Hot stamping method for performance gradient distribution of high-strength steel parts

A high-strength, high-component technology, applied in the field of hot stamping, can solve problems such as part deformation, achieve the effects of reducing difficulty, high production efficiency, and improving elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

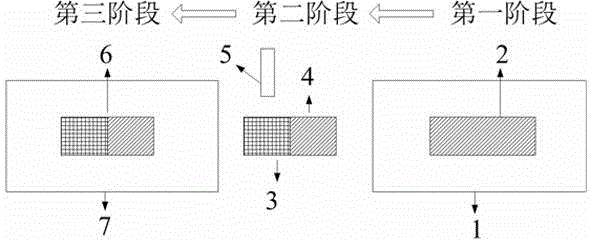

[0028] Such as figure 1 Shown, the present invention selects flowing medium to carry out partial quenching for use, and its specific implementation is as follows:

[0029] 1. The hot-rolled, cold-rolled or annealed sheet for hot stamping first enters the heating furnace I and is heated until it is completely austenitized (such as figure 1 ,The first stage);

[0030] 2. After the heating is completed, a flow medium injection device (which can spray water, nitrogen and other fluid medium) is used to locally cool down to below the Ms point (such as figure 1 In the second stage, use room temperature water for quenching, and quench to room temperature (about 25°C) within 5s.

[0031] 3. The non-uniform sheet enters the heating furnace II for heating and heat preservation (such as figure 1 In the third stage, in the furnace at 930°C, the heating time is 55s).

[0032] 4. The non-uniform sheet metal after heat preservation is transferred to a press for hot stamping forming and qu...

example 2

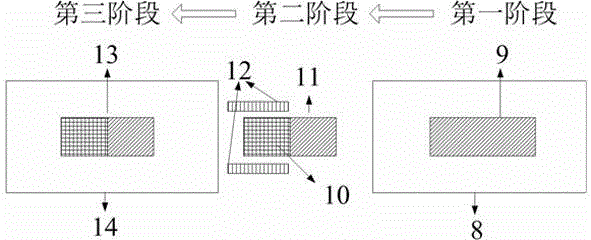

[0034] Such as figure 2 As shown, if the present invention selects non-flowing medium (die) for quenching, its specific implementation is as follows:

[0035] 1. The hot-rolled, cold-rolled or annealed sheet for hot stamping first enters the heating furnace I and is heated until it is completely austenitized (such as figure 2 ,The first stage);

[0036] 2. After the heating is completed, the temperature of the flat mold with cooling water under the press is partially cooled to below the Ms point (such as figure 2 In the second stage, the temperature of the mold surface is room temperature 25°C, the pressure is maintained for 10s, and the temperature of the sheet metal is lowered to about 150°C).

[0037] 3. Non-uniform sheets enter the heating furnace II for heating or heat preservation (such as figure 2 In the third stage, in the 930°C holding furnace, the holding time is 45s).

[0038] 4. The non-uniform sheet metal after heat preservation is transferred to a press f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com