Patents

Literature

469 results about "Fluosilicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluosilicates salts of fluosilicic acid, H2SiF6. They decompose upon heating—for example, CaSiF6=CaF2 + SiF4. The sodium, potassium, rubidium, cesium, and barium salts are only slightly soluble in water; the characteristic crystals formed are used in quantitative and microchemical analysis. Sodium fluosilicate has found widest practical application ...

Bi-component aqueous ground hardening agent and preparation method thereof

The invention belongs to the field of construction materials, in particular to a bi-component aqueous ground hardening agent and a preparation method thereof. The bi-component aqueous ground hardening agent comprises the following components in percentage by weight: 12-35 percent of first component and 65-88 percent of second component, wherein the first component is a lithium silicate solution, and the second component contains magnesium fluosilicate, silane emulsion, crylic acid resin emulsion, petrolin and water. The bi-component aqueous ground hardening agent has favorable effects of abrasion resistance, reinforcement, compactness, water prevention and seal and can improve the surface smoothness; and after being applied to the concrete ground, the bi-component aqueous ground hardening agent can improve the surface smoothness of concrete and reduce the dust.

Owner:TONGJI UNIV

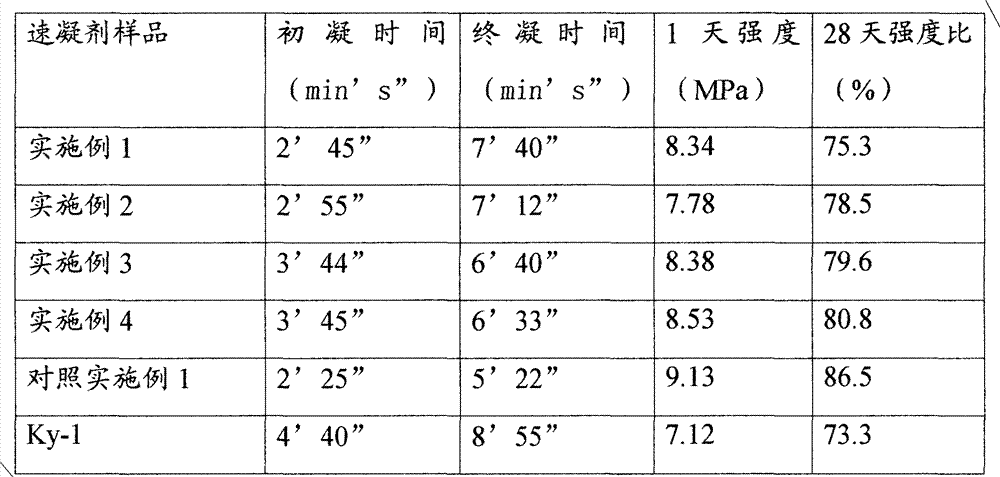

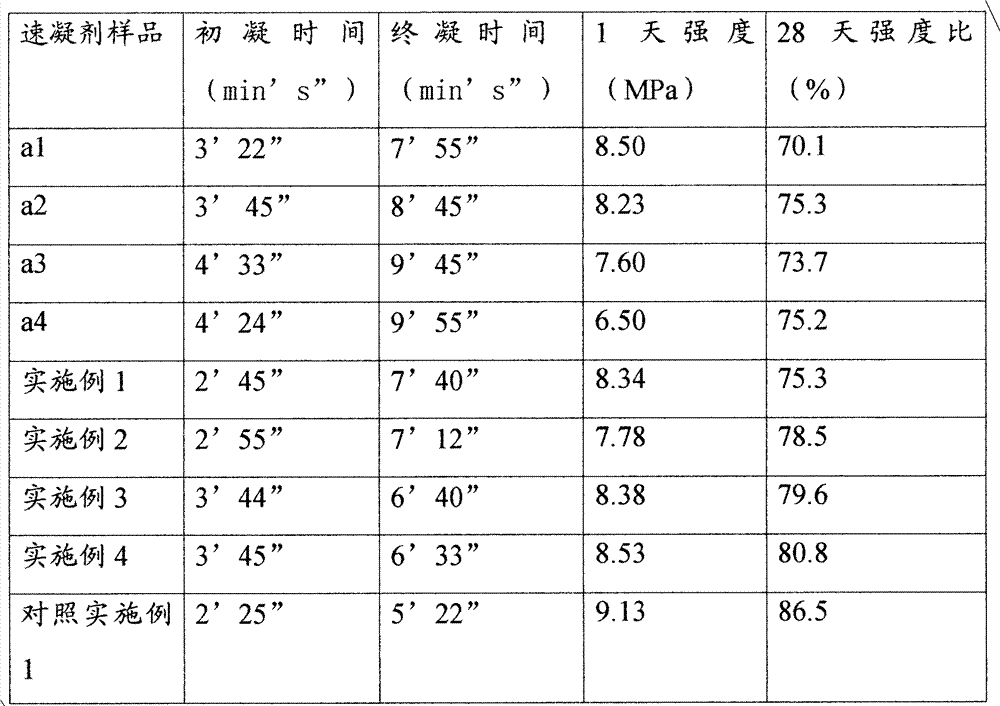

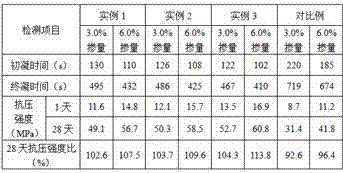

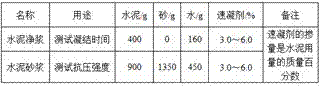

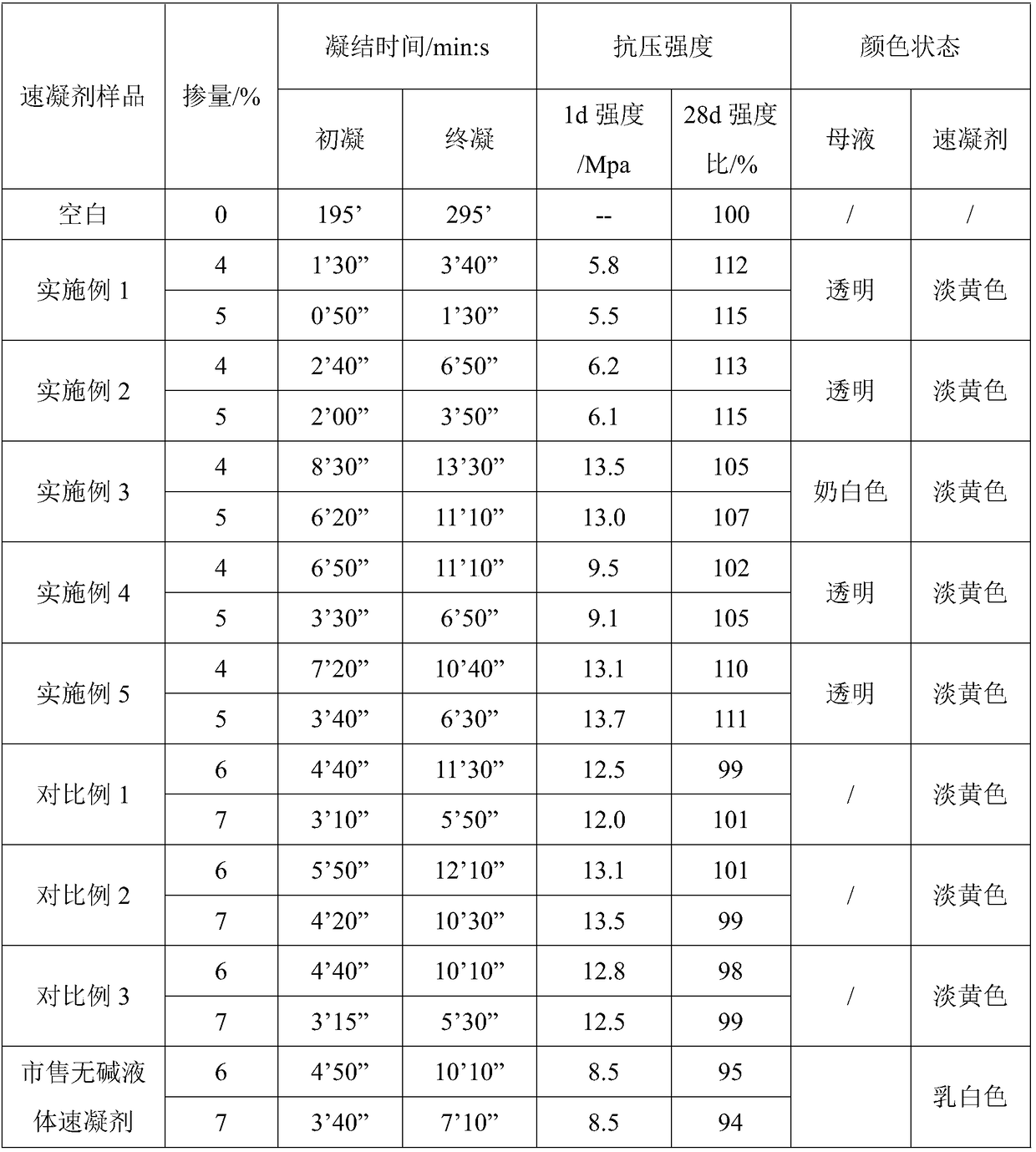

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

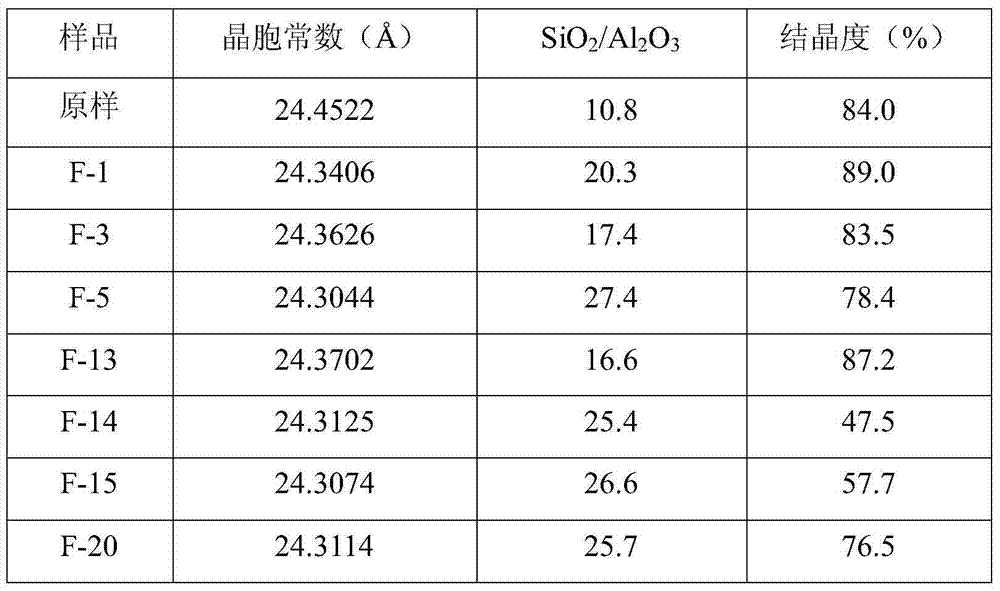

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cementitious capillary crystalline waterproofing agent

InactiveCN101759414AImprove impermeabilityPromotes self-healingSolid waste managementSelf-healingSodium Bentonite

The invention discloses a cementitious capillary crystalline waterproofing agent, which contains the following raw materials in parts by weight: 50 parts of Portland cement; 25 parts of quartz sand; 9 parts of siliceous dust; 3 parts of calcium hydroxide; 2 parts of sodium bentonite; 1 part of kieselguhr; 3.9 parts of instant sodium silicate; 2.5 parts of aluminum potassium sulfate; 0.3 parts of zinc fluosilicate; 0.20 parts of sodium polyacrylate; 0.2 parts of hydroxypropyl methyl cellulose; 2 parts of zinc stearate; 0.5 parts of naphthalene water reducer; 0.2 parts of sugar lime; 0.1 parts of citric acid; and 0.1 parts of antifoaming agent. After the raw materials are weighed according to the proportions, the raw materials are ground into particles with grain size more than or equal to 200-mesh sieve in a ball mill to obtain the finished product. The invention has the advantages that the cost is low, the anti-permeability is good, the self-healing performance is good, the bonding power is strong, the steel bar corrosion is prevented, no toxicity and no harmfulness are caused and the construction is easy.

Owner:河南奥思达新材料有限公司

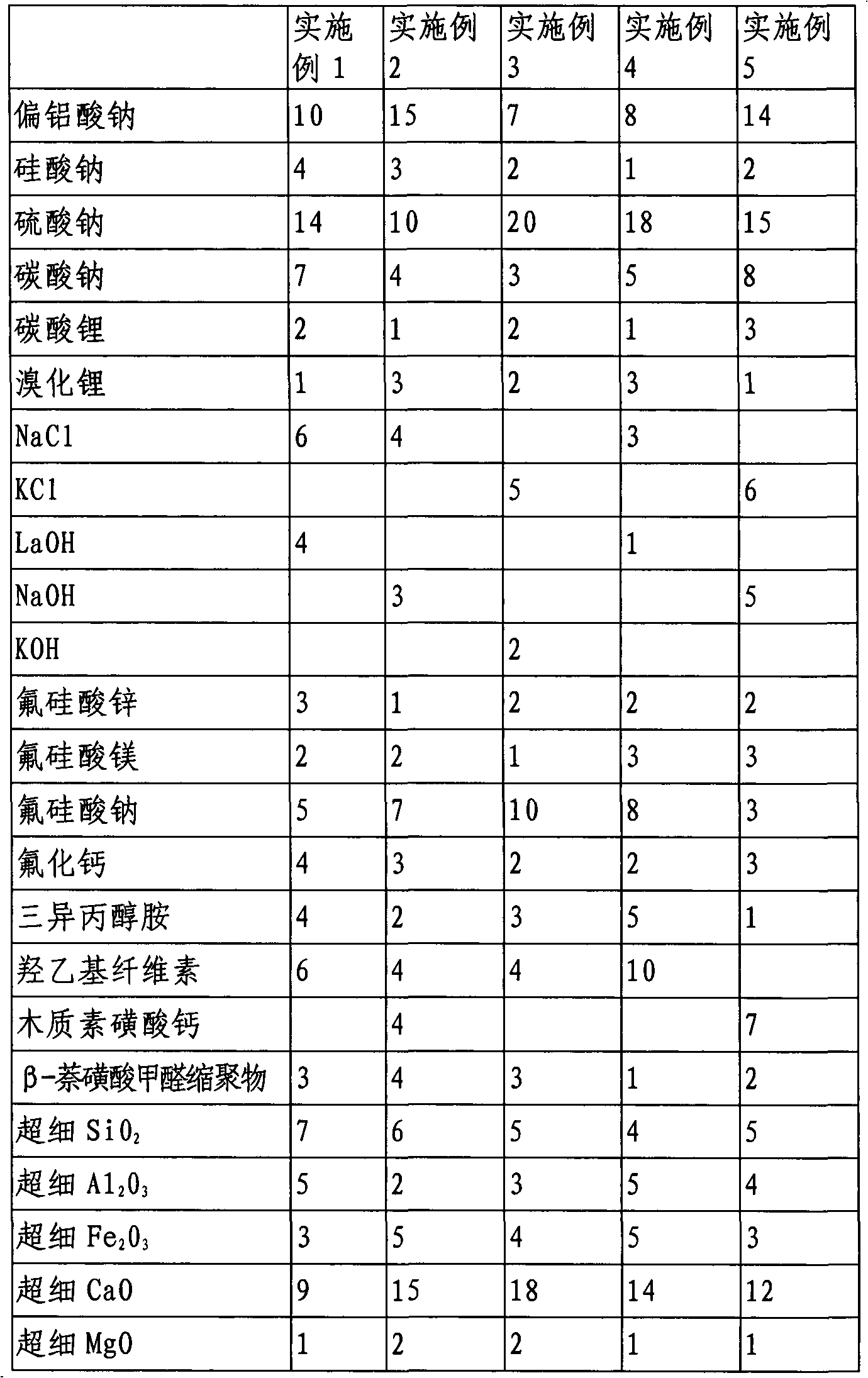

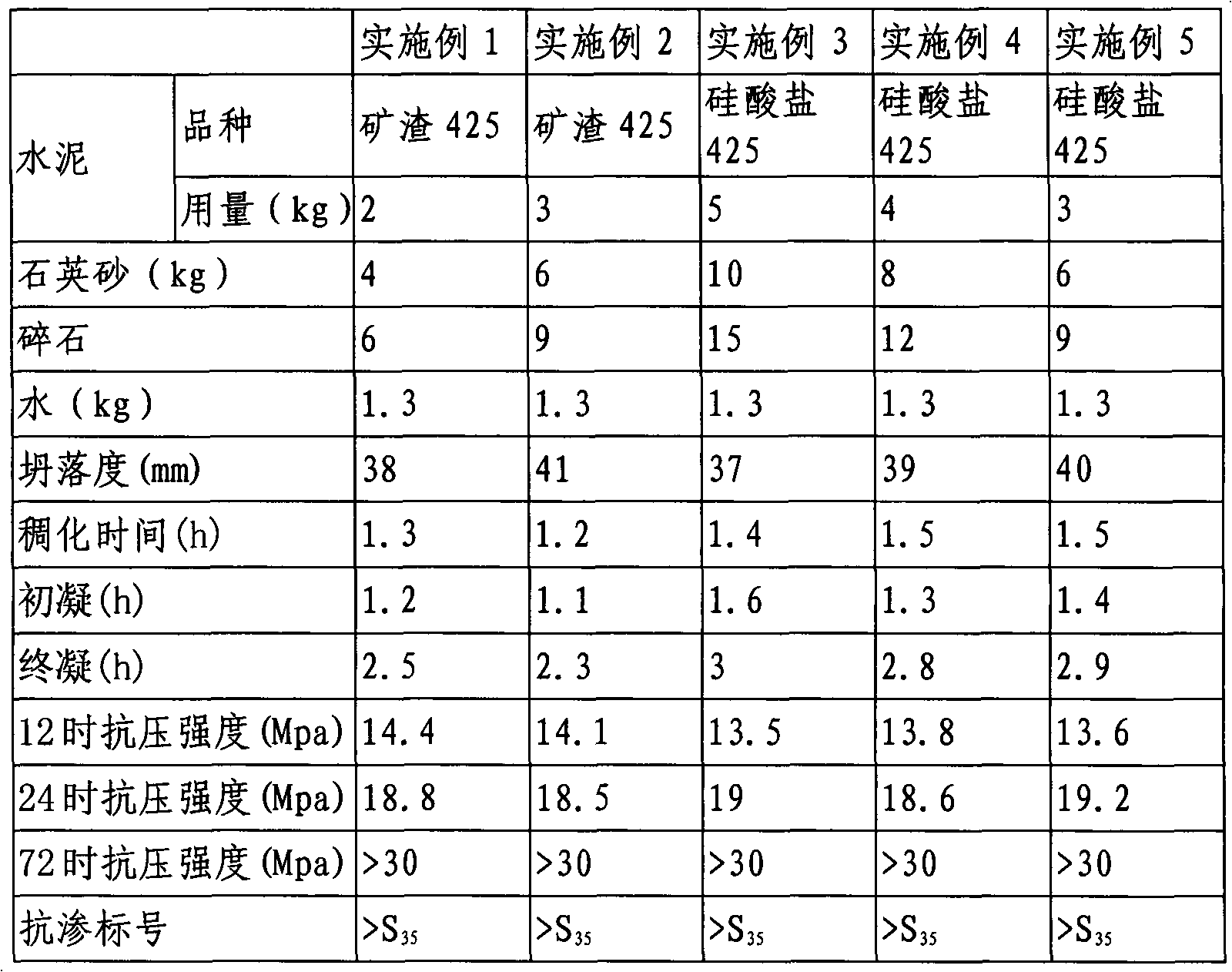

Low-temperature concrete early strength agent

The invention relates to a low-temperature concrete early strength agent, which belongs to cement additives. The early strength agent consists of sodium metaaluminate, sodium silicate, sodium sulfate, sodium carbonate, lithium carbonate, lithium bromide, alkali metal chlorides, alkali metal hydroxides, zinc fluosilicate, magnesium fluosilicate, sodium fluosilicate, calcium fluoride, triisopropanolamine, a filtrate reducer, beta-naphthalene formaldehyde sulfonate polycondensate, ultrafine powder SiO2, ultrafine powder Al2O3, ultrafine powder Fe2O3, ultrafine powder CaO and ultrafine powder MgO. The early strength agent is mainly applied to winter concrete construction or low-temperature environmental emergency projects; when the early strength agent is used, the composition mixture is added into concrete according to 2 to 5 percent of the total weight of cement, water is added and then stirring is performed; and a cement block with the strength of 13.5MPa can be formed in a low-temperature environment at the ambient temperature of approximately 4 DEG C within 12 hours, a cement block with the strength of 18.5MPa can be formed within 24 hours and a cement block with the high strength of 30MPa can be formed within three days.

Owner:陈子川

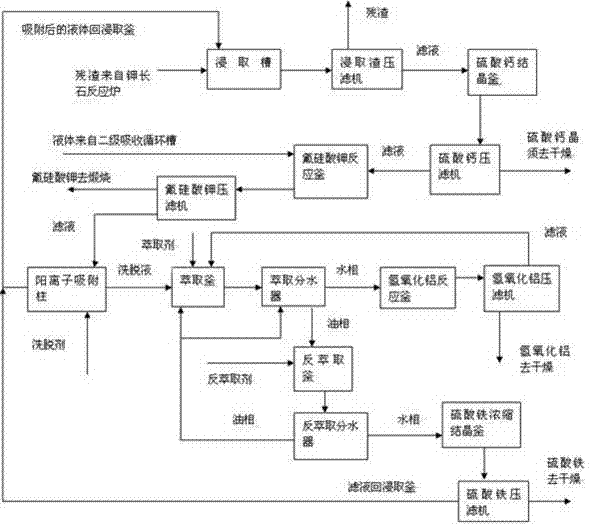

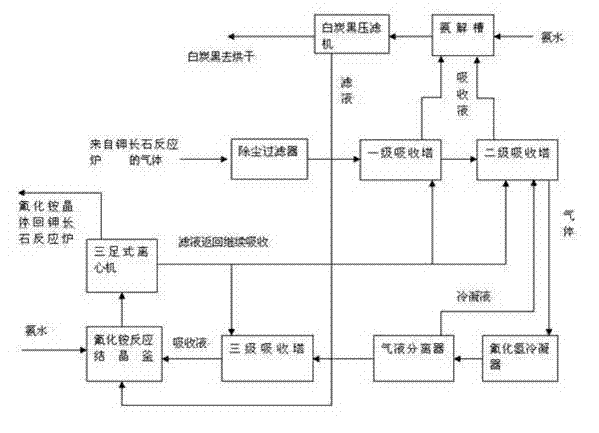

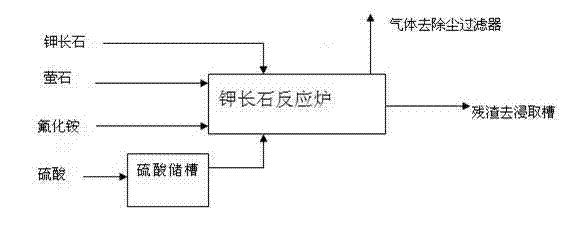

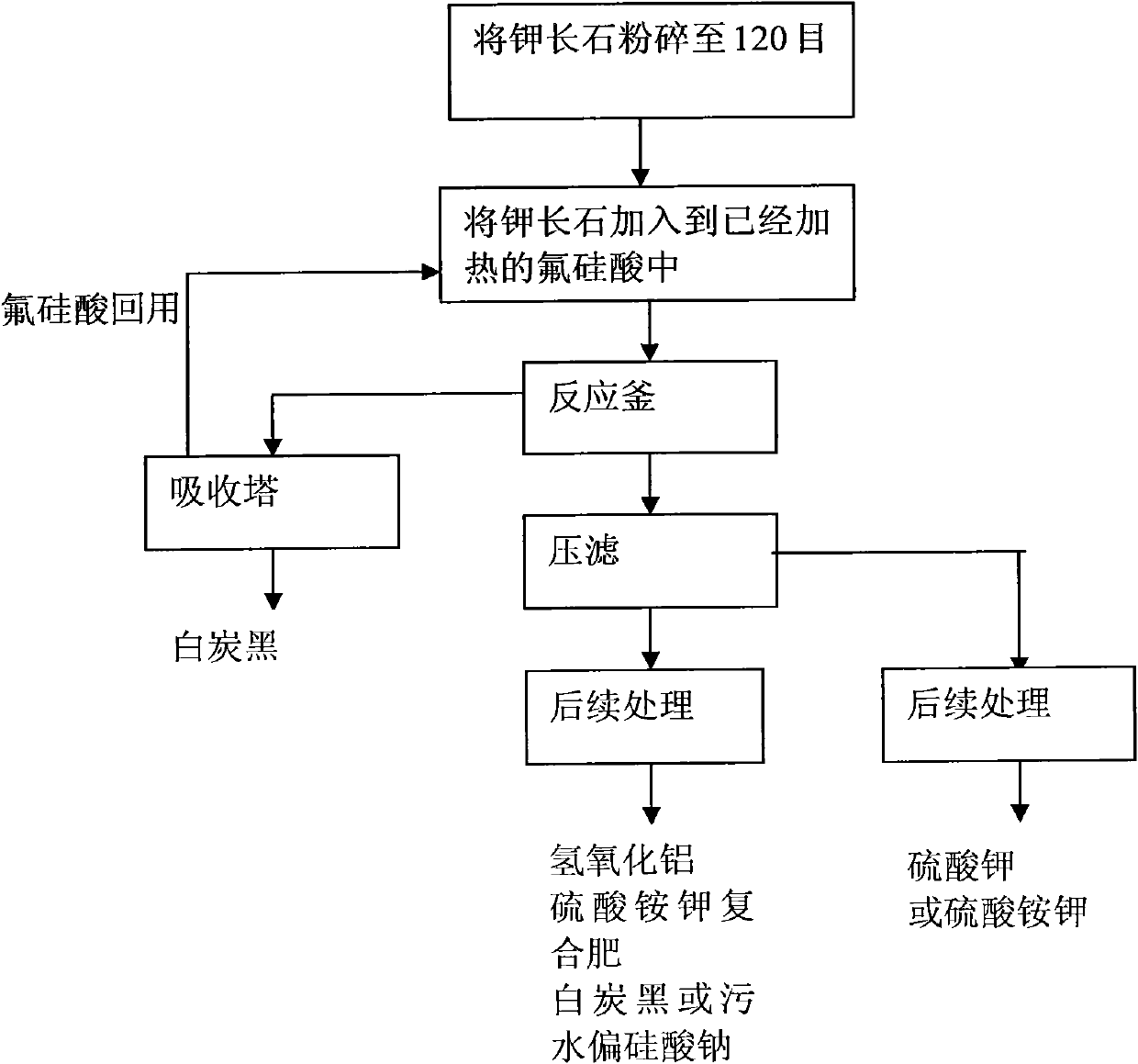

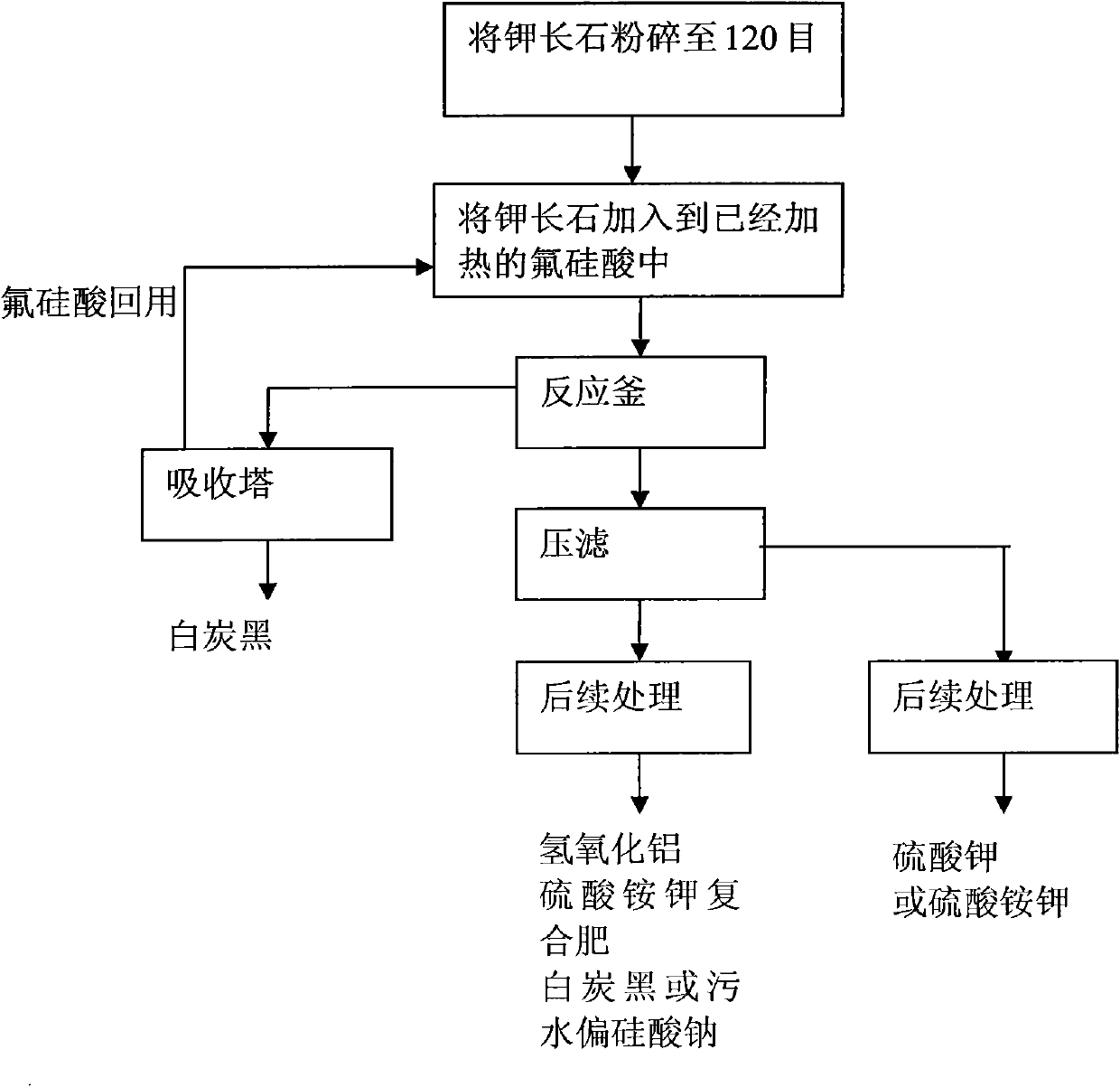

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

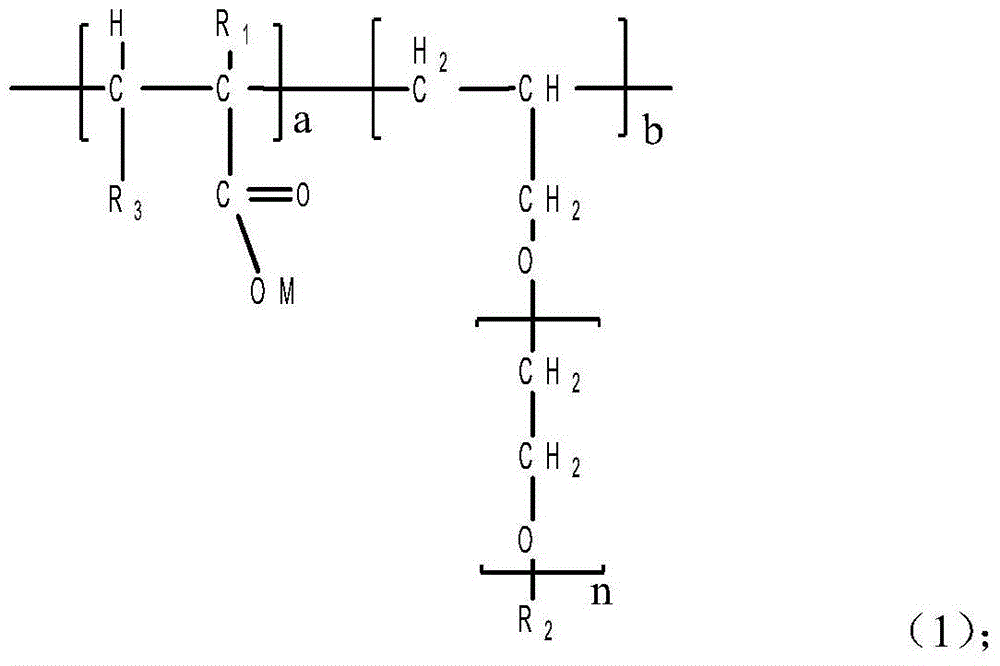

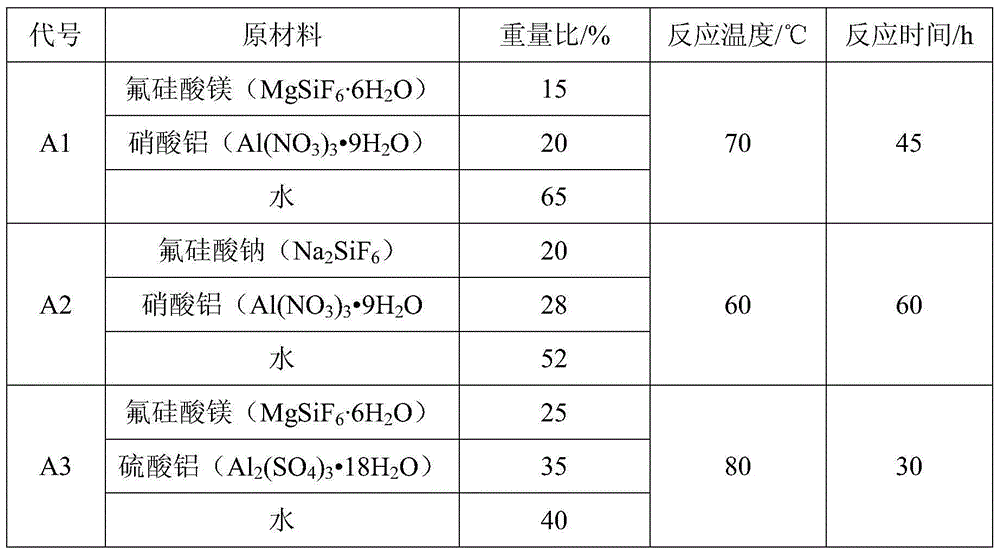

Nano-suspension concrete early strength accelerator and preparation method thereof

The invention provides a nano-suspension concrete early strength accelerator which can be stably dispersed in an aqueous solution and is prepared from a thixotropic solution and a nano-calcium silicate suspension according to mass ratio of 1:4-9. The thixotropic solution is prepared from the following ingredients, by weight, 15-25% of soluble fluosilicate, 20-35% of soluble aluminium salt and the balance being water. The nano-calcium silicate suspension is prepared from the following ingredients, by weight, 5-20% of soluble silicate, 8-18% of soluble calcium salt, 3-10% of a high-molecular polymer dispersant and the balance being water. The invention also provides a preparation method of the early strength accelerator. On one hand, the early strength accelerator contains no chlorine salt and has no corrosion effect on steel bars in concrete. On the other hand, the early strength accelerator is a stable suspension system, is convenient to add and is easy to uniformly disperse during the preparation process of concrete; and the early strength accelerator can remarkably raise early strength of concrete, has an obvious early strength effect especially on concrete obtained by the use of high volume of mineral admixtures and is especially suitable for production of precast concrete components.

Owner:JIANGSU SOBUTE NEW MATERIALS

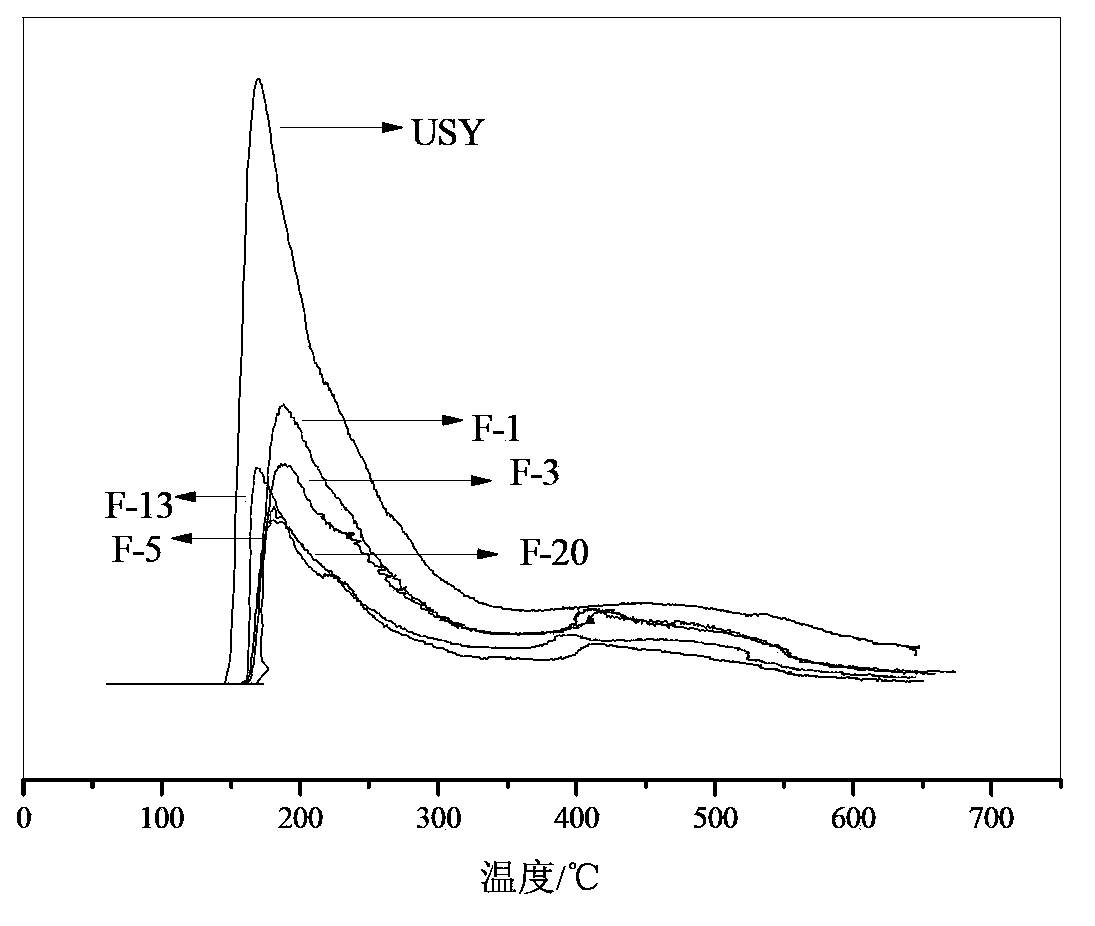

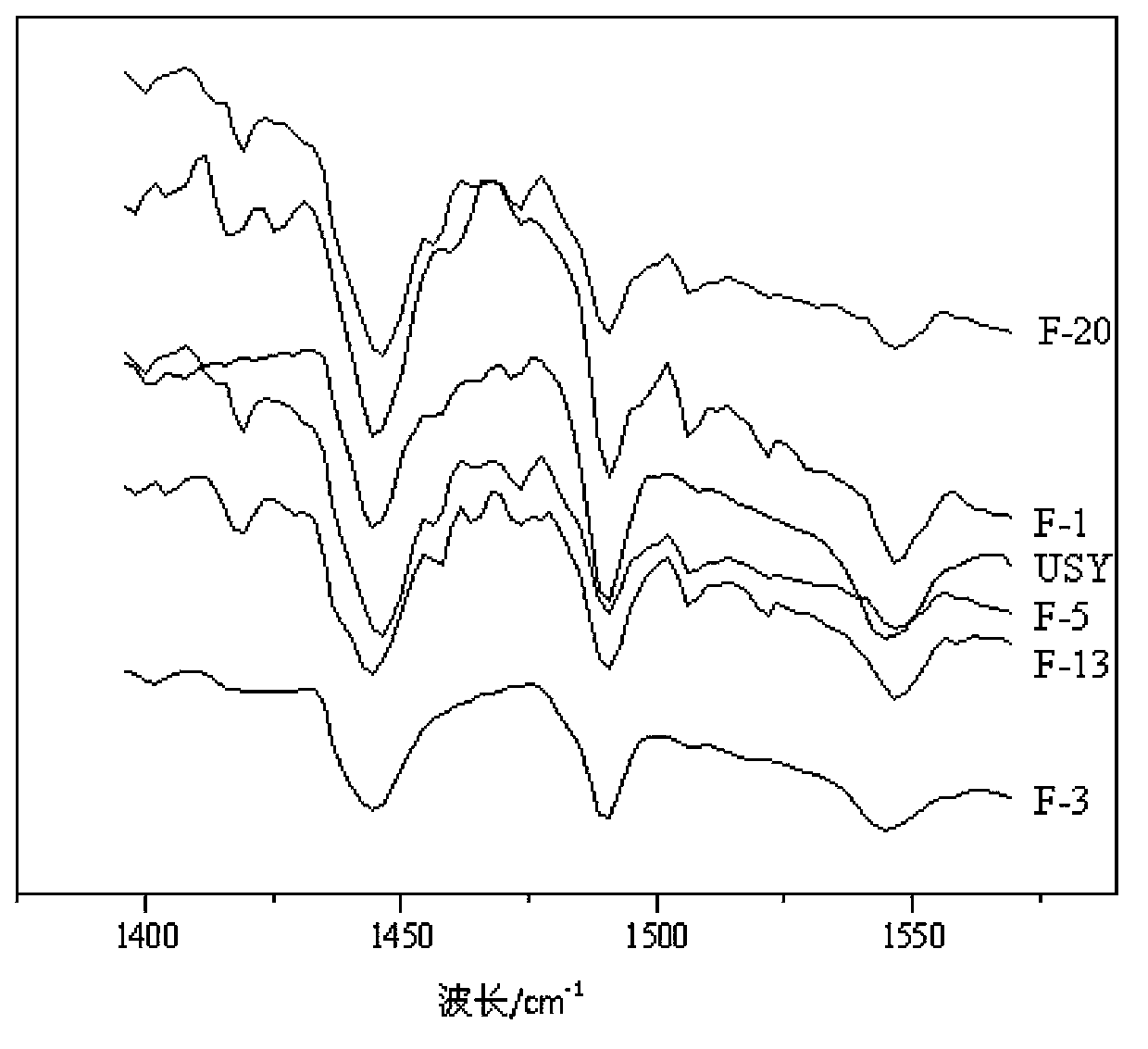

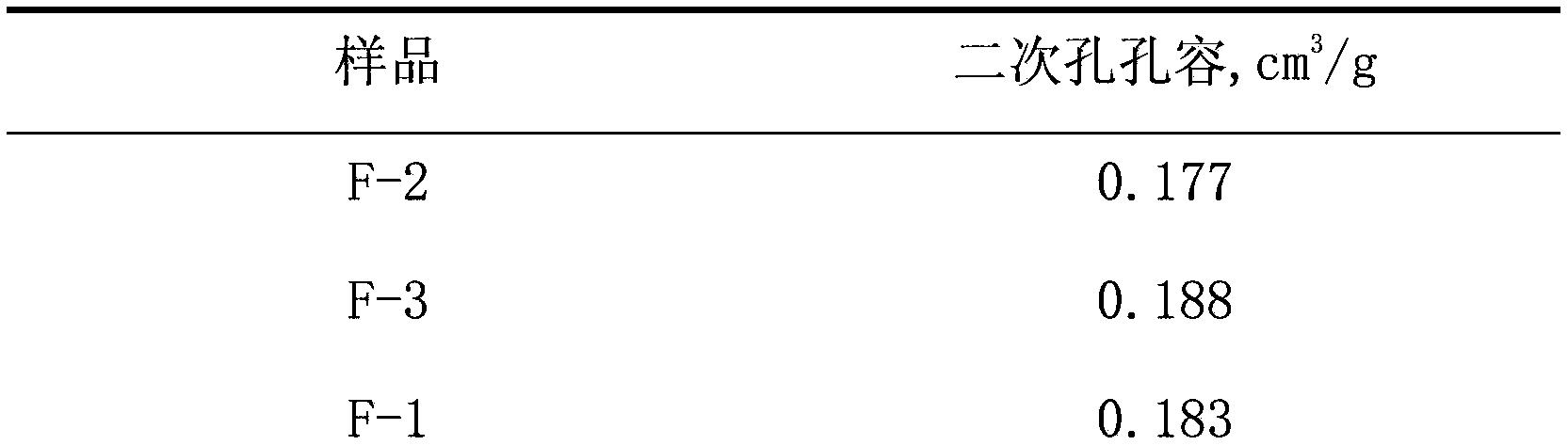

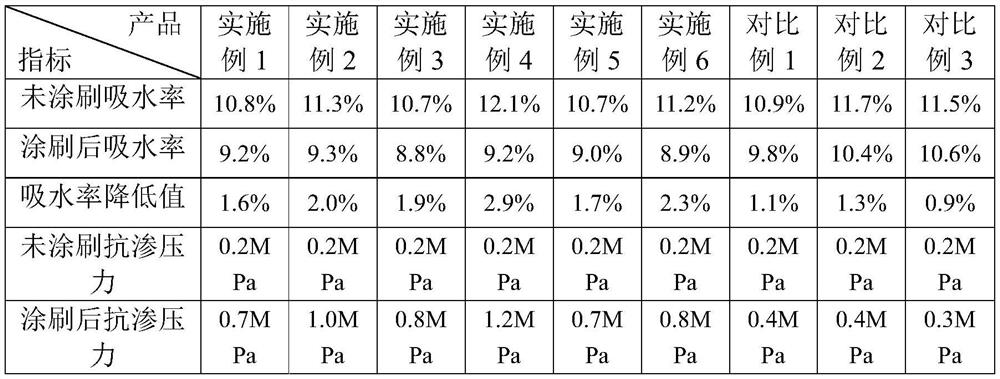

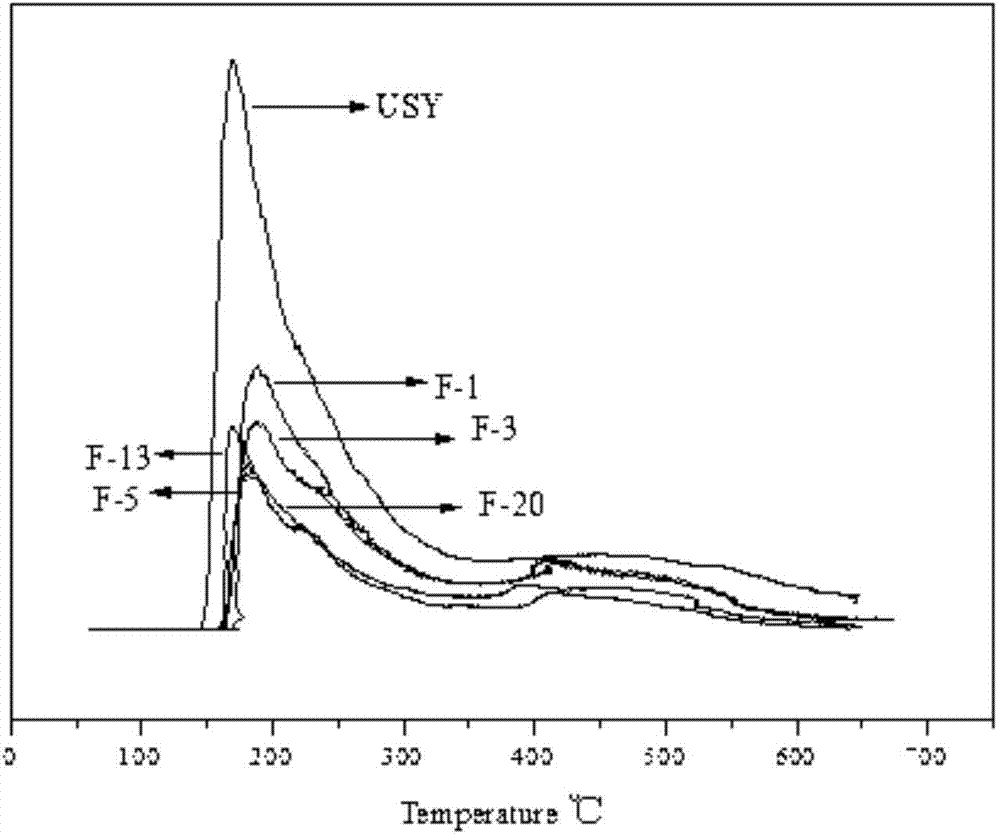

USY molecular sieve modification method

InactiveCN104096586AHigh ratio of silicon to aluminumHigh crystallinityMolecular sieve catalystsMolecular sieveReaction temperature

The invention relates to a USY molecular sieve modification method. The USY molecular sieve modification method comprises the following steps of adding a citric acid solution having a concentration of 0.10-0.35mol / L into a USY molecular sieve according to a solid-liquid quality ratio of 1: 5 for modification with stirring at a reaction temperature of 500-1200 DEG C, after a temperature is increased to a preset temperature of 600-900 DEG C, adding an ammonium fluosilicate solution having a concentration of 0.05-0.20mol / L into the reaction product at a rate of 0.1-3.5ml / min according to a volume ratio of citric acid to the ammonium fluosilicate solution of 0.5-3.0, after material addition, carrying out a reaction process at a temperature of 50-120 DEG C for 1-6h, carrying out washing by deionized water until a pH value is 7, and carrying out constant-temperature drying at a temperature of 110 DEG C. The USY molecular sieve obtained by the USY molecular sieve modification method has substantially improved specific surface, secondary pore volume and moderate strong acid level and can be used for a hydrocracking catalyst for maximizing middle distillates as desired products.

Owner:PETROCHINA CO LTD

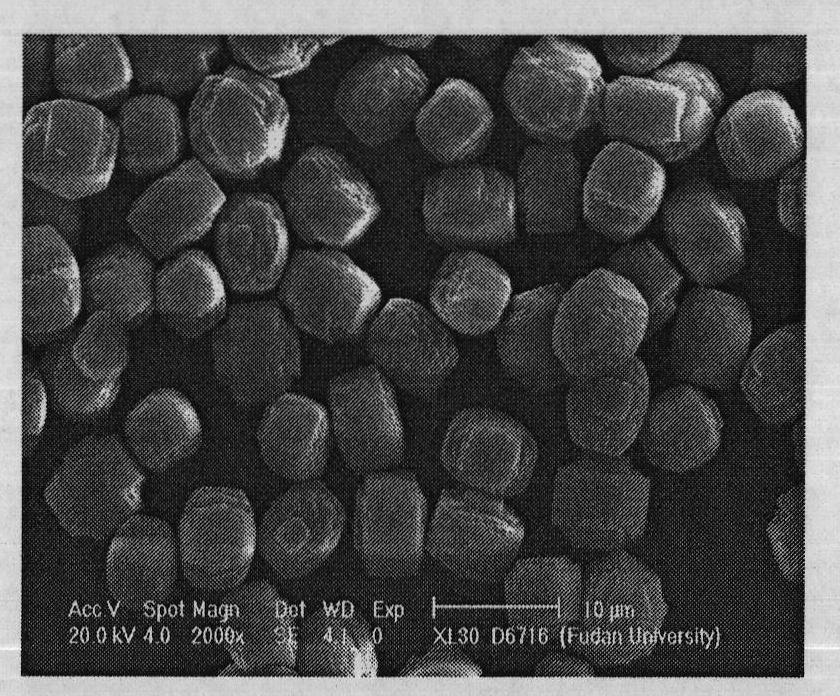

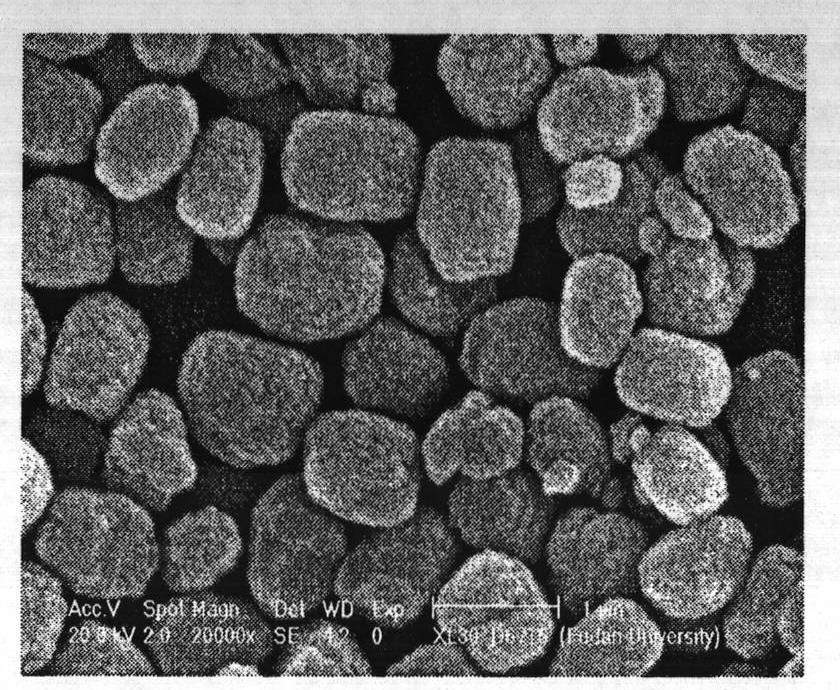

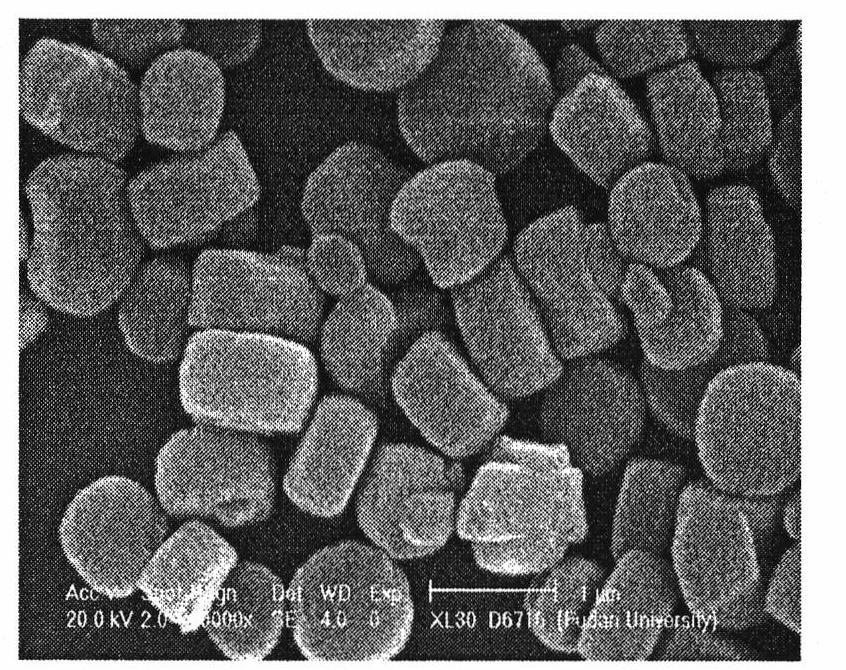

Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

InactiveCN101857243ASmall surface pore sizeMaintain skeleton structurePentasil aluminosilicate zeolitePore diameterFluosilicates

The invention belongs to the technical field of zeolite molecular sieves, in particular to a method for adjusting a surface hole diameter of a ZSM-5 molecular sieve by surface dealuminizing and compensating silicon. The invention accurately controls the surface hole diameter of the molecular sieve by using the treating measure of dealuminizing and compensating silicon on the ZSM-5 zeolite molecular sieve with ammonium fluosilicate solution. An ultrathin layer enriched with silicon is formed on the surface of the ZSM-5 zeolite molecular sieve treated by the method so that the hole caliber on the surface of the molecular sieve is shrunk. The ZSM-5 zeolite molecular sieves with different hole caliber shrinkage level can be selectively obtained by changing different treating conditions. The SM-5 zeolite molecular sieves modified by the method can be used for absorbing a mixture of three isomerides of P-, M-and O-Xylene.

Owner:FUDAN UNIV

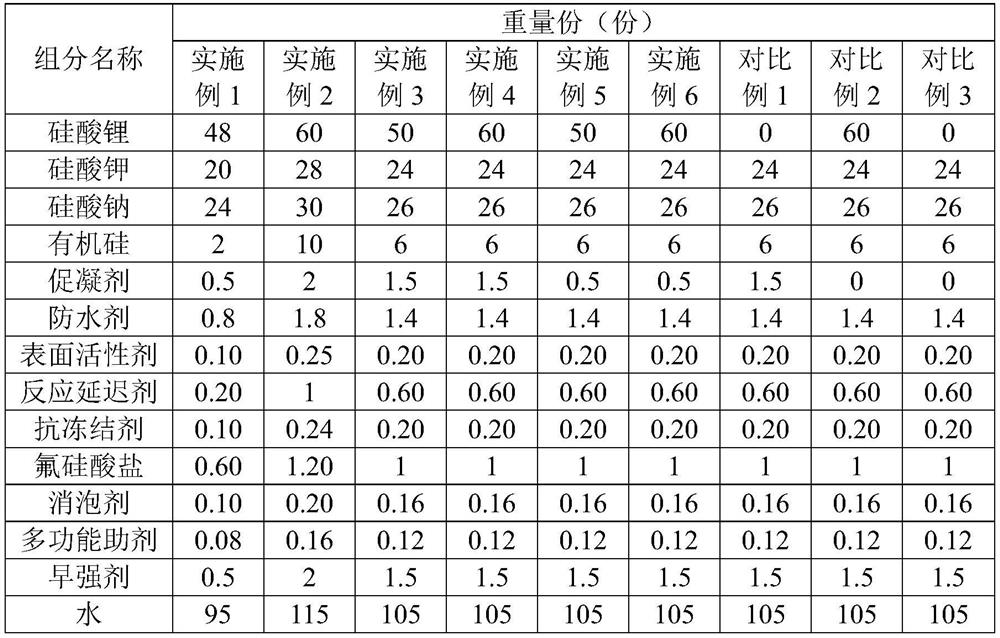

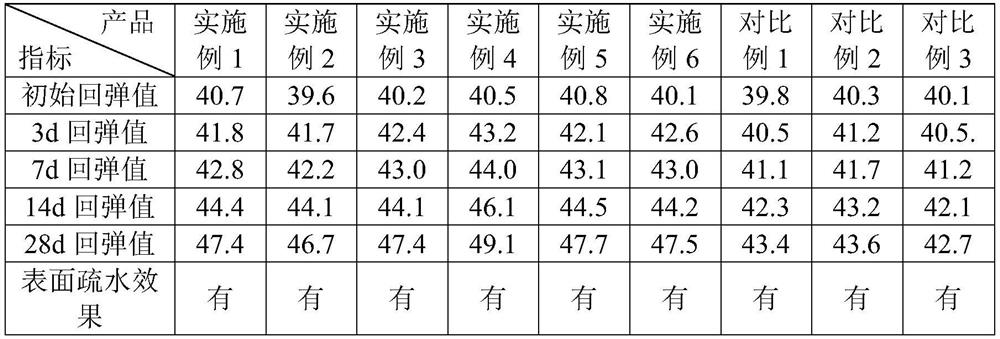

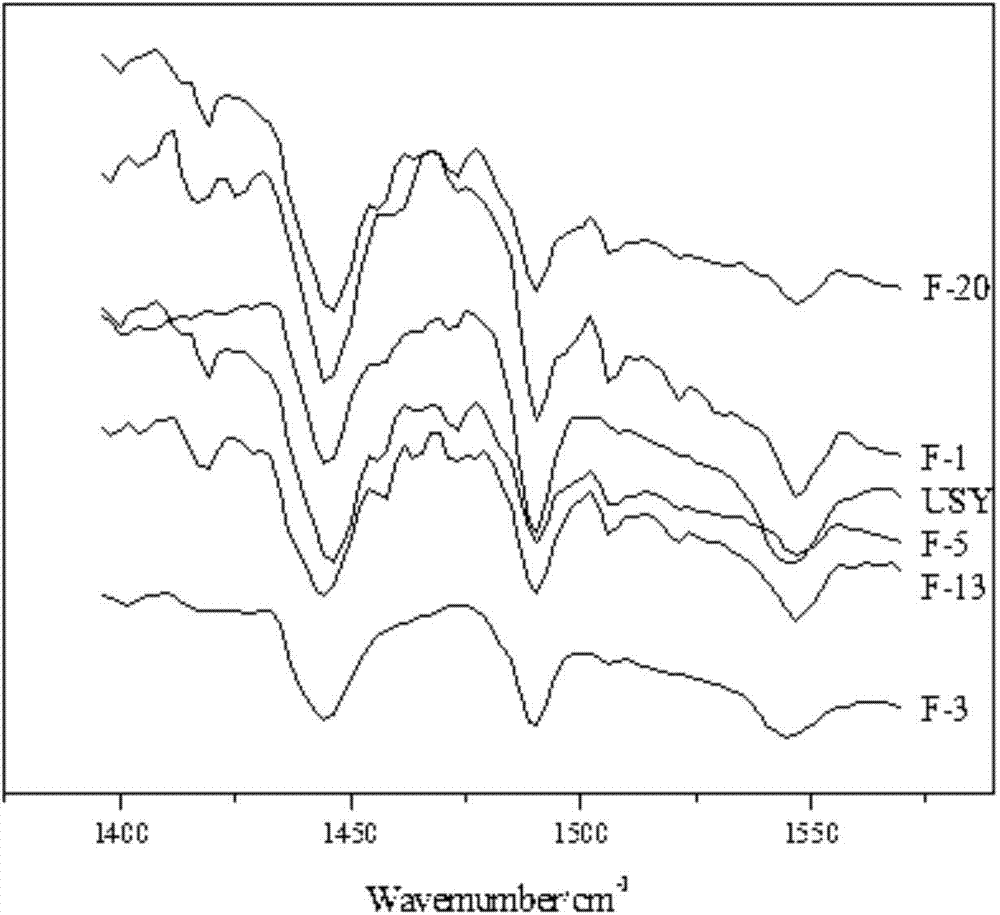

Water-based capillary crystalline concrete surface layer repairing and reinforcing material as well as preparation method and application thereof

The invention discloses a water-based capillary crystalline type concrete surface layer repairing and reinforcing material as well as a preparation method and application thereof. The material comprises 48-60 parts of lithium silicate, 20-28 parts of potassium silicate, 24-30 parts of sodium silicate, 2-10 parts of organosilicon, 0.5-2 parts of a coagulant, 0.8-1.8 parts of a waterproof agent, 0.1-0.25 parts of a surfactant, 0.2-1 part of a reaction retarder, 0.1-0.24 parts of an anti-freezing agent, 0.6-1.2 parts of fluosilicate, 0.1-0.2 parts of an antifoaming agent, 0.08-0.16 parts of a multifunctional auxiliary agent, 0.5-2 parts of an early strength agent and 95-115 parts of water. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material hasthe characteristic of quick strength improvement, has an obvious repairing effect on concrete and mortar, and can repair and heal cracks and fine cracks, so that the water permeability resistance ofthe concrete can be improved. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material is good in durability, long in service life, simple and convenient toprepare and convenient to construct.

Owner:苏州佳固士新材料科技有限公司

Acid pickling and waste acid treatment process for improving purity of powdery quartz sand

The invention provides an acid pickling and waste acid treatment process for improving purity of powdery quartz sand. The process includes the steps: putting the powdery quartz sand in an acid pickling purification device, and using an acid pump for pumping acid pickling solution into the acid pickling purification device, wherein the acid pickling solution is composed of hydrofluoric acid, fluorosilicic acid, oxalic acid and water or composed of fluorosilicic acid, oxalic acid and water; removing the acid pickling solution after acid pickling, and collecting; delivering the powdery quartz sand to a washing device by clear water after acid pickling, washing to neutral, and dewatering to obtain a finished product of powdery quartz sand; transferring waste acid into a neutralization tank for neutralization, delivering into a sedimentation tank by the pump, and allowing calcium fluosilicate and calcium oxalate to precipitate; delivering the clear water into a regulation tank after precipitation to realize pH adjustment for precipitation of iron ions; using oxalic acid or fluorosilicic acid to adjust pH, precipitating calcium fluosilicate and calcium oxalate again, filtering to obtain clear water, and delivering the clear water to a workshop for recycling. The acid pickling and waste acid treatment process for improving purity of the powdery quartz sand has the advantages of remarkable purity improvement and impurity reduction and simplicity and convenience in subsequent treatment.

Owner:HUANGGANG NORMAL UNIV +1

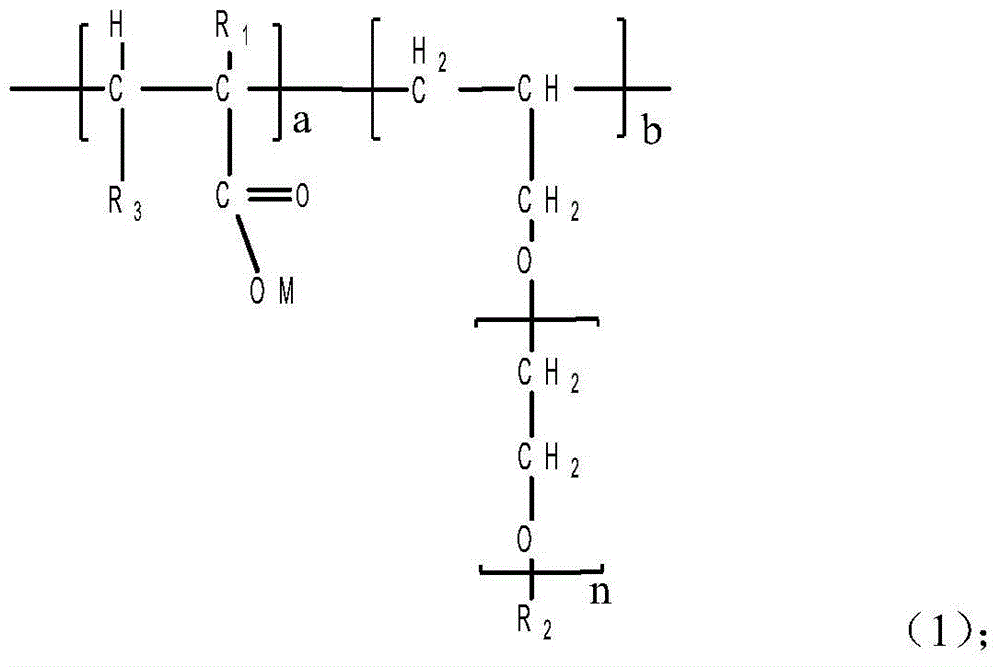

Low-superficial area ratio marine antifouling coating of silicofluoride block polymer and its production

InactiveCN101029207ALower surface energyLow costAntifouling/underwater paintsPaints with biocidesMethacrylatePolydimethyl siloxane

A fluosilicate block polymer low-surface energy marine anti-fouling coating and its production are disclosed. The coating consists of base material polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer, accessory methyl silicone oil and di-n-octyl ester phthalate and coating solvent butyrin acetate. The process is carried out by mixing methyl silicone oil with di-n-octyl ester phthalate to obtain coating accessory, mixing polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer with pigment to obtain coating base material and pigment mixture, adding coating accessory into mixture of coating base material and pigment, mixing, dissolving it into butyrin acetate and laying aside. It has excellent anti-fouling effect and no environmental pollution.

Owner:XIAMEN UNIV

Compound modification method for USY molecular sieve

InactiveCN103880035ARich secondary pore structureRich medium strong acidMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveStrong acids

The invention relates to a method for a structural design of a USY molecular sieve, and particularly relates to a compound modification method for the USY molecular sieve, wherein ammonium fluosilicate and citric acid are taken as a modifying agent in the method. The method is used for preparing a modified USY molecular sieve which has abundant secondary porous structures, high crystallinity and abundant medium-strong acid, and the modified USY molecular sieve is applicable to a hydrocracking catalyst which is used for producing prolific middle distillate as a target product.

Owner:PETROCHINA CO LTD +1

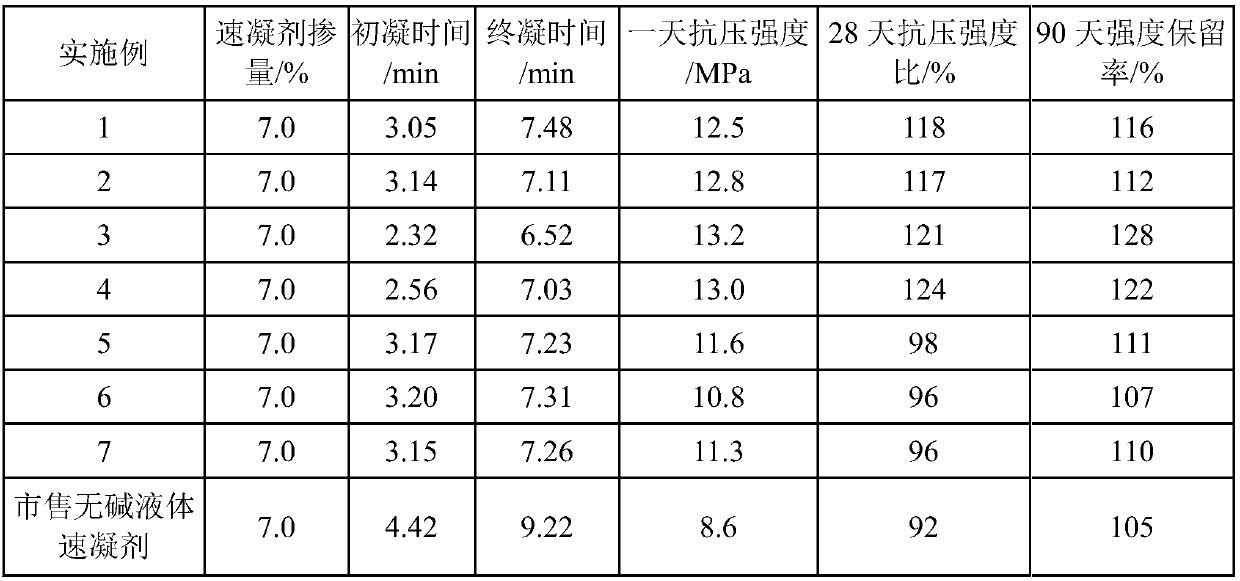

Chlorine-free and alkali-free liquid setting accelerator and preparation method thereof

The invention belongs to the technical field of preparation of additives, and in particular relates to a chlorine-free and alkali-free liquid setting accelerator and a preparation method thereof. The preparation method comprises the steps of adding aluminum sulfate and aluminum hydroxide into deionized water, and heating to obtain mother liquor of aluminate; then, adding magnesium fluosilicate and disodium ethylenediamine tetraacetate into the deionized water, and heating to obtain a magnesium fluosilicate solution; mixing the magnesium fluosilicate solution with the mother liquor of aluminate, then adding organic amine, organic acid and a stabilizer, and stirring to obtain the chlorine-free and alkali-free liquid setting accelerator. The setting accelerator prepared by the method has the characteristics of being small in mixing amount and good in setting acceleration effect; furthermore, after the setting accelerator is used, the mechanical properties of the concrete are improved, and the compressive strength of the concrete is increased; therefore, the chlorine-free and alkali-free liquid setting accelerator is an ideal concrete additive.

Owner:常州文诺纺织品有限公司

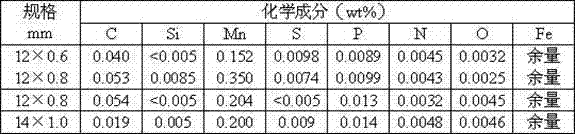

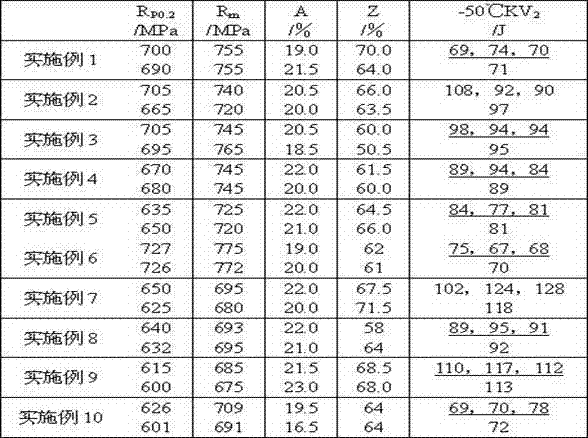

High-strength and high-toughness metal powder type flux-cored wire with no need of being pre-heated before welded

ActiveCN103028864AGood welding performanceGood workmanshipWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a high-strength and high-toughness metal powder type flux-cored wire with no need of being pre-heated before welded. Steel skin is 79-84% of a total weight of a welding wire and a flux core is 16-21% of the total weight of the welding wire. The steel skin is manufactured by using a cold rolling carbon steel strip and comprises the following components: 0.02-0.055% of C, 0.005-0.0085% of Si, 0.15-0.35% of Mn and the balance of iron; and the flux core comprises the following components: 12-18% of nickel powder, 2-4% of manganese powder, 3-7% of silicon iron, 2-6% of ferro-molybdenum, 0.8-2.5% of ferrotitanium, 1-5% of mid-carbon ferromanganese, 0.8-2.5% of potassium fluosilicate and rear earth oxide in sum, and the balance of iron powder. The flux-cored wire provided by the invention has the advantages of good welding process, high melting efficiency and less slag quantity; the yield strength of deposited metal can be more than 590 MPa; the impact rigidity at a temperature of -50 DEG C can be more than 70J; and the diffusible hydrogen is in an ultralow hydrogen level.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

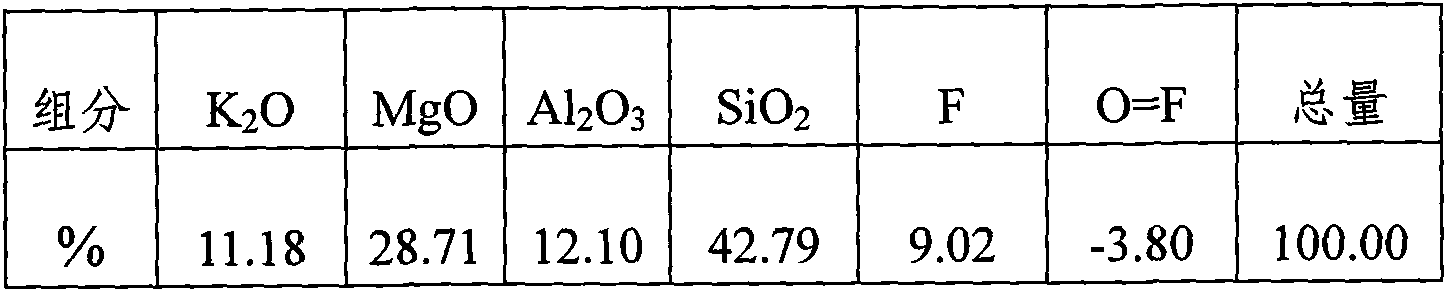

Synthetic mica prepared from calcined talcum and preparation method and processing method of fluorophlogopite powder and fluorophlogopite pearlescent pigment

ActiveCN101671034AHigh purityLess impuritiesPigmenting treatmentSilicon compoundsPotassiumHigh pressure

The invention discloses a kind of synthetic mica prepared from calcined talcum and other raw materials and a wet processing method of fluorophlogopite powder and fluorophlogopite pearlescent pigment by using the synthetic mica as raw material. The mica is prepared by fusing five raw materials--calcined talcum, heavy magnesium oxide, potassium fluosilicate, alumina and potassium carbonate. The preparation method of the mica comprises the following steps: heating raw materials with a electric furnace to fuse the raw materials, then keeping temperature, reducing temperature, cooling naturally toobtain mica plates; then crushing the mica plates with a gear high pressure crusher, then grinding and repairing the obtained product with a special grinder to obtain fluorophlogopite powder; then using the fluorophlogopite powder to prepare synthetic fluorophlogopite pearlescent pigment through the hydrolysis method. The mica prepared by the method of the invention is high purity transparent monocrystals, the surface is smooth, the mica is well-crystallized and cleavage flake is thin; the prepared fluorophlogopite powder has high diameter-thickness ratio, fine and smooth hand feeling and highwhiteness; the prepared fluorophlogopite pearlescent pigment has strong luster and niveous appearance.

Owner:JIANGYIN YOUJIA PEARLESCENT MICA

Fire resistant water-based self-adhesion coating

The invention discloses a high-temperature resistance water-based self-adhering paint, which comprises the following parts: 10-80% main agent, which contains alkaline metal silicate from one of quaternary amine, tertiary amine and silicate of guanidine (23.5- 46.3% silicate or 67.8-83.9% phosphate); 26.8-45.1% solidifier, which concludes metal oxide, aluminium hydroxide, magnesium fluosilicate, magnesium borate, zinc borate, magnesium phosphate or potassium phosphate; 16.1-32.2% filler, which contains silica, alumina, mullite, boron nitride or mica.

Owner:BAOSHAN IRON & STEEL CO LTD

Silicon solar cell front face electrode lead-free silver paste and preparing method thereof

InactiveCN104157332AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureTetramethylammonium hydroxidePotassium

The invention discloses silicon solar cell front face electrode lead-free silver paste and a preparing method thereof. The silicon solar cell front face electrode lead-free silver paste is characterized in that inorganic glass powder is not contained in the silver paste, and the silver paste comprises, by mass, 75-85 percent of conductive silver powder, 1-5 percent of antireflective film corrosive, 10-20 percent of organic vehicle and 1-5 percent of additive; the conductive silver powder is formed by mixing micro silver powder and nano silver powder with the mass ratio of 10:1-2; the antireflective film corrosive comprises one or more of potassium fluotitanate, potassium fluoroaluminate, potassium fluosilicate and potassium fluoborate; the additive comprises one or more of ethanol amine, diethanol amine, triethanol amine, tetramethylammonium hydroxide, tetraethylammonium hydroxide and tetramethylammonium hydroxide. According to the silicon solar cell front face electrode lead-free silver paste and the preparing method thereof, lead-free silver paste printing and antireflective film removing are conducted in one step, sintering can be conducted at a low temperature, the compactness and the smoothness of a silver electrode film are improved, and the photoelectric conversion efficiency of a silicon cell piece is improved.

Owner:TIANJIN VOCATIONAL INST

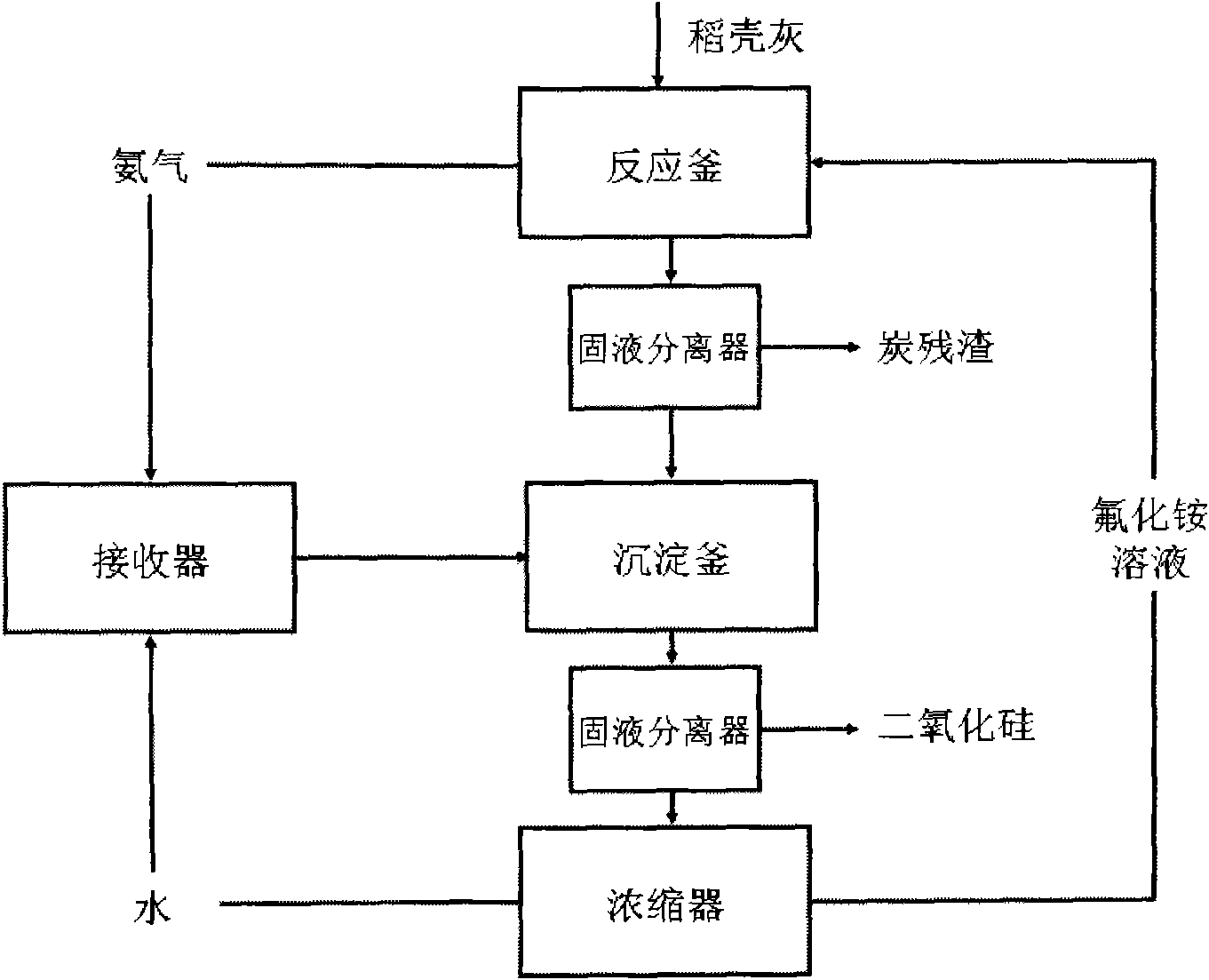

New method for preparing silicon dioxide by utilizing rice hull ash

The invention discloses a new method for preparing silicon dioxide by utilizing rice hull ash, comprising the following steps: neutralizing and dissolving the soluble impurities in the rice hull ash by utilizing a sulfuric acid solution; adding an ammonium fluoride solution in proportion; heating and dissolving to generate ammonium fluosilicate and discharge ammonia; modulating the concentration of the ammonia water to be 10-30wt% by the ammonia generated in the water recovering reaction; placing into a seal stillpot; regulating the temperature to be 50-90 DEG C; adding the ammonium fluosilicate solution into the ammonia water in proportion; separating out the sedimentation; ageing for 0.5-3h; filtering and performing solid-liquid separation; returning the filter liquor to a silicon dissolving procedure for recycling after the filter liquor concentration is adjusted; and washing and drying the filter cakes to obtain the silicon dioxide. The method of the invention takes the regenerated resource rice hull ash as a silicon source, and adopts constant-voltage low-temperature liquid phase dissolving silicon; and the reactant ammonium fluoride and the by-product ammonia can be recycled, which not only saves the energy consumption and lowers the cost, but also has no other by-product generation and no greenhouse gas emission, thus belonging to a low-carbon green new process.

Owner:JILIN UNIV

Sponge composite metallic organic framework material for adsorption separation

ActiveCN110038540AStrong loadHigh load rateGas treatmentOther chemical processesFragilityMetal-organic framework

The invention relates to a sponge composite metallic organic framework material for adsorption separation and belongs to the technical field of materials. According to the invention, a two-step in-situ growth method is adopted for loading MOFs (metallic organic framework material) into a duct in a sponge carrier. The MOFs is synthesized from following organic ligands and metal salts, wherein the organic ligands include pyrazine, trimesic acid, terephthalic acid, 2,5-dihydroxyterephthalic acid, and the metal salts include cupric fluosilicate, magnesium nitrate, zirconium chloride, cupric nitrate, chromic nitrate, ferric nitrate, aluminum nitrate and hydrates thereof. According to a preparation method provided by the invention, a large amount of MOFs loaded in the duct in the sponge carriercan be realized; MOFs load rate is high; load is stable; the defects of fragility and easiness in loss of MOFs powder can be overcome; a breakthrough experiment proves that the material provided by the invention has the characteristics of high CO2-absorbing capacity, high adsorption separation selectivity, stable adsorption separation property, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Low-doping-amount and high-performance alkali-free and chlorine-free liquid setting accelerator and preparation method thereof

The invention provides a low-doping-amount and high-performance alkali-free and chlorine-free liquid setting accelerator and a preparation method thereof and belongs to the field of building materials. The setting accelerator is prepared from the following raw materials in percentage by weight: 30 to 60 parts of potassium sulfate, 0 to 20 parts of magnesium sulfate, 0.5 to 2.0 parts of precipitated magnesium silicate hydrate, 0.5 to 2.0 parts of magnesium oxide, 1 to 3 parts of magnesium fluosilicate, 1 to 3 parts of alkylol amine, 0.5 to 1.5 parts of a high polymer, 0.2 to 1.0 part of a stabilizing agent, 5 to 40 parts of a mother solution and 30 to 50 parts of water. The obtained liquid setting accelerator has the density of 1.3 to 1.5g / cm<3>, the pH (Potential of Hydrogen) value of 2.5to 3.5, the solid content of 37 to 45 percent and the alkali content of less than or equal to 1.0 percent. The alkali-free liquid setting accelerator provided by the invention has the advantage of nocorrosive and irritating odor, low doping amount, good adaptability to cement, rapid condensation speed and high strength and good stability; and the stabilization period reaches 180 days or more, thetechnology feasibility is strong and the liquid setting accelerator is suitable for large-scale industrial production.

Owner:PANZHIHUA CITY JIYUAN TECH

Method for processing potassium-containing rocks

InactiveCN101948115AShort reaction timeReduce energy consumptionSilicaAluminium silicatesChemical treatmentPotassium

The invention discloses a method for processing potassium-containing rocks, which mainly comprises: coarsely and finely crushing the potassium-containing rocks to 100 to 200 meshes; and adding the potassium-containing rocks to fluosilicic acid according to a ratio to react the potassium-containing rocks with fluosilicic acid fully to obtain a mixed material containing potassium fluosilicate, aluminium fluosilicate and silica gel. In the invention, the fluosilicic acid is used alone to decompose the potassium-containing rocks, the fluosilicic acid and ore powder are fed into a reaction kettle in turn under a stirring condition, the reaction kettle is heated to 110 to 170 to allow the reactants to react fully, the reaction time is 1 to 3 hours, the fluosilicic acid suspension is reserved and subjected to subsequent chemical processing, acidification is performed, and the fluosilicic acid is reclaimed. Compared with the conventional mixed acid method, the method can process 1 ton of potassium-containing rock raw material by using 0.2 ton of coal containing 5,000 large calories of heat; and compared with the method of evaporating the mixed acid to dryness, the method can save 60 to 80percent of energy consumption and reduce processing time by 4 to 6 folds.

Owner:薛彦辉

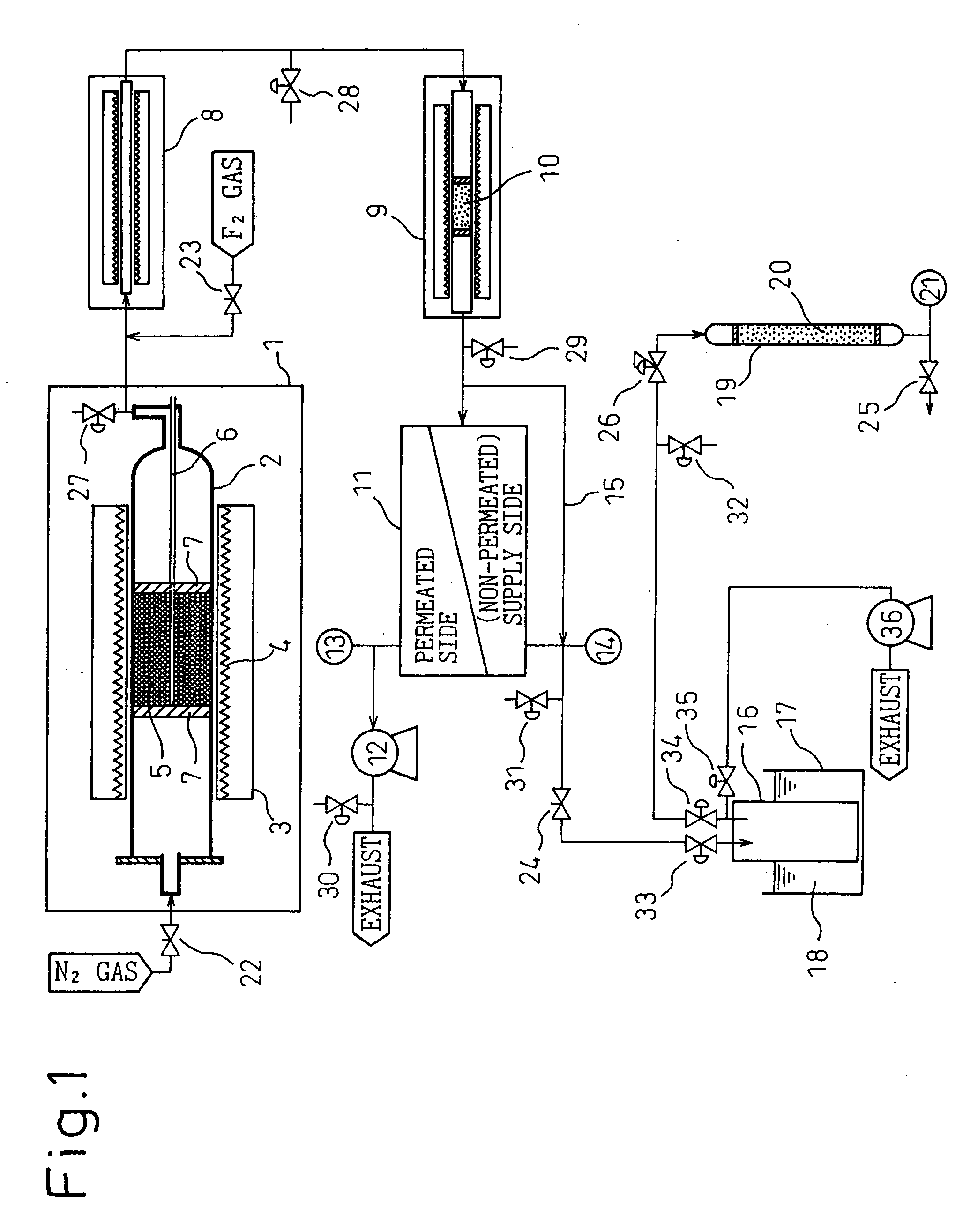

Production and use of tetrafluorosilane

Tetrafluorosilane is produced by a process comprising a step (1) of heating a hexafluorosilicate, a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas, a step (2-2) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a highvalent metal fluoxide, or a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas and a step (2-3) of reacting a tetrafluorosilane gas produced in the step (2-1) with a highvalent metal fluoride. Further, impurities in high-purity tetrafluorosilane are analyzed.

Owner:SHOWA DENKO KK

Dry mixing gunite material in use for underworkings of coal mine, and preparation method

InactiveCN101092047AHigh viscosityNo pollution in the processCement mixing apparatusManufacturing technologySlurry

The invention relates to a dry-mixed slurry spraying material used in coal mine laneway. It includes concrete, quartz sand or crushed sand, CaCO3, cellulose, and fiber. The feature is that concrete contains 100 portions, quartz sand or crushed sand contains 150-300portions, calcium carbonate is 0-50 portions, HPMC is 0.2-0.3 portions, polymer emulsion is 10-30 portions, polypropylene fiber is 0.1-0.2 portions, zinc fluosilicate is 5-10 portions, water reducing agent is 0.5-0.7 portions, and early strength agent is 0.2-0.3 portions. The method includes the following steps: weighing the raw material accurately, whisking in high efficiency blender for 20 minutes, mixing to equal and packaging. The invention has the advantages of light, high intension, high binding glue, inflaming, water proof, simple manufacturing technology, etc.

Owner:ZIBO MINING GRP +1

Additive for aluminum alloy melting

The invention discloses an additive for aluminum alloy melting. The additive comprises: by mass, 65 to 75% of metal powder having granularity of 80 to 100 meshes, 20 to 30% of one or more halide salt cosolvents, 1 to 3% of paraffin powder and 1 to 3% of a moisture-proofing agent. The metal powder is at least one of iron powder, copper powder, manganese powder, titanium powder and nickel powder. The one or more halide salt cosolvents are selected from potassium chloride, potassium fluoride, potassium iodide, potassium fluosilicate and potassium fluoroaluminate. Through use of the paraffin powder and the one or more halide salt cosolvents, good bonding effects on metal powder are obtained; pulverization of metal powder is prevented effectively; an additive falling speed is reduced; and a melting speed is obviously improved. The additive provided by the invention solves the problems of a high additive melting temperature and a low metal powder absorption rate, realizes a high metal powder absorption rate reaching to 99%, and improves the quality of an aluminum alloy ingot casting.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

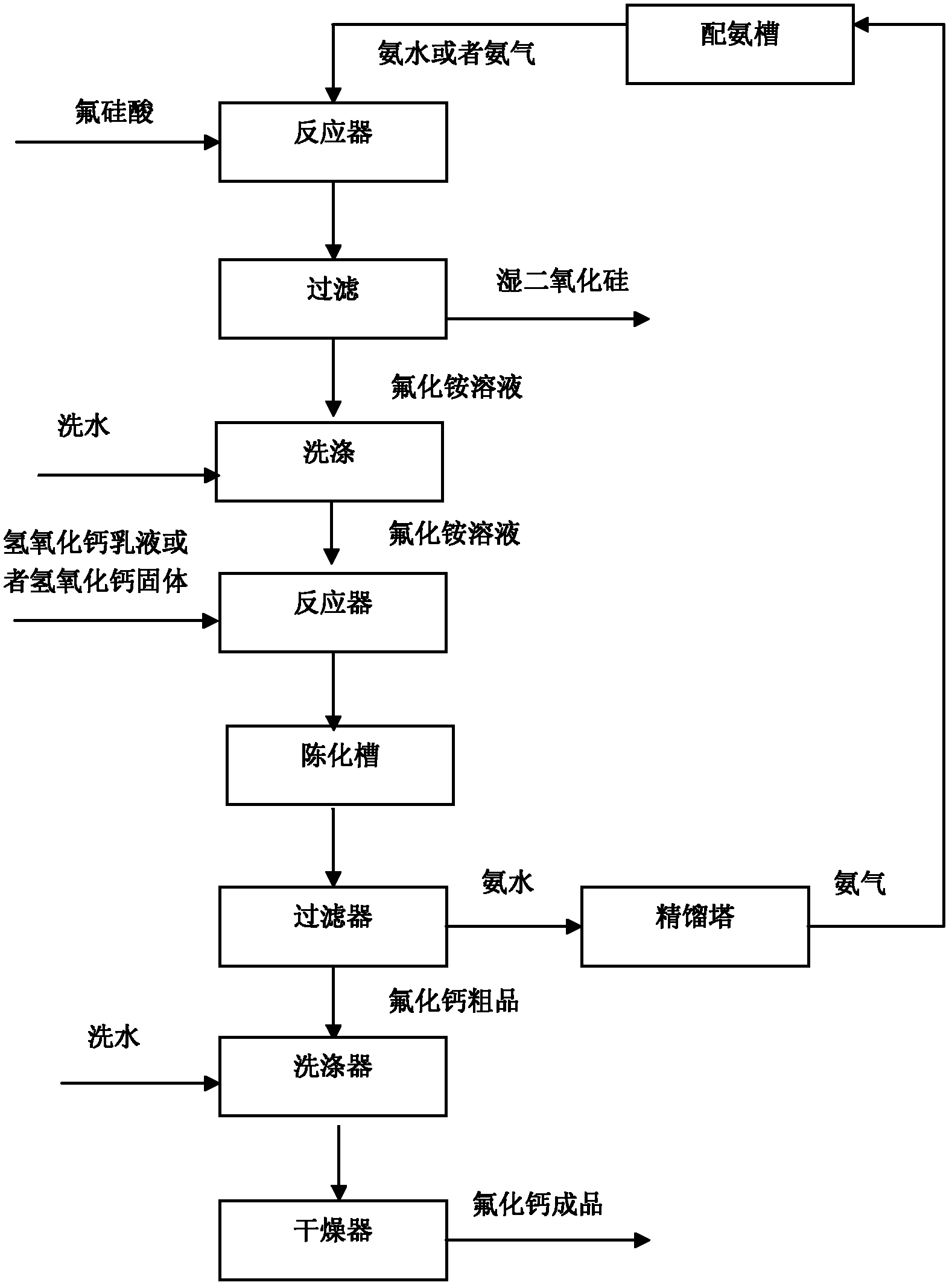

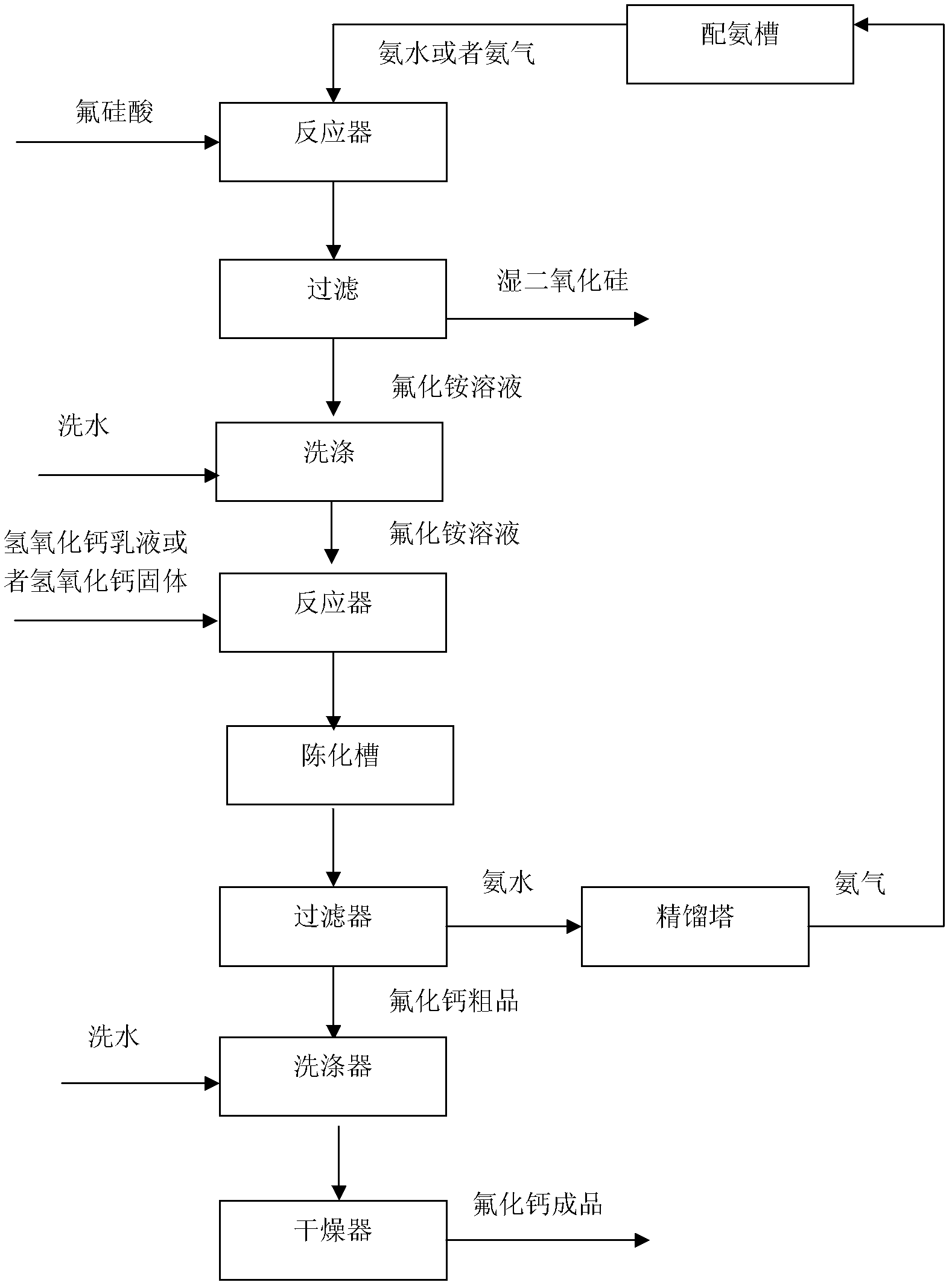

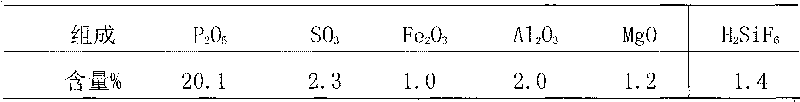

Synthetic method of calcium fluoride

ActiveCN102502753AImprove solubilityAchieve separationCalcium/strontium/barium fluoridesSolubilityTwo step

The invention relates to a synthetic method of calcium fluoride, hydrofluosilicic acid produced during a phosphate fertilizer production process is adopted as raw materials so as to synthesize calcium fluoride through two steps of reaction, the first step of reaction is that ammonium fluoride and silicon dioxide are produced through the reaction of fluosilicic acid and ammonia gas or ammonia water, the solubility of ammonium fluoride is high, and the separation of ammonium fluoride from silicon dioxide is achieved through the method of filtering and washing; the second step of reaction is that calcium fluoride and ammonia water are produced through the reaction of ammonium fluoride solution and calcium hydroxide, the separation of calcium fluoride from ammonia water is achieved through the filtering way, ammonia gas is obtained by rectifying the ammonia water, and calcium fluoride is produced by taking ammonium fluoride as an intermediate product. Therefore, the invention overcomes defects of insufficient reaction during the process of synthesizing calcium fluoride through the reaction of hydrofluosilicic acid and calcium hydroxide, and mass of calcium fluosilicate contained in calcium fluoride products, further solves the problem of difficulty separation of calcium fluoride from silicon dioxide mixture, and achieves efficient utilization of by-product hydrofluosilicic acid ofphosphate fertilizer.

Owner:KUNMING DAOERSEN TECH

Method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer

InactiveCN101717290AIncrease profitSave resourcesFertilizer mixturesChemical industryPhosphoric acid

The invention relates to a method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer, which belongs to the technical field of production in the chemical industry. The method comprises the following steps of: firstly, adding soluble sylvite (or sodium salt) into fluosilicic acid in wet phosphoric acid to generate potassium fluosilicate (or sodium fluosilicate) precipitate, wherein after separating the potassium fluosilicate (or sodium fluosilicate) precipitate, the potassium fluosilicate (or sodium fluosilicate) precipitate is used as byproduct; then mixing the defluorinated wet phosphoric acid with converted potassium bisulfate at low temperature, carrying out neutralization reaction on mixed acid and gas ammonia; and granulating, drying, sieving, cooling and packing the neutralized slurry to prepare the defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer. The invention is mainly used for producing chemical fertilizers.

Owner:SHANDONG HONGRI ACRON CHEM

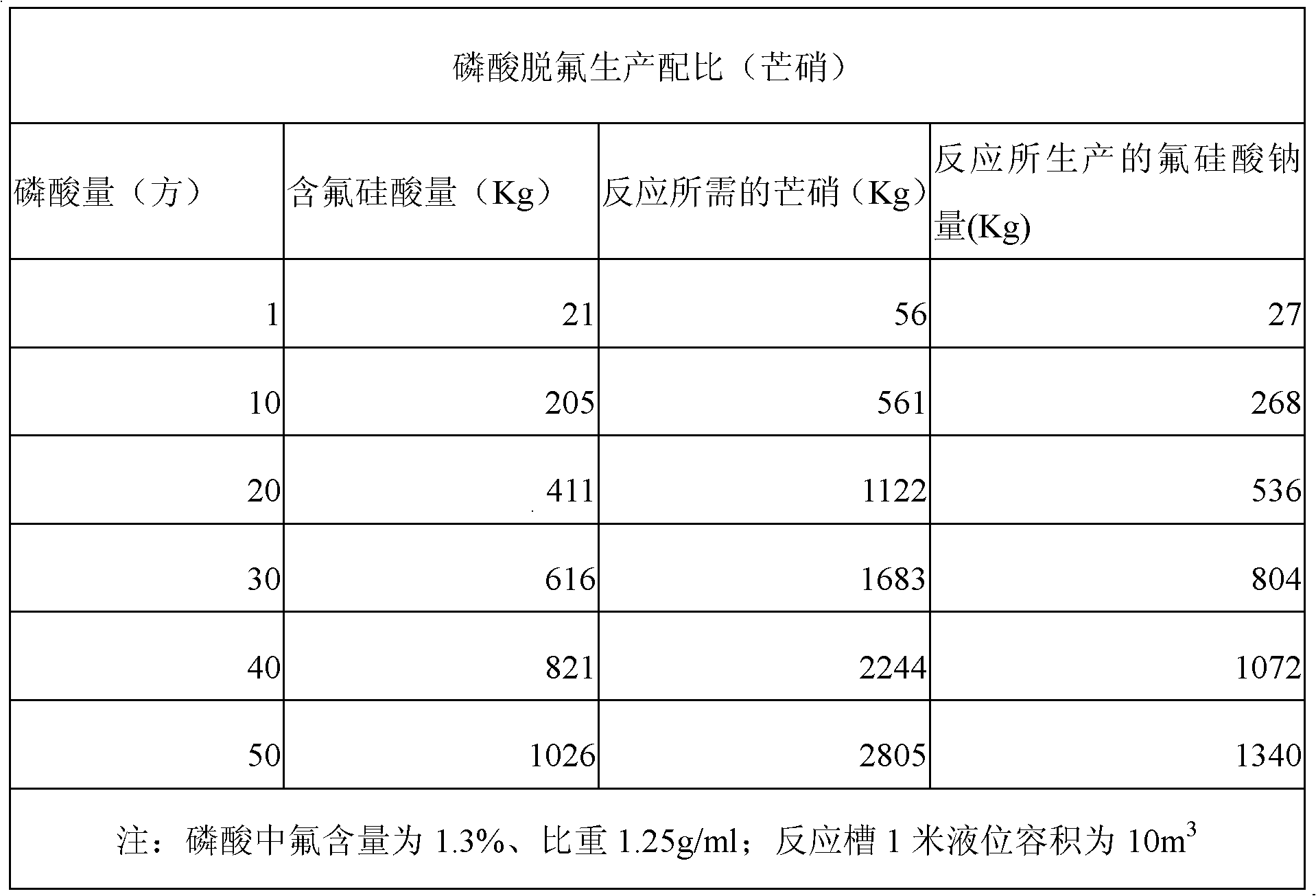

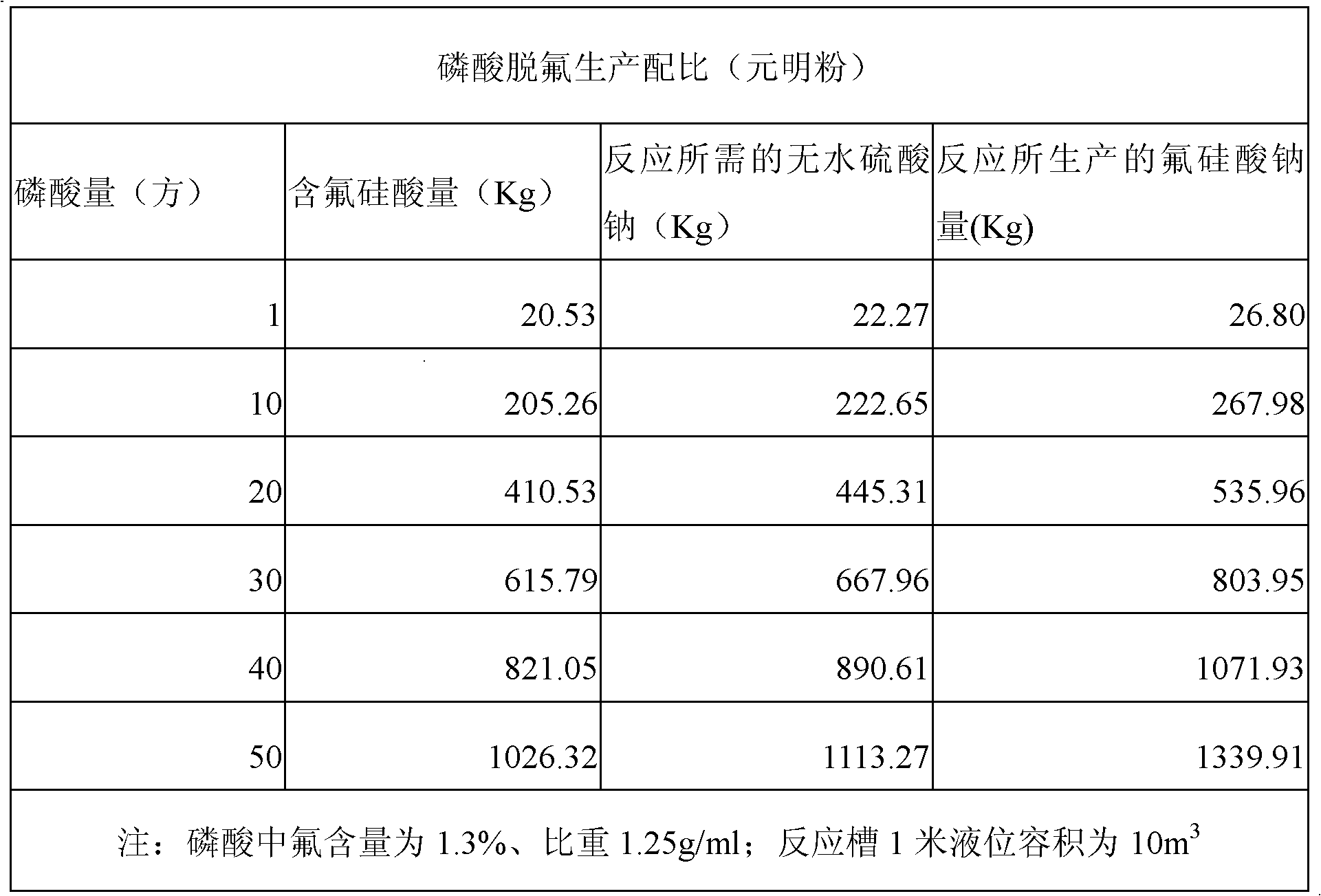

Production method of sodium fluosilicate

InactiveCN102153091AQuality improvementReduce or eliminate hazardsSilicon halogen compoundsPhosphoric acidEconomic benefits

The invention relates to a production method of sodium fluosilicate. The method comprises the following steps: adding a phosphoric acid purification device to purify the phosphoric acid produced in a phosphoric acid workshop; injecting the purified phosphoric acid in a filtrate receiver, injecting in a reaction tank by using a variable frequency pump; injecting fluorine-removing agent in the reaction tank at a ratio according to the fluorine content of phosphoric acid, reacting by utilizing the stirring action of the reaction tank; injecting the obtained mixture in a settling tank by using a pump after the reaction in the reaction tank, centrifuging the settled precipitate, and drying to obtain a sodium fluosilicate product and obtain the defluorinated phosphoric acid on the upper layer. In the method, after wet-process phosphoric acid is purified, fluorine-removing agent is used to remove about 2% of fluorine in phosphoric acid and form insoluble fluosilicate, and the fluosilicate is precipitated, washed, separated and dried to obtain a sodium fluosilicate product, thus the rational utilization of resource can be realized and the economic benefit of the enterprise can be increased. By adopting the method, fluorine resource can be fully recycled in the production process of compound fertilizer, high quality fluorine-free compound fertilizer can be produced and the damages to soil can be reduced or eliminated.

Owner:山东聊城鲁西化工第四化肥有限公司

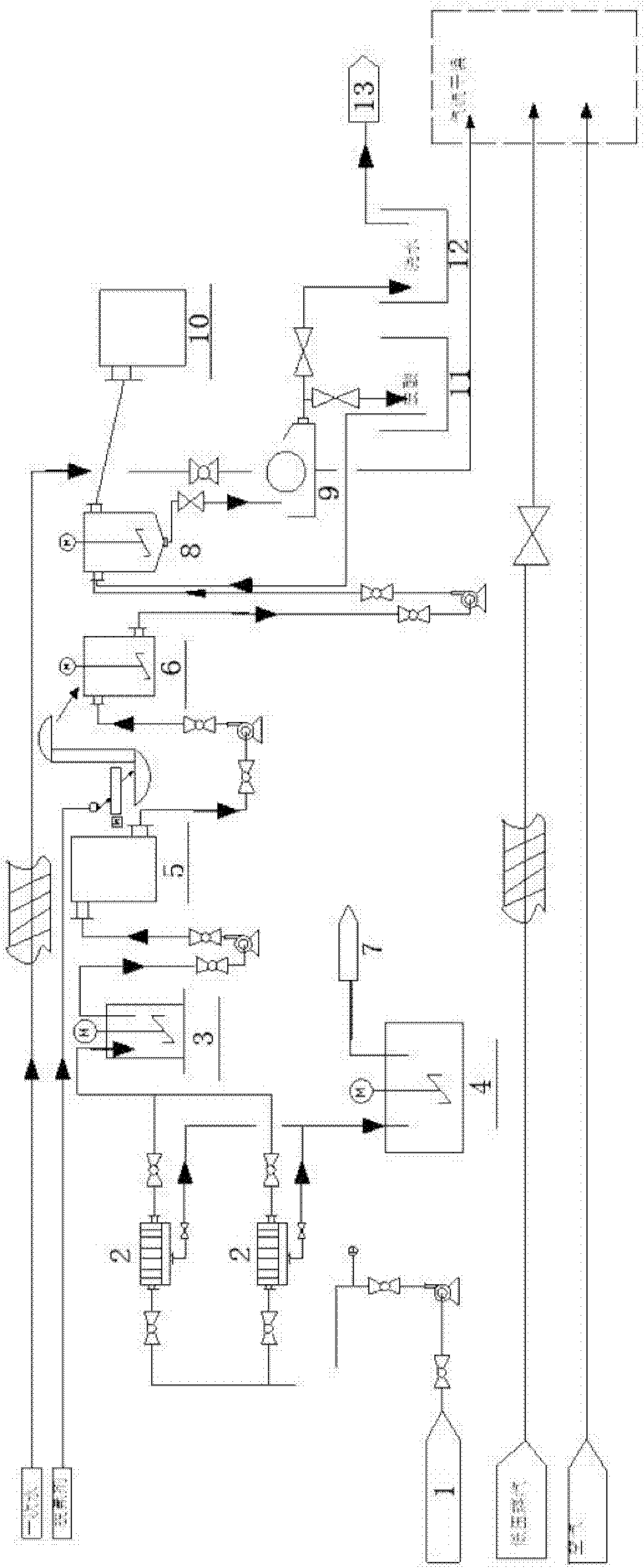

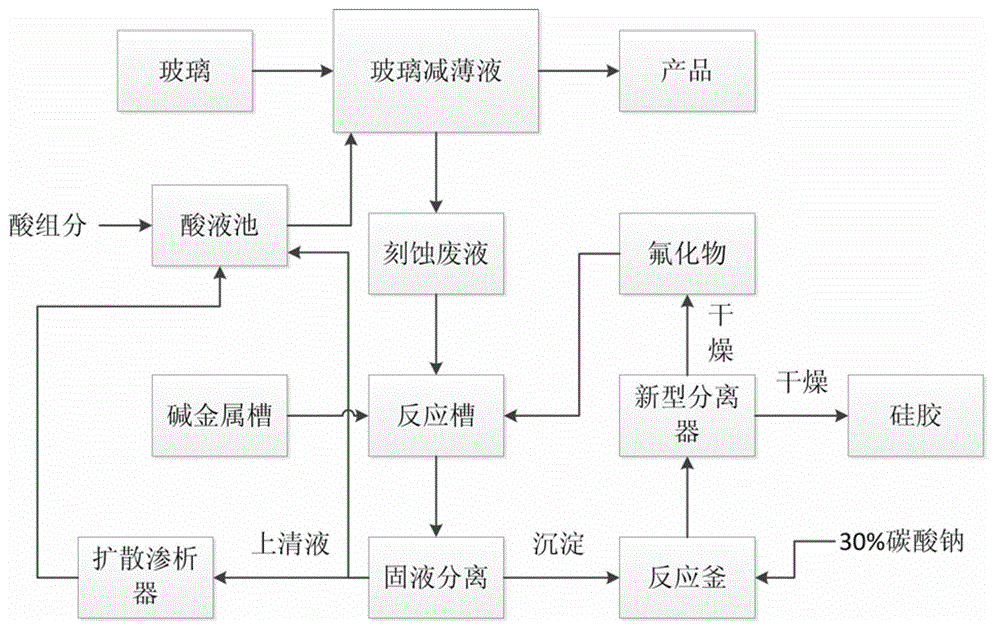

Method for treating and recycling glass thinning and etching waste liquor

InactiveCN102745837AImprove removal efficiencyLow costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThinningSilica gel

The invention relates to a method for treating and recycling glass thinning and etching waste liquor. The method comprises the steps of: (1) mixing glass thinning and etching waste liquor with alkali metal salt, so as to generate fluosilicate precipitate in fluorosilicic acid in the glass thinning waste liquor to be separated out; (2) settling and filtering the fluosilicate precipitate to carry out solid-liquid separation; (3) introducing a filtrate to a diffusion dialysis device, removing redundant alkali metal ion in the filtrate to acquire acid liquor; (4) supplementing components to the acid liquor, so as to achieve the glass thinning and etching usage requirements and recycle; (5) reacting the fluosilicate precipitate acquired by filtering in the step (2) with soda ash solution to generate metal fluoride and silica gel precipitate; (6) separating the generated metal fluoride and the silica gel precipitate, wherein the metal fluoride is used for treating fluosilicic acid, and the silica gel is to be sold. Compared with the prior art, the method has the advantages that etching waste liquor can be recycled, the exhaustion of waste liquor and waste residue can eb reduced, the environment pollution risks are reduced, and the production cost is saved.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com