Method for producing volatile fatty acid through promoting anaerobic fermentation of kitchen wastes

A technology for volatile fatty acids and kitchen waste, applied in the field of waste recycling, can solve problems such as undeveloped, and achieve the effects of easy implementation, reduced processing costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

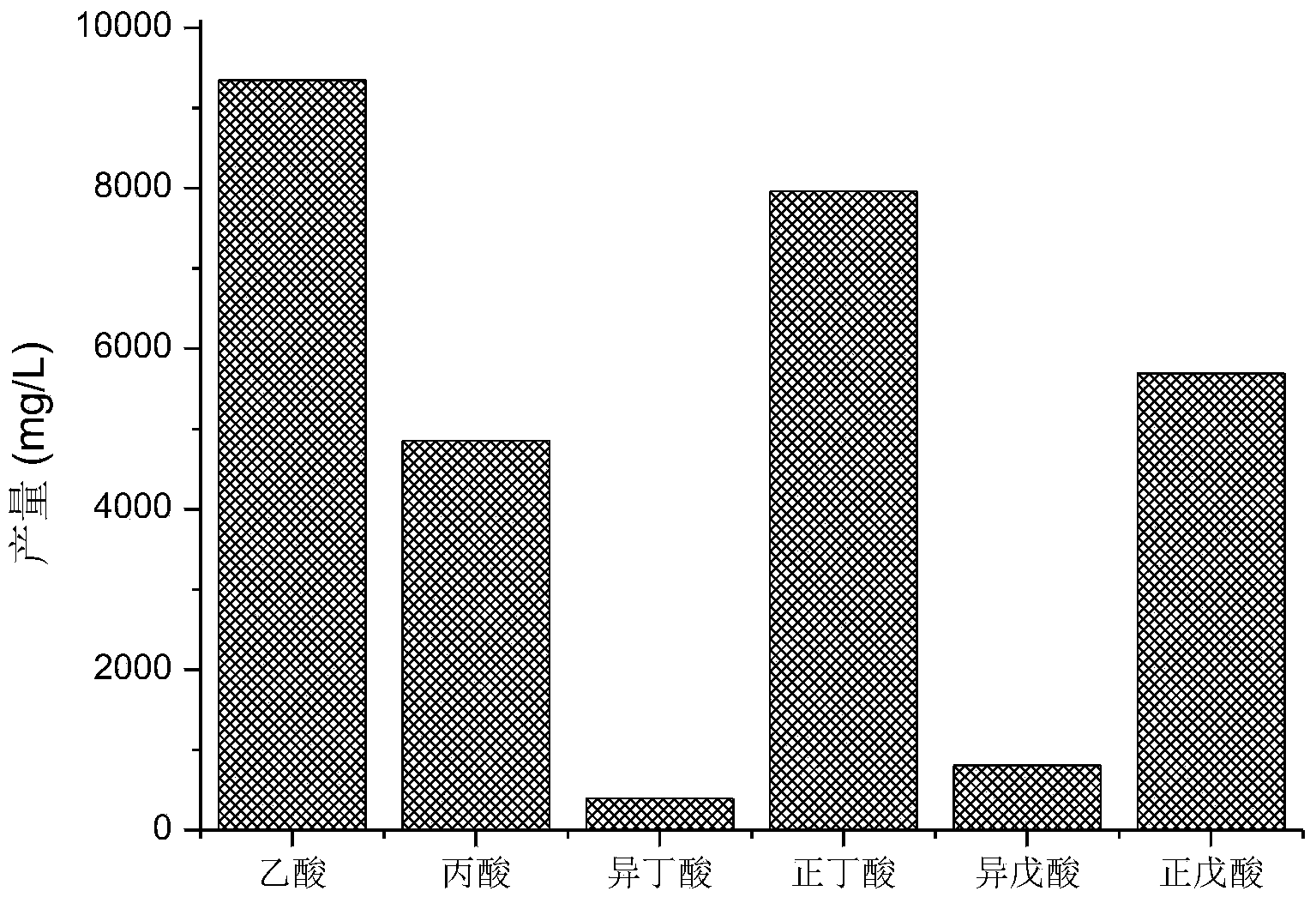

Examples

Embodiment 1

[0017] The first step is to manually sort out the bones, fish bones, plastic bags, chopsticks and other sundries in the fresh kitchen waste produced in the Xiyuan canteen of a university in Shanghai, and then crush them to reduce the particle size of the organic matter to In the range of 1-5mm (in order to make the food waste uniform), the food waste reaction liquid is obtained, and then the food waste reaction liquid is fermented in the anaerobic fermentation reactor. After testing, the pH of the kitchen waste reaction liquid in the anaerobic fermentation reactor is about 4.5, and the VS / TS is 94%.

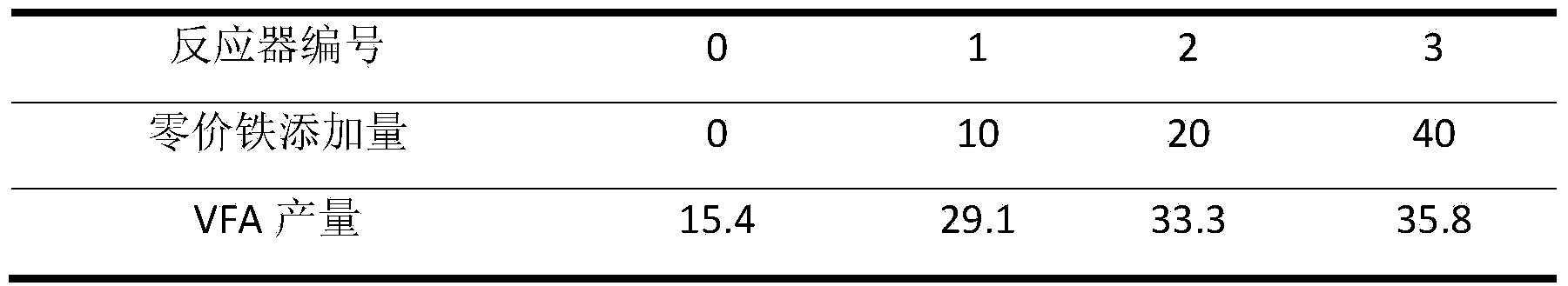

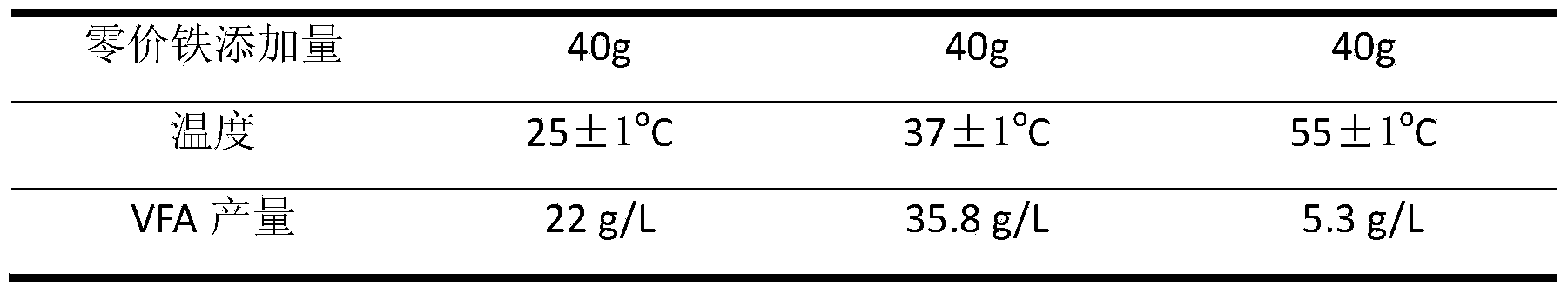

[0018] In the second step, an appropriate amount of water is added to the anaerobic fermentation reactor, and the total solid content in the kitchen waste reaction solution is adjusted to be 100g / L, and zero-valent iron with a particle size of 800 mesh produced by Shanghai Chuanghui Magnetic Materials The amount of valence iron added is the 10-40g / L kitchen waste reaction solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com