Patents

Literature

323results about How to "Improve industrial production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing supported catalyst for preparing cyclopentanone with furfural through hydrogenation

ActiveCN103111299AHigh catalytic efficiencyReduce usageMetal/metal-oxides/metal-hydroxide catalystsPreparation from heterocyclic compoundsCatalytic effectAdipic acid

The invention discloses a method for preparing a supported catalyst for preparing cyclopentanone with furfural through hydrogenation. An activated carbon nano tube is adopted as a carrier, and loading metal comprises Ni, Cu, Co and Mg. The method for preparing the catalyst adopts a double dropwise adding and coprecipitation method, thus preparing the catalyst with high capacity and improving the catalytic effect of the catalyst; the preparation condition for the catalyst is easy to realize; and the range of raw materials for preparation is wide, precursors of all components are general and the raw materials for preparation can be selected flexibly according to market price. The catalyst prepared by the method has higher catalytic activity, the furfural conversion efficiency is above 96.6%, and the cyclopentanone selectivity is above 95.4%, so that the catalyst can be used for preparing the cyclpentanone with the furfural as a raw material, the problem that cyclopentanone self polymerization is easy to occur so as to generate a material with high boiling point in the process of generation of cyclopentanone by taking adipic acid as a raw material is solved, and the product yield is improved.

Owner:SOUTHEAST UNIV

Hot stamping method for performance gradient distribution of high-strength steel parts

ActiveCN104668326AEasy to industrializeReduce difficultyQuenching devicesHot stampingUltimate tensile strength

The invention relates to a hot stamping method for performance gradient distribution of high-strength steel parts. The hot stamping method comprises the following steps: locally and quickly cooling homogenized sheets heated to reach austenitization to a certain temperature (cooling to be below Ms point within 1 to 30s) and quenching; feeding the sheets with non-uniform temperature into another furnace for heating at the temperature of 600 to 1,000DEG C for 0.5 to 10min; after heating, obtaining structures in a low-strength area, namely ferrites, tempered martensiteas and austenites of certain amounts, and obtaining microstructures in the high-strength area, which are still complete austenitizing structures; transferring the sheets with different microstructures into a die with cooling water for stamping, and finally obtaining hot stamping forming parts with different mechanical properties.

Owner:东营广大金科机器人有限公司

Method for preparing small expended and vitrified ball with reinforcing layer coated on surface

The invention relates to a method for preparing a small expended and vitrified ball with a reinforcing layer coated on the surface. By combining the advantages of the small expended and vitrified ball and a thermosetting polymer material, the small expended and vitrified ball with the reinforcing layer coated on the surface is prepared by forming an insoluble and infusible high molecular protective film on the surface of the small expended and vitrified ball through the crosslinking and solidification of thermosetting resin. The strength and the heat-preservation and heat-insulating performance of the small expended and vitrified ball with the reinforcing layer coated on the surface are improved, the problems that the small expended and vitrified ball is easy to crack in use and the like are reduced, and meanwhile, the water absorption rate of the small expended and vitrified ball is reduced greatly. The method has the advantages that the preparation process is simple, the small expended and vitrified ball is easy to control and the like. The small expended and vitrified ball with the reinforcing layer coated on the surface can be used as heat-preservation light mortar and a plaster material, a heat-preservation and heat-insulating layer in oil cans, liquefied gas storage tanks and industrial gas storage tanks and a raw material of a light high-grade refractory material.

Owner:WUHAN TEXTILE UNIV

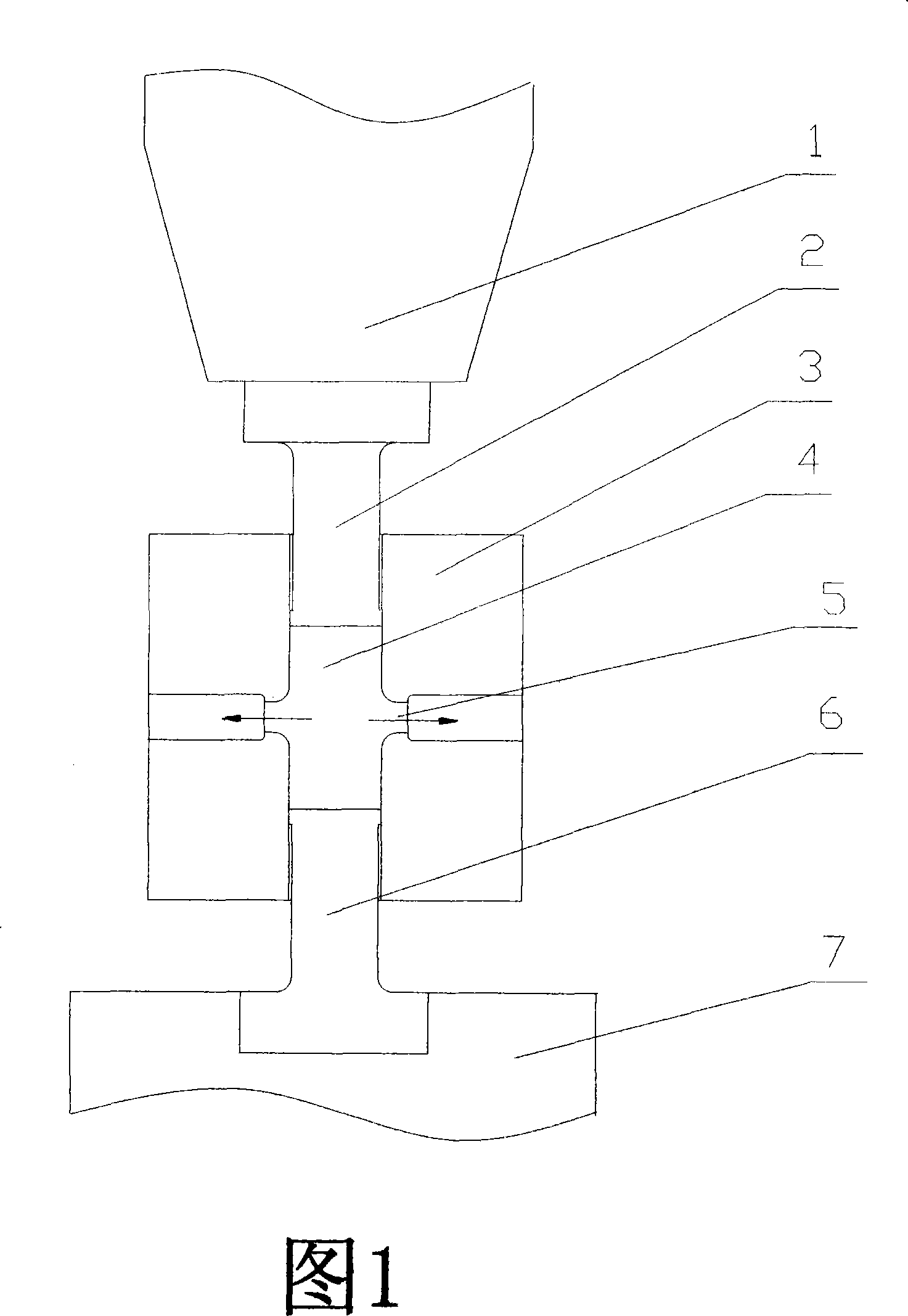

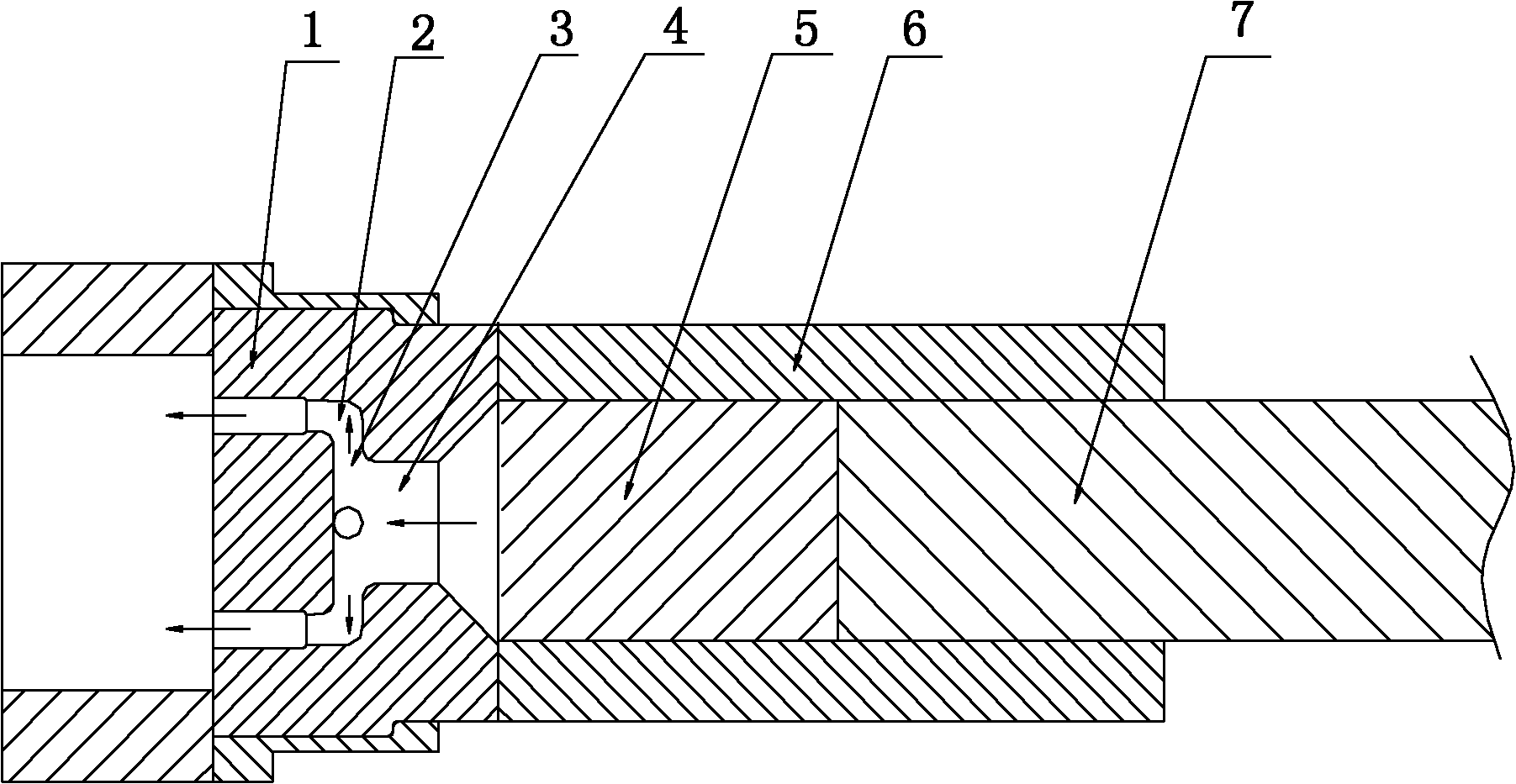

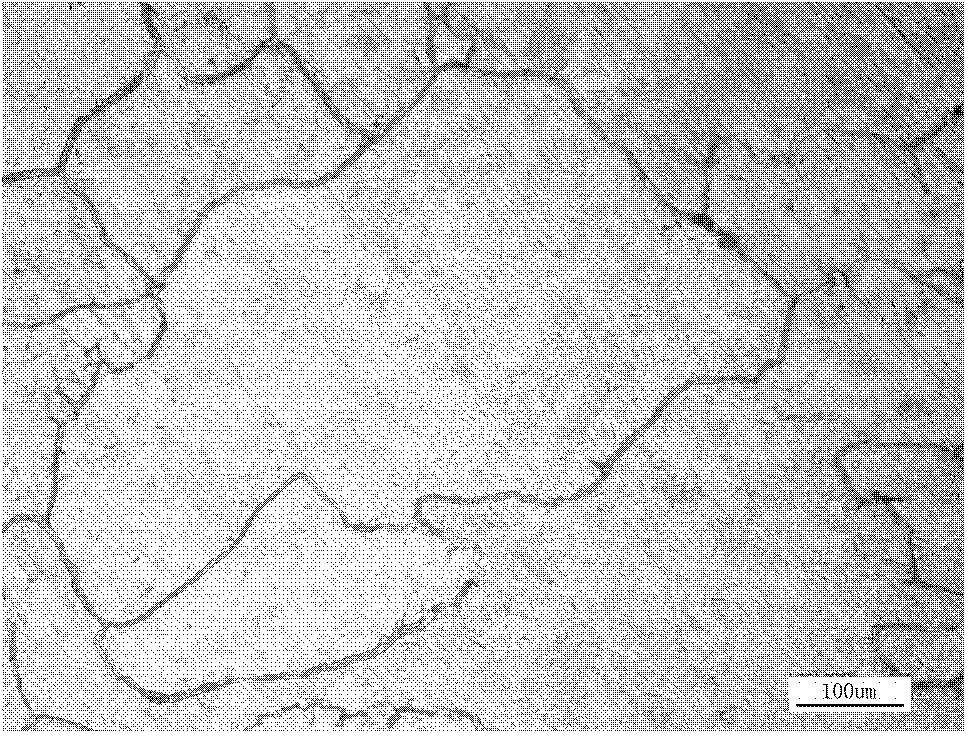

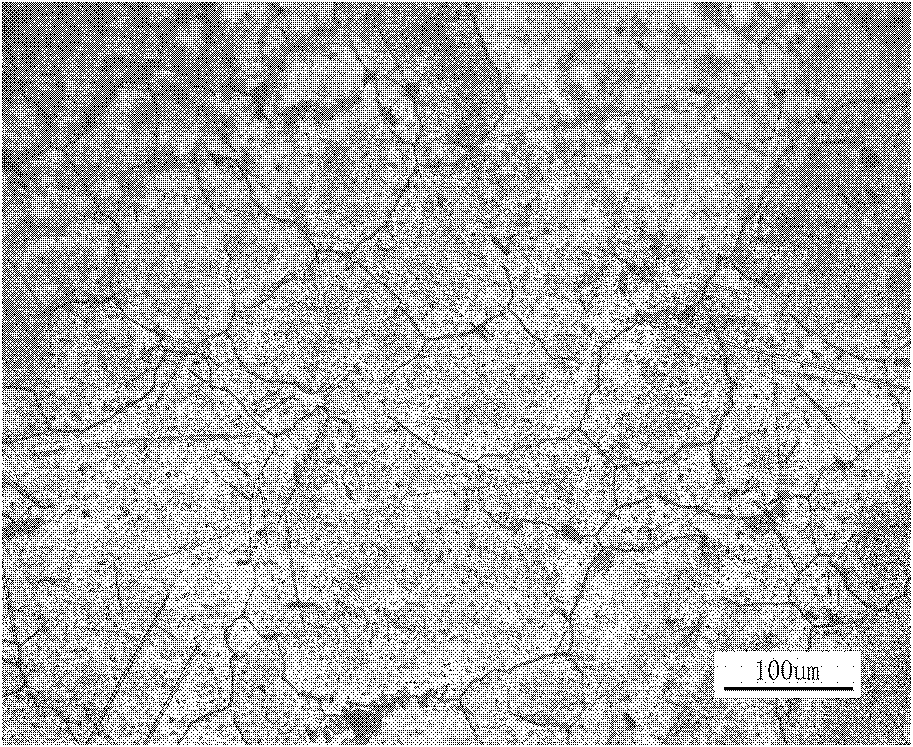

Magnesium alloy extrusion deforming processing method

InactiveCN101099978AHigh tensile strengthHigh yield strengthExtrusion diesExtrusion control devicesLubricantMagnesium alloy

The magnesium alloy extruding deformation process includes the following steps: heating the extruding die for bidirectional extrusion and flowing diameter change and painting lubricant to the extrusion passage, heating magnesium alloy blank through homogenizing treatment and setting into the extrusion passage, and bidirectional extrusion on the magnesium alloy blank from its two ends with two male dies moving in opposite direction in the speed of 1.5-2.5 m / min and force of 2.5-5 MPa to realize flowing extrusion deformation. The magnesium alloy extruding deformation process can fine the crystal grain of magnesium alloy greatly, raise its comprehensive mechanical performance, low extrusion temperature and high production efficiency.

Owner:CHONGQING UNIV

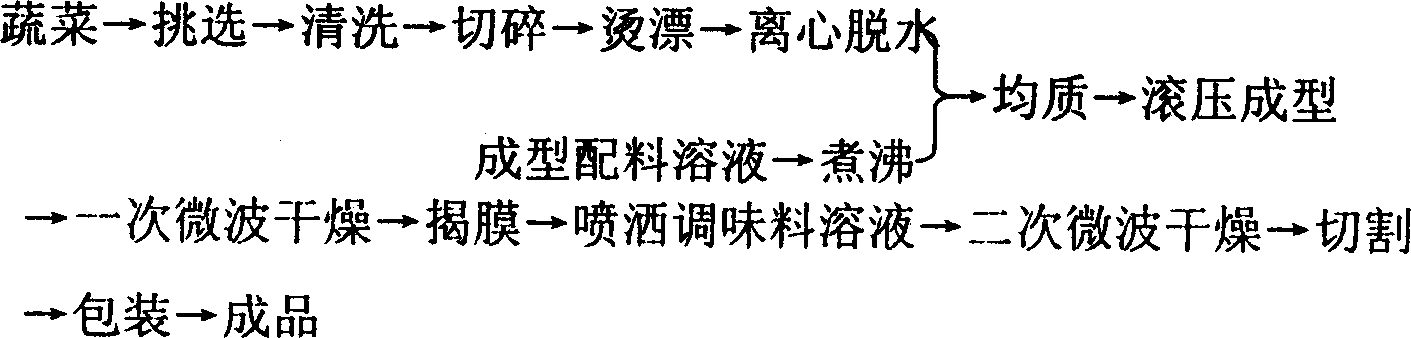

Paper-like vegetables processing method

InactiveCN1792232ARich in colorRich flavorFood preservationFood shapingVegetable processingMicrowave

Owner:JINAN UNIVERSITY

Industrial production method of lycopene microemulsion

ActiveCN106344510AIncrease dosageAvoid lostHydrocarbon active ingredientsAntinoxious agentsVegetable oilOrganic solvent

The invention discloses an industrial production method of a lycopene microemulsion. The method comprises the following steps: uniformly mixing a lycopene crystal, a co-emulsifier, an oil-soluble emulsifier and an antioxidant to obtain a suspension; carrying out nano grinding on the suspension to obtain an oil phase; uniformly mixing water with a water-soluble emulsifier to obtain a water phase; and finally, uniformly mixing the water phase and oil phase, thereby obtaining the lycopene microemulsion. According to the method, the co-emulsifier and oil-soluble emulsifier are added into the raw material lycopene crystal and subjected to nano grinding to obtain the nano oil suspension, and the nano oil suspension is mixed with the water and water-soluble emulsifier to obtain the lycopene microemulsion. The material treatment capacity is increased, and the industrial production efficiency is enhanced only by grinding the oil phase without using vegetable oil or organic solvent to dissolve the lycopene. The method has the advantages of simple technique and high product safety, can prepare the high-content lycopene microemulsion, is suitable for industrialized continuous production, and has obvious economic benefits.

Owner:CHENGUANG BIOTECH GRP CO LTD

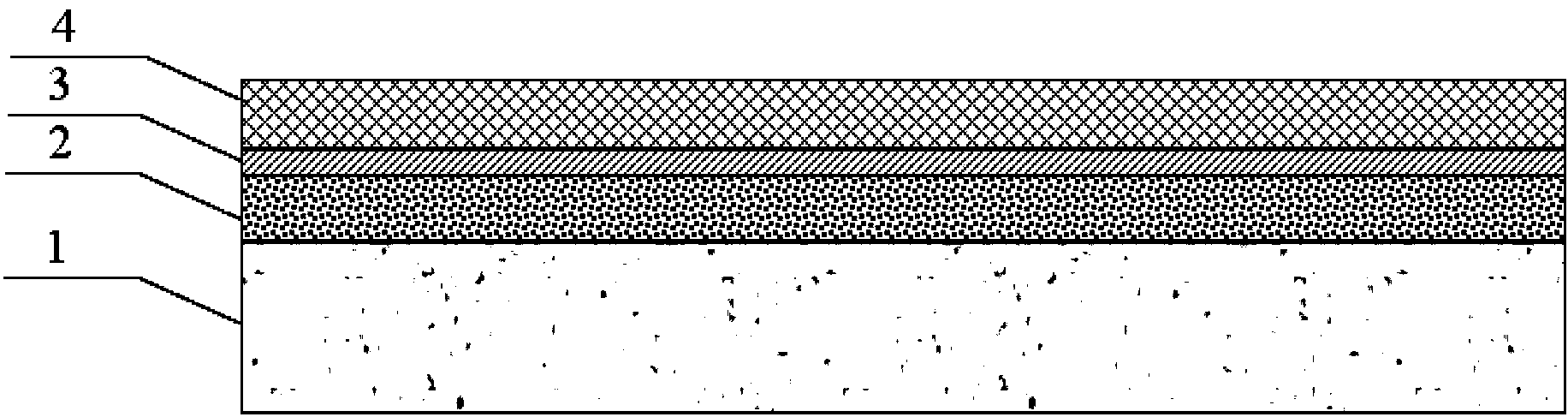

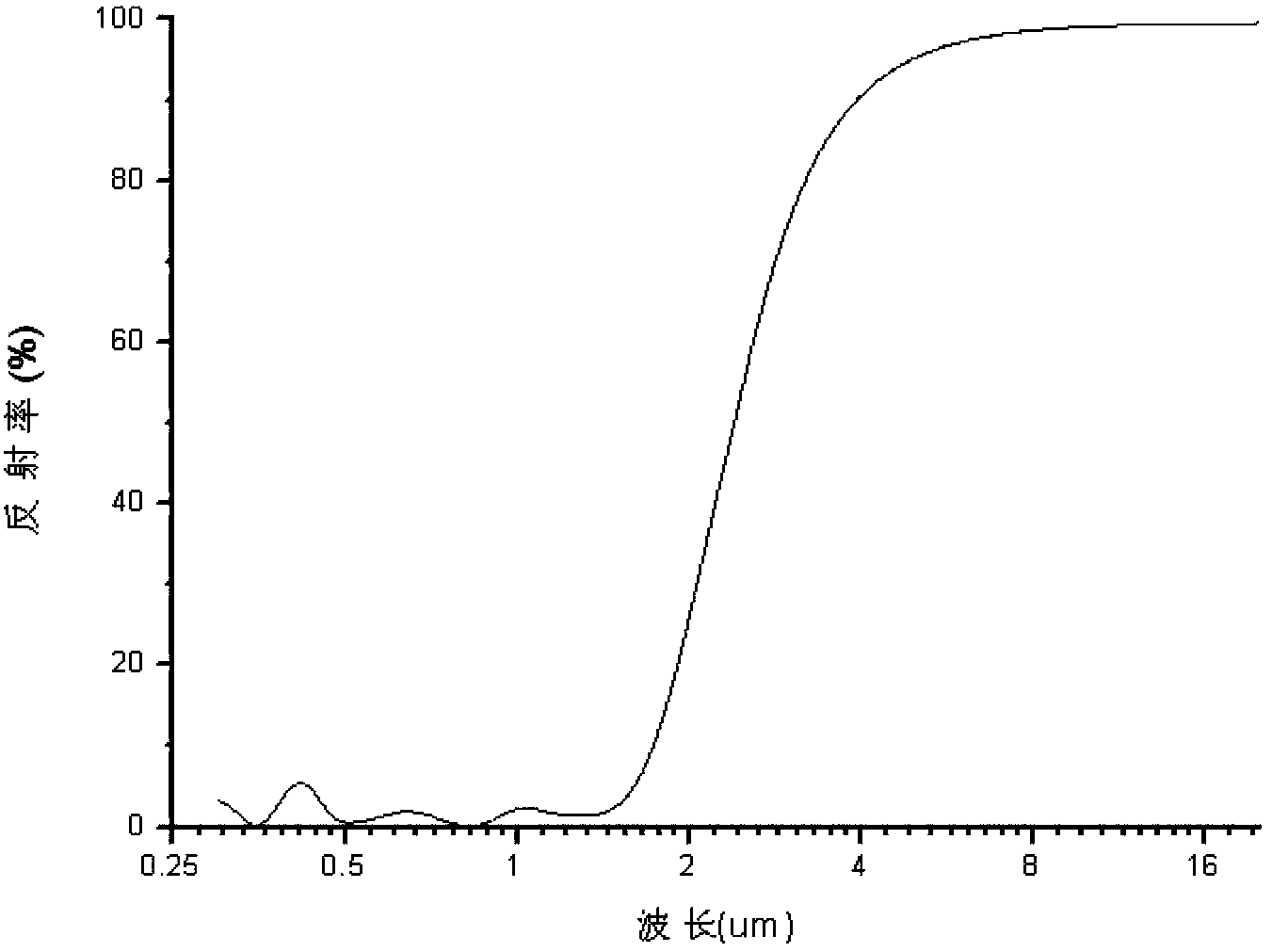

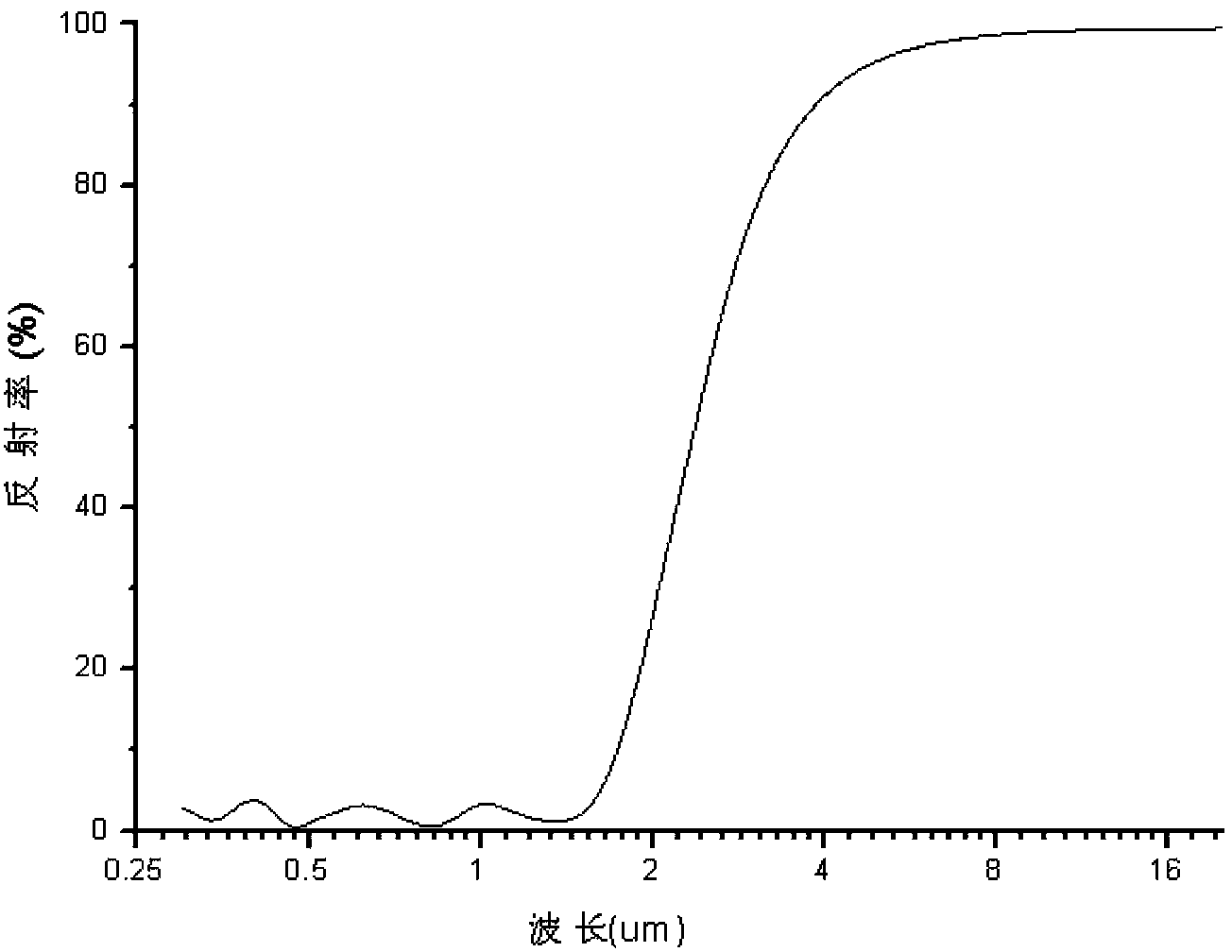

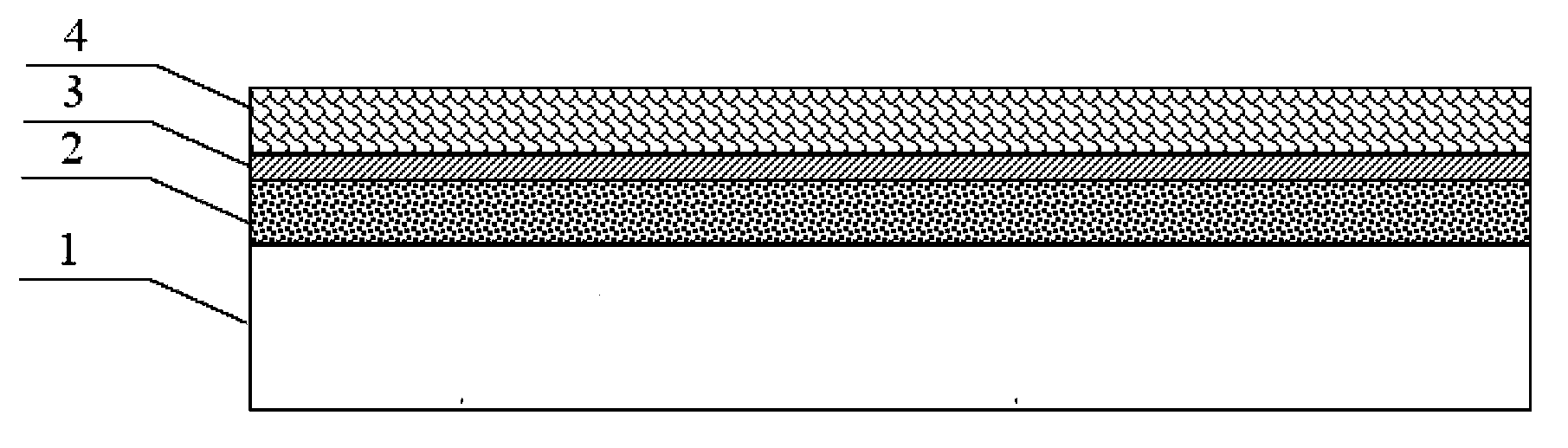

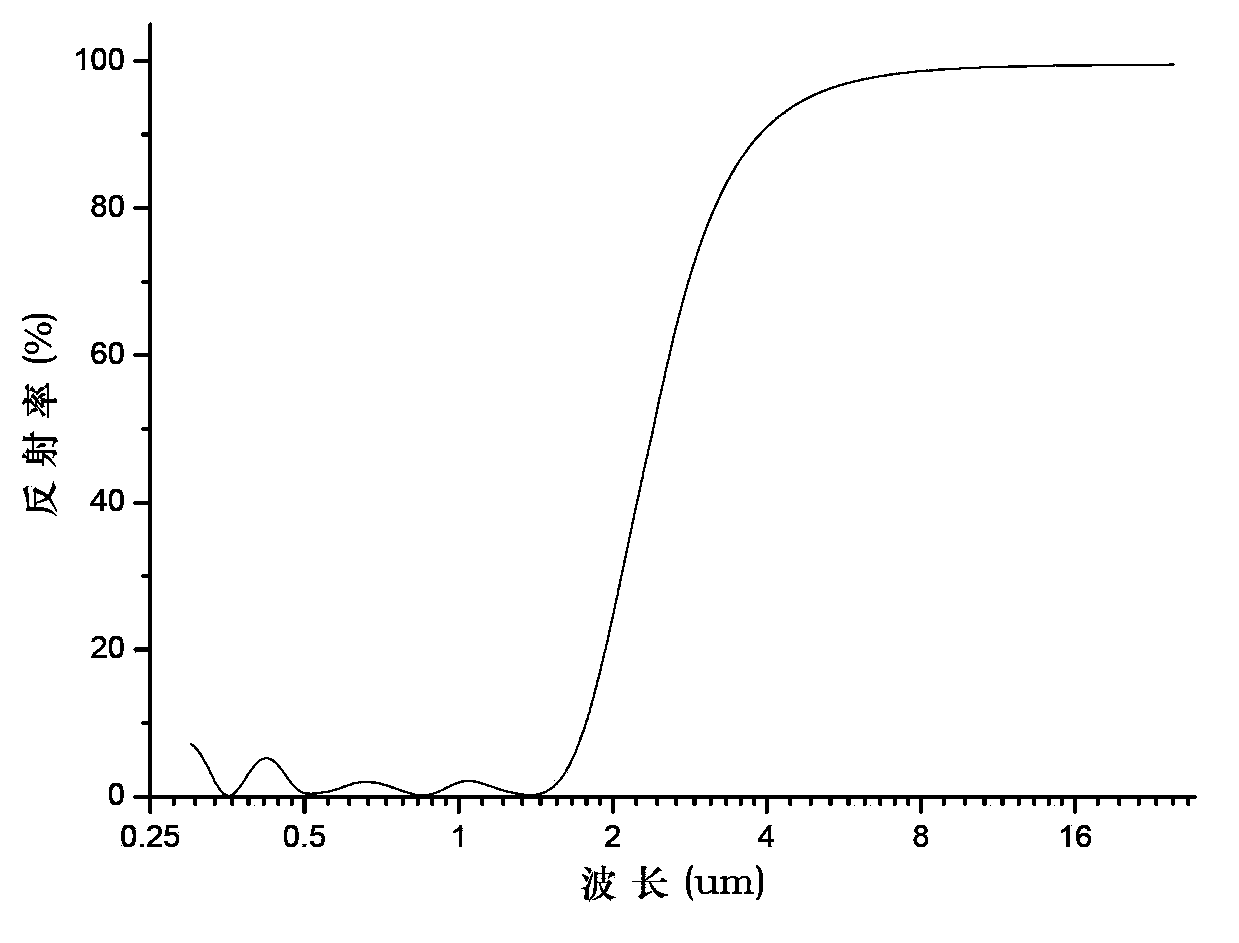

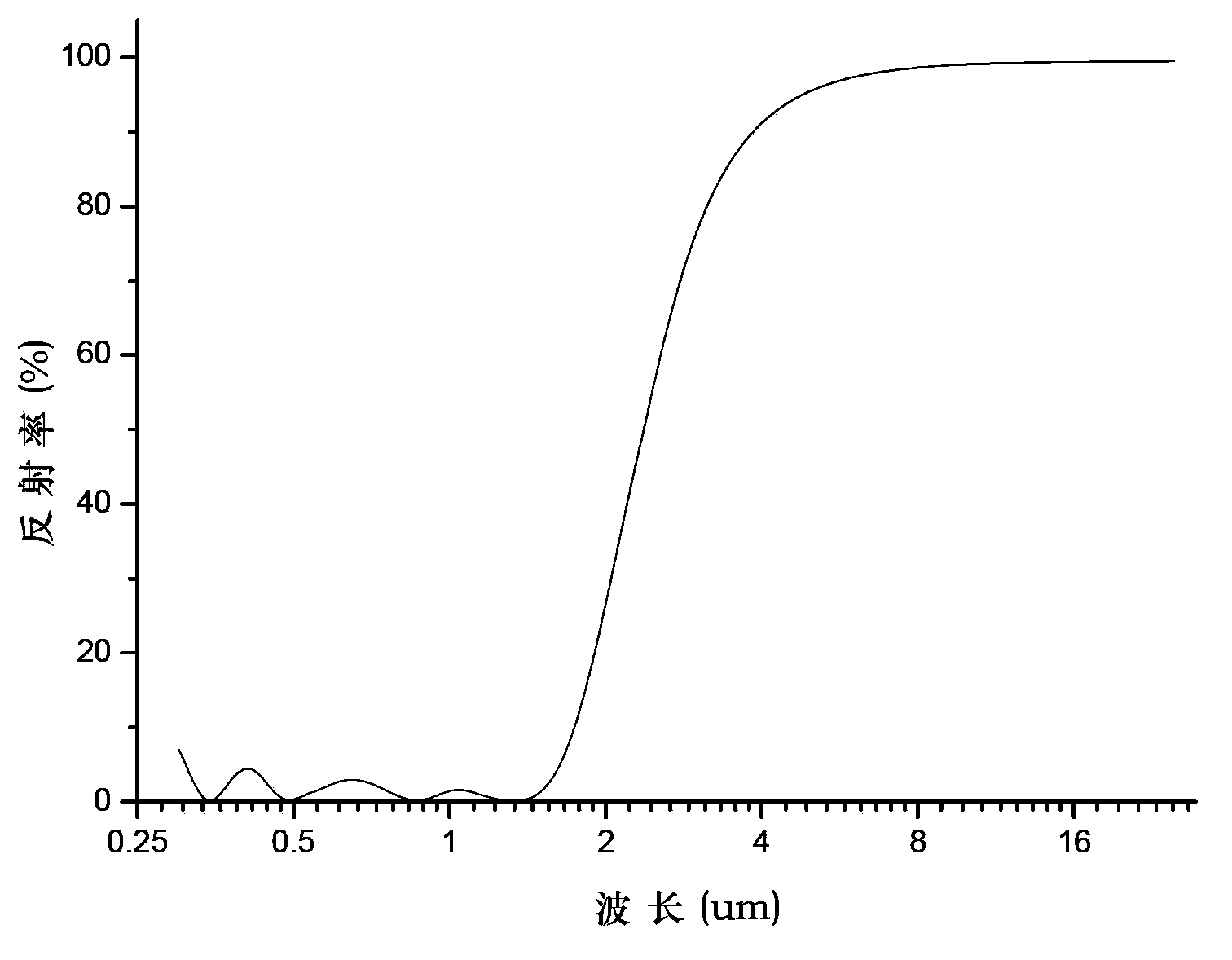

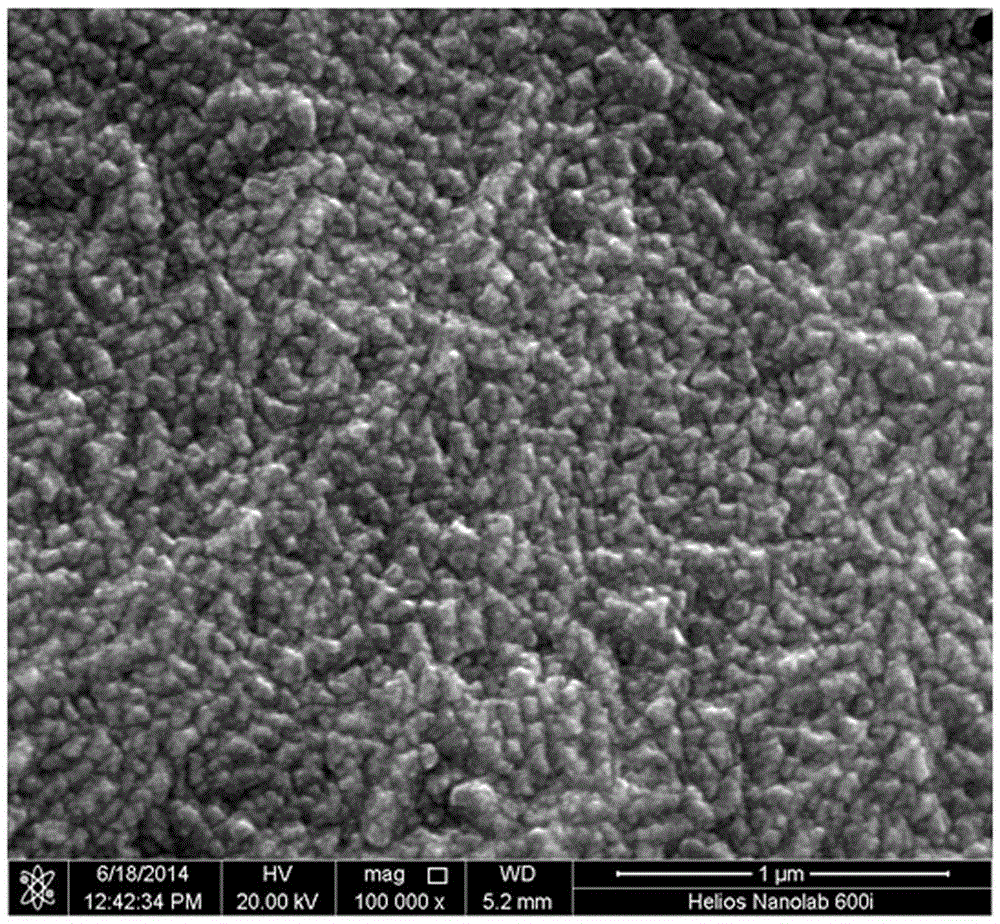

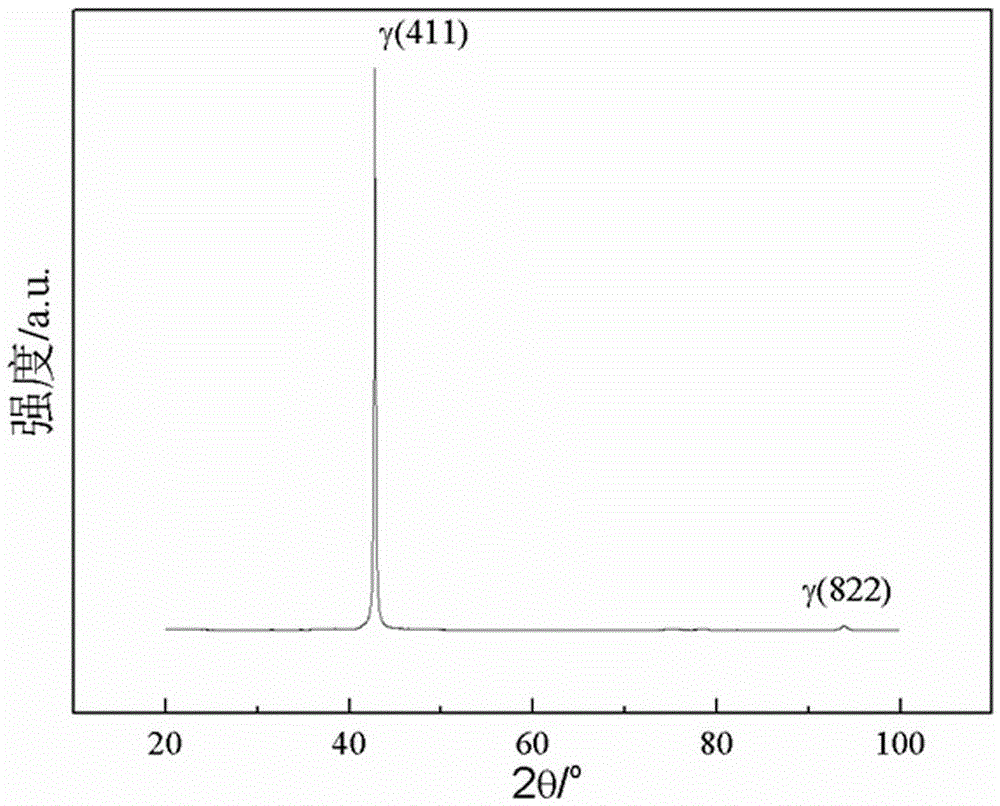

Selective absorbing film set of radiation absorbing layer based on mixture

InactiveCN103411335APromote absorptionReduce radiation effectsSolar heat devicesLayered productsHigh absorptionLow emissivity

The invention discloses a selective absorbing film set of a radiation absorbing layer based on mixture. The mixture is mixed by a superabsorbent material and a transparent material. The absorbing film comprises a metal substrate, and a selective absorbing film of the radiation absorbing layer based on the mixture, an antireflection dielectric film and a protective film which are deposited sequentially on the substrate. According to the selective absorbing film set, performances of the absorbing film can be controlled flexibly by adjusting the parameters of materials of the film set, the thickness of the coating, ingredients of the mixed film, the size, the shape and the like. The premise of maintaining high absorption and low emissivity can be met, and meanwhile, requirements of diversification and individuation of solar thermal products of solar water heaters and solar air conditioners can be met. The selective absorbing film set has the advantages that structure is simple, and the selective absorbing film set is adaptable to various processing and producing and has an important significance to development of the field of solar selective thermal absorbing films.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

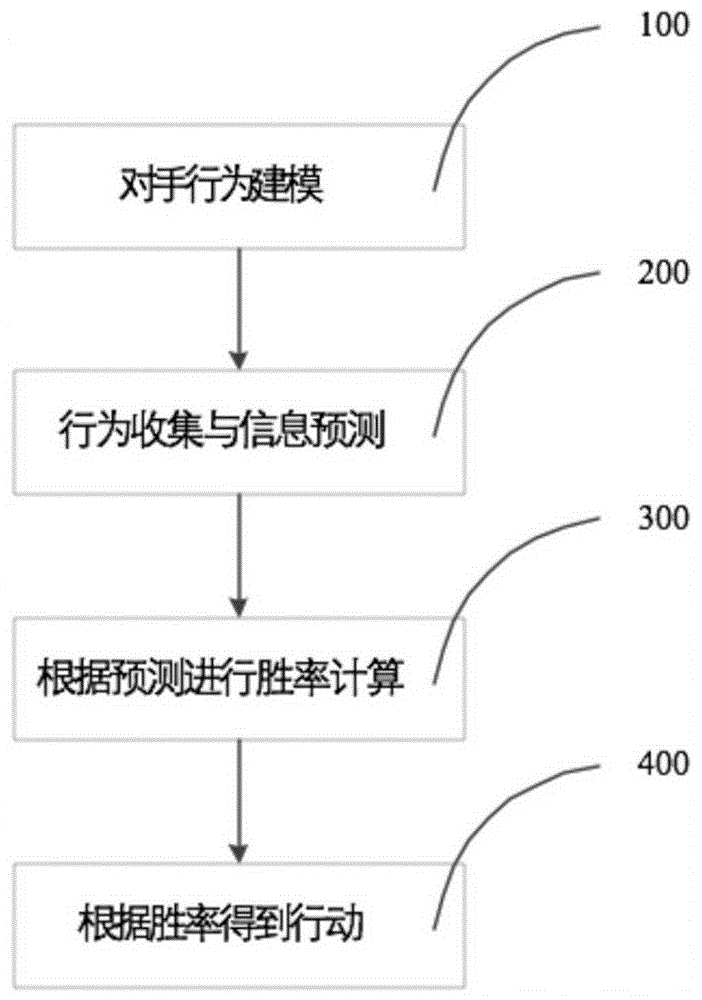

Game strategy generation method of non-complete information

InactiveCN105426969ASolve bottlenecksClear logicMathematical modelsResourcesSimulationArtificial intelligence

The invention relates to a strategy generation method under non-complete information gaming. The method comprises following specific steps: the opponent behavior modeling step that, before gaming is performed, according to a specific rule of the gaming, modeling for each behavior of an opponent is performed; the behavior collection and information prediction step that, in the gaming process, information of each action of the opponent is recorded, and the information is converted into probability distribution of opponent information through a model; the win rate calculation step which is performed according to a prediction and that, according to the probability distribution, a simulation is performed through a monte carlo method to obtain an own win rate; and the step that an expect benefit of each behavior is calculated according to the win rate finally, and the haviro having the highest expect benefit is selected to be taken as a final decision. A new thought is provided for the non-complete information gaming, the method has the advantages of clear logic, simple implementation and accurate calculations of the opponent information and the win rate, the decision-making capability in specific situation can be improved, a decision benefit is maximized, and then industrial production efficiency is improved.

Owner:ZHEJIANG UNIV

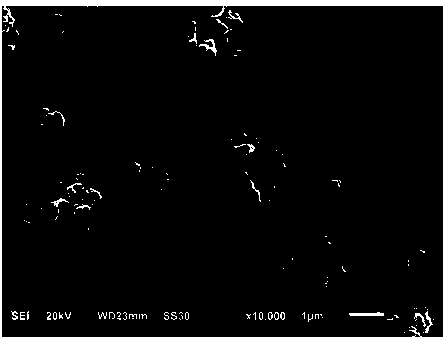

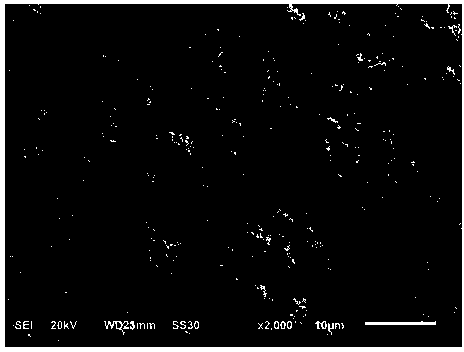

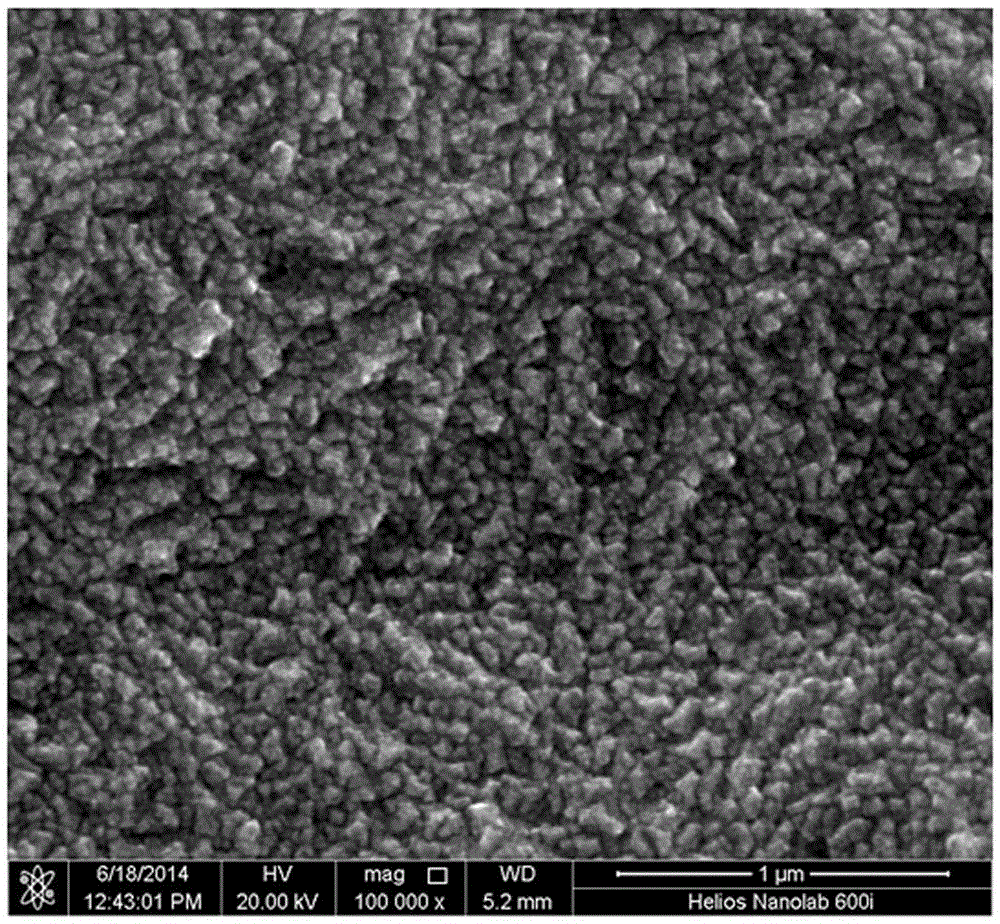

Method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with method

The invention relates to a method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with the method. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder comprises the following steps of A, preparing a first water solution; B, preparing a second water solution; C, conducting reduction treatment; D, conducting washing; E, conducting drying and sieving, and obtaining the dried finished high-specific-surface-area cotton-shaped super-fine silver powder. According to the silver powder prepared with the method, the specific surface area is over 6.5 m<2> / g, and the burning lose content is smaller than 1.5 after heat treatment is conducted for one hour at the temperature of 538 DEG C. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder and the silver powder prepared with the method have the advantages that the method is controlled effectively, the prepared silver powder is high in quality and stable, the production efficiency is high, pollution is avoided, the requirement for environment protection is met, after the silver power is prepared into silver paste, the viscosity and the rheological property of electrocondution slurry are maintained, the conductivity of a silver film obtained by burning the electrocondution slurry is not changed, and the proportion of the silver powder in the electrocondution slurry can be reduced. The silver powder prepared with the method has the outstanding advantages that the particle size distribution range is narrow, the dispersibility is high, the purity is high, and the specific surface area is high and is an ideal material for silver paste for electrodes of electronic components.

Owner:中船黄冈贵金属有限公司

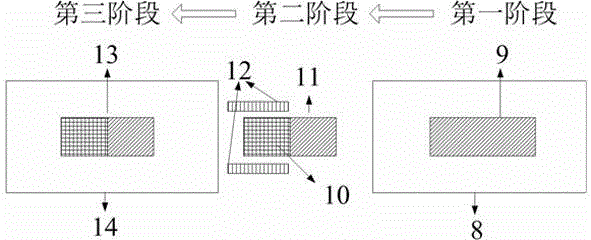

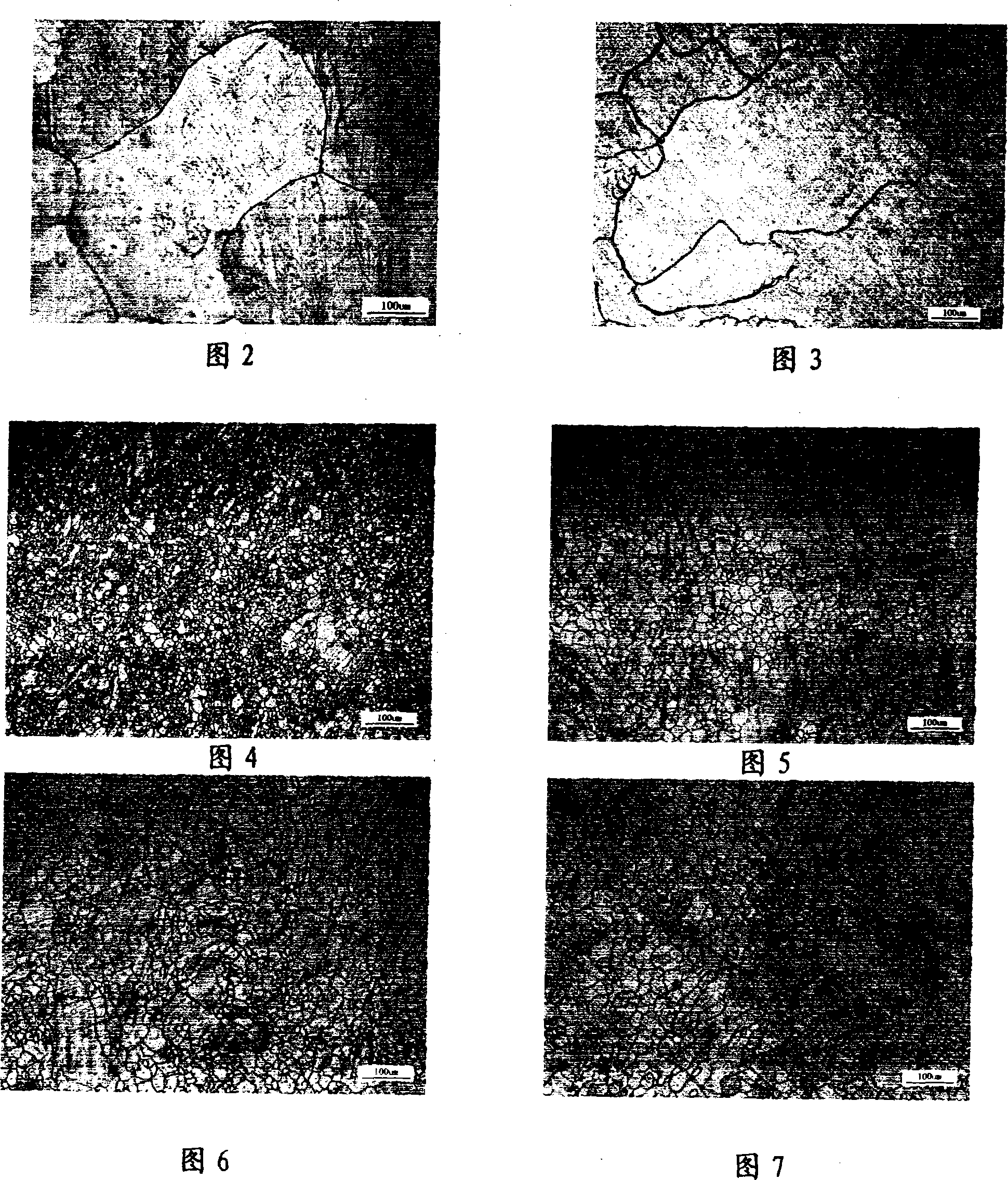

Continuous extrusion deformation method of magnesium alloy

InactiveCN101912891AImprove industrial production efficiencyHigh compressive strengthContinuous flowCrystallite

The invention discloses a continuous extrusion deformation method of magnesium alloy, which comprises the steps that: the temperature of a homogenized magnesium alloy blank is heated to 350 to 450 DEG C, an extrusion die, with the temperature lower than that of the magnesium alloy blank by 10 to 30 DEG C, is used for performing first-pass one-way continuous extrusion at the constant-speed extrusion rate of 1m / min to 3m / min in an order of forward extrusion, change channel angular extrusion at 90-degree corner and equal channel angular extrusion at 90-degree corner, so that the magnesium alloy blank, after the forward extrusion at one end of the die, is equivalently divided into a plurality of streams, which are subject to the change channel angular extrusion and the equal channel angular extrusion to form the magnesium alloy at the other end of the die, followed by mold stripping, thus continuous flowing extrusion deformation is formed, the extrusion ratio of the forward extrusion to the change channel angular extrusion at 90-degree corner is 16:1, and the extrusion ratio of the change channel angular extrusion to the equal channel angular extrusion at 90-degree corner is 1:1. The method can not only obtain extremely prominent grain refining effect and more homogenous structure of the magnesium alloy, but can also enhance industrial production efficiency, lower production cost and ensure production quality by increasing the extrusion ratio and the extrusion speed.

Owner:CHONGQING UNIV

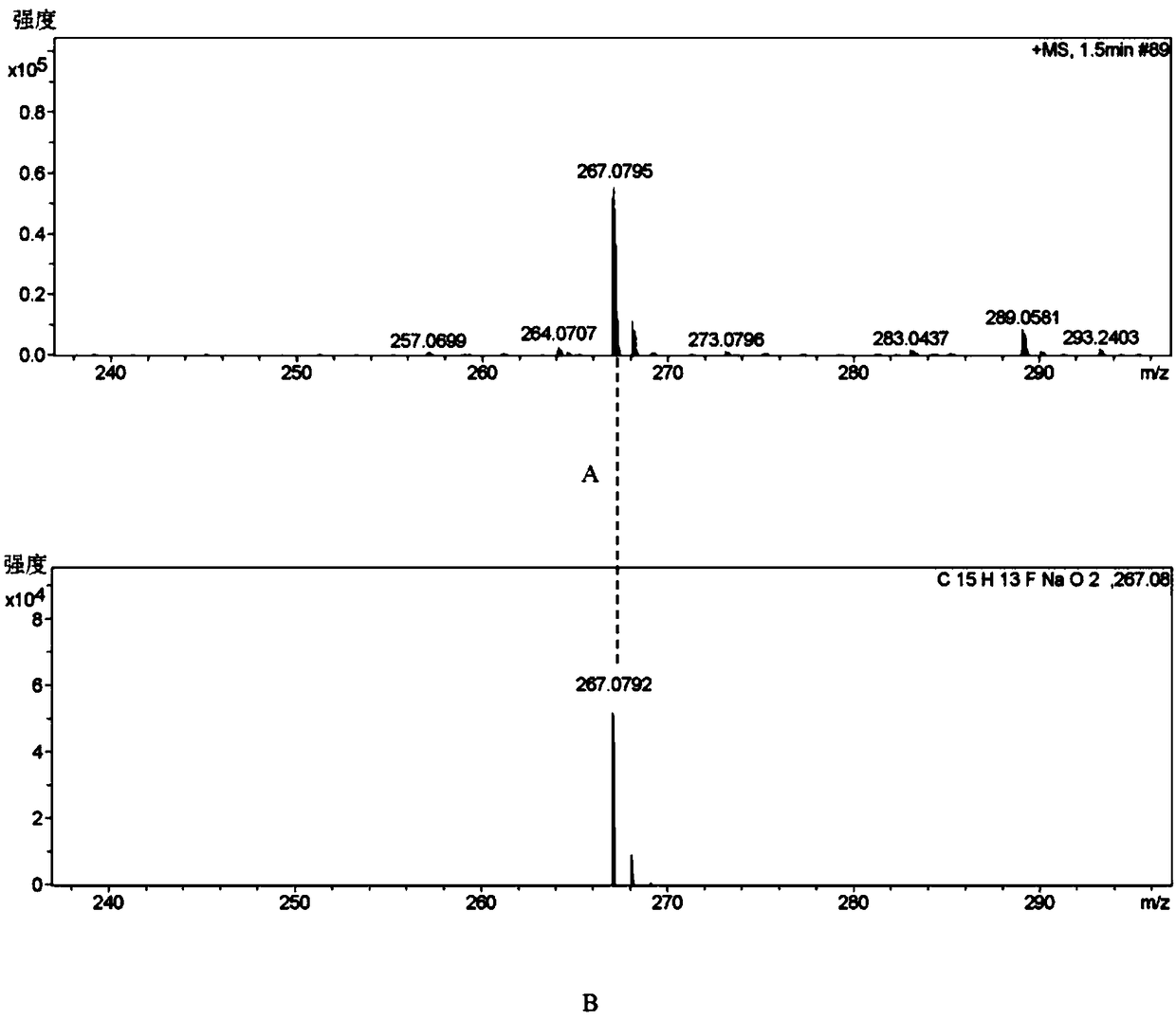

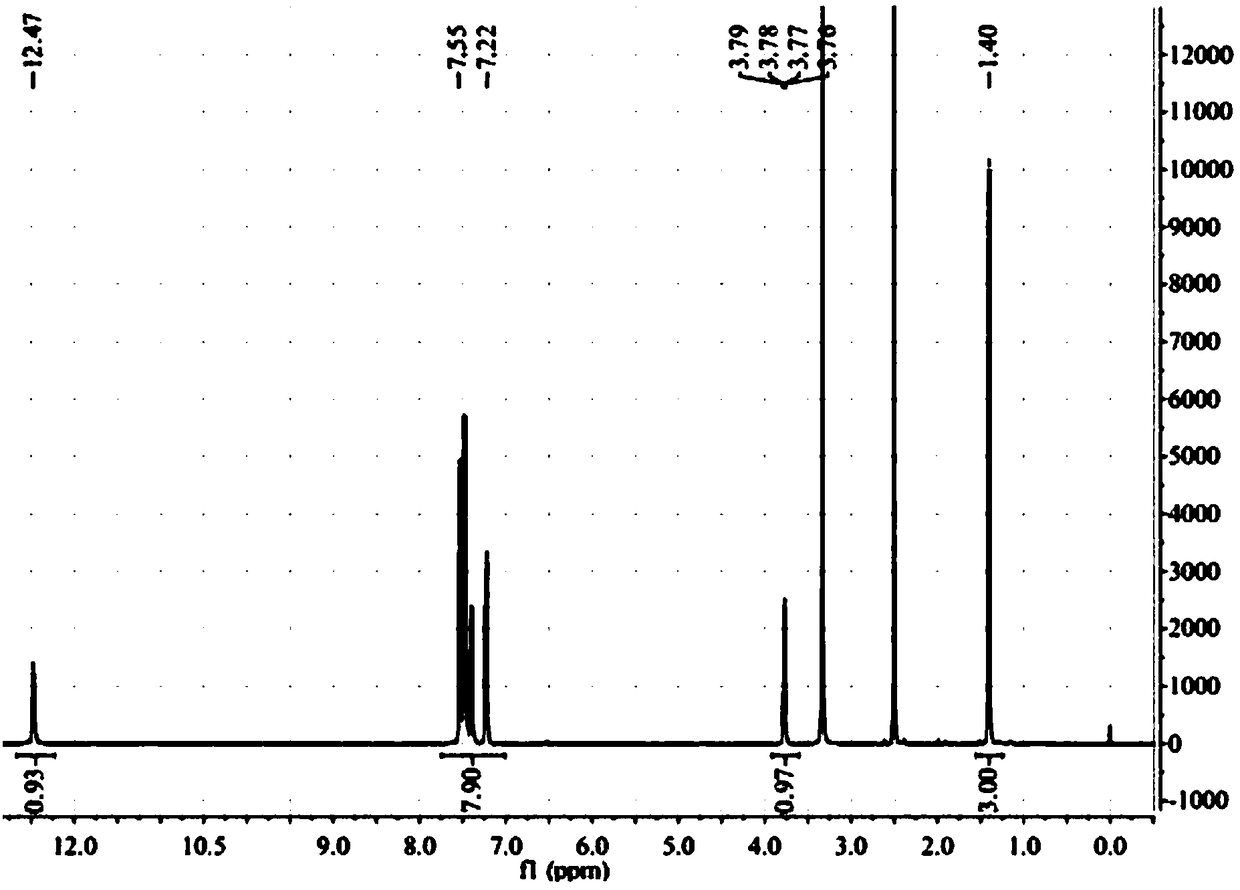

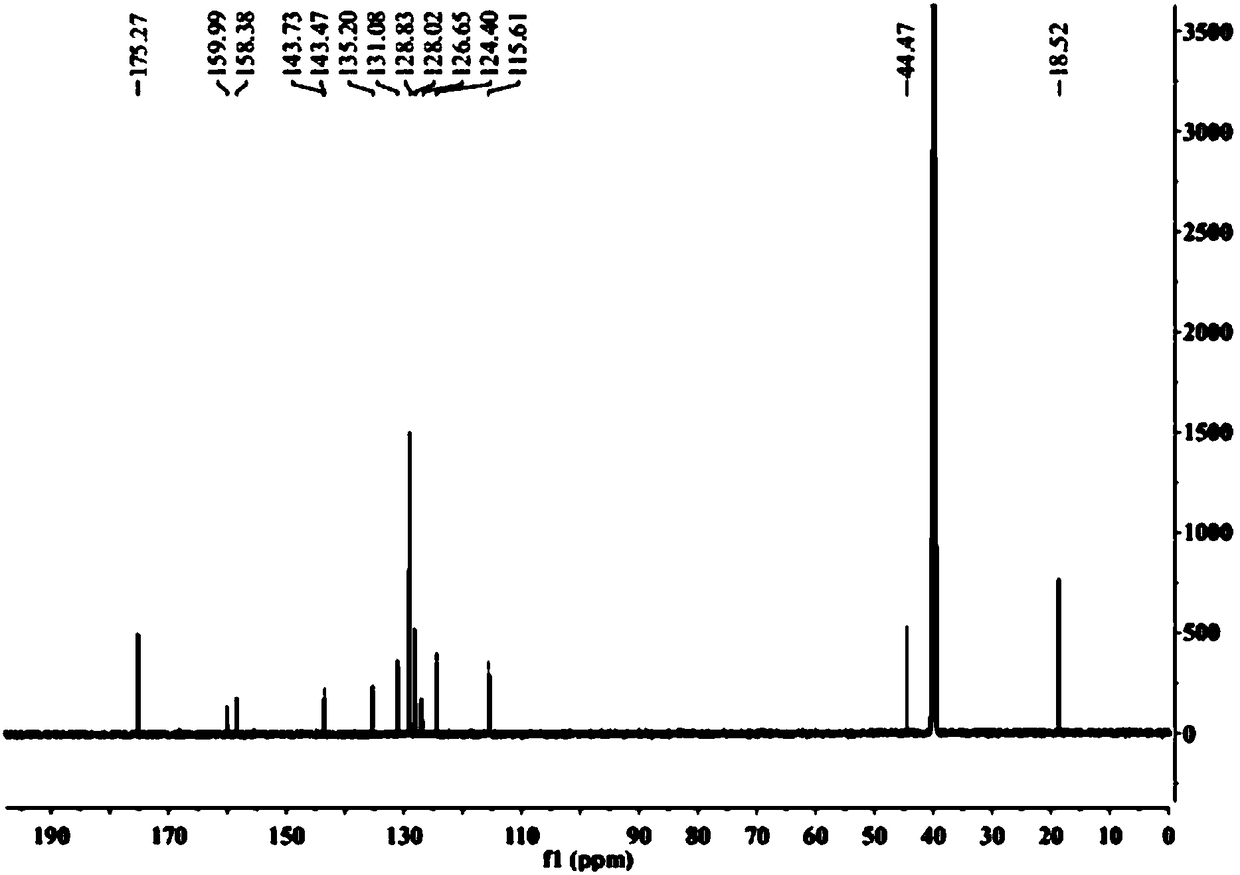

Preparation method of flurbiprofen and preparation method of flurbiprofen axetil

InactiveCN108558651ALow costHigh purityPreparation from carboxylic acid saltsOxygen-containing compound preparationChemical synthesisBromine

The invention relates to the field of pharmaceutical chemical synthesis, in particular to a preparation method of flurbiprofen and a preparation method of flurbiprofen axetil. The preparation method of the flurbiprofen comprises the steps of carrying out a Grignard reaction by using 4-bromine-2-fluorine biphenyl as a raw material, carrying out a coupling reaction, and acidizing to obtain the flurbiprofen; the yield is 90%, and the purity is 99.5%; then, the flurbiprofen axetil is prepared by using the flurbiprofen, obtained by the method, as a raw material, the yield reaches up to 90%, and thepurity reaches up to 99.5%. The preparation methods are high in quality controllability and industrial reproducibility.

Owner:上海峰林生物科技有限公司

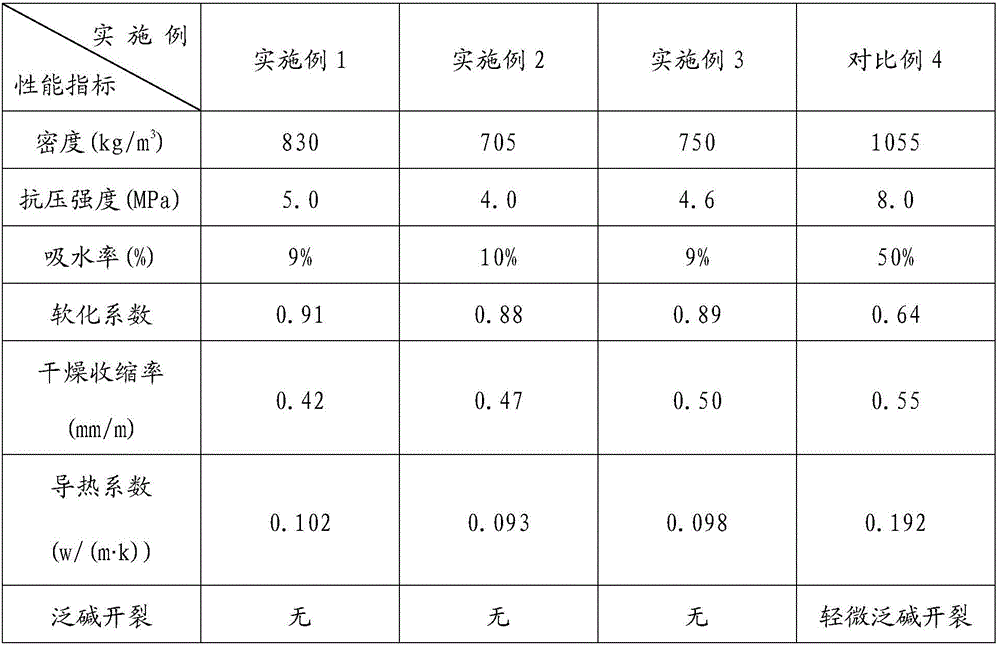

Gypsum-based composite material for self-insulation wall and preparation method of gypsum-based composite material

ActiveCN106007613AIncrease profitReduce economic costsSolid waste managementCeramicwareFoaming agentMicrobubbles

The invention relates to a gypsum-based composite material for a self-insulation wall and a preparation method of the gypsum-based composite material. The material is prepared from dry materials and an aqueous solution, wherein the dry materials comprise semi-hydrated gypsum powder, cement, fly ash, quicklime, mineral powder, expansion silica gel and silica fume; the aqueous solution is prepared from a modified additive, a fine foaming agent and water. The dry materials are added after the aqueous solution is evenly stirred, the mixture is stirred rapidly continuously to be mixed with air, so that microbubbles are formed and can be mixed homogeneously with the gypsum mixture, and the production efficiency and the stability are improved. The gypsum-based composite material for the self-insulation wall has the advantages of being light, high in strength, thermal-insulating, sound-insulating, water resistant, alkali-resistant, capable of being molded through quick pouring and the like.

Owner:SOUTHEAST UNIV

Ti-alloy nitride selective-absorption film system and preparation method thereof

InactiveCN103383155AHigh photothermal conversion efficiencyImprove absorption rateSolar heat devicesLayered productsLow emissivitySolar water

The invention discloses a Ti-alloy nitride selective-absorption film system. The selective-absorption film system comprises a metal substrate and further comprises a Ti-alloy nitride selective-absorption film, an anti-reflection dielectric film and an SiO2 protective film which are deposited on the metal substrate in sequence. The selective-absorption film system provided by the invention is characterized in that the solar absorptivity is greater than 97%; the solar emissivity is smaller than 3%; both the photo-thermal conversion efficiency and the heat-collecting efficiency are high. Under the premise of keeping high absorptivity and low emissivity, the selective-absorption film can meet the requirements of diversification and individuation of photo-thermal products such as solar water heaters and solar air conditioners by adjusting the components of Ti alloy. The selective-absorption film system is simple in structure and free from oxygen deposition, and has the characteristics of simple preparation technology and using less target materials, so that the production efficiency is greatly improved; the industrial large-scale production cost is lowered. Therefore, the selective-absorption film system is of great significance for the development of the field of solar selective heat absorption films.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

The invention discloses an alkaline non-cyanide zinc plating nickel alloy plating solution and an electroplating process thereof. The plating solution is prepared with hydantoin or a hydantoin derivative as a main coordination agent by adding an auxiliary coordination agent, zinc sulfate, nickel sulfate, potassium carbonate and water. The plating solution comprises 20 g-400 g / L of the main coordination agent, 5 g-300 g / L of the auxiliary coordination agent, 5 g-200 g / L of the zinc sulfate, 1 g-150 g / L of the nickel sulfate and 5 g-435 g / L of the potassium carbonate. The electroplating process of the plating solution comprises the steps of substrate pretreatment and zinc-nickel alloy electroplating. A constant current electroplating mode is adopted for zinc-nickel alloy electroplating. The electric current density is 0.5 A-5 A / dm2. The temperature of the plating solution is 30 DEG C-60 DEG C. The distance between a cathode and an anode is 0.5 cm-25 cm. The stirring speed of the plating solution is 0 rpm-3000 rpm. The electroplating time is 1 min-120 min. According to the plating solution and the electroplating process thereof, the hydantoin or the hydantoin derivative serves as the main coordination agent for the first time, and zinc-nickel alloy with the nickel content of 10 wt.%-13 wt.% is obtained through electro-deposition by using the main coordination agent and the auxiliary coordination agent in a combination mode. An obtained coating is good in corrosion resistance. The stability of the plating solution is improved immensely compared with using of a single coordination agent.

Owner:宏正(福建)化学品有限公司

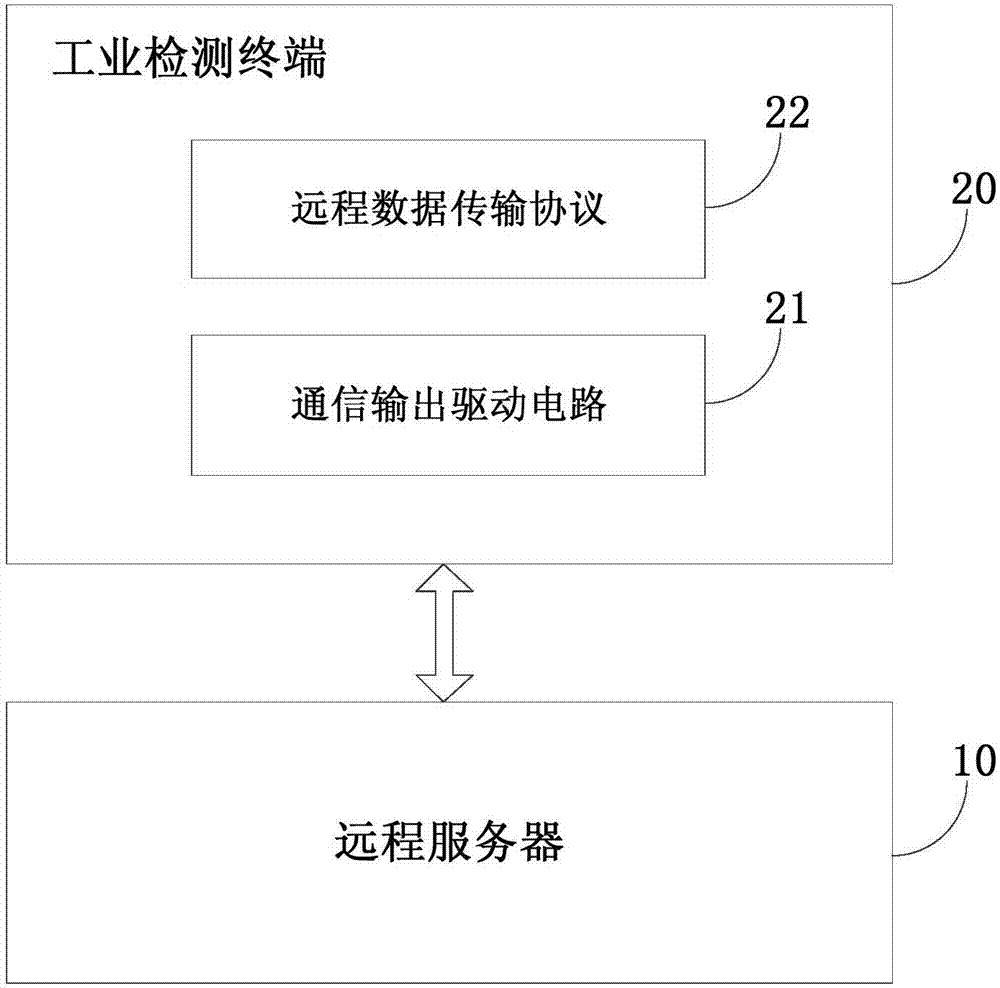

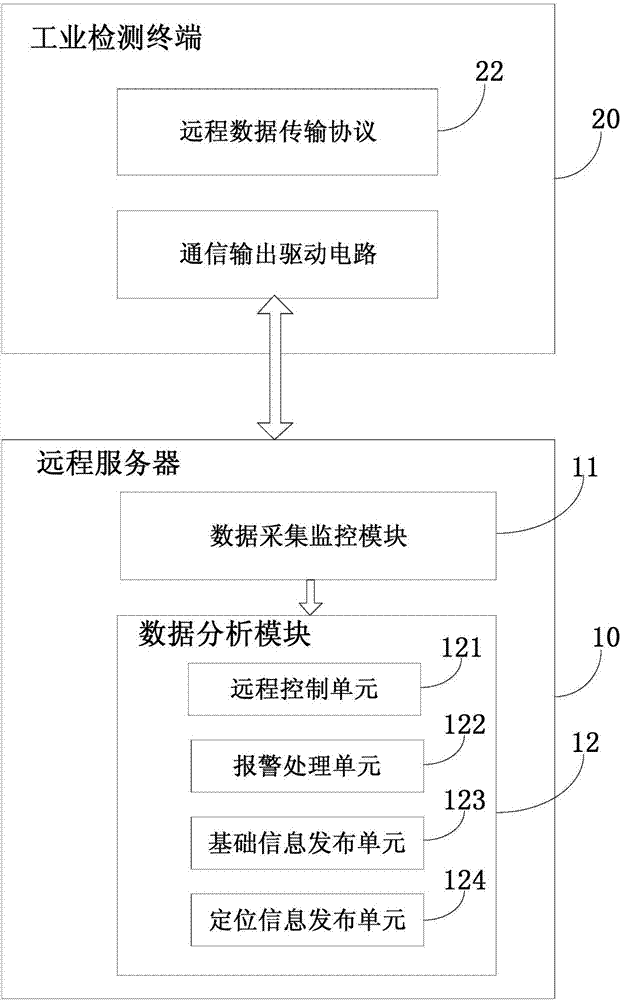

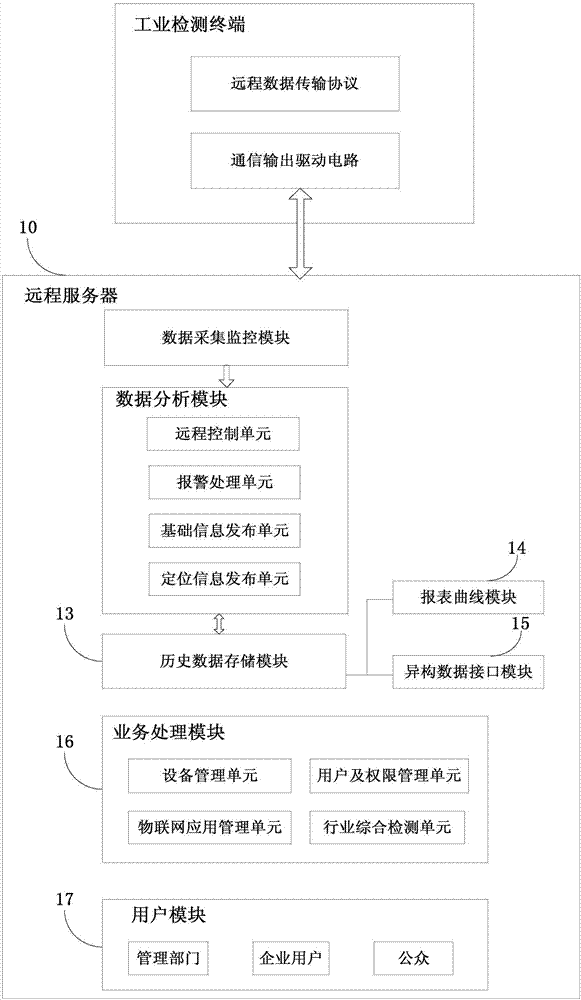

Industrial Internet of things system

InactiveCN106973097AGuaranteed stabilityImprove industrial production efficiencyTechnology managementTransmissionRemote controlComputer terminal

The embodiment of the invention discloses an industrial Internet of things system. The system comprises an industrial detection terminal and a remote server. The industrial detection terminal comprises a communication output drive circuit and bears a remote data transmission protocol. The industrial detection terminal establishes remote communication connection with the remote server through the communication output drive circuit. The industrial detection terminal carries out instruction and data interaction with the remote server based on the remote data transmission protocol through the established remote communication connection. According to the technical scheme provided by the embodiment of the invention, an industrial field can be remote controlled, and the industrial production efficiency is improved.

Owner:ANALOG SYST SH

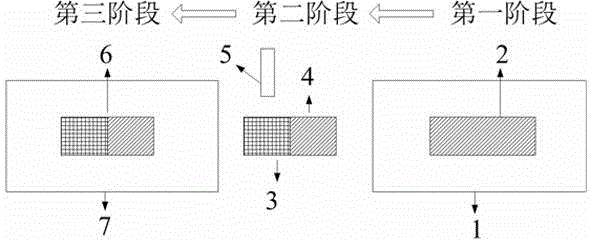

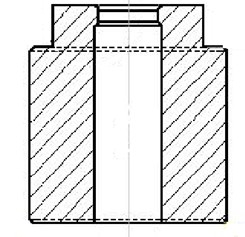

Secondary continuous extrusion processing method of magnesium alloy and die plate insert for secondary continuous extrusion processing method

InactiveCN102632095AImprove performanceExtrusion ratio decreasedExtrusion diesExtrusion control devicesMagnesium alloyExtrusion

Owner:SHANGHAI JIAO TONG UNIV

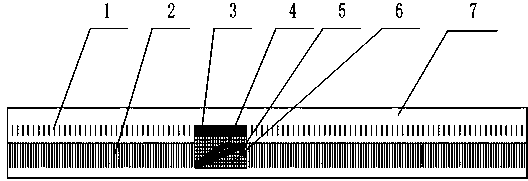

Code micro-macro combined collection method of absolute grating ruler

InactiveCN103411635AFast measurementImprove measurement resolutionMeasurement/indication equipmentsRecording measured valuesCMOS sensorEngineering

The invention discloses a code micro-macro combined collection method of an absolute grating ruler. The absolute grating ruler is a double-code-channel grating ruler with a low-accuracy encoding code channel and a high-accuracy encoding code channel which are arranged side by side. The code micro-macro combined collection method of the absolute grating ruler is characterized in that a cmos sensor is arranged on the absolute grating ruler, the cmos sensor comprises a multi-line scanning mode, an inclined scanning read-out mode and a parabola scanning read-out mode, one line of encode channel is scanned through the multi-line scanning mode, another line of encode channel is scanned through the inclined scanning read-out mode and the parabola scanning read-out mode , and the multi-line scanning mode, the inclined scanning read-out mode and the parabola scanning read-out mode are combined in a micro-macro mode to collect codes. The code micro-macro combined collection method of the absolute grating ruler achieves that a reading head of the absolute grating ruler carries out micro-macro combined reading, and meanwhile the collection time of each frame of image is shortened to achieve the collection of high frame frequency images. The code micro-macro combined collection method of the absolute grating ruler can improve the pollution-resistant capacity of the absolute grating ruler, and improves the reliability and correction rate of decoding.

Owner:GUANGDONG UNIV OF TECH

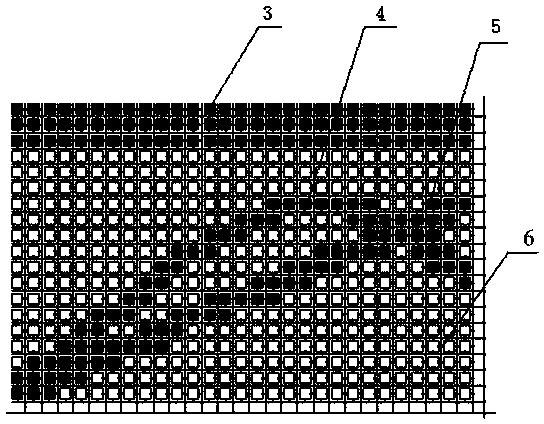

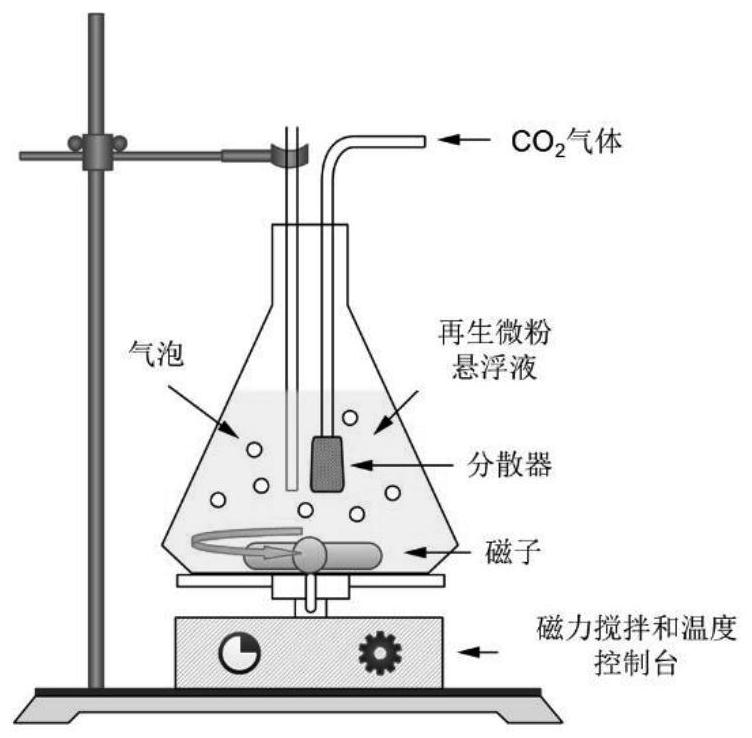

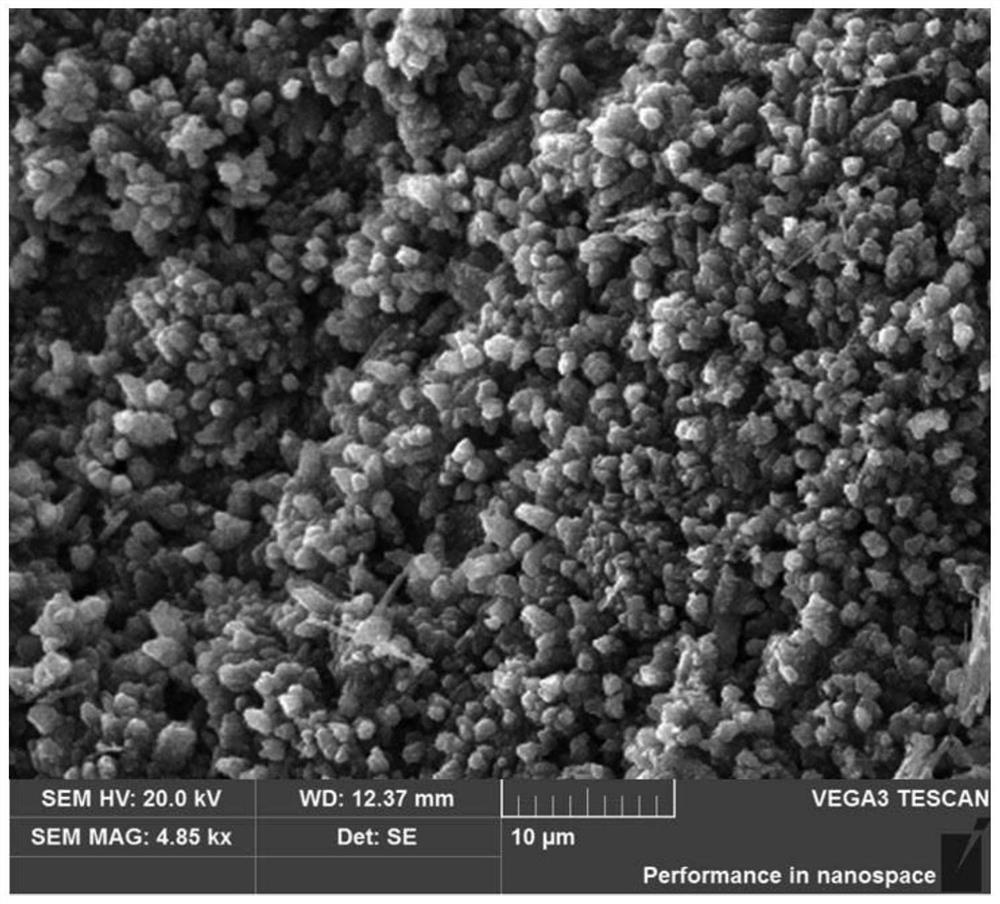

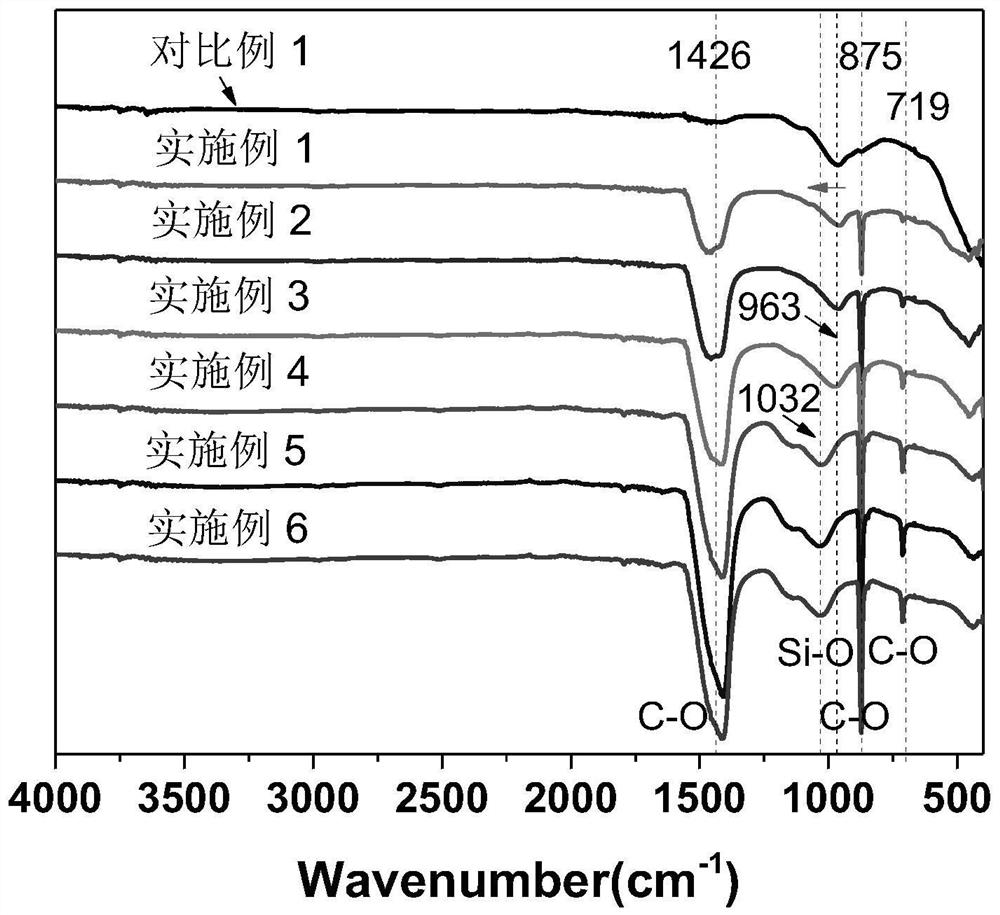

Method for carbonizing and activating waste concrete recycled micro powder by wet process and application of regenerated micro-powder

ActiveCN112125541AHigh activityEasy to achieve continuous productionCement productionSilica fumeIndustrial waste

The invention provides a method for carbonizing and activating waste concrete recycled micro powder by a wet process, which comprises the following steps of: taking powder generated in the process ofproducing recycled aggregate by crushing waste concrete as recycled micro powder, dispersing the recycled micro powder into water to form mixed slurry, and continuously introducing industrial waste gas containing carbon dioxide into the mixed slurry, in the process, carbon dioxide contained in the industrial waste gas and the regenerated micro powder are subjected to a carbonization reaction. According to the invention, the regenerated micro-powder is subjected to the carbonization reaction in an aqueous solution, the activity of calcium carbonate and silicon dioxide generated by carbonizationis higher, the volcanic ash activity is superior to that of common auxiliary cementing materials such as fly ash and silica fume, and the regenerated micro-powder can be used as an auxiliary cementing material.

Owner:HENAN POLYTECHNIC UNIV

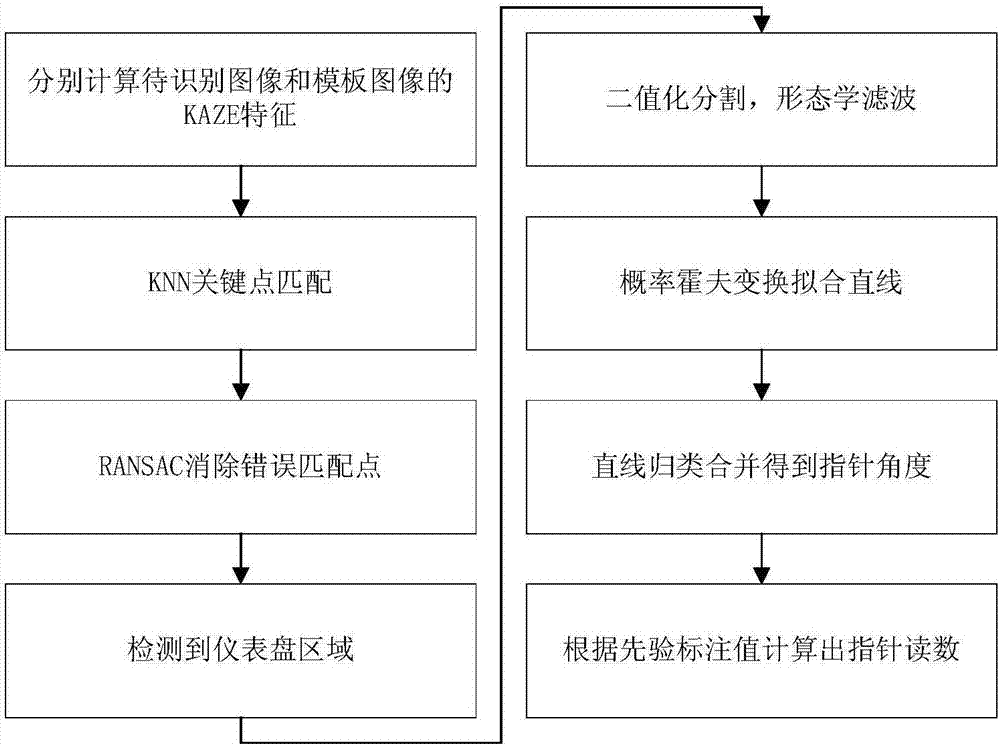

Pointer type instrument panel automatic reading method under long-distance and multi-view environment

ActiveCN107145890ASimple methodImprove accuracyCharacter and pattern recognitionComputer scienceAngle of view

The present invention discloses a pointer type instrument panel automatic reading method under a long-distance and multi-view environment. The method comprises the steps of dial plate area determination, segmentation processing, pointer extraction fitting and reading estimation, and is characterized by determining a dial plate area in an image by matching the key points of a to-be-identified image and a template dial plate, then distributing a binaryzation dial plate according to a histogram, obtaining the internal information of the dial plate by the binary image morphologic processing, and then inducing and merging the straight lines obtained by the progressive probabilistic Hough transform fitting to obtain a pointer angle, and finally calculating the pointer reading according to a transcendental pointer. The pointer type instrument panel automatic reading method of the present invention solves the problems that the distortion of the dial plate is severe under a long-distance strabismus angle, the scales are fuzzy, and the reading can not be identified completely by the eyes, and has the higher accuracy.

Owner:JIANGSU HAOHAN INFORMATION TECH

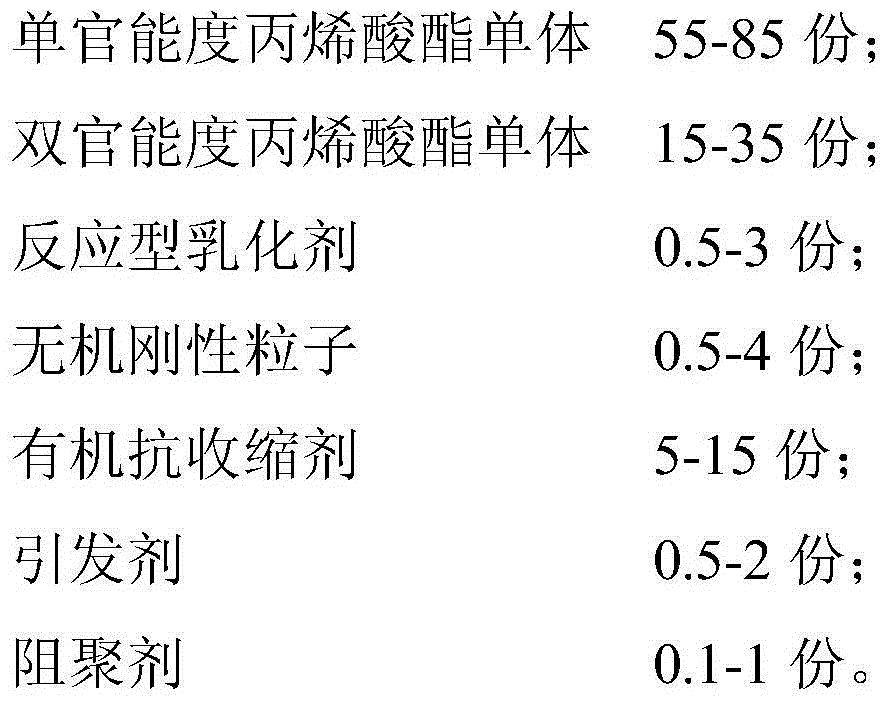

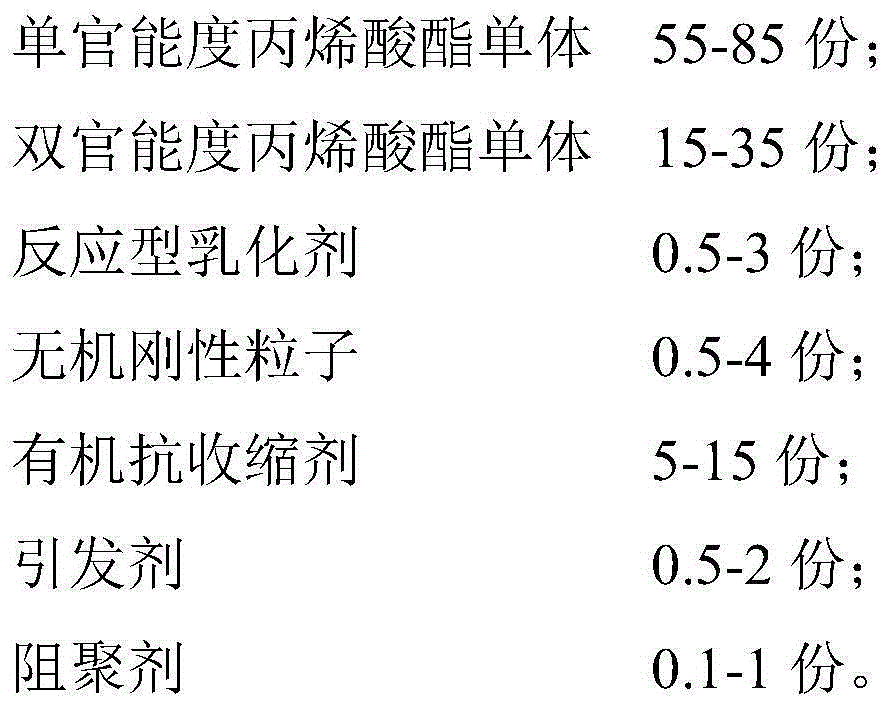

Low-shrinkage acrylic ester type vacuum impregnation agent for sealing reinforcement

The invention discloses a low-shrinkage acrylic ester type vacuum impregnation agent for sealing reinforcement. The impregnation agent is prepared by uniformly mixing a mono-functionality acrylate monomer, a bifunctionality acrylate monomer, a reactive emulsifier, inorganic rigid particles, an organic anti-shrinkage agent, an initiator and a polymerization inhibitor. The appearance of the impregnation agent is colorless and transparent oily liquid; the specific gravity is 0.950-1.100kg / m<3>; the gelation time lasts for 240-360 seconds; the viscosity is smaller than 10.03mPa.s; the hardness of cured gel bar is greater than 85Shore A; the volume shrinkage rate before and after curing is less than or equal to 9.00%. The impregnation agent is low in viscosity and low in toxicity; the gelation time and hardness of the cured gel bar can meet the requirements of industrial production; the impregnation agent is low in volume shrinkage rate, and large micropores can be efficiently plugged by the impregnation agent; the impregnation agent is high in efficiency of plugging the micropores at one time; the impregnation agent is an ideal impregnation agent for metal sealing reinforcement.

Owner:NANJING AIBUNA SEALING TECH CO LTD

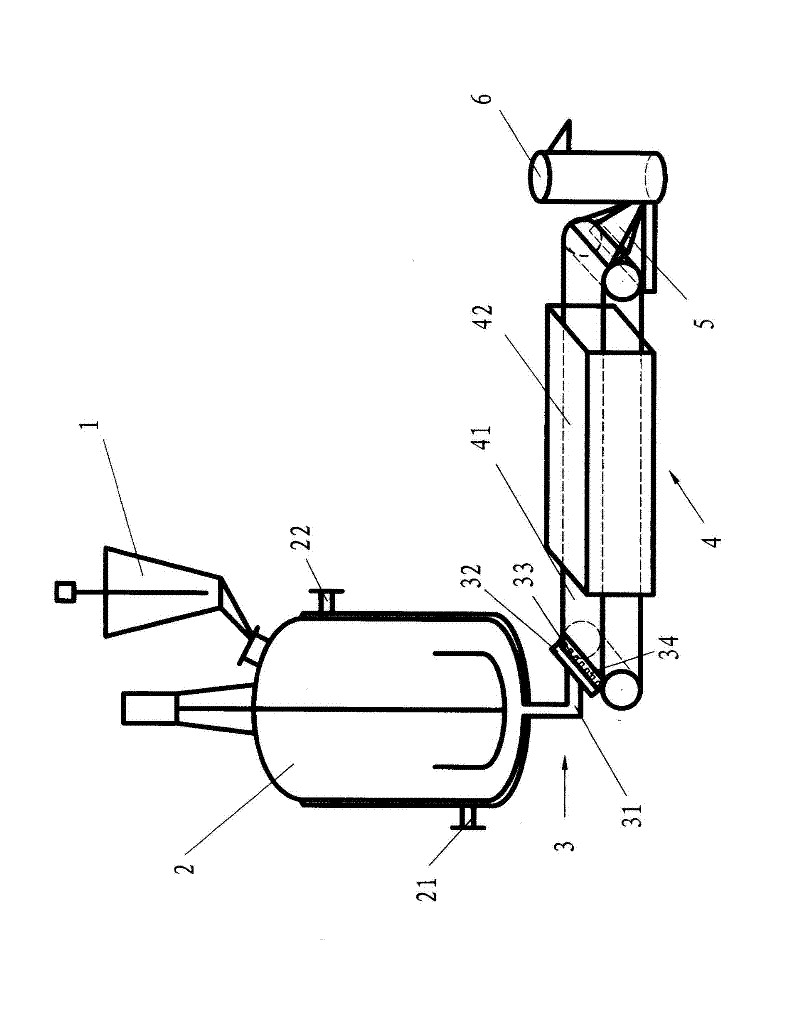

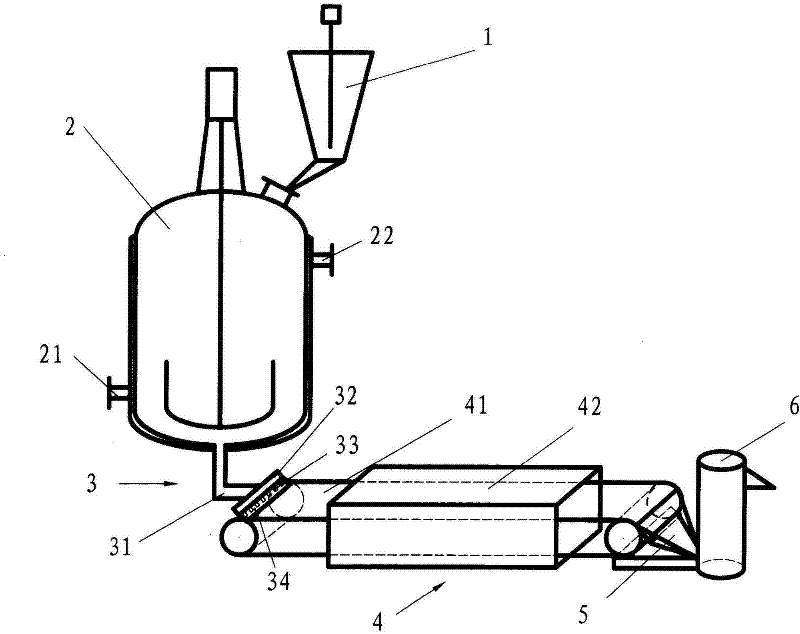

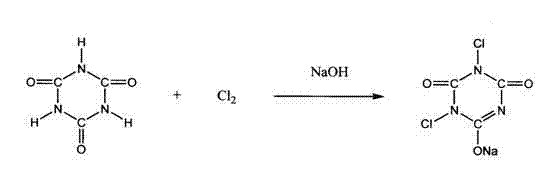

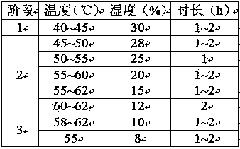

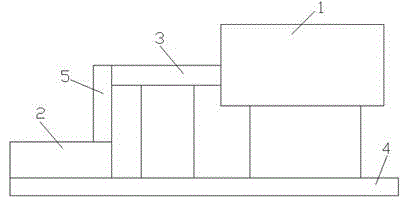

Preparation method of high-yield cyanuric acid and its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid

A preparation method of high-yield cyanuric acid and its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid comprises the following steps of: uniformly mixing urea and a catalyst ammonium sulfate, adding the mixture into a reaction vessel, forming a uniform thin material layer on a conveyor belt when the materials reach a certain temperature, liquid viscosity is increased and the liquid is still at a liquid state, and allowing the thin material layer to pass through a tunnel type heating chamber of a tunnel type heating device for heating at high temperature such that the temperature of the materials is rapidly raised to 250-280 DEG C in a short time. As the reaction time of the materials is short and the reaction speed is fast, there are few side effects and product decomposition is low. The cyanuric acid crude product prepared in the invention has high purity and high yield. During the refining process, inorganic dilute acid is used to process the cyanuric acid crude product. After centrifugation, a cyanuric acid refined product is directly used in the synthesis of its derivatives sodium dichloroisocyanurate and trichloroisocyanuric acid without being dried. By the adoption of the method, the adhesive problem of heating surface in production preparation is solved, production speediness and continuity are realized, and industrial production efficiency is raised.

Owner:河北田加力生物科技股份有限公司

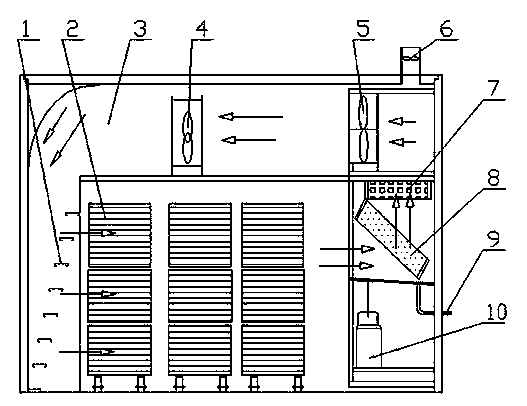

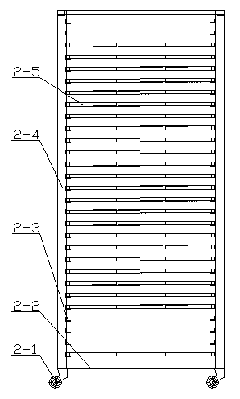

Drying method of organic edible flower

ActiveCN103988890AEasy to operateEasy to controlFruits/vegetable preservation by dehydrationBiotechnologyHigh humidity

A drying method of an organic edible flower comprises the following steps: 1) grading and selecting picked organic chrysanthemum, then artificially placing a dish; 2) drying with a heat pump, to be more specific, the moisture content of a product is 9.5%-11.5% by selection of heat pump type drying for 9-13h, the heat pump type drying is divided into three stages comprising low temperature high humidity slow drying for 1-2h in the first stage being, gradual warming dehumidifying drying for 5-8 h in the second stage and high temperature low humidity drying for 3-4h in the third stage; 3) again grading and selecting the dried organic chrysanthemum according to quality, and filling nitrogen to pack each piece of organic chrysanthemum. The drying method is environmentally friendly and efficient, zero-pollution to a dry matter and the environment, and simple in operation and control process, can work continuously, is high in industrial production efficiency, avoids petal scattering and falling phenomena of organic edible flowers, improves the appearance aroma and taste of the prepared flower, and ensures the nutritional effects of a product, and the product is high in quality and long in storage time.

Owner:江西隆平有机农业有限公司

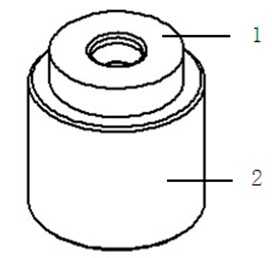

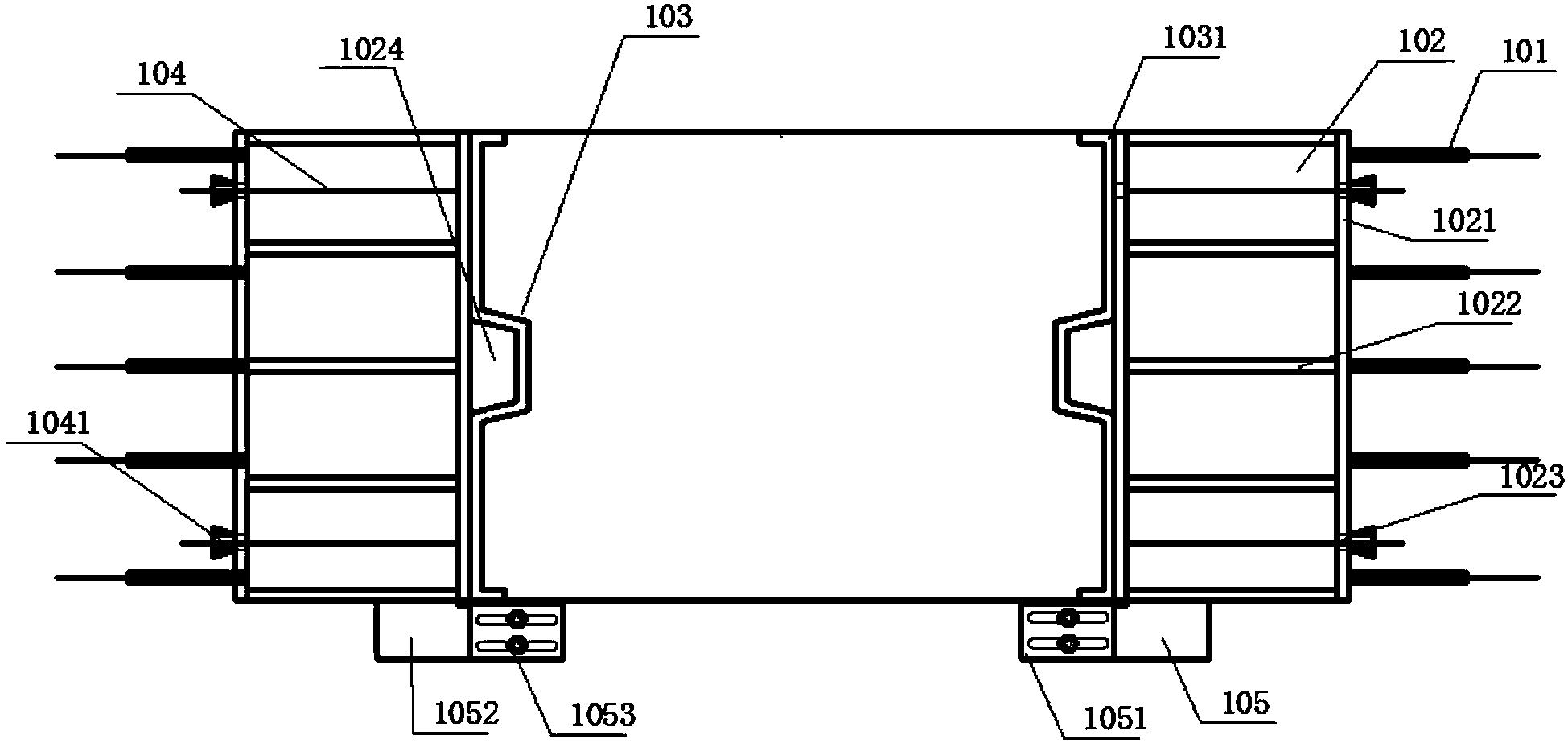

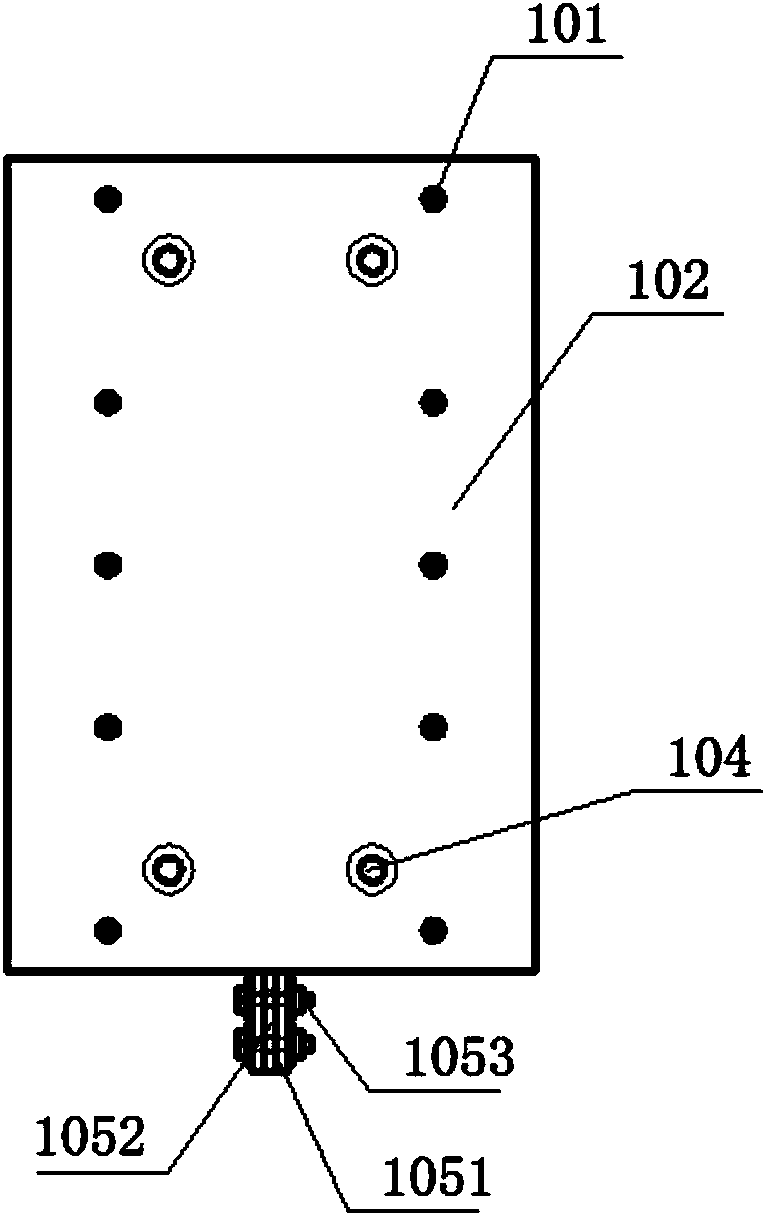

A lotus root processing device

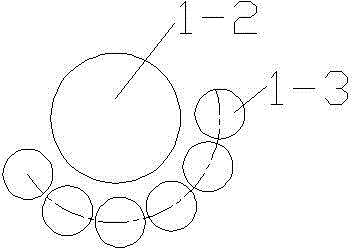

ActiveCN104886731ASatisfy cleaningMeet needsFood shapingMetal working apparatusEngineeringLotus root

The present invention relates to a lotus root processing device comprising a body frame, a lotus root washing mechanism is arranged on one side of the body frame, and a slicing mechanism is arranged on the other side of the body frame. The device is characterized in that a lotus root transmission mechanism is also arranged between the lotus root washing mechanism and the slicing mechanism on the body frame, the lotus root washing mechanism includes a sink arranged on the body frame, a discharge port arranged on one side wall of the sink, and a plurality of brush rollers in fan-shaped distribution hinged with the side wall of the sink with the discharge port as the center of a circle. The device is simple in structure and convenient in operation, and can effectively meet the needs of lotus root washing, slicing and processing and improve the efficiency of industrial production.

Owner:徐州淳康生物科技有限公司

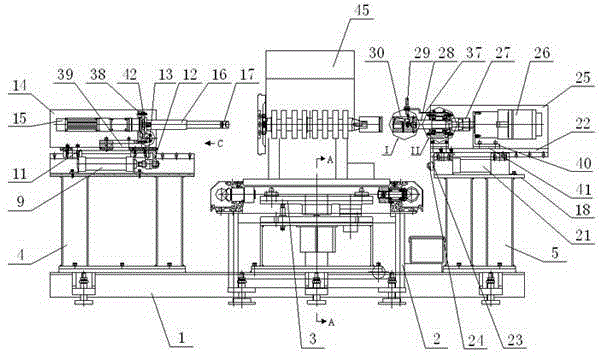

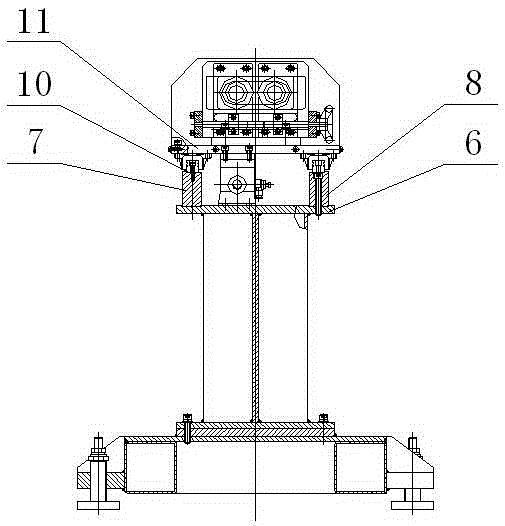

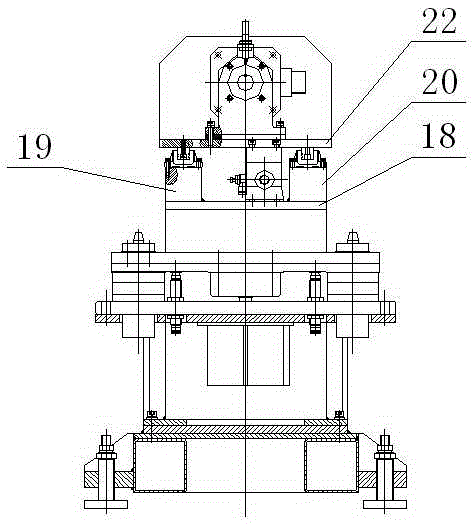

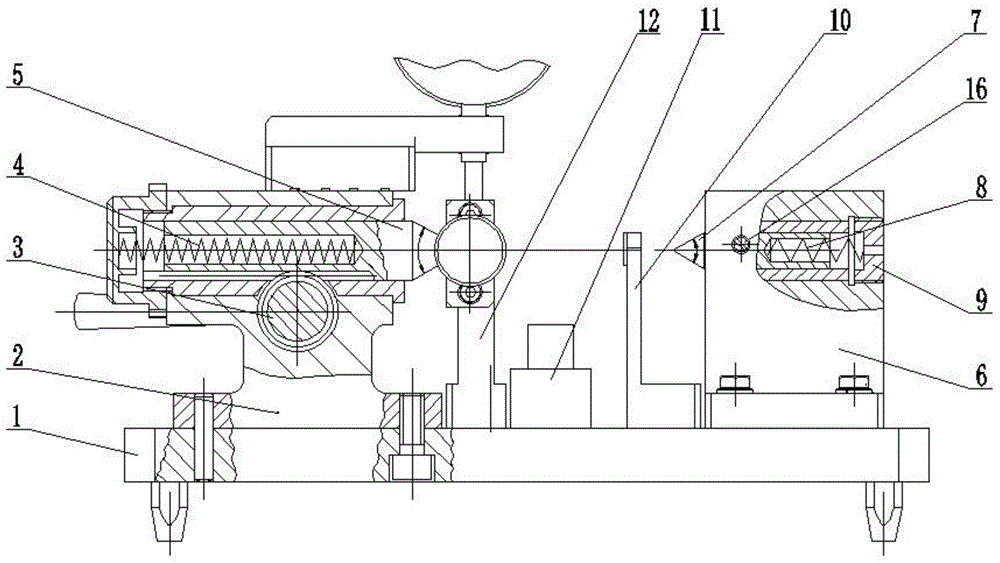

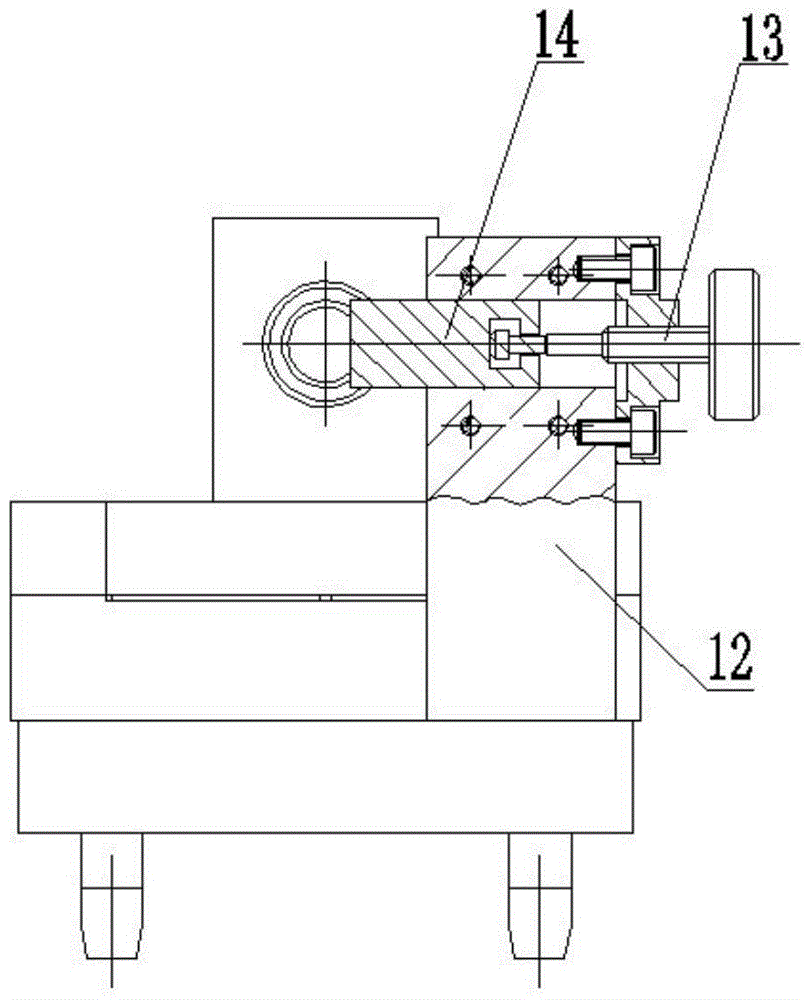

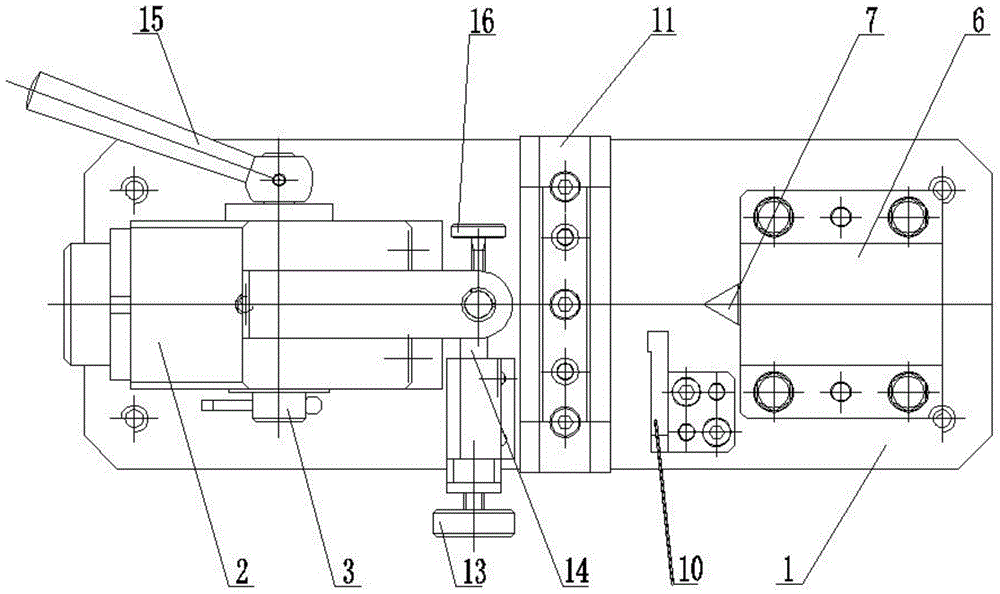

Bolt screwing machine for automobile engine flywheel

InactiveCN105269309AReduce the burden onHigh degree of automationVehicle componentsMetal working apparatusFreewheelEngineering

The invention discloses a bolt screwing machine for an automobile engine flywheel. The bolt screwing machine comprises a base. A lifting installing frame is fixed to the middle of the base. A lifting device is arranged on the lifting installing frame. A first machine base and a second machine base are fixed to the two sides of the base respectively. A first supporting plate is fixed to the first machine base. A first sliding rail cushion plate and a second sliding rail cushion plate are arranged on the two sides of the first supporting plate respectively. A first air cylinder is installed in the middle of the first supporting plate. Linear sliding rails are arranged on the first sliding rail cushion plate and the second sliding rail cushion plate respectively. A first installing plate is in sliding connection with the first sliding rail cushion plate and the second sliding rail cushion plate. A first air cylinder push plate is connected to the bottom of the first installing plate. One side of the first air cylinder push plate is fixed to the first installing plate. The other side of the first air cylinder push plate is connected with a first floating connector fixed to an output shaft of the first air cylinder. The bolt screwing machine is high in automation degree and has high pertinence; and in addition, the installing error is reduced, and the part installing precision and the part production efficiency are improved.

Owner:CHONGQING TECH & BUSINESS INST

Low-contraction acrylic acid ester vacuum infiltration agent used for sealed reinforcement

The invention discloses a low contraction acrylic acid ester vacuum infiltration agent used for sealed reinforcement, which contains a monofuctional acrylate monomer, a difunctional acrylate monomer, a reaction emulsifier, inorganic rigid particles, an organic anti-contraction agent, an initiator and a polymerization inhibitor, the vacuum infiltration agent is obtained by uniformly mixing the above components under normal temperature, appearance of the vacuum infiltration agent is a colorless transparent oily liquid, proportion is 0.950-1.100kg / m<3>, gelling time is 240-360s, viscosity is less than 10.03mPa.s, the glue rod hardness after solidification is greater than 85Shore A, and the volume shrinkage before and after solidification is less than or equal to 9.00%. The infiltration agent has the advantages of low viscosity and little toxicity, gelling time and glue rod hardness after solidification can satisfy the requirement of industrial production, the vacuum infiltration agent has low volume shrinkage, has capability for plugging large micro apertures with high efficiency, the efficiency for plugging the micro aperture at one time is high, and the vacuum infiltration agent is the ideal infiltration agent for sealed reinforcement.

Owner:NANJING AIBUNA SEALING TECH CO LTD

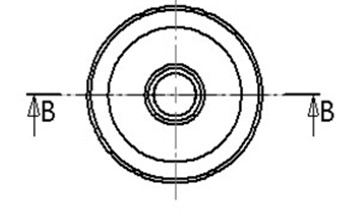

Fixation apparatus for stator blade profile and journal bounce detection

The invention relates to a fixation apparatus for stator blade profile and journal bounce detection. The fixation apparatus comprises a first foot block and a second foot block which are fixed at the two sides of a base; the axial positioning of a blade is finished by clamping a baled axle center by use of two opposite finials in the two foot blocks and attaching an axial positioning plate to a blade axial positioning surface; by use of the attachment of an angle positioning plate in a body seat and a blade profile, the angle positioning of the blade is realized, and the blade profile is further detected; by use of the push effects of the plug screw arranged at the second foot block, the blade is enabled to disengage from the axial positioning plate and rotate on the two finials; and then journal bounce detection is performed on the blade. The fixation apparatus solves the problem of performing blade profile detection and journal bounce detection at the same measuring tool, facilitates one-time multiple dimension clamping and processing on numerical control equipment in terms of process to finish needed detection means, and reduces the labor intensity of repeated positioning.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

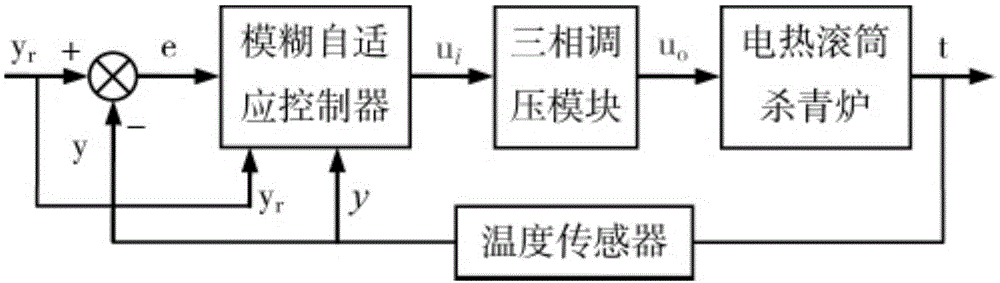

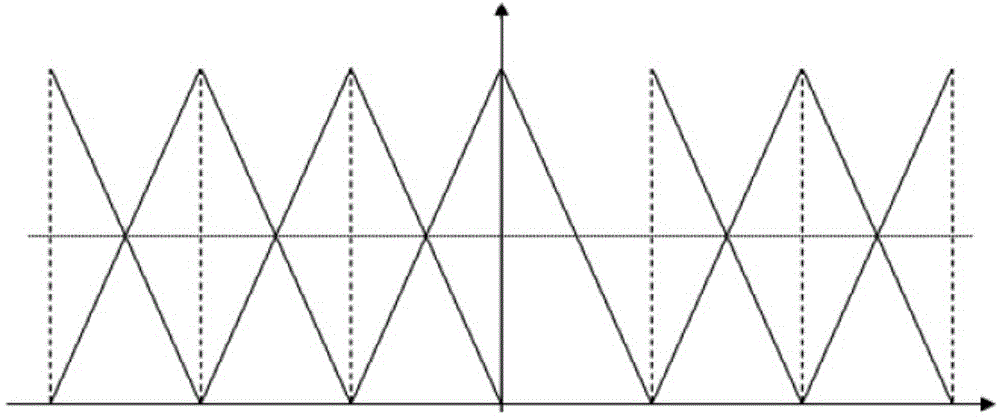

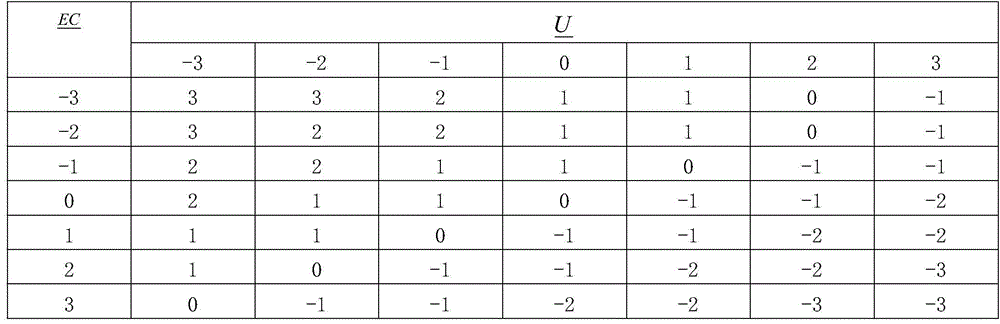

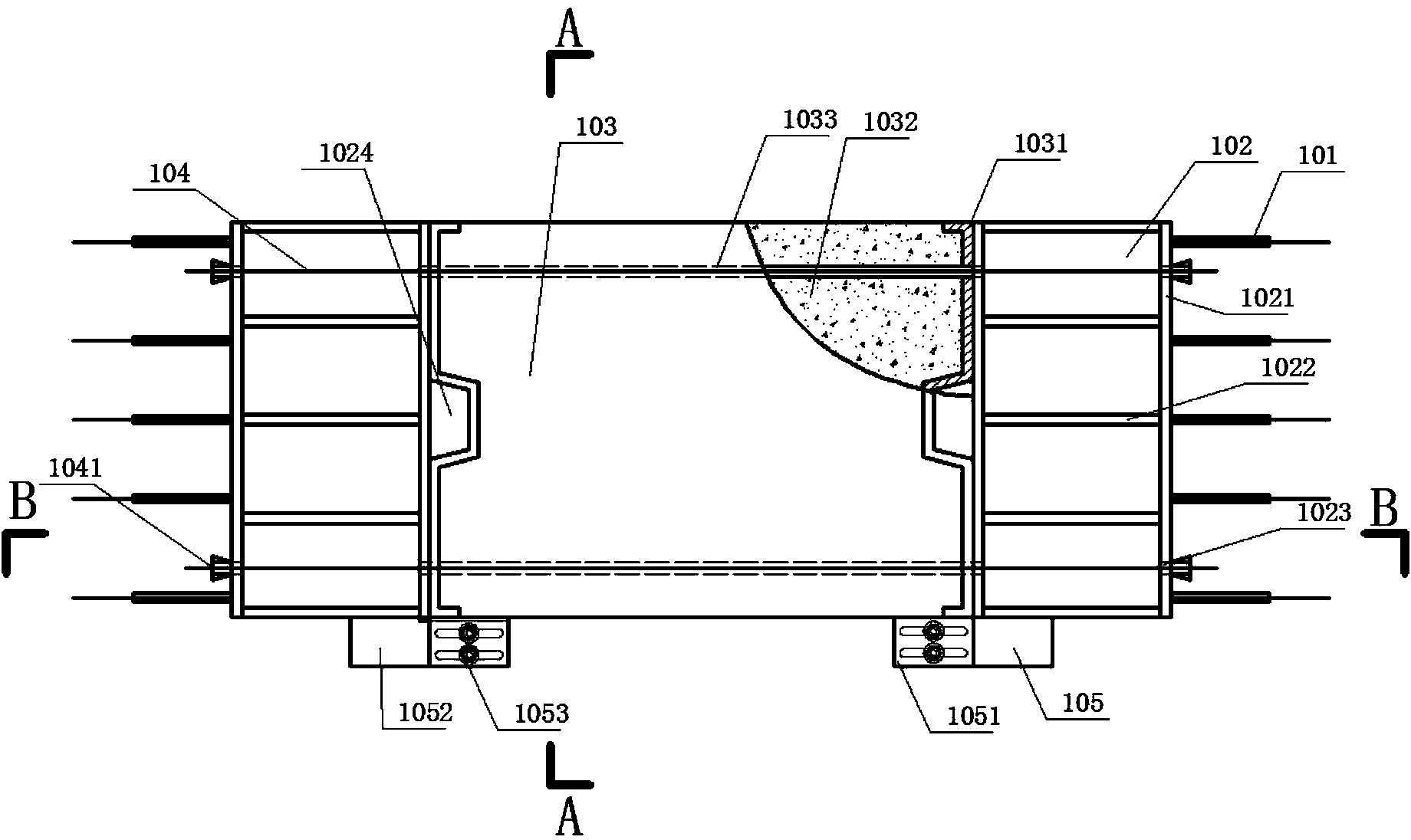

Temperature control method based on fuzzy self-adaptive controller

InactiveCN103941584AHeating evenlyPrecise temperature controlAdaptive controlTemperature controlFuzzy control system

The invention discloses a temperature control method based on a fuzzy self-adaptive controller. The temperature control method is realized via the fuzzy self-adaptive controller, a three-phase voltage-regulating module, a heating module and a temperature sensor. The fuzzy self-adaptive controller is composed of generalized prediction control and fuzzy control. The fuzzy self-adaptive controller is generated via combination of the generalized prediction control and the fuzzy control. The generalized prediction control or the fuzzy control are selected by the fuzzy self-adaptive controller to realize flexible control of a heating system according to different error situations of the system so that heating is more uniform, temperature control is more accurate and thus industrial production efficiency is enhanced.

Owner:NORTHWEST A & F UNIV

Novel self-reset friction damper

ActiveCN104032848AOvercome existing shortcomingsAvoid disadvantagesShock proofingPull forceReinforced concrete

The invention discloses a novel self-reset friction damper, and belongs to the technical field of energy dissipation and shock absorption of civil engineering structures. The structure of the damper is that the two sides of an outer covering steel plate concrete connecting section are respectively provided with a profile steel connecting section; anchoring steel bars are welded to the outer sides of the profile steel connecting sections, and are poured in a reinforced concrete main structure simultaneously; the bottom ends of the outer covering steel plate concrete connecting sections and the bottom ends of the profile steel connecting sections are connected through friction energy dissipation plates; the outer covering steel plate concrete connecting sections are connected with the profile steel connecting section on one side or the profile steel connecting sections on the two sides through a plurality of prestressed cables. When the main structure deforms under seismic excitation, the prestressed cables anchored on the outer sides of profile steel are extended, and self-reset tension force is provided; meanwhile, the friction energy dissipation plates connected between the profile steel and the concrete connecting sections deform relatively, seismic energy is dissipated, and energy dissipation and shock absorption are achieved.

Owner:TSINGHUA UNIV

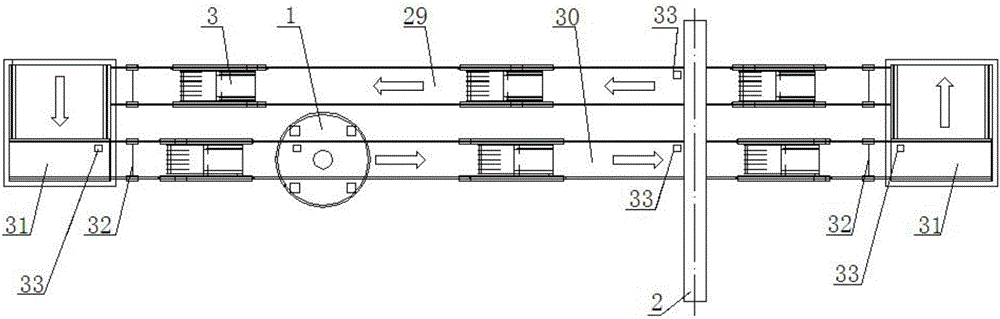

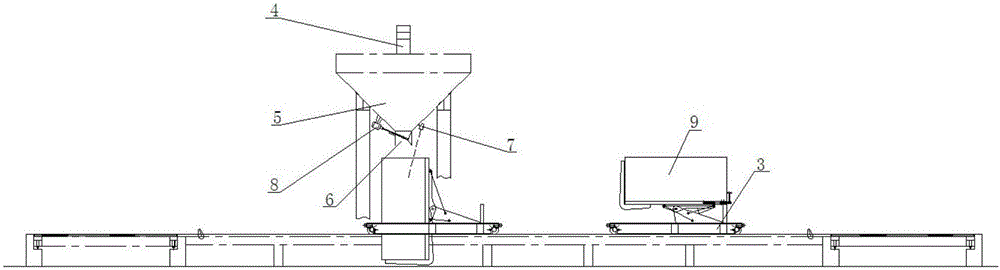

Lump coal boxing system and boxing method thereof

ActiveCN104986582AImprove dumping efficiencyAchieve brokenControl devices for conveyorsLoading/unloadingControl systemMechanical engineering

The invention discloses an automated lump coal boxing system and a boxing method thereof. A control system in the automated lump coal boxing system is connected with overturning trolleys (3) and trolley moving tables (31) respectively, detecting switches (33) are uniformly distributed on the trolley moving tables (31) in the lump coal boxing system, an empty trolley line (29) and a boxing line (30)which are under a hoisting device (2), and the boxing line (30) under a feeding mechanism (6), and the detecting switches (33) are connected with the control system; a hopper position detecting device (7) and a door opener (8) are arranged on a hopper (5) of a hopper device (1), and the hopper position detecting device (7) and the door opener (8) are respectively connected with the control system. The boxing method disclosed by the invention comprises the following steps: charging lump coal; controlling the overturning trolleys (3) to travel and overturn; and enabling a container (9) to be hoisted and placed to a transporting vehicle by the hoisting device (2). Through the adoption of the automated lump coal boxing system and the boxing method thereof, the overturning efficiency and the dismounting efficiency of the container are improved, and large-scale industrial production can be realized.

Owner:WUHAN POWER EQUIP WORKS

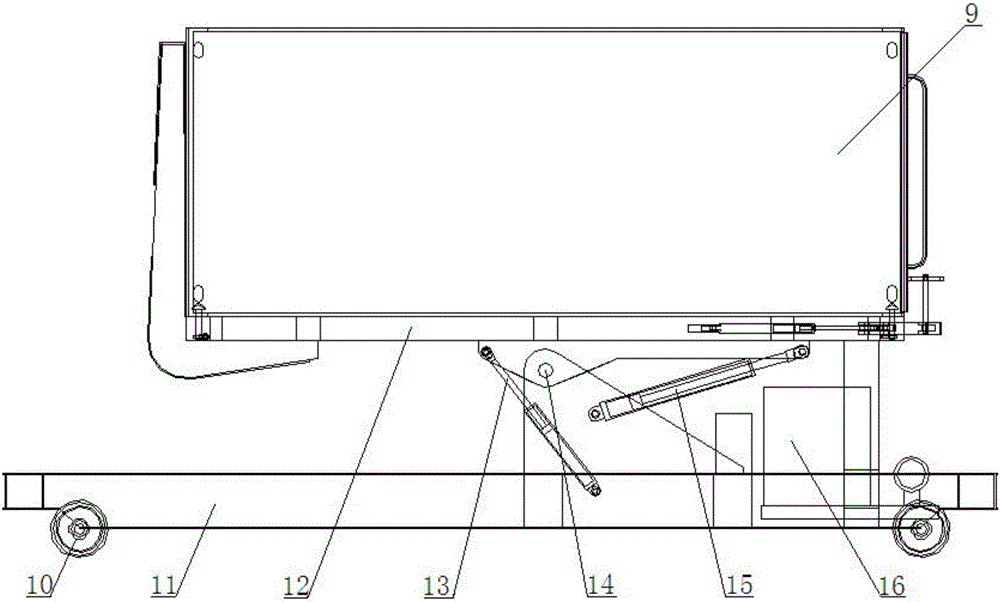

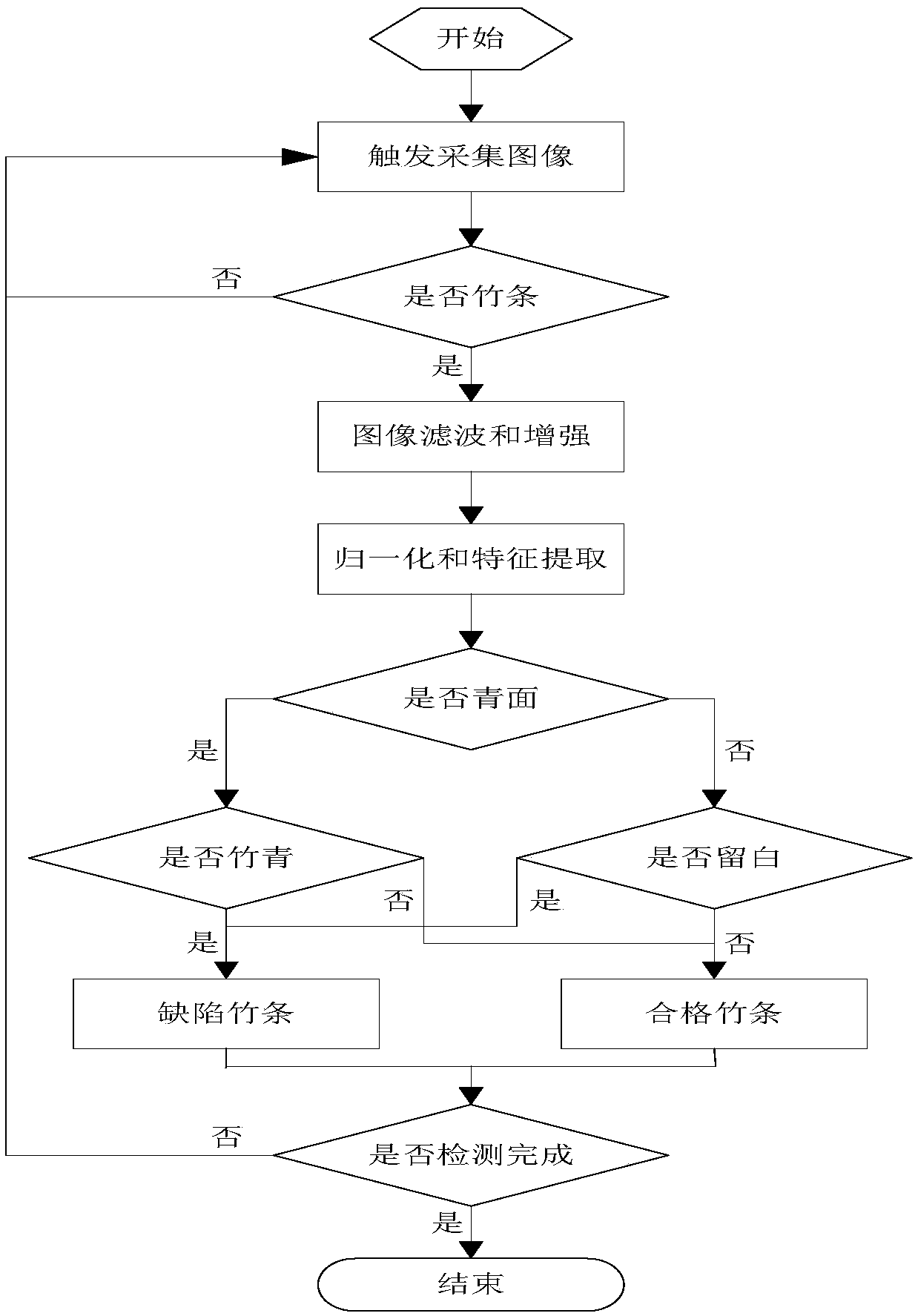

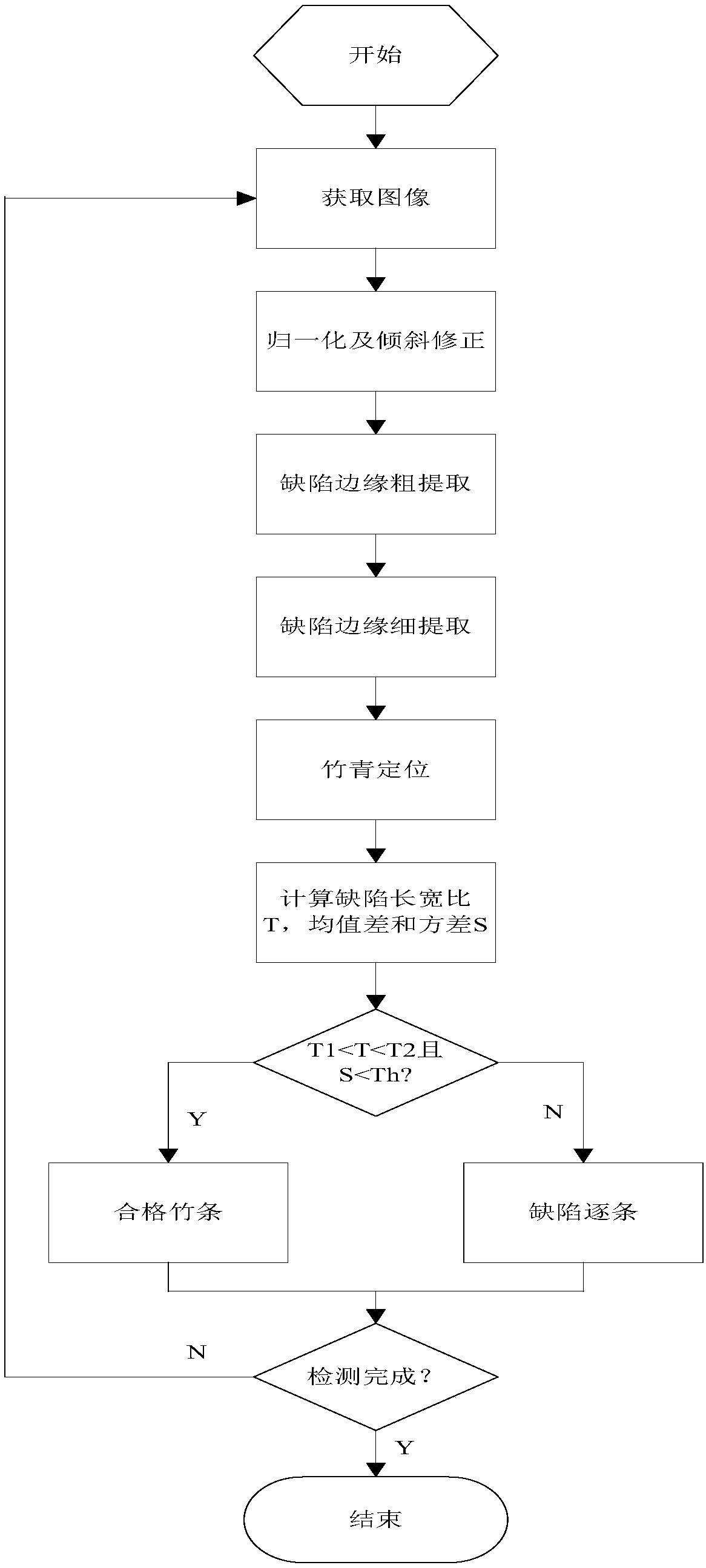

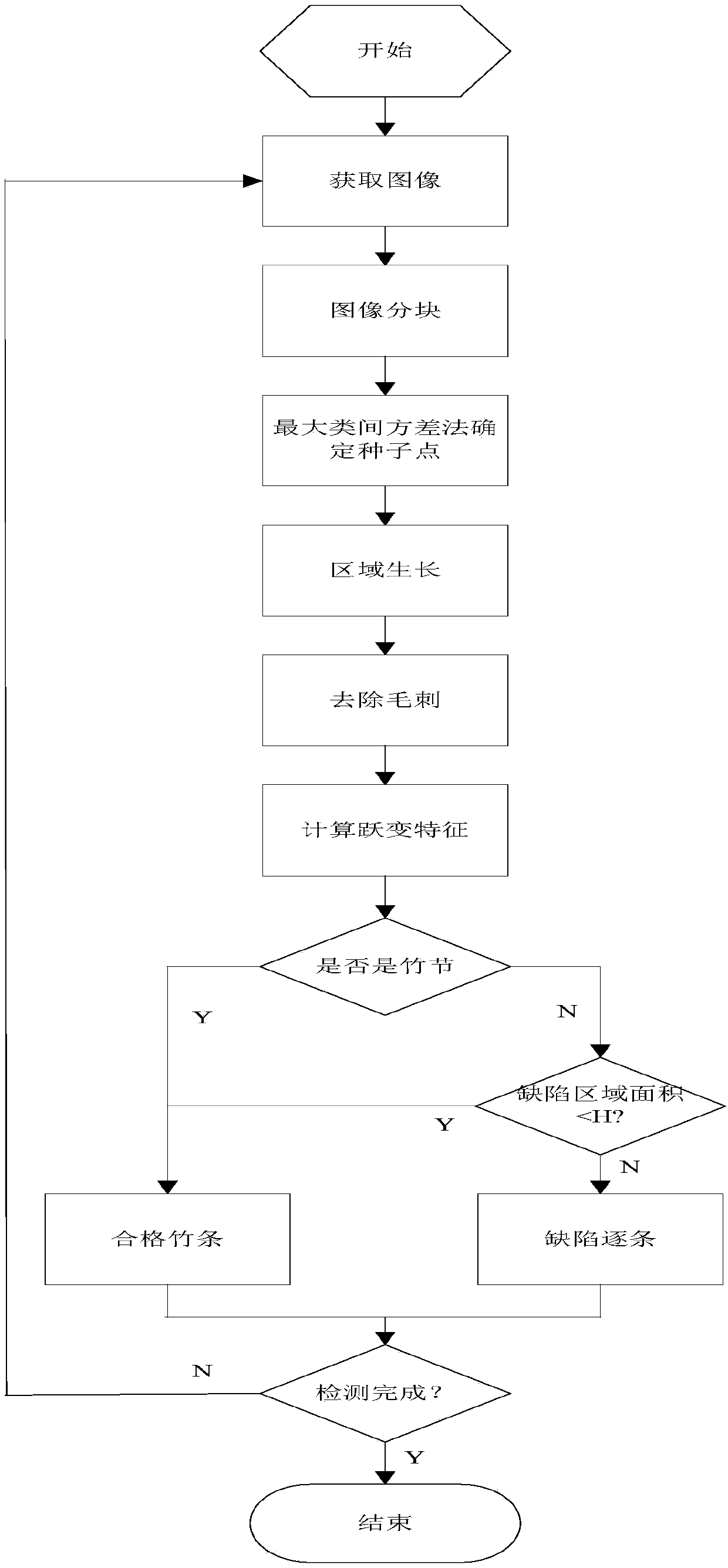

Machine vision based bamboo strip defect detection method

ActiveCN108181316AAvoid slow recognitionQuick classificationImage enhancementInvestigation of vegetal materialFeature extractionMachine vision

The invention provides a machine vision based bamboo strip defect detection method which comprises the following steps of S1, establishing a neural network structure used for bamboo strip recognitionto obtain a recognition model used for recognizing the yellow-green face of a bamboo strip; S2, collecting an original image of the bamboo strip to be detected; S3, performing normalized processing onthe original image of the bamboo strip to be detected; S4, performing feature extraction on image data after normalized processing; and S5, inputting features extracted in the step S4 into the recognition model in the step S1, judging the condition of the yellow-green face of the bamboo strip image, and performing defect detection of bamboo greenness and left blank according to a judgment resultrespectively. The invention provides the machine vision based bamboo strip defect detection method which can rapidly recognize and classify the bamboo strip. The machine vision based bamboo strip defect detection method is simple and feasible, can relatively rapidly realize effective detection of the bamboo strip under the condition of invariable illumination condition, increases the automation degree of bamboo product processing and improves the industrial production efficiency.

Owner:GUANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com