Patents

Literature

32results about How to "Easy to achieve continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

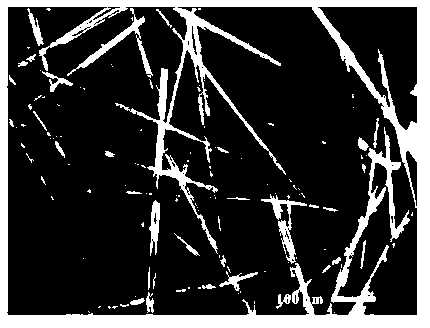

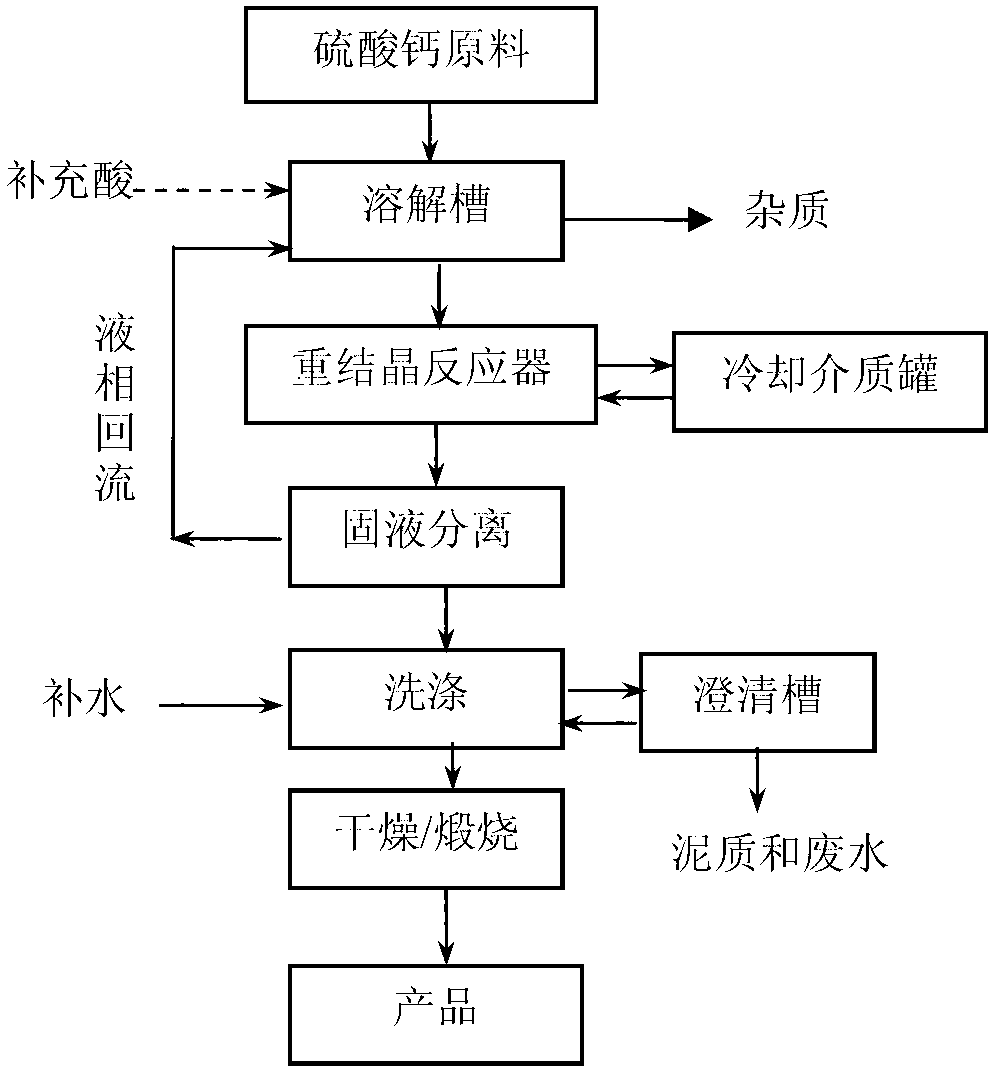

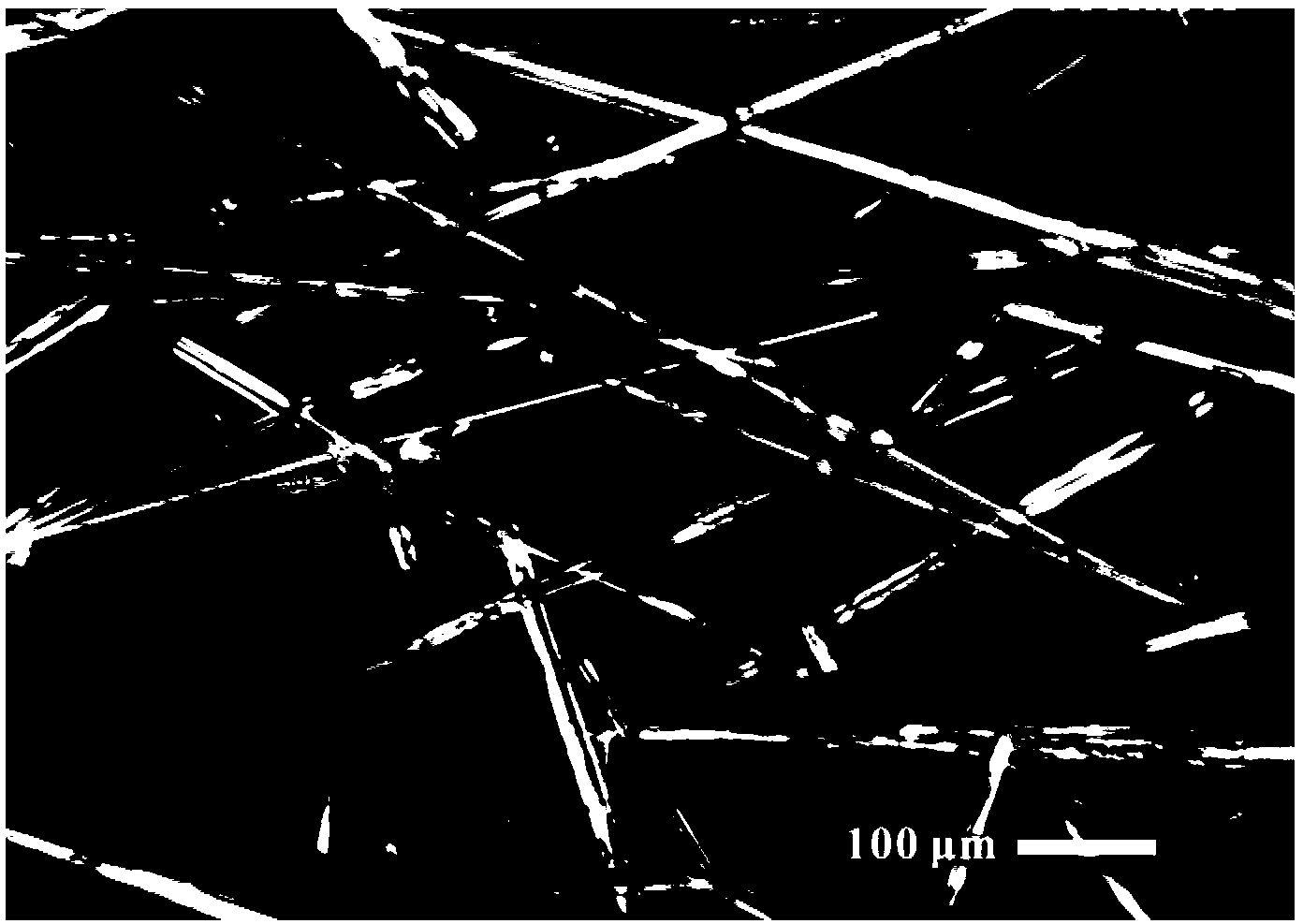

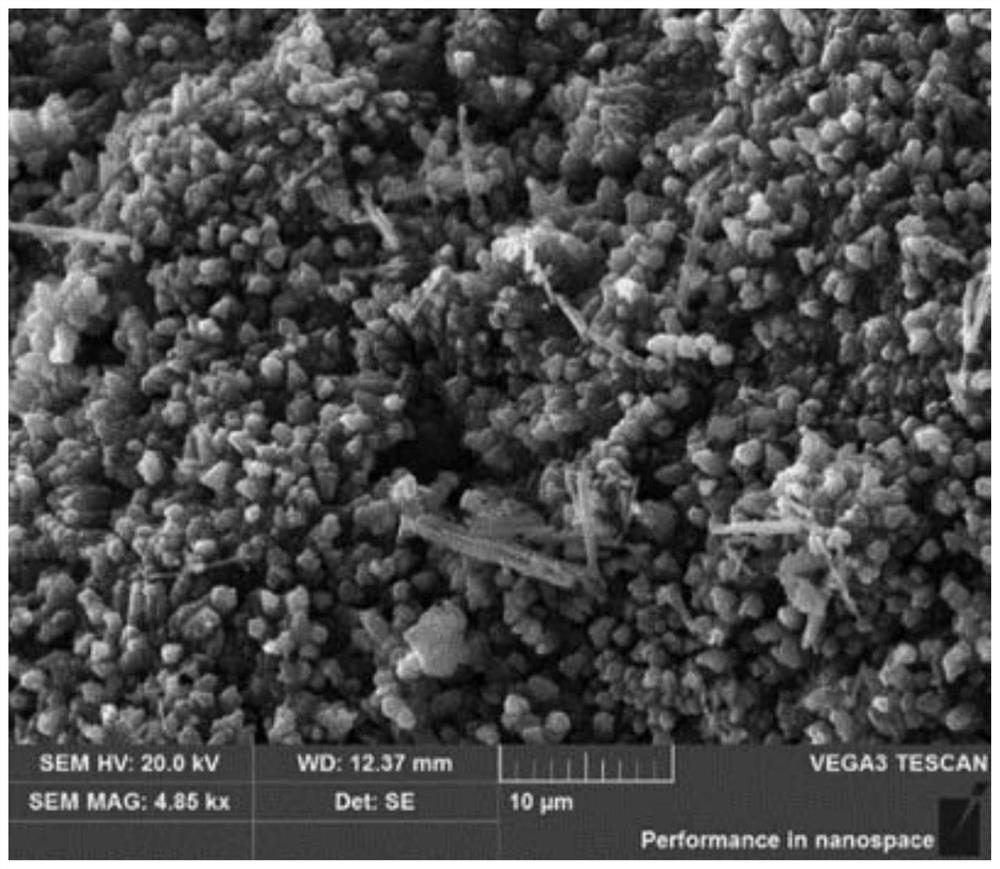

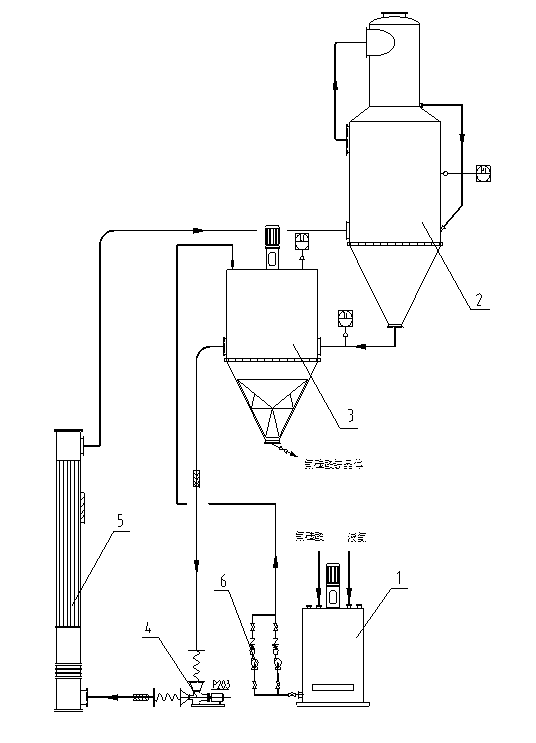

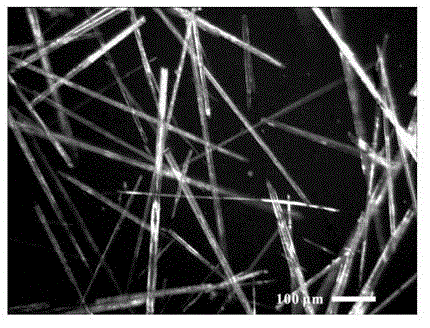

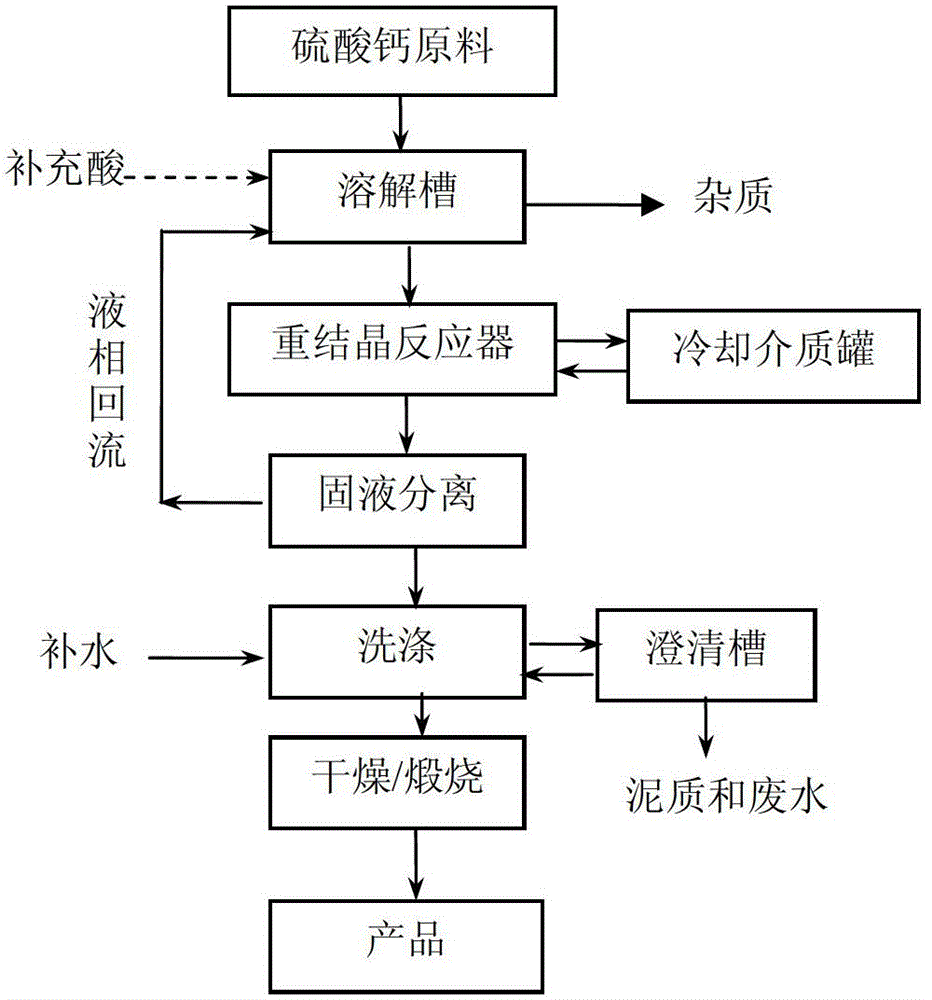

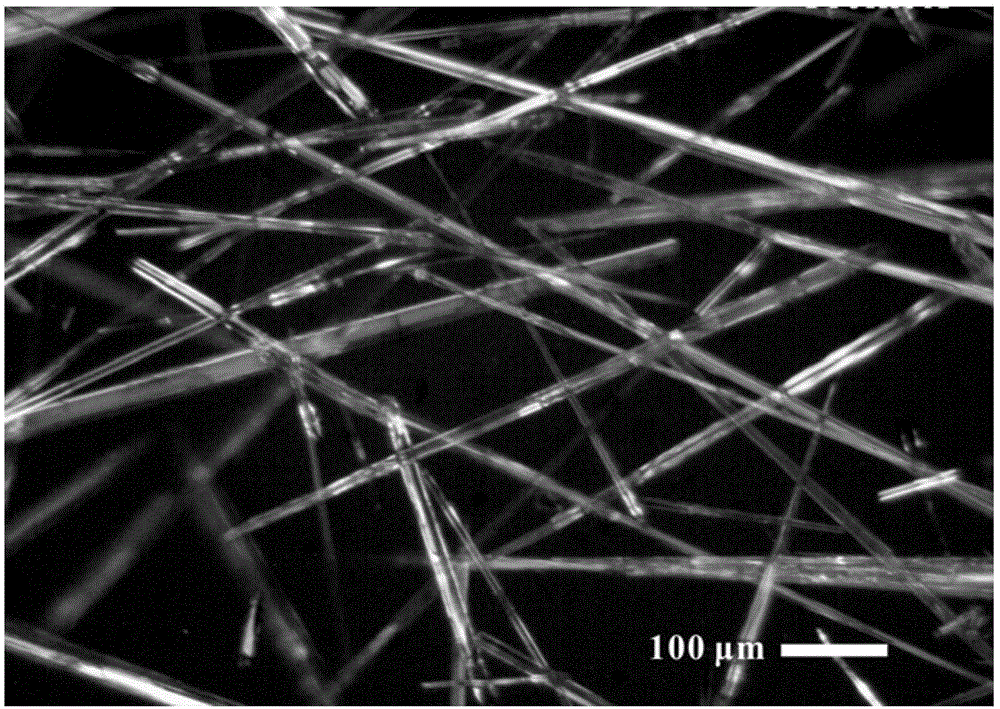

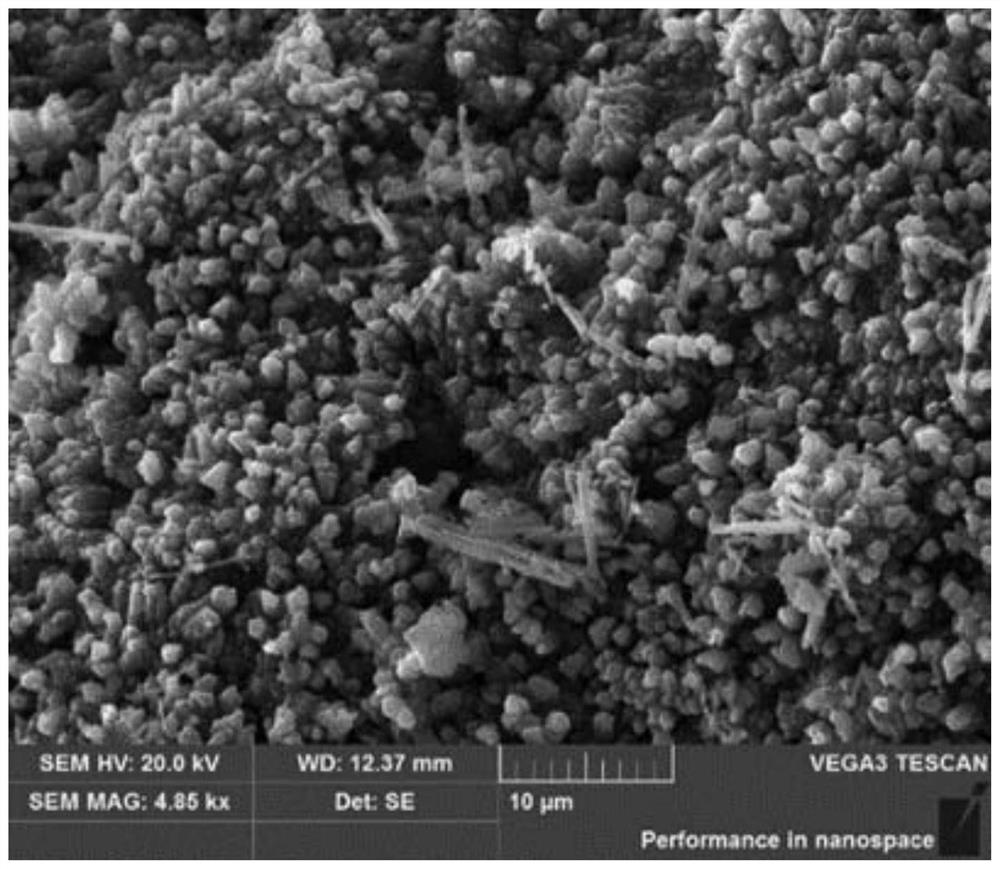

Method for preparing calcium sulfate whisker through recrystallization

ActiveCN103074667AReliable principleSimple technical processPolycrystalline material growthFrom normal temperature solutionsSolid phasesChemistry

The invention discloses a method for preparing a calcium sulfate whisker through recrystallization. The method is characterized in that the method comprises the steps of (1), conducting program control on heating and dissolution courses: putting a raw material with a main ingredient of calcium sulfate into a sulphuric acid solution for stirring, heating simultaneously, heating a mixture to 60-95 DEG C at a certain rate with the adoption of the program control, dissolving for 20min-1h, (2), conducting the program control on cooling and recrystallization courses: using the program control to cool a suspension obtained by dissolution to 10-30 DEG C, ageing for 20min-2h, (3), conducting separating and washing courses: conducting solid-liquid separation on the suspension, washing a separated solid-phase product, and (4), conducting a drying course: drying the washed solid-phase product at a certain temperature, and obtaining the calcium sulphate dihydrate whisker. The calcium sulfate whisker is prepared by utilizing a recrystallization principle under an ordinary-pressure mild condition, and a relatively economical technological approach can be provided for the resource utilization of industrial by-products such as desulfurization gypsum and phosphogypsum.

Owner:XIANGTAN UNIV

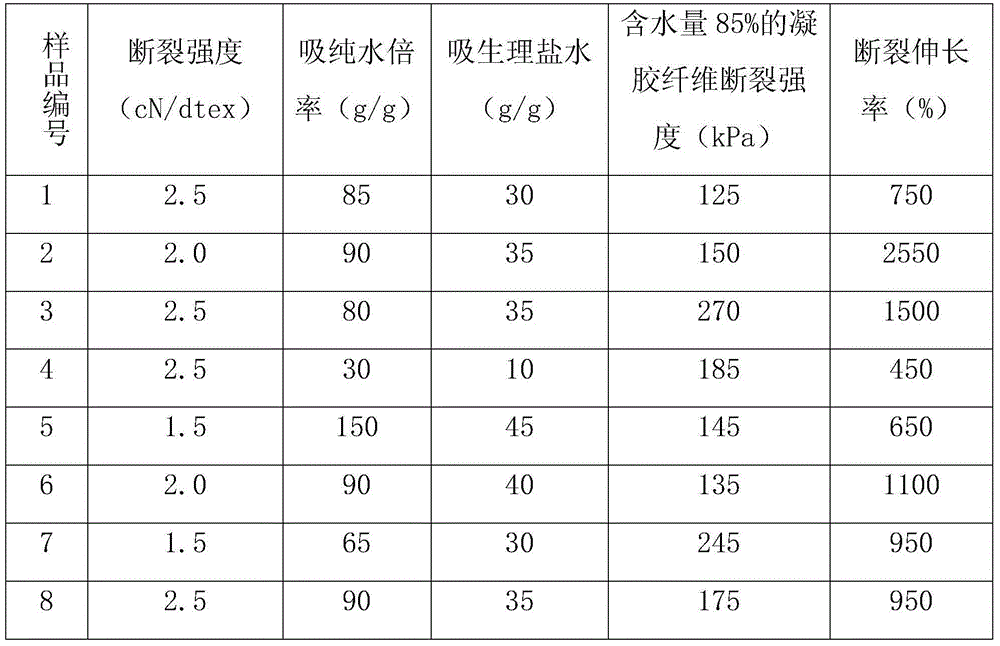

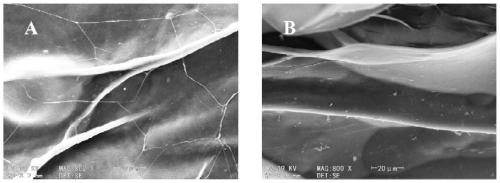

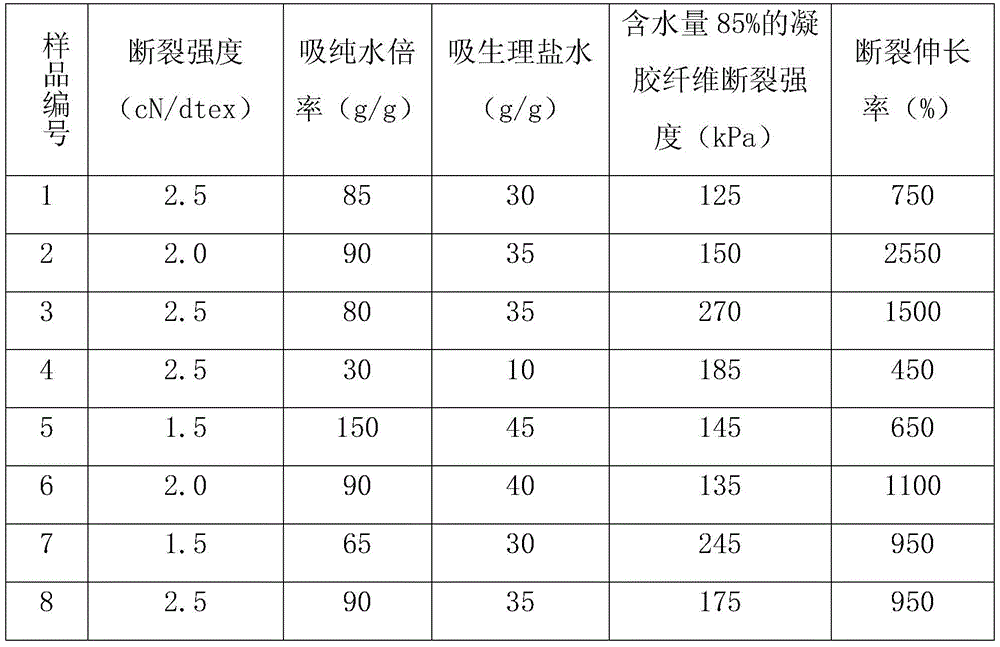

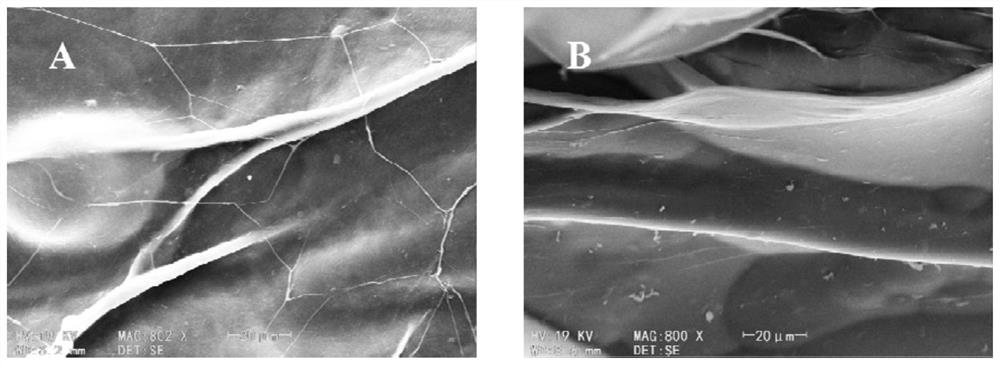

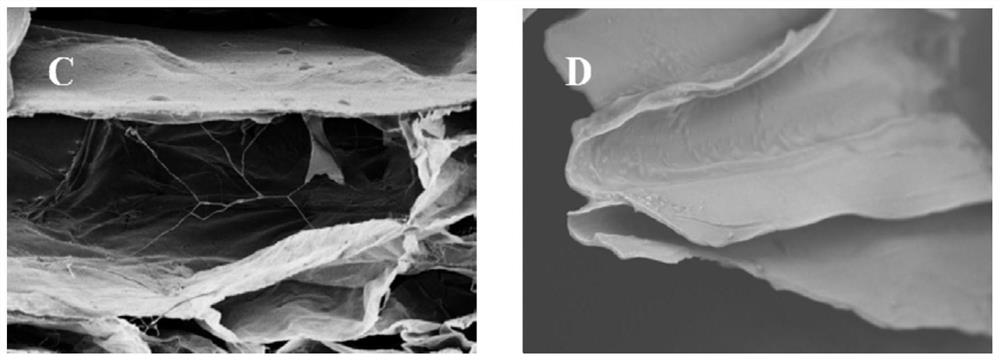

Preparation method of double-net hydrogel fiber and product thereof

ActiveCN104652119ALow priceReduce product costPhysical treatmentMonocomponent synthetic polymer artificial filamentWater solubleRadiation

The invention discloses a preparation method of a double-net hydrogel fiber and a product thereof. The preparation method mainly includes following steps: (1) preparation of a spinning raw solution: dissolving one or more water-soluble natural polysaccharides and a water-soluble acrylamide polymer in water with stirring uniformly, and performing filtration and defoaming to obtain a mixed spinning raw solution containing the natural polysaccharides and the acrylamide polymer; (2) preparation of a water-containing primary gel fiber: performing wet spinning, or dry-wet spinning or gel spinning to the mixed spinning raw solution prepared in the step (1), performing a spinning process at a preset speed, mixing the mixed spinning raw solution with a coagulating bath, to obtain the water-containing primary gel fiber; and (3) radiation crosslinking: drafting the primary gel fiber into an ionizing radiation apparatus and performing the radiation crosslinking to the primary gel fiber prepared in the step (2), and performing a subsequent drafting operation, a thermal-moulding operation, a winding-up operation and a fiber-cutting operation to obtain the double-net hydrogel fiber.

Owner:THE HONG KONG POLYTECHNIC UNIV

Method for preparing elemental silicon

The invention discloses a method for preparing elemental silicon. The method comprises the following steps of: dissolving SiO2 in an alkali metal or alkaline earth metal oxide-containing chloride molten salt, or dissolving alkali metal or alkaline earth metal silicate in the chloride molten salt, wherein the temperature of the chloride molten salt is 600 to 1,000 DEG C, electrolyzing by using graphite or silicon or a metal as a cathode and using graphite or an inert material as an anode to electrically deposit siliconic acid radicals at the cathode, and separating the electrodeposition to obtain the elemental silicon. In the method, the operation temperature is low; raw materials are cheap and available; the molten salt is stable; and the purity of the product is high. The process can be controlled through consistent current; continuous production is easy to be realized; the current efficiency is high; and the production energy consumption and cost of silicon can be obviously reduced.

Owner:WUHAN UNIV

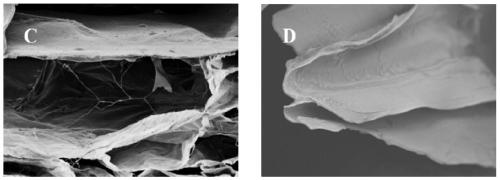

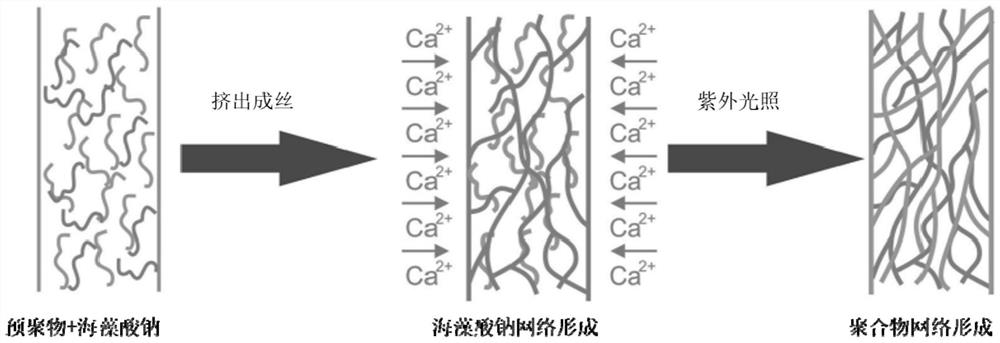

Konjac glucomannan glycosyl antibacterial hydrogel fiber and preparation method thereof

ActiveCN110067042AUniform structureStrong water absorptionConjugated artificial filamentsArtifical filament manufactureFiberBiocompatibility Testing

The invention discloses a konjac glucomannan glycosyl antibacterial hydrogel fiber and a preparation method thereof. The fiber comprises the following raw material components in parts by weight: 50-100 parts of konjac glucomannan polymerizable monomers, 100-800 parts of alginate, 10-20 parts of organic guanidine salt polymerizable monomers, 10000-40000 parts of deionized water and 0.1-5 parts of an initiator. The preparation method comprises the following steps: (1) preparing modified konjac glucomannan with double bonds on side groups and the organic guanidine salt polymerizable monomer; (2)preparing a spinning liquid; and (3) preparing a hydrogel fiber by using a two-step crosslinking method. The preparation method disclosed by the invention is simple and safe, low in cost, rich in material and good in experiment repeatability; no high-voltage electric field is used in the preparation process, no organic solvent is used, no pollution can be caused, cell damage can be avoided, and cell packaging can be achieved; the prepared hydrogel is not only uniform, controllable in size, high in mechanical property and good in water absorption performance, but also good in biocompatibility,and has an excellent antibacterial property and a wide application prospect, particularly in the field of sanitary materials.

Owner:DONGHUA UNIV

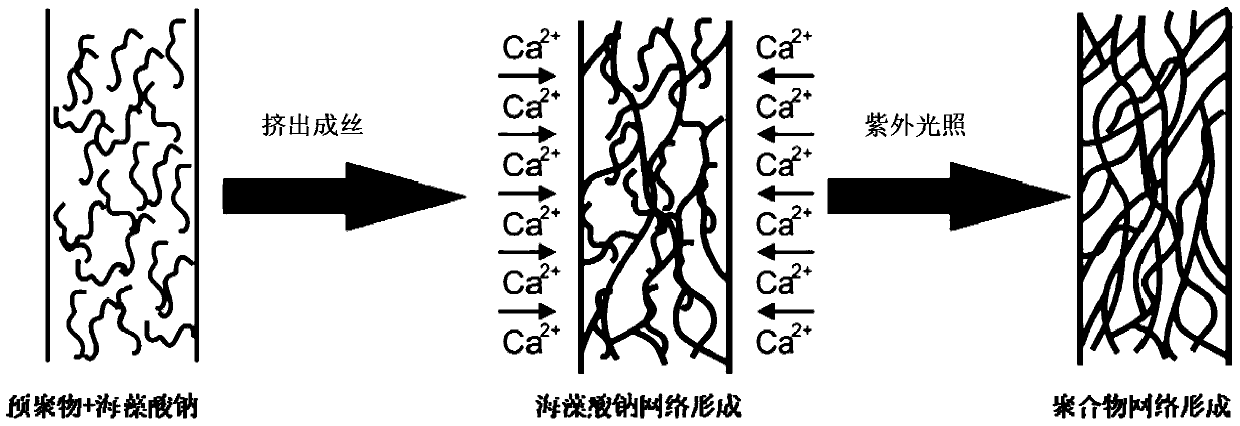

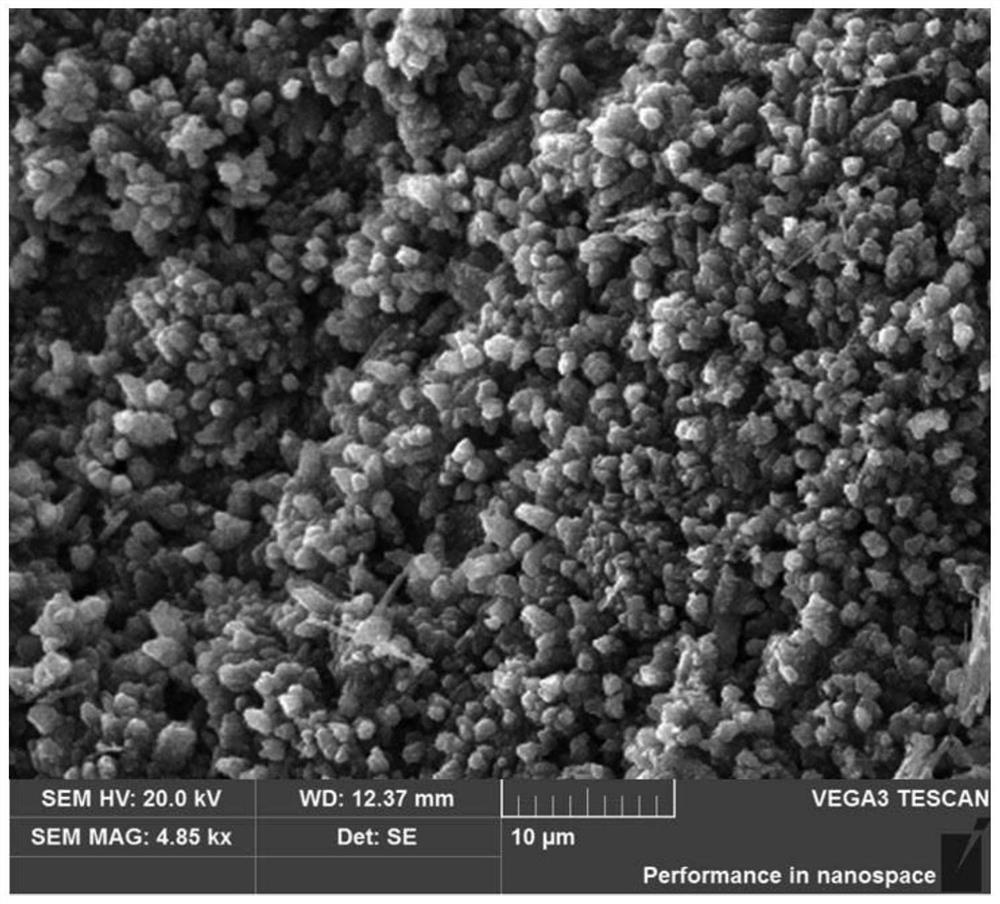

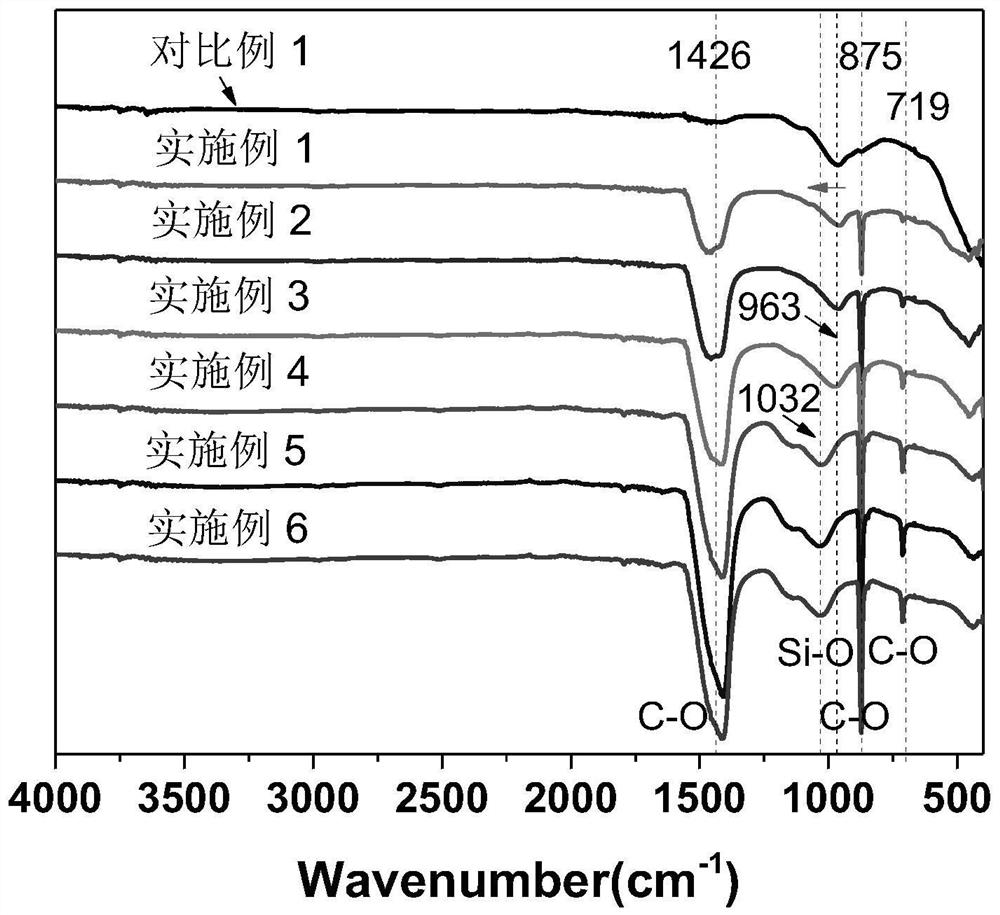

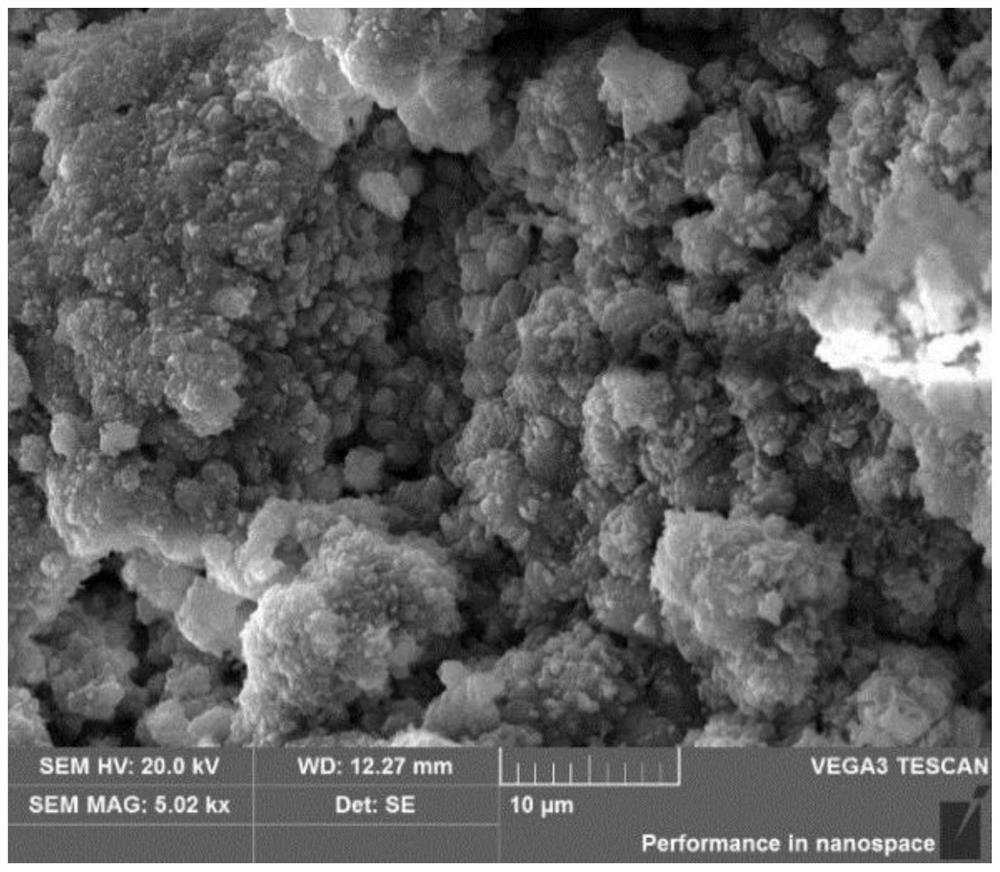

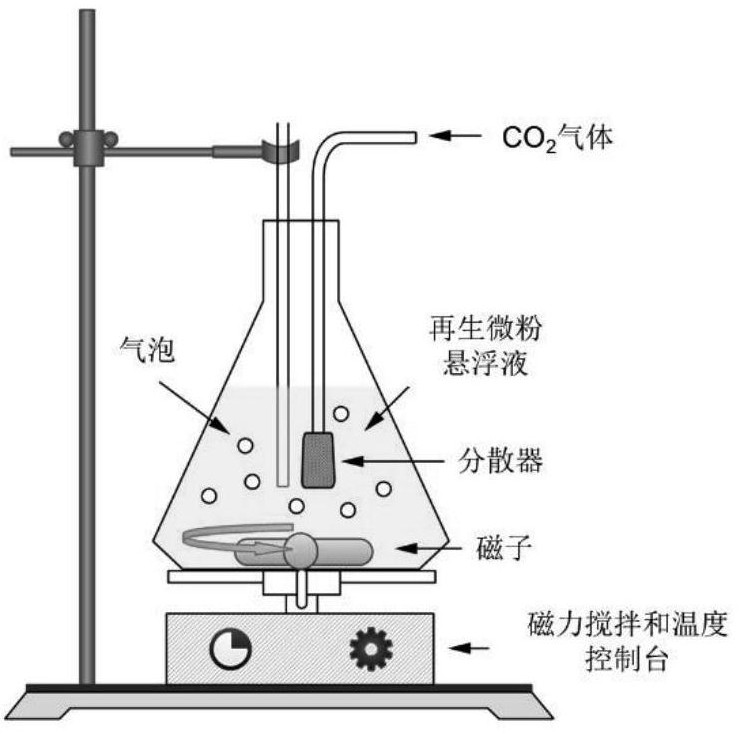

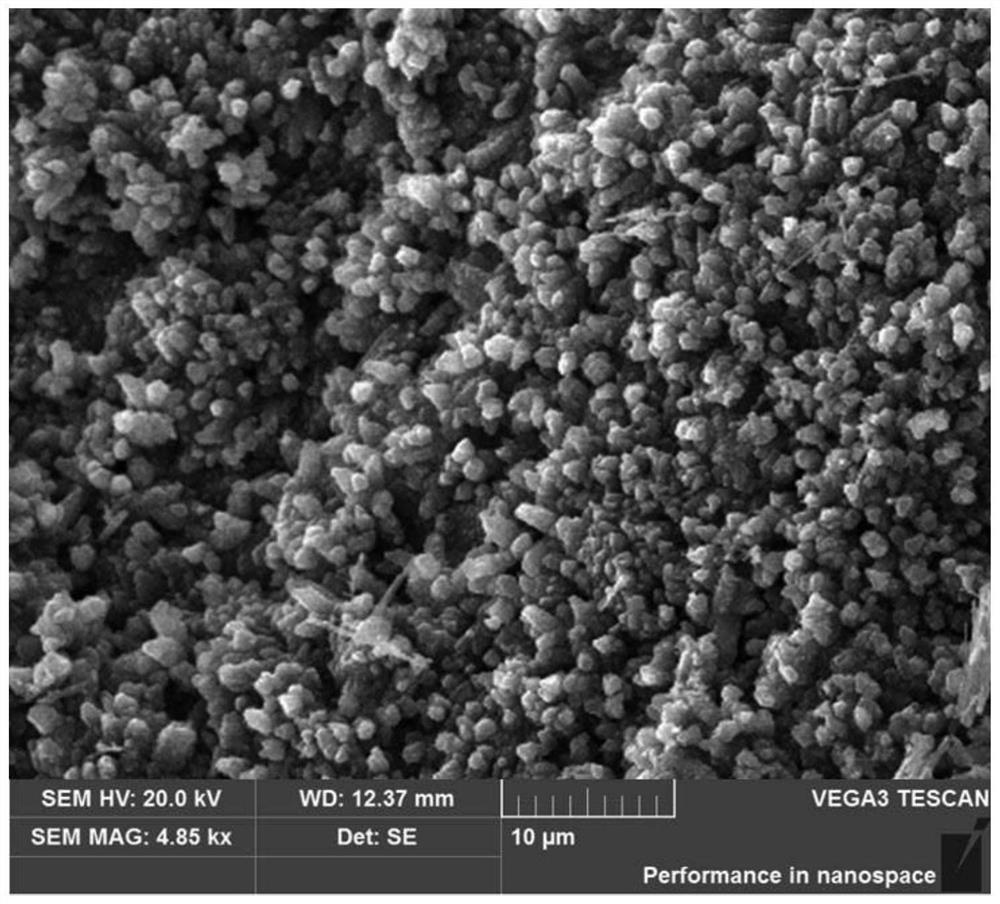

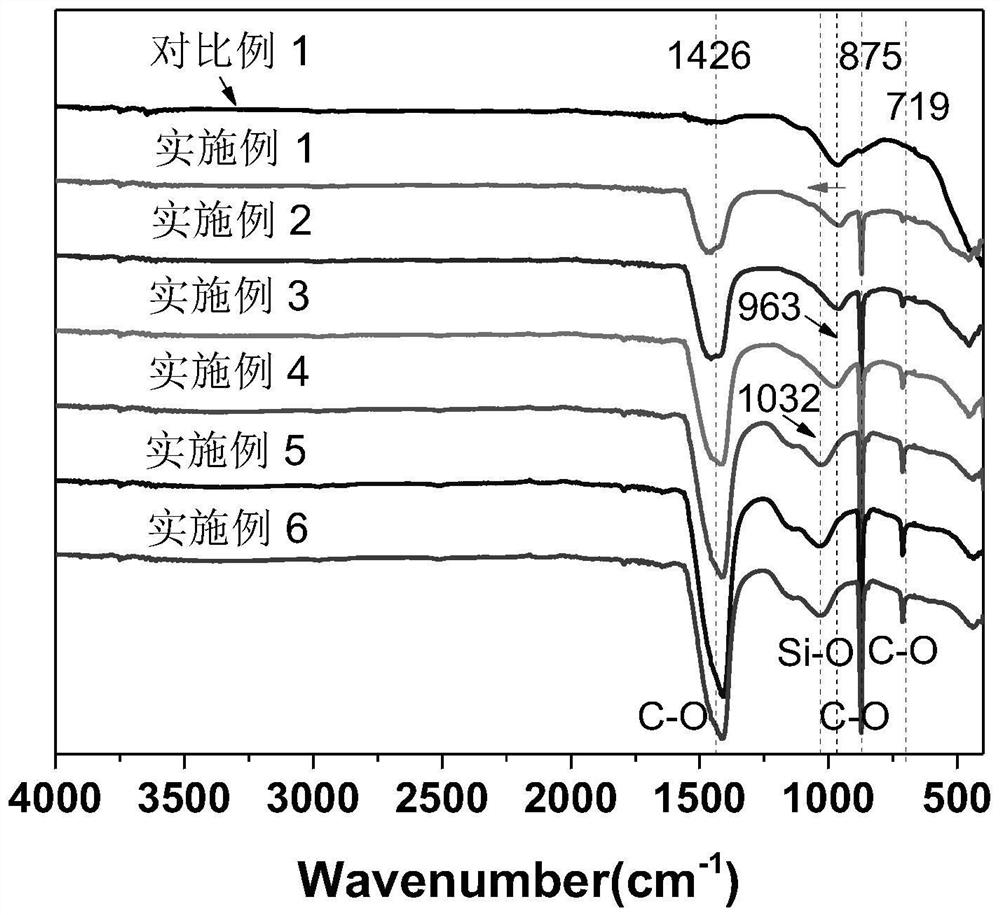

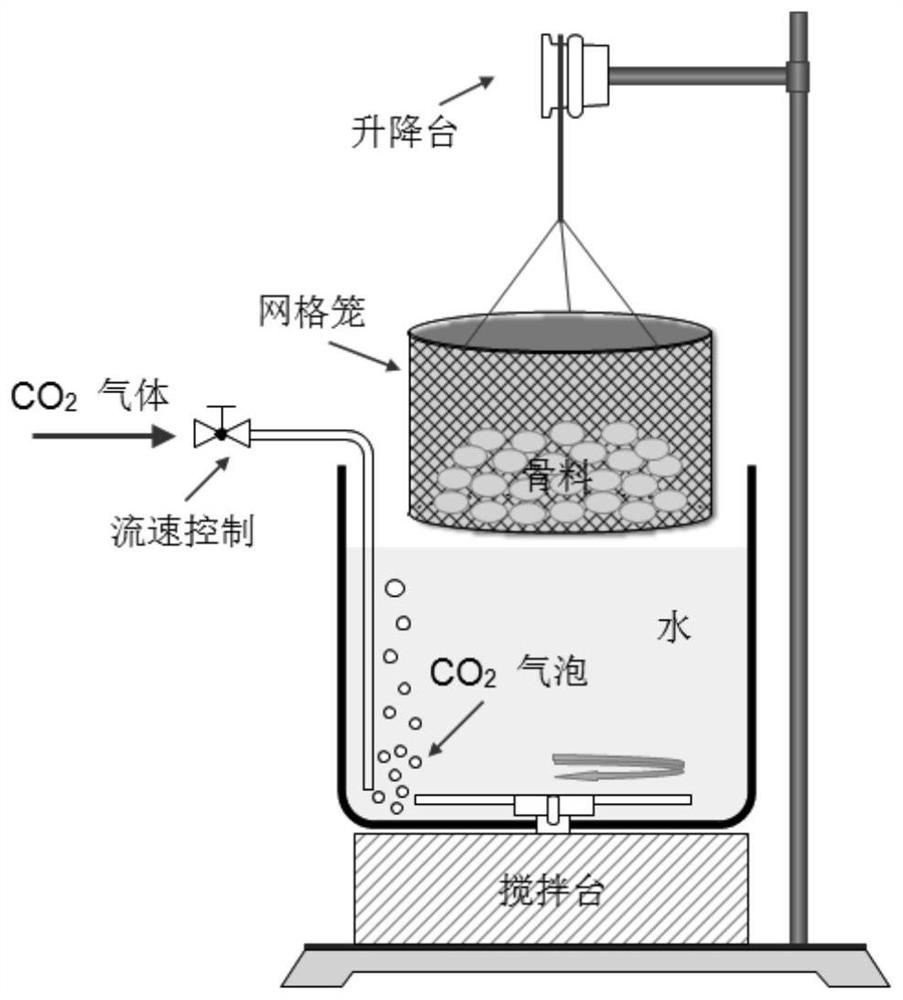

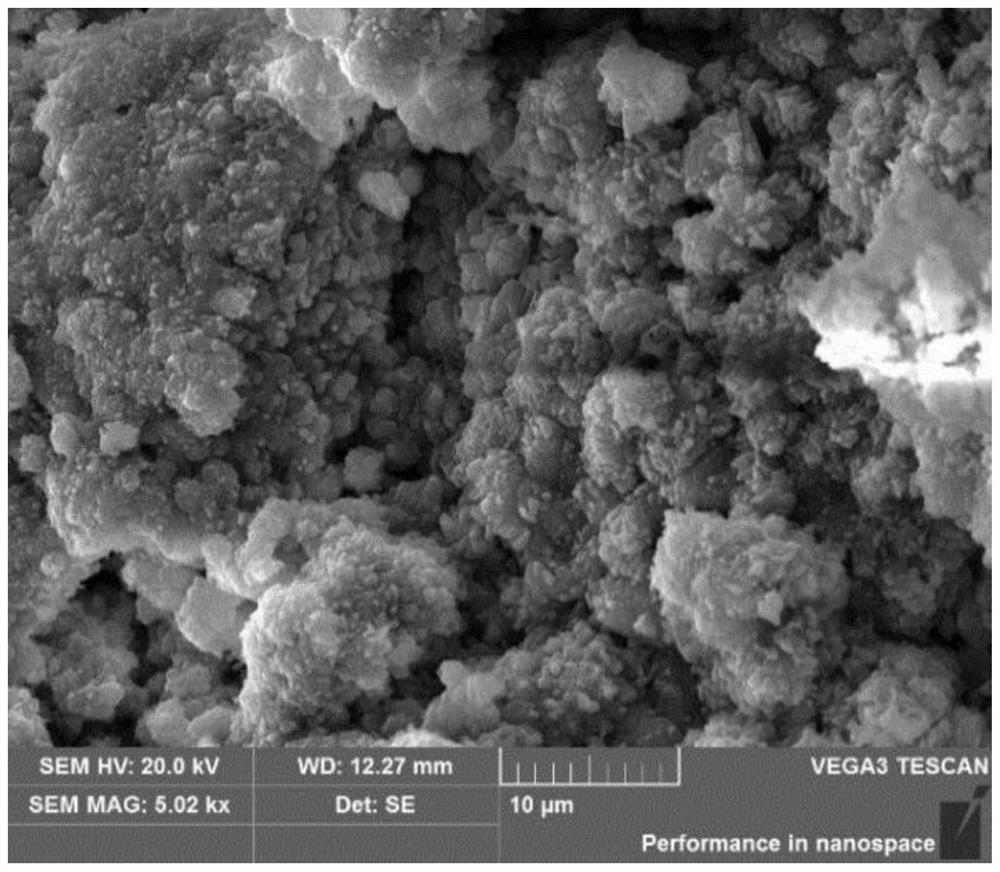

Method for carbonizing and activating waste concrete recycled micro powder by wet process and application of regenerated micro-powder

ActiveCN112125541AHigh activityEasy to achieve continuous productionCement productionSilica fumeIndustrial waste

The invention provides a method for carbonizing and activating waste concrete recycled micro powder by a wet process, which comprises the following steps of: taking powder generated in the process ofproducing recycled aggregate by crushing waste concrete as recycled micro powder, dispersing the recycled micro powder into water to form mixed slurry, and continuously introducing industrial waste gas containing carbon dioxide into the mixed slurry, in the process, carbon dioxide contained in the industrial waste gas and the regenerated micro powder are subjected to a carbonization reaction. According to the invention, the regenerated micro-powder is subjected to the carbonization reaction in an aqueous solution, the activity of calcium carbonate and silicon dioxide generated by carbonizationis higher, the volcanic ash activity is superior to that of common auxiliary cementing materials such as fly ash and silica fume, and the regenerated micro-powder can be used as an auxiliary cementing material.

Owner:HENAN POLYTECHNIC UNIV

Method for preparing refractory active metal or alloy

This invention relates to a method for preparation of refractory active metals or alloys, which comprises the following steps: selecting CaCl2 or mixed salt electrolyte mainly including CaCl2 as flux, coining or perfusing refractory active metals to be block-shaped, sintering them to get sintered cake, compounding sintered cake and liquid of conductive cathode group and making them as cathode, making graphite or inert electrode as anode; making electrolyzation voltage no lower than academic decomposition voltage of melted salt, and making electrochemical reduction carryed out on cathode, but not forming compact sedimentary deposit to prevent the touch of compounds and electrolyte, controlling electrolyzation temperature at 500-1000 degrees, controlling the electrolyzation time according to 1-4 times theoretical electrical energy demand, making sure inert atmosphere in electrolytic process; then getting refractory metals or alloys which is electrolyzation product. The invention has short flow of production, low energy consumption, little contamination, and is easy to product continuously.

Owner:WUHAN UNIV +1

Process for preparing lithium hexafluorophosphate by organic solvent method

InactiveCN102180457ARich sourcesReduce manufacturing costPhosphorus compoundsSolventLithium electrode

The invention discloses a process for preparing lithium hexafluorophosphate by adopting an organic solvent and solubilizer method. The process comprises the following steps of: reacting liquid anhydrous hydrofluoric acid with phosphorus pentachloride to generate phosphorus pentafluoride gas; reacting the phosphorus pentafluoride with lithium fluoride in an organic solvent dissolved with less solubilizer to generate lithium hexafluorophosphate; and filtering reaction slurry to obtain the residual lithium fluoride, cooling down a filtrate for crystallizing, filtering and vacuum drying to obtain a high-purity lithium hexafluorophosphate product. In the process for preparing the lithium hexafluorophosphate by adopting the organic solvent and solubilizer method disclosed by the invention, various raw materials are cheap and easy to obtain, and the production cost is low; the organic solvent with a few dissolved solubilizers is taken as a reaction medium, thus continuous production is easy to implement due to the reaction conditions, the reaction efficiency is high, the yield of the lithium hexafluorophosphate product is over 92%, and the purity of the lithium hexafluorophosphate product can reach more than 99.9%; in addition, the lithium hexafluorophosphate product prepared by the process disclosed by the invention is suitable for being used as an electrolyte of lithium ion batteries and the like.

Owner:CENT SOUTH UNIV +2

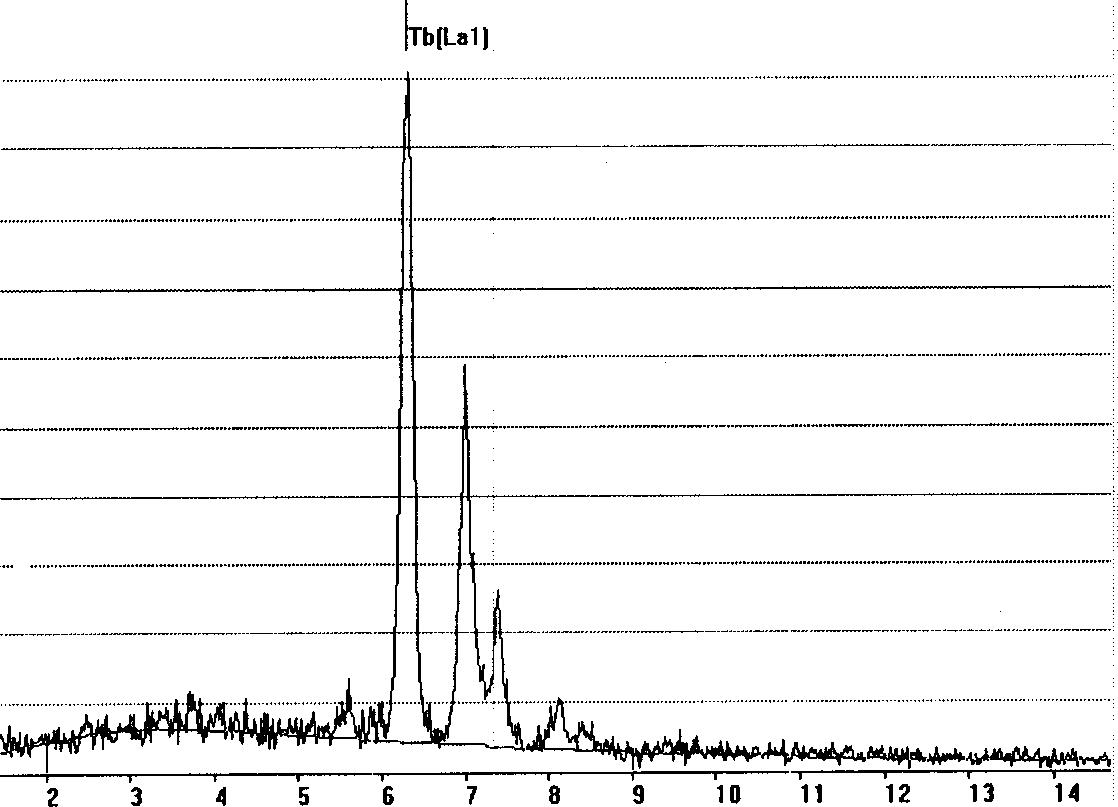

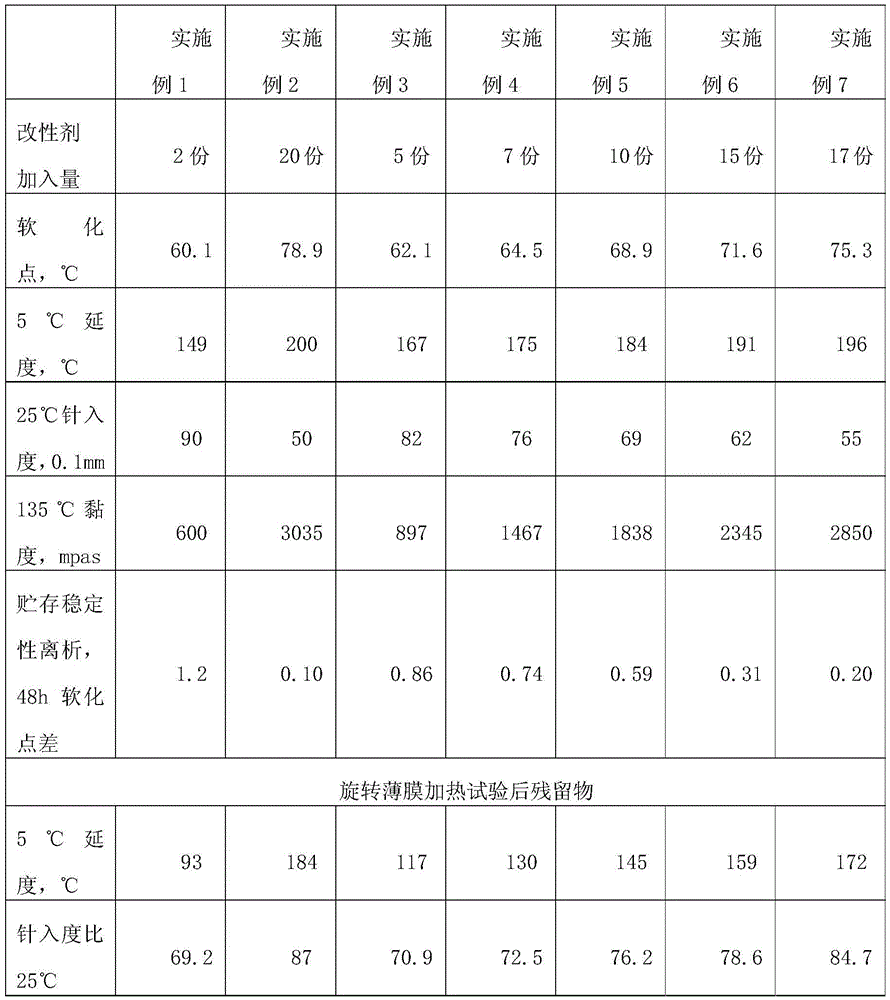

Method for preparing nanoclay/styrene-butadiene rubber powder modified asphalt by adopting spray drying method

The invention discloses a method for preparing nanoclay / styrene-butadiene rubber powder modified asphalt by adopting the spray drying method. The method comprises the following steps: preparing a clay suspension; preparing a mixed liquor of the clay suspension and butadiene-styrene latex; spray-drying the mixed liquor to prepare clay / butadiene-styrene rubber powder, so as to serve as an asphalt modifier; mixing the asphalt modifier with matrix asphalt according to a certain proportion, and shearing with a high speed shearing machine, so as to obtain the nanoclay / styrene-butadiene rubber compound modified asphalt. The preparation method provided by the invention is simple in process and low in cost, and at the same time the prepared compound modified asphalt has excellent high-and-low temperature performance and ageing resistance, and is also improved in the storage stability.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing silicon-calcium alloy

InactiveCN101979715ALower operating temperatureRaw materials are cheap and easy to getElectrolysisAlloy

Owner:WUHAN UNIV

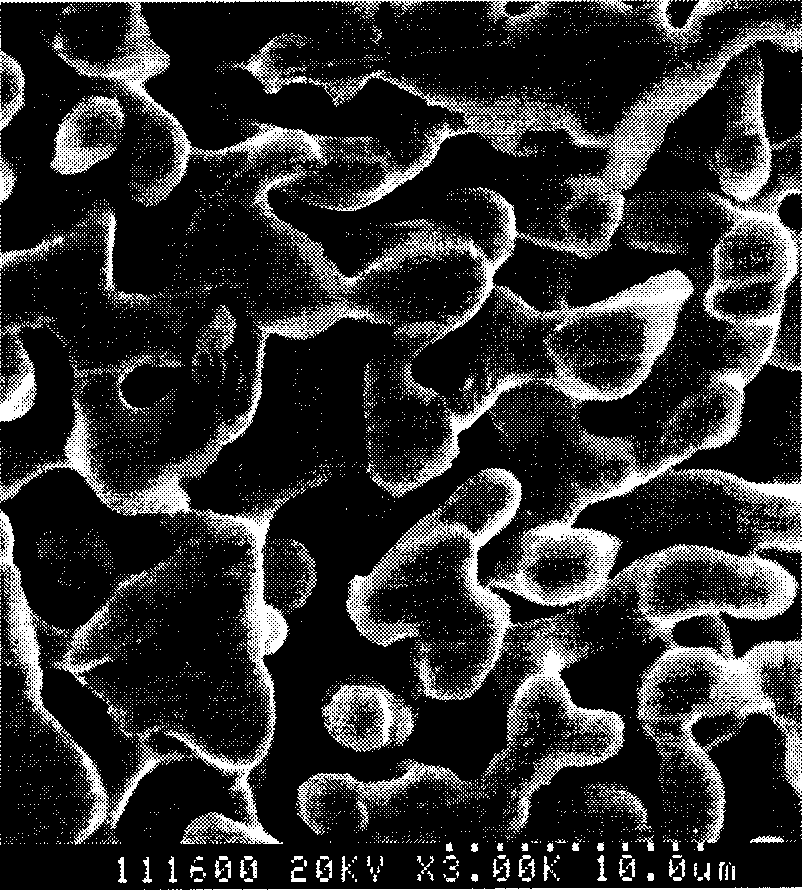

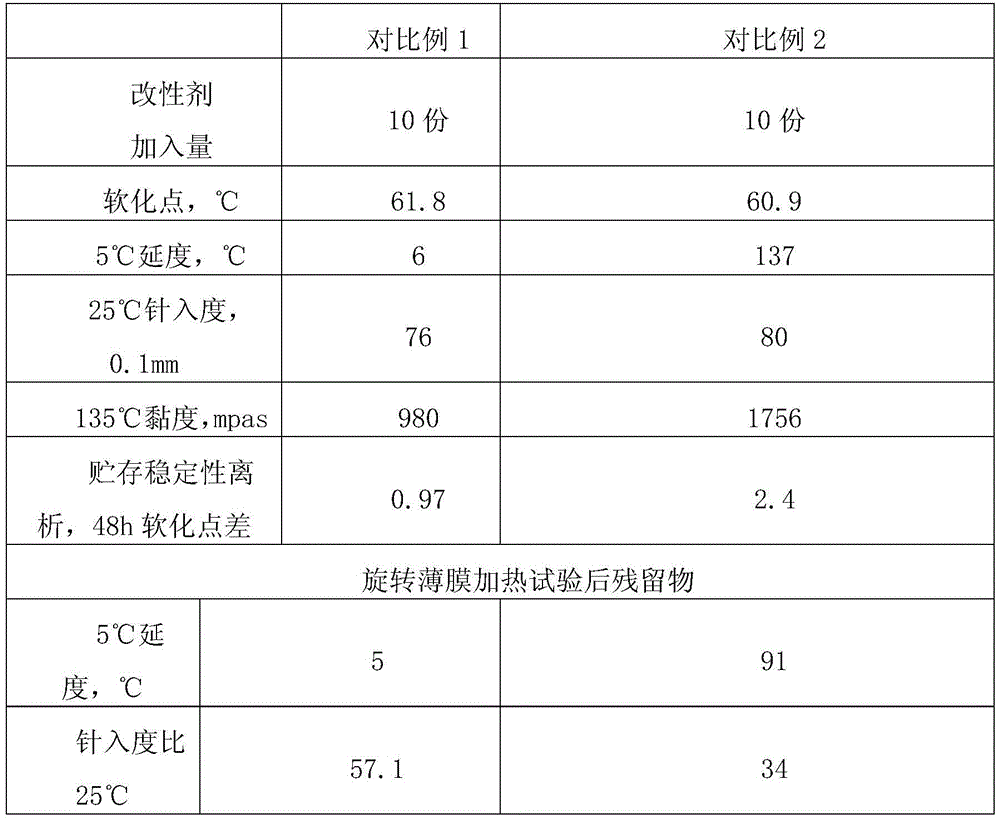

Method for open type carbonization strengthening of waste concrete recycled aggregate

ActiveCN112125550AImprove efficiencyEasy to achieve continuous productionSolid waste managementCarbonizationExhaust fumes

The invention provides a method for open type carbonization strengthening of waste concrete recycled aggregate, which comprises the following steps: crushing waste concrete to obtain granular recycledaggregate, soaking the granular recycled aggregate in water, continuously introducing industrial waste gas containing carbon dioxide, in the soaking process, performing a carbonization reaction on carbon dioxide contained in the industrial waste gas and mortar attached to the surface of the granular recycled aggregate. A carbon dioxide sealing carbonization device is not needed, continuous production is easy, and carbon dioxide industrial waste gas with different concentrations can be utilized.

Owner:HENAN POLYTECHNIC UNIV

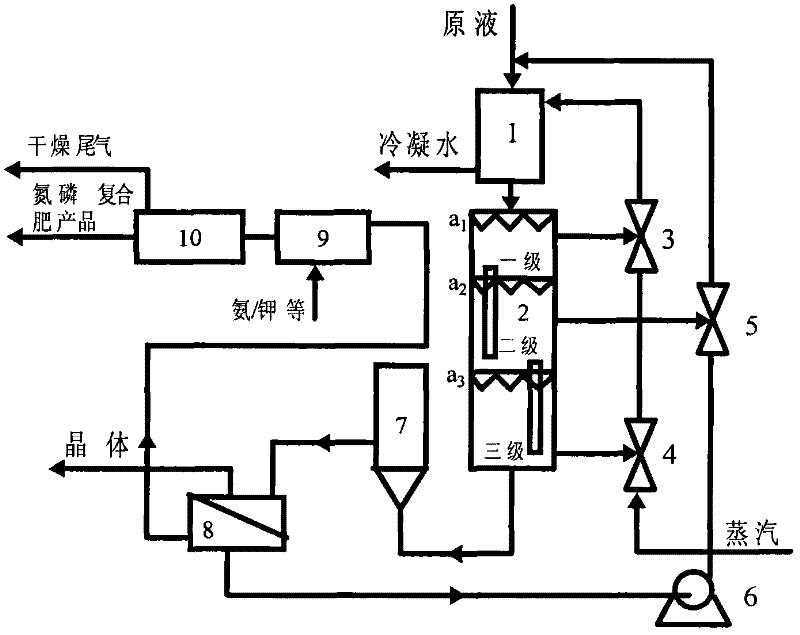

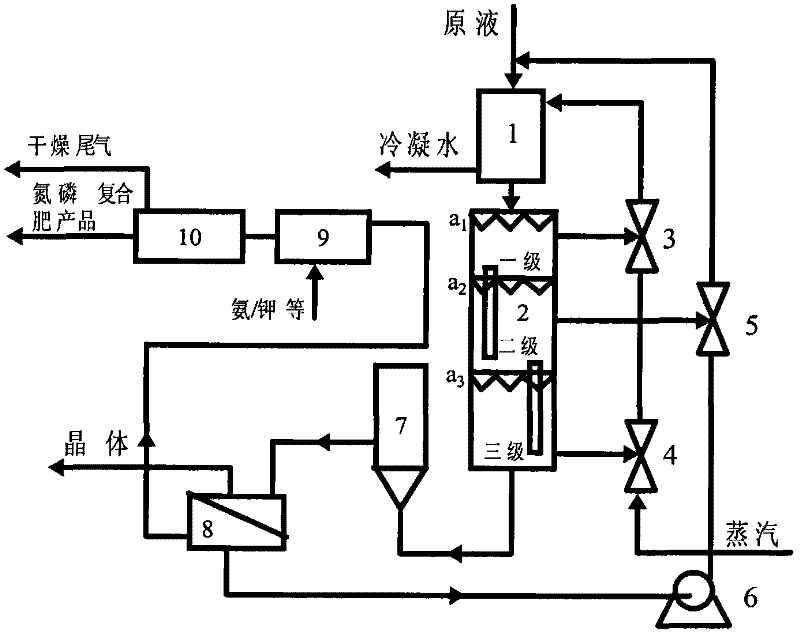

Method for producing nitric phosphate fertilizer at low temperature under vacuum through concentrated crystallization and calcium removal as well asdevice

InactiveCN102584386ALess investmentEasy to achieve continuous productionFertilizer mixturesHigh concentrationFiltration

The invention discloses a method for producing nitric phosphate fertilizers at a low temperature under vacuum through concentrated crystallization and calcium removal and a device. A vacuum condition is created through adopting steam jet, steam kinetic energy is used to achieve jet refrigeration to evaporate a phosphorite nitric acid hydrolysis solution under low back pressure, and steam is used to absorb heat to achieve the solution refrigeration, so that the separation calcium nitrate from other acid non-soluble substances is achieved in a crystallization fluidized bed. After mother liquor is neutralized and concentrated by gaseous ammonia and a certain amount of potassium is added, the spraying granulation is conducted to obtain a high-concentration ternary compound fertilizer. After calcium nitrate crystals separated through filtration is enabled to be dissolved, and the acid non-soluble substances are removed, the solution absorbs carbon dioxide and gaseous ammonia to produce ammonium nitrate and calcium carbonate to be respectively processed into products. The flow process is shortened, the energy consumption is reduced, the investment of production equipment is reduced, the single-series continuous production of equipment is easy to realize, more importantly, the limitation to the phosphorite impurities is widened, the requirements on the nitric acid concentration are reduced, and the refrigeration temperature is raised.

Owner:WENGFU (GRP) CO LTD

Method for preparing high-purity ammonium fluosilicate

InactiveCN102701214AReduce energy consumptionOperational securitySilicon halogen compoundsWater vaporAmmonium fluorosilicate

The invention discloses a method for preparing high-purity ammonium fluosilicate. The method comprises the following steps of: (1) feeding fluorosilicic acid of which the concentration is not less than 10 percent and liquid ammonia into a reaction tank for neutral reaction, when a pH value of a reaction system reaches 3 to 5, reaction is finished; (2) pumping a reaction liquid into a low-temperature flash evaporation concentration system to perform low-temperature flash evaporation in a vacuum state, removing a large amount of water in a neutral liquid of the ammonium fluosilicate, concentrating to a saturated state, and then precipitating crystal, wherein steam generated during flash evaporation is subjected to despumation and is discharged to atmosphere air; (3) introducing a solution after flash evaporation into a setting tank, and discharging a material containing ammonium fluosilicate crystal from the setting tank; and (4) filtering the discharged material, and thus obtaining a high-purity ammonium fluosilicate product with purity over 90 percent, wherein a filtering liquid is returned to the reaction tank of neutral reaction for recovery. According to the method, the ammonium fluosilicate crystal product with purity over 90 percent can be produced, energy consumption of a process is low, operation is safe and reliable, continuous production is easy to realize, and the method is applicable for comprehensive utilization of a fluorine resource of a large-scale phosphate fertilizer enterprise.

Owner:GUIZHOU KAILIN GRP CO LTD

Method for preparing calcium sulfate whisker through recrystallization

ActiveCN103074667BThe principle of the method is reliableSimple technical processPolycrystalline material growthFrom normal temperature solutionsResource utilizationDissolution

The invention discloses a method for preparing a calcium sulfate whisker through recrystallization. The method is characterized in that the method comprises the steps of (1), conducting program control on heating and dissolution courses: putting a raw material with a main ingredient of calcium sulfate into a sulphuric acid solution for stirring, heating simultaneously, heating a mixture to 60-95 DEG C at a certain rate with the adoption of the program control, dissolving for 20min-1h, (2), conducting the program control on cooling and recrystallization courses: using the program control to cool a suspension obtained by dissolution to 10-30 DEG C, ageing for 20min-2h, (3), conducting separating and washing courses: conducting solid-liquid separation on the suspension, washing a separated solid-phase product, and (4), conducting a drying course: drying the washed solid-phase product at a certain temperature, and obtaining the calcium sulphate dihydrate whisker. The calcium sulfate whisker is prepared by utilizing a recrystallization principle under an ordinary-pressure mild condition, and a relatively economical technological approach can be provided for the resource utilization of industrial by-products such as desulfurization gypsum and phosphogypsum.

Owner:XIANGTAN UNIV

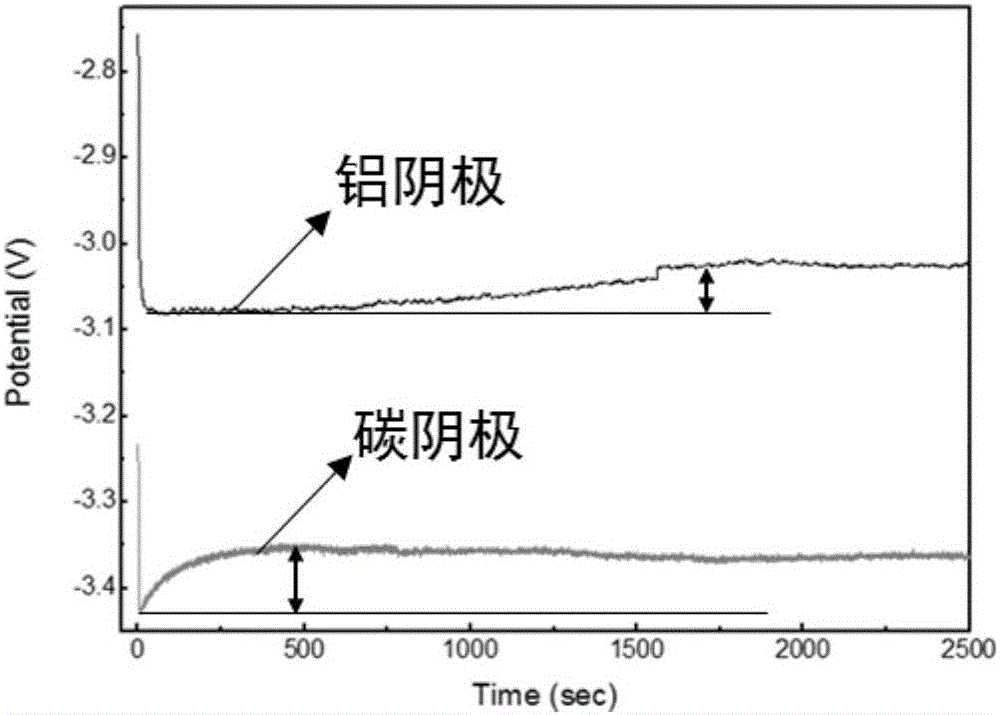

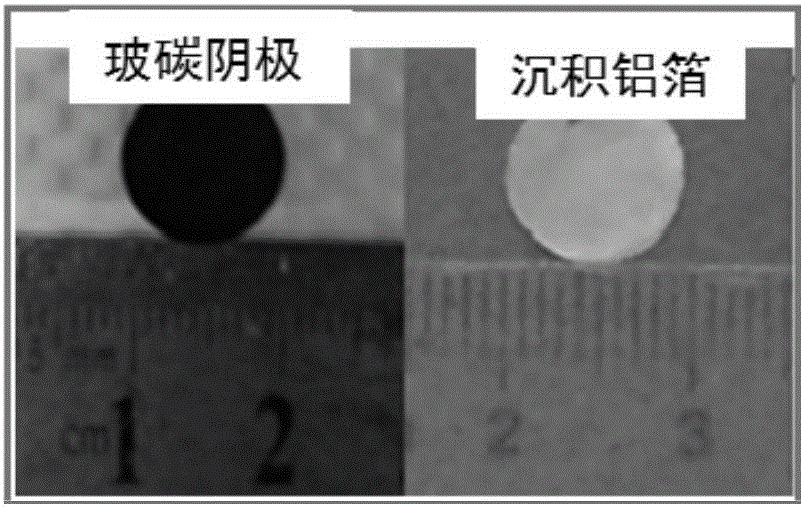

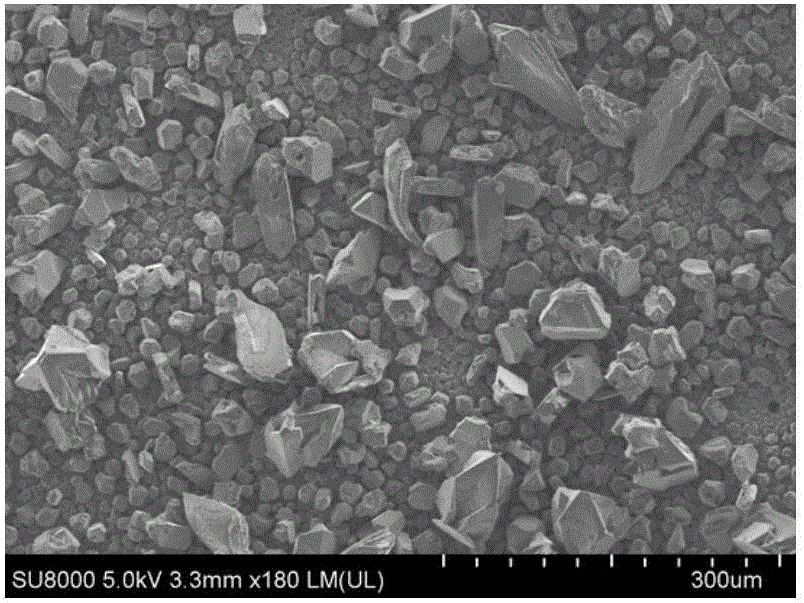

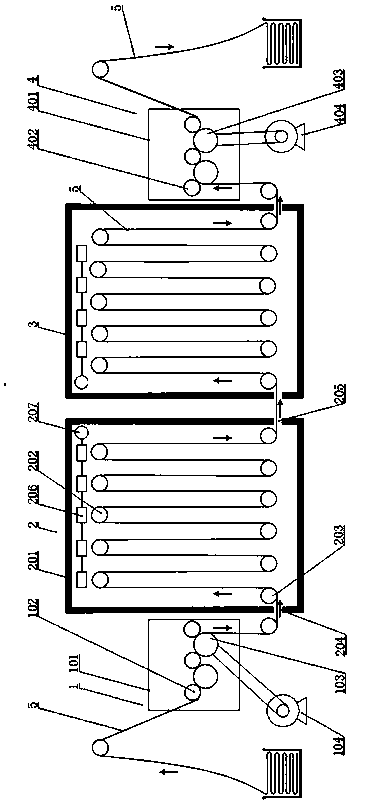

Method for directly preparing aluminum foil through low temperature electrolysis

InactiveCN105671598AEasy to separateReduce adhesionElectroforming processesMetallic aluminumElectrolysis

The invention discloses a method for directly preparing an aluminum foil through electrolysis at low temperature in an ionic liquid medium.Not only is the problem that a compact deposition layer is difficult to strip in the electrodeposition process of metallic aluminum in ionic liquid solved, but also a novel approach is provided for electrochemical preparation of the aluminum foil.The method is characterized in that a higher nucleation overpotential of metallic aluminum on a carbon cathode is utilized, a compact deposition layer is formed, and meanwhile the compatibility between the metallic aluminum and carbon material lattices is poor, so that the compact aluminum foil on the surface of the cathode is easy to strip.According to the method for directly preparing the aluminum foil through electrolysis, the low-temperature ionic liquid serves as the electrolyte, a carbon material with a smooth surface serves as the cathode, and by means of the characteristics that the ionic liquid is low in melting point and not prone to volatilization, the metallic aluminum foil is successfully prepared within the low-temperature range of 25 DEG C-100 DEG C.The method for directly preparing the aluminum foil through electrolysis has the advantages that the operation temperature is low, and the technological steps are simple and easy to operate; continuous production is easy to achieve, and the production energy consumption and cost of the aluminum and the aluminum foil can be significantly reduced.The method has a good application prospect in the aspect of preparation of the metallic aluminum and aluminum foil through low-temperature electrolysis.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

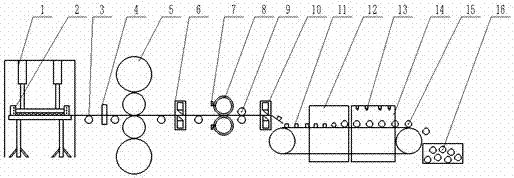

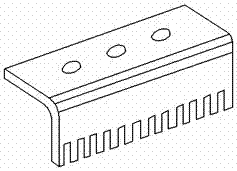

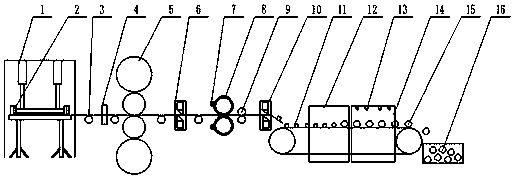

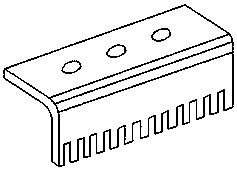

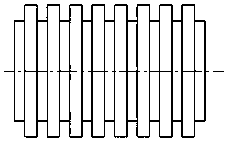

A method for setting the shape of nylon fishing net

ActiveCN106337256BThe nodules are firmGood lookingFibre typesHeating/cooling textile fabricsChemical structurePulp and paper industry

The invention discloses a method for shaping nylon fishing net mesh, which is to solve the problem that the chemical structure of the nylon is unstable due to the presence of high-temperature steam shaping, and the tubercle shape is not stable and cannot be produced continuously. The invention relates to a knot of a nylon fishing net mesh, which is woven from a web-weaving machine, and is introduced into a pre-rolling machine, and then introduced into a pre-rolling machine to carry out one-time rolling and leveling process. Then, the first drying box, the second drying box, the heating and drying processing and the traction stretching and fixing processing of the first drying box and the second drying box are respectively guided through different predetermined temperatures, and after the heating and drying treatment, the mesh is re-introduced into the rear rolling mill to be rolled and leveled, and finally, dried in the air-drying field, cooled naturally at normal temperature, and contracted and fixed. The invention relates to a shaping method of the nylon fishing net mesh, which has the advantages of reasonable process, strong operability and easy realization of continuous production. The profiled nylon fishing net has stable structure, stable tubercle shape, no deformation and good appearance effect.

Owner:WEIHAI HAOYUNTONG NETAB TECH

Method for shaping nylon fishing net mesh

ActiveCN106337256AThe nodules are firmGood lookingFibre typesHeating/cooling textile fabricsChemical structureOperability

The invention discloses a method for shaping nylon fishing net mesh, which is to solve the problem that the chemical structure of the nylon is unstable due to the presence of high-temperature steam shaping, and the tubercle shape is not stable and cannot be produced continuously. The invention relates to a knot of a nylon fishing net mesh, which is woven from a web-weaving machine, and is introduced into a pre-rolling machine, and then introduced into a pre-rolling machine to carry out one-time rolling and leveling process. Then, the first drying box, the second drying box, the heating and drying processing and the traction stretching and fixing processing of the first drying box and the second drying box are respectively guided through different predetermined temperatures, and after the heating and drying treatment, the mesh is re-introduced into the rear rolling mill to be rolled and leveled, and finally, dried in the air-drying field, cooled naturally at normal temperature, and contracted and fixed. The invention relates to a shaping method of the nylon fishing net mesh, which has the advantages of reasonable process, strong operability and easy realization of continuous production. The profiled nylon fishing net has stable structure, stable tubercle shape, no deformation and good appearance effect.

Owner:WEIHAI HAOYUNTONG NETAB TECH

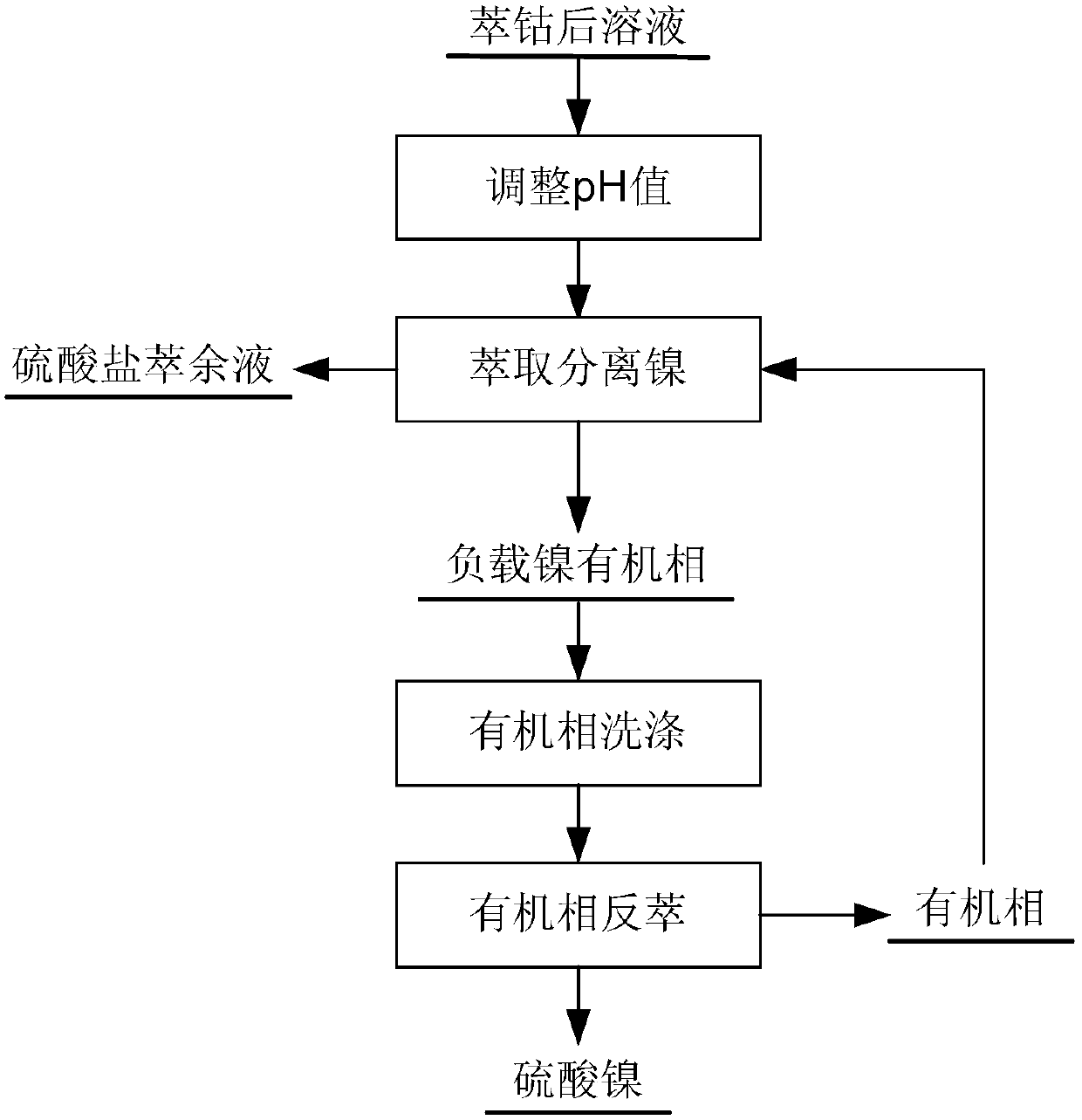

Separation method of nickel in sulfate solution

InactiveCN107746951AReduce energy consumptionLess reagent consumptionProcess efficiency improvementContinuous operationNickel

The invention discloses a separation method of nickel in a sulfate solution. The separation method includes the steps of: adjusting the pH value of a solution after cobalt extraction to 7-10 via a complexing neutralizer, and extracting and separating nickel with 260# solvent oil as a diluent and a nickel extraction agent as an organic phase to obtain an organic phase supporting nickel and a sulfate raffinate; and washing and reversal-extracting the organic phase supporting nickel to prepare a reversal-extract containing nickel and an organic phase. The method can effectively separate nickel ina high-concentration sulfate solution, is low in energy and reagent consumption, has short operation process, is low in equipment demand and can easily achieve continuous operation.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

A method of wet carbonization to activate waste concrete regenerated micropowder and the application of regenerated micropowder

ActiveCN112125541BHigh activityEasy to achieve continuous productionCement productionCarbonizationPhysical chemistry

The present invention proposes a method for activating recycled micropowder of waste concrete by wet carbonization. The powder produced in the process of crushing waste concrete to produce recycled aggregate is used as regenerated micropowder, and the regenerated micropowder is dispersed in water to form a mixed slurry, which is mixed in the The industrial waste gas containing carbon dioxide is continuously fed into the slurry, and during this process, the carbon dioxide contained in the industrial waste gas and the regenerated micropowder undergo a carbonization reaction. In the present invention, the regenerated micropowder is subjected to carbonization reaction in an aqueous solution, and the calcium carbonate and silicon dioxide produced by carbonization have higher activity, and the pozzolanic ash activity is better than auxiliary gelling materials such as commonly used fly ash and silica fume, and can be used as auxiliary gelling materials material used.

Owner:HENAN POLYTECHNIC UNIV

Continuous preparing technology of advanced-pore-state foamed aluminum balls

The invention discloses a continuous preparing technology of advanced-pore-state foamed aluminum balls. A device is used for continuously producing APM foam padding balls in a batched manner. According to the technical scheme, Al powder, Si powder and TiH2 powder mixed powder which are evenly mixed and have a certain mass ratio are added into a hot pressure machine, cracked portions on the edge of a board subject to hot pressing are cut off through a reversible type hot rolling machine, and a prefabricated board with a certain compactness is obtained; the prefabricated board subject to hot rolling in the second step is cut into a plurality of strip-shaped foaming precursors with the square section through a cutting roller, then the precursors enter a limiting flat roller, the strip-shaped precursors stretching by a certain length are cut into cubic small blocks with a certain specification through a flying shear, the cubic small blocks enter a high-temperature electric heating tunnel furnace through a conveying belt, and the blocks are subject to temperature rise and foaming in the electric heating tunnel furnace; when the foaming bodies are subject to temperature rise and expand to be in the near spherical shape, the foaming bodies enter an atomizing area, atomized cooling water is sprayed out, and the balls are rapidly cooled and molded.

Owner:郭荞毓

A kind of preparation method of double network hydrogel fiber and its product

ActiveCN104652119BExpand the scope of industrial applicationRaw materials are easy to getPhysical treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of a double-net hydrogel fiber and a product thereof. The preparation method mainly includes following steps: (1) preparation of a spinning raw solution: dissolving one or more water-soluble natural polysaccharides and a water-soluble acrylamide polymer in water with stirring uniformly, and performing filtration and defoaming to obtain a mixed spinning raw solution containing the natural polysaccharides and the acrylamide polymer; (2) preparation of a water-containing primary gel fiber: performing wet spinning, or dry-wet spinning or gel spinning to the mixed spinning raw solution prepared in the step (1), performing a spinning process at a preset speed, mixing the mixed spinning raw solution with a coagulating bath, to obtain the water-containing primary gel fiber; and (3) radiation crosslinking: drafting the primary gel fiber into an ionizing radiation apparatus and performing the radiation crosslinking to the primary gel fiber prepared in the step (2), and performing a subsequent drafting operation, a thermal-moulding operation, a winding-up operation and a fiber-cutting operation to obtain the double-net hydrogel fiber.

Owner:THE HONG KONG POLYTECHNIC UNIV

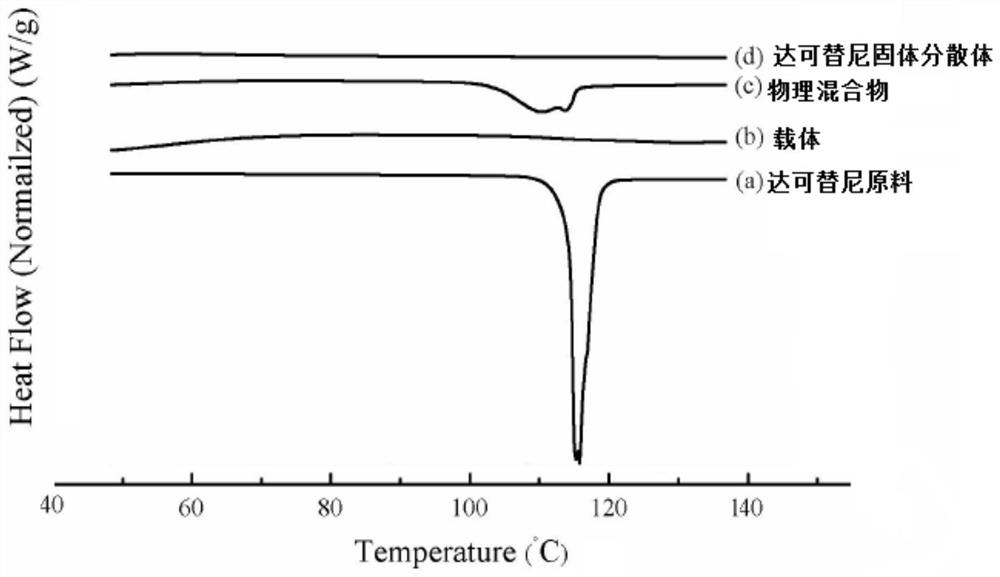

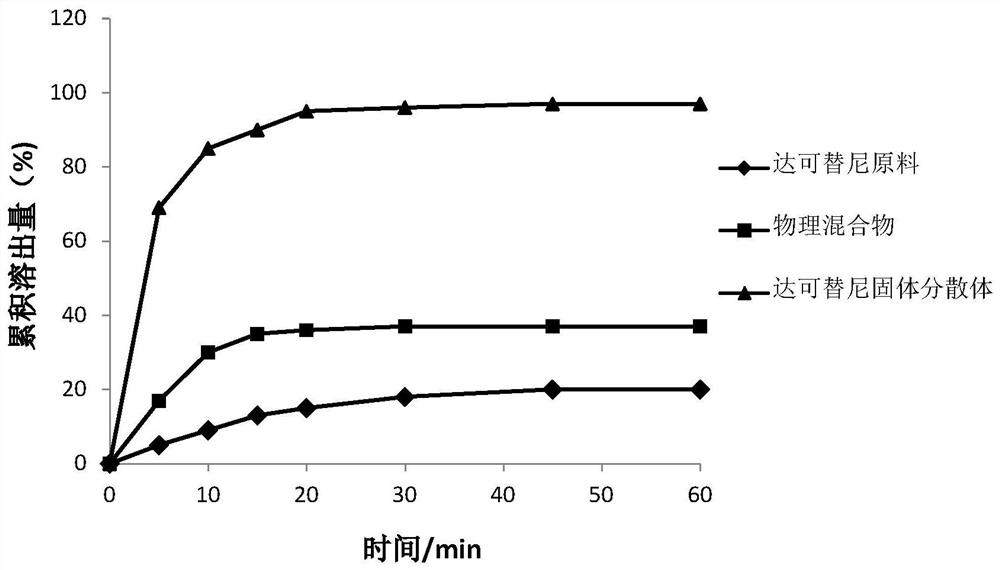

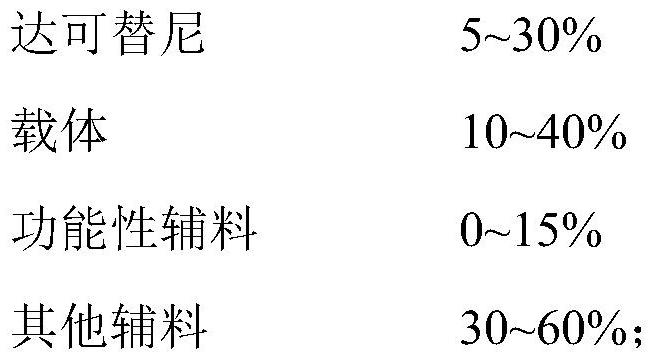

Dacomitinib quick-release preparation and preparation method thereof

PendingCN112245397AImprove wettabilityImprove solubilityOrganic active ingredientsPharmaceutical non-active ingredientsAlcohol sugarsOrganosolv

The invention relates to the technical field of pharmacy, in particular to a dacomitinib quick-release preparation and a preparation method thereof. The dacomitinib quick-release preparation is prepared by the following steps: taking hydroxypropyl methylcellulose phthalate acetate or hydroxypropyl methylcellulose phthalate as a dispersion carrier material, adding a sugar alcohol functional auxiliary material as a plasticizer, performing high-temperature extrusion on the plasticizer and a dacomitinib bulk drug by virtue of a hot melt extruder, performing cooling and crushing, fully mixing a crushed mixture with a filler, a disintegrating agent and a lubricating agent, and performing tabletting directly to prepare the preparation. According to the dacomitinib quick-release preparation, the problems of poor solubility and poor in-vitro dissolution of dacomitinib are solved, the in-vivo bioavailability of dacomitinib is improved, and finally, the treatment effect is improved. The preparation method is simple in process, free of organic solvent, high in automation degree, easy for continuous production and suitable for industrial production.

Owner:REYOUNG PHARMA

A continuous preparation process of aluminum foam pellets with advanced pore shape

The invention discloses a continuous preparing technology of advanced-pore-state foamed aluminum balls. A device is used for continuously producing APM foam padding balls in a batched manner. According to the technical scheme, Al powder, Si powder and TiH2 powder mixed powder which are evenly mixed and have a certain mass ratio are added into a hot pressure machine, cracked portions on the edge of a board subject to hot pressing are cut off through a reversible type hot rolling machine, and a prefabricated board with a certain compactness is obtained; the prefabricated board subject to hot rolling in the second step is cut into a plurality of strip-shaped foaming precursors with the square section through a cutting roller, then the precursors enter a limiting flat roller, the strip-shaped precursors stretching by a certain length are cut into cubic small blocks with a certain specification through a flying shear, the cubic small blocks enter a high-temperature electric heating tunnel furnace through a conveying belt, and the blocks are subject to temperature rise and foaming in the electric heating tunnel furnace; when the foaming bodies are subject to temperature rise and expand to be in the near spherical shape, the foaming bodies enter an atomizing area, atomized cooling water is sprayed out, and the balls are rapidly cooled and molded.

Owner:郭荞毓

A five-layer co-extruded solar cell back plate containing PP and a preparation method thereof

InactiveCN109065653AGood heat resistanceAffordableSynthetic resin layered productsPhotovoltaic energy generationEnvironmentally friendlyEngineering

The invention discloses a five-layer co-extruded solar cell back plate containing PP and a preparation method thereof, belonging to the technical field of solar cell back plate. The outer weathering layer and the structure reinforcing layer are fixed together by an outer adhesive layer, and the structure reinforcing layer and the inner weathering layer are fixed together by an inner adhesive layer. The outer weathering layer and the structure reinforcing layer are fixed together by an outer adhesive layer. The invention adopts a co-extrusion process to melt each layer of material into different flow channels and directly extrude and mold, the operation process is simple, and it is difficult to separate the adhesive layers and the adhesive layers are not likely to fall off. As that preparation method of the invention can not only simplify the processing process, but also has good weatherability, mechanical property and long-term stability; meanwhile, no organic solvent is use in the preparation process, and the preparation method is environmentally friendly and green.

Owner:杭州福禧新材料有限公司

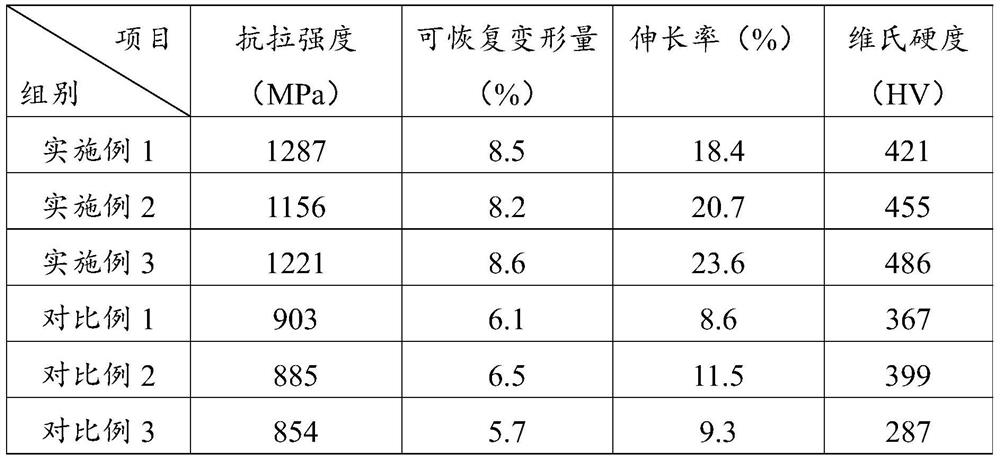

Boron-containing shape memory alloy and preparation method thereof

The invention discloses a boron-containing shape memory alloy and a preparation method thereof. The boron-containing shape memory alloy is prepared from Ni, Ti, Zr and B, and the chemical formula of the boron-containing shape memory alloy is Ni < 51-y > Ti < 49-x > Zr < x > By, wherein, x is equal to 1.0-5.0, y is equal to 1.0-3.0, and x and y are the mole percent of Zr and the mole percent of B in the alloy respectively. According to the boron-containing shape memory alloy, a boron element is added to form TiB2 particles with the nanoscale, the TiB2 particles serve as heterogeneous nucleation cores to refine a matrix structure to improve the strength of the alloy and improve the plasticity of the alloy, and therefore the alloy has the advantages of being high in toughness and elasticity and good in recoverability, and the use requirements of the shape memory alloy on high thermal stability and excellent plasticity can be met; and the preparation method of the boron-containing shape memory alloy is simple in overall process, easy in control, easy in realizing continuous production and low in production cost.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING +1

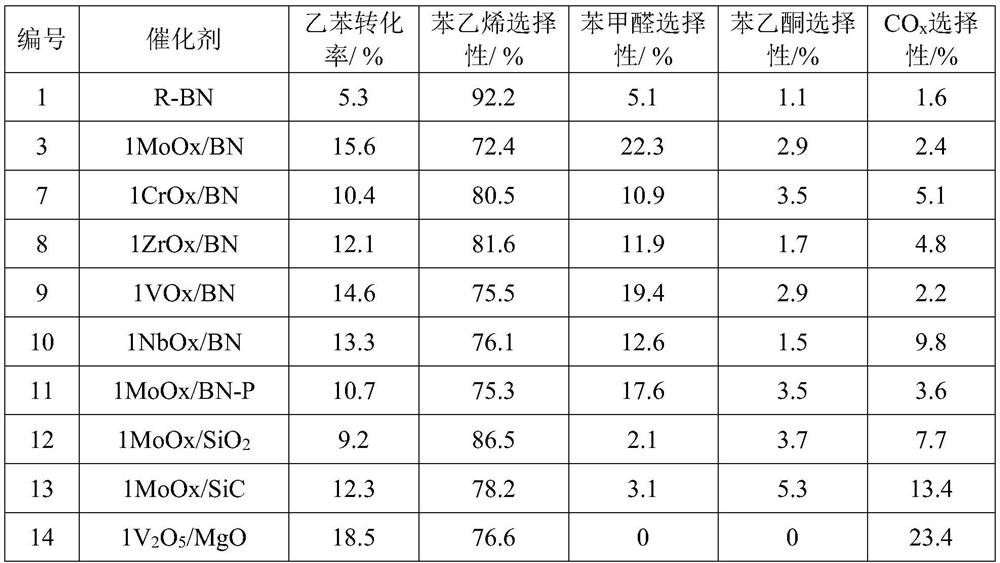

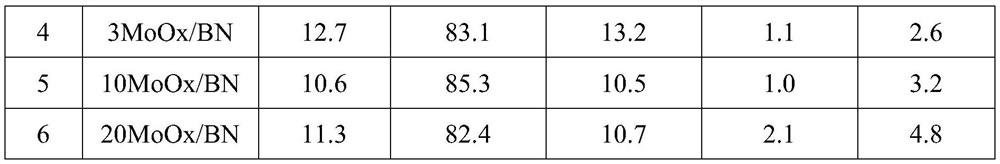

A kind of gas-solid phase joint production method of styrene and benzaldehyde

ActiveCN111302882BEasy to separatePromote generationOrganic compound preparationHydrocarbonsPtru catalystBenzaldehyde

Owner:DALIAN UNIV OF TECH

A method of open carbonation strengthening recycled aggregate of waste concrete

ActiveCN112125550BLow water absorptionImprove concrete performanceSolid waste managementExhaust fumesCarbonization

Owner:HENAN POLYTECHNIC UNIV

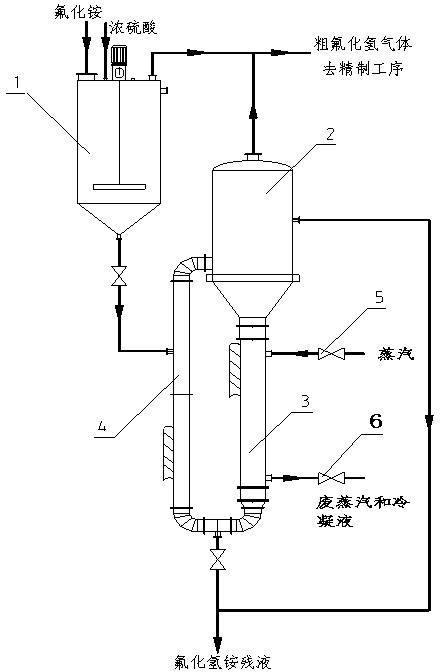

Preparation method of hydrogen fluoride

ActiveCN102689877BSimple processReduce energy consumptionFluorine/hydrogen-fluorideHydrogen fluorideHydrofluoric acid

The invention discloses a preparation method of hydrogen fluoride. The preparation method comprises the following steps of: (1) carrying out acidolysis reaction on ammonium fluoride crystals and concentrated sulfuric acid which are added in a reactor, and educing coarse hydrogen fluoride gasses generated in the acidolysis reaction from a hydrogen fluoride gas outlet on the upper part of the reactor; (2) carrying out indirect heating and analysis on liquid after reaction entering into a tube still heater below a resolver through steam so as to analyze and volatize a great quantity of hydrogen fluoride dissolved in the reaction liquid, educing hydrogen fluoride from a hydrogen fluoride outlet on the top of the resolver, then mixing hydrogen fluoride with the coarse hydrogen fluoride gas on the upper part of the reactor, and carrying out concentration and crystallization on NH4HSO4 serving as resolving liquid to obtain a NH4HSO4 product; and (3) carrying out conventional purification, condensation and rectification on the mixed coarse hydrogen fluoride gas which is sent to be in a refining procedure, so as to obtain anhydrous hydrofluoric acid with the purity being 99.7%. The preparation method can be used for producing the anhydrous hydrofluoric acid product with high purity, is simple in process, low in energy consumption and safe and reliable to operate, and continuous production is easy to realize. The preparation method is suitable for comprehensive utilization of fluorine resources in phosphate fertilizer industries.

Owner:GUIZHOU KAILIN GRP CO LTD

A kind of konjac glucomannan-based antibacterial hydrogel fiber and preparation method thereof

ActiveCN110067042BUniform structureStrong water absorptionConjugated artificial filamentsArtifical filament manufactureFiberSpinning

A konjac glucomannan-based antibacterial hydrogel fiber and a preparation method thereof, the method comprising: in parts by weight, the raw material components include: 50-100 parts of konjac glucomannan polymerizable monomers, alginate 100-800 parts, 10-20 parts of organic guanidine salt polymerizable monomers, 10,000-40,000 parts of deionized water, and 0.1-5 parts of initiator. The preparation process includes three steps: (1) preparation of modified konjac glucomannan with double bond in side group and antibacterial organic guanidine salt polymerizable monomer; (2) preparation of spinning solution; (3) two-step cross-linking preparation of hydrogel fibers. The preparation method of the invention is simple and safe, low in cost, rich in raw materials and strong in experiment repeatability; no high-voltage electric field is involved in the preparation process, no organic solvent is involved, no pollution, no damage to cells, and cell encapsulation can be realized; The obtained hydrogel fibers are not only uniform, controllable in size, improved in mechanical properties, good in water absorption, but also have good biocompatibility, excellent antibacterial properties, and have broad application prospects, especially in the field of sanitary materials.

Owner:DONGHUA UNIV

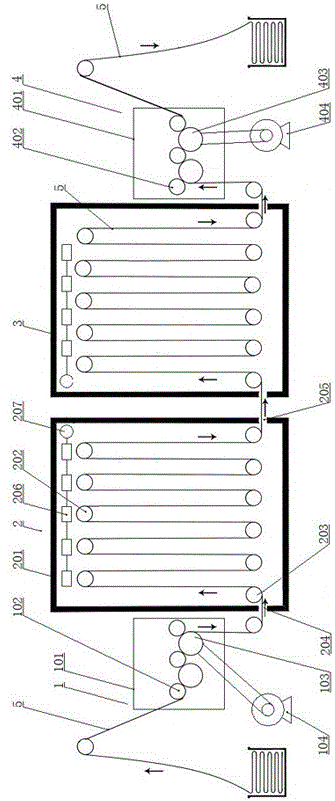

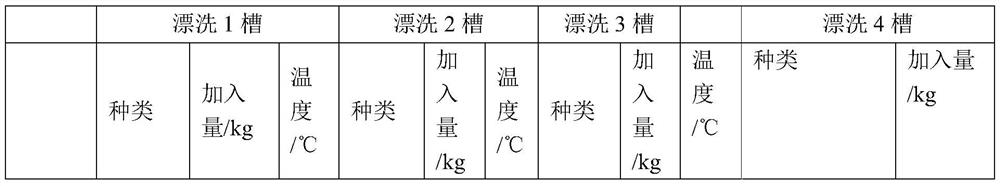

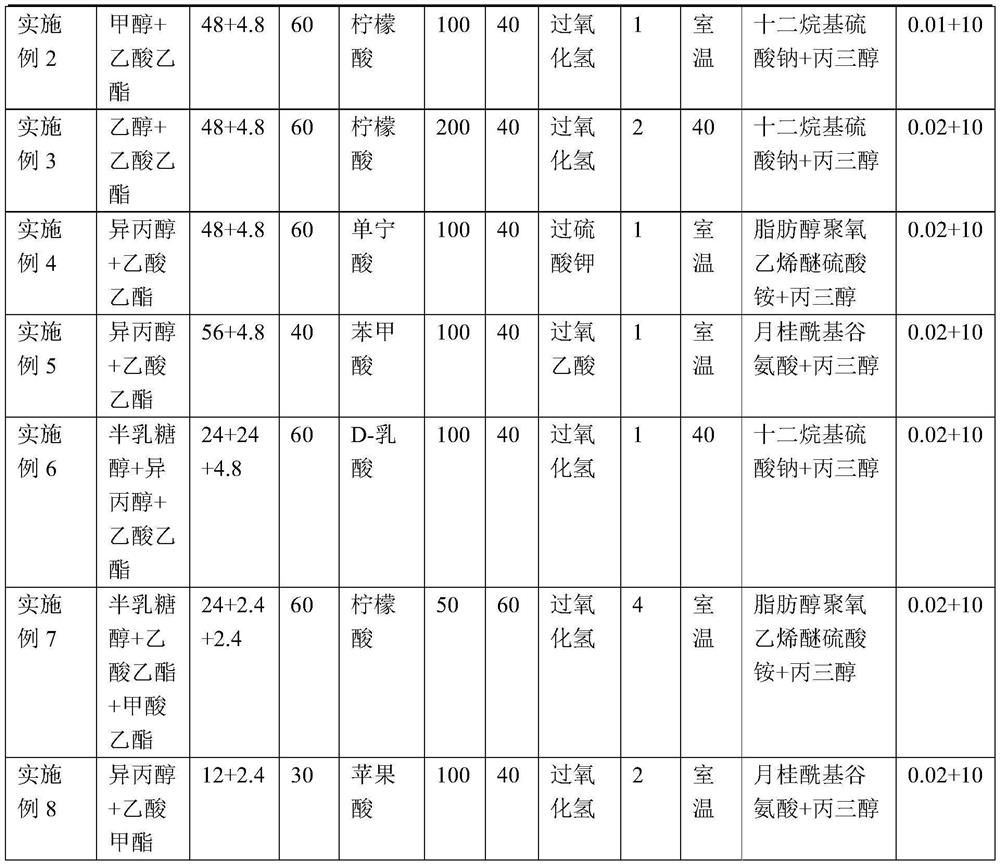

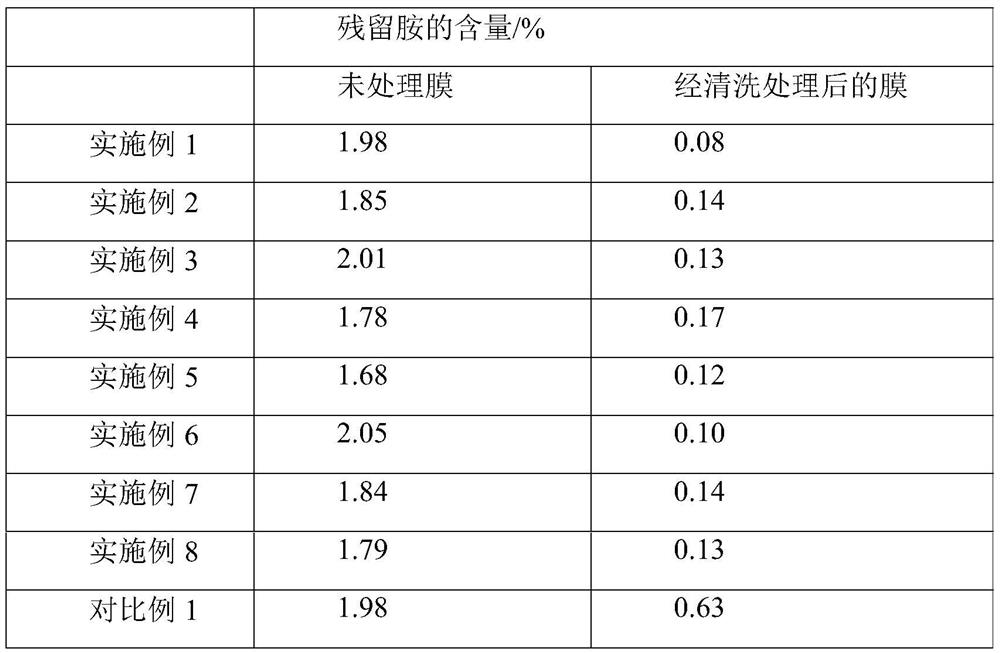

Reverse osmosis membrane chemical cleaning system and method

PendingCN112657341AImprove throughputHigh desalination rateSemi-permeable membranesGeneral water supply conservationActive agentReverse osmosis

The invention belongs to the technical field of reverse osmosis membranes, and particularly relates to a reverse osmosis membrane chemical cleaning system and method. The chemical cleaning system comprises a first rinsing tank, a first washing tank, a second rinsing tank, a second washing tank, a third rinsing tank, a third washing tank, a fourth rinsing tank and a fourth washing tank, wherein the first rinsing tank is filled with a hydrophilic additive and an ester substance, the second rinsing tank is filled with a water-soluble acid solution, the third rinsing tank is filled with a strong oxidizing substance solution, the fourth rinsing tank is filled with glycerol and a surfactant, and the mass concentration of the strong oxidizing substance in the third rinsing tank is 0.01%-2%. The low-concentration oxidizing agent thoroughly cleans a small amount of residual amine on the membrane, improves the cleaning effect, effectively cleans organic matters and aromatic amine substances, avoids oxidation discoloration in the storage or use process, further improves the flux and desalination rate of the reverse osmosis membrane, and enhances the oxidation resistance.

Owner:HUNAN KEENSEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com