Patents

Literature

317 results about "Pentanoic Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straight-chain CARBOXYLIC ACIDS with the general formula C5H10O2.

Method of reducing the sucrose ester concentration of a tobacco mixture

InactiveUS7025066B2Altering flavorAltering aroma characteristicTobacco preparationTobacco treatmentFlavor3-methylbutyric acid

The flavor and aroma characteristics of the smoke of a tobacco blend incorporating Oriental tobacco are improved by subjecting that blend to heat treatment. Oriental tobacco having a relatively high sucrose ester content is combined with a second dissimilar Oriental tobacco material and / or a non-Oriental tobacco material to form a tobacco mixture, and that mixture is heated for a time and under conditions sufficient to reduce the concentration of sucrose esters in the Oriental tobacco. Tobacco blends having reduced levels of sucrose esters yield smoke that does not possess undesirable off-notes provided by pyrolysis products of those sucrose esters; namely, 2-methylpropionic acid, 3-methylbutyric acid and 3-methylpentanoic acid.

Owner:R J REYNOLDS TOBACCO COMPANY

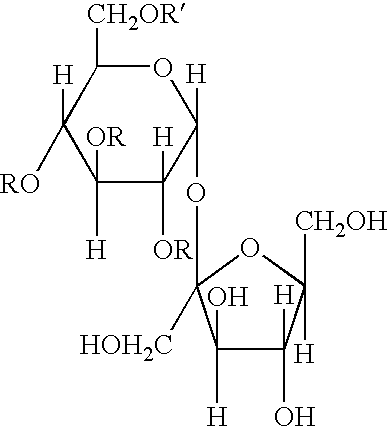

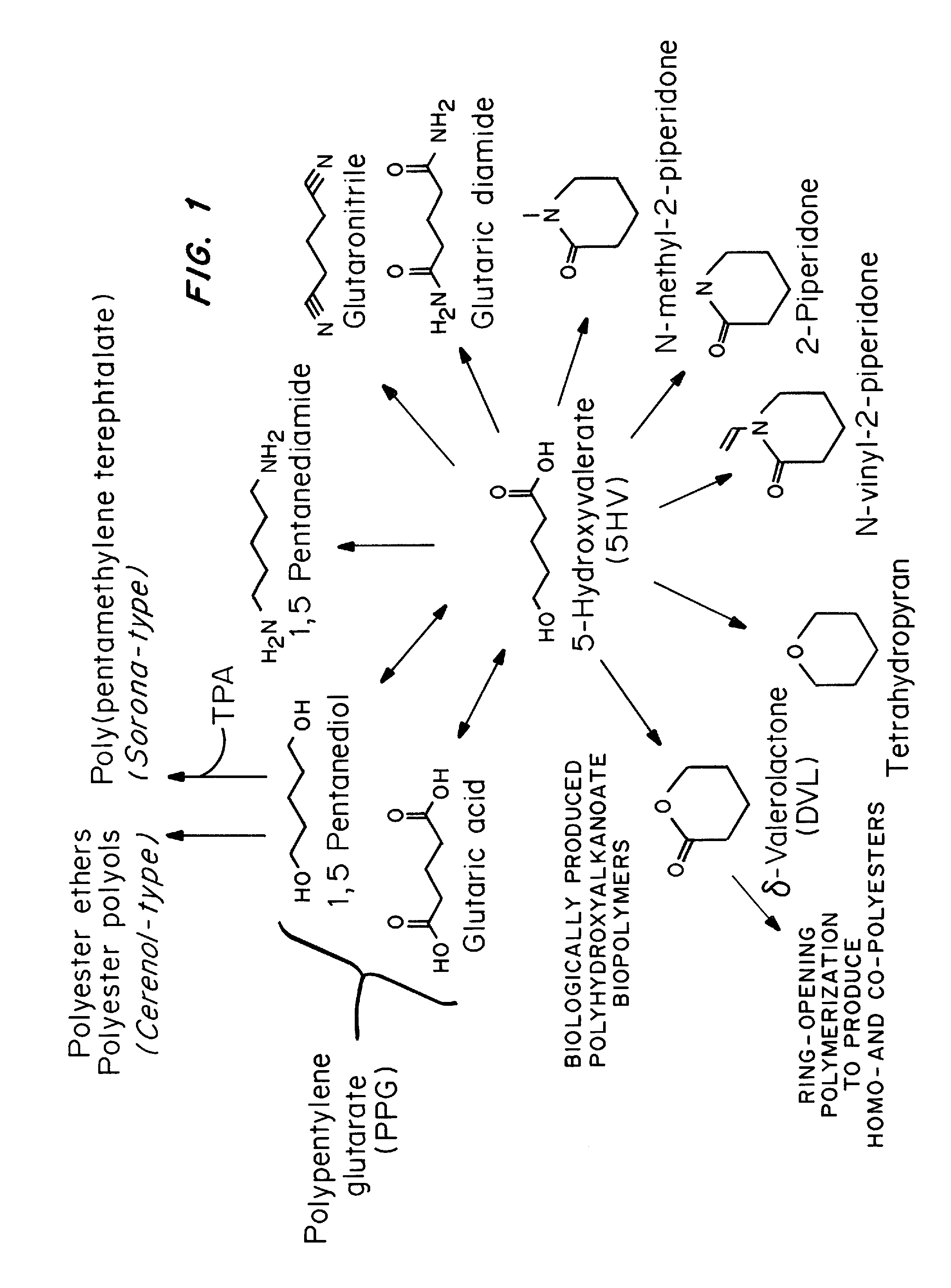

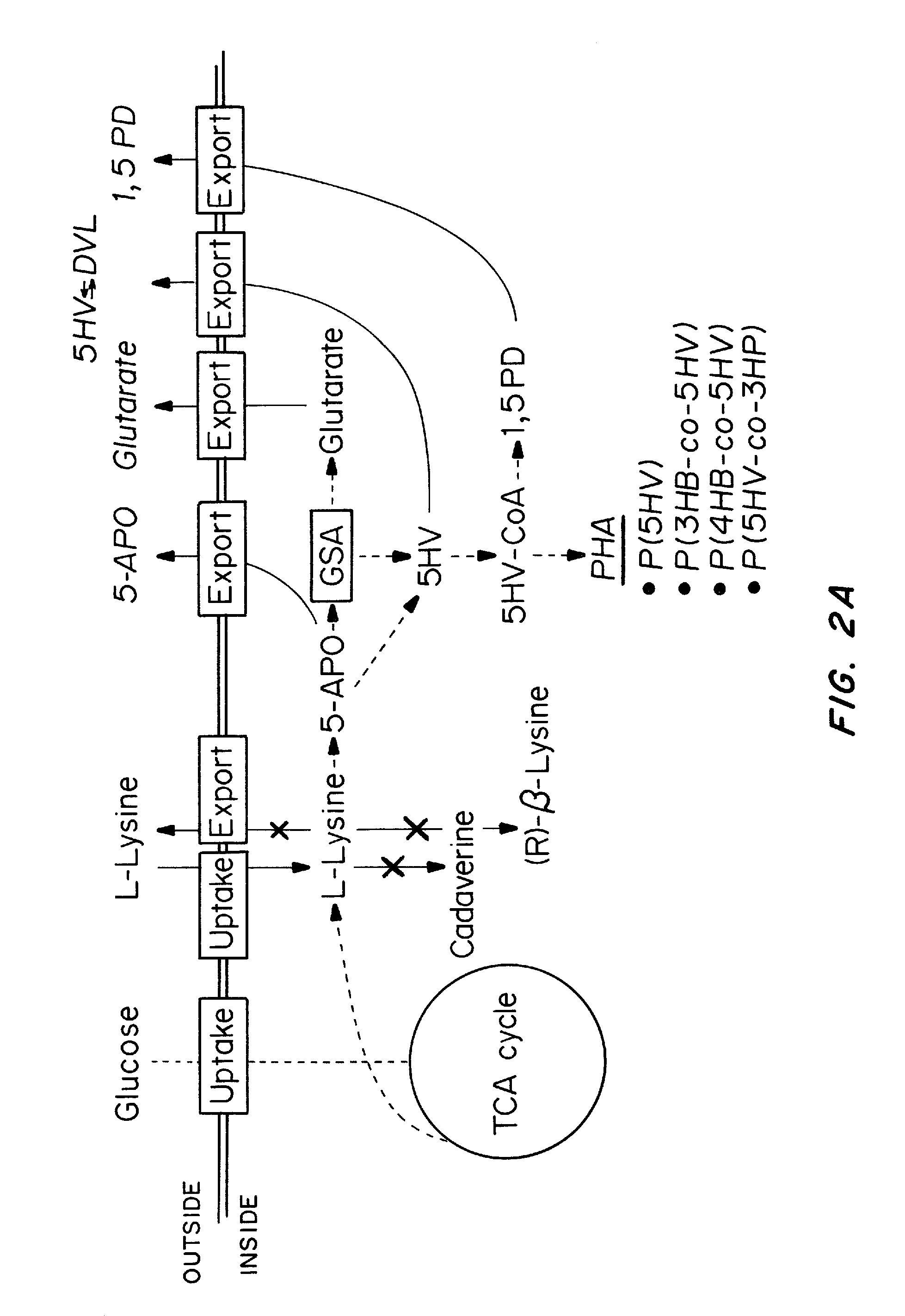

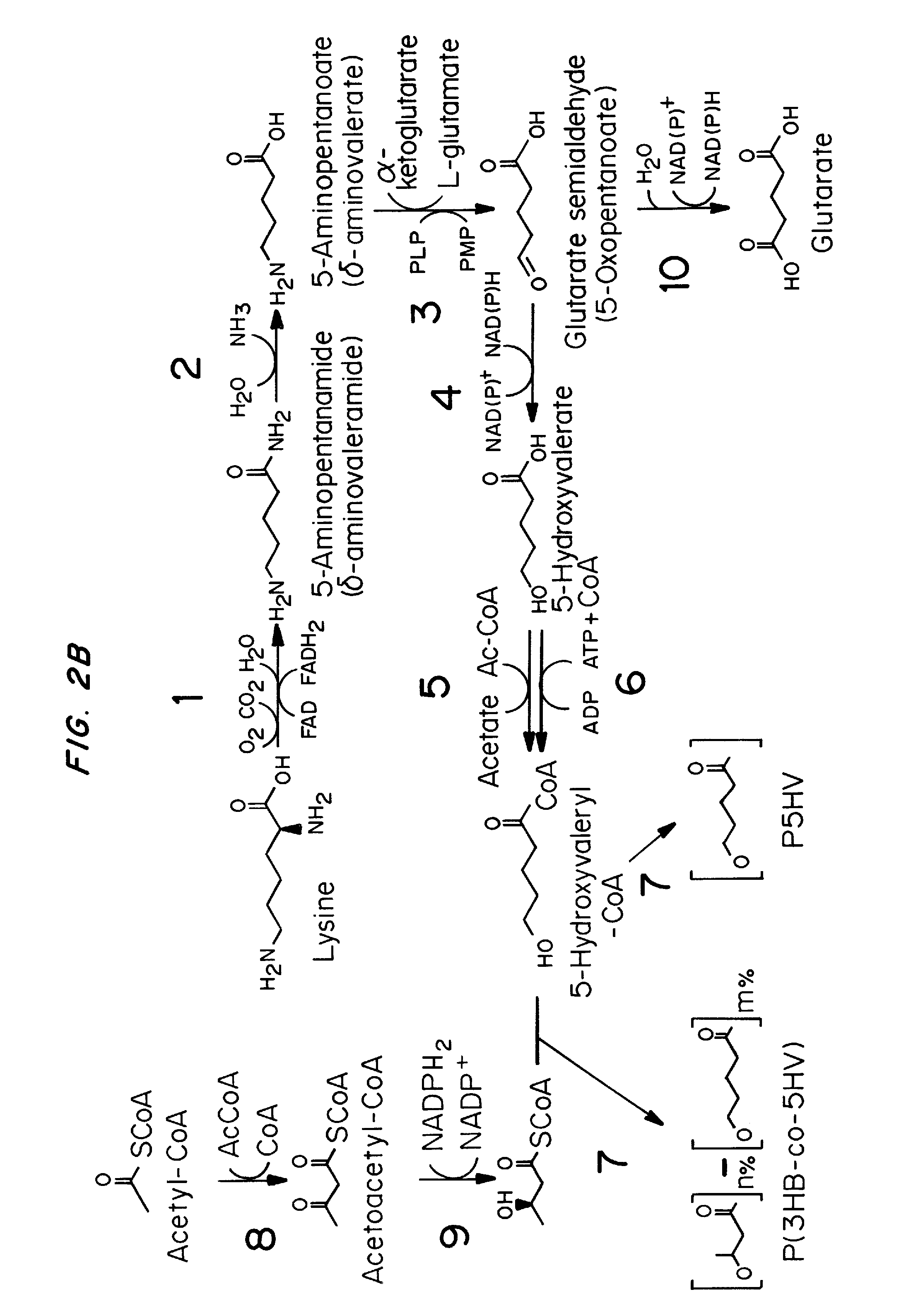

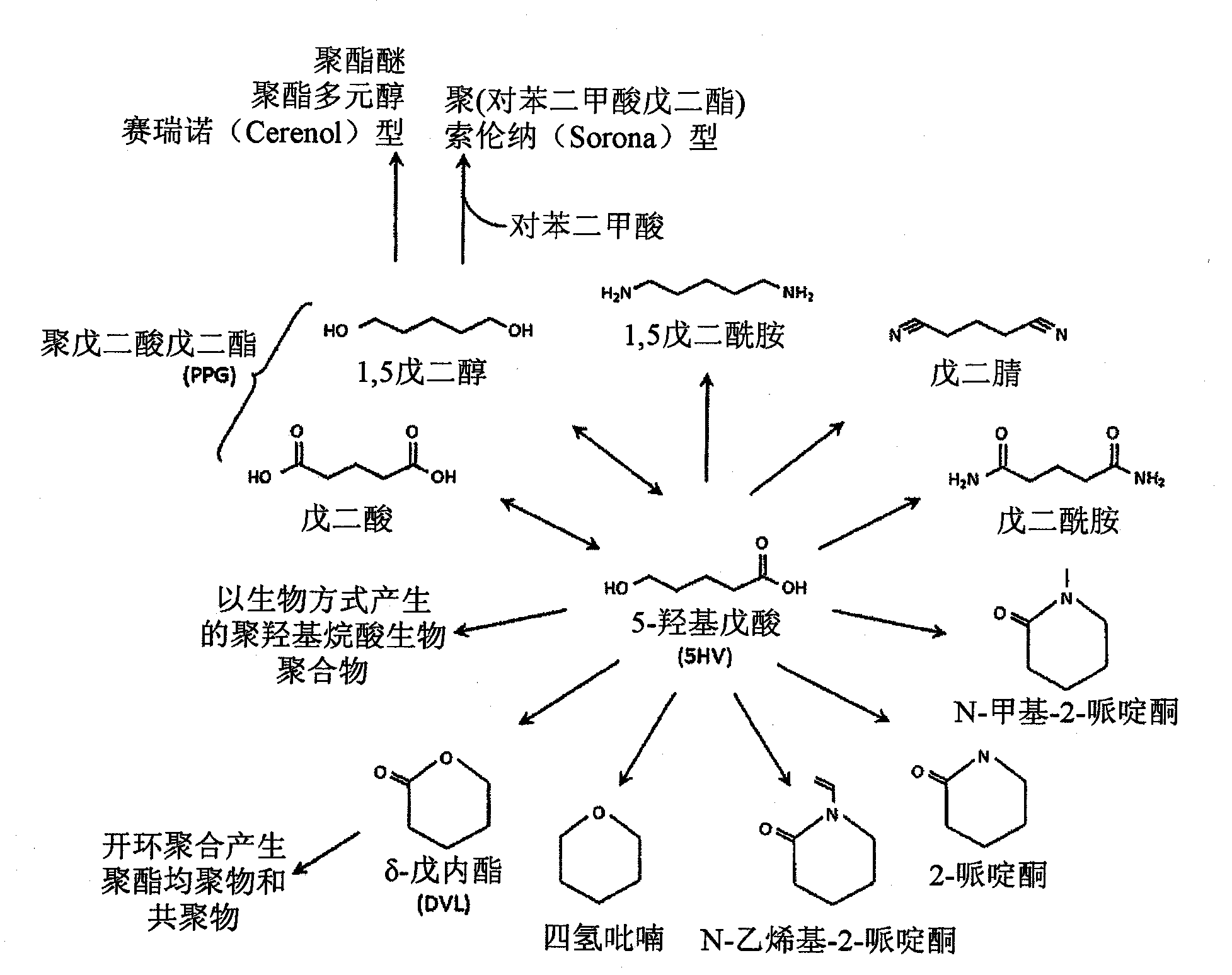

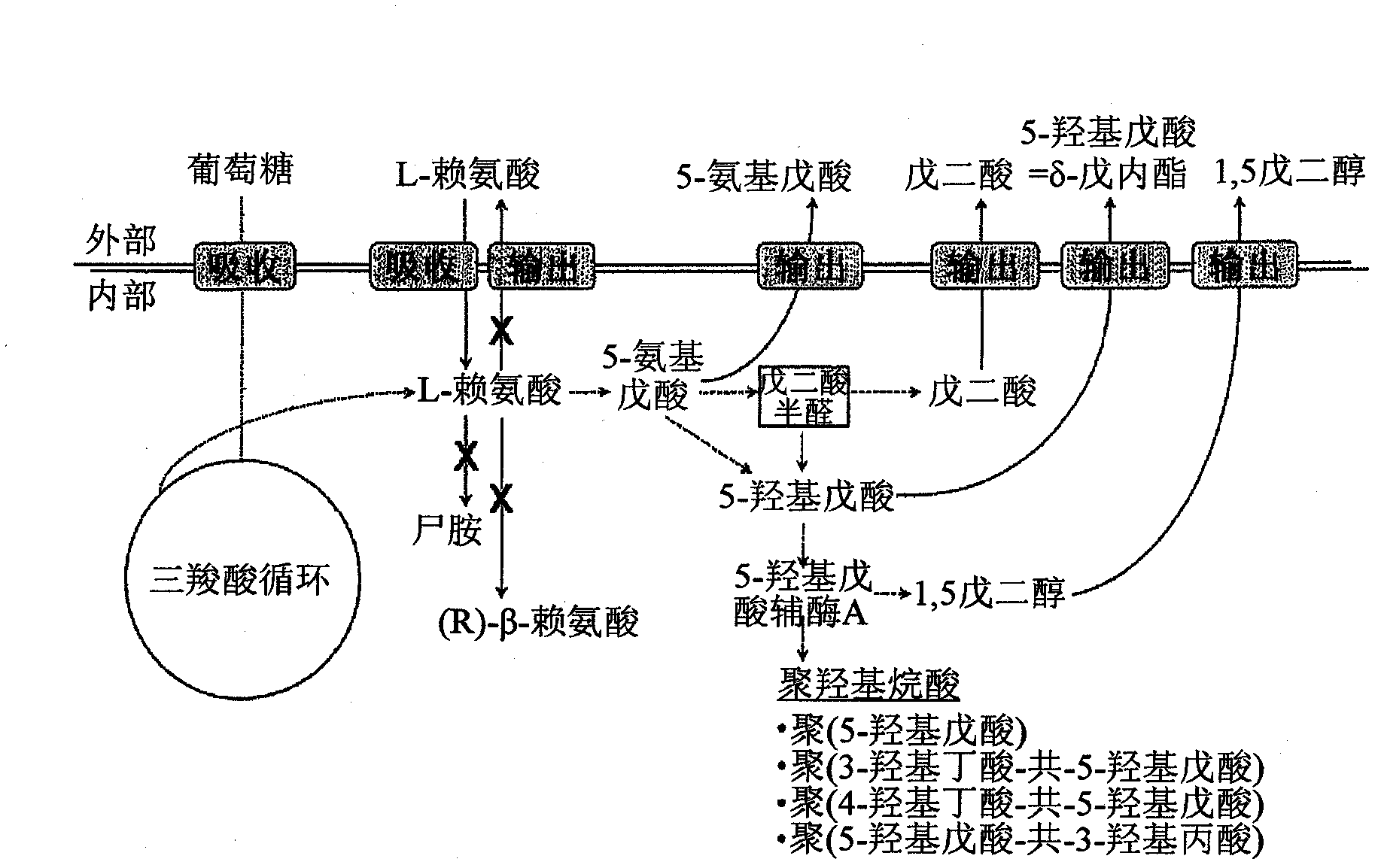

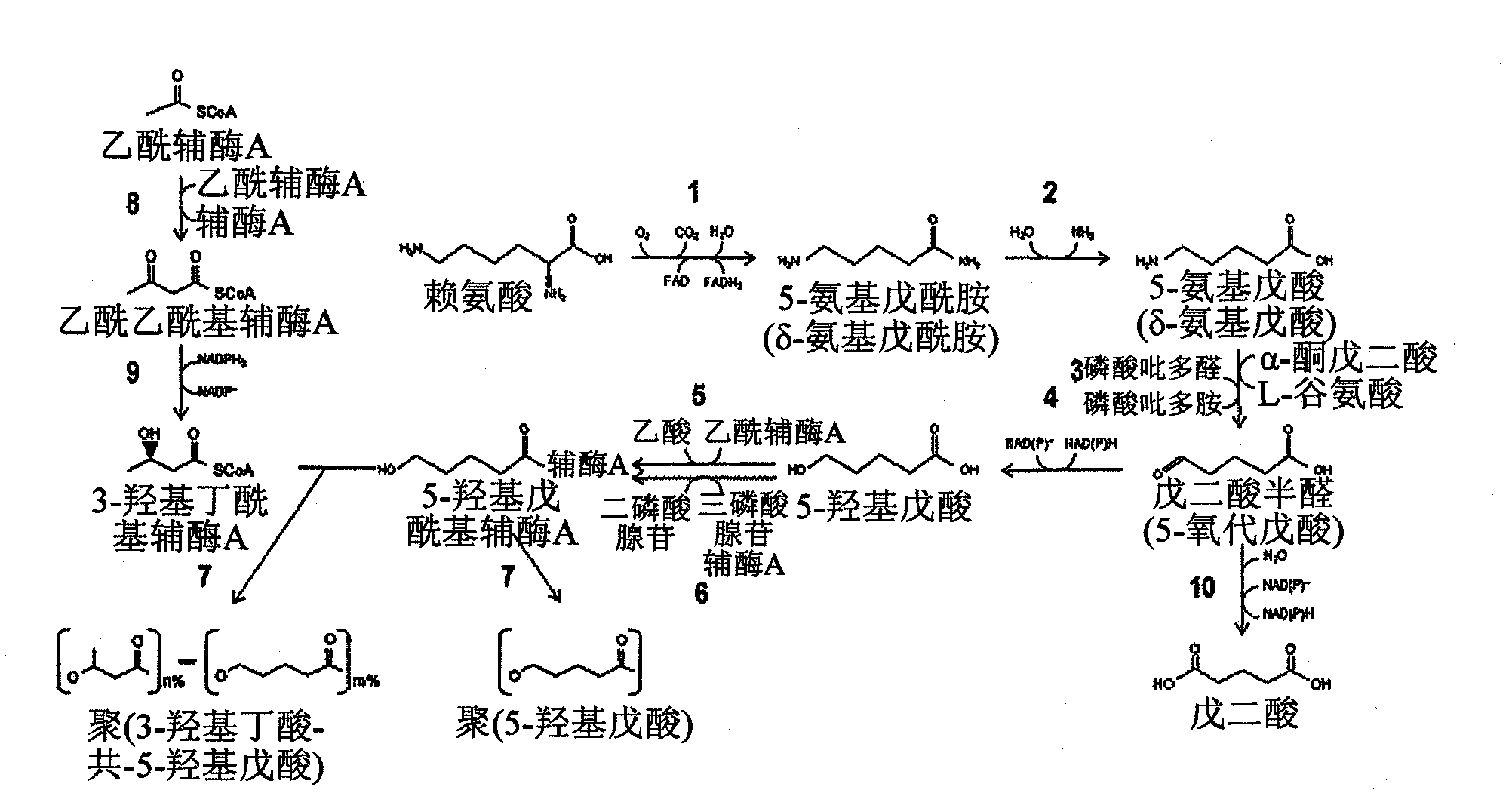

Green process and compositions for producing poly(5HV) and 5 carbon chemicals

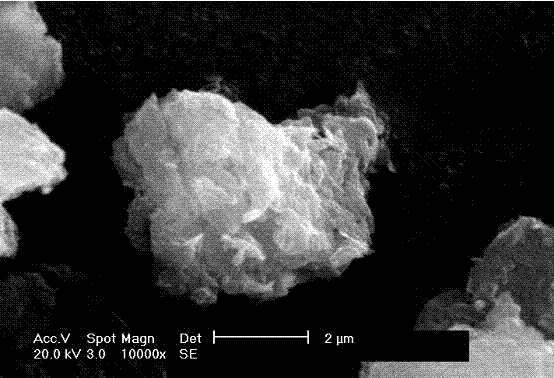

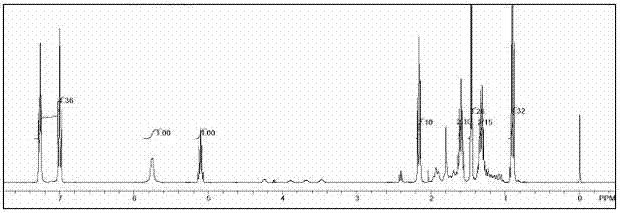

Recombinant hosts for producing polyhydroxyalkanoates and methods of producing polyhydroxyalkanoates from renewable carbon substrates are provided. Certain recombinant hosts that produce 5 carbon chemicals such as 5-aminopentanoate (5AP), 5-hydroxyvalerate (5HV), glutarate, and 1,5 pentanediol (PDO) are also provided. One embodiment provides a recombinant host expressing a gene encoding a heterologous enzyme selected from the group consisting of a polyhydroxyalkanoate synthase and a 5-hydroxyvalerate-CoA (5HV-CoA) transferase, wherein the host produces a polymer containing 5-hydroxyvalerate. Preferably, the host expresses both a polyhydroxyalkanoate synthase and a 5HV-CoA transferase. The host can be prokaryotic or eukaryotic. A preferred prokaryotic host is E. coli. The polymers produced by the recombinant hosts can be homopolymers or copolymers of 5-hydroxyvalerate. A preferred copolymer is poly(3-hydroxybutyrate-co-5-hydroxyvalerate).

Owner:CJ CHEILJEDANG CORP

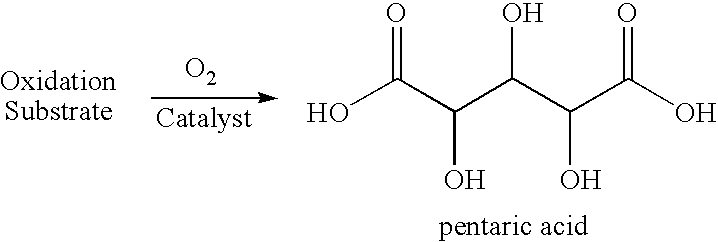

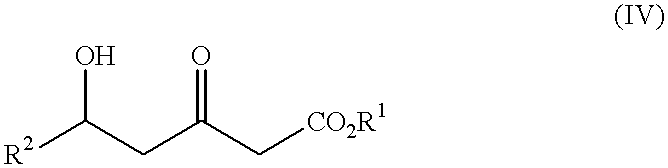

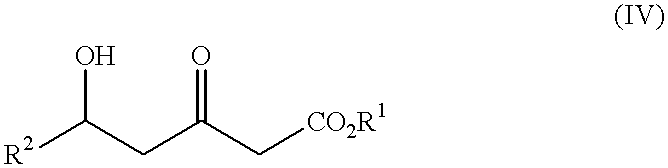

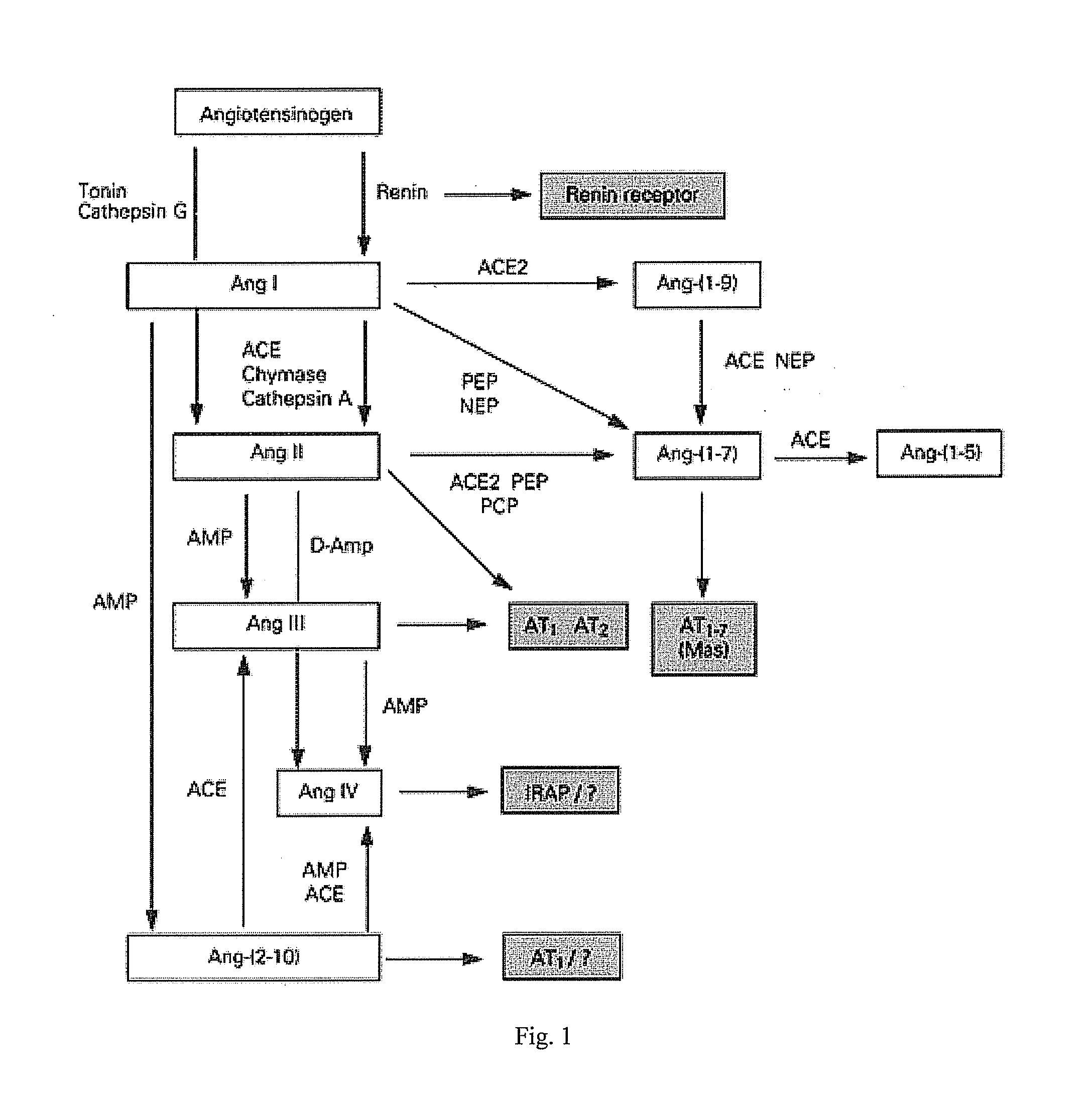

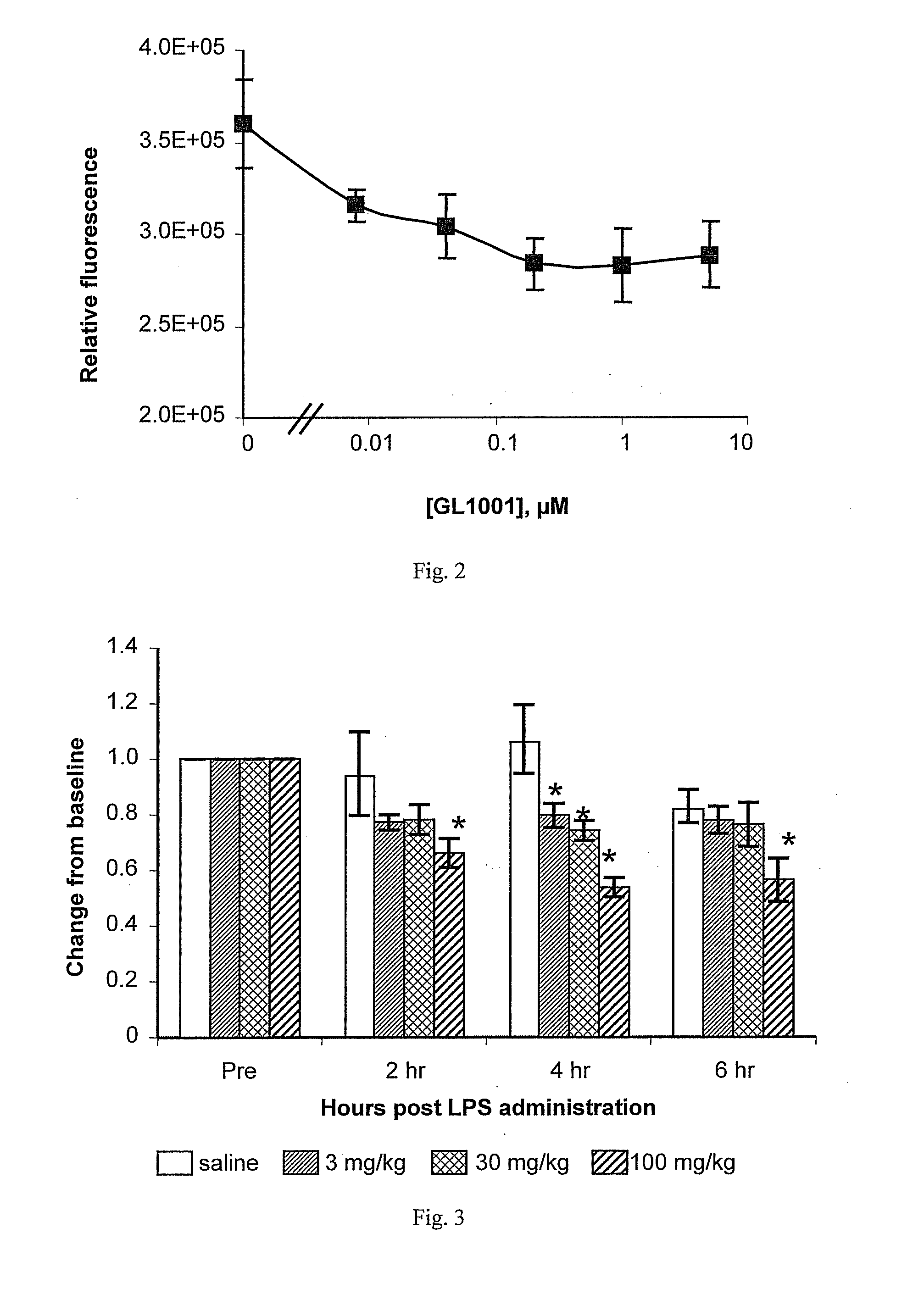

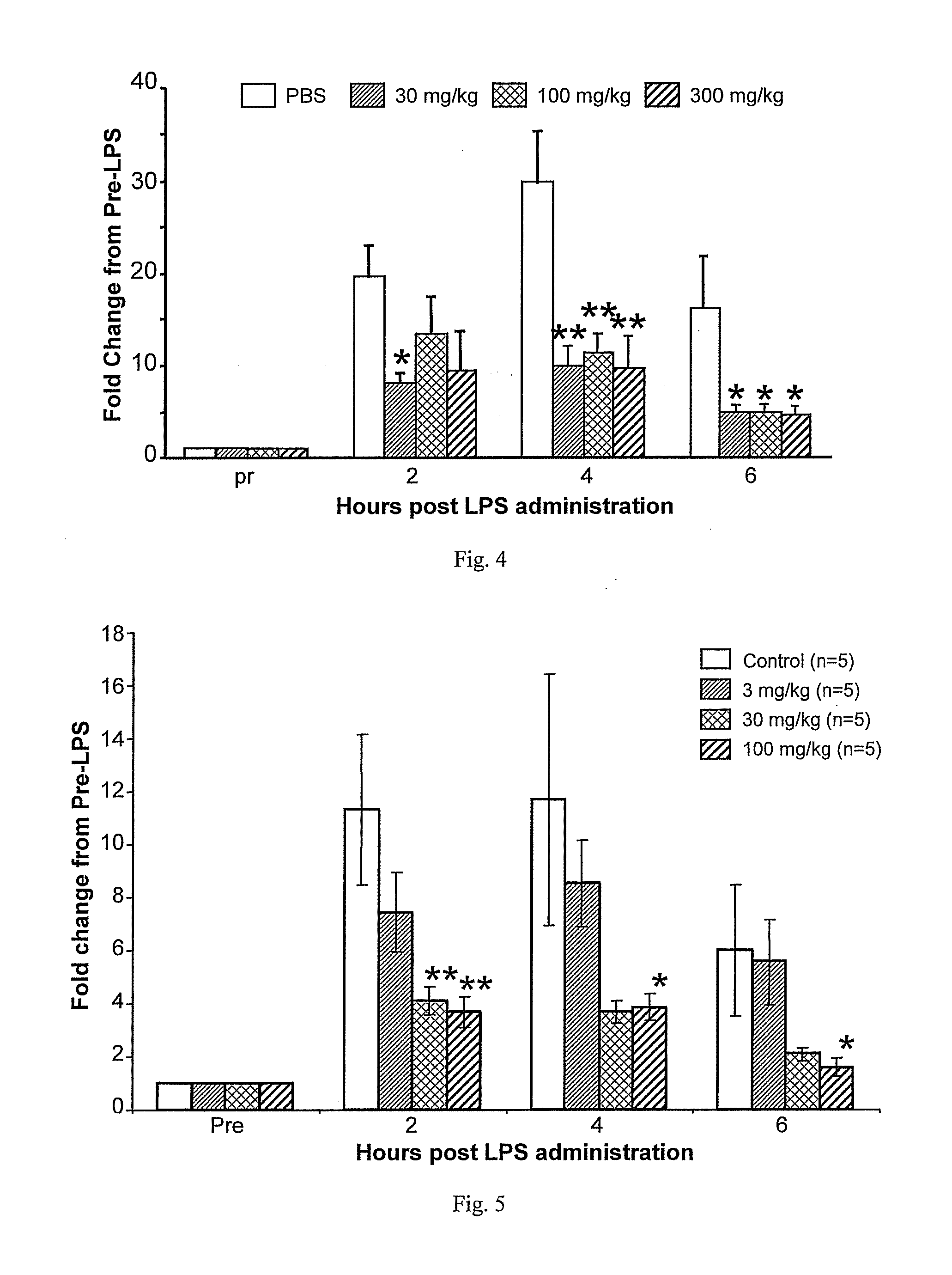

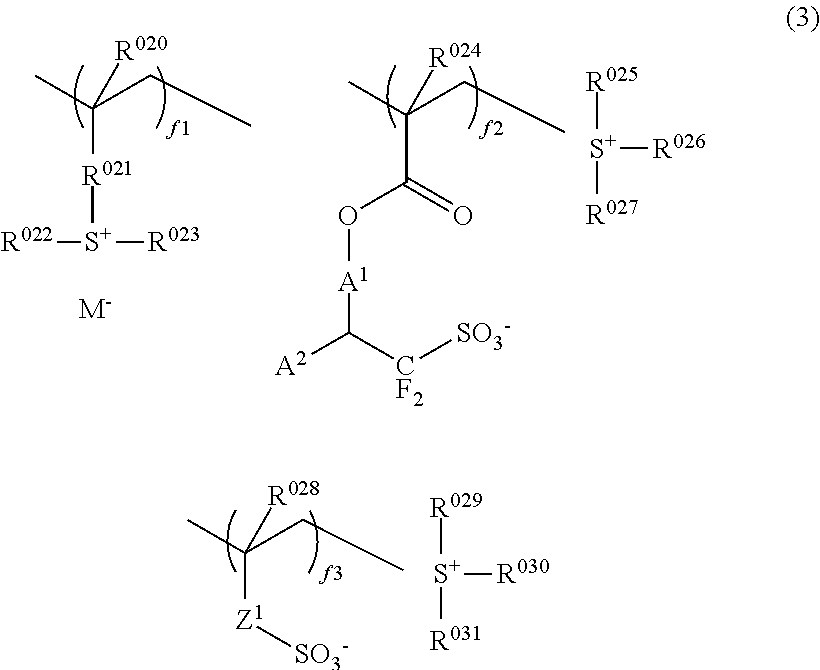

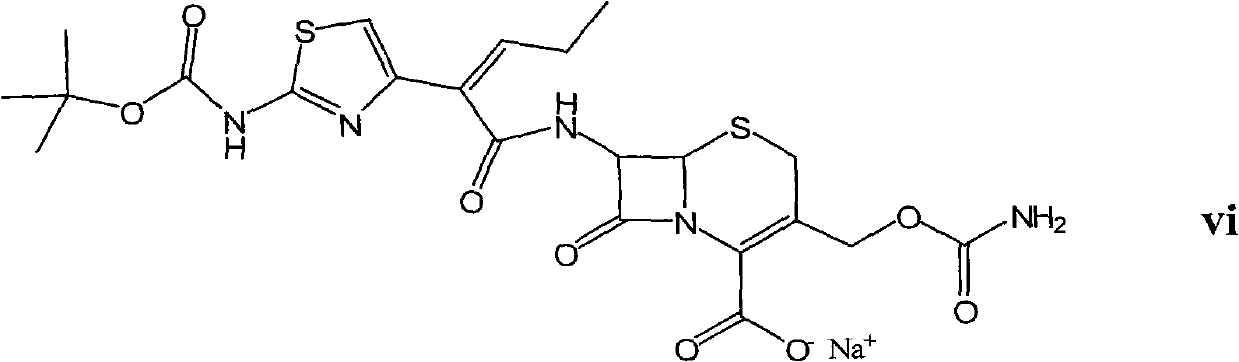

Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations

A compound of an angiotensin receptor antagonist (ARB), a neutral endopeptidase inhibitor (NEPi) and one or more monovalent cations are useful for the treatment of hypertension and / or heart failure. ARB includes S—N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine in the anion form, NEPi includes (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester in the anion form and cation includes monovalent cations such as Na+. The compound includes trisodium [3-((1S,3R)-1-biphenyl-4-ylmethyl-3-ethoxycarbonyl-1-butylcarbamoyl)propionate-(S)-3′-methyl-2′-(pentanoyl{2″-(tetrazol-5-ylate)biphenyl-4′-ylmethyl}amino)butyrate] hemipentahydrate.

Owner:NOVARTIS PHARM CORP

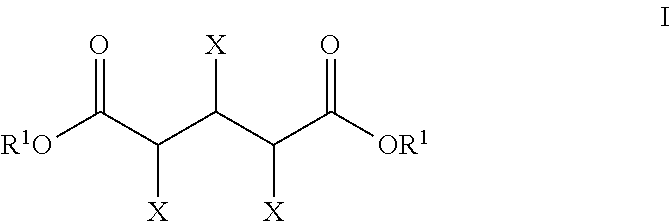

Production of glutaric acid and derivatives from carbohydrate-containing materials

ActiveUS8785683B2Low costCarboxylic acid nitrile preparationOrganic compound preparationGlutaric acidHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a pentose source to a glutaric acid product. The present invention includes processes for the conversion of pentose to a glutaric acid product via pentaric acid or derivatives thereof. The present invention also includes processes comprising the catalytic oxidation of pentose to pentaric acid and catalytic hydrodeoxygenation of pentaric acid or derivatives thereof to a glutaric acid product.

Owner:ARCHER DANIELS MIDLAND CO

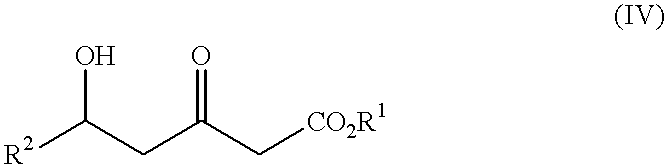

Processes for the preparation of 5-hydroxy-3-oxopentanoic acid derivatives

InactiveUS6340767B1Increase productionGreat advantageCarboxylic acid nitrile preparationOrganic compound preparationAcetic acid3-Hydroxypropionic acid

This invention provides a process for producing a 5-hydroxy-3-oxopentanoic acid, a useful pharmaceutical intermediate, easily from a readily available, inexpensive starting material without using any extraordinary production equipment such as a very-low-temperature reactor.Thus, this invention provides a process for producing a 5-hydroxy-3-oxopentanoic acidwhich comprises permitting a lithium amide to act upon a mixture of an acetic acid ester and a 3-hydroxypropionic acid derivative at not below -20° C.Further, this invention also provides a process for producing a 5-hydroxy-3-oxopentanoic acidwhich comprises treating a mixture of an acetic acid ester and a 3-hydroxypropionic acid derivative with a Grignard reagent to prepare a mixture of a compound and an acetic acid ester of the above formula (I),and permitting a lithium amide to act upon the mixture at a temperature not below -20° C.

Owner:KANEKA CORP

Method for catalyzing dynamic kinetic resolution of arylamine via racemization catalyst

InactiveCN102533922AGood stability for repeated useMild reaction conditionsOrganic chemistry methodsChemical recyclingChlorobenzenePtru catalyst

The invention discloses a method for catalyzing dynamic kinetic resolution of arylamine via a racemization catalyst, comprising the following steps of: 1) adding p-chlorophenol, n-pentanoic acid, dicyclohexylcarbodiimide and 4-dimethylamino-pyridine, and carrying out mixing, filtration, drying, concentration and column chromatography to obtain a pentanoic acid p-chlorophenyl ester acyl donor; 2) carrying out coprecipitation on magnesium chloride solution and aluminum chloride solution and carrying out water-heat treatment to obtain chloridion intercalated hydrotalcite, adding the chloridion intercalated hydrotalcite in lauryl sodium sulfate aqueous solution, and carrying out backflow, cooling, centrifugation, water washing, acetone washing and drying to obtain a carrier; 3) adding palladium salt and the carrier, and carrying out heating, ascorbic acid addition, centrifugation, water washing, acetone washing and freeze-drying to obtain the racemization catalyst; and 4) adding arylamine, the acyl donor, lipase and the racemization catalyst in toluene and placing in a stainless steel reactor to add hydrogen so as to obtain amide. The method provided by the invention is used for catalyzing the dynamic kinetic resolution of arylamine, has rapid reaction rate, low temperature, high conversion rate and high product optical purity, and has great application value.

Owner:ZHEJIANG UNIV

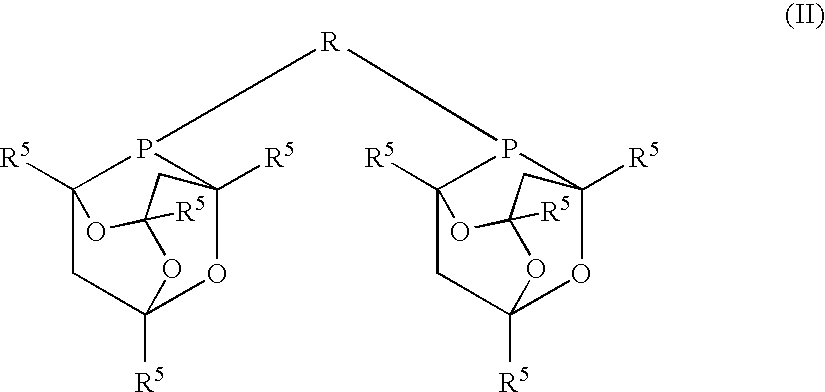

Process for the carbonylation of pentenenitrile

Processes to prepare 5-cyanovaleric acid or its ester are provided, by carbonylation of a pentenenitrile, wherein pentenenitrile is reacted with carbon monoxide and water and / or an alcohol in the presence of a catalyst system. The catalyst system contains:(a) a metal of Group VIII or a compound thereof and(b) a bidentate phosphine, arsine and / or stibine ligand, wherein the bidentate ligand has the general formula (I):R1R2-M1-R-M2-R3R4 (I) wherein M1 and M2 are independently P, As or Sb, R is a divalent organic bridging group, which bridging group comprises a chain of 3 to 5 atoms directly connecting the 2 phosphorus atoms, which chain consists of carbon atoms and optionally a nitrogen, oxygen or sulphur atom or a silano or dialkylsilicon group, which alkyl groups independently comprise from 1 to 4 carbon atoms, and R1–R4 represent the same or different optionally substituted tertiary alkyl groups,(c) an acid having a pKa less than 3, as measured at 18° C. in an aqueous solution.ε-caprolactam is also prepared by reduction of 5-cyanovaleric acid or ester obtained above to 6-aminocaproic acid or ester, and then cyclisation of the 6-aminocaproic acid or ester to ε-caprolactam.

Owner:SHELL OIL CO

Polyol ester lubricants for refrigerating compressors operating at high temperature

InactiveUS6267906B1Good hygroscopicityPromote undesirable corrosionLiquid carbonaceous fuelsHeat-exchange elementsPentaerythritolNonanoic acid

A high quality lubricant for heavy duty service air conditioner and refrigerator compressors, especially those using chlorine free hydrofluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably di-pentaerythritol, usually mixed with some pentaerythritol, with a mixture of carboxylic acids including at least some of each of iso-pentanoic acid and iso-nonanoic acid.

Owner:COGNIS IP MANAGEMENT GMBH

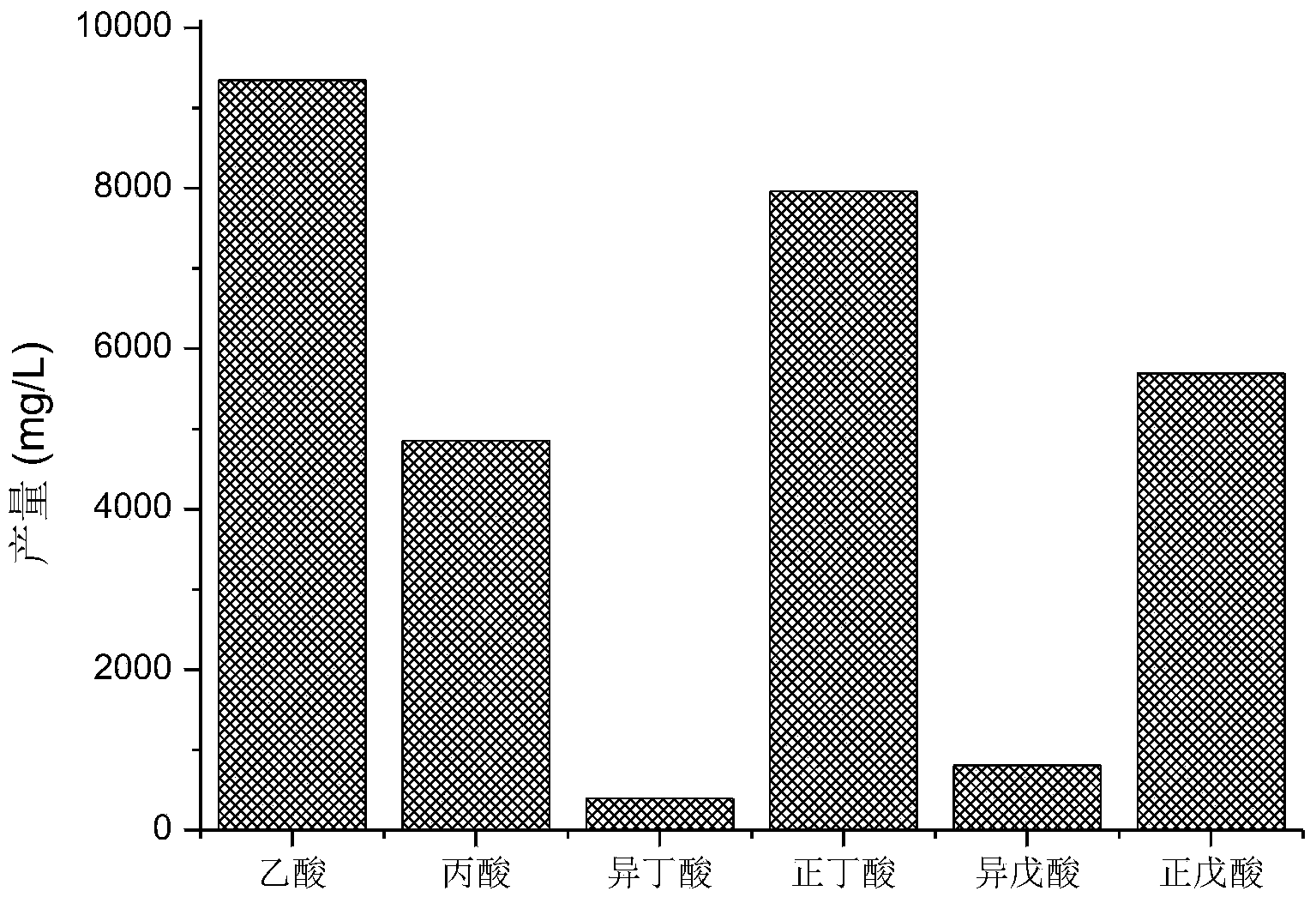

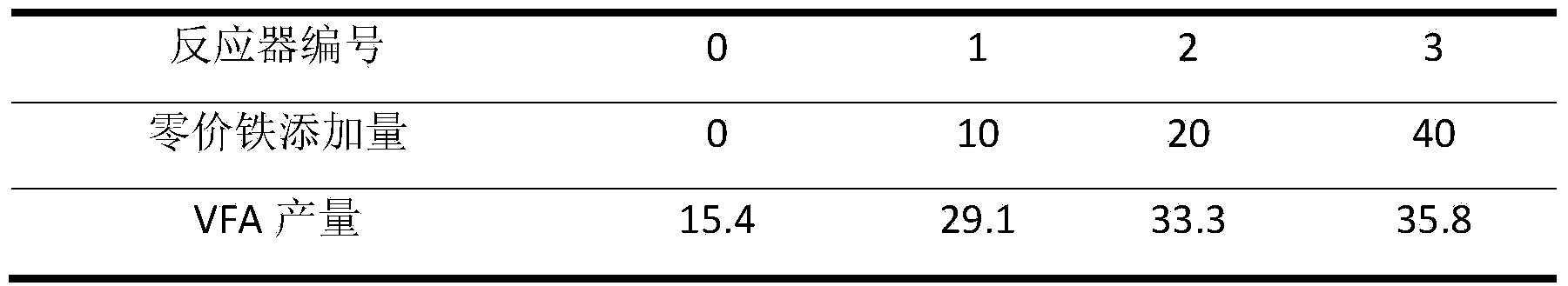

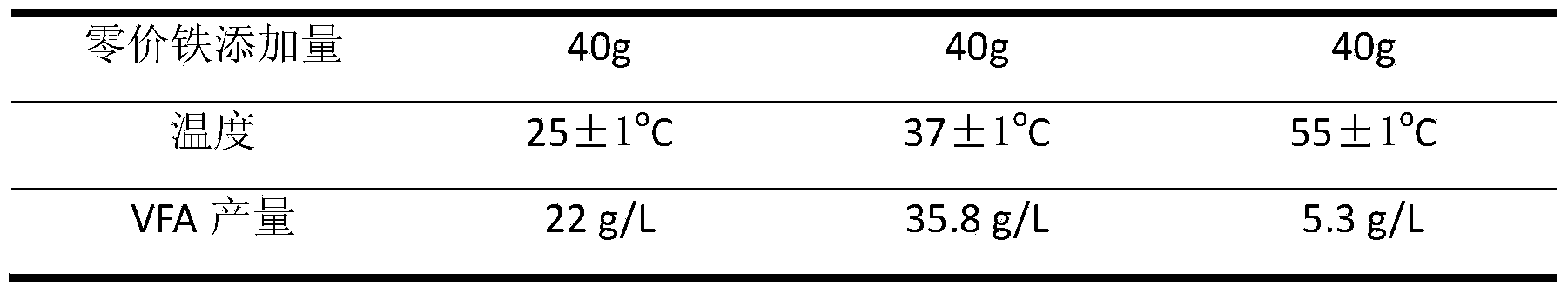

Method for producing volatile fatty acid through promoting anaerobic fermentation of kitchen wastes

InactiveCN103555775AReduce processing costsReduce investment and operating costsFermentationAcetic acidPropanoic acid

The invention relates to a method for producing volatile fatty acid through promoting the anaerobic fermentation of kitchen wastes. The method comprises the steps of firstly, crushing the kitchen wastes to be up to the particle size of 1-5mm; then, regulating the content of solids to 100mg / L; next, placing the crushed kitchen wastes into an anaerobic fermentation reactor, adding 10-40g / L of marketing zero-valent iron with the particle size of 800 meshes, fermenting at the temperature of 15-40 DEG C for 4-17 days while stirring at the rotating speed of 120r / min, centrifuging, recycling the zero-valent iron in filter residues, and taking out the residual organic components to be composted or used as a liquid fertilizer to obtain the volatile fatty acid with the yield of 29.1-35.8g / L in a supernatant liquid, wherein the volatile fatty acid is detected to contain 32% of acetic acid, 17% of propionic acid, 27% of n-butanoic acid and 20% of n-pentanoic acid when the yield of the volatile fatty acid in the supernatant liquid is 29.1g / L. Compared with the conventional anaerobic fermentation for the kitchen wastes, the method has the advantages that the content of the volatile fatty acid in the supernatant liquid is increased by 2.3-13 times, the recycling of the kitchen wastes is effectively realized, and the method is low in cost, high in speed and high in social, economic and environmental benefits.

Owner:TONGJI UNIV

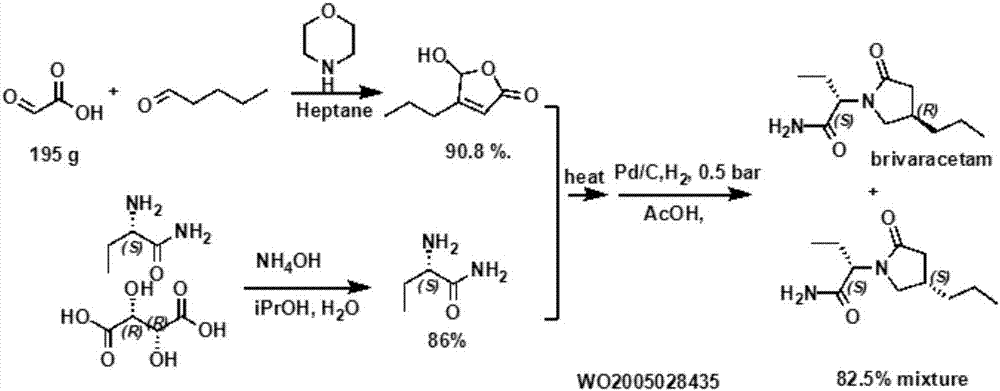

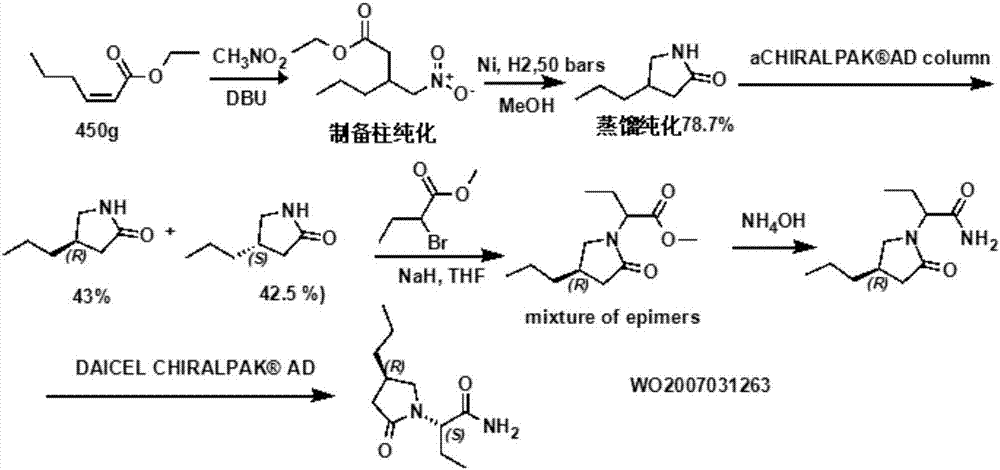

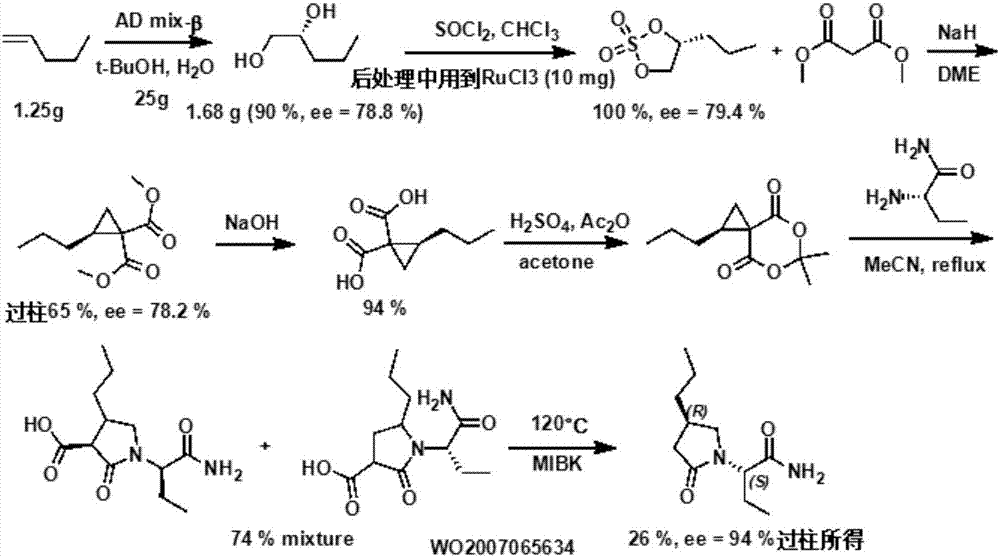

New synthesis method of brivaracetam

InactiveCN107216276AHigh yieldIncrease production capacityOrganic chemistrySynthesis methodsBrivaracetam

The invention provides a synthesis method of brivaracetam. The method adopts cheap and easily available pentanoic acid or valeryl halide as an initial raw material, and provides a brand new synthesis route of a brivaracetam medicine, and the whole reaction route has a high total yield. The method has the advantages of high productivity, low cost, and suitableness for large-scale industrial production.

Owner:ASTATECH CHENGDU BIOPHARM CORP

Medicament for fast preventing and controlling malignant aquatic weed and algae and uses thereof

ActiveCN101263829AAvoid photosynthesisReduced normal lifeBiocideEnergy based wastewater treatmentBenzoic acidPropanoic acid

The invention relates to a medicament for fast preventing the malignant float grasses and the water algae and the application thereof, belonging to the pesticide formulation technical field, which is characterized in that the medicament comprises from 40% to 90% of a plant vinegar fluid, from 5% to 35% of an organic acid, and from 1% to 20% of pesticide addition agent, the plant vinegar fluid is either a bamboo vinegar fluid, a wooden vinegar fluid, and (or) grass vinegar fluid, the organic acid is one of or a mixture of more than one of a formic acid, an acetic acid, a propionic acid, a 2-methyl propionic acid, an ethyl acetic acid, a 4-hydroxy ethyl acetic acid, a pentanoic acid, a benzoic acid, a 2,6-hydroxy benzoic acid, a 3-hydroxy-4-methoxy benzoic acid or a 3-methoxy-4-hydroxy benzoic acid. The medicament has the advantages of fast destroying the chlorophyll, stopping the plant to do the photosynthesis, commonly killing the water algae in a half hour and the float grass in three hours by spraying, having low production cost, strong killing capability, wide adaptable temperature range and pH value range. The active component of the invention has the advantages of being the natural-occurring substance, no corrosion, nonirritant, safe use, and reliability, easy biodegradation, and no secondary pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Polyol ester lubricants for refrigerator compressors operating at high temperatures

InactiveUS6296782B1Good hygroscopicityPromote undesirable corrosionPlastic/resin/waxes insulatorsHeat-exchange elementsPolyolesterPentaerythritol

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above and below normal human comfort temperatures, especially those using chlorine free hydrofluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including iso-pentanoic acid, trimethylhexanoic acid, and preferably n-pentanoic acid.

Owner:COGNIS IP MANAGEMENT GMBH

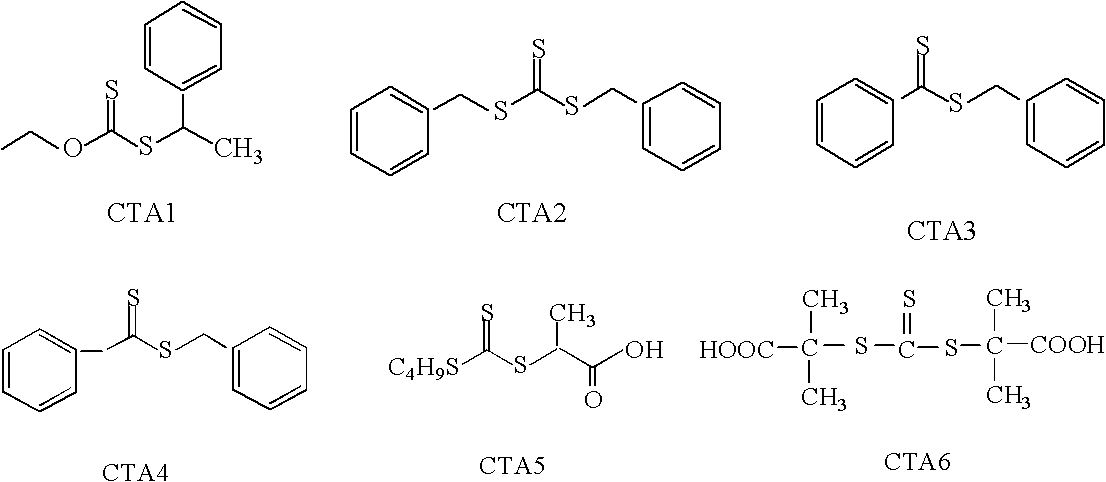

Method for constructing simulated outer cell membrane structure coating on material surface by RAFT (reversible addition fragmentation chain transfer) polymerization technology

ActiveCN102888013AImprove adhesionHigh densityPharmaceutical containersMedical packagingBenzoic acidPolymer science

The invention discloses a method for constructing a simulated outer cell membrane structure coating on a material surface by an RAFT (reversible addition fragmentation chain transfer) polymerization technology, which comprises the following steps of: immobilizing a chain transfer agent 4-cyanopentanoic acid dithiobenzoate on the material surface via primary amino grafting on substrate surface by acylation; then performing free radical polymerization with polymerizable monomers of methacryloyloxyethyl phosphorylcholine in solution to obtain the coating modified by grafted polymers on the surface. The method provided by the invention obtains PMPC (polymerized methacryloyloxyethyl phosphorylcholine) molecular brushes with controllable molecular weight and narrow molecular weight distribution on the surface by grafting and polymerizing the MPC (methacryloyloxyethyl phosphorylcholine) on the surface through the RAFT polymerization; a good effect of resisting against platelet adhesion is reflected on the modified substrate surface of the prepared simulated outer cell membrane structure; and the prepared coating is useable as the coating on the surface of blood contact materials such as artificial hearts, artificial blood vessels and hemodialyzers.

Owner:NORTHWEST UNIV(CN)

Method for treating inflammatory diseases of the digestive tract

InactiveUS20080107650A1Avoiding corticosteroid therapyBiocideDigestive systemInflammatory bowel diseaseDisease cause

A method for treating an inflammatory disease of the digestive tract, for example inflammatory bowel disease, in a subject comprises administering to the subject a therapeutically effective amount of a compound selected from the group consisting of (S,S)-2-[1-carboxy-2-[3-(3,5-dichlorobenzyl)-3H-imidazol-4-yl]-ethylamino]-4-methylpentanoic acid, pharmaceutically acceptable salts thereof and prodrugs thereof.

Owner:ORE PHARMA

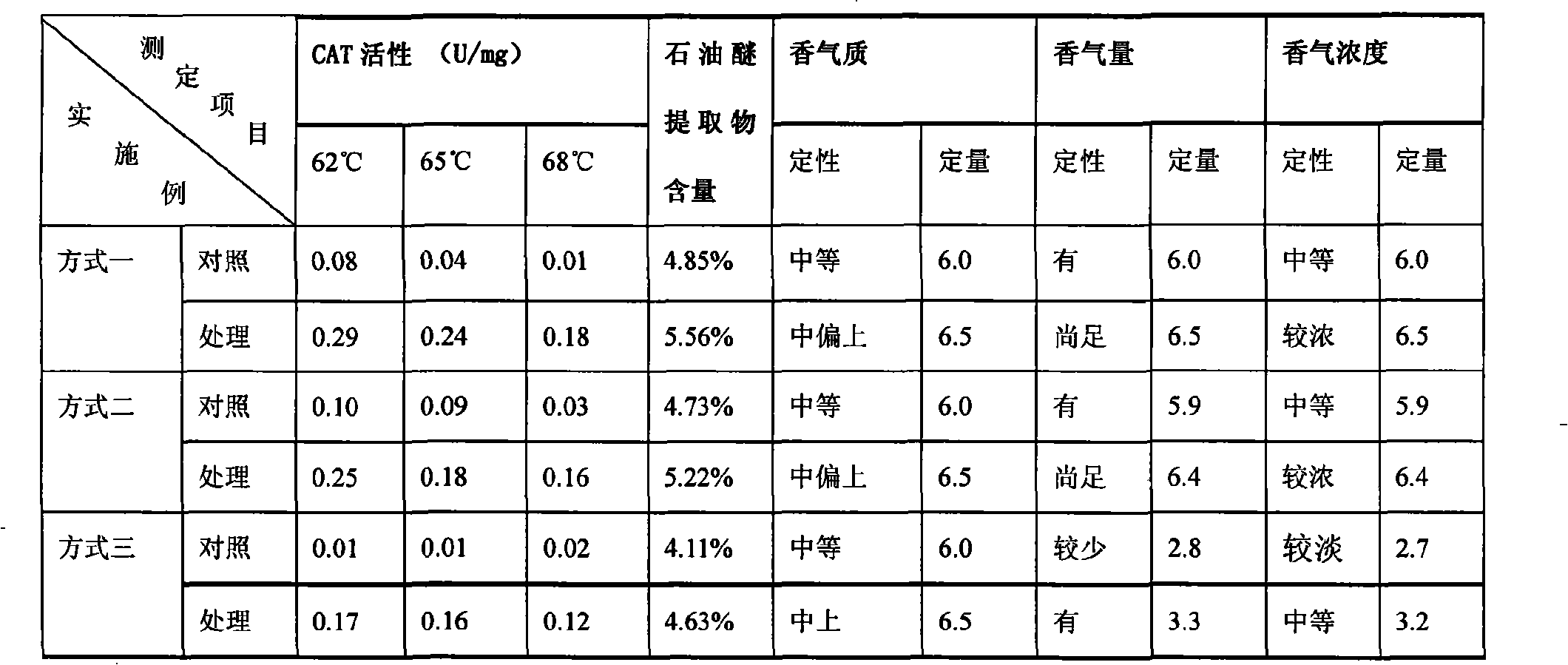

Cure tobacco leaf roasting aroma-extracting agent and use thereof

InactiveCN101356995AIncrease aromaIncrease the amount of aromaTobacco preparationTobacco treatmentAcetic acidEthyl maltol

A baking flavoring agent of fire-cured tobacco leaves is characterized in that the flavoring agent is made from the following components by weight percentages: 1%-5% of hydrogen peroxide, 0.05%-0.25% of beta-methyl pentanoic acid, 0.01%-0.05% of ethyl maltol, 1%-4% of acetic acid, and 90.70%-97.94% of water. The way for using the flavoring agent is as follows: after the tobacco leaves ripen and are picked, the flavoring agent is evenly sprayed on the front face and rear face of the tobacco leaves by a sprayer until the surfaces of the tobacco leaves become wet but not drop water; 200g-250g of the flavoring agent is used for every 100 tobacco leaves; after being sequentially arranged on rods, the tobacco leaves are put in a cool place for airing, and then put in a baking room for normal baking. Test data prove that application of the flavoring agent of the invention to the pre-baking treatment of the fire-cured tobacco leaves can greatly improve the content of a petroleum ether extract in the tobacco leaves, effectively promote the aroma quality, and obviously improve the aroma content and aroma concentration.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

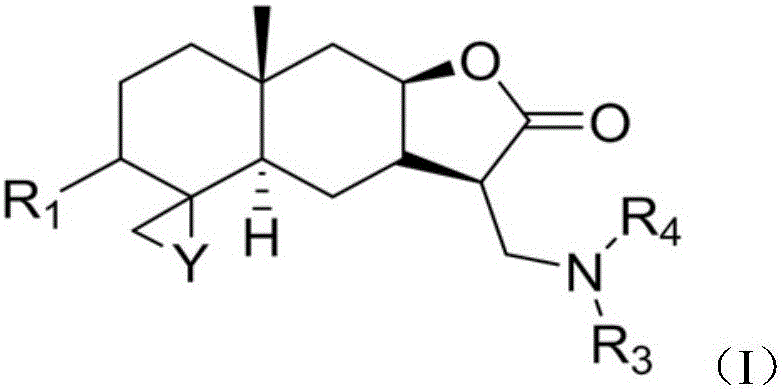

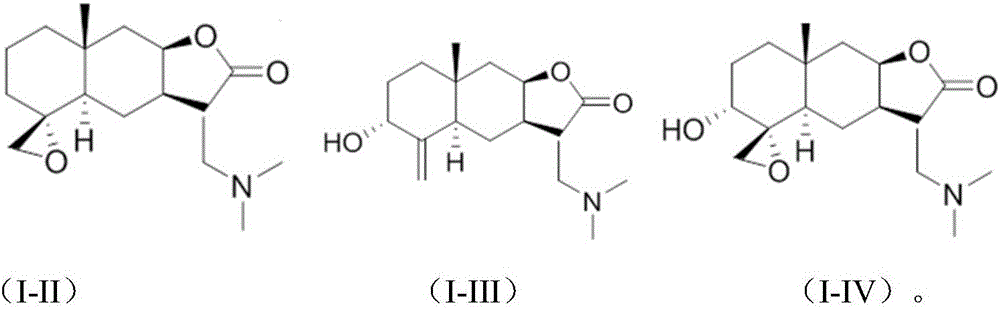

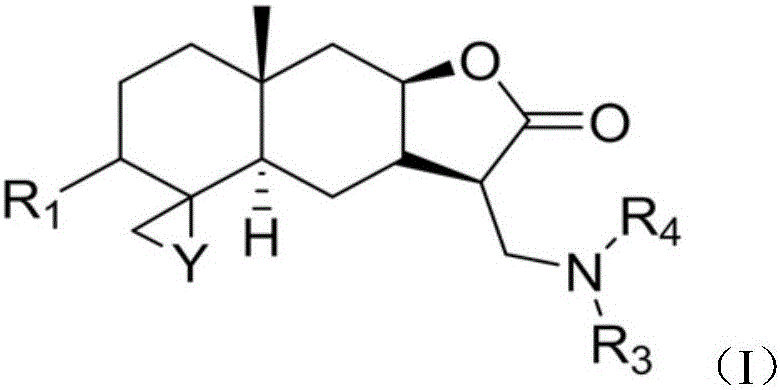

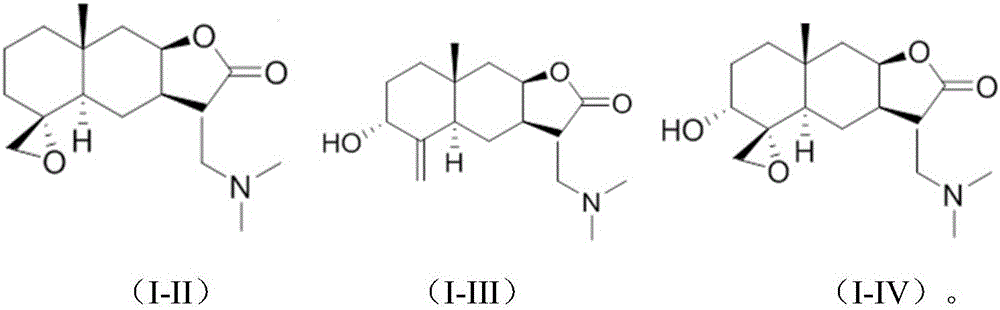

Isoalantolactone derivative and salt thereof

InactiveCN106478569AImprove tumor inhibition rateProlong lifeOrganic active ingredientsAntipyreticBenzoic acidPhosphomolybdic acid

The invention relates to isoalantolactone derivatives and salts thereof and provides an isoalantolactone derivative as shown in a formula (I). Salification acids are selected from inorganic acids or organic acids; the inorganic acids are selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulphurous acid; the organic acids are selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methylsulfonic acid, pentanoic acid, oleic acid, lauric acid, p-toluene sulfonic acid, 1-naphthalenesulfonic acid, 2-naphthalenesulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycolic acid, mercaptan acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid or substituted benzoic acid.

Owner:NANKAI UNIV

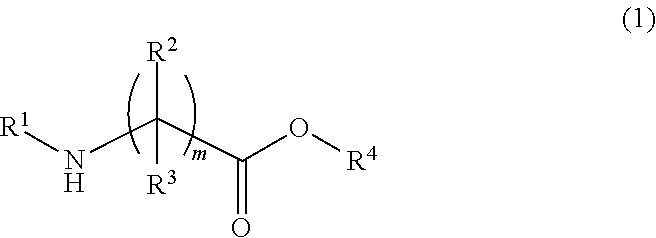

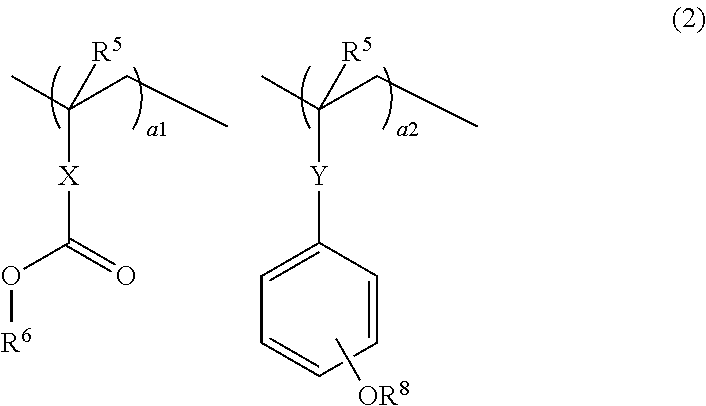

Chemically amplified resist composition and patterning process

ActiveUS20140080055A1Wide focusIncrease contrastElectric discharge tubesPhotosensitive materialsNonanoic acidPolymer science

A chemically amplified resist composition comprising a base polymer and an amine quencher in the form of a β-alanine, γ-aminobutyric acid, 5-aminovaleric acid, 6-aminocaproic acid, 7-aminoheptanoic acid. 8-aminooctanoic acid or 9-aminononanoic acid derivative having an unsubstituted carboxyl group has a high contrast of alkaline dissolution in rate before and after exposure and forms a pattern of good profile at a high resolution, minimal roughness and wide DOF.

Owner:SHIN ETSU CHEM IND CO LTD

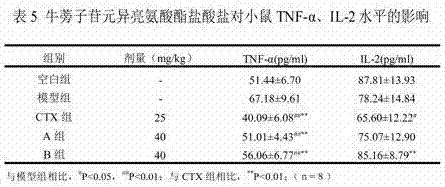

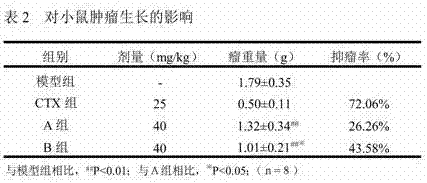

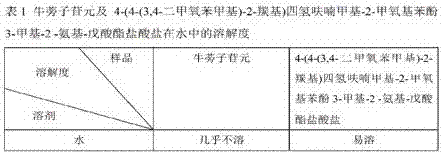

Arctigenin isoleucinate hydrochloride

The invention provides 4-(4-(3,4-dimethoxybenzyl)-2-carbonyl) tetrahydrofuran methyl-2-methoxyphenol-3-methyl-2-amino-pentanoate hydrochloride with a structural formula shown as formula I, applicableto an antineoplastic purpose, belonging to the field of researches on antineoplastic drugs. Experimental results show that the 4-(4-(3,4-dimethoxybenzyl)-2-carbonyl) tetrahydrofuran methyl-2-methoxyphenol-3-methyl-2-amino-pentanoate hydrochloride can take an obvious inhibitory effect on H22 transplanted tumor mice, so that immune organs of a body can be protected and immunologic functions of the body can be enhanced (Formula).

Owner:JILIN AGRICULTURAL UNIV

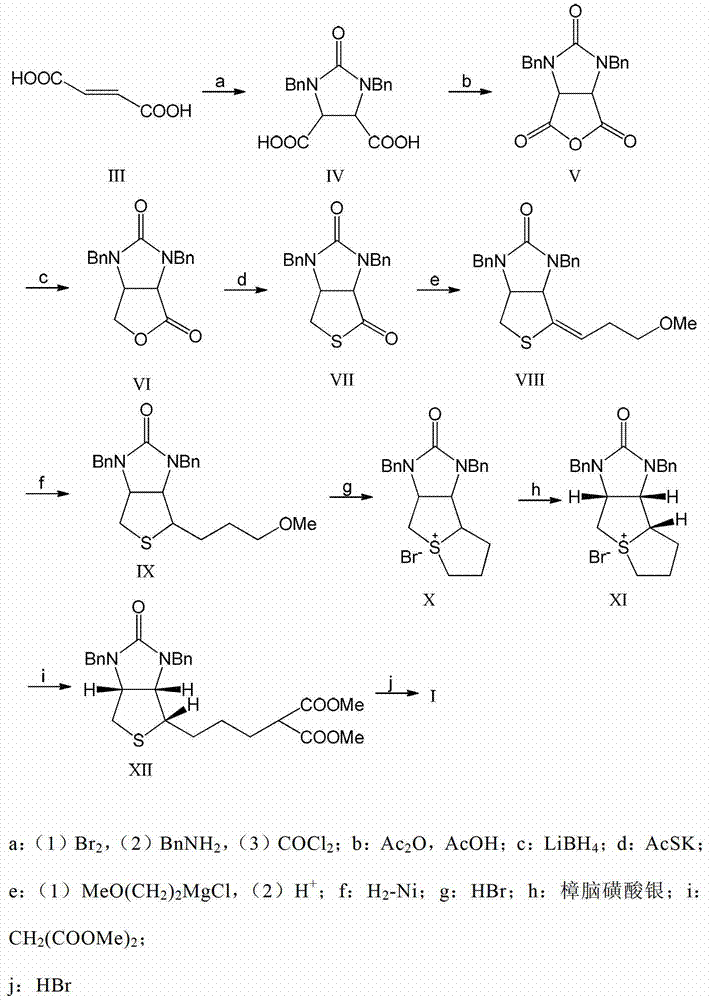

Method for preparing (3S,6aR)-1,3-dibenzyl-tetrahydro-1H-thieno [3,4-d] imidazole-2(3H)-ketone-4-normal pentanoic acid

A process for preparing (3aS, 6aR)-1,3-bibenzyl- tetrahydro-1H-thieno [3,4-d] imidazole-2(3H)-one-4- n-pentanoic acid includes such steps as Grignand reaction of (3aS, 6aR)-1,3-bibenzyl-tetrahydro-4H- thieno [3,4-d] imidazole-2,4(1H)-dione on 1,4-dimagnesium halobutane in organic solution, introducing Co2, carboxylation reaction to obtain (3aS, 6aR)-1,3-bibenzyl-4-n-pentanoic acid, and high steroselective catalytic hydrogenating in organic solvent to obtain (3aS, 4S, 6aR)-1,3-bibenzyl- tetrahydro-1H-thieno[3,4-d] imidazole-2(3H)-one-4-n- pentanoic acid. Its output is higher than 90% and its ee is higher than 97.5%.

Owner:FUDAN UNIV

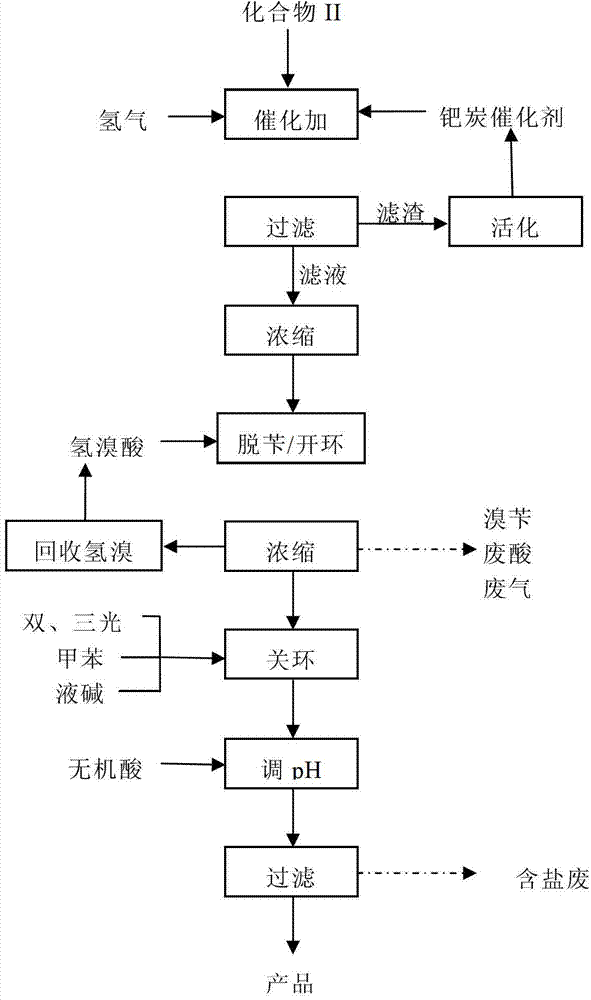

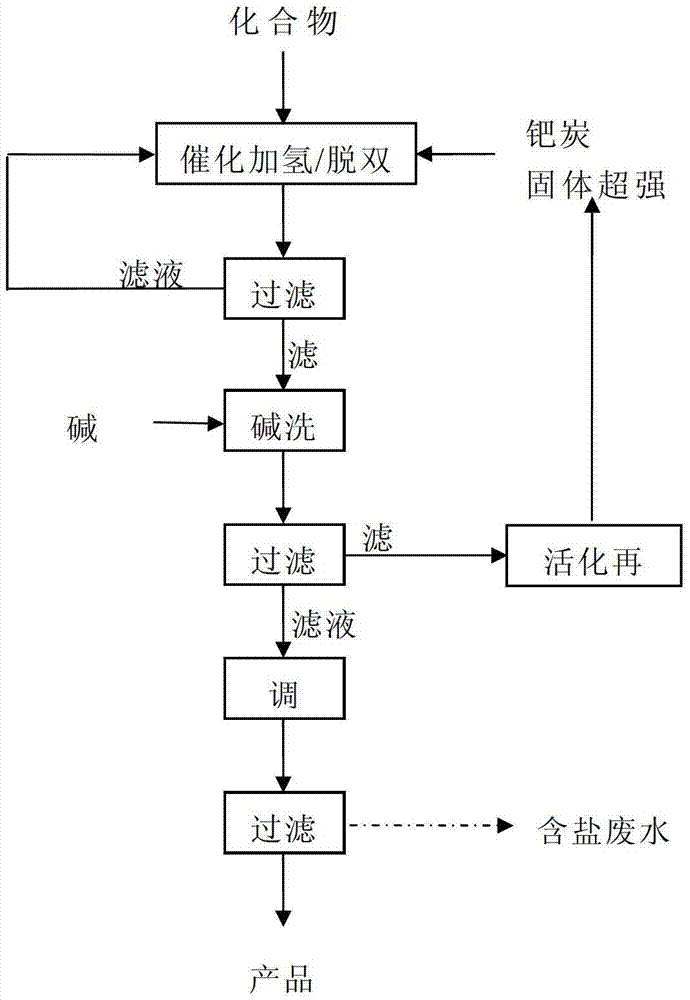

Method for synthesizing d-biotin by catalytic double debenzylation

ActiveCN102786531AHigh purityImprove industrial production efficiencyOrganic chemistry4-pentenoic acidHydrogen

Disclosed is a method for synthesizing d-biotin by catalytic double debenzylation. The method is simple in process, high in yield and low in cost. The method includes: dissolving (3aS, 6aR)-hexahydro-2-oxo-1, 3-dibenzyl-1Hthieno [3, 4-d] imidazole-4-pentenoic acid into low molecular alcohol, adding mixed catalyst of Palladium-carbon and solid superacid, and feeding hydrogen for stirring reaction for 2-12 hours at 80-200 DEG C and 2.5-12.5 MPa; filtering after reaction, and washing residue with 1-20% (weight ratio) aqueous alkali; filtering, adjusting pH of filtrate to acidity, and standing for crystallization; and filtering to obtain the crystallized d-biotin. The method is applicable to production of the d-biotin.

Owner:FUYANG KEXING BIOCHEM

Application of isoalantolactone derivative and salt thereof in preparation of medicines for treating lung fibration

ActiveCN106496243AGood treatment effectOrganic active ingredientsOrganic chemistryBenzoic acidPhosphomolybdic acid

The invention relates to an application of an isoalantolactone derivative and a salt thereof in the preparation of medicines for treating lung fibration, and provides an isoalantolactone derivative represented by formula (I). An acid for forming the salt is an inorganic acid or an organic acid, the inorganic acid is selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulfurous acid, and the organic acid is selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-lactic acid, oxalic acid, methanesulfonic acid, pentanoic acid, oleic acid, lauric acid, p-methyl benzenesulfonic acid, 1-naphthalenesulfonic acid, 2-naphthalenesulfonic acid, phthalic acid, tartaric acid, propane diacid, succinic acid, fumaric acid, glycollic acid, thioglycollic acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid and substituted benzoic acid.

Owner:NANKAI UNIV

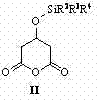

Preparation method of (3R,5R)-3,5-dihydroxy-6-methyl cyan-caproate

InactiveCN102827030AHigh yieldHigh stereoselectivityCarboxylic acid nitrile preparationOrganic compound preparationCyanide compoundPtru catalyst

The invention relates to a preparation method of (3R, 5R)-3,5-dihydroxy-6-methyl cyan-caproate (I) and belongs to the technical field of pharmaceutical chemistry. The preparation method concretely comprises the following steps of: firstly, carrying out asymmetric catalysis alcoholysis on 3-siloxy cyclopentane anhydride (II) to prepare (R)-3-siloxy-5-alkoxy-5-oxo-pentanoate (III); secondly, condensing the (R)-3-siloxy-5-alkoxy-5-oxo-pentanoate (III) and methyl cyanoacetate to prepare (R)-2-cyano-3-oxo-5-siloxy diethyl pimelate (IV); thirdly, carrying out decarboxylation on the (R)-2-cyano-3-oxo-5-siloxy diethyl pimelate (IV) to prepare (R)-3-hydroxy-5-oxo-6-benzyl cyanohexanoate (V) by using desilicication protective groups; and fourthly, carrying out asymmetric reduction on the (R)-3-hydroxy-5-oxo-6-benzyl cyanohexanoate to prepare a product of (3R,5R)-3,5-dihydroxy-6-methyl cyan-caproate (I). The preparation method is mild in reaction conditions, simple and convenient to operate, high in stereoselectivity, environment-friendly, and suitable for industrial production; and products have high yield, the used chiral catalyst is small in dosage and can be recovered with fix quantify, raw materials which are easily obtained are low in cost, and particularly hypertoxic cyanides are avoided.

Owner:FUDAN UNIV

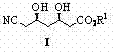

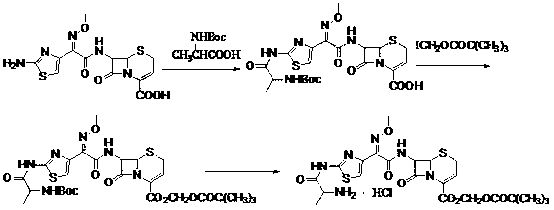

Method for preparing ceftizoxime alapivoxil hydrochloride

ActiveCN103059047AFew reaction stepsLow costOrganic chemistryBulk chemical productionBiotechnologyTert-Butyloxycarbonyl protecting group

The invention discloses a new method for preparing ceftizoxime alapivoxil hydrochloride and belongs to the technical field of medicine synthesis. The method comprises the following steps: step (1), performing Boc protection on 7-amino of raw material 7-amino-3-cephem-4-carboxylic acid (7-ANCA) and then making the raw material have reaction with iodomethyl pivalate, then removing Boc protection group to obtain a midbody 7-amino-3-cephem-4-carboxylic pivaloyl oxymethyl ester (7-ANCA-POM); step (2), making N-t-butyloxycarboryl-L-alanine (Boc-L-Ala) and methoxyiminoacetic acid (ATMA) have condensation reaction to obtain a midbody 2-(2-N-t-butyloxycarboryl-amino-(S)-triacylamino-thiazole-4-yl)-2-(Z)-methoxyimino-acetic acid (Boc-L-Ala-ATMA); step (3), activating the midbody Boc-L-Ala-ATMA and making the midbody Boc-L-Ala-ATMA have condensation reaction with the midbody 7-ANCA-POM, and then removing the Boc protection group to prepare a target compound ceftizoxime alapivoxil hydrochloride (CZX-AP-HC1,I). The method adopts a collection type synthesis route, is simple and convenient to operate and mild in technical conditions, has high product quality and low cost, and avoids the problem about benzothiazole residue caused by the use of AE active ester in the present technique, so the collection type synthesis route is a good synthesis route suitable for industrial production.

Owner:江苏慈星药业有限公司

Hair and skin conditioning compositions

Compositions for providing hair and skin care benefits, such as smoothing, anti-static control, color protection, frizz control and moisturization are disclosed. The compositions maintain clarity, show no separation upon standing, and remain flowable liquids at room temperature. The compositions comprise a silicone or hydrocarbon component having a viscosity of from about 2,500 to about 600,000 cSt at 25° C. (such as dimethicone gum or hydrogenated polydecene), together with a carrier fluid having a viscosity less than about 100 cSt at 25° C. and a flash point greater than about 85° C. (such as caprylyl methicone, isodecyl neopentanoate, or hydrogenated polyisobutene (250)). Hair care compositions, such as shampoos and conditioners containing those combinations, as well as the method of conditioning hair utilizing those compositions is also disclosed. The compositions can be applied directly to the hair (i.e., “neat”) or via a conventional hair treatment composition, such as a shampoo or a conditioner. Skin care compositions and methods are also disclosed.

Owner:KAO CORP

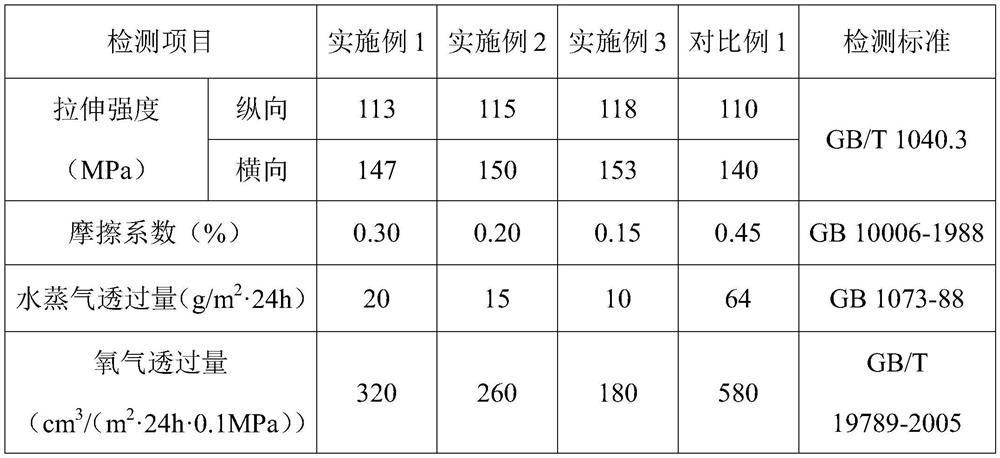

High-barrier all-biodegradable BOPLA film and preparation method thereof

InactiveCN111703166AHigh barrierGood physical and mechanical propertiesSynthetic resin layered productsFlat articlesHydroxybutyric acidPolymer science

The invention discloses a high-barrier all-biodegradable BOPLA film and a preparation method thereof, and relates to the technical field of BOPLA films. The film comprises an upper surface layer, a core layer and a lower surface layer, wherein the upper surface layer is an organic polymer anti-sticking layer and is formed by blending the following components in percentage by weight: 92-95% of polylactic acid slices and 5.0-8.0% of organic polymer anti-sticking master batch; the core layer is a quaternary compound polylactic acid layer and is prepared by blending the following components in percentage by weight: 45 to 80 percent of polylactic acid slices, 3 to 30 percent of polycaprolactone, 3 to 30 percent of polypropylene carbonate and 3 to 30 percent of poly 3-hydroxybutyrate; the lowersurface layer is a barrier layer and is prepared by blending the following components in percentage by weight: 65-75% of polylactic acid slices and 25-35% of polyhydroxybutyrate-hydroxyvaleric acid copolyester. The BOPLA film prepared by the method is excellent in physical and mechanical performance indexes, has high barrier property, can be quickly and completely biodegraded in a specific environment, effectively eliminates white pollution and marine plastic pollution, and is green and environment-friendly.

Owner:ANHUI GUOFENG PLASTIC

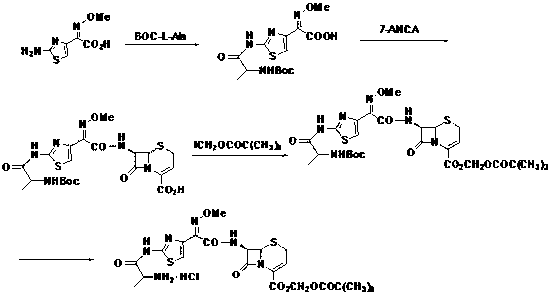

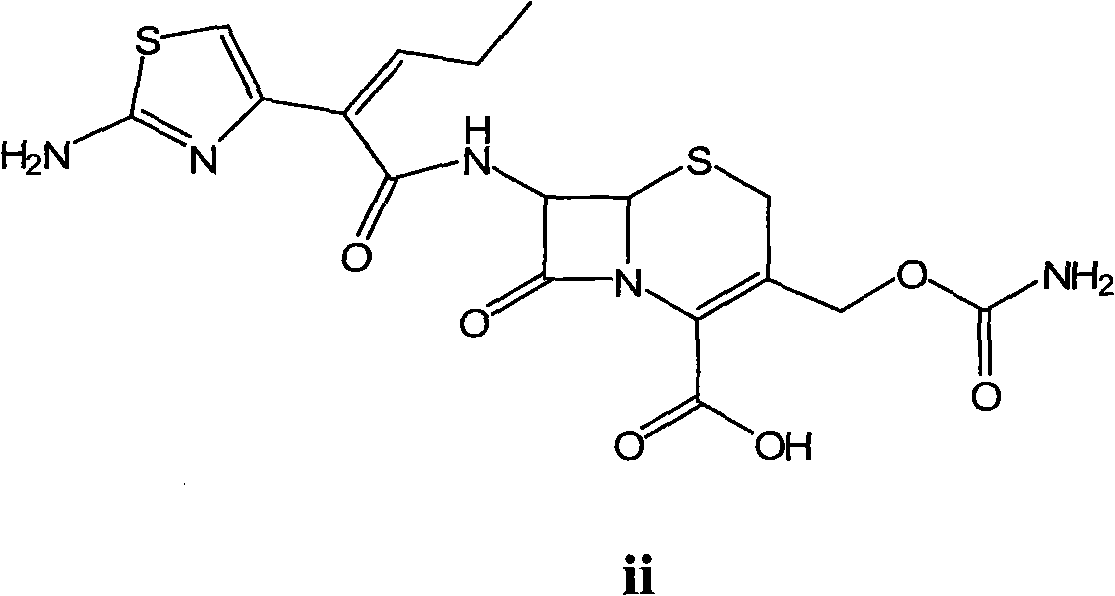

Cefcapene pivoxil hydrochloride and method for preparing its intermediate

ActiveCN102485727ARaw materials are cheap and easy to getFew synthetic stepsOrganic chemistryBulk chemical productionSide chainTert-Butyloxycarbonyl protecting group

The invention relates to a cefcapene pivoxil hydrochloride and a method for preparing an intermediate of cefcapene pivoxil hydrochloride, the method is characterized in that 7-DACA (iii) is taken as a raw material, and is performed condensation reaction with cefcapene pivoxil hydrochloride side chain acid (iv) and a carbamylated reagent to obtain tertbutyloxycarbonyl cefcapene acid sodium salt (vi), an amino protective group is removed to obtain the cephalospene acid (ii), then performed esterification reaction with iodomethyl pivalate, salifying with hydrochloric acid to obtain the cefcapene pivoxil hydrochloride hydrate (i) (a flow chart is shown as follows). The preparation method has the advantages of cheap raw material, easy raw material acquisition, less reaction step, high yield and high purity of intermediate and product, and is suitable for industrial production.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

Green process and compositions for producing poly(5HV) and 5 carbon chemicals

Recombinant hosts for producing polyhydroxyalkanoates and methods of producing polyhydroxyalkanoates from renewable carbon substrates are provided. Certain recombinant hosts that produce 5 carbon chemicals such as 5-amino?entanoate (5AP), 5 -hydroxy valerate (5HV), glutarate, and 1,5 pentanediol (PDO) are also provided. One embodiment provides a recombinant host expressing a gene encoding a heterologous enzyme selected from the group consisting of a polyhydroxyalkanoate synthase and a 5-hydroxyvalerate-CoA (5HV-CoA) transferase, wherein the host produces a polymer containing 5-hydroxyvalerate. Preferably, the host expresses both a polyhydroxyalkanoate synthase and a 5HV-CoA transferase. The host can be prokaryotic or eukaryotic. A preferred prokaryotic host is E. coli. The polymers produced by the recombinant hosts can be homopolymers or copolymers of 5-hydroxyvalerate.; A preferred copolymer is poly(3-hydroxybutyrate-co-5-hydroxyvalerate).

Owner:CJ CHEILJEDANG CORP

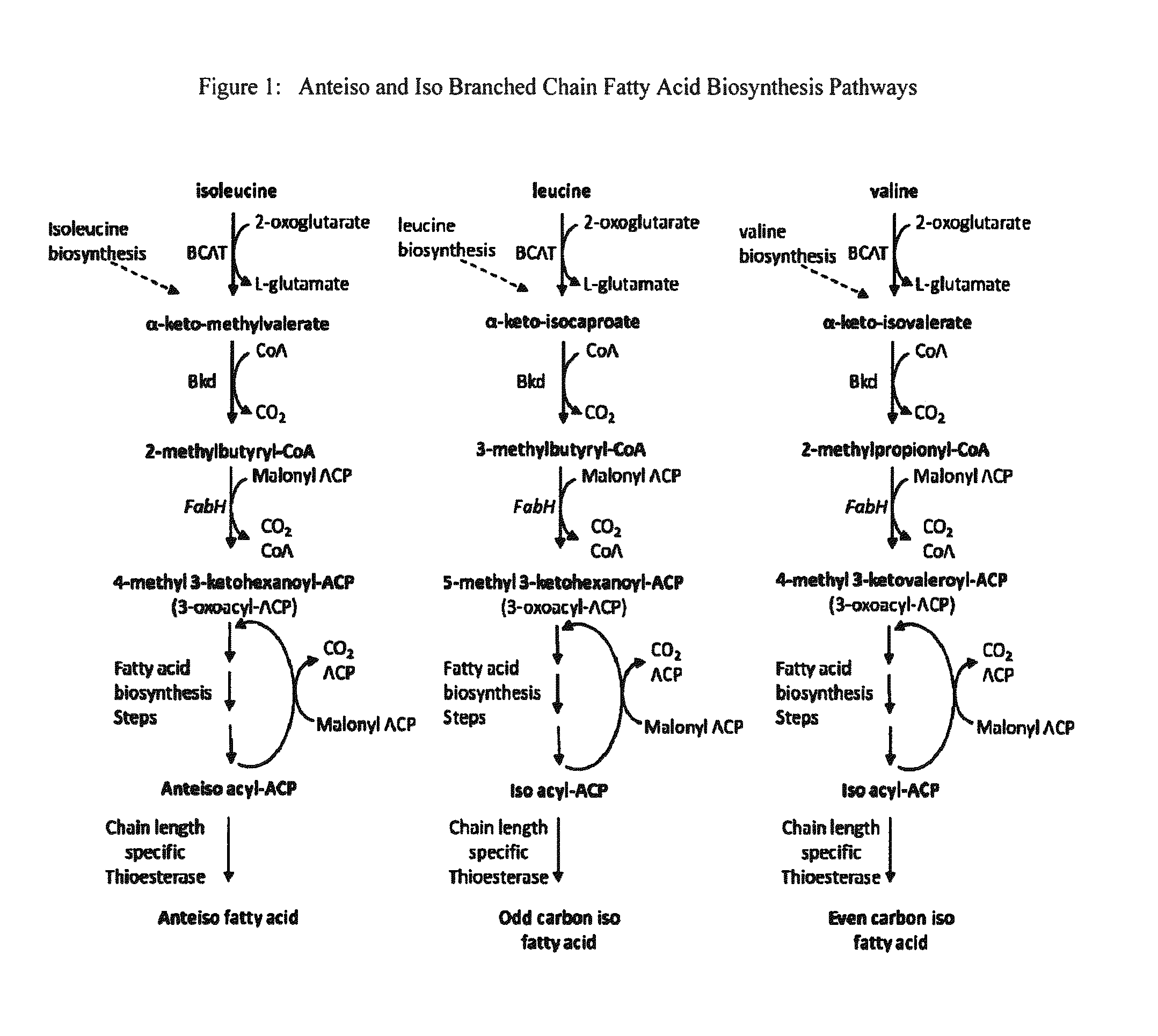

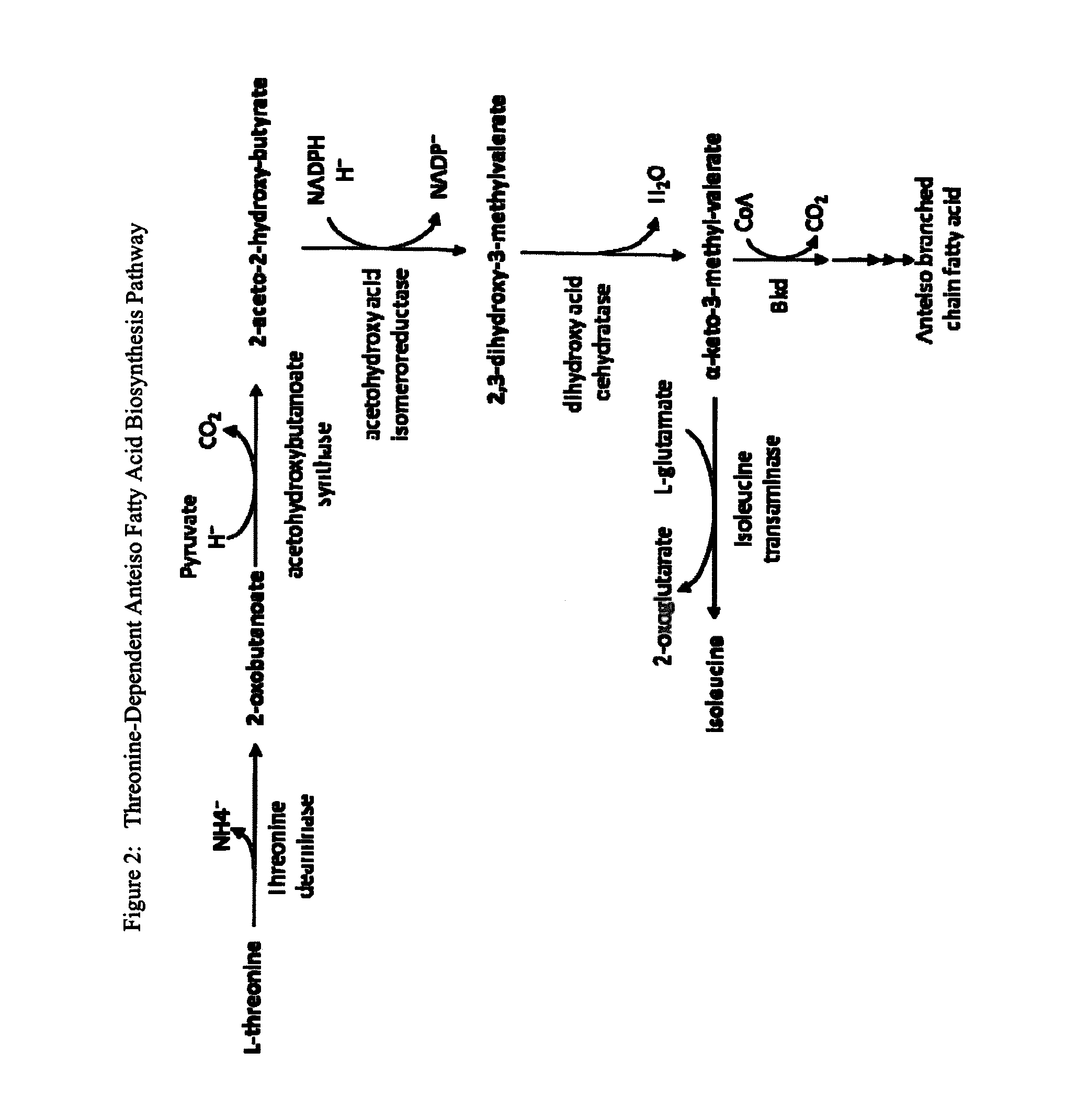

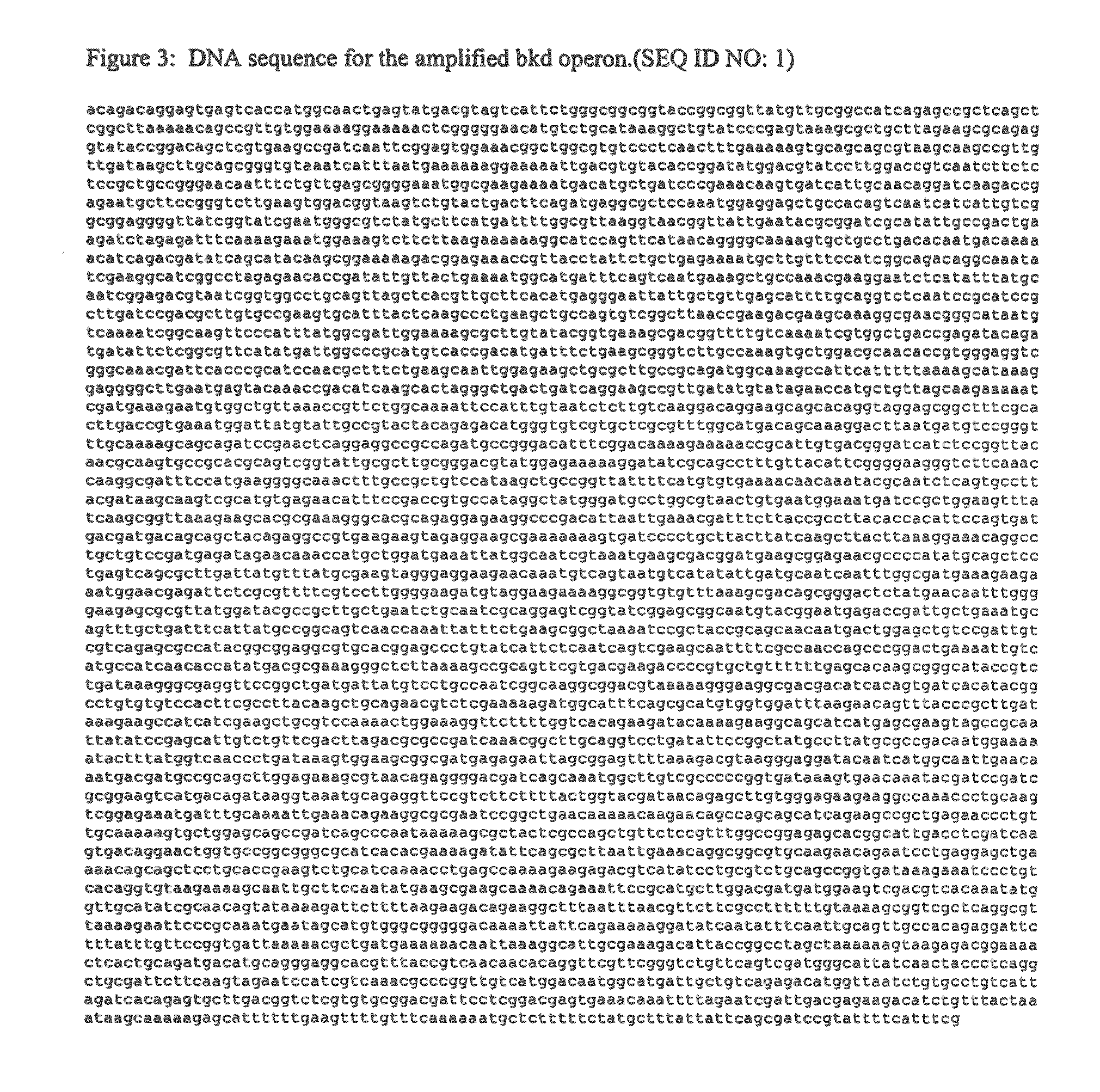

Branched-Chain Fatty Acids And Biological Production Thereof

InactiveUS20110151526A1Increasing anteiso fatty acidIncreasing iso and anteiso fatty acid productionCarbon-nitrogen lyasesBacteriaHydroxycitric acidNucleic acid sequence

A method for producing anteiso fatty acid is provided. The method comprises culturing a cell comprising at least one exogenous or overexpressed polynucleotide comprising a nucleic acid sequence encoding a polypeptide that catalyzes at least one of the following reactions: conversion of pyruvate to citramalate; conversion of citramalate to citraconate; conversion of citraconate to β-methyl-D-malate; conversion of β-methyl-D-malate to 2-oxobutanoate; or conversion of threonine to 2-oxobutanoate, under conditions allowing expression of the polynucleotide(s) and production of anteiso fatty acid. Optionally the cell further comprises at least one exogenous or overexpressed polynucleotide comprising a nucleic acid sequence encoding a polypeptide that catalyzes conversion of 2-oxobutanoate to 2-aceto-2-hydroxy-butyrate, conversion of 2-aceto-2-hydroxy-butyrate to 2,3-dihydroxy-3-methylvalerate, and / or conversion of 2,3-dihydroxy-3-methylvalerate to α-keto-3-methylvalerate. A cell that produces anteiso fatty acid and a method of using the cell to produce anteiso fatty acid also are provided.

Owner:THE PROCTER & GAMBLE COMPANY

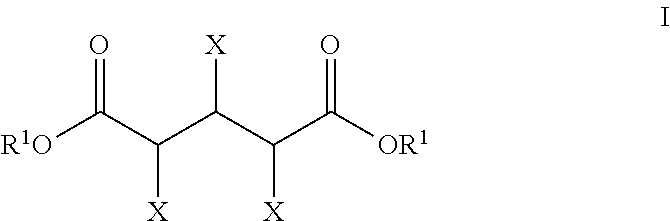

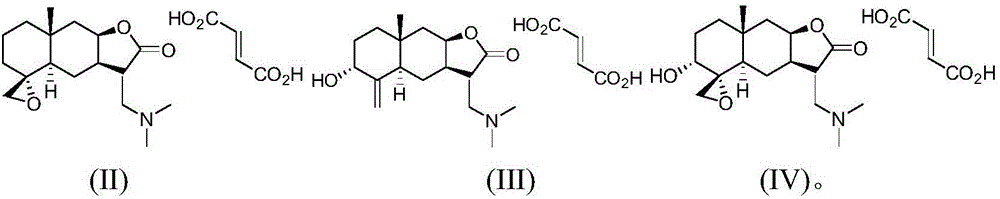

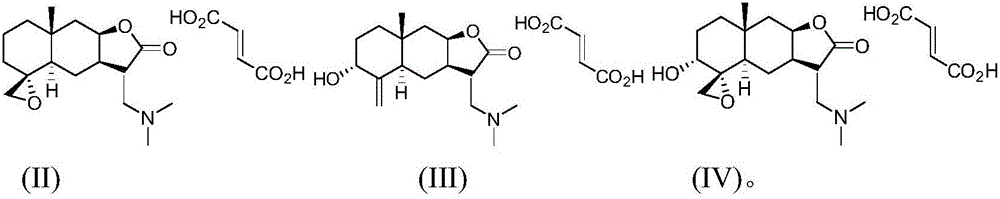

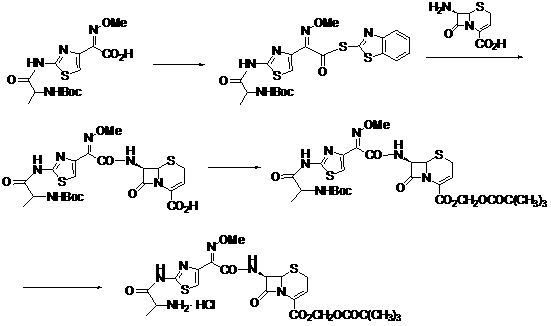

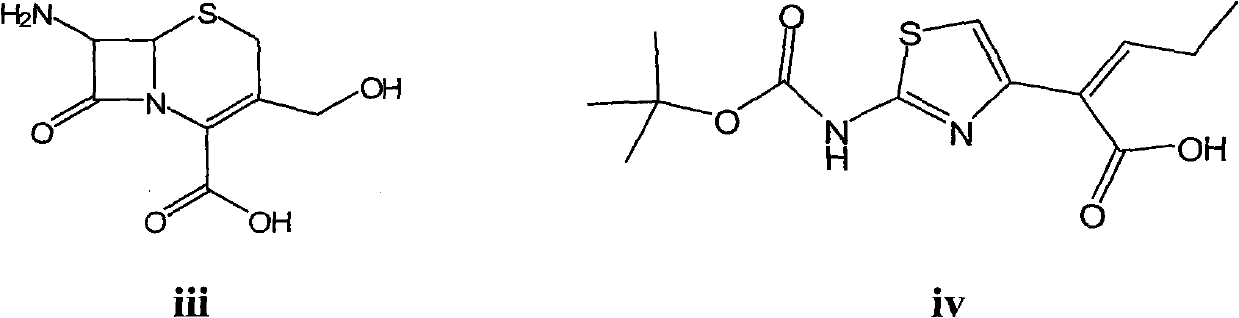

PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE

InactiveUS20130184493A1Minimize formationOrganic compound preparationCarboxylic acid amide separation/purificationDiketoneKetone

A process for preparation of 4-fluoro-α-[2-methyl-1-oxopropyl]-γ-oxo-N-β-diphenylbenzene butane amide also known as a diketone intermediate of atorvastatin, completely devoid of impurities 3,4-difluoro-α-[2-methyl-1-oxopropyl]-γ-oxo-n-β-diphenylbenzene butane amide; methyl, 2{-2[-(4-fluorophenyl)-2-oxo-1-phenylethyl)]}-4-methyl-3-oxo pentanoate; 1,4-bis(4-fluorophenyl)-2,3-diphenylbutane-1,4-dione, 1-(4-fluorophenyl)-2-phenyl ethanone; 1-(4-fluorophenyl)-2-phenyl ethanone and containing about 0.05% or less of 2-methyl-1-oxopropyl]-γ-oxo-N-β-diphenylbenzene butane amide. In that process the said diketone intermediate of formula 1 is obtained by maintaining temperature −25° C. to 50° C. during Friedel-Crafts acylation, in situ halogenation of formula II in presence of a solvent and nucleophilic substitution from a compound of formula III with formula IV in presence of a base.

Owner:VIJAYASRI ORGANICS

Preparation method of high-molecular surface active agent

InactiveCN101864049AImprove abilitiesImprove stabilityTransportation and packagingMixingThio-Active agent

The invention relates to a preparation method of high-molecular surface active agent, which is characterized in that: 2 - {[(dodecyl thio) formyl thio] thio} succinic acid alkyl, acrylic acid, absolute ethyl alcohol are reacted with 4, 4'-azo-bis (4 - cyano acid) under the protection of argon gas at the temperature of 55 to 95 DEG C to obtain polyacrylic acid; absolute ethyl alcohol, 4, 4'-azo-bis (4 - cyano acid) and butyl acrylate are added in the polyacrylic acid, the temperature is increased to 55 to 95 DEG C to be reacted for 2 to 8 hours and to be decompressed and distilled after introducing argon gas, and wheat product, i.e. high-molecular surface active agent is obtained after being dried. The prepared molecular surface active agent not only can be used for emulsifying acrylate monomer, but also can be used as emulsifier for polymerizing emulsion. Amphipathy embedded copolymer is riveted on emulsion particles in the emulsion polymerization, and hydrophilic chain section extends into water phase, so the emulsion particles are stable through the space steric effect and the static effect so as to improve the electrolytic-resistant capacity and the frozen stability of the emulsion.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations](https://images-eureka.patsnap.com/patent_img/eb239ae2-f451-4c9e-8101-694067a7ab8d/US08877938-20141104-D00000.png)

![Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations](https://images-eureka.patsnap.com/patent_img/eb239ae2-f451-4c9e-8101-694067a7ab8d/US08877938-20141104-D00001.png)

![Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations Compounds containing S-N-valeryl-N-{[2′-(1H-tetrazole-5-yl)-biphenyl-4-yl]-methyl}-valine and (2R,4S)-5-biphenyl-4-yl-4-(3-carboxy-propionylamino)-2-methyl-pentanoic acid ethyl ester moieties and cations](https://images-eureka.patsnap.com/patent_img/eb239ae2-f451-4c9e-8101-694067a7ab8d/US08877938-20141104-C00001.png)

![PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE](https://images-eureka.patsnap.com/patent_img/37d2ab3d-394d-44ae-9485-bdb31c6d67c8/US20130184493A1-20130718-D00001.png)

![PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE](https://images-eureka.patsnap.com/patent_img/37d2ab3d-394d-44ae-9485-bdb31c6d67c8/US20130184493A1-20130718-D00002.png)

![PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE PROCESS FOR PREPARATION OF 4-FLUORO-alpha-[2METHYL-L-OXOPROPYL]-gamma-OXO-N-beta-DIPHENYLBENZENE BUTANE AMIDE](https://images-eureka.patsnap.com/patent_img/37d2ab3d-394d-44ae-9485-bdb31c6d67c8/US20130184493A1-20130718-D00003.png)