Highly purified fluoride fused salt and preparation method thereof

A fluoride salt and fluoride technology, applied in the field of high-purity fluoride molten salt and its preparation, can solve the problems of difficult preparation, long preparation period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] In the present invention, the preparation method steps of preferred molten salt are as follows:

[0092] (i) providing ammonium bifluoride-fluoride salt mixture, wherein said mixture contains fluoride salts LiF, NaF and KF and ammonium bifluoride, wherein said ammonium bifluoride has a purity ≥ 99.9wt%;

[0093] (ii) heating and melting the ammonium bifluoride-fluoride salt mixture to form a high-purity fluoride salt melt; wherein, the oxides in the fluoride salt react with hydrogen fluoride released by the decomposition of ammonium bifluoride to generate water, and the water vapor venting; and

[0094] (iii) Cooling said high-purity fluoride salt melt, thereby fluoride molten salt.

[0095] Wherein, step (i) includes: providing a fluoride salt mixture, wherein the fluoride salt includes LiF, NaF and KF; and adding ammonium bifluoride with a purity ≥ 99.9wt% to the fluoride salt mixture, thereby obtaining ammonium bifluoride-fluoride salt mixture; and / or

[0096] Pro...

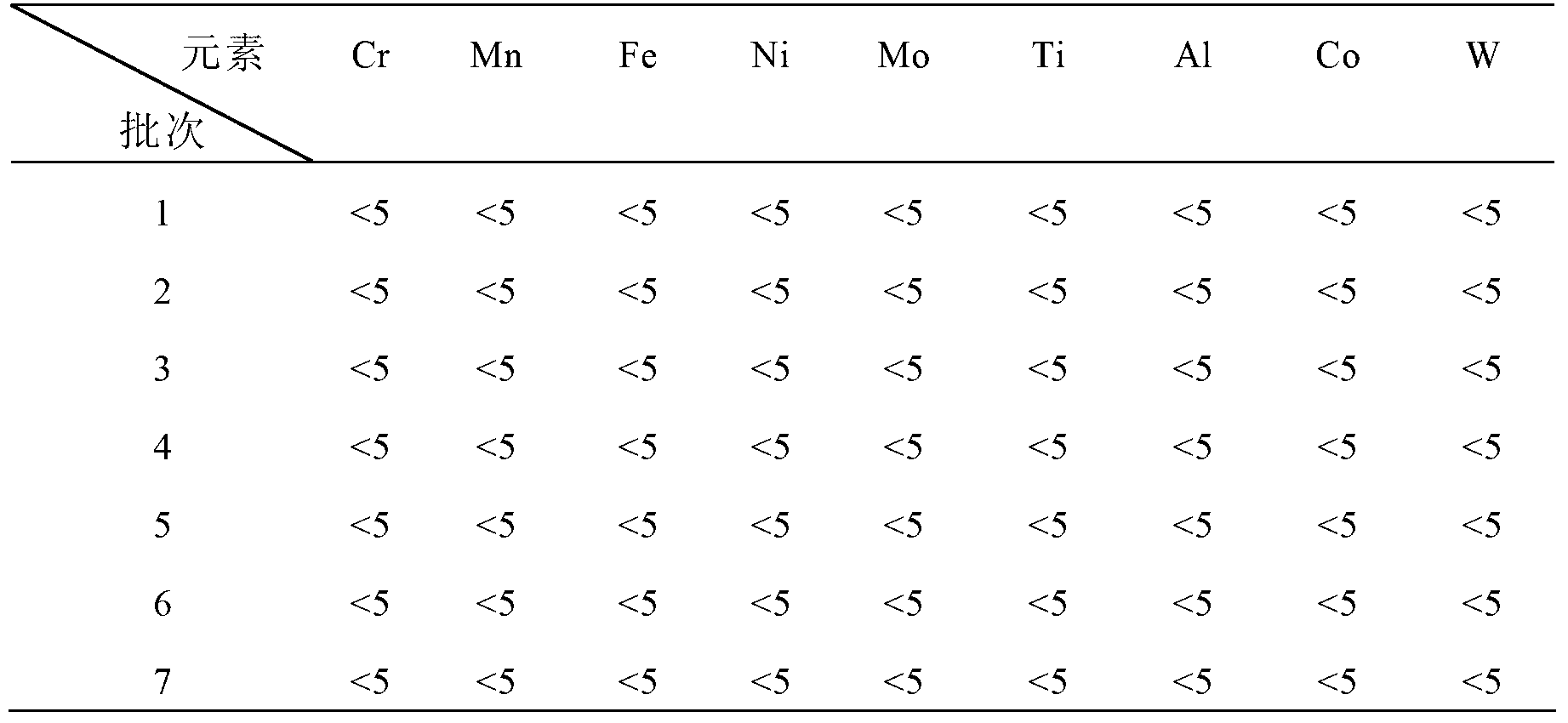

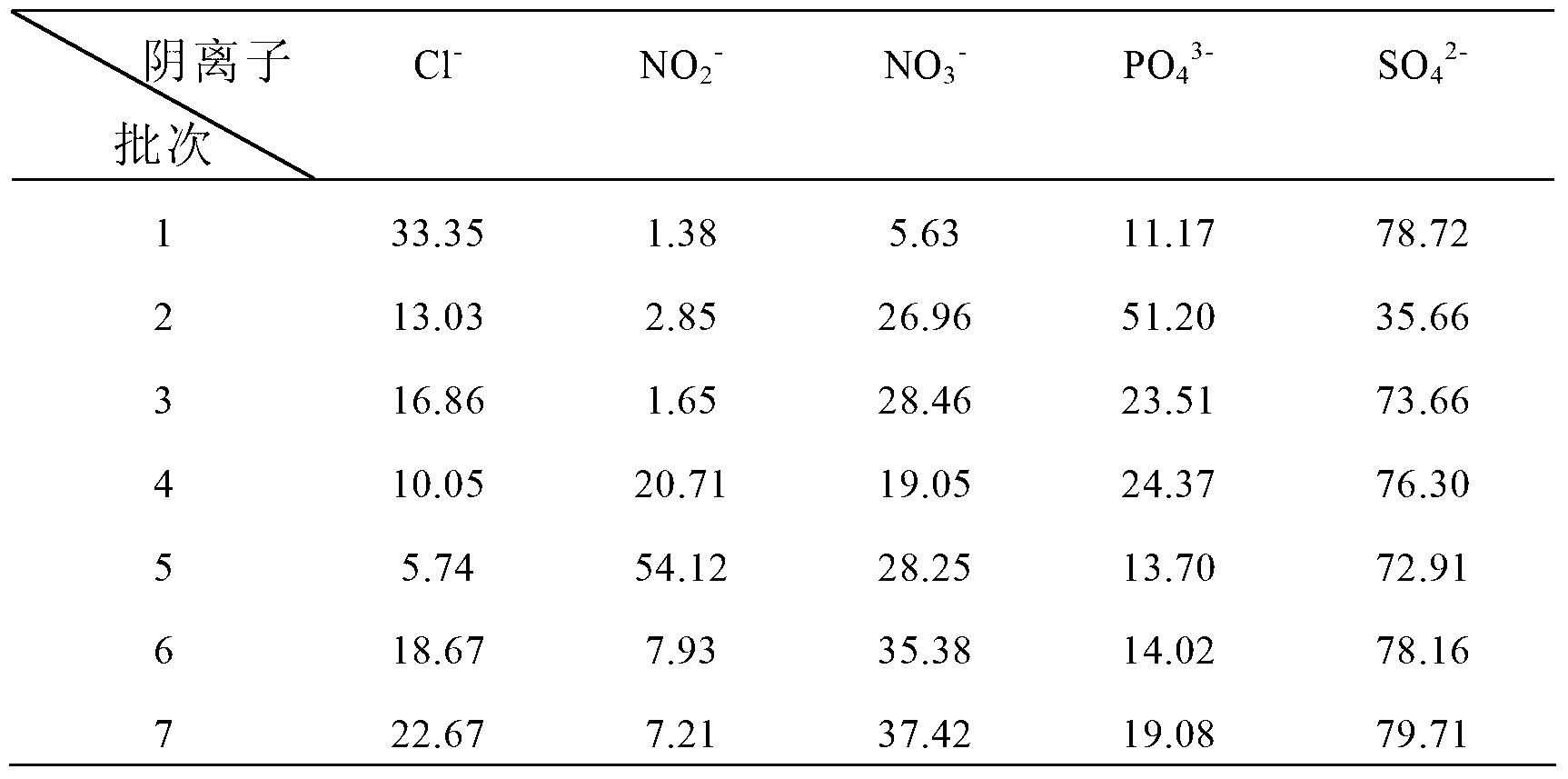

Embodiment 1

[0119] Preparation and detection of embodiment 1 high-purity ammonium bifluoride

[0120] Raw materials: 99% ammonium bifluoride (purchased from Shanghai Wujiaoxing Technology Co., Ltd.), wherein the chloride ion content is 322ppm, the nitrate is 10ppm, the phosphate is 20ppm, and the sulfate is 60ppm. Deionized water that has been treated by itself, and absolute ethanol after treatment.

[0121] Add 1L of deionized water to a 2L PTFE reactor, heat it in a water bath to 80 degrees, slowly add 1.2kg of ammonium bifluoride, and after it is completely dissolved, filter it with a PTFE membrane while it is still hot, and wait for slow cooling to crystallize. The crystals were filtered out, washed with ethanol for 5 times, crushed, and dried in a vacuum oven at 80°C.

[0122] The content of ammonium bifluoride obtained by the method is greater than 99.9%, the chloride ion content is lower than 85ppm, the nitrate radical is lower than 10ppm, the phosphate radical is lower than 20ppm...

Embodiment 2

[0123] The preparation of embodiment 2LiF-NaF-KF molten salt (No.1)

[0124] Using LiF, NaF and KF as raw materials, the content of LiF and NaF is 99.9%, and the content of KF is 99.97%. The above raw materials are all treated in a vacuum oven at 300-400°C for 4 hours, and then the molar percentage is LiF:NaF:KF =46.5:11.5:42 ratio weighing, a total of 20kg. Add 3.0 kg of high-purity ammonium bifluoride with a mass ratio of 15% as a fluorination reagent, seal and mix. Transfer the mixed fluoride salt mixture to the graphite crucible of the vacuum induction melting furnace, seal it, evacuate it to below 10Pa, and remove water under high vacuum for 1 hour. Fill high-purity N2 to normal pressure, heat and melt according to the set program: heating from room temperature to 300°C takes 1 hour; heating from 300°C to 450°C takes 2 hours; heating from 450°C to 700°C takes 1 hour; 700 ° C for 2 hours, a total of 6 hours. Then it is cooled to about 600°C, and the crucible is rotated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com