantages of small particles on the surface and even distribution of the particles, high light transmissivity, good antiglare effect, etc.

Owner:DONGHUA UNIV

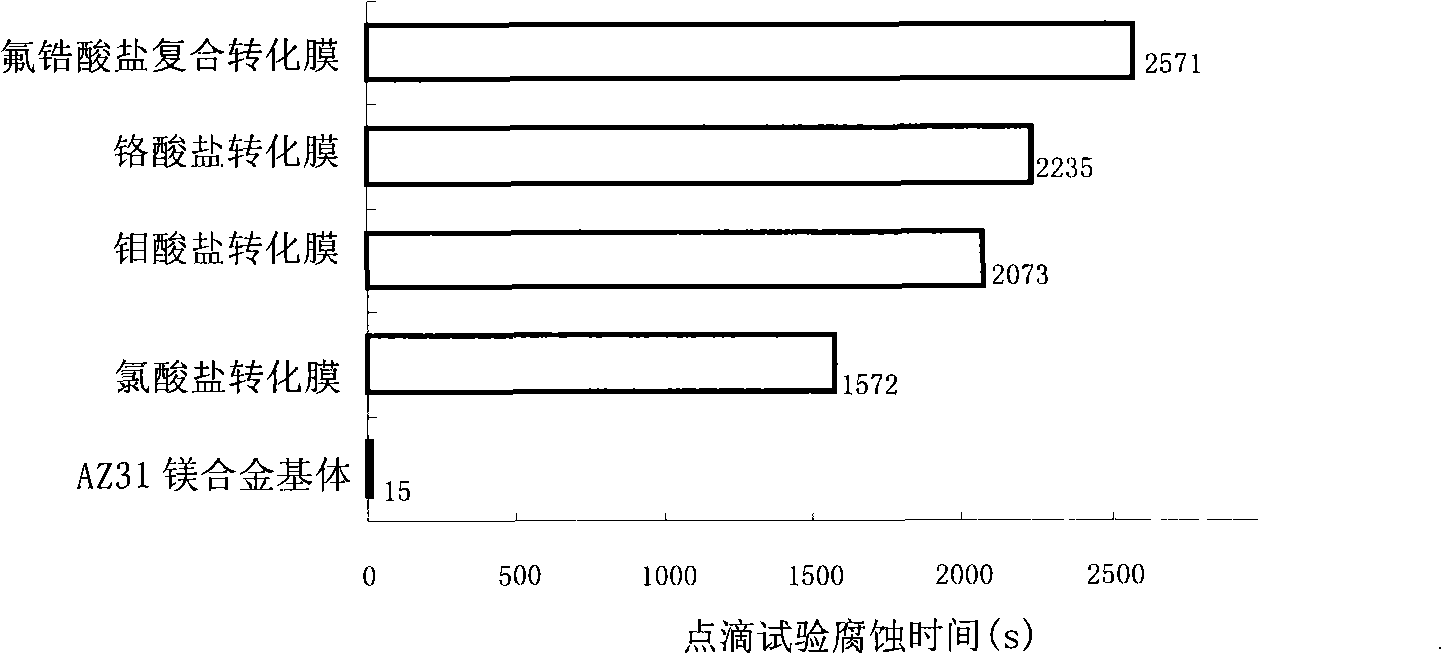

Treatment method on surface of magnesium alloy

ActiveCN101538707AAvoid instabilityAvoid pollutionMetallic material coating processesIonAmmonium bifluoride

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

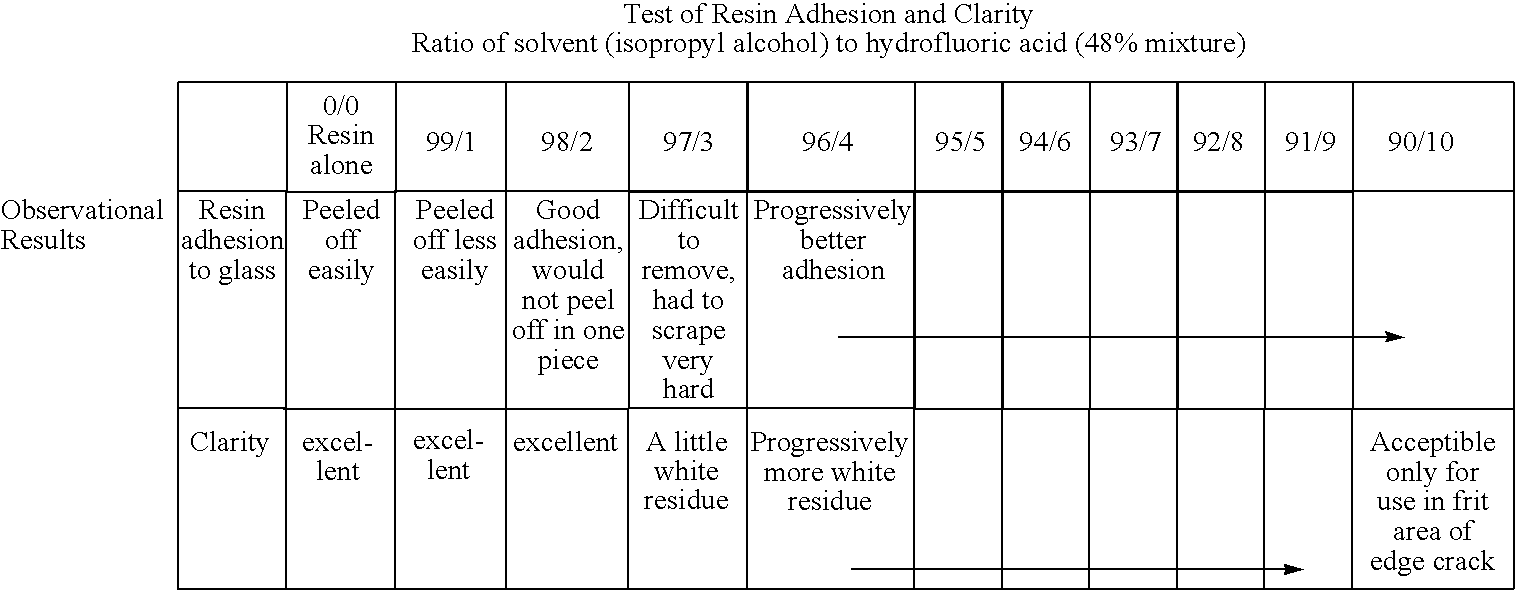

Method and System for Repair of Glass

A pre-treatment chemical mixture of hydrofluoric acid or ammonium bifluoride and isopropyl alcohol for glass adhesive applications. In one particular a pretreatment for the repair of stone breaks and long cracks in windshields. The pretreatment improves the repair by removing, through evaporation of the solvent, isopropyl alcohol, the hydrophobic coating that has been applied to the windshield when it was manufactured and simultaneously etching the sides of the stone break or long crack in a way that allows better adhesion by the adhesive repair resin while not leaving any trace of the etching after the repair is complete, thereby keeping the windshield or other glass, clear.

Owner:CAMPFIELD RICHARD +1

Normal temperature passivated zinc coating trivalent chromium color passivating agent

InactiveCN1858303AReduce concentrationReduce manufacturing costMetallic material coating processesMolybdateMalonic acid

The present invention discloses trivalent chromium color zinc coating passivator for passivation at normal temperature and its preparation process. The trivalent chromium color zinc coating passivator includes Cr3+ 1-7.5g / L, molybdate 1-25g / L, cobalt sulfate 5-15, ammonium bifluoride 1-8g / L, malonic acid 1-12g / L, phosphate 1-12 g / L, and silicate 0.2-6g / L. The trivalent chromium color zinc coating passivator solution has pH 1.8-2.3 regulated with sodium carbonate or nitric acid, passivating temperature of 20-35deg.c, passivating time of 30-60 sec and stoving temperature of 70-80deg.c. The present invention has the advantages of being practical and good use effect.

Owner:SUR PRECISION METAL TECH

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

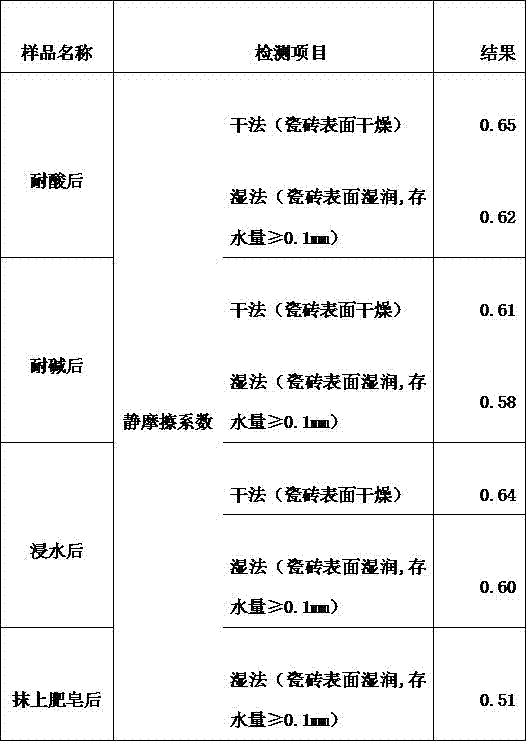

Slipproofing agent for surface of ceramic tile and preparation method of slipproofing agent

The invention provides a slipproofing agent for the surface of a ceramic tile and a preparation method of the slipproofing agent. The slipproofing agent is prepared from villiaumite, a corrosion inhibitor, a surfactant, a humectant, essence and the balance of water, wherein the villiaumite is ammonium fluoride and / or ammonium hydrogen fluoride. The preparation method of the slipproofing agent comprises the following steps:, at 25 to 30 DEG C, weighing and taking proper raw materials in sequence, and uniformly agitating the proper raw materials, so as to subsequently obtain the slipproofing agent for the surface of the ceramic tile. According to the slipproofing agent, the villiaumite is used as a main raw material; a product is a neutral aqueous solution; a fluorine ion generates a chemical reaction with a silicate component in the ceramic tile under the action of an ammonium ion in a formula, so as to produce silicon fluoride gas for escaping; the direct effect of the chemical reaction is that numerous nano-sized microporous structures are formed in the surface of the ceramic tile; thus, a slipproofing effect is achieved; nontoxic and harmless raw materials are used by the formula of the slipproofing agent; a neutral solution is convenient to transport and use; further, the slipproofing agent provided by the invention has ultrahigh seepage force.

Owner:GUANGDONG QINGZHU TECH CO LTD

High anti-corrosion zinc coating trivalent chromium lue-white passivating agent and its preparing method

InactiveCN1858302AReduce concentrationReduce manufacturing costMetallic material coating processesAcetic acidMalonic acid

The present invention discloses anticorrosive trivalent chromium blue-white zinc coating passivator and its preparation process. The anticorrosive trivalent chromium blue-white zinc coating passivator includes Cr3+ 1-5 g / L, NaNO3 1-20 g / L, malonic acid 1-10 g / L, cobalt sulfate 5-20 g / L, acetic acid 1-10 g / L, phosphate 1-6 g / L, ammonium bifluoride 1-5 g / L and silicate 0.2-5 g / L. The preparation process includes dissolving the said materials in pure water successively through stirring to obtain transparent passivator. The present invention has the advantages of being practical and good use effect.

Owner:SUR PRECISION METAL TECH

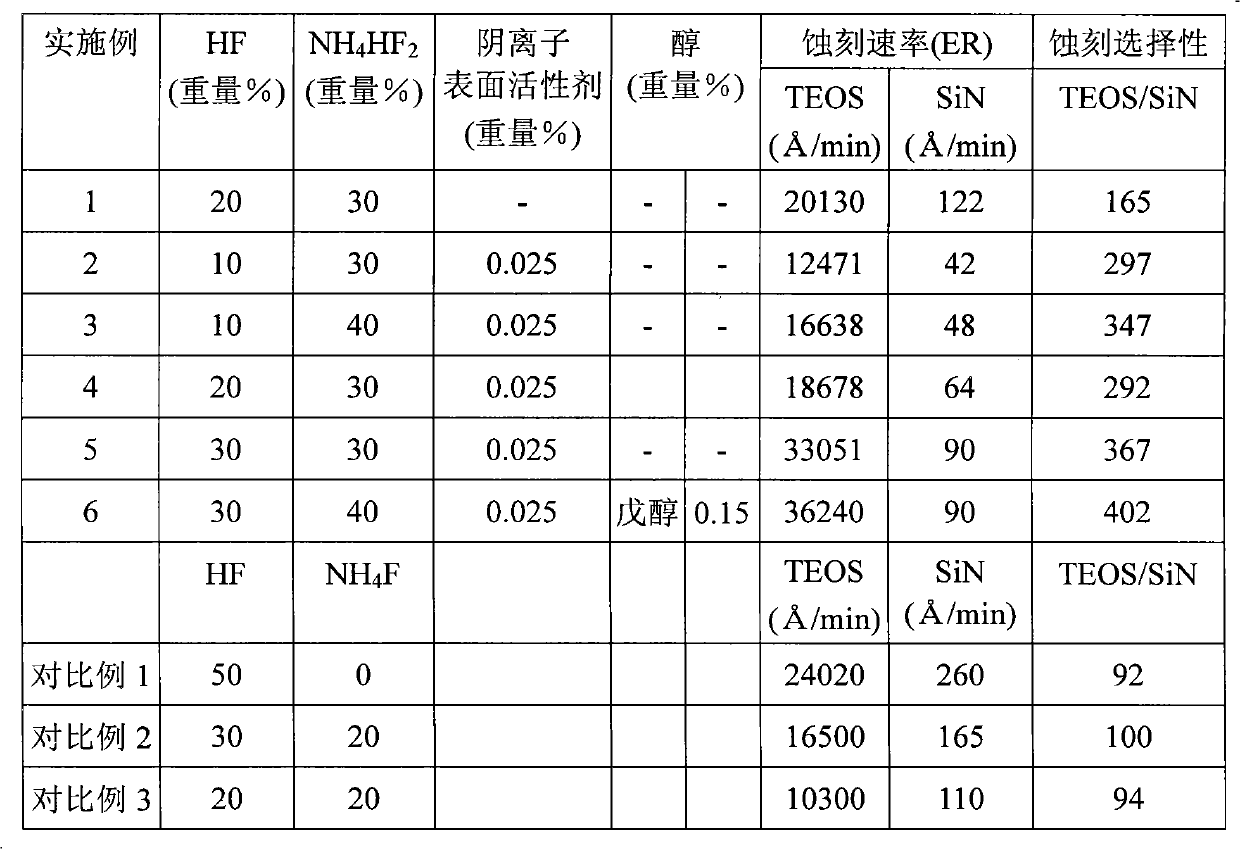

Compound for wet etching silicon dioxide

ActiveCN102443395AImprove etch selectivityReduce processing timeSemiconductor/solid-state device manufacturingSurface treatment compositionsHydrogen fluorideSurface-active agents

The invention provides an etching compound for selectively removing silicon dioxide at high etching rate, in particular, the compound for wet etching silicon dioxide contains the following materials by weight percent: 1-40 weight percent of hydrogen fluoride (HF), 5-40 weight percent of ammonium bifluoride (NH4HF2) and water, and further contains surface active agent to improve the selectivity of silicon dioxide and silicon nitride film. Since the compound for wet etching silicon dioxide has higher etching selectivity of silicon dioxide with respect to silicon nitride film, the compound can be used for selectively removing silicon dioxide.

Owner:SOULBRAIN CO LTD

Method for producing ammonium bifluoride by recovering fluorine resource from fluorine-containing silicon slag

ActiveCN102491370AReduce dosageIncrease concentrationSolid waste disposalAmmonium halidesHydrogen fluoridePhysical chemistry

The invention discloses a method for producing ammonium bifluoride by recovering a fluorine resource from fluorine-containing silicon slag. The method comprises the following steps of: dissolving fluorine-containing silicon slag and an ammonium fluoride solution, cooling an obtained ammonium fluosilicate solution, introducing gas ammonia, and precipitating white carbon black out; filtering and washing to obtain a white carbon black solid and an ammonium fluoride solution; introducing anhydrous hydrogen fluoride into the ammonium fluoride solution, uniformly mixing the anhydrous hydrogen fluoride with the ammonium fluoride solution, and fully reacting till the pH of the solution is 2-4 to obtain an ammonium hydrogen fluoride of which the mass concentration is 21-37 percent; mixing with a crystallized ammonium hydrogen fluoride mother solution, and performing triple-effect evaporation and concentration till the mass concentration of the ammonium hydrogen fluoride is 60-80 percent; feeding into a crystallizer, and cooling and crystallizing for 3-7 hours to obtain an ammonium hydrogen fluoride solid-liquid mixture; and separating to obtain an ammonium bifluoride product and an ammonium bifluoride mother solution. The method has the advantages of low using amount of fluorine hydride, high concentration of ammonium bifluoride, low energy consumption in a concentrating process, low production cost, easiness and convenience for operating, and easiness for realizing industrialization.

Owner:WENGFU (GRP) CO LTD +1

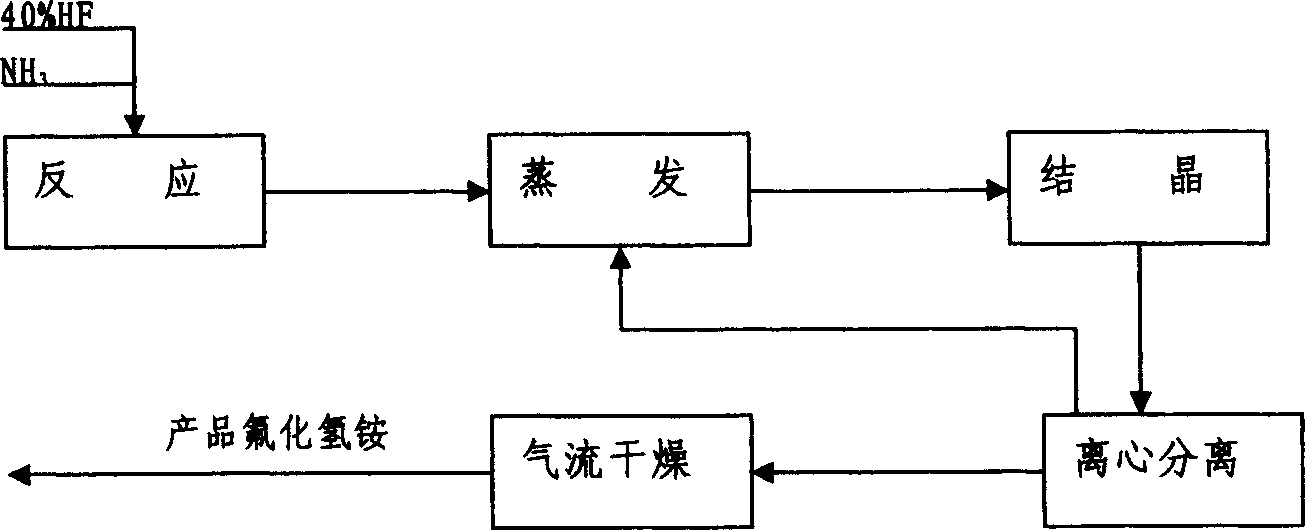

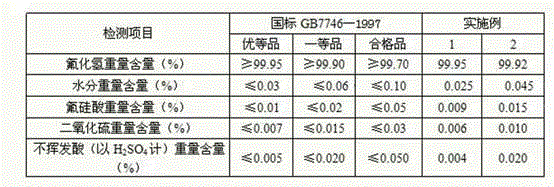

Method for producing high-purity ammonium bifluoride

The invention discloses a method for producing high-purity ammonium bifluoride, which comprises the following steps of: (1) under the stirring condition, introducing anhydrous hydrogen fluoride into saturated solution of ammonium fluoride until the pH value of the reaction liquid ranges from 1 to 4, and stopping introducing the anhydrous hydrogen fluoride, wherein the temperature is controlled between 25 and 50 DEG C in the reaction process; (2) cooling the reaction liquid to the temperature of between 5 and 20 DEG C, and keeping the temperature for 2 to 4 hours until crystals separate out; and (3) filtering, drying a filter cake to obtain the product of high-purity ammonium bifluoride, and recycling the filter liquor. The method for producing the high-purity ammonium bifluoride has the advantages of small equipment investment, simple process, easy operation, and low moisture content, high purity, high dissolving speed, convenient use, hard agglomeration, and long-term storage of the product ammonium bifluoride. The mother solution is circulated in a closed loop, and the whole technical process has no liquid waste discharge. The raw material ammonium fluoride is prepared by ammonolysis of a byproduct fluosilicic acid in the phosphate fertilizer industry, and the method has the advantages of easily obtained raw materials, low cost, and low production cost. The method provides a new fluoride source, and solves the problem of environmental pollution in the phosphate fertilizer industry.

Owner:焦作市增氟科技有限公司

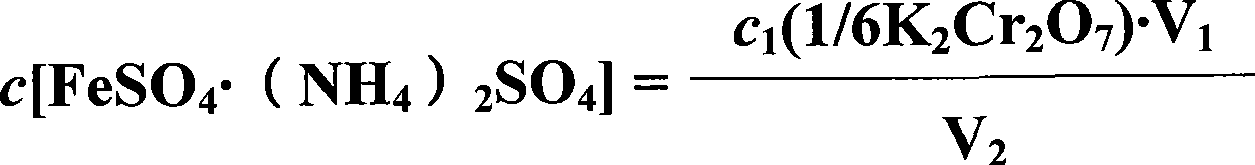

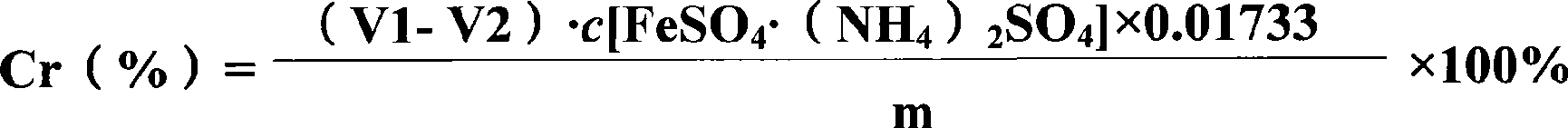

Method for measuring chromium content in tungsten substrate added with chromium or simultaneously added with chromium and vanadium

InactiveCN101430287AThe test result is accurateImprove detection accuracyAnalysis using chemical indicatorsChemical analysis using titrationFerrous ammonium sulfateVanadium atom

The invention relates to a method of mensurating the content of chrome in tungsten matrix which is added with the chrome and vanadium separately or synchronously. The method is characterized in that a sample is melted by sodium dioxide and is soaked in hot water; meanwhile, the sodium dioxide is also used as oxidant to oxidize the chrome into high valence chrome; ammonium bifluoride is used for complexing main body tungsten and avoiding tungstenic acid cementing out; the whole analysis process avoids the occurrence of precipitation and opacification; titration can be carried out under completely limpid and transparent state; and titration result is exact and reliable. The limpid and transparent solution during the titration is very important to the accuracy of titration analysis. The solution is always limpid and transparent during the whole mensuration process, thereby ensuring that the interference of the vanadium is eliminated exactly and quantitatively when the chrome is mensurated. After the interference of the vanadium is oxidized by potassium permanganate, ferrous ammonium sulphate standard solution is used for titrating to eliminate by a subtraction method. The mensurating method ensures that the mensuration is carried out under the completely limpid and transparent state, and the method eliminates the interference of the vanadium completely and quantitatively and improves the accuracy and the speed for detecting the content of the chrome in the tungsten matrix which is added with the chrome and the vanadium separately or synchronously.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

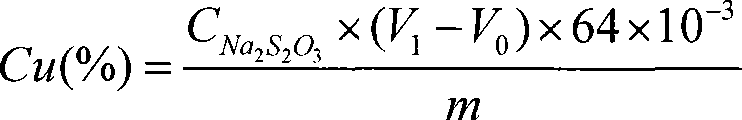

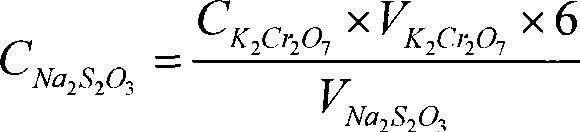

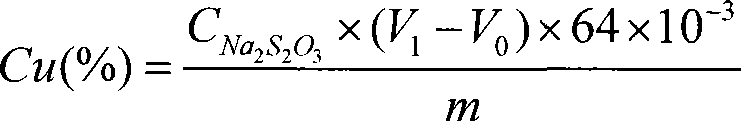

Method for detecting whole copper in soil

InactiveCN101419174AEasy to operateHigh precisionMaterial analysis by observing effect on chemical indicatorSpecial data processing applicationsHydrogen fluorideCopper

The invention relates to measurement for full copper in soil, in particular to a method for measuring full copper in soil. The method comprises the following steps: counteracting a soil sample by using HCl-HNO3-HF-HClO4; adjusting acidity of the solution by using ammonia water and HAC; adding ammonium hydrogen fluoride to mask iron; controlling pH value of the solution between 3.5 and 4.5; adding excessive KI to act with Cu2+; using starch as indicator of the precipitated I2; and using standard Na2S2O3 solution to titrate. The method has the advantages of good repeatability, and accurate and reliable results.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

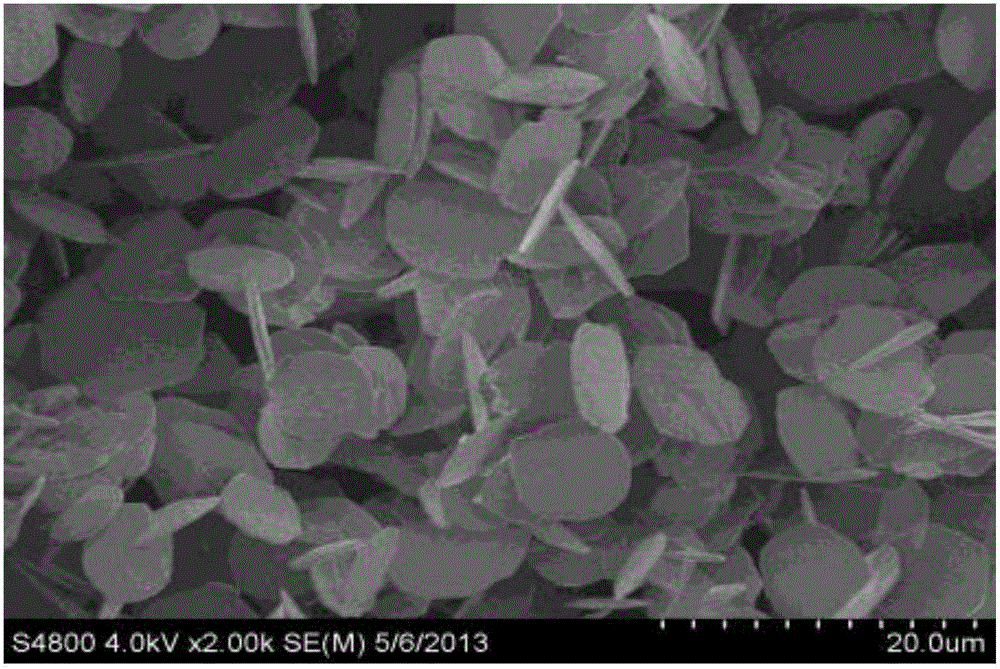

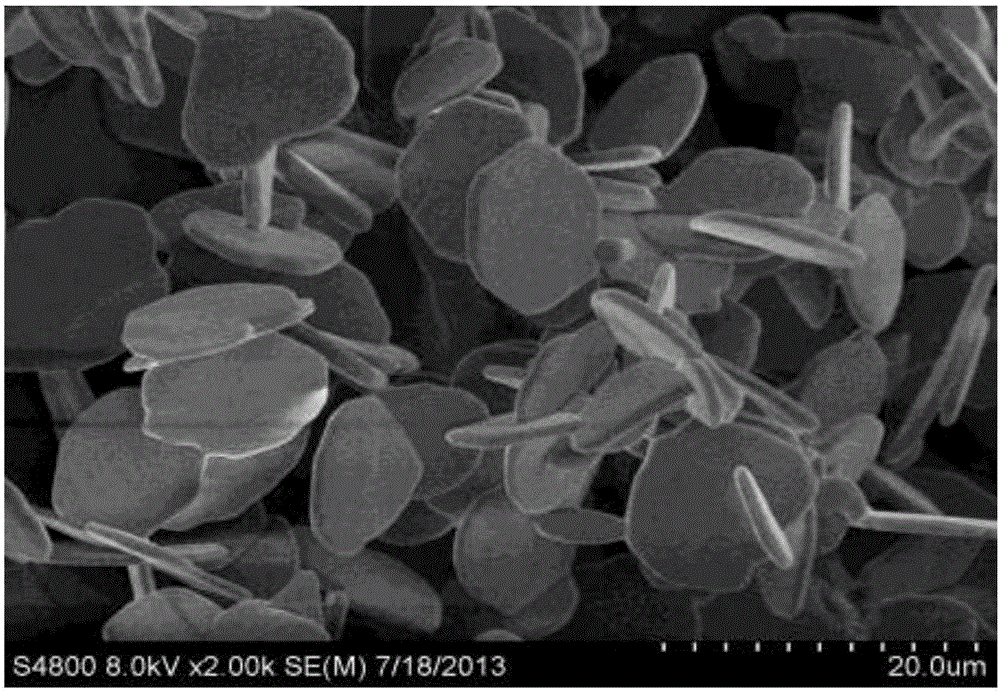

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

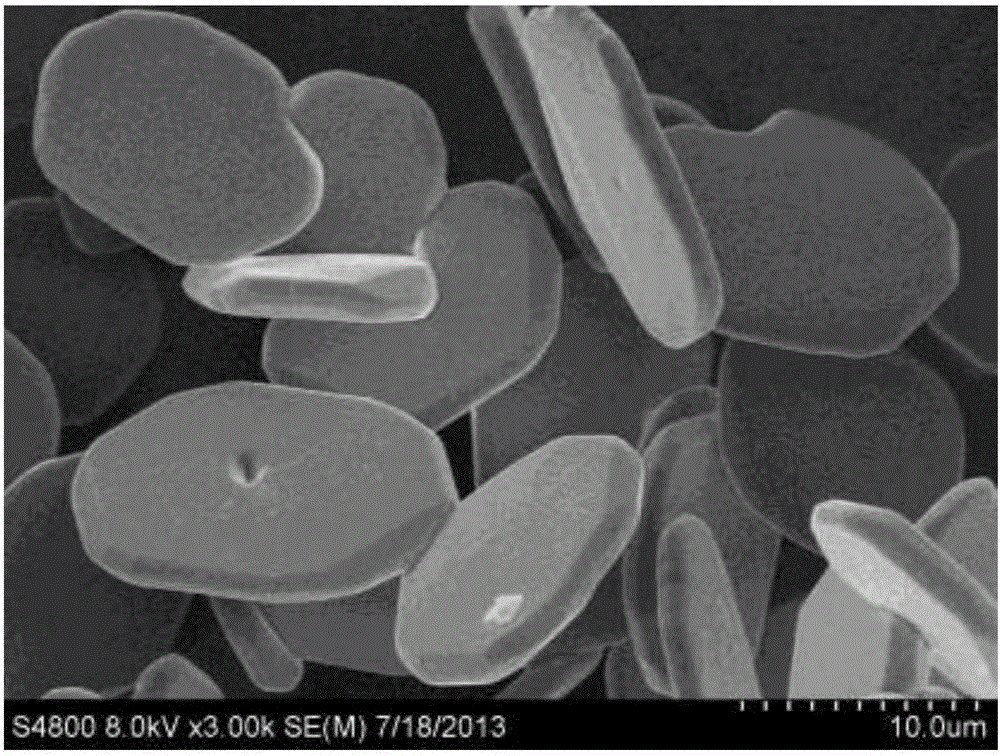

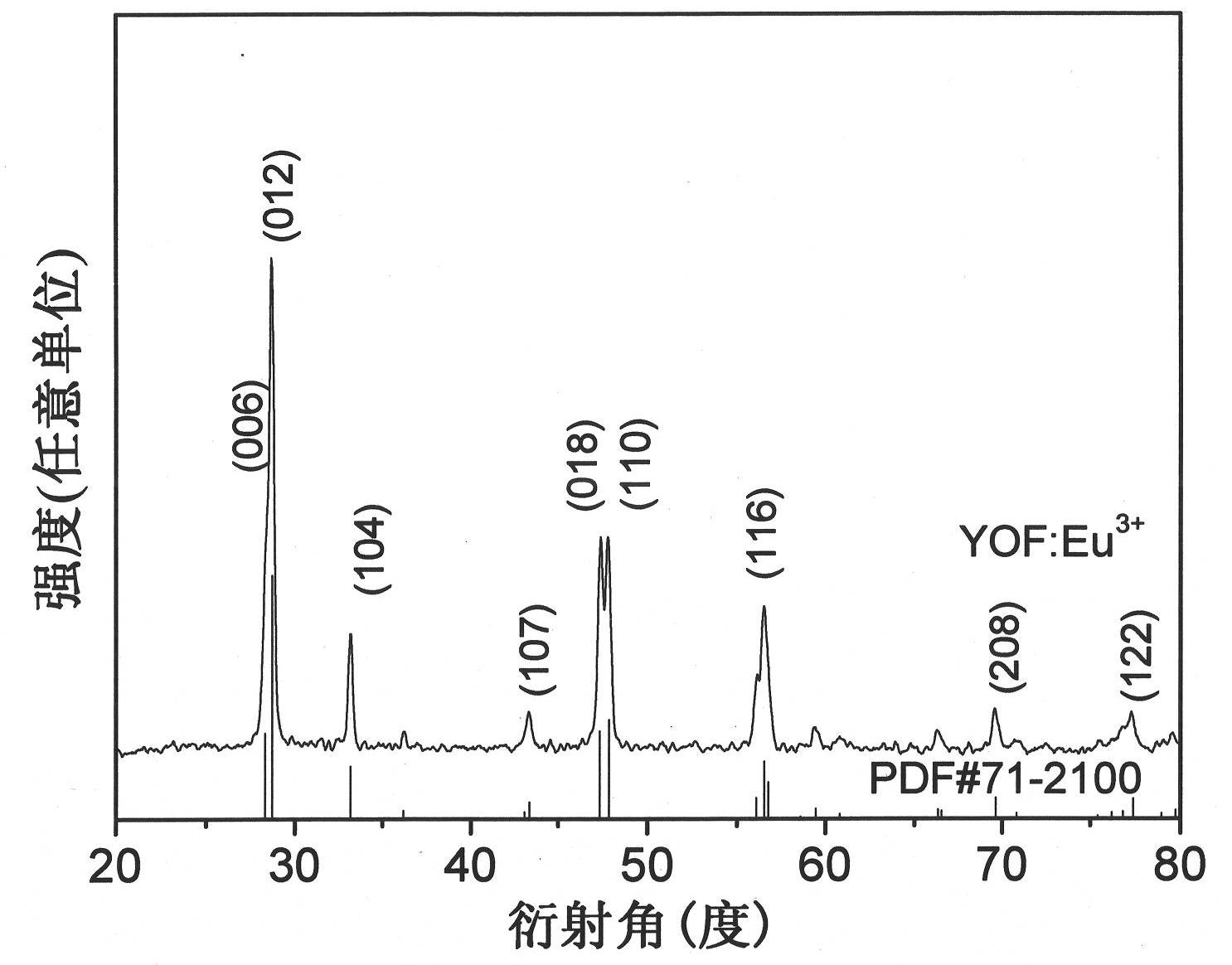

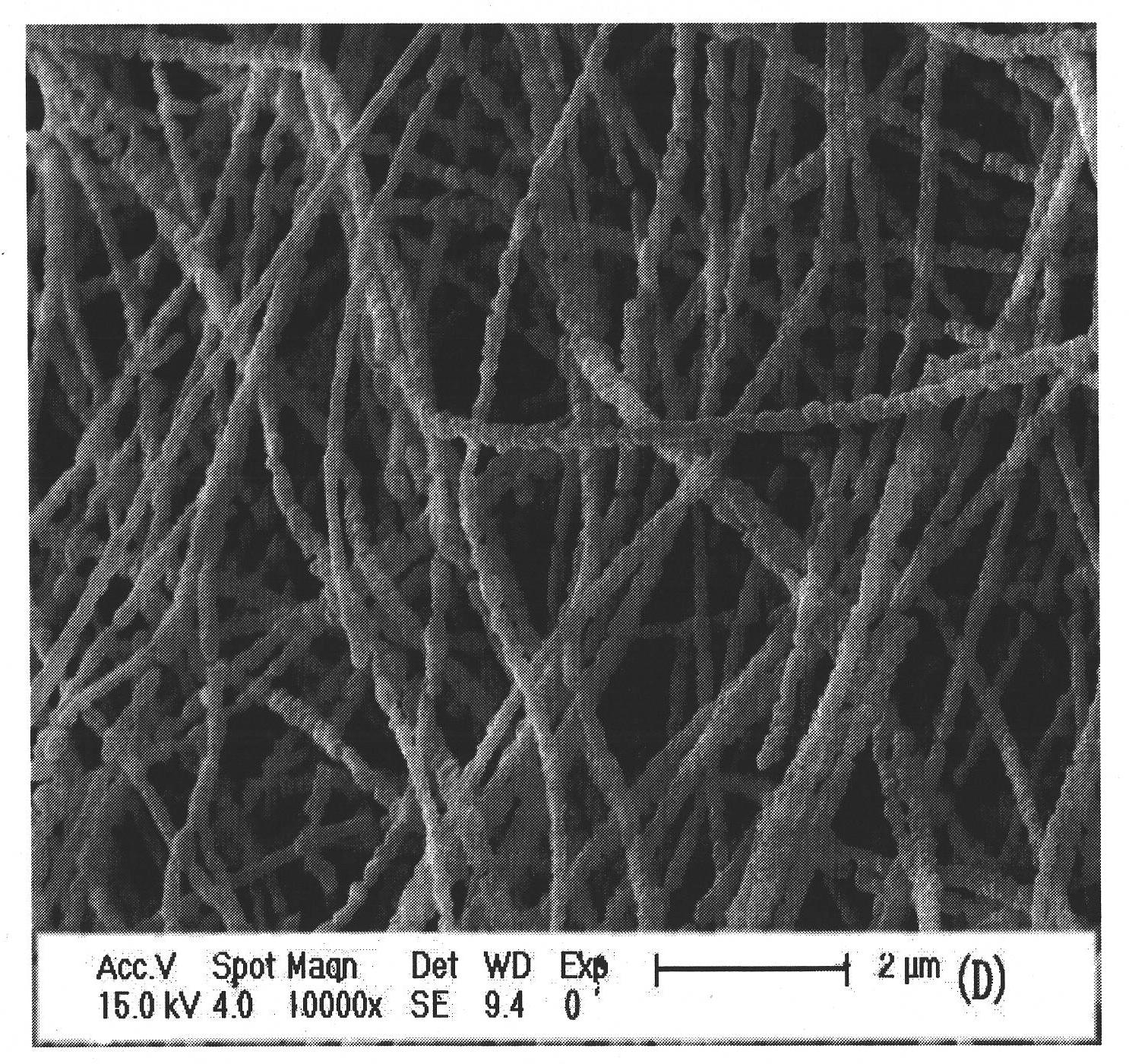

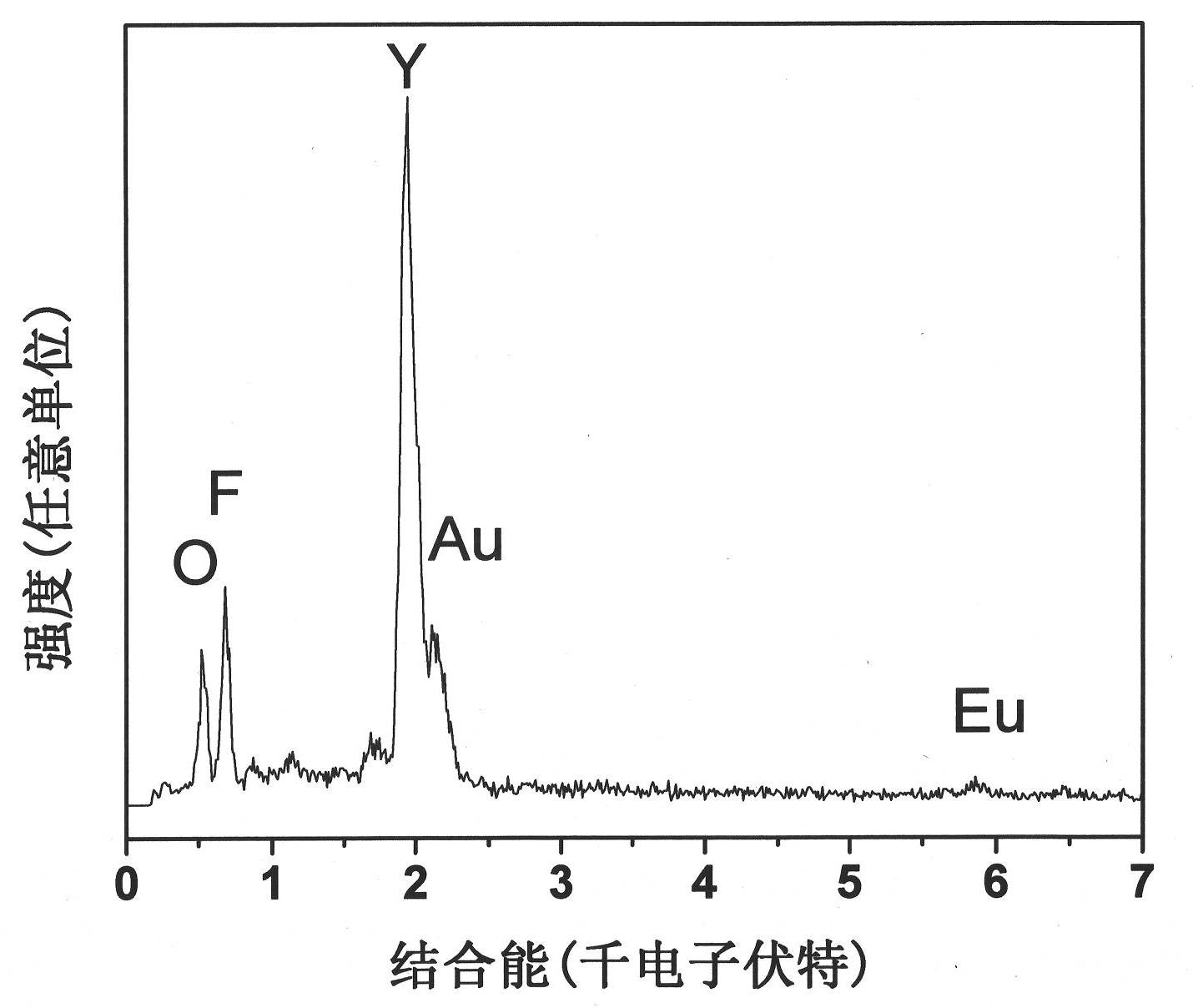

Method for preparing europium and fluorine-doped yttrium oxide nanofibres

InactiveCN102041583AInorganic material artificial filamentsFilament/thread formingComposite nanofibersFluorescence

The invention relates to a method for preparing europium and fluorine-doped yttrium oxide nanofibres, belonging to the technical field of preparing nano materials. The prior art is used for preparing rare earth fluorides / rare earth oxyfluoride composite nanofibres. The method provided by the invention comprises the three following steps: (1) preparation of Y2O3:5%Eu<3+> nanofibres: adopting an electrostatic spinning technology to prepare PVP / [Y(NO3)3+Eu(NO3)3] composite nanofibres, and then carrying out heat treatment to obtain the Y2O3:5% Eu<3+> nanofibres; (2) preparation of YF3:5%Eu<3+> nanofibres: using a double-crucible process to carry out fluoridation on the Y2O3:5%Eu<3+> nanofibres to obtain the YF3:5%Eu<3+> nanofibres by taking ammonium bifluoride as a fluorination reagent; and (3) preparation of YOF:5%Eu<3+> nanofibres: heating the YF3:5%Eu<3+> nanofibres at a temperature of 700 DEG C in the air for 9 hours to obtain the YOF:5%Eu<3+> nanofibres, wherein the diameter of the YOF:5%Eu<3+> nanofibre is 150-190nm, and the length of the YOF:5%Eu<3+> nanofibre is more than 300 mu m. The europium and fluorine-doping yttrium oxide nanofibres are novel and important red nano flourescent materials, and are wide in application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

Highly purified fluoride fused salt and preparation method thereof

The invention provides a highly purified fluoride fused salt and a preparation method thereof. Specifically, the method comprises the following steps of: (i) providing a ammonium bifluoride-fluoride salt mixture, wherein the mixture contains the components of fluoride salts LiF, NaF, KF and ammonium bifluoride, and the purity of the ammonium bifluoride is not less than 99.9wt%; (ii) heating and fusing the ammonium bifluoride-fluoride salt mixture so as to obtain a highly purified fluoride salt melt; and (iii) cooling the high purified fluoride salt melt so as to obtain the fluoride fused salt. The fused slat is few in impurity, high in purity, stable in physicochemical property, and suitable for the wide preparation and application in the nuclear industry.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Compositions for Cleaning Ion Implanted Photoresist in Front End of Line Applications

InactiveUS20080171682A1Eliminate needDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrogen fluorideOrganic acid

A front end of the line (FEOL) stripping and cleaning composition for cleaning unashed ion-implanted photoresist from a wafer substrate comprises: a) at least one organic stripping solvent, b) fluoride ions from at least one of ammonium fluoride, ammonium bifluoride or hydrogen fluoride, c) at least one acidifying agent selected from inorganic or organic acids, and d) water, with an oxidizing agent optionally also being present in the composition.

Owner:AVANTOR PERFORMANCE MATERIALS INC

Polishing solution and polishing method

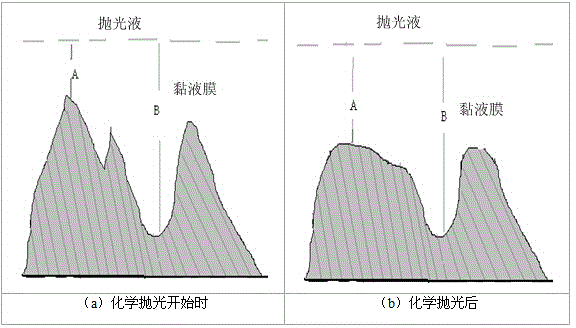

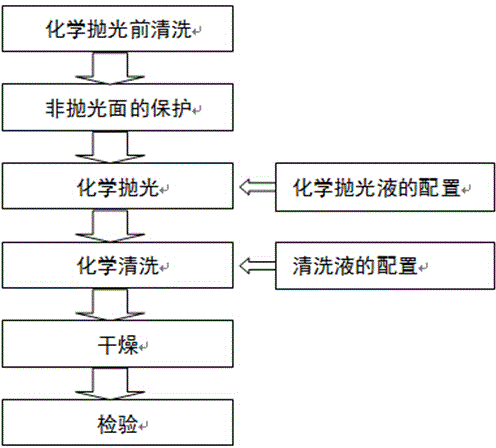

The invention discloses a polishing solution which comprises fluorine salt, a hydrofluoric acid, an inorganic strong acid and an additive, wherein the fluoride salt is one or two of ammonium fluoride and ammonium bifluoride; the inorganic strong acid is at least one of hydrochloric acid, nitric acid and sulfuric acid; the additive is a mixture of glycerol, ethylene glycol and cetyltrimethyl ammonium chloride; the invention further discloses a preparation process of the polishing solution and an application of the polishing solution for polishing optical microcrystal glass parts mainly comprising Li-Al-Si. According to the invention, the problem that the traditional polishing methods cannot realize the chemical polishing of complex structural parts is solved effectively, the removal rate of polishing can be controlled strictly through the polishing time, and the polishing is controllable.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

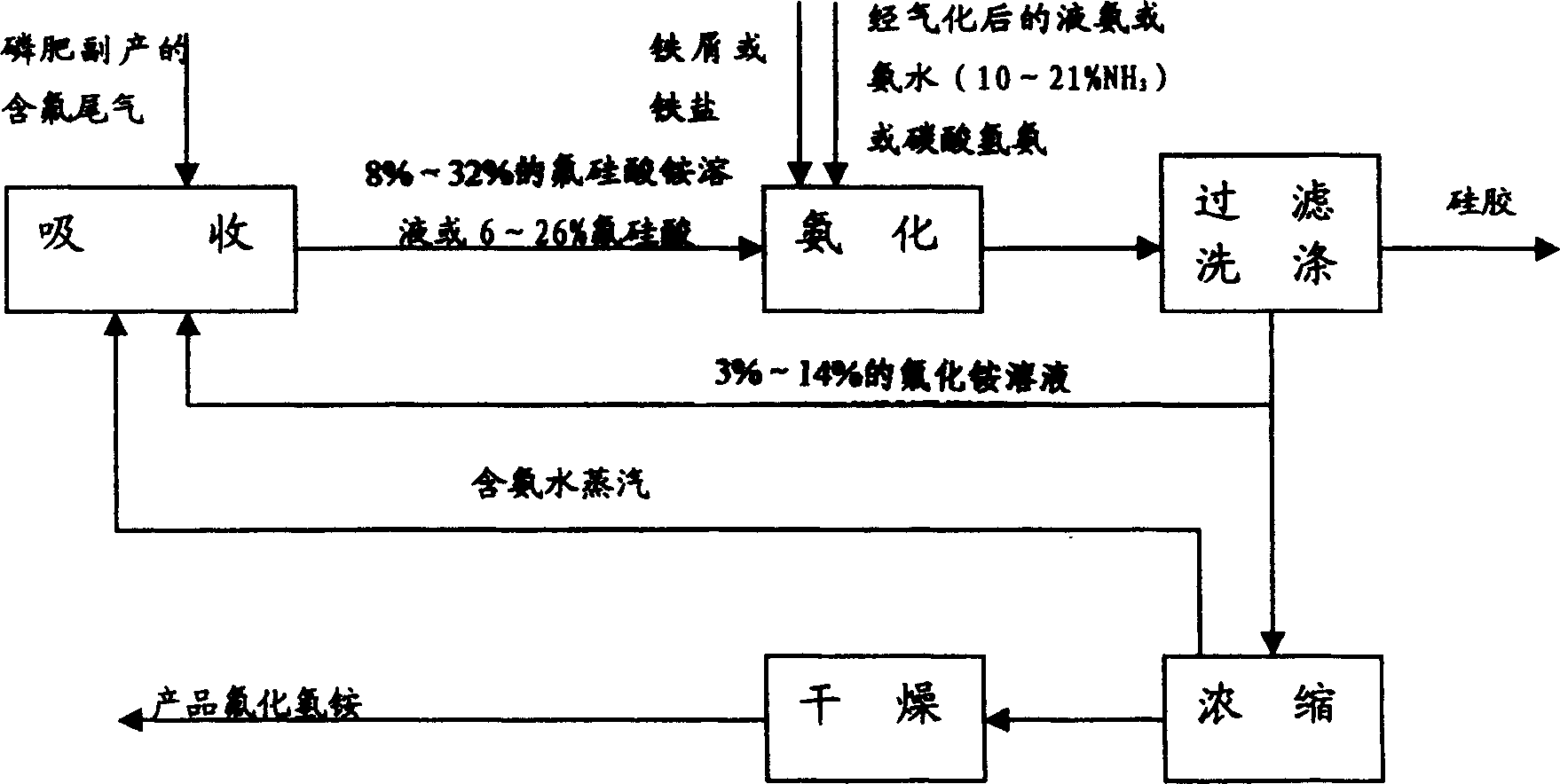

Process for preparing ammonium hydrogen fluoride

InactiveCN1554586AReasonable designReduce material requirementsFluoride preparationSolid waste disposalIron saltsHexafluorosilicic acid

The present invention discloses production process of ammonium hydrogen fluoride. Ammonium fluoride solution in 3-14% concentration is used to absorb fluorine containing tail gas as side product of phosphate fertilizer production to obtain ammonium fluorosilicate solution of 8-12% ammonium fluorosilicate content. Iron scrap or iron salt is added into ammonium fluorosilicate solution or one other side product from phosphate fertilizer production to eliminate phosphorus; and through adding gasified liquid ammonia or ammonia water or ammonium bicarbonate, filtering, washing to eliminate SiO2 precipitate, returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying, the ammonium hydrogen fluoride product is obtained.

Owner:云南云天化国际化工有限公司 +1

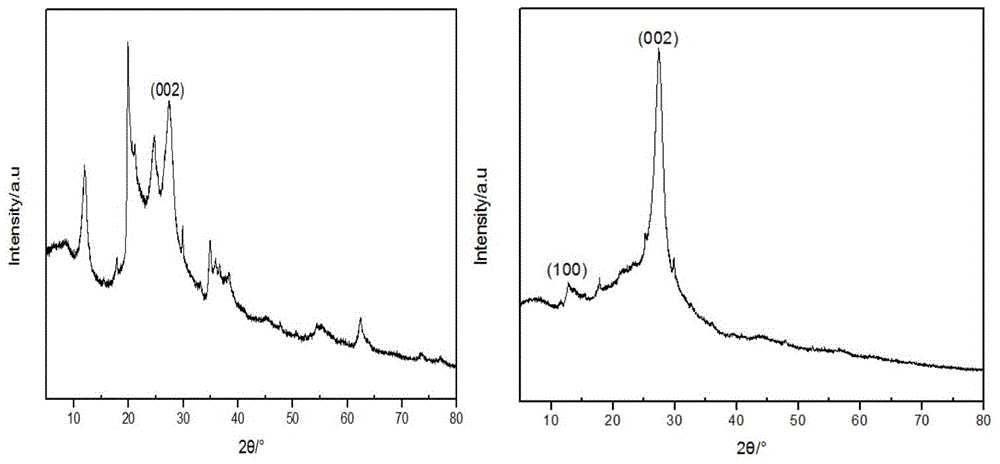

Preparation method of tubular carbon nitride

InactiveCN105236364AGood removal effectLarge specific surface areaMaterial nanotechnologyNitrogen and non-metal compoundsHydrogen fluorideCarbon nitride

The invention belongs to the field of preparation of nano functional materials and particularly relates to a method of preparing tubular-structured carbon nitride with natural rod-like silicate clay as a template. The method includes the steps of adding the rod-like silicate clay to an acidic solution and performing stirring activation to obtain silicate clay slurry; adding a raw material being rich in carbon and nitrogen, performing ultrasonic dispersion to obtain silicate clay composite slurry; and treating the silicate clay composite slurry at 450-580 DEG C with temperature maintenance for 2-7 h to obtain a silicate clay / C3N4 composition; and finally adding the silicate clay / C3N4 composition into a hydrogen fluoride or an ammonium bifluoride solution, allowing the mixture to stand, and filtering, washing and drying the mixture to obtain the tubular carbon nitride.

Owner:CHANGZHOU UNIV

Direct chemical nickel-phosphate plating solution and chemical nickel-phosphate plating coating process for magnesium alloy

ActiveCN102994988ANo pollution in the processAvoid emissionsLiquid/solution decomposition chemical coatingNickel phosphateReducing agent

The invention relates to magnesium alloy surface treatment technology, in particular to a direct chemical nickel-phosphate plating solution and chemical nickel-phosphate plating coating process for magnesium alloy, belonging to the field of magnesium alloy surface treatment. A chemical nickel-phosphate plating coating takes nickel acetate or nickel sulfate as main salts, phosphinic acid as a reducing agent, sodium citrate, glycine or sodium succinate as a complexing agent, ammonium bifluoride as a corrosion inhibitor, sodium acetate as a buffering agent and cadmium chloride as a stabilizer, and the plating application temperature is 80-95 DEG C. The chemical nickel-phosphate plating coating process comprises the steps: organic solvent oil removal, blow-drying, alkaline washing, water washing, chemical nickel-phosphate plating, water washing and roasting in sequence. According to the process, the problems that the chemical nickel-phosphate alloy plating coating technology in the prior can not be directly applied to magnesium alloy and causes harm to the environment can be solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anti-scaling multi-hydrogen retarded acid for highly argillaceous sandstone reservoir

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titanium alloy black anodic oxidation method capable of reducing oxidation film layer stress

ActiveCN101457383ASmall size changeExtended service lifeSurface reaction electrolytic coatingAnodizingPyrophosphate

The invention relates to a black anodizing process method for eliminating parasitic light from the surface of a titanium alloy component, in particular to a titanium alloy black anodizing method capable of reducing the stress on an oxide film. The titanium alloy black anodizing method comprises the following steps: removing oil from an alkaline chemical surface, activating an acid surface and black anodizing. The titanium alloy black anodizing method is characterized by comprising the following surface chemical micro etching after the step of removing the oil from the alkaline chemical surface and before the step of activating the acid surface: a micro etching solution is an aqueous solution containing 70-100g of ammonium sulfate, 50-80g of ammonium bifluoride and 30-50g of ammonium pyrophosphate in each liter of water; and etching is performed at the temperature of 45-65 DEG C for 10-30min . The titanium alloy black anodizing method has the advantages of less change of the size of a workpiece and good parasitic light eliminating property, is especially suitable for black anodizing parasitic light eliminating treatment and helps obviously improve the service life of the components.

Owner:CHANGCHUN UP OPTOTECH

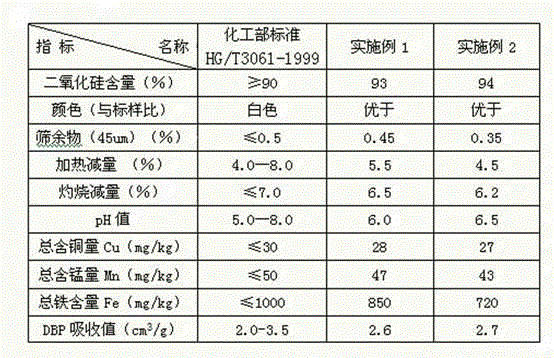

Method for producing anhydrous hydrogen fluoride and coproducing silica white from low-grade fluorine resources

ActiveCN102795601ALow impurity contentIncrease profitSilicaFluorine/hydrogen-fluorideSlurryHexafluorosilicic acid

The invention discloses a method for producing anhydrous hydrogen fluoride and coproducing silica white from low-grade fluorine resources, which comprises the following steps: carrying out ammonolysis on a phosphate fertilizer byproduct fluosilicic acid solution to obtain an ammonium fluoride solution and silicon dioxide, washing the filter cake, and drying to obtain the silica white product, wherein the filtrate ammonium fluoride solution is used for the next production step; concentrating the ammonium fluoride solution, and carrying out pyrolysis to obtain an ammonium bifluoride solution and ammonia gas, wherein the ammonium bifluoride solution is used for the next production step, and the ammonia gas is used for ammonolysis of the fluosilicic acid solution; reacting the ammonium bifluoride solution and sodium fluoride to generate a sodium bifluoride slurry, and drying the filter cake to obtain sodium bifluoride, wherein the filtrate ammonium fluoride solution can be recycled; and carrying out pyrolysis on the sodium bifluoride to obtain crude anhydrous hydrogen fluoride and sodium fluoride, and purifying the anhydrous hydrogen fluoride to obtain the anhydrous hydrogen fluoride product, wherein the sodium fluoride can be recycled. The method disclosed by the invention has the advantages of accessible raw materials, low price, simple production technique and lower cost for the anhydrous hydrogen fluoride product, solves the bottleneck of environmental protection in the development of low-grade fluorine resource industry, and does not generate secondary pollution in the production process.

Owner:DO FLUORIDE CHEM CO LTD

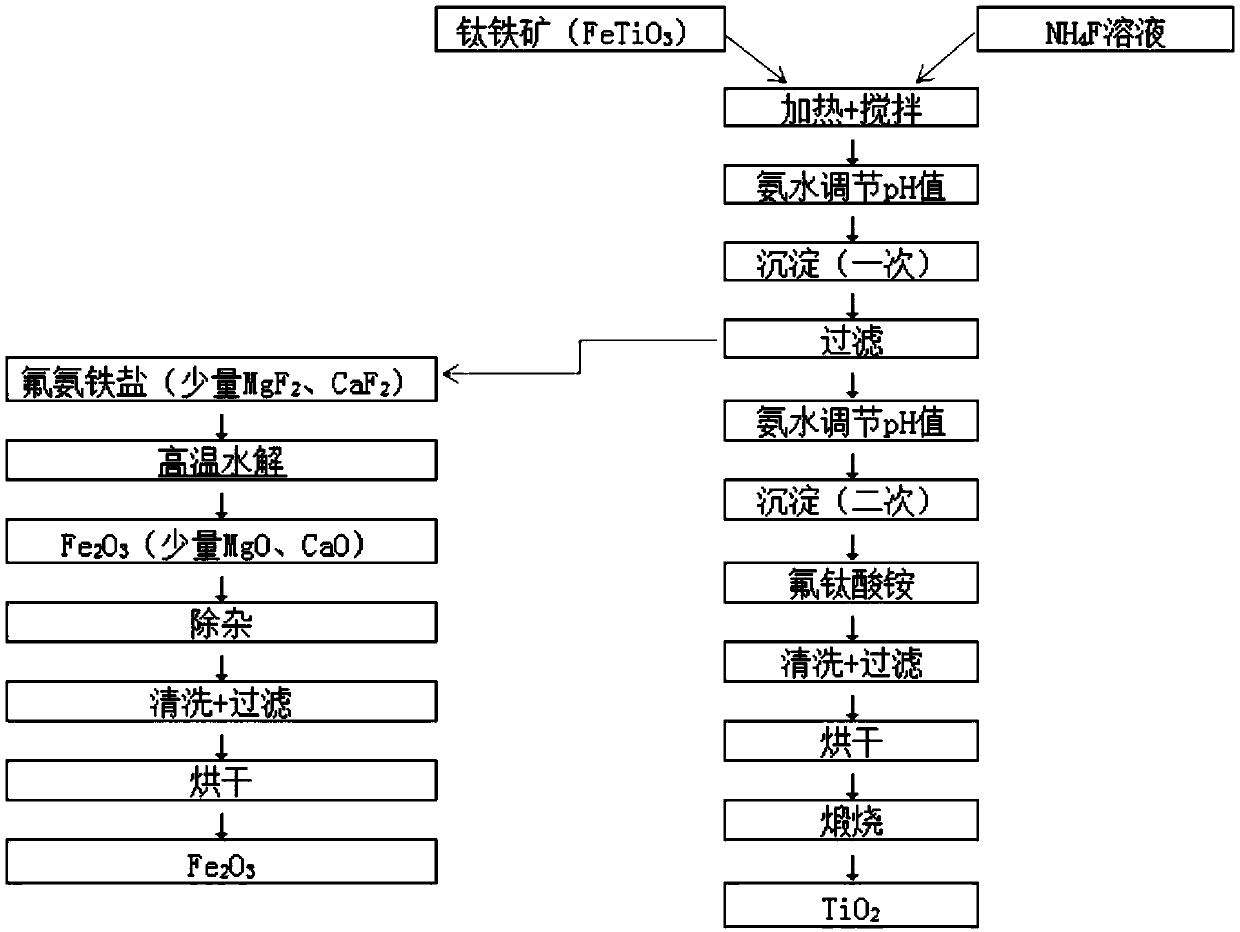

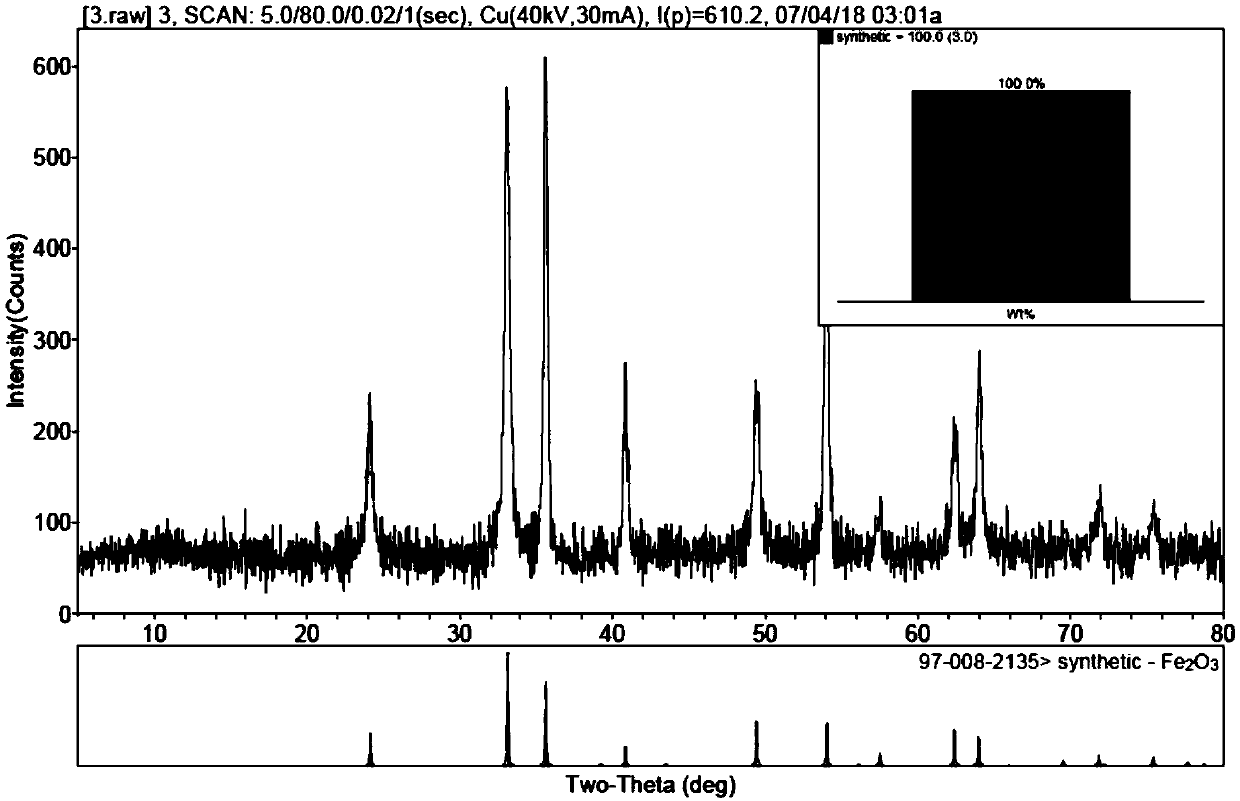

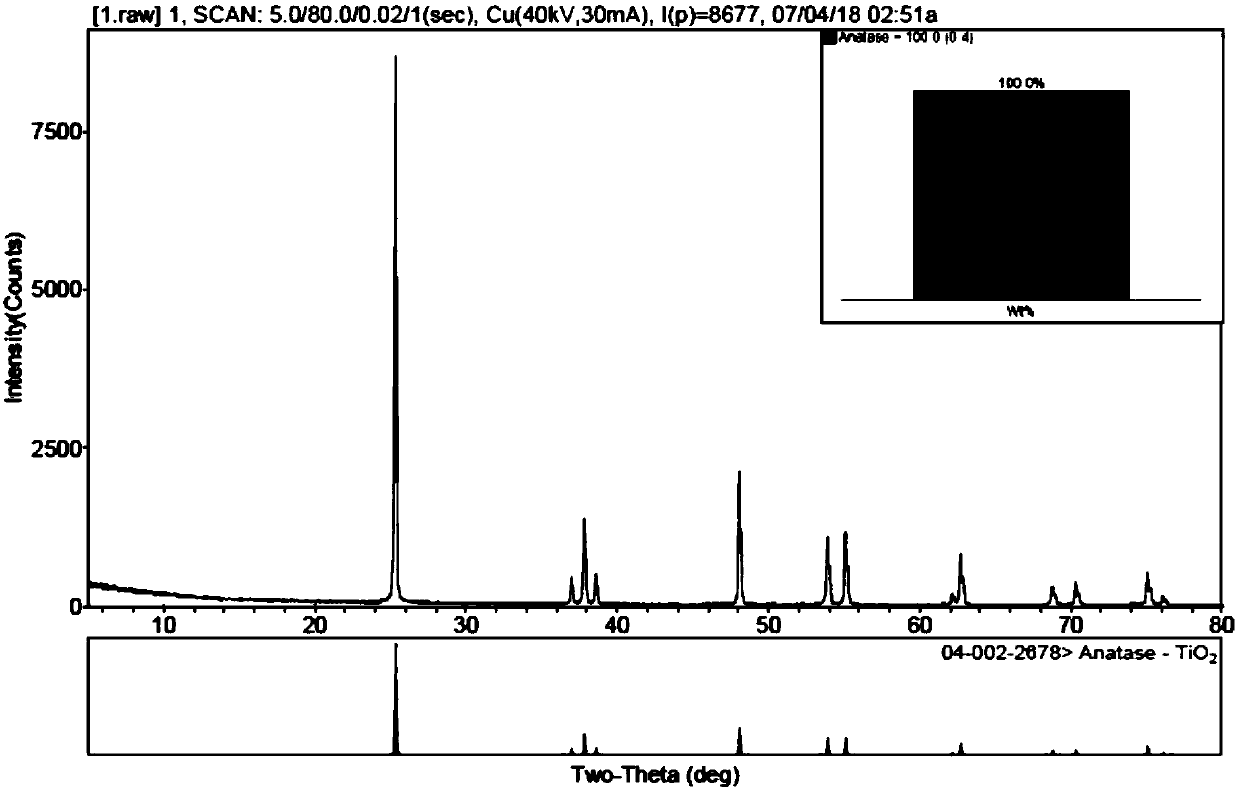

Method for preparing titanium dioxide and iron oxide by using fluoride purifying titanium-iron material

InactiveCN109626420ALow calcium and magnesium impuritiesEasy to separateMaterial nanotechnologyFerric oxidesIron(II) oxideAmmonium compounds

The invention provides a method for preparing titanium dioxide and iron oxide by using a fluoride purifying titanium-iron material. The method comprises the steps of mixing and heating a titanium-ironmaterial and a fluorine ammonium compound solution to obtain a mixture, wherein the fluorine ammonium compound is an ammonium fluoride or ammonium hydrogen fluoride; regulating the primary pH of themixture to obtain a first precipitate; separating the first precipitate and then regulating the secondary pH of the residual material to obtain a second precipitate; hydrolyzing the first precipitateat high temperature to obtain Fe2O3; roasting the second precipitate to obtain TiO2. By adopting the method, titanium and iron elements in the titanium-iron material can be thoroughly separated, and high-quality TiO2 and Fe2O3 pigment products are respectively obtained. The method is especially suitable for purifying and purifying treatment of high-calcium-magnesium titanium iron resources in a Panxi area (components and their analogs), materials with low calcium and magnesium impurity contents are obtained, namely titanium-rich materials, and titanium dioxide or titanium metal is produced fora subsequent sulfuric acid method and a chlorination method.

Owner:HUNAN KUNTAI METALLURGICAL ENG TECHCO LTD

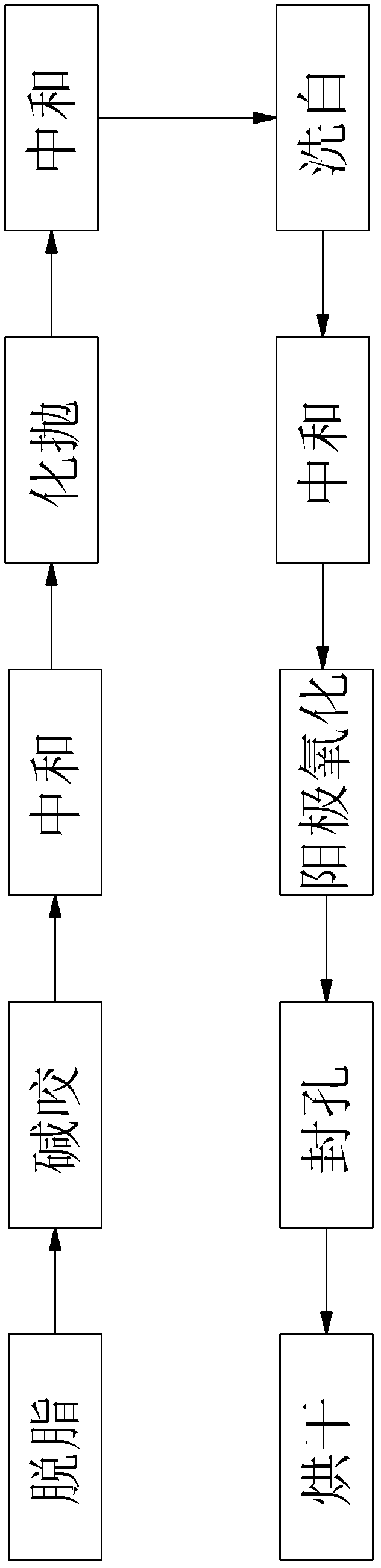

Aluminum alloy surface whitening solution and surface treatment method thereof

The invention provides an aluminum alloy surface whitening solution. By taking water as a solvent, each liter of whitening solution comprises 8-10g of ammonium chloride, 40-50k of ammonium sulfate, 50-60g of ammonium fluoride and 90-100g of ammonium bifluoride. The invention also provides a method for performing surface treatment on the aluminum alloy surface by utilizing the aluminum alloy surface whitening solution. The method sequentially comprises the following steps: degreasing, alkali erosion, neutralizing, chemical polishing, neutralizing, whitening, anodic oxidation, hole sealing and drying. Compared with the prior art, the aluminum alloy surface whitening solution and the aluminum alloy surface treatment method have the advantages that an aluminum alloy anode product of which the surface has a good matte whitening appearance effect can be obtained, the surface hardness and corrosion resistance of the product subjected to anodic oxidation treatment are improved, and when the aluminum alloy surface whitening solution is applied to production, the production cost can be greatly reduced.

Owner:SUZHOU MITAC PRECISION TECH

Tantalum Concentrates Dissolution and Purification Method

InactiveUS20040213716A1Safer and easy to handleSafer and easy to and storeSolvent extractionTantalum compoundsHydrogen fluorideFluoride

A method for the dissolution and purification of tantalum ore and synthetic concentrates is described. The method preferably uses ammonium bifluoride as the fluoride source in place of the hydrofluoric acid used in the conventional methods. Other fluoride compounds such as NaF, KF, and CaF2 may be used alone or in combination with ammonium bifluoride. The tantalum concentrate and fluoride source are combined with sulfuric acid to form a solution containing tantalum values and impurities. The tantalum values are then separated from the impurities by solvent extraction.

Owner:GLOBAL TUNGSTEN & POWDERS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com