Method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates

A kind of vanadium titanomagnetite concentrate, wet processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

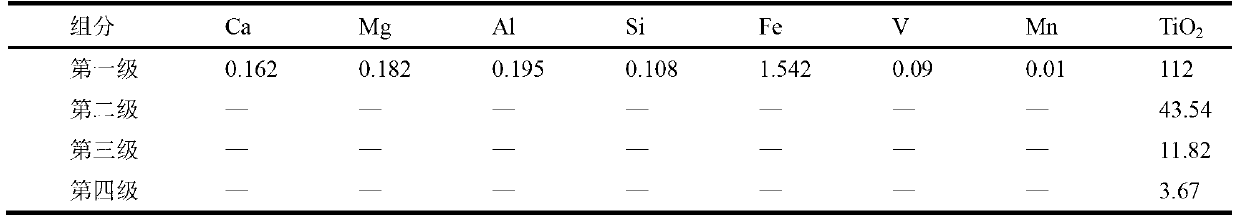

Embodiment 1

[0036] The vanadium-titanium magnetite concentrate is leached in a closed container with 30% hydrochloric acid at 150°C. The liquid-solid ratio of hydrochloric acid to the concentrate is 2:1. The liquid-solid ratio of the leaching residue is 10:1, 80°C, 20min). Washing slag and NaOH are mixed at a ratio of 1:5 and then added to a stainless steel reactor for molten salt decomposition reaction at a reaction temperature of 550°C for 5 hours to obtain a molten salt reaction material. The molten salt reaction material is washed with water (temperature 70°C, time 90min, washing liquid to solid ratio 10:1), and then pickled (sulfuric acid concentration 100g / L, temperature 70°C, time 90min, pH value of the pickling slurry is 6.7) . The pickling material is acid-dissolved with 400g / L sulfuric acid at 90°C for 3 hours to obtain the acid-dissolved material, and the liquid-solid ratio of the sulfuric acid solution to the pickling material is 1:1. Add the acid-dissolved material to 200g / ...

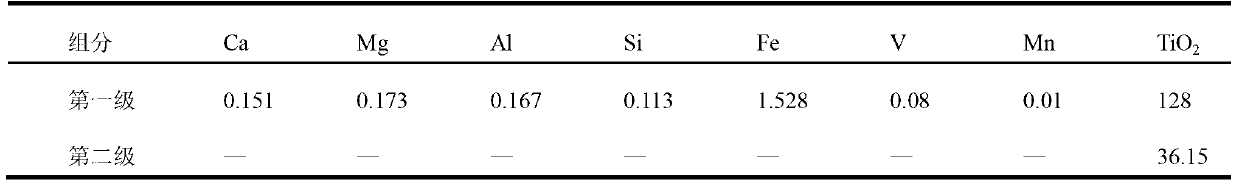

Embodiment 2

[0041] The vanadium-titanium magnetite concentrate is leached in a closed container with 10% hydrochloric acid at 130°C. The liquid-solid ratio of hydrochloric acid to the concentrate is 10:1. The liquid-solid ratio of the leaching residue is 5:1, 80°C, 30min). Washing slag and NaOH are mixed at a ratio of 1:0.5 and then added to a stainless steel reactor for molten salt decomposition reaction. The reaction temperature is 550°C and the time is 1h to obtain molten salt reaction material. The molten salt reaction material is washed with water (temperature 30°C, time 60min, washing solution to solid ratio 5:1), and then pickled (sulfuric acid concentration 80g / L, temperature 30°C, time 60min, pH value of the pickling slurry is 3.2) . The pickling material is acid-dissolved with 500g / L sulfuric acid at 40°C for 3 hours to obtain the acid-dissolved material. The liquid-solid ratio of the sulfuric acid solution to the pickling material is 0.6:1. Add the acid-dissolved material to ...

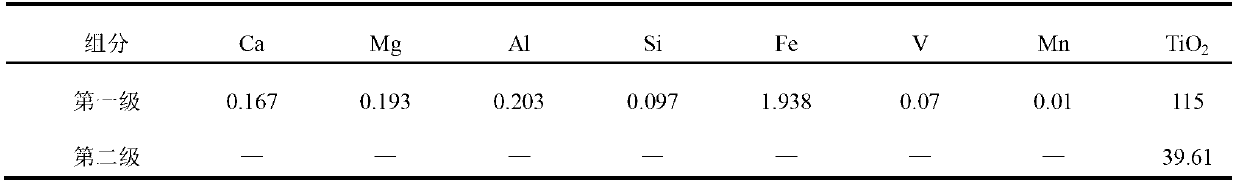

Embodiment 3

[0046]The vanadium-titanium magnetite concentrate is leached with 20% hydrochloric acid at 110°C under normal pressure. The liquid-solid ratio of hydrochloric acid and concentrate is 5:1. The liquid-solid ratio is 3:1, 30°C, 60min). Washing slag and NaOH are mixed at a ratio of 1:1 and then added to a stainless steel reactor for molten salt decomposition reaction at a reaction temperature of 400°C for 2 hours to obtain a molten salt reaction material. The molten salt reaction material is washed with water (temperature 50°C, time 30min, washing liquid to solid ratio 3:1), and then pickled (sulfuric acid concentration 200g / L, temperature 50°C, time 30min, pH value of the pickling slurry is 4.8) . The pickling material is acid-dissolved with 500g / L sulfuric acid at 40°C for 4 hours to obtain the acid-dissolved material. The liquid-solid ratio of the sulfuric acid solution to the pickling material is 1.2:1. Add the acid-dissolved material to 250g / L sulfuric acid solution for lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com