Carbothermal Reduction Method Using Melt Waste Heat

A technology of waste heat and melt, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of unusable powder materials, achieve full utilization, save pelletizing costs, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

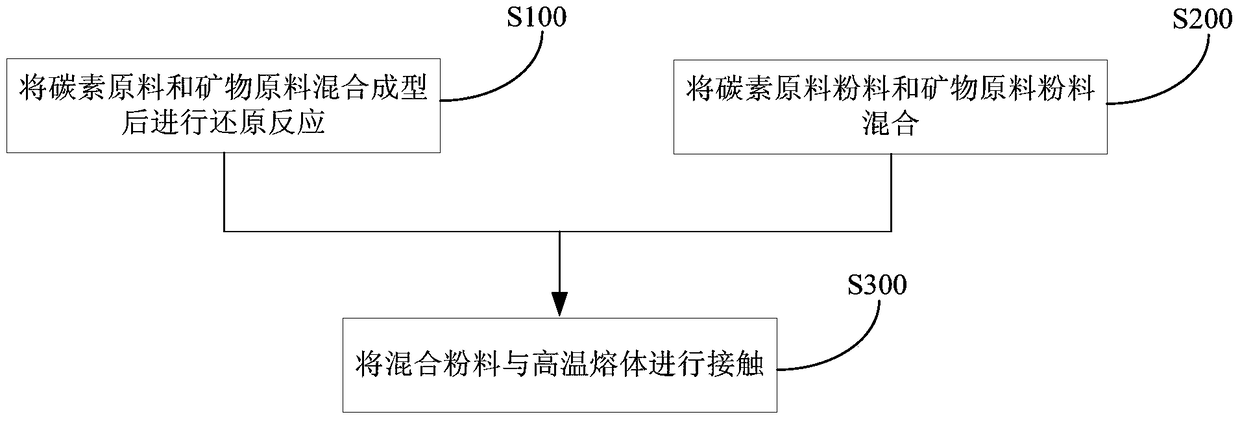

Method used

Image

Examples

Embodiment 1

[0036] Lime and semi-coke are mixed and formed for reduction reaction to obtain liquid calcium carbide (high-temperature melt, temperature is 2100 degrees Celsius), and then the lime powder and semi-coke powder obtained after drying and grinding (the average particle size of the two is 5μm~30μm) are mixed according to the mixing ratio of lime and semi-coke to obtain mixed powder. The bottom feeding method is used to spread the mixed powder at the bottom of the container, and then add liquid calcium carbide to make the lime and semi-coke in the mixed powder. The residual heat of the liquid calcium carbide undergoes a reduction reaction to obtain calcium carbide products. The mass of the mixed powder accounts for 5% of the mass of the liquid calcium carbide. After the reaction is completed, the calcium carbide product is taken out and cooled slowly in the air, and the bottom sample is taken for gas generation measurement. , the result is 302L / kg, the calcium carbide product is a su...

Embodiment 2

[0038] Lime and coke are mixed and molded and subjected to reduction reaction to obtain liquid calcium carbide (high-temperature melt at a temperature of 2000 degrees Celsius), and then dry and grind the obtained lime powder and coke powder (the average particle size of the two is less than 74 Micron (accounting for 80%)) are mixed according to the mixing ratio of lime and coke to obtain a mixed powder. The bottom feeding method is used to spread the mixed powder at the bottom of the container, and then add liquid calcium carbide, so that the lime and coke in the mixed powder can be used The residual heat of the liquid calcium carbide undergoes a reduction reaction to obtain calcium carbide products. The mass of the mixed powder accounts for 10% of the mass of the liquid calcium carbide. After the reaction is completed, the calcium carbide product is taken out and cooled slowly in the air, and the bottom sample is taken for gas generation measurement. , the result is 297L / kg, c...

Embodiment 3

[0040] Mix lime and anthracite and carry out reduction reaction to obtain liquid calcium carbide (high-temperature melt, temperature 2200 degrees Celsius), and then dry and grind the obtained lime powder and anthracite powder (the average particle size of the two is less than 74 The micron accounts for 80%) according to the mixing ratio of lime and anthracite to obtain mixed powder. The powder injection method is used to inject the mixed powder while discharging the liquid calcium carbide, so that the lime and anthracite in the mixed powder can be used in liquid state. The residual heat of calcium carbide undergoes a reduction reaction, wherein the mass of the mixed powder is 20% of the mass of the liquid calcium carbide. After the reaction is completed, the calcium carbide product is taken out and cooled slowly in the air, and the bottom sample is taken for gas generation measurement. The result is 284L / kg, calcium carbide products are first-class products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com