Patents

Literature

54results about How to "The ingredients are designed to be simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acicular constituent high strength weathering resistant steel and producing method thereof

InactiveCN1609257AThe ingredients are designed to be simpleGood weather resistanceWeather resistanceAlloy steel

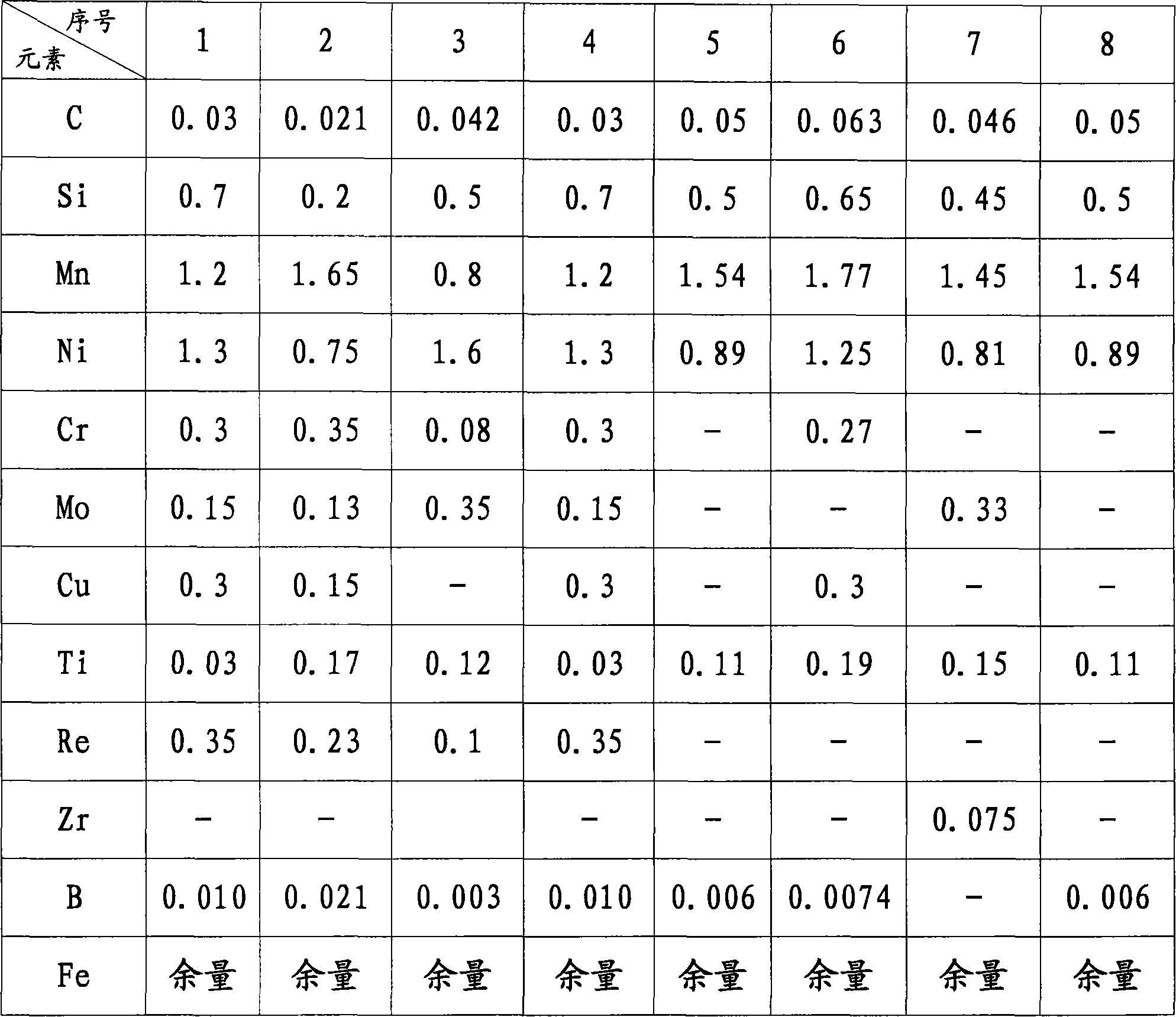

The present invention relates to high strength high weather resistance steel with needle structure and its production process, and belongs to the field of low alloy steel making. The present invention adopts very low carbon content to result in normal temperature dissolvability in alpha-Fe not higher than 0.0218 wt%, adds Cu, Cr, Ni, Mo, Nb, Ti, Al, Zr, RE and Ca, and ensures the main structure is needle-like structure for excellent weather resistance. The steel of the present invention is produced by means of hot rolling technology and relaxation-separation control technology and has low production cost and short production period. It has excellent weather resistance, excellent toughness, and excellent weldability needing no preheating before welding and heat treatment after welding, and may be used widely in bridge, building, traffic facility, sea platform, etc.

Owner:武汉钢铁有限公司 +1

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

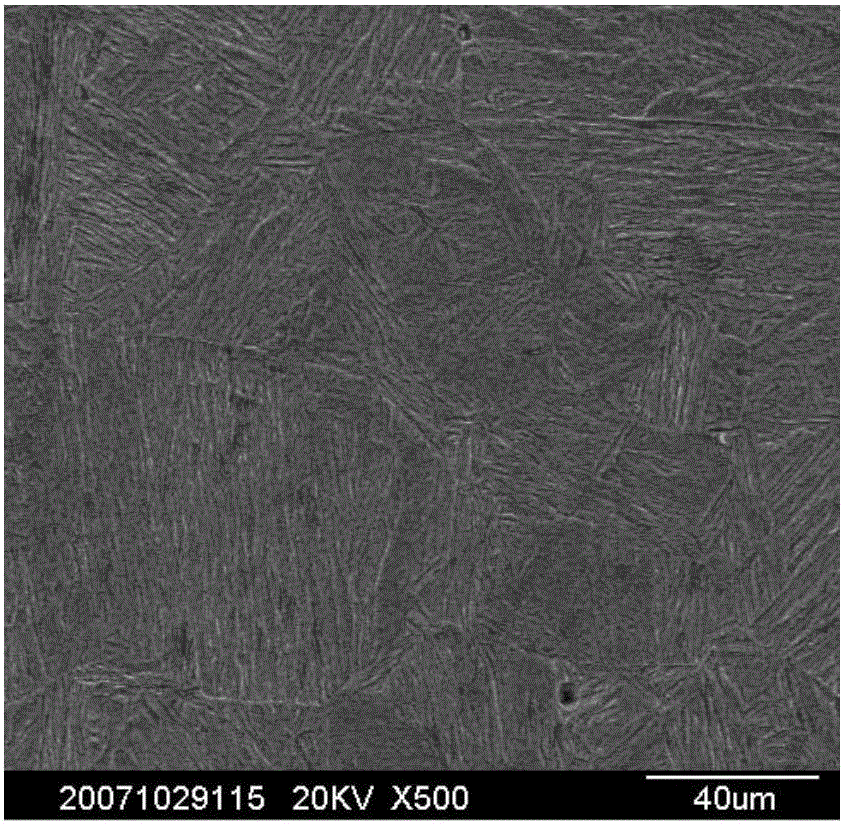

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

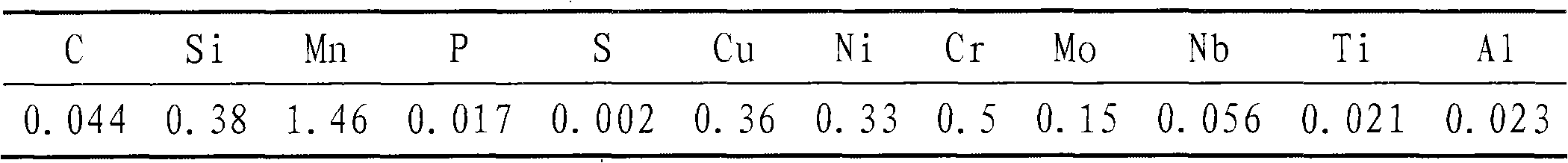

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

High-strength gas-defended welding wire material

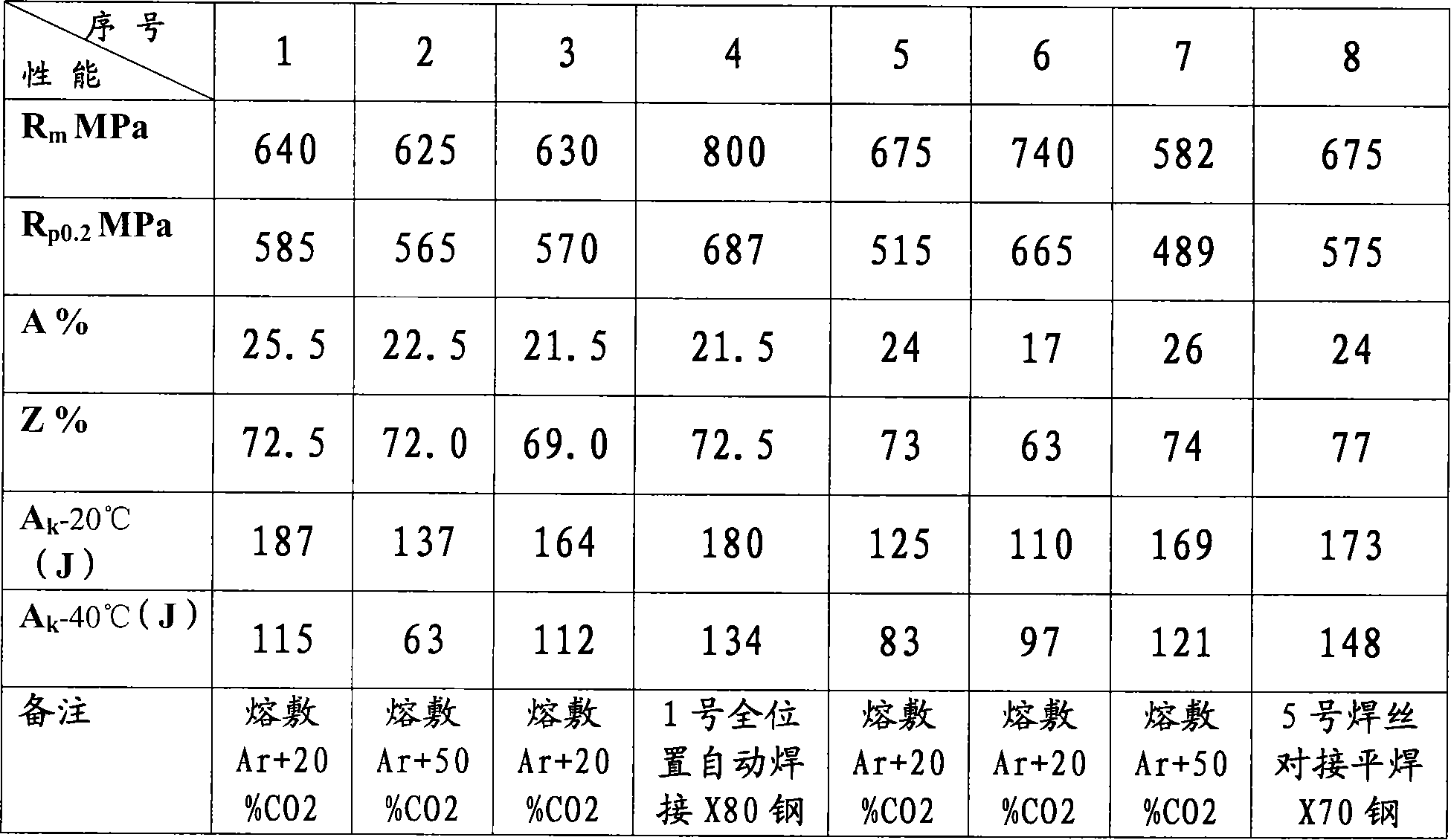

ActiveCN101116930AReasonable design of ingredientsWide range of applicationsWelding/cutting media/materialsSoldering mediaHigh intensityWeld line

The invention belongs to the full position automatic welding material making field, in particular to a high strength gas protecting welding wire of synthesis mechanics good function in the welding line by adopting the rich argon gas protecting welding. The specific ingredient weight percent of the welding wire is that C is less than 0.05 percent, Si is ranged from 0.1 percent to 0.8 percent, Mn is ranged from 0.5 percent to 2.0 percent, S is less than 0.01 percent, P is less than 0.015percent, Ni is ranged from 0.5 percent to 2.0 percent, Cr is ranged from 0.05 percent to 0.50 percent , Mo is ranged from 0.1 percent to 0.5 percent, Cu is less than 0.3 percent, Ti is ranged from 0.01 percent to 0.25 percent, Re 0.05 is ranged from percent to 0.5 percent, B is ranged from 0.001 percent to 0.030 percent and remained iron. Compared with the prior art, the invention welding wire material has fine synthesis mechanics function of reasonable, simple, economic ingredient design of the welding wire material, high strength and low temperature toughness of the welding line smelt apply metal. The invention is characterized in that the wide applicable range of CO2 content in the gas is protected and the full position automatic welding has good manufacturability.

Owner:CENT IRON & STEEL RES INST

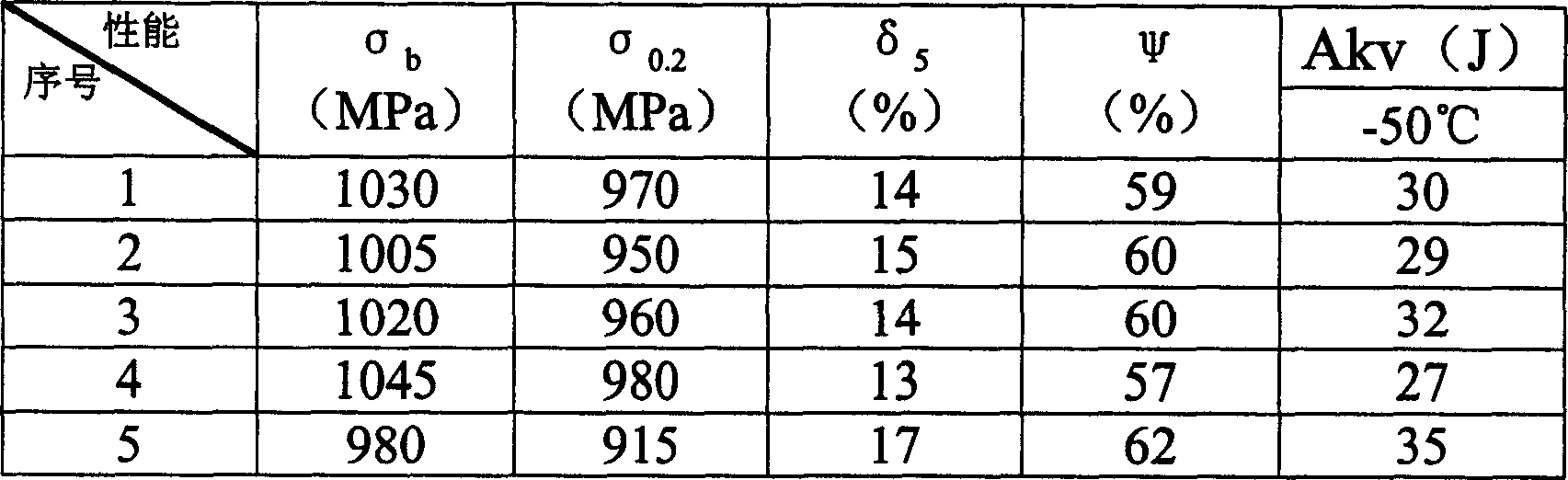

High-strength welding electrode

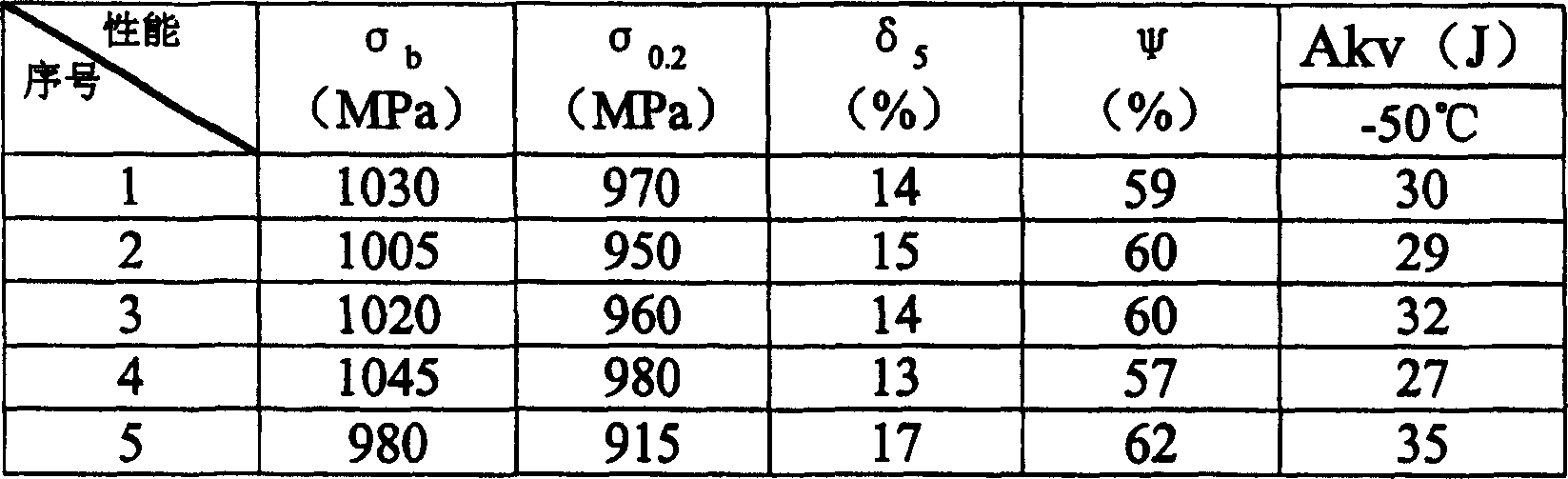

InactiveCN1528555AThe ingredients are designed to be simpleReasonable design of ingredientsWelding/cutting media/materialsSoldering mediaHigh intensityMechanical property

The invention is a high-intensity welding rod used in the welding state, able to weld high intensity structural steel whose yield strength is greater than 950MPa. The chemical components of its deposited metal: C not greater than 0.07%; Si 0.1-0.6%; Mn 1.2-1.9%; Ni 2.6-3.8%; Cr 0.41-1.50%; Mo 0.66-1.6%; Ti 0.003-0.03%; the rest Fe. Its deposited metal has good synthetical mechanical property and has tensile strength greater than 1000MPa, yield strength above 950MPa and impact work greater than 27J at -50 deg.C.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Pressure container steel plate resistant to hydrogen induced cracking and manufacturing method thereof

ActiveCN105886909AHigh strengthImprove low temperature impact toughnessFurnace typesHeat treatment furnacesNon-metallic inclusionsHardness

The invention relates to a pressure container steel plate resistant to hydrogen induced cracking. The steel plate comprises, by weight, 0.16%-0.20% of C, 0.15%-0.40% of Si, 1.05%-1.20% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, less than or equal to 0.01% of Nb, less than or equal to 0.01% of V, less than or equal to 0.01% of Ti, less than or equal to 0.0005% of B, and the balance Fe and inevitable impurity elements. The carbon equivalent Ceq is less than or equal to 0.42%, and a calculation formula for the carbon equivalent Ceq is Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The steel plate is high in strength and low-temperature impact toughness, low in hardness and good in HIC resistance. The steel plate has fine grains and low nonmetal inclusion content, and obvious banded structures do not exist. After long-time simulation of postweld heat treatment at a high temperature, the strength and the low-temperature impact toughness of the steel plate are not obviously weakened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-tenacity low-alloy high-strength steel and quenched-tempered heat treatment method thereof

ActiveCN103131962AThe ingredients are designed to be simpleImprove impact toughnessChemical compositionTempering

The invention provides high-tenacity low-alloy high-strength steel and a quenched-tempered heat treatment method of the steel. Chemical components of the low-alloy high-strength steel comprise, by mass, 0.23% to 0.35% of C, 0.20% to 0.35% of Si, 1.0% to 4.0% of Ni, 0.8% to 1.2% of Cr, 0.4% to 1.0% of Mn, 0.4% to 1.0% of Mo, 0.01% to 0.12% of V, <=0.010% of S, <=0.010% of P, and the balance Fe. The quenched-tempered heat treatment method comprises the following steps: the steel is normalized under the temperature of 850 DEG C to 900 DEG C, then the steel is quenched under the temperature of 830 DEG C to 920 DEG C so as to form martensite, at last, tempering treatment is conducted on the martensite under the temperature between 590 DEG C and 660 DEG C so as to obtain a tempered martensite structure. The low-alloy high-strength steel after quenched-tempered treatment can satisfy the requirements of the low-alloy high-strength steel to the comprehensive performance such as tenacity, yield ratio, low temperature impact toughness and elongation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

InactiveCN1546694AThe ingredients are designed to be simpleReduce manufacturing costHigh power lasersChemical compound

The invention relates to a laser synthesis preparation method of intermetallic compound and granule reinforced composite material which includes, using the powder stock containing the same elements with the intermetallic compound to be prepared, adding additionally elements during the process of sedimentation and mixing, forming local molten pool on the base material surface through high power laser irradiation, feeding the mixed powder into molten pool, stacking up to obtain large area coating, block material or formed parts, adjusting powder components or laser technique to obtain intermetallic compound or particle reinforcement intermetallic composite material with dissimilar compositions, structure and property.

Owner:TSINGHUA UNIV

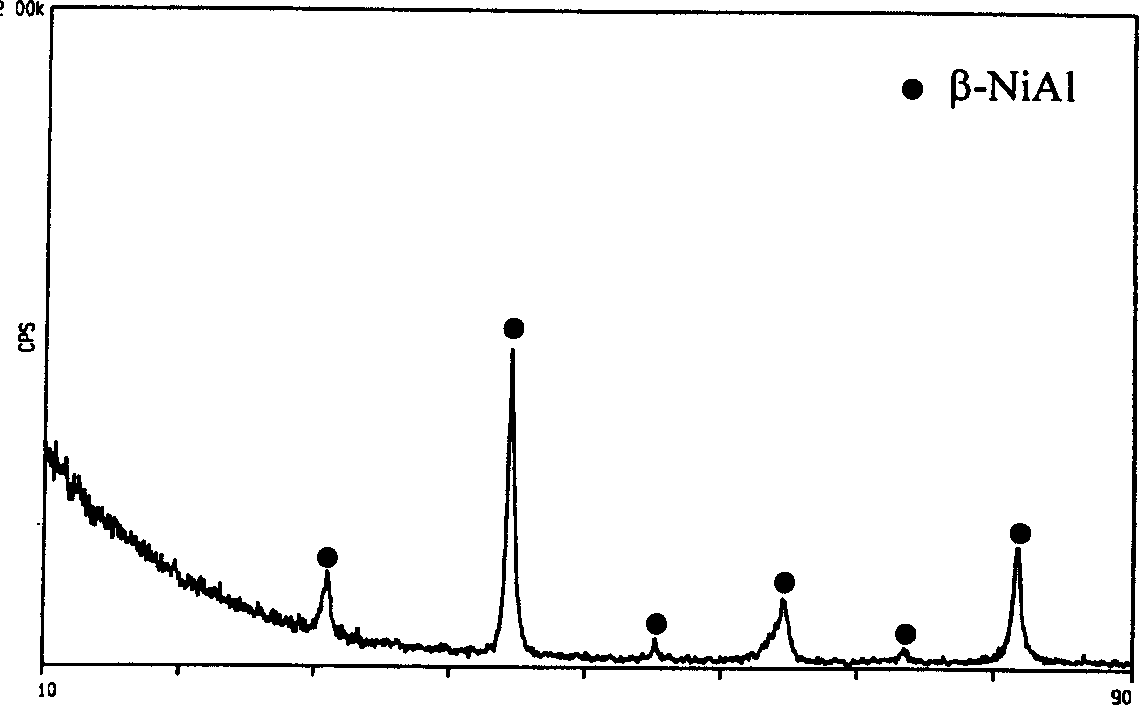

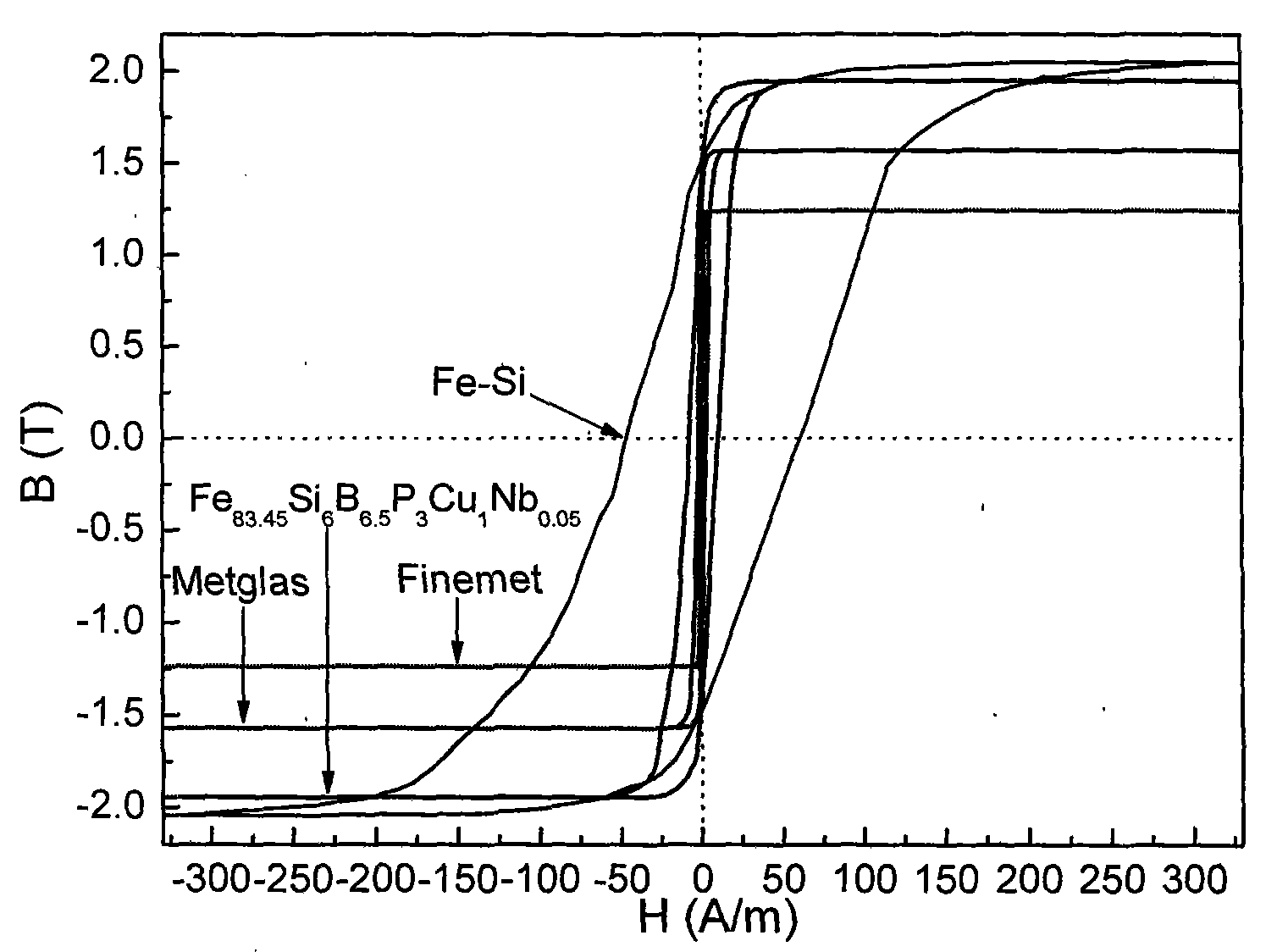

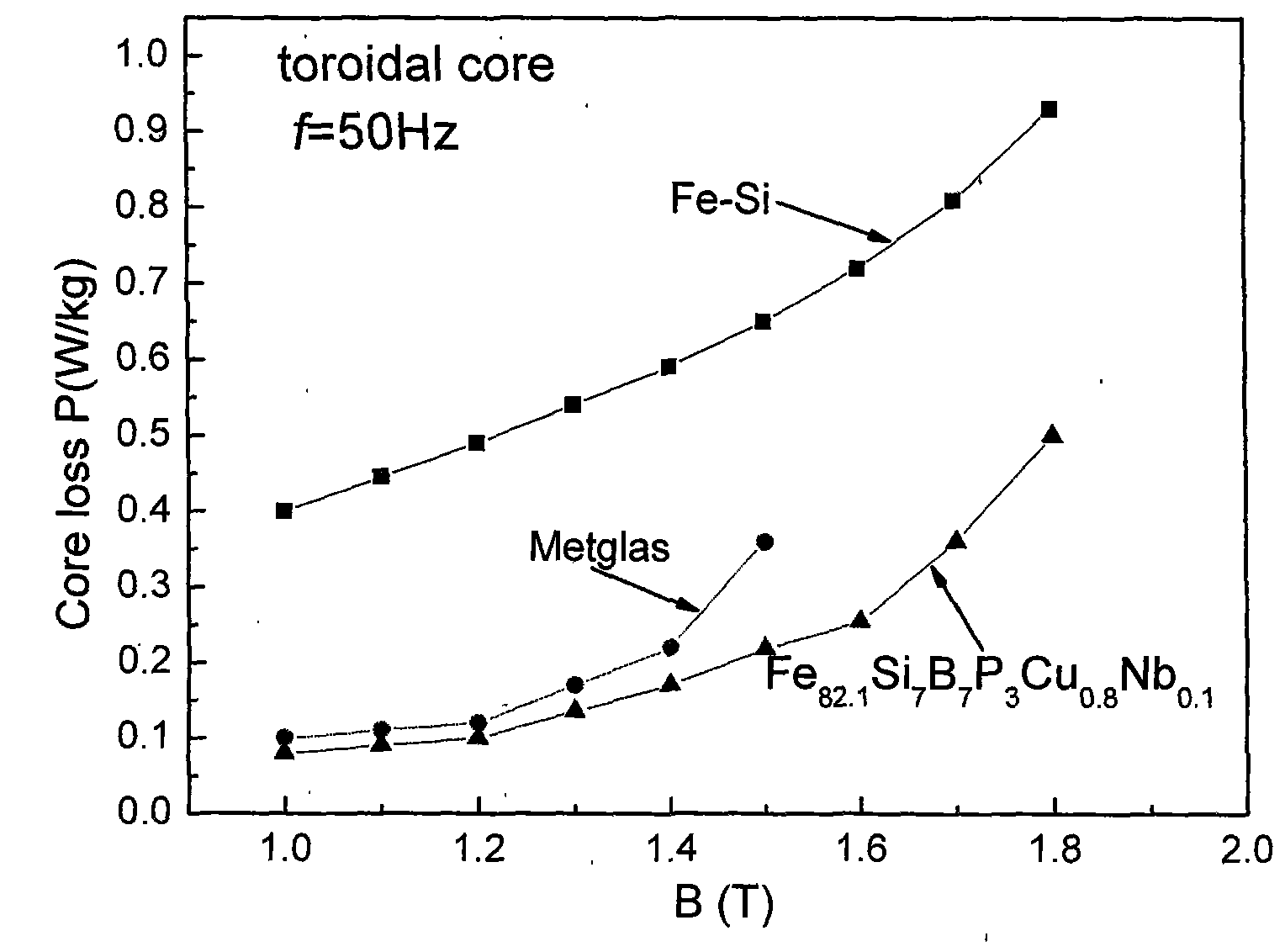

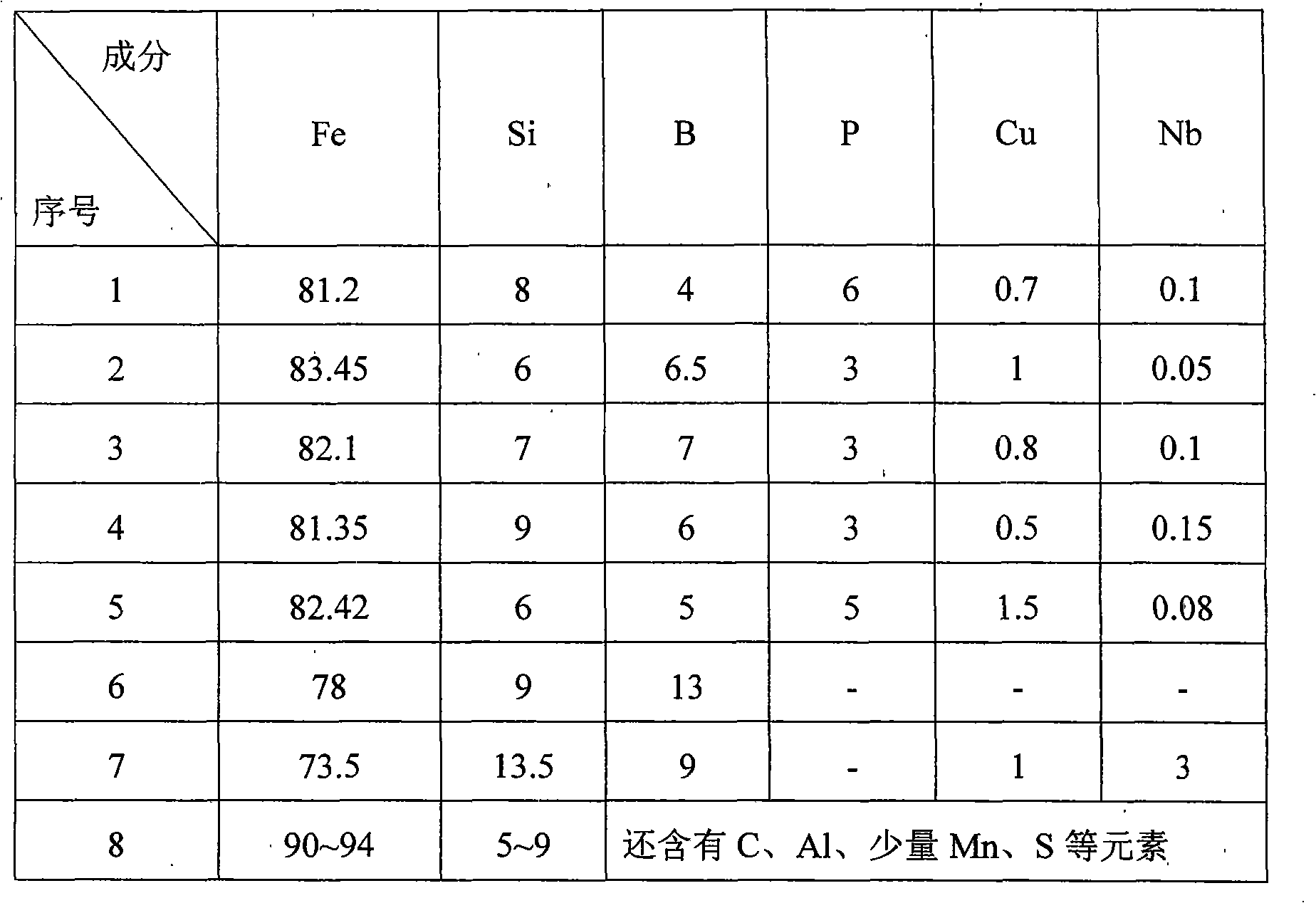

Iron-based nanocrystalline soft magnetic alloy with low cost and high soft magnetic property

InactiveCN101629265AImprove performanceThe ingredients are designed to be simpleMagnetic materialsChemical compositionTransformer

The invention belongs to the field of preparing a soft magnetic alloy in functional materials, in particular relates to a novel iron-based nanocrystalline soft magnetic alloy material with excellent comprehensive performance, such as low cost, high saturation magnetic induction intensity, low loss, and the like. The novel iron-based nanocrystalline soft magnetic alloy material comprises the following chemical constituents by atomic percentage: 6-9 Si, 4-7 B, 3-6 P, 0.5-1.5 Cu, 0.05-0.15 Nb and the balance of Fe. Compared with traditional iron-based amorphous or nanocrystalline soft magnetic alloys, such as Metglas, Finemet, Nanoperm and the like, the iron-based nanocrystalline soft magnetic alloy greatly decreases the consumption of the noble element Nb, has the advantages of simple constituent design, low cost and excellent comprehensive performance of the materials by substituting low-price P for noble B, can substitute the prior silicon-steel sheets and iron-based amorphous or nanocrystalline soft magnetic alloys and can be widely applied to the fields, such as power transformers, mutual inductors, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

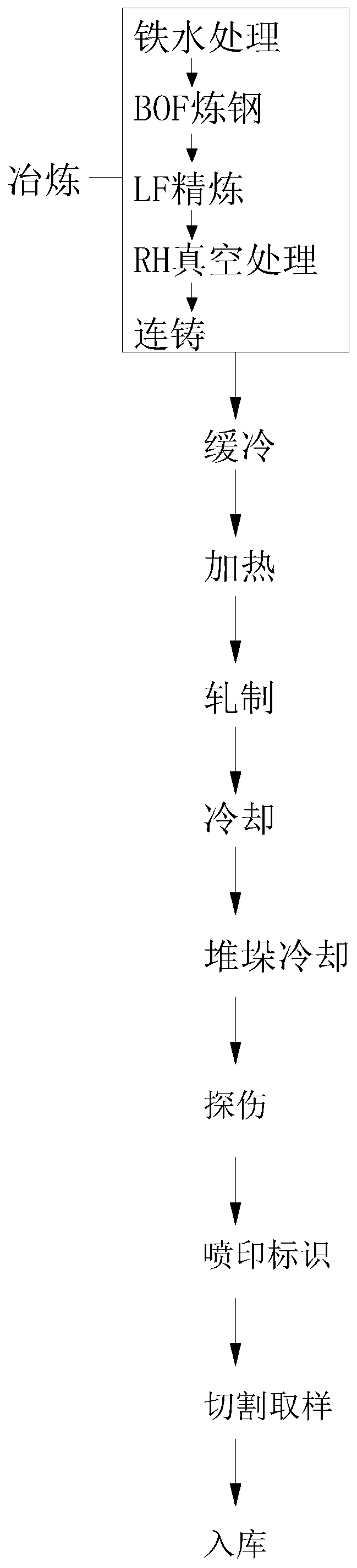

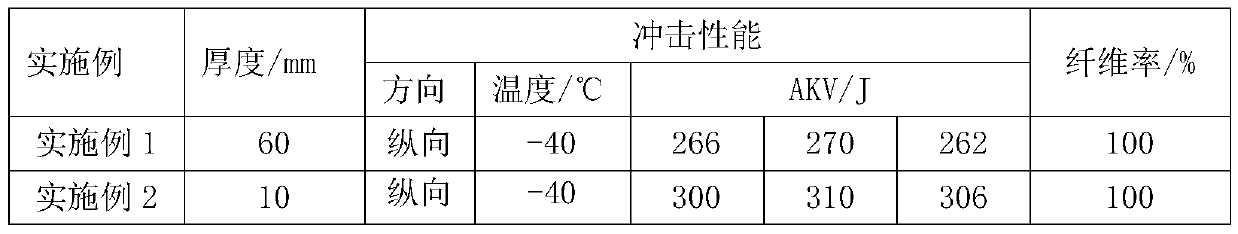

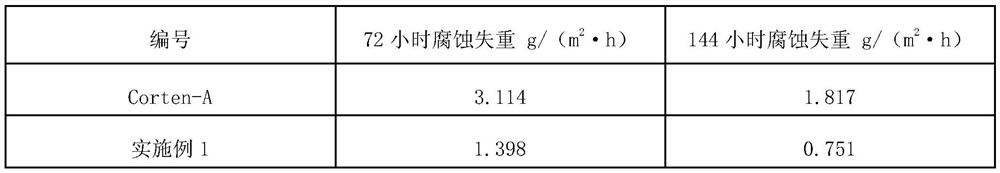

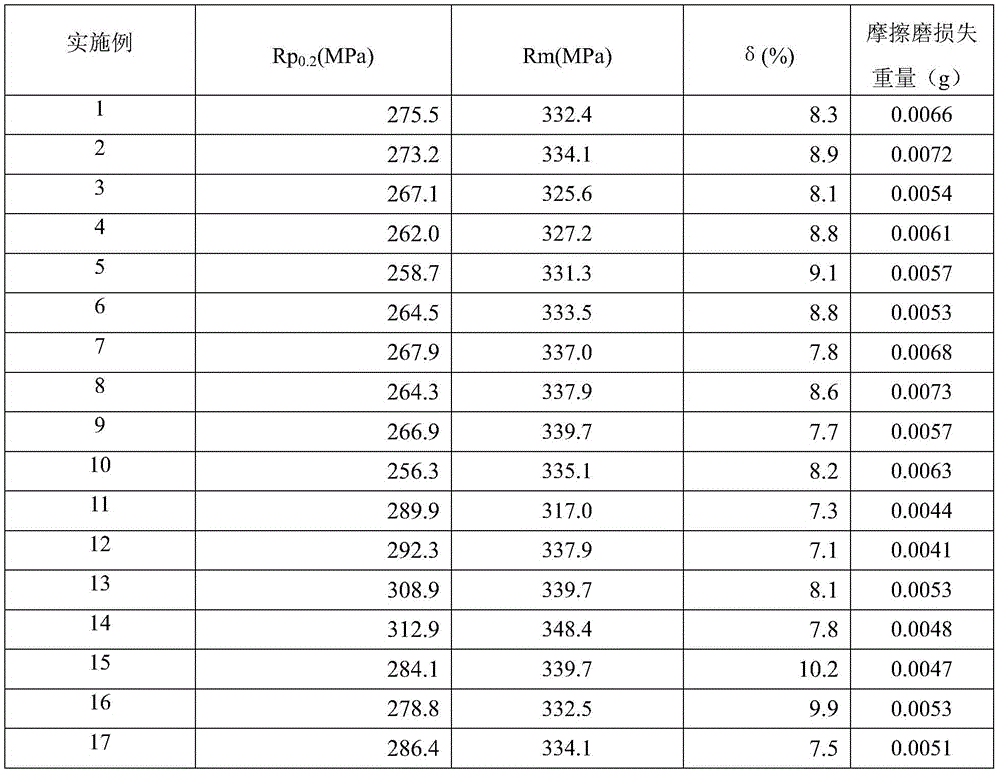

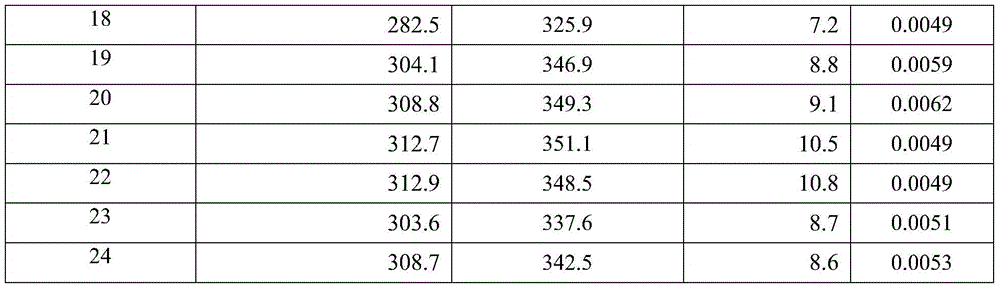

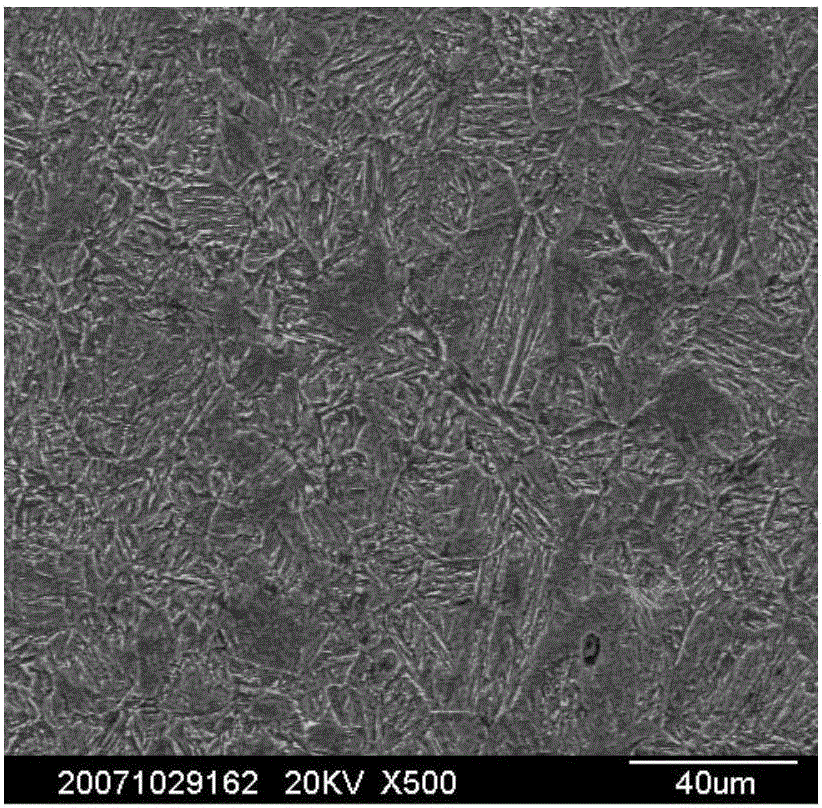

Weather-resistant bridge steel with yield strength not less than 345 MPa and preparation method thereof

The invention relates to weather-resistant bridge steel with yield strength not less than 345 MPa and a preparation method thereof. The weather-resistant bridge steel with the yield strength not lessthan 345 MPa comprises the following components of, in percentage by weight, 0.07%-0.11% of C, 0.15%-0.30% of Si, 0.80-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.01-0.04% of Al, 0.20-0.40% of Cr, 0.20-0.40% of Cu, 0.20-0.50% of Ni, 0.020-0.050% of Nb, 0.010-0.040% of Ti and the balance Fe and inevitable impurities; and the preparation method comprises thefollowing steps of smelting, slow cooling, heating, rolling, cooling and stacking and cooling. According to the weather-resistant bridge steel with the yield strength not less than 345 MPa and the preparation method thereof, the low-cost micro-alloying design is adopted, the production period is short, the cost is low, popularization and application are facilitated, the weather-resistant bridge steel has excellent welding performance, strong toughness and strong plasticity matching performance, low yield ratio, corrosion resistance, weather resistance, welding performance and anti-fatigue performance, compared with traditional weather-resistant steel, the weather resistance is improved by one time or above, the weather-resistant bridge steel can replace the traditional high-strength weathering steel, and can be applied to the fields of bridges, outdoor tower frames and the like without coating, so that the use cost and the maintenance cost are reduced.

Owner:SD STEEL RIZHAO CO LTD

Manufacturing method of hot-dip galvanized steel belt with yield strength over 580 Mpa level

ActiveCN111020437AReduce consumptionThe ingredients are designed to be simpleHot-dipping/immersion processesIncreasing energy efficiencyChemical compositionUltimate tensile strength

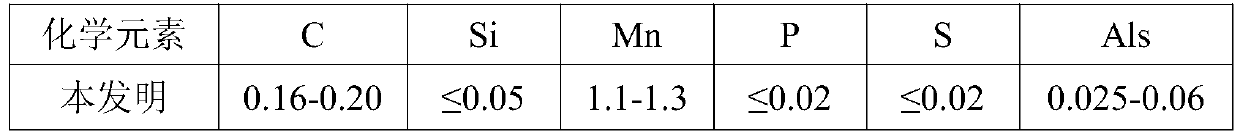

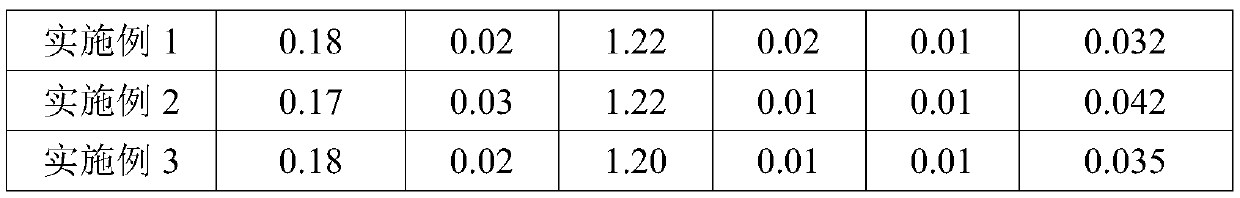

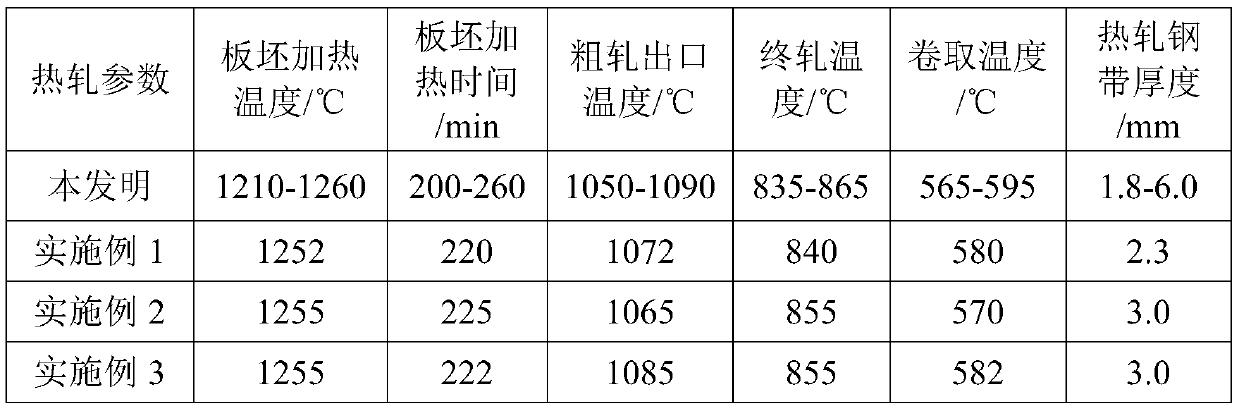

The invention discloses a manufacturing method of a hot-dip galvanized steel belt with yield strength over the 580 Mpa level. The method comprises the following steps that chemical compositions and mass percentage for manufacturing the steel belt are selected, and the chemical compositions comprise 0.16%-0.20% of C, smaller than or equal to 0.05% of Si, 1.1%-1.3% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.02% of S, 0.025%-0.06% of Als and the balance Fe and inevitable impurity; the chemical compositions are subjected to smelting and continuous casting, a plate blankis formed, and the thickness of the plate blank is 230 mm; the working procedure of hot rolling is carried out; the working procedure of acid continuous rolling is carried out; and the working procedure of hot-dip galvanizing is carried out. According to the manufacturing method of the hot-dip galvanized steel belt with yield strength over the 580 Mpa level, the composition design is simple, precious alloy elements are not added, the 600-630 DEG C semi-annealing technology is adopted, energy consumption is small, the production cost is low, the high yield strength and certain machining performance can be achieved, and the requirements of industries like building can be met.

Owner:SD STEEL RIZHAO CO LTD

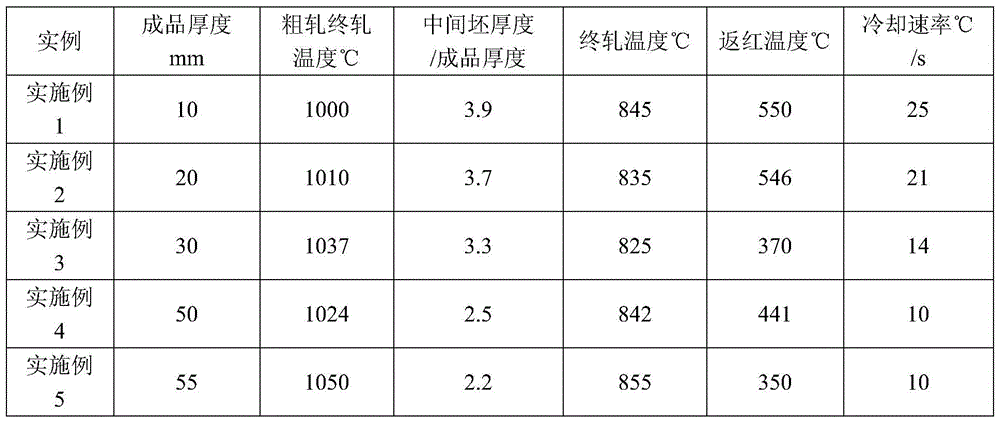

Ship plate steel with thickness not greater than 100mm and yield strength of 390MPa and preparation method

The invention discloses ship plate steel with thickness not greater than 100mm and yield strength of 390MPa and a preparation method. The ship plate steel comprises C, Si, Mn, P, S, Nb, V, Al, Ti, Mo,Cr, Cu, Ni, and the balance Fe and impurities. The preparation method comprises the following steps: heating a continuous casting slab which comprises the same components with the ship plate steel; the continuous casting slab is sequentially processed by cooling through first laminar flow, air cooling and cooling through second laminar flow after being subjected to two-section type rolling; thenthe continuous casting slab is cooled through air until room temperature is reached, thus obtaining the ship plate steel. The ship plate steel has the obvious advantages that the thickness of the shipplate steel is not greater than 100mm; the yield strength is 390MPa; the low-temperature toughness is outstanding; in addition, the component design is simple; the welding performance and the corrosion resistance are outstanding; the comprehensive mechanical property is high.

Owner:NANJING IRON & STEEL CO LTD

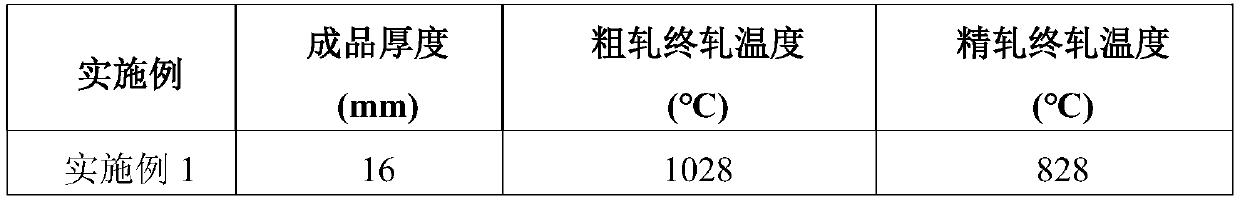

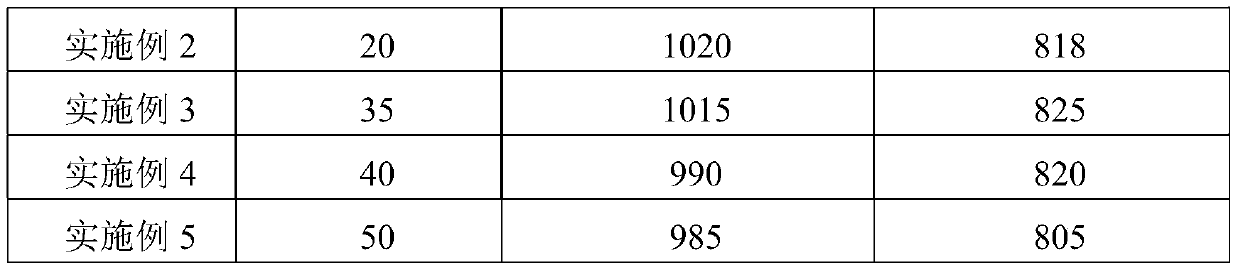

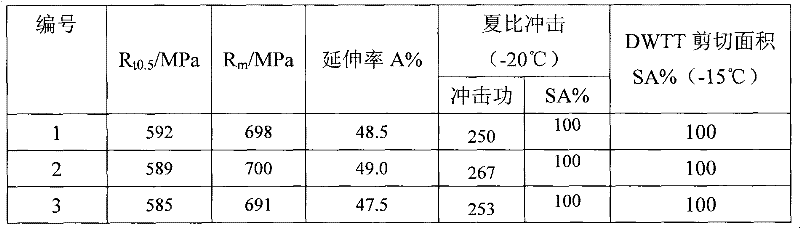

Production process of wear-resistant X70 pipeline steel plate

InactiveCN103774046AThe ingredients are designed to be simpleSimple production processSteel platesSmelting process

The invention discloses a production process of a wear-resistant X70 pipeline steel plate. A slab is obtained through a smelting process, an external refining process, a vacuum treatment process and a continuous casting process. The slab comprises the following chemical components in percentage by weight: 0.05-0.10% of C, 0.10-0.35% of Si, 1.20-1.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 0.03-0.06% of Nb, 0.01-0.025% of Ti, 0.10-0.50% of Cr, 0.01-0.06% of Alt and the balance of Fe and unavoidable impurities. The slab is prepared into the pipeline steel plate through a reheating process, a controlled rolling process and a cooling process. The strength and toughness of the pipeline steel plate prepared by the invention conform to the technical indexes, and the pipeline steel plate has the advantages of good wear resistance and long service life.

Owner:NANJING IRON & STEEL CO LTD

Cavitation-corrosion-resistant surfacing welding material

ActiveCN101704168AThe ingredients are designed to be simpleEasy to useWelding/cutting media/materialsSoldering mediaChemical compositionCavitation

The invention provides a cavitation-corrosion-resistant surfacing welding material, which belongs to the field of novel welding materials. The surfacing material specifically comprises the following chemical components in percentage by mass: less than or equal to 0.10 percent of C, 12 to 25 percent of Cr, 1.0 to 2.0 percent of Co, 1.5 to 2.5 percent of Mo, 6.0 to 8.0 percent of Ni, 0.5 to 1.0 percent of Mn, 0.3 to 0.8 percent of Si, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, and the balance of Fe. The invention has cavitation-corrosion-resistant stainless steel, cobalt-based alloy or nickel-based alloy prepared into cavitation-corrosion-resistant surfacing welding wires and then performs surfacing on conventional materials, and the cavitation-corrosion resistance and lifespan of workpieces subjected to surfacing are greatly improved, while maintenance cost is reduced.

Owner:镇江艾康医疗器械有限公司

Ultralow carbon welding rod for welding heat resisting steel and stainless steel

InactiveCN1706586ASimple welding processGood metallurgical performanceWelding/cutting media/materialsSoldering mediaChemical compositionPearlite

The present invention belongs to the field of welding material technology, and is welding rod for welding joint of different kinds of steel, especially of heat resistant pearlite steel and stainless steel. The ultralow carbon welding rod of the present invention consists of: C 0.03-0.06 wt%, Si 0.2-0.5 wt%, Mn 0.5-0.8 wt%, Cr 1.5-2.5 wt%, Mo 0.4-0.65 wt% and V 0.10-0.35 wt%, except Fe. Compared with available technology, the present invention has simple and reasonable component design, capacity of effectively preventing the formation of the carbon immigrating layer in fusion area of joint, no martensite structure formed in the joint, excellent welding performance and high normal temperature and high temperature performance of the welded joint.

Owner:SHENYANG POLYTECHNIC UNIV

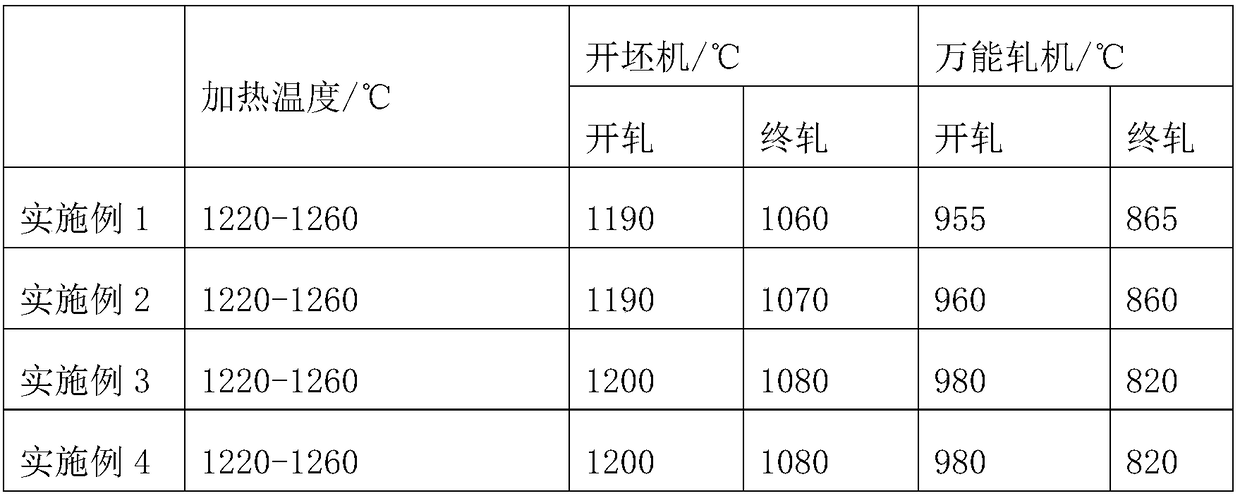

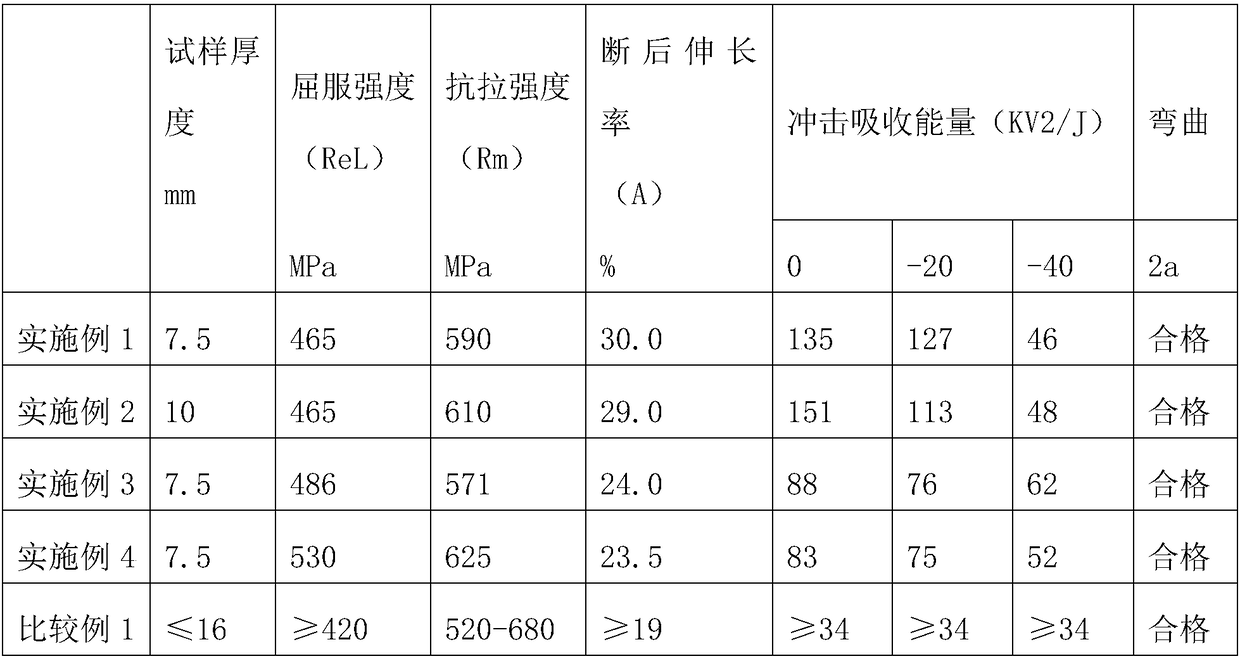

Low-alloy high-strength structure steel hot-rolled H-shaped steel and production method thereof

InactiveCN109234630AThe ingredients are designed to be simpleReduce Als contentTemperature control deviceChemical compositionAlloy

The invention relates to the technical field of the production of a metal material, in particular to low-alloy high-strength structure steel hot-rolled H-shaped steel and a production method thereof.The steel is prepared from the following chemical components by in percentage by weight: 0.12 to 0.18 percent of C, 0.30 to 0.50 percent of Si, 1.20 to 1.60 percent of Mn, 0.020 to 0.065 percent of V,0.006 to 0.012 percent of Als, less than or equal to 0.025 percent of P, less than or equal to 0.020 percent of S, and the balance of Fe and micro impurities. The production method comprises the following steps: smelting in a converter, LF refining, pouring a specially-shaped blank under a semi-protection condition, and rolling the H-shaped steel. In the production process of the hot-rolled H-shaped steel, the rolling temperature of the H-shaped steel is controlled, specifically, the heating temperature of a heating furnace is controlled, the rolling temperature of a blank opening machine iscontrolled, and the rolling temperature of a universal rolling machine is controlled. The yield strength of the low-alloy high-strength structure hot-rolled H-shaped steel produced in the invention can reach 420 MPa by designing chemical components and controlling the rolling process, the elongation percentage is 19 percent and above, and the hot-rolled H-shaped steel is good in low-temperature impact toughness.

Owner:SHOUGANG CHANGZHI IRON & STEEL

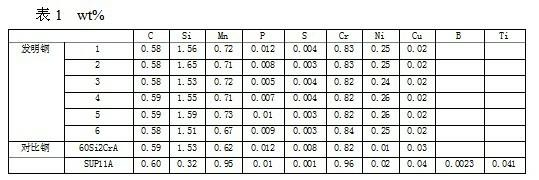

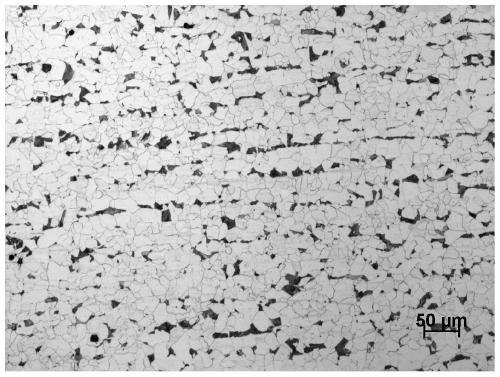

Hardenability-remaining high-strength low-temperature toughness spring steel

The invention relates to hardenability-remaining high-strength low-temperature toughness spring steel, which belongs to the technical field of alloy steel. The technical scheme is that chemical components are as follows, by weight percentage, 0.56-0.64% of C, 1.40-2.00% of Si, 0.40-0.80% of Mn, 0.70-1.00% of Cr, 0.10-0.40% of Ni, Cu<=0.25%, P<=0.025%, S<=0.025% and the balance Fe and impurities. Tempering tensile strength of the spring steel >=1750Mpa, the temperature of the spring steel is 880+ / -20 DEG C before quenching, and after quenching the temperature is 430+ / -50 DEG C. Aku2>=20J at normal temperature or at the temperature of -40 DEG C, the Aku2 is impact energy of a 2mm U-shaped notch, and the unit is J. In an end-quenching test, J20>=55HRC, J20 represents hardness of a position in the end-quenching test 20mm away from a water spraying end, and the unit is HRC. The hardenability-remaining high-strength low-temperature toughness spring steel has the advantages of improving hardenability of steel and impact toughness and being especially suitable for manufacturing a cylindrical spiral spring with specification <=phi50 mm.

Owner:SHIJIAZHUANG IRON & STEEL +1

290 MPa-grade anti-seismic low-yield strength steel and manufacturing method thereof

InactiveCN110172639AThe ingredients are designed to be simpleLow manufacturing costTemperature control deviceFurnace typesAlloy elementSteel plates

The invention discloses 290 MPa-grade anti-seismic low-yield strength steel and a manufacturing method thereof. The steel comprises the following components of, in percentage by weight, 0.06%-0.12% ofC, 0.1%-0.3% of Si, 0.9%-1.2% of Mn, less than or equal to 0.026% of P, less than or equal to 0.016% of S, less than or equal to 0.0060% of N, and the balance Fe and inevitable impurities. Through simple chemical component design, two-stage rolling and cooling processes, a low-yield strength steel plate can be obtained, wherein the the thickness of the steel plate is less than or equal to 100 mm,and the yield strength YP of the steel plate is 270-310 Mpa, the low-yield strength steel plate is simple in component, does not contain expensive alloy elements, and is relatively low in manufacturing cost. The steel has good impact and welding performance and low-cycle fatigue performance, the elongation rate is very high, and the steel is mainly used for anti-seismic design of a building structure.

Owner:NANJING IRON & STEEL CO LTD

Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening and preparation method for deformation material of Ti-containing high-silicon aluminum alloy

InactiveCN105695811AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention belongs to the technical field of aluminum alloy, and relates to a Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening. The Ti-containing high-silicon aluminum alloy is characterized by being prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 0.8% of Ti, not larger than 0.5% of Fe, not larger than 0.15% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5% by weight. A preparation method for the aluminum alloy and a deformation material of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 aging. The Ti-containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, no modification is needed, a DC casting process is adopted, double-stage homogenization is combined with deformation thermal treatment, and therefore the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

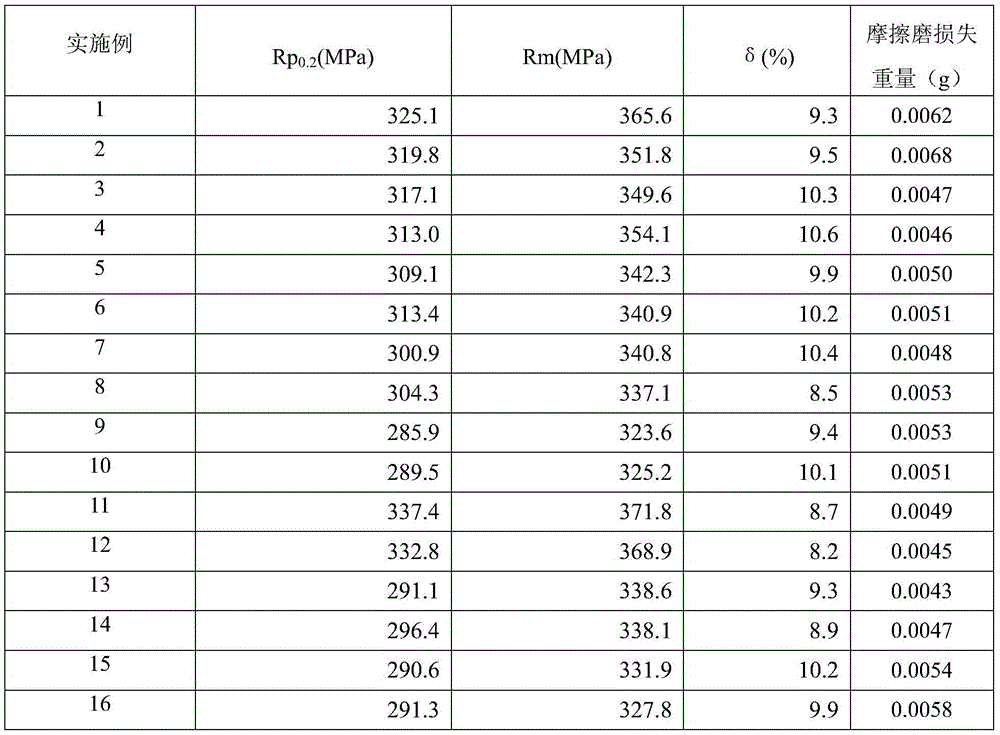

High-strength weathering steel and method of manufacturing same

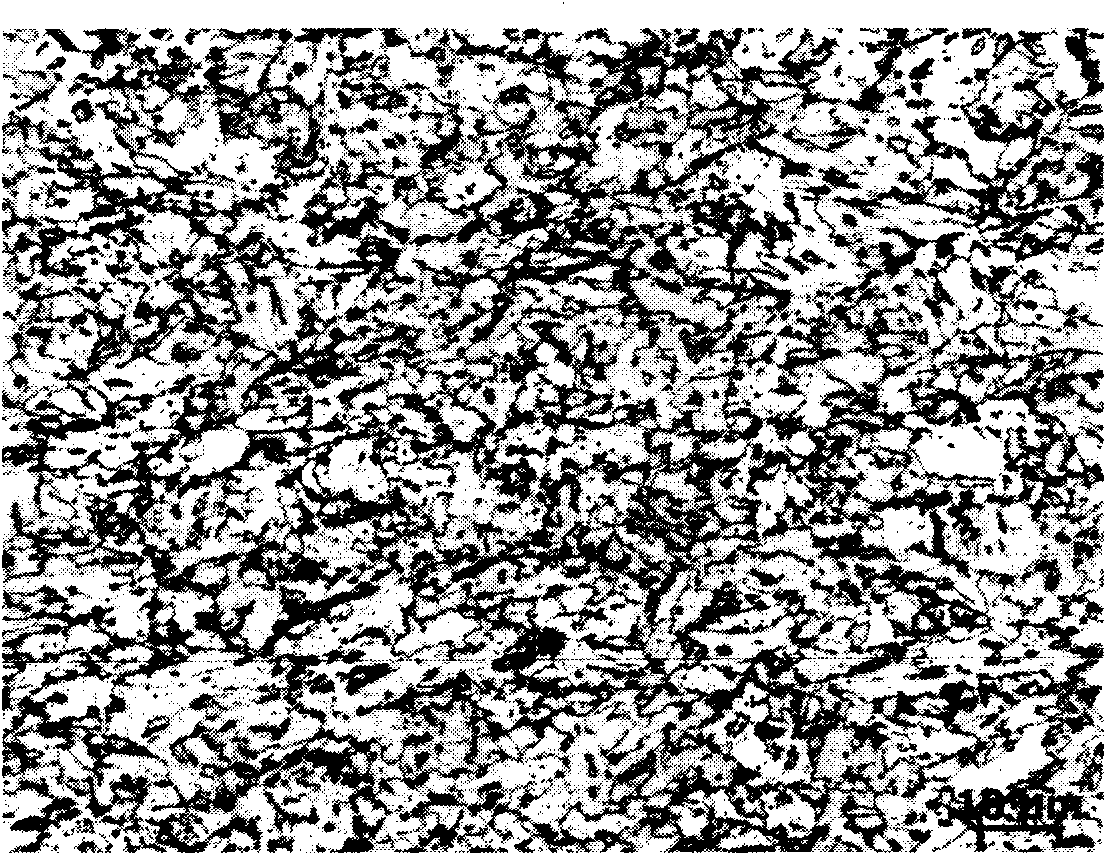

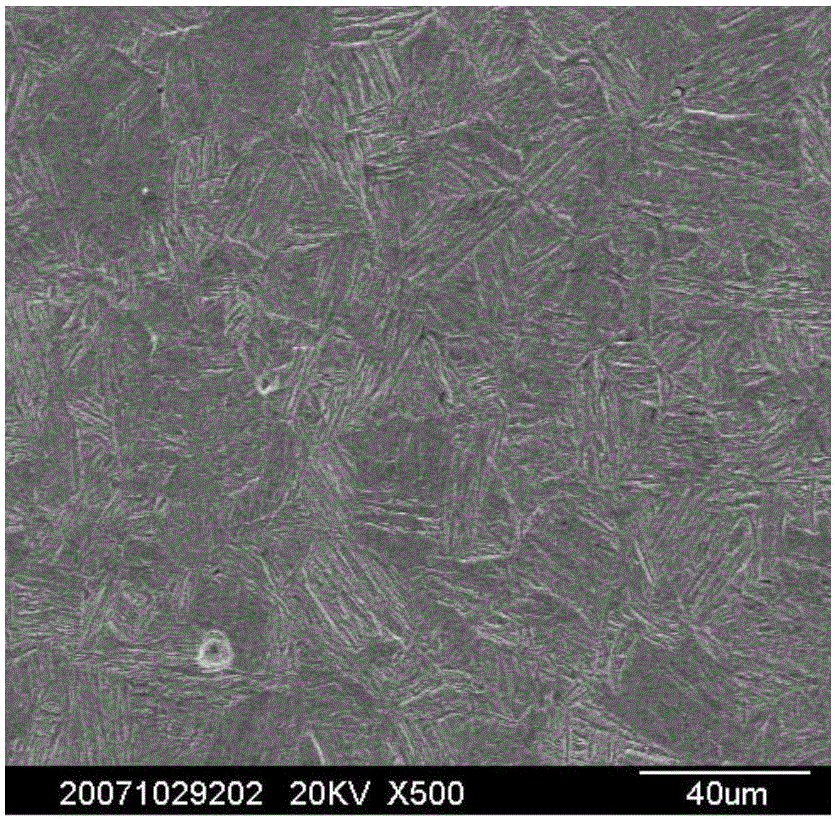

InactiveCN100455692CThe ingredients are designed to be simpleGood weather resistanceRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

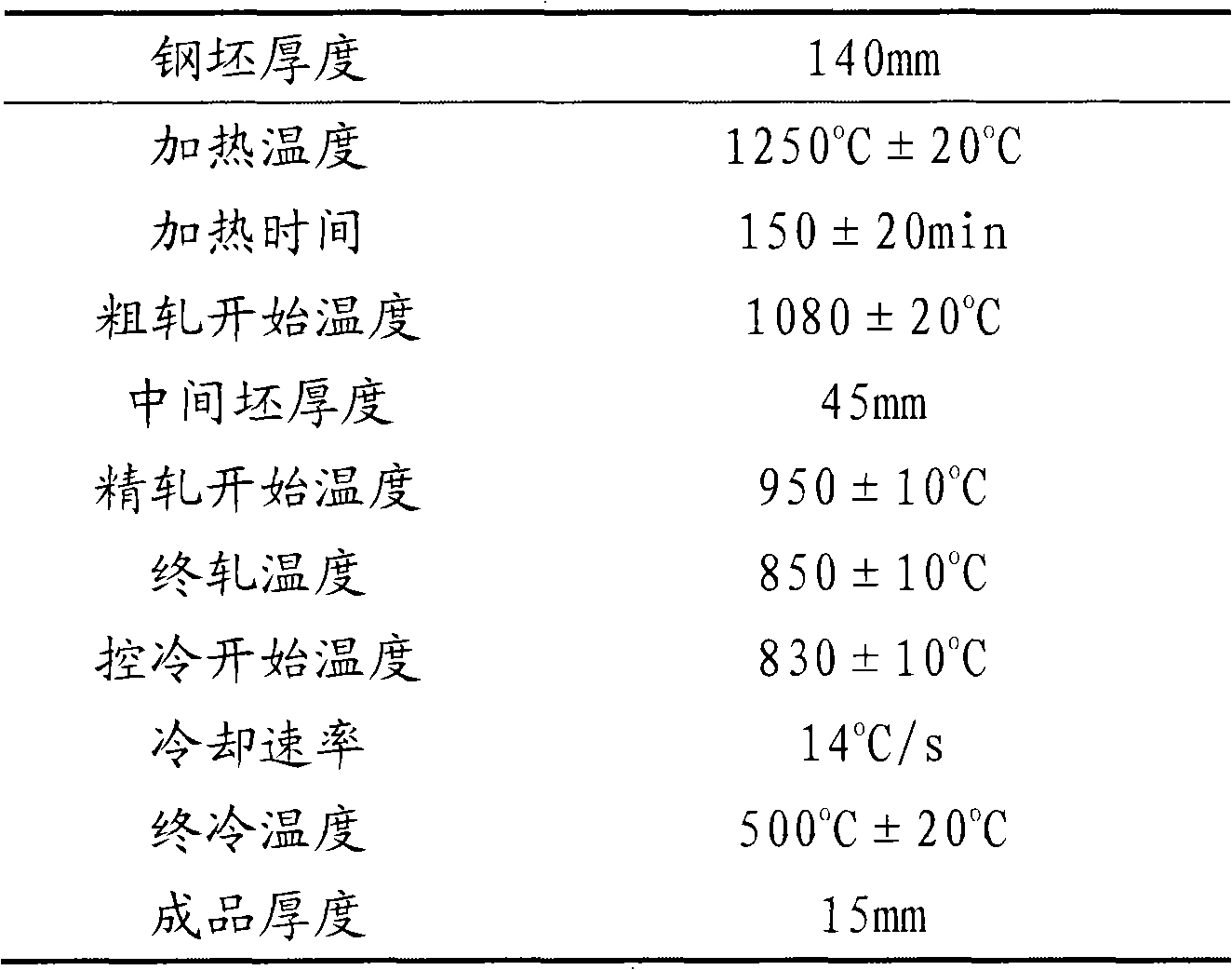

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

Acicular constituent high strength weathering resistant steel and producing method thereof

InactiveCN1323187CThe ingredients are designed to be simpleGood weather resistanceWeather resistanceToughness

The present invention relates to high strength high weather resistance steel with needle structure and its production process, and belongs to the field of low alloy steel making. The present invention adopts very low carbon content to result in normal temperature dissolvability in alpha-Fe not higher than 0.0218 wt%, adds Cu, Cr, Ni, Mo, Nb, Ti, Al, Zr, RE and Ca, and ensures the main structure is needle-like structure for excellent weather resistance. The steel of the present invention is produced by means of hot rolling technology and relaxation-separation control technology and has low production cost and short production period. It has excellent weather resistance, excellent toughness, and excellent weldability needing no preheating before welding and heat treatment after welding, and may be used widely in bridge, building, traffic facility, sea platform, etc.

Owner:武汉钢铁有限公司 +1

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

ActiveCN113957346AThe ingredients are designed to be simpleGood microstructure uniformitySteel platesWeather resistance

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening and preparation method of deformation material thereof

ActiveCN105695810AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention discloses an Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening, and belongs to the technical field of aluminum alloy. The Mn containing high-silicon aluminum alloy is characterized in that the alloy is prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 3.0% of Mn, not larger than 0.5% of Fe, not larger than 0.2% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5%. The preparation method of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 ageing. The Mn containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, a DC casting melt casting process is adopted, and modification is not needed; and double-stage homogenization is combined with deformation thermal treatment, the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance, and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

Alitizing modified steel used for P110-grade oil sleeve and tubular product manufacturing method of alitizing modified P110-grade steel

ActiveCN105088082AGood mechanical propertiesImprove crack arrest performanceChemical compositionPunching

The invention discloses alitizing modified steel used for a P110-grade oil sleeve and a tubular product manufacturing method of the alitizing modified steel. The alitizing modified steel comprises, by weight, 0.07-0.09% of C, 2.10-2.35% of Mn, 1.0-1.2% of Cr, 0.60-0.80% of Si, not more than 0.03% of S, not more than 0.03% of P, not more than 0.020% of Ti, the balance iron and inevitable impurities. A tubular product is obtained by heating a tube blank, conducting punching, conducting sizing after conducting rolling, and conducting slow refrigeration after conducting air cooling. The manufactured tubular product completely meets the requirements of API SPEC 5CT for performance of steel used for the P110 oil sleeve, the production and manufacture cost can be reduced, and the production manufacturability is improved. In addition, the carbon content of chemical components is low, microalloying is achieved, the impact toughness is high, the welding performance is good, the anti-corrosion performance is good, and the oil sleeve steel has good crack arrest capacity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of q460 grade fire-resistant and weather-resistant steel and its preparation method

ActiveCN104561819BImprove high temperature yield strengthSimple designWeather resistanceFire resistance

The invention discloses a Q460-grade fire-resistant weathering steel which comprises the following chemical components in percentage by weight: 0.01-0.20% of C, 0.1-0.4% of Si, 0.5-1.5% of Mn, 0.1-1.0% of Cr, at most 1.0% of Ni, at most 1.0% of Cu, 0.01-0.05% of Nb, 0.01-0.05% of Ti, at most 0.015% of P, at most 0.0020% of S, and the balance of Fe and inevitable impurities, wherein the total amount of the impurity elements does not exceed 0.05%. The steel is subjected to smelting and two-stage rolling, so the prepared steel has excellent fire resistance and weather resistance. The method cancels the component of the precious metal Mo, and enhances the grade of the finished steel.

Owner:NANJING IRON & STEEL CO LTD

Ultra-thin ammonia corrosion resisting moving pressure container steel plate and production method thereof

ActiveCN110331328AExcellent ammonia corrosion resistanceGood welding performanceTemperature control deviceFurnace typesRare-earth elementHydrogen

The invention discloses an ultra-thin ammonia corrosion resisting moving pressure container steel plate and a preparing method thereof. Steel comprises following chemical components including, by masspercent, smaller than or equal to 0.23% of C, 0.31%-0.68% of Si, 0.71%-1.35% of Mn, smaller than or equal to 0.008% of P, smaller than or equal to 0.003% of S, 0.51%-1.55% of Al, smaller than or equal to 0.02% of W, 0.04%-0.13% of V, 0.0007%-0.0013% of B, smaller than or equal to 0.10% of Ce and the balance Fe and other inevitable inclusions. Through adding of a small amount of Al, W, the V microalloy element and the rare earth element Ce, steel ball inclusions are effectively purified, and grains are purified; through combination of the alloy elements, hydrogen and nitrogen, obvious hydrogenand nitrogen corrosion resisting performance is achieved; and through rolling technology parameter optimization and the proper heat treatment technology, the steel has good strength, low-temperaturetenacity and ammonia corrosion resisting performance, technology parameters are easy to control, cost is low, efficiency is high, and the ultra-thin ammonia corrosion resisting moving pressure container steel plate is suitable for large-scale production.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Method for eliminating surface crystalline oxides of welded joint

ActiveCN111659990AReduce brittlenessImprove plastic toughnessPlasma welding apparatusCrystalline oxideCrystallography

The invention relates to a method for eliminating surface crystalline oxides of a welded joint and belongs to the technical field of steel welding. According to the method for eliminating the surfacecrystalline oxides of the welded joint, a first steel plate and a second steel plate are welded to form a welded joint, welding adopts a plasma welding method, the first steel plate and the second steel plate are both made of acid pickling plates, and according to the weight ratio, the content of Si is controlled to be smaller than or equal to 0.05% in the chemical ingredients of each acid pickling plate. By finding the main reason of generating surface crystalline oxides during plasma welding of the acid pickling plates, the technical means of controlling the mass fraction of the Si in the steel to be smaller than or equal to 0.05% is adopted, so that the problem that a weld joint generates surface oxides is solved, and the potential safety hazard that the oxides on the shell of a compression exceed the standard is eliminated. Practice verifies that by the adoption of the method for eliminating the surface crystalline oxides of the welded joint, the surface of the welded joint is smooth, and the crystalline oxides are not generated.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

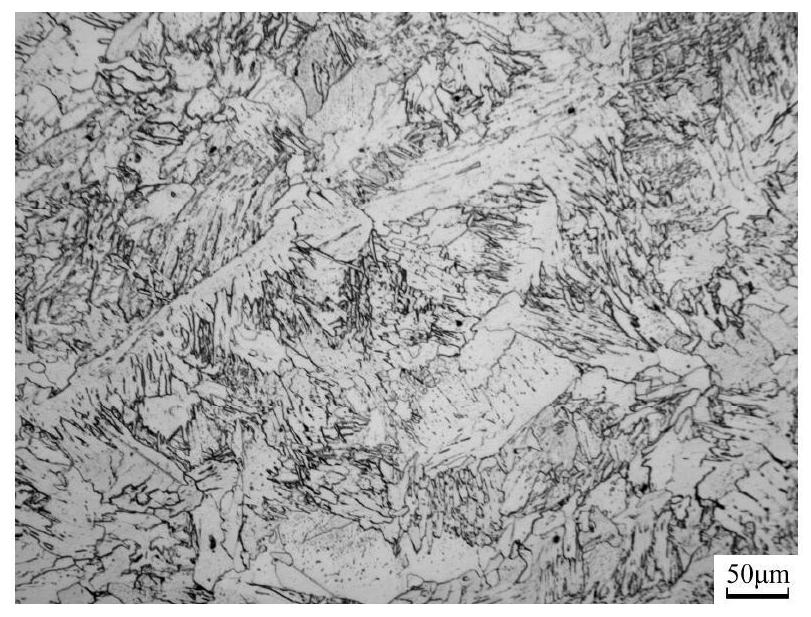

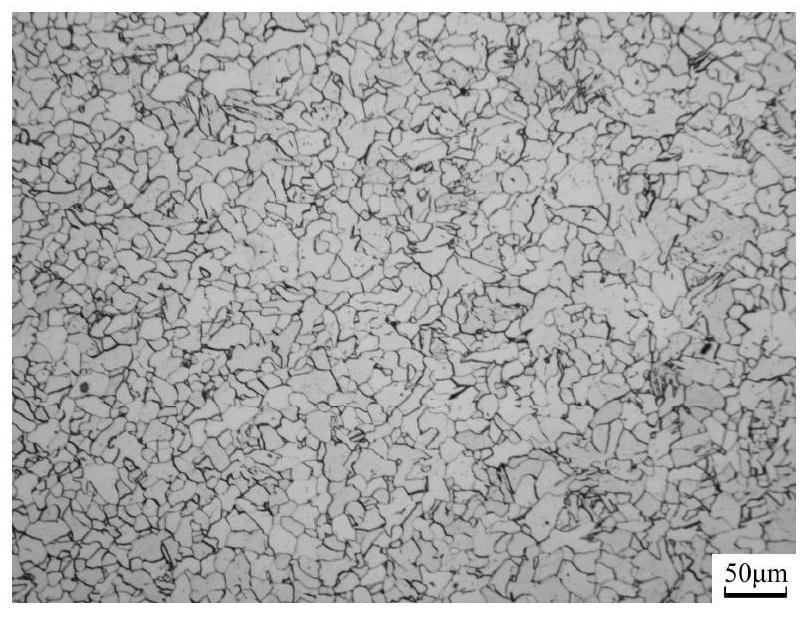

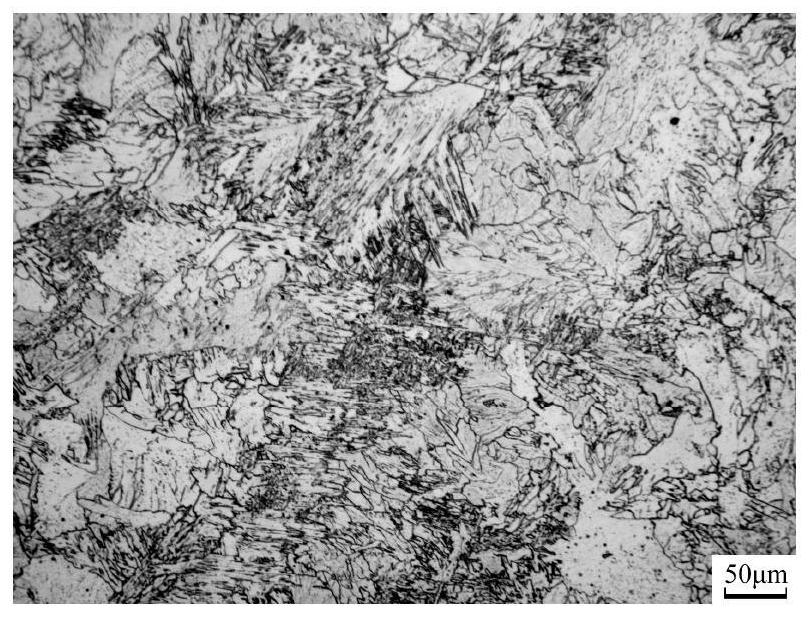

Preparation method of fine-grain biological magnesium-zinc alloy plate

The invention provides a preparation method of a fine-grain biological magnesium-zinc alloy plate. The method comprises the following steps of preparing a magnesium-zinc alloy casting blank which comprises the following elements in percentage by weight: 1.8%-2.2% of Zn and the balance of Mg; and heating the magnesium-zinc alloy casting blank to 290 DEG C to 300 DEG C, and conducting one-pass rollat the temperature of 290 DEG C to 300 DEG C and the rolling reduction of 75%-85% in order to obtain the magnesium-zinc alloy plate with the fine grain size. According to the method, the grain size ofthe magnesium-zinc alloy can be effectively refined, the mechanical property and corrosion resistance of the biological magnesium-zinc alloy are improved, the steps of the preparation method are simple, and batch production is facilitated.

Owner:上海隽美医疗科技有限公司

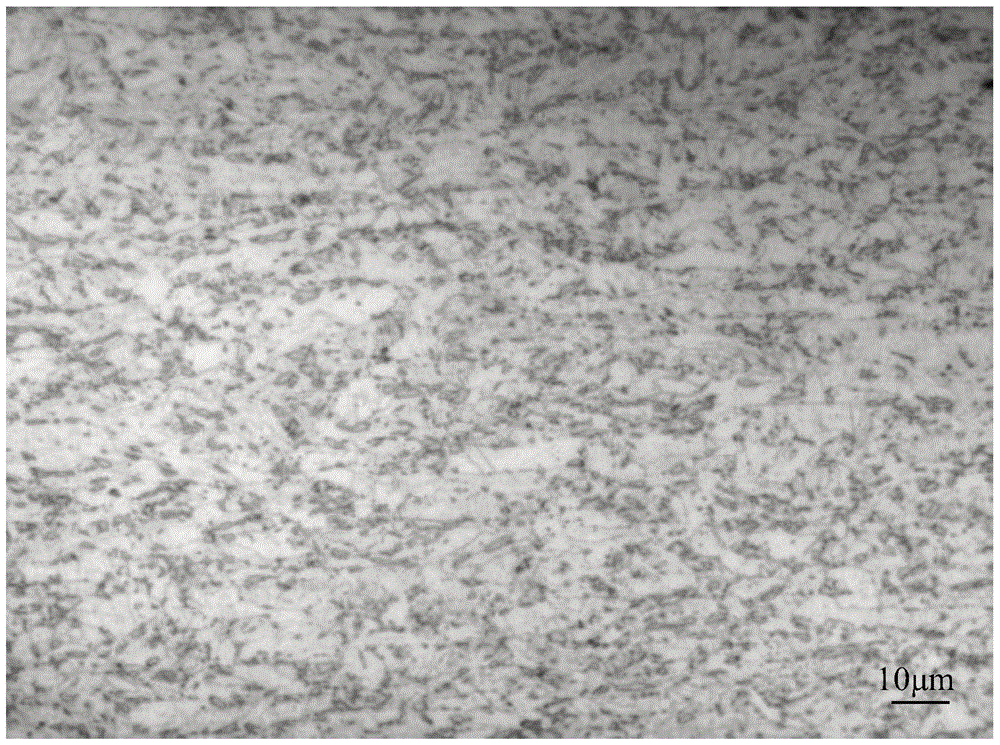

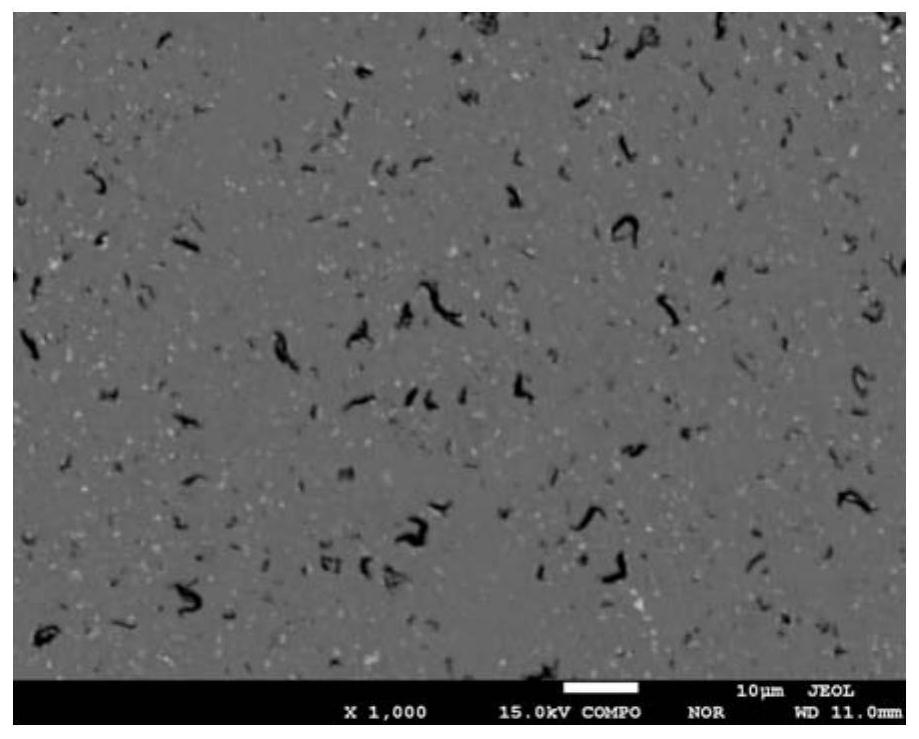

Method for producing Mo-free low-Nb X80 pipeline steel hot rolled steel plate

The invention relates to a method for producing an Mo-free low-Nb X80 pipeline steel hot rolled steel plate. The method comprises the following steps of: preparing raw materials in a ratio; smelting the raw materials by using a converter or an electric furnace; refining the smelted raw materials out of the furnace; casting the refined raw materials; reheating a plate blank; and performing controlled rolling and controlled cooling. The method is characterized in that: the heating temperature of the plate blank is of between 1,100 and 1,250 DEG C; the starting temperature of the controlled rolling in a recrystallization zone is of between 1,080 and 1,200 DEG C; the final temperature of the controlled rolling in the recrystallization zone is of between 950 and 1,080 DEG C; the starting temperature of the controlled rolling in a non-recrystallization zone is of between 860 and 950 DEG C; the compression ratio of the controlled rolling in the non-recrystallization zone is more than or equal to 75 percent; the final rolling temperature is of between 730 and 860 DEG C; the final cooling temperature is of between 300 and 550 DEG C; the cooling rate is of between 10 and 35 DEG C / s; produced steel has acicular ferrite and bainite structures and meets the requirement of API SPEC 5L on the performance of X90 pipeline steel; and production-manufacturing is low.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

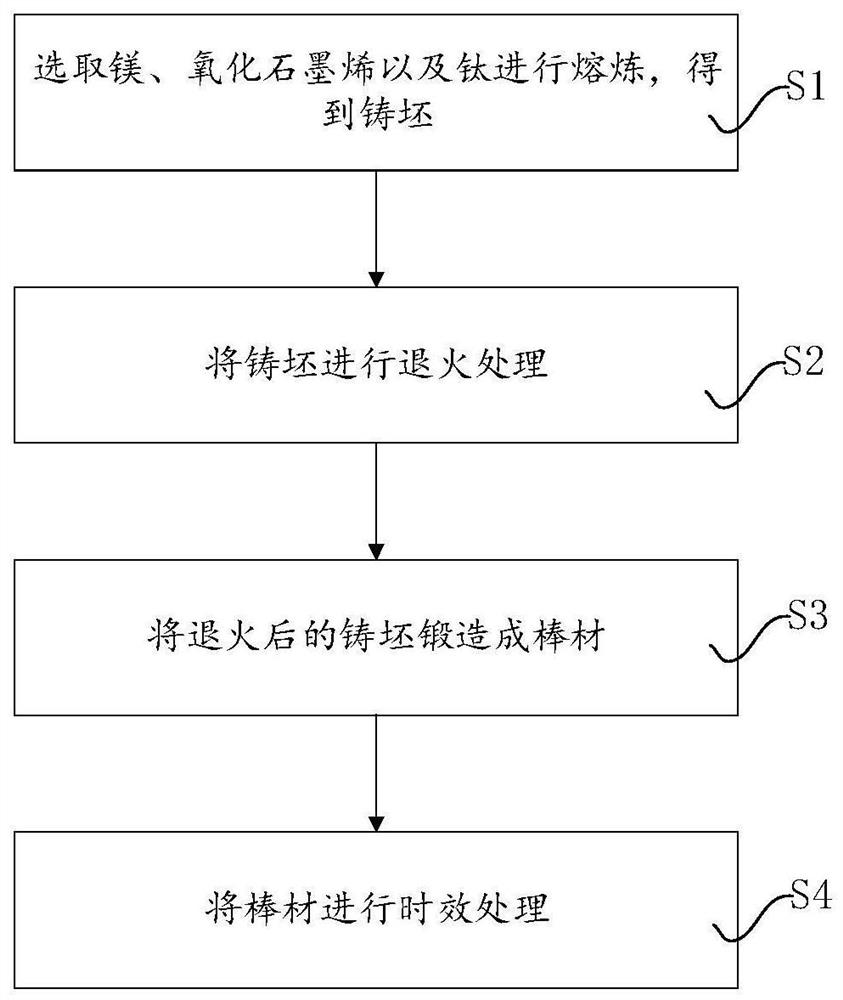

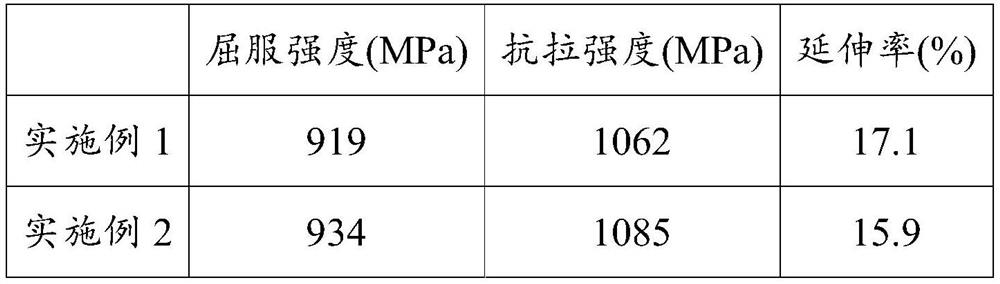

A kind of graphene oxide reinforced titanium alloy and preparation method thereof

The invention belongs to the field of titanium alloys, and discloses a graphene oxide-reinforced titanium alloy and a preparation method thereof. The graphene oxide-reinforced titanium alloy includes magnesium: 0.10% to 0.30% and graphene oxide: 0.45% by weight percentage. %~0.50%; the rest is titanium and unavoidable impurities. The preparation method includes: selecting magnesium, graphene oxide and titanium for smelting to obtain cast slabs, annealing the cast slabs at a temperature of 910-960°C, and forging the annealed cast slabs into rods at a forging temperature of 800-960°C, the bar is subjected to aging treatment, the aging treatment temperature is 700-800°C, and the holding time is 1-2h. The solid-solution strengthening effect of Mg element and its neutral stabilizing effect on α-phase and β-phase are fully utilized. The process is simple and the processing performance is good. The prepared graphene oxide-reinforced titanium alloy has high strength and does not reduce , Even improve the ductility of the alloy, so that the titanium alloy material has excellent strength and plasticity at the same time, and can process larger-sized finished products.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-strength welding electrode

InactiveCN1257039CThe ingredients are designed to be simpleReasonable design of ingredientsWelding/cutting media/materialsSoldering mediaChemical compositionHigh intensity

The invention belongs to the field of welding materials. The electrode is a high-strength electrode used in the welding state, and can be used for welding high-strength structural steel with a yield strength greater than 950MPa. The high-strength electrode of the present invention is characterized in that the chemical composition of the deposited metal forming the electrode is: C≤0.07%; Si 0.1-0.6%; Mn 1.2-1.9%; Ni 2.6-3.8%; Cr 0.41-1.50%; Mo 0.66- 1.6%; Ti 0.003-0.03%; the rest is Fe. Compared with the prior art, the welding rod of the invention has reasonable composition design. The deposited metal of the electrode has good comprehensive mechanical properties, the tensile strength is greater than 1000MPa; the yield strength is greater than 950MPa; the impact energy at -50°C is greater than 27J.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com