Method for preparing high-purity ammonium fluosilicate

A technology of ammonium fluorosilicate and fluorosilicic acid, applied in the direction of halogenated silicon compounds, etc., can solve the problems of difficult filtration, difficult continuous process, large process energy consumption, etc., and achieves safe and reliable operation, easy continuous production, and process energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

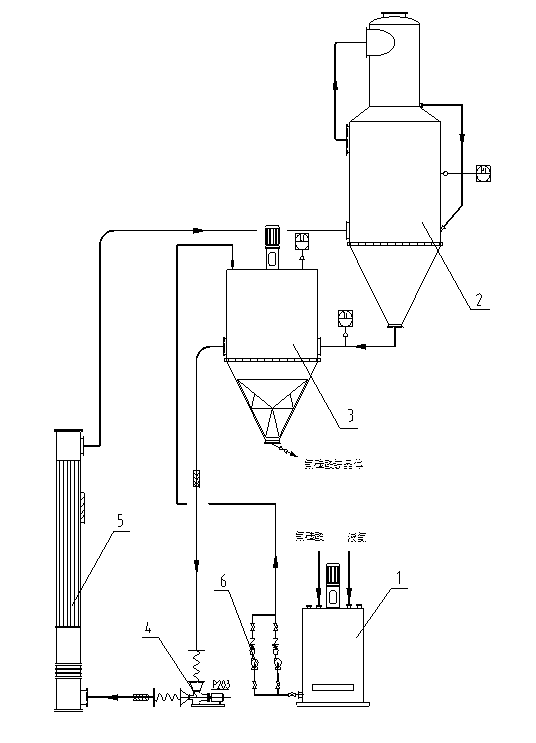

Image

Examples

Embodiment

[0018] The 1000t / a anhydrous hydrofluoric acid industrialization demonstration plant of Guizhou Kailin Group Co., Ltd. adopts this method to produce the intermediate ammonium fluorosilicate.

[0019] The raw material ammonium fluorosilicate concentration is 12%, and the ammonia content in the liquid ammonia is greater than 99.9%. It is sent to the reaction tank for neutralization reaction. The reaction temperature is 30°C-100°C, and the reaction time is 2-30min. When the pH of the reaction system reaches 3 to 5 o'clock, the reaction reaches the end point; pump the reaction liquid into the low-temperature flash evaporation concentration system, flash at a vacuum of 80kPa and a temperature of 70°C, remove water, and concentrate to a saturated state to precipitate crystals; after flash evaporation The solution enters the settling tank, and the material containing ammonium fluorosilicate crystals is released from the bottom of the settling tank. After filtering, a high-purity ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com