Catalytic Hydrotreating Process of Rectification Raffinate of Chloropivaloyl Chloride

A technology of chloropivaloyl chloride and catalytic hydrogenation, which is applied in the field of chemical technology, can solve the problems of high cost, low utilization rate of raw materials, environmental pollution, etc., and achieve the goal of reducing the generation of three wastes, saving production costs, and huge economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

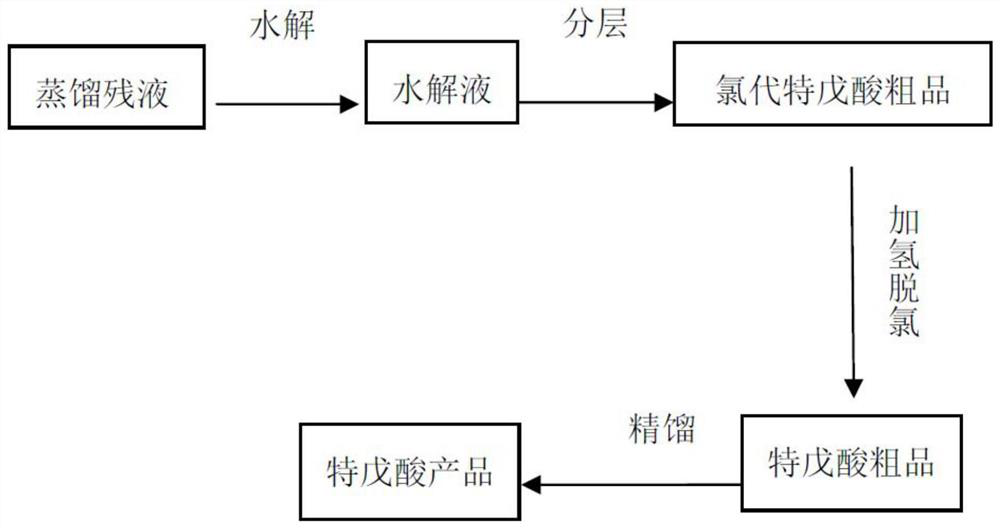

Image

Examples

Embodiment 1

[0023] A kind of catalytic hydrotreating process of rectification raffinate of chlorpivaloyl chloride:

[0024] Add 1500kg of rectification residue of chlorpivaloyl chloride into the hydrolysis kettle, turn on the mechanical stirring, heat to 50°C under normal pressure, then add 285kg of water, add 5.7kg of manganese chloride tetrahydrate, and dissolve the manganese chloride tetrahydrate with water in advance. Control the temperature of the hydrolysis tank to react at 65°C for 1.5 hours, and let the layers stand for 0.5 hours. The black water-containing impurities are first separated from the lower layer, and then the crude chloropivalic acid is separated from the upper layer; the crude chloropivalic acid is sent to the composite catalyst The hydrogenation tower of Sn-Pd / C carries out catalytic hydrodechlorination reaction, the weight content of Sn in the composite catalyst Sn-Pd / C is 0.3%, the weight content of Pd is 0.5%, the temperature of catalytic hydrogenation reaction is...

Embodiment 2

[0030] A kind of catalytic hydrotreating process of rectification raffinate of chlorpivaloyl chloride:

[0031] Add 1500kg of chlorpivaloyl chloride rectification residue into the hydrolysis kettle, turn on the mechanical stirring, heat to 50°C under normal pressure, then add 285kg of water, add 5.4kg of manganese chloride tetrahydrate, and dissolve the manganese chloride tetrahydrate with water in advance. Control the temperature of the hydrolysis tank at 70°C for 1.5 hours, let stand and separate the layers for 0.5 hours, the lower layer first separates black water-containing impurities, and then separates the upper layer of crude chloropivalic acid; send the crude chloropivalic acid to the composite catalyst The hydrogenation tower of Sn-Pd / C carries out catalytic hydrodechlorination reaction, the weight content of Sn in the composite catalyst Sn-Pd / C is 0.3%, the weight content of Pd is 0.5%, the temperature of catalytic hydrogenation reaction is 130 ±10°C, pressure 0.22Mp...

Embodiment 3

[0036] A kind of catalytic hydrotreating process of rectification raffinate of chlorpivaloyl chloride:

[0037] Add 1500kg of rectification residue of chlorpivaloyl chloride into the hydrolysis kettle, start the mechanical stirring, heat to 50°C under normal pressure, then add 300kg of water, add 5.7kg of manganese chloride tetrahydrate, and dissolve the manganese chloride tetrahydrate with water in advance, Control the temperature of the hydrolysis tank to react at 65°C for 1.5 hours, and let the layers stand for 0.5 hours. The black water-containing impurities are first separated from the lower layer, and then the crude chloropivalic acid is separated from the upper layer; the crude chloropivalic acid is sent to the composite catalyst The hydrogenation tower of Sn-Pd / C carries out catalytic hydrodechlorination reaction, the weight content of Sn in the composite catalyst Sn-Pd / C is 0.3%, the weight content of Pd is 0.5%, the temperature of catalytic hydrogenation reaction is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com