Method for carbonizing and activating waste concrete recycled micro powder by wet process and application of regenerated micro-powder

A technology of waste concrete and recycled micropowder, applied in cement production and other directions, can solve problems such as low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

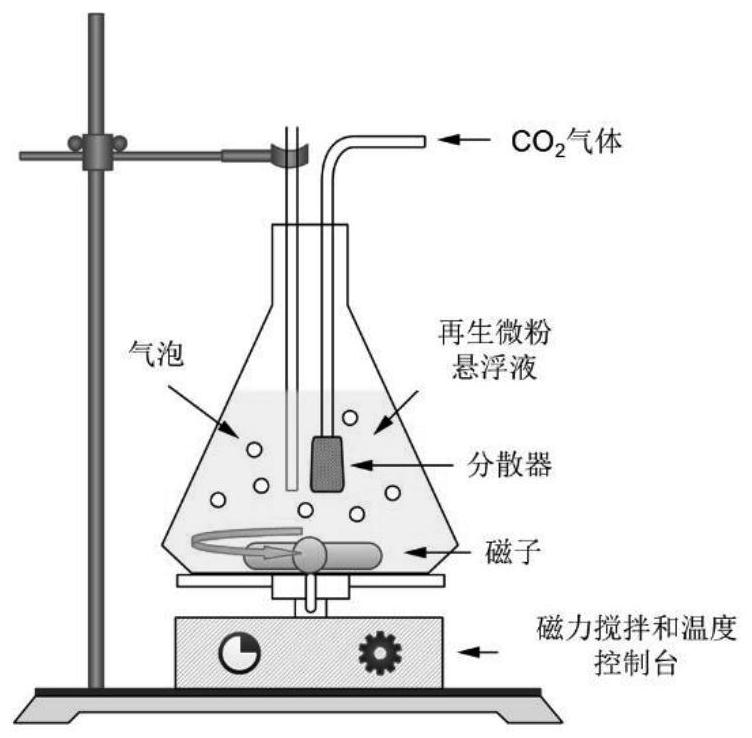

[0040] A method for wet carbonization to activate waste concrete regenerated micropowder, comprising the following steps:

[0041] (1) After the waste concrete is crushed and screened, the regenerated micropowder with a particle size of less than 150 microns is collected, and the regenerated micropowder is added to water to form a mixed slurry with a concentration of 90 g / L. The water temperature is 20° C., and the stirring speed is 500 r / min;

[0042] (2) then pass into the industrial waste gas containing carbon dioxide in the mixed slurry formed in step (1), this industrial waste gas is the industrial waste gas of chemical industry, wherein the carbon dioxide volume fraction is 95%, and the ventilation rate of this industrial waste gas It is 0.2L / min / g, and the ventilation time is 10 minutes. During this process, the carbonization reaction between the regenerated micropowder and carbon dioxide occurs;

[0043] (3) Filtrating and drying the mixed slurry after the carbonizatio...

Embodiment 2

[0046] A method for wet carbonization to activate waste concrete regenerated micropowder, comprising the following steps:

[0047] (1) After crushing and screening the waste concrete, regenerated micropowder with a particle size of less than 150 microns is obtained, and the regenerated micropowder is added to water to form a mixed slurry with a concentration of 90 g / L. The water temperature is 20° C., and the stirring speed is 500 r / min;

[0048] (2) then pass into the industrial waste gas containing carbon dioxide in the mixed slurry formed in step (1), this industrial waste gas is the industrial waste gas of _ chemical industry, wherein the carbon dioxide volume fraction is 95%, and the ventilating of this industrial waste gas The rate is 0.2L / min / g, and the aeration time is 20 minutes. During this process, the carbonization reaction between the regenerated micropowder and carbon dioxide occurs;

[0049] (3) After the carbonization reaction in step (2) is completed, the mixe...

Embodiment 3

[0052] A method for wet carbonization to activate waste concrete regenerated micropowder, comprising the following steps:

[0053] (1) After crushing and screening waste concrete, regenerated micropowder with a particle size of less than 150 microns is obtained, and the regenerated micropowder is added to water to form a mixed slurry with a concentration of 60 g / L. The water temperature is 20° C., and the stirring speed is 300 r / min;

[0054] (2) then pass into the industrial waste gas containing carbon dioxide in the mixed slurry formed in step (1), this industrial waste gas is lime kiln industrial flue gas, wherein the carbon dioxide volume fraction is 37%, and the ventilation rate of this industrial waste gas It is 0.3L / min / g, and the ventilation time is 30 minutes. During this process, the carbonization reaction between the regenerated micropowder and carbon dioxide occurs;

[0055] (3) After the carbonization reaction in step (2) is completed, the mixed slurry is filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com