A kind of graphene oxide reinforced titanium alloy and preparation method thereof

A graphene and titanium alloy technology, applied in the field of titanium alloy, can solve the problems of low tensile strength, poor plastic deformation ability, complex process, etc., and achieve the effect of improving ductility, excellent strength and plasticity, and simple composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

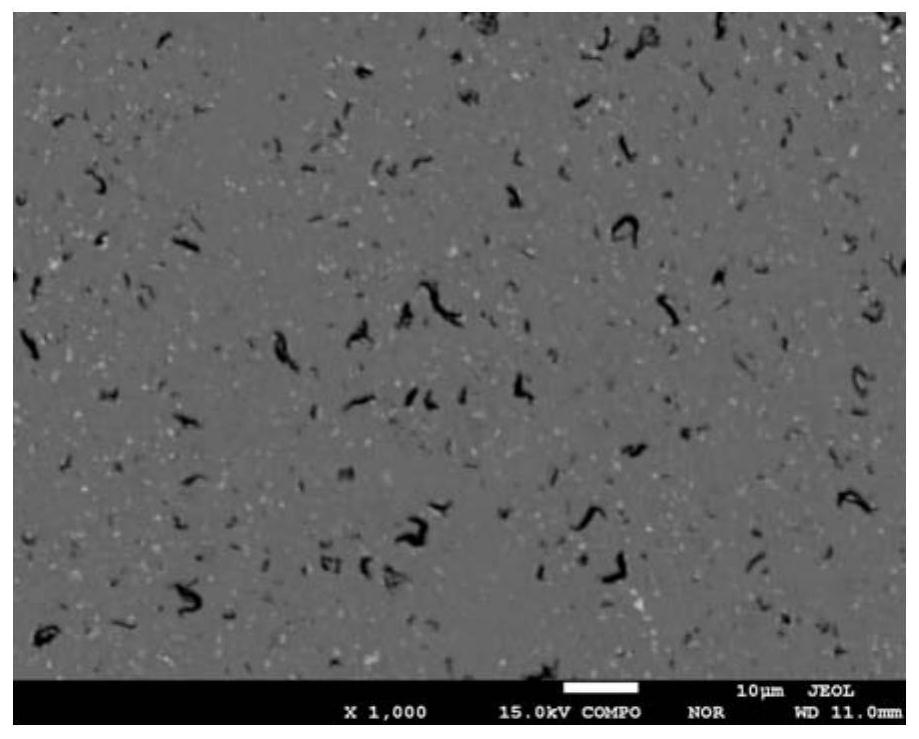

Image

Examples

preparation example Construction

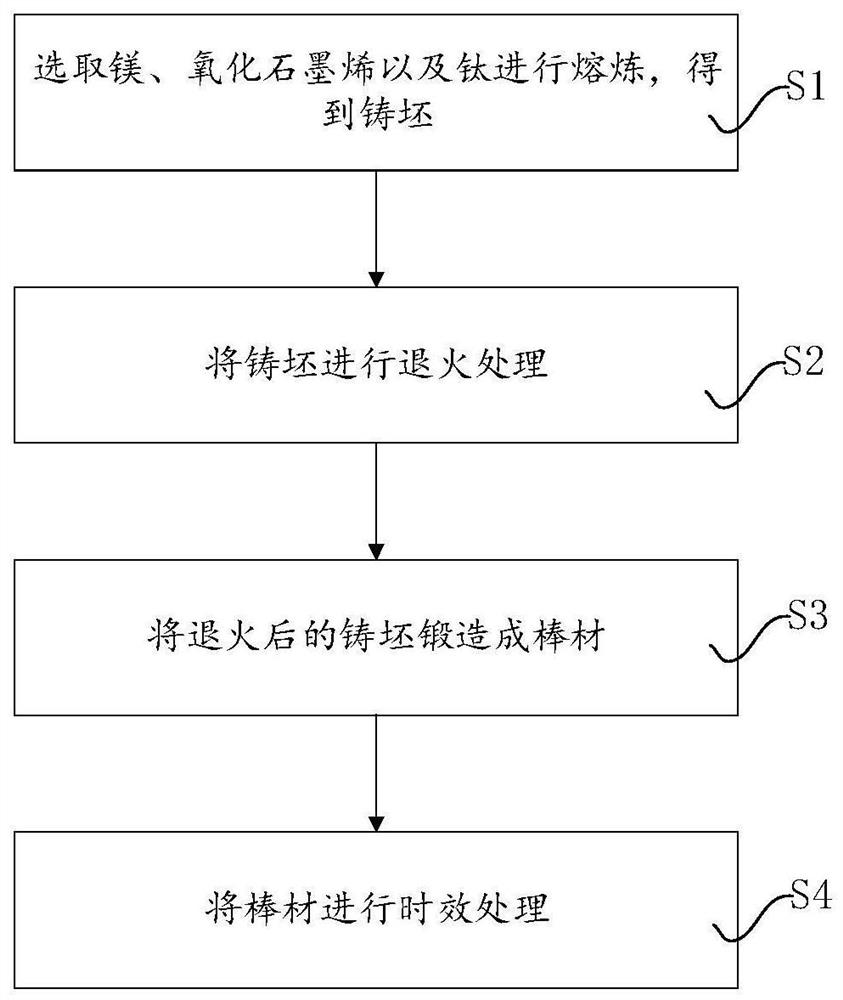

[0040] see figure 2 , the preparation method of graphene oxide reinforced titanium alloy of the present invention comprises the following steps:

[0041] S1: Magnesium, graphene oxide and titanium are selected for smelting to obtain a cast slab; wherein, by weight percentage, magnesium: 0.10%-0.30%; graphene oxide: 0.45%-0.50%; titanium: 99.20%-99.45%.

[0042] Specifically, when magnesium, graphene oxide and titanium are selected for smelting, the vacuum suspension casting method is used for smelting, and the vacuum degree in the furnace is ≤10 -2 Pa, the furnace temperature is 1600°C. Among them, titanium is zero-grade sponge titanium, and the purity of magnesium, graphene oxide and titanium are all ≥99.99%.

[0043] Preferably, it also includes: skinning the casting slab after the casting slab is cooled to remove the oxide layer on the surface of the casting slab.

[0044] S2: performing annealing treatment on the slab, and the annealing temperature is 910-960°C.

[00...

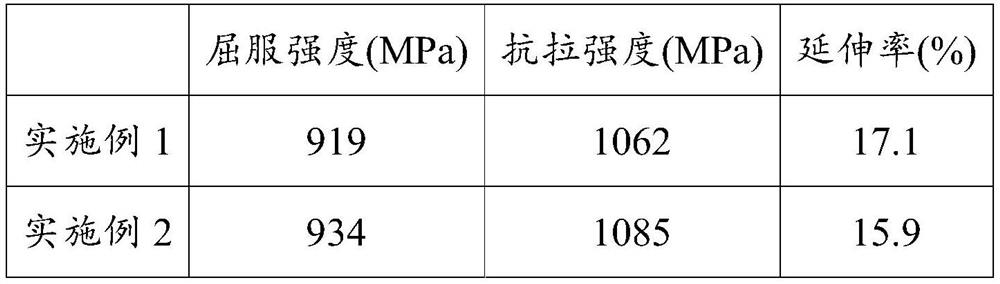

Embodiment 1

[0052] 1. Ingredients: In terms of weight percentage, magnesium: 0.10%; graphene oxide: 0.45%; the rest is the ratio of titanium and unavoidable impurities, and zero-grade sponge Ti, industrial pure Mg and graphene oxide are prepared respectively. Moreover, the purity of zero-grade sponge Ti, industrial pure Mg and graphene oxide is all ≥99.99%.

[0053] 2. Melting and casting: Vacuum suspension casting method is used for melting. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600°C, and the alloy billet is obtained. After sufficient cooling, skin the slab to remove the oxide layer on the surface of the slab.

[0054] 3. Homogenization annealing treatment: annealing treatment is carried out in a resistance furnace, the annealing temperature is 910°C, the holding time is 1h, and the cooling method is furnace cooling.

[0055] 4. Forging treatment: forging the billet into bars, wherein the starting forging temperature is 96...

Embodiment 2

[0058] 1. Ingredients: In terms of weight percentage, magnesium: 0.20%; graphene oxide: 0.45%; the rest is the ratio of titanium and unavoidable impurities, and zero-grade sponge Ti, industrial pure Mg and graphene oxide are prepared respectively. Moreover, the purity of zero-grade sponge Ti, industrial pure Mg and graphene oxide is all ≥99.99%.

[0059] 2. Melting and casting: Vacuum suspension casting method is used for melting. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the furnace temperature is 1600°C, and the alloy billet is obtained. After sufficient cooling, skin the slab to remove the oxide layer on the surface of the slab.

[0060] 3. Homogenizing annealing treatment: annealing treatment is carried out in a resistance furnace, the annealing temperature is 930°C, the holding time is 1h, and the cooling method is furnace cooling.

[0061] 4. Forging treatment: forging the billet into bars, wherein the starting forging temperature is 960°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com