High-strength and high-toughness metal powder type flux-cored wire with no need of being pre-heated before welded

A flux-cored wire, high-strength and toughness technology, used in metal processing equipment, welding media, welding equipment, etc., can solve the problems of low yield strength of deposited metal, inability to meet strength requirements, mismatched structural steel strength, etc. The effect of high application efficiency, good low temperature impact toughness and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment this patent is further explained and illustrated. But the scope of protection of this patent is not limited to the specific implementation.

[0030] The silicon content of ferrosilicon in the embodiment is 45%; the molybdenum content of ferromolybdenum is 55%; the titanium content of ferrotitanium is 33%; the carbon content of medium carbon ferromanganese is 1.1%, and the manganese content is 80%. The content of ceria in rare earth oxide is 99.95%.

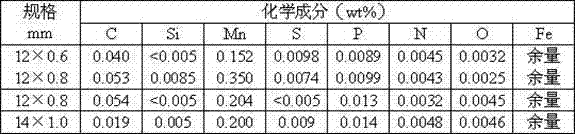

[0031] The steel sheath of the flux-cored wire is made of 12×0.6, 12×0.8 and 14×1.0mm cold-rolled carbon steel strips, and its chemical composition is shown in Table 1. The steel strip is filled with 16~23% flux core powder, and the finished welding wire with a diameter of 1.2~1.6mm is formed by rolling and drawing. .

[0032] Table 1 Chemical composition of the steel strip used for the manufacture of the flux-cored welding wire of the present invention

[0033]

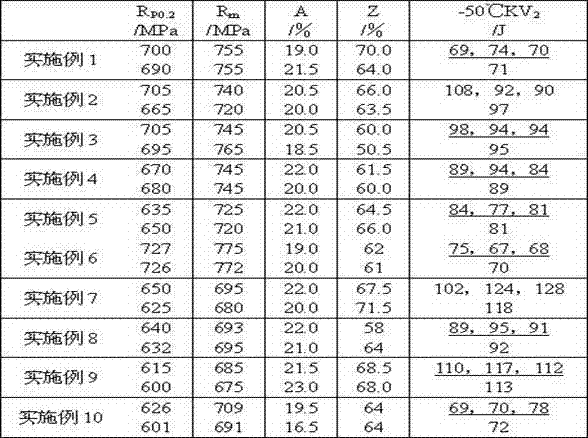

[0034] Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com