Reverse osmosis membrane chemical cleaning system and method

A chemical cleaning and reverse osmosis membrane technology, applied in the field of reverse osmosis membrane chemical cleaning system, can solve the problems of decreased flux and desalination rate, easy discoloration of the membrane, reduced membrane performance and service life, etc., to improve flux and desalination efficiency, avoid oxidation and discoloration, and enhance the effect of anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A novel reverse osmosis membrane rinsing system, which sequentially includes a first rinsing tank, a first rinsing tank, a second rinsing tank, a second rinsing tank, a third rinsing tank, a third rinsing tank, a fourth rinsing tank and a fourth rinsing tank .

[0026] The first rinsing tank is equipped with a hydrophilic additive and an ester mixed solution, and the hydrophilic additive solution is an aqueous solution of 40% isopropanol and 2% ethyl acetate by mass;

[0027] A water-soluble acid solution is housed in the second rinse tank, and the water-soluble acid solution is citric acid with a mass concentration of 5%;

[0028] An oxidizing agent is housed in the third rinsing tank, and the oxidizing agent is hydrogen peroxide with a mass concentration of 0.05%;

[0029] Surfactant and glycerin are housed in the fourth rinsing tank, wherein the concentrations of the surfactant and the glycerol are 0.01% and 5% respectively, and the surfactant is sodium lauryl sulfa...

Embodiment 2~8

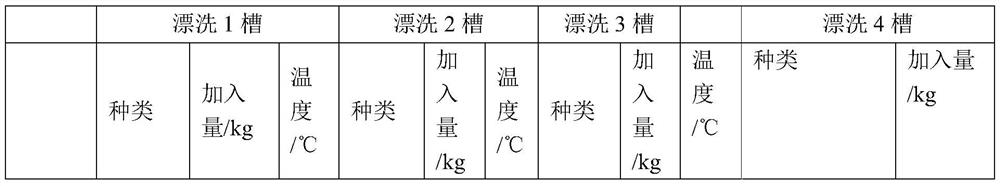

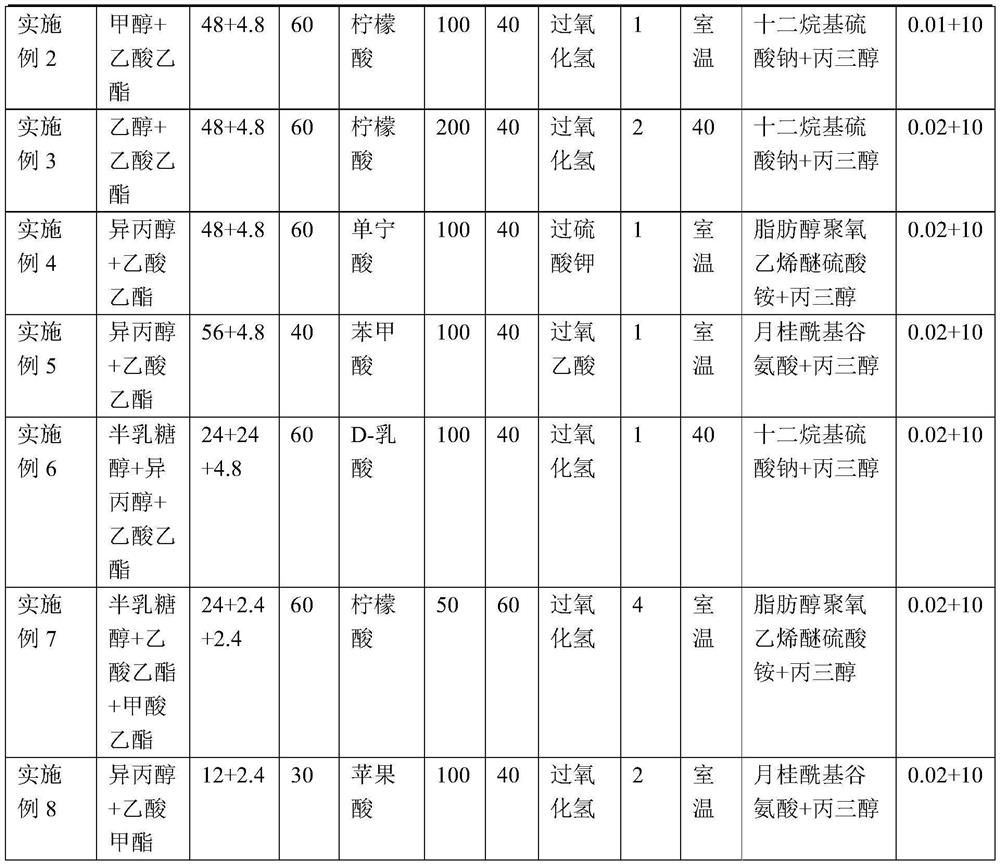

[0039] The parameters of the reverse osmosis membrane chemical cleaning system and cleaning method in Examples 2 to 8 are shown in Table 1, and the other unlisted parameters are the same as in Example 1.

[0040] Table 1

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com